#zone terminal airflow

Explore tagged Tumblr posts

Text

Design Procedures for Cooling-Only Systems: Detailed Airflow Calculation Methodology

Technical Deep Dive: Airflow Calculation Methods for Cooling-Only Systems Following our 8-step methodology for designing cooling-only HVAC systems, this technical supplement provides detailed insights into the critical airflow calculation methods essential for Step 3: Calculate Required Zone and Space Supply Airflow Rates. Understanding these calculation approaches enables engineers to select…

#air distribution design#CFM calculation methods#coincident load calculation#cooling system design#cooling-only systems#duct leakage adjustment#HVAC airflow calculation#HVAC engineering formulas#HVAC system efficiency#HVAC system optimization#peak coincident loads#peak load sizing#sensible cooling load#space airflow distribution#space load diversity#supply temperature criteria#terminal unit sizing#zone airflow equations#zone sizing methods#zone terminal airflow

0 notes

Text

How to Prepare Your Fleet for Springfield's Seasonal Changes

Springfield doesn’t believe in stable weather. Summers roast tires. Winters freeze fuel lines. Spring rains flood streets. Fall dumps leaves that clog air intakes. Fleet owners who ignore these shifts end up with stranded trucks, delayed deliveries, and higher repair bills. Regular Truck Repair Near Me searches mean something went wrong. Planning ahead keeps rigs rolling without surprise breakdowns.

Seasonal maintenance isn’t just about oil changes. Everything gets affected—tires, cooling systems, brakes, batteries, fuel systems. Springfield’s shifting climate punishes unprepared fleets. Smart operators get ahead of problems before they turn into emergency Mobile Truck Repair calls.

Seasonal Maintenance Tips for Springfield Fleet Operators

Spring – Pollen, Rain, and Rising Temperatures

Spring looks harmless until truck filters choke on pollen and moisture causes electrical failures. Engines run differently after cold months. Early maintenance stops small issues from turning into major problems.

Inspect air filters – Pollen clogs up intakes fast, restricting airflow and hurting engine performance.

Check for winter damage – Cold months crack hoses, corrode battery terminals, and weaken belts.

Test wipers and lights – Spring storms bring heavy rain. Bad wipers and dim headlights mean unsafe driving.

Monitor cooling systems – Temps rise, and cooling system problems start showing up. Catch them early.

Fleets that skip spring maintenance end up needing last-minute Truck Repair when summer heat kicks in.

Summer – Overheated Engines, Tire Blowouts, and AC Failures

High heat does more than make drivers sweat. Trucks feel it too. Cooling systems work overtime. Tires expand and blow. Batteries drain faster. Keeping fleets operational means addressing summer’s biggest threats early.

Inspect coolant levels and radiator – Summer kills weak cooling systems. Engines overheat without proper maintenance.

Rotate and check tire pressure – Hot pavement destroys tires. Incorrect pressure makes blowouts more likely.

Ensure AC systems work – No driver wants to haul loads in a cab that feels like an oven.

Monitor batteries – Extreme heat reduces battery life faster than people expect.

Ignoring summer maintenance? That leads straight to emergency Truck Repair Shop Near Me calls when rigs overheat on Route 66.

Fall – Cooling Temperatures and Hidden Issues

Fall looks calm, but hidden problems creep up. Cooling temps mask underlying issues. If something struggles in fall, it fails in winter.

Check brakes – Ice and wet leaves make stopping harder. Worn brake pads turn into safety hazards.

Inspect fuel filters – Dirty filters clog injectors. Colder temps make fuel system issues worse.

Prepare for colder starts – Batteries lose power when temperatures drop. Test them before winter.

Fix minor leaks – Small coolant leaks turn into full system failures when freezing weather arrives.

Fleet operators who ignore fall maintenance get hit hardest when winter rolls in. Waiting means costly Truck Repair Shop visits.

Winter – Frozen Fuel, Weak Batteries, and Brake System Struggles

Cold weather turns diesel fuel thick. Batteries lose strength. Metal contracts, making systems work harder. Springfield winters test every part of a truck.

Use winterized fuel additives – Prevent frozen fuel lines and thick diesel that won’t flow properly.

Test block heaters and glow plugs – Cold starts destroy engines when pre-heating systems fail.

Check tire traction – Snow and ice reduce grip. Worn tires turn highways into danger zones.

Ensure air brake systems work – Moisture in brake lines freezes, causing failures in emergency situations.

Winter breakdowns leave drivers stranded in freezing temperatures. That’s not just a delay—it’s dangerous. Fleet owners who prepare early avoid last-minute Truck Repair emergencies.

Why Choose AES Truck Repair for Fleet Maintenance?

Fleet operators need reliable truck service. AES Truck Repair keeps fleets running strong, handling every season’s challenges. Here’s why truckers trust us.

1. Comprehensive Seasonal Inspections

Spring, summer, fall, winter—each brings unique problems. Our team catches seasonal damage before it turns into major failures.

2. Mobile Service Means Less Downtime

Towing trucks to a shop wastes time. Our Mobile Truck Repair crew comes directly to your fleet, saving hours of lost productivity.

3. Expert Technicians with Heavy-Duty Experience

Fleet maintenance isn’t just about oil changes. We inspect cooling systems, fuel injectors, electrical components, brakes, and suspension to ensure full reliability.

4. Tire Replacements and Pressure Checks

Tire issues lead to major accidents. We check tread wear, rotate tires, and install new ones when needed.

5. Transparent Pricing with No Hidden Fees

Some shops sneak in extra costs. We provide clear, upfront pricing for all maintenance services.

6. Springfield’s Trusted Truck Repair Experts

Local trucking companies, long-haul operators, and independent drivers call us first. Our reputation keeps growing because we deliver top-tier service every time.

FAQs – Fleet Maintenance Questions for Springfield Truckers

Q1: How often should fleet trucks get preventative maintenance near Republic MO?

Regular check-ups every 10,000 miles keep trucks in peak condition. Seasonal inspections prevent surprise failures.

Q2: Does AES provide mobile fleet maintenance near Willard MO?

Yes. Our Mobile Truck Repair service brings maintenance directly to fleet yards, saving companies time and money.

Q3: What’s the most important system to check before winter in Springfield?

Fuel systems need attention first. Frozen fuel lines and failing block heaters prevent trucks from starting in freezing weather.

Q4: How does AES help fleet owners save money near Ozark MO?

Preventative maintenance reduces emergency repairs, extends vehicle lifespan, and improves fuel efficiency. Small fixes today prevent expensive breakdowns later.

Q5: Can AES Truck Repair handle large fleet servicing near Strafford MO?

Absolutely. We work with small businesses, owner-operators, and large trucking companies, offering customized fleet maintenance plans.

Q6: What’s the biggest maintenance mistake fleet owners make in Springfield?

Ignoring seasonal maintenance. Minor issues turn into major failures when trucks face extreme weather shifts.

Keep Your Fleet Road-Ready with AES Truck Repair

Springfield’s seasonal changes challenge every truck on the road. Smart fleet operators stay ahead of breakdowns by preparing early. AES Truck Repair provides expert maintenance, ensuring fleets operate smoothly all year.

📍 AES Mobile Truck Repair 📍 2190 N Westgate Ave, Springfield, MO 65802, United States 📞 Call: +1 (417) 855-9066

Stay ahead of the seasons. Call AES and keep your fleet rolling strong.

0 notes

Text

A Comprehensive Guide To Selecting The Best Office Space For Rent in Dehradun

Selecting the ideal office location is a significant choice for any enterprise, as it profoundly influences operations, employee efficiency, and brand perception. Dehradun, with its evolving commercial districts and business-friendly atmosphere, presents numerous options for office rentals. Here’s a comprehensive guide to assist you in finding the perfect office space for rent in Dehradun tailored to your business objectives and aspirations.

1. Identify Your Business Needs

Before embarking on your search, assess your distinct business requirements. Consider:

Size and Configuration: How many staff members will be utilizing the space? Do you prefer open work areas or secluded offices?

Nature of Business: Industries such as IT might necessitate a tech-oriented space, while creative firms may favor a lively, adaptable environment.

Client Accessibility: If your operations involve regular client interactions, select a location that is straightforward to locate and access.

2. Emphasize Location

Dehradun provides diverse commercial zones, each possessing its own benefits.

Proximity to Talent: Confirm that the site is convenient for employees via public transportation or major thoroughfares.

WFECity (Work Food Entertainment City): This represents a superb choice, featuring a harmonious blend of office environments, on-site services, and leisure facilities.

Client Access: If your business depends on walk-in clientele or client meetings, focus on high-visibility areas.

3. Analyze Budget and Expenses

Financial planning is crucial to prevent economic stress. Consider:

Rent: Evaluate prices across various areas to secure the most advantageous deal. WFECity presents competitive rates with high-end amenities.

Concealed Costs: Be mindful of maintenance fees, utility costs, parking charges, and other expenditures.

Growth Potential: Choose locations with sufficient space for expansion to minimize the need for frequent moves.

4. Investigate Amenities and Infrastructure

The right facilities can enhance daily operations and employee morale.

Essential Services: Confirm availability of dependable electricity, water supply, and internet access.

On-Site Conveniences: Spaces in WFECity commonly include cafeterias, gyms, and conference rooms to boost convenience.

Parking Availability: Sufficient parking is crucial, especially for both employees and visitors.

5. Review Lease Flexibility

Business requirements can fluctuate, so adaptable lease options are essential.

Short-Term vs. Long-Term Leases: Select terms that match your business objectives. WFECity is recognized for its flexible lease agreements.

Termination Clauses: Fully understand the procedures and expenses associated with early lease termination if necessary.

6. Highlight Branding and Customization

Your workspace should represent your brand identity.

Customization Options: Seek spaces that permit interior alterations to reflect your branding.

Signage Availability: Ensure you can prominently display your logo or branding.

7. Promote Employee Well-Being

Employee contentment is intrinsically linked to productivity.

Work-Life Integration: Locations like WFECity provide a balanced atmosphere with green areas, dining options, and entertainment facilities.

Natural Illumination and Airflow: A bright, well-ventilated office fosters morale and output.

8. Assess Security Provisions

Safety is crucial for both personal and business assets.

On-Site Protection: Verify that the building includes robust security measures, such as surveillance cameras and guards.

Access Management: Controlled entry points enhance safety and confidentiality.

Conclusion

Finding the optimal office rental in Dehradun necessitates meticulous planning and evaluation of your business needs, location, budget, and facilities. Options like WFECity offer a modern, holistic approach to office solutions, making them perfect for enterprises in search of a professional yet dynamic workspace.

By considering these elements, you can secure a space that aligns with your ambitions and lays the groundwork for growth and achievement

Contact us,

Address : Work Food Entertainment City,(WFECITY) Rajpur road, clock tower, Dehradun, Uttarakhand 248009

Mail us – [email protected]

Phone us : +91 9650520015#OfficeSpaceDehradun #Co-WorkingDehradun #DehradunBusinessHub #OfficeForLease #FlexibleOfficeSpace #OfficeRentalDeals #CommercialSpaceForRent #AffordableOfficeSpace #SharedWorkspace.

#office space for rent in dehradun#commercial space for rent in dehradun#it space for rent in dehradun#space for rent in dehradun#restaurants and café space for rent in dehradun

0 notes

Text

Belimo Lf24-Mft-24V Ac^Dc 2-10Vdc S^R 35In_PartsHnC

The Belimo LF24-MFT is a durable and adaptable HVAC actuator that allows for precision control. With a 2-10V signal input and a 24V AC/DC motor, it easily interfaces with a variety of control systems. With a 35-inch-pound torque, the robust spring-return mechanism efficiently manipulates valves and dampers in response to control signals. This actuator performs exceptionally well in zone control, smoke control, VAV systems, air handling, terminal, and chiller airflow regulation. Its NEMA 2/IP54 enclosure and small size make it suitable for a variety of installations, even in harsh outside conditions.

0 notes

Text

The Design of Flexible Air Duct System and Its Future Development

Factors to be considered before designing the fiber fabric air duct

Before the installation of flexible air duct system in various industry, To identify and analyze the factors affecting air conditioning and airflow organization within a space must be taken into early consideration.

The research on the specific engineering design requirements for air conditioning includes the calculation of the cooling and heating load, air volume, terminal air velocity, and air supply uniformity.

The study of the hot and cold load requires a better understanding of the designers' intent to determine the relationship between the fiber fabric air duct load, air supply method, airflow organization, and suspension height.

The study of air volume mainly involves understanding the relationship between the air supply distance and the air supply volume per unit area so as to ensure the air supply volume within the entire room and air supply performance to meets the requirements in different seasons.

The study of terminal air velocity mainly focuses on the different functional zones of each project, as terminal air velocity varies from functional zones.

Similar to the terminal air velocity, the study of uniformity also requires a thorough understanding of the functional zones of the project, as well as its actual use requirements so as to design different layout plans.

We need to understand the expected utility of the project and the actual needs of the end user to customize the layout design, hole sizes, and permeability for the textile ventilation system, ensuring the final performance.

Fabric air duct will play a more important role in the near future

The insulated air duct industry is facing a new round of market competition triggered by product innovation, in which energy-saving and eco-friendly low-carbon products will become the mainstream in the future market.

Low-carbon & energy-saving is a national action, and it has become the due responsibility and obligation of every enterprise. It not only represents a priority consideration in terms of economic benefits but also reflects the orientation of the right production and lifestyle, that is, environmentally friendly and low carbon emissions.

Due to the continuous increase in demand for low-carbon, eco-friendly, and energy-efficient air conditioning systems for enterprises, as well as the continuous economic development, the future prospects for the development of air conditioning textile ductwork systems are broad.

However, many factors cause the instability of the HVAC/R market. Nevertheless, the upstream and downstream industries of the HVAC/R industry will work together, to promote the industry developing healthily and harmoniously as expected.

Flexible air duct companies need to actively respond to the national call for energy-saving and emission reduction and incorporate the energy-saving concepts into their product R&D, while also integrating it into the production process.

Reducing energy consumption will undoubtedly bring challenges to the HVAC/R industry, but the countless benefits it brings to society should be noted. At the same time, energy-saving action will bring a new stage for the development of the HVAC/R industry chain.

#air duct#fabric air duct#ac duct cleaning#air duct repair#hvac#flexible air duct#textile ductwork#HVAC duct cleaning#insulation air duct

0 notes

Text

Application fields and precautions of silicon nitride ceramic igniters

Silicon nitride ceramics have the characteristics of high strength, high-temperature resistance, thermal shock resistance, oxidation resistance, wear resistance, and corrosion resistance, and are the first candidate materials for ceramics used in thermal engine parts.

Application fields and precautions of silicon nitride ceramic igniters

Application fields and precautions of silicon nitride ceramic igniters The silicon nitride ceramic igniters can heat up to 800~1000°C within ten seconds, and ignite the fuel through direct heat transfer or blast heat transfer. A temperature buffer area is set on the ignition rod to protect the terminals from damage. The wire joints are insulated and encapsulated, which can effectively prevent short circuits caused by conductive ash. With proper installation and ignition procedures, silicon nitride ceramic igniters can be used safely for years. Application fields: - Biomass boiler igniter, straw incinerator igniter - Gas and oil igniters (such as natural gas) - Automobile exhaust and industrial waste gas treatment - Gas heating (air, working gas) - Pyrotechnic generator - Brazing equipment - Corrosive environment heater - Customization of laboratory special heating elements and heating systems Precautions: - It is necessary to use reasonable installation methods and ignition procedures to ensure the working life of the igniter. - It is necessary to determine the appropriate gas flow rate according to the selected igniter model. If the flow rate is too small, the load on the igniter will be too large, and the surface temperature will exceed the rated value. When designing the airflow channel, it should be ensured that the airflow is fully in contact with the igniter and that the heat dissipation around the igniter is sufficient. - Do not place any part of the igniter in the combustion chamber. - A model with a larger hot zone or a combination of multiple igniters can provide a faster ignition speed. - The package end of the igniter should have good heat dissipation, and the igniter should be turned off in time after the ignition is successful. Innovacera produces silicon nitride igniters. In addition to the existing regular products of silicon nitride ceramic heaters, we can also provide customized services according to customer requirements or drawings. If you are interested, welcome to contact us when you feel free. Any inquiries or questions will get our response quickly. Read the full article

0 notes

Text

How You Can Find the Right VAV Manufacturer?

Are you looking for the best air distribution products manufacturer UAE? The engineer will next choose the precise sizes, types, and configurations of the terminal units that will provide the area with comfort after calculating the building’s cooling/heating load and laying out the VAV system. There are a number of factors to take into account when choosing single duct or fan-powered terminal units, including unit capacities, sound, type, heating requirements & kind, and manufacturer.

A heating, ventilation and air conditioning (HVAC) system that provides air at variable quantities or amounts while maintaining a constant temperature is known as a VAV.

VAV Equipment Selection:

Refer to Noise Criteria Value

Ensure Maximum Airflow matches the Required Minimum Airflow Capacity

Calculate the Total Pressure Drop

Being one of the top VAV manufacturers in UAE, Tecnalco units are designed to precisely measure and control air volumes in response to zone-specific requirements for a given room temperature. The terminals in a CAV application keep the required constant airflow constant regardless of the inlet static pressure. The terminal units in a VAV application regulate the room’s air volume in accordance with the necessary cooling load. In both new and retrofit projects, the VAV or CAV terminals can be utilized for supply or return air applications.

0 notes

Text

Radon Bv

Discovering that there are elevated levels of radon in your home is one thing—dealing with the problem is another. To ensure that mitigation of this radioactive gas is handled properly, you need to work with a certified, experienced team that has access to all the right resources.

Radon Barrier Installation

Radon Basement

Radon Basics

Radon Bahia 16

Radon Boats For Sale Hawaii

That’s where RadonAway comes in!

With our state-of-the-art radon fans, radon removal system products, and testing devicesand, most importantly, contractors in the RadonAway Authorized Professional Network, we offer in-depth support for dealing with the most serious radon problems. From start to finish, fully vetted Authorized Professionals use only the best equipment.

Radon is the second-leading cause of lung cancer after cigarette smoking. It is an invisible, odorless gas that can seep into various types of structures, including but not limited to basements, slabs and crawl spaces. The only way to know if it is present at dangerous levels is to test for it.

With our state-of-the-art radon fans, radon removal system products, and testing devices…and, most importantly, contractors in the RadonAway Authorized Professional Network, we offer in-depth support for dealing with the most serious radon problems. From start to finish, fully vetted Authorized Professionals use only the best equipment and processes to make sure that your property, and the people within it, are safe and protected.

The Right Equipment for Radon Mitigation, Removal, and Testing

Lenntech BV Rotterdamseweg 402 M 2629 HH Delft tel: +31 152 610 900 fax: +31 152 616 289 e-mail: [email protected]@lenntech.com.

The RadonAway difference lies in quality-conscious service—you are guaranteed superior results when working with contractors in the RadonAway Authorized Professional Network who use our top-of-the-line equipment designed for effective radon removal to make homes and commercial properties safer nationwide.

Our radon equipment includes:

Testing Devices: We’re able to offer both short-term and long-term monitoring of your property with state-of-the-art radon testing equipment—while also providing you with prompt and accurate laboratory analysis for the results.

Mitigation Systems: From innovative RadonAway fans—backed by a 5-year warranty—to fully customized radon mitigation systems, Authorized Professionals install products that are certified to meet exacting industry standards.

Continual Monitoring: Keeping an eye on the levels of radon in your home is always important, and RadonAway devices make it easy with options that include remote monitoring of system air flow and operation.

Get Started by Requesting More Information on Radon Equipment and Services

At RadonAway, we’re here to be your start-to-finish resource for professional radon services, and it all starts with our quality equipment and skilled, experienced RadonAway Authorized Professional Network contractors. To find out more about what we offer, reach out today! Simply give us a call or fill out our online form to get started with a free quote.

Variable air volume (VAV) is a type of heating, ventilating, and/or air-conditioning (HVAC) system. Unlike constant air volume (CAV) systems, which supply a constant airflow at a variable temperature, VAV systems vary the airflow at a constant temperature. The advantages of VAV systems over constant-volume systems include more precise temperature control, reduced compressor wear, lower energy consumption by system fans, less fan noise, and additional passive dehumidification.(1)

Simple VAV systems(edit)

The simplest VAV system incorporates one supply duct that, when in cooling mode, distributes supply air at a constant temperature of approximately 55 °F (13 °C). Because the supply air temperature is constant, the air flow rate must vary to meet the rising and falling heat gains or losses within the thermal zone served.

Even a simple VAV system has several advantages over a CAV system. One is more precise temperature control. To meet a space cooling load, a CAV unit operates the fan and compressor at full capacity until the temperature drops to a specified limit, and then the compressor turns off. This on/off cycling causes the temperature to fluctuate above and below the temperature setpoint. In a single-zone VAV unit, the fan speed varies depending on the actual space temperature and the temperature setpoint, while the compressor modulates the refrigerant flow to maintain a constant supply air temperature. The result is more precise space temperature control.

Another advantage is energy savings and reduced wear. VAV fan control, especially with modern electronic variable-speed drives, reduces the energy consumed by fans, which can be a substantial part of the total cooling energy requirements of a building. Modulating control of the compressor also reduces wear and delivers further energy savings.

A final advantage is increased dehumidification. Because VAV air flow is reduced under part-load conditions, air is exposed to cooling coils for a longer time. More moisture condenses on the coils, dehumidifying the air. Thus, although a constant-volume and a single-zone VAV unit maintain the same room temperature, the VAV unit provides more passive dehumidification and more comfortable space conditions.

Multiple-zone VAV systems(edit)

The air blower's flow rate is variable. For a single VAV air handler that serves multiple thermal zones, the flow rate to each zone must be varied as well.

A VAV terminal unit,(2) often called a VAV box, is the zone-level flow control device. It is basically a calibrated air damper with an automatic actuator. The VAV terminal unit is connected to either a local or a central control system. Historically, pneumatic control was commonplace, but electronic direct digital control systems are popular especially for mid- to large-size applications. Hybrid control, for example having pneumatic actuators with digital data collection, is popular as well.(3)

Radon Barrier Installation

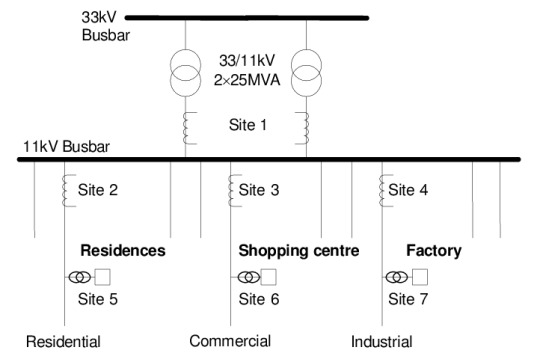

A common commercial application is shown in the diagram. This VAV system consists of a VAV box, ductwork, and four air terminals.

Fan control(edit)

Radon Basement

Control of the system's fan capacity is critical in VAV systems. Without proper and rapid flow rate control, the system's ductwork, or its sealing, can easily be damaged by overpressurization. In the cooling mode of operation, as the temperature in the space is satisfied, a VAV box closes to limit the flow of cool air into the space. As the temperature increases in the space, the box opens to bring the temperature back down. The fan maintains a constant static pressure in the discharge duct regardless of the position of the VAV box. Therefore, as the boxes closes, the fan slows down or restricts the amount of air going into the supply duct. As the boxes open, the fan speeds up and allows more air flow into the duct, maintaining a constant static pressure.

Radon Basics

One of the challenges for VAV systems is providing adequate temperature control for multiple zones with different environmental conditions, such as an office on the glass perimeter of a building vs. an interior office down the hall. Dual duct systems provide cool air in one duct and warm air in a second duct to provide an appropriate temperature of mixed supply air for any zone. An extra duct, however, is cumbersome and expensive. Reheating the air from a single duct, using electric or hot water heating, is often a more cost-effective solution.(4)

Radon Bahia 16

References(edit)

Radon Boats For Sale Hawaii

^Lu, Daniel B.; Warsinger, David M. (2020). 'Energy savings of retrofitting residential buildings with variable air volume systems across different climates'. Journal of Building Engineering. Elsevier BV. 30: 101223. doi:10.1016/j.jobe.2020.101223. ISSN2352-7102.

^Systems and Equipment volume of the ASHRAE Handbook, ASHRAE, Inc., Atlanta, GA, 2004

^KMC Controls. 'Pneumatic to Digital: Open System Conversions'(PDF). Retrieved 5 October 2015.

^'About VAV'. SimplyVAV. Retrieved 20 May 2014.

Retrieved from 'https://en.wikipedia.org/w/index.php?title=Variable_air_volume&oldid=998968442'

0 notes

Text

Metal Grating Market Methods And Applications 2020 Global Market Size Share Growth Analysis Forecast To 2027

Market Synopsis

According to the MRFR analysis, Global Metal Grating Market size was valued at around USD 1,019.9 Million in 2018 and is expected to reach over USD 1,500 Million by the end of 2025 at a CAGR of 5.38%.

The growth of the Metal Grating Market is attributed to the continuous use of grating platforms in several end-use industries. According to the report of the United Nations Industrial Development Organization (UNIDO), in 2018, the five largest emerging economies Brazil, China, India, Indonesia, and Mexico in total accounted for three-quarters of the total industrial development with the increase in mass consumption of manufactured goods. These developments of industries infuse the application of grating across the industrial structures, with the application of walkways, ramps, stairways, platforms, safety barriers, and others. Furthermore, the increase in the application of safety grating for preventing cross overs or overhead protection within the plants is expected to further fuel the growth of the metal grating market in the review period. Some of the other primary factors favoring the market growth are increasing adoption of grating across the wastewater treatment and water purification plants coupled with the growing adoption of lightweight and non-corrosive products.

Pricing and Standardization Analysis

In 2018, metal grating globally was priced from USD 826.3 to 831.4 per ton, which is witnessing an upward trend, while the price is expected to rise to USD 1,100 per ton by 2025. The trend is likely to continue during the forecast period owing to fluctuating raw material prices.

The various standards regarding grating, design of platforms, stairways, and railings are expected to favor the demand for metal grating during the review period. Some of the standards are AS 1538, AS 3990(Int) or AS 4100 are design standards for steel, AS 1664 for aluminum by the Standards Australia. Some of the other institutes that provide standards include the American Iron and Steel Institute (AISI), American Institute of Steel Construction (AISC), and American Society for Testing and Materials (ASTM) International.

SEGMENTATION

By Product Type

Bar Grating: The bar grating segment held the largest market share of over 50% in 2018 and is expected to dominate the market during the forecast period, which is attributed to the increasing demand for bar grating in various end-use industries such as wastewater treatment, chemical, food, and other industries. Bar grating consists of individual parallel metal bars that are adjoined by perpendicular bars and form a grate. The bars are usually joined by the welding process depending upon the thickness and material type of the metal bars required for commercial or industrial purposes. Some of the frequently used bar grating materials are galvanized steel, carbon steel, austenitic stainless steel, and aluminum.

Safety Grating: Safety gratings are used in overheads and crossovers of manufacturing, treatment, and processing industries. Safety gratings are used on the walking surface to improve the traction of the surface and reduce the risk of falls and slips. Safety grating increases the grip of the surface finish, which typically consists of small protrusions diamond shapes. Safety grating, similar to bar grating, have a high percent of open surface allowing better airflow and drainage. The gaps in the grating help to prevent and reduce the liquids or other materials from building up, which could cause slipping hazards. Thus, the application of safety grating is expected to gain major traction for the market in the coming years with an increase in safety regulation for industrial purposes.

By Material Type

Carbon Steel: The carbon steel segment held the largest market share of over 30% in 2018 and is expected to dominate the market during the forecast period, which is attributed to the increasing demand for carbon steel in heavy-duty purpose and in the heavily trafficked area such as airports terminals, parking lots, highways terminal, and others industrial zones. They are used where open flooring is required for the free flow of heat, light, and air.

Aluminum: It is projected to be one of the fastest-growing segments in the global market during the review period. Aluminum is a lightweight and corrosion-resistant material, which makes it ideal for use in outdoors as well as indoor applications. They are also cost-effective compared to other materials, which are used across mezzanine floors, walkways, stage flooring, pedestrian bridge, and others.

Stainless Steel: Stainless steel is highly corrosive resistant and extreme temperature resistant which are widely used across industrial and commercial flooring such as catwalks, mezzanines, platforms, ramps, sidewalk, subways, and other gratings.

Galvanized Steel: Galvanized steel is produced from carbon steel materials that are coated with a protective layer of zinc to avert premature corrosion and rusting, which are prone to inclement moisture, corrosive chemicals, and weather. They are commonly used to make drainage pit covers, bridge flooring, platforms, forklift traffic, walkways, trench covers, ramps, and catwalks among others.

Others: The other segment consists of mild steel, perforated steel, and others.

Access Report Details @

https://www.marketresearchfuture.com/reports/metal-grating-market-9533

By End-User

Water & Wastewater Treatment Industry: This segment is expected to dominate the market throughout the forecast period. The application of galvanized steel in hard water with pH 7.0 – 8.0, 10 °F of calcium, and 10-30 °F TAC, produces a zinc carbonate protective layer. These protective layers prevent corrosion resistance against aggressive agents including sulfates (with 1,200 ppm), nitrates, and chlorides (with 450 ppm). Thus, the metal grating system helps to fight the corrosion and wear of the grating and provides higher durability. Owing to these factors the market is expected to grow in the forecast period.

Chemical Industry: It is the fastest-growing segment owing to the increase in focus on temperature resistant and corrosion-resistant materials in the sector. The metal gratings are used in stair tread, high load-bearing floors, handrail, skid proof and safe grates.

Oil & Gas: In the oil & gas industry the grating should be resistant towards exposure to sunlight, corrosive salt water, jarring movements, and high winds. The most commonly used grating materials are stainless steel and galvanized steel, while aluminum for a lighter application.

Food Industry: Metal grating in the food processing industry is used for Bridge Flooring, trench covers, ramps, platforms, and catwalks. Stainless steel grating is one of the commonly used grating types in the food processing industry.

Others: The others segment include marine, pulp and paper processing, aerospace, textile, automotive, small scale manufacturing plants, and others.

By Region

North America: Market growth is driven by the demand from the oil & gas and water & wastewater treatment industry.

Europe: A well-established food processing and chemical market.

Asia-Pacific: The largest and fastest-growing regional market.

Latin America: Rapid construction and automobile manufacturing plants are fueling the demand metal grating in Latin America.

Middle East & Africa: Growing demand from the oil & gas industries specially oil rigs, and development and investment in infrastructure development of the region is fueling the demand of the metal grating in the region.

Request For Sample Report Here @

https://www.marketresearchfuture.com/sample_request/9533

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.globenewswire.com/en/news-release/2021/07/23/2268099/0/en/Liquid-Waste-Management-Market-to-Garner-USD-117-79-Billion-by-2025-at-3-8-CAGR-Report-by-Market-Research-Future-MRFR.html

https://www.globenewswire.com/en/news-release/2021/07/21/2266131/0/en/Soap-Noodles-Market-to-Garner-USD-1-217-0-Million-Revenue-by-2027-at-3-0-CAGR-Report-by-Market-Research-Future-MRFR.html

https://www.globenewswire.com/en/news-release/2021/07/19/2264656/0/en/Syntactic-Foam-Market-Size-Worth-USD-233-7-Million-by-2028-at-5-85-CAGR-Report-by-Market-Research-Future-MRFR.html

https://www.globenewswire.com/en/news-release/2021/07/15/2263279/0/en/Prepreg-Market-Size-to-Reach-USD-10-Billion-by-2028-at-9-CAGR-Report-by-Market-Research-Future-MRFR.html

https://www.globenewswire.com/en/news-release/2021/09/23/2302010/0/en/Advanced-Glass-Market-worth-USD-109-89-billion-by-2028-registering-a-CAGR-of-9-17-Report-by-Market-Research-Future-MRFR.html

0 notes

Text

Understanding the Basics of Area-Specific Air Distribution Principles

Air distribution is an underrated but extremely important aspect of an HVAC system. Moreover, Air Distribution is an engineering specialization that underlines the operations of central air conditioning units, air coolers, kitchen exhausts, and a host of other setups concerning heating, ventilation, and air conditioning.

In the subsequent sections, we shall talk about the basics of air distribution while taking all the primary and secondary factors into account:

More about the Terminologies

Air jets come out of slot diffusers, perforated panels, and grilles but the extent and distribution depend on the three important concepts, including Throw, Drop, and Spread. The horizontal airstream travel is termed as the air throw and is determined by the pressure difference in select sections of the room or the concerned space.

Vertical distance covered by the air stream is termed as the drop whereas the divergence in both vertical and horizontal plans is termed as air spread.

Components Involved

Although the air terminal devices help with circulation several components are actively involved in determining the air quality. These include ductwork, HVAC filters, fans, and more. All these components are actively involved in designing specific air distribution systems. Every distribution system concerns pressure differences better termed as static pressure and velocity pressure.

Every reliable HVAC consultant needs to have a good understanding of the concepts of velocity and static pressure, for designing a functional air distribution system. Whilestatic pressure is the air pressing against the ducts, velocity pressure is the horizontal component regulating the airflow.

Types of Air Distribution Systems

Now that we have established the components that determine the efficacy of an air distribution system, we shall now talk about the systems in general based on air volume, airflow rate, dual duct, and other aspects.

Single Zone Distribution System

This HVAC system features a heat source, distribution ducting, cooling source, and air handling unit. This kind of system is mainly seen in rooftop air conditioning and ventilation units. Single-zone systems work in the same thermal layout and are excellent choices if you are looking for a simple design that’s easy to maintain.

However, you always connect with credible HVAC contractors like Searcho for setting up a single zone system as any irregularity can reduce the airflow and leads to defects in the HVAC system. In the case of central air conditioning units, a two-element single zone HVAC setup is mainly preferred. This includes a thermostat for controlling operations and a sink for calculating the throw, drop, and spread.

Different rooms in the same building often come under a unified thermal zone. What most companies fail to realize is that the movement of individuals can also determine the thermal energy and therefore efficacy of the single zone air distribution system. For example, in malls, based on the structure and the architectural elements, a single zone system is often persisted with.

Multi-Zone Air Distribution System

The basic premise of a multi-zone system is the availability of different thermal layouts. To be precise, there is a common inflow of hot and cold air, and based on the thermal layout, the components are adequately mixed and distributed. The highlights of a multi-zone system are the availability of parallel ducts that supply air based on changing thermal requirements.

In addition to that, multi-zone units also feature mixing dampeners, cooling coils, and heating coils. Air handlers are added, depending on individual preferences. The HVAC setup costs go up as you require multiple supply ducts for serving diverse zones.

Based on different technologies and concepts laid down by ISHRAE, a leading HVAC consultant i.e. Searcho comes with additional systems for air distribution. These include the terminal reheat system that uses a specific heating load but isn’t energy-efficient. Another system is the dual duct layout that is an extension of a multi-zone system but it minimizes the issues that come with separate ducts for sending across the air to different thermal regions.

Bottom-Line

A good and reliable HVAC consultant like Searcho abides by the diverse guidelines tabulated by ISHRAE, therefore making way for efficient air distribution systems. Be it the inclusion of fan coil units for heating the cooling and heating coils of the multi-zone system or the induction units for mixing air based on requirements, air distribution isn’t an easy concept to understand. However, Searcho makes it easier for individuals to understand and even makes sure that the technicians demonstrate every technology in detail while installing the systems.

#fan coil units#HVAC consultant#HVAC system#entral air conditioning#ventilation units.#slot diffusers#suppliers#searcho

0 notes

Text

Form 4 in Switchboards (Form of Separation)

INTRODUCTION The Main & primary function of Switchgear assembly partition/separation is to protect the maintenance or installer personal from any electrical risks (i.e. Internal Arc Flashes). It must be very well verified the IP level in line with international standards IEC60529. Related to my own journey in switchboards manufacturing, I personally experienced without knowing fundamental of Ingress Protection, it's very difficult to achieve From of Separation in Switchgear Assembly. ABOUT SELECTION OF FORM-4 The higher the form of separation level leads to more barrier and partition implant in switchboards but it again leads to poor ventilation, block airflow, and cover more space in the switchboard. At a higher level of separation restrict the maintenance area in switchboards and tracking of fault becomes more stringent to a quick resolution. Form-4 level of switchboards needs experienced electricians or engineers to access the zones in resolving any issue by removing multiple-barrier or partitions. In many applications, I personally experienced that Form-3b will perform better for ease of maintenance or accessibility of functional units, busbars, and cable chambers. Form-4 is highly recommended due to its property of inherently safe switchboard. Selection of Form-4 is very critical in many areas or applications where mass transportation or use in severe applications i.e. METRO, Shopping Malls, Gas Stations, Airports, Hospitals, etc. Although maintenance at this level is very stringent but very safe to do activities Functional unit wise which is having separate cable chambers. FORM-4 in DETAILS There are 7 ways for achieving Form-4 in switchboards by implanting barriers and partitions according to the design in two categories 4a & 4b. These barriers can be metallic or non-metallic area wise w.r.t. the live part protection. For the requirement to comply with Form-4 by any of 7 methods & these are totally specified by the customer/user and the manufacturer's mutual agreement w.r.t. IEC standards:-

FORM-4a in Details

FORM-4b in Details (Whereas we will use ‘a’ then it denotes terminal are inside the functional unit separated from the busbar and where we use ‘b’ then it denotes terminal outside the functional units separated from the busbar.)

FORM-4a explanation with relevant Pictures FORM-4a Type-1 Here the main Busbar is separated by the insulation applied on it e.g. PVC sleeving, wrapping, or coating. Due to covering over Busbars, terminals are separated from the busbars but inside the functional units. (refer figure above) FORM-4a Type-2 Here the main Busbar is separated by a metallic or non-metallic rigid barriers or partitions. Due to barriers or partitions above Busbars, terminals are separated from the busbars but inside the functional units. Cable glands outside the panel and termination in the functional unit area. (refer figure above) FORM-4a Type-3 In this criteria, the main Busbar is separated by a metallic or non-metallic rigid barriers or partitions. Due to barriers or partitions above Busbars, terminals are separated from the busbars but inside the functional units. Cable glands and termination inside the functional unit area. (refer figure above)

FORM-4b explanation with relevant Pictures FORM-4b Type-4 Here the main Busbar is separated by the insulation applied on it e.g. PVC sleeving, wrapping, or coating. Due to covering over Busbars, terminals are separated from the busbars and functional units also separated by a metallic or non-metallic rigid barrier or partition. Cable glands outside the panel and termination in the functional unit area with a boot applied on cable termination. (refer figure above) FORM-4b Type-5 Here the main Busbar & Functional Units are separated by a metallic or non-metallic rigid barriers or partitions. Due to barriers or partitions above Busbars, terminals are separated from the busbars as well as from the functional units. Cable glands outside the panel and termination in the functional unit area with a boot applied on cable termination. (refer figure above) FORM-4b Type-6 Here the main Busbar and Functional Units with its individual Cable Chambers (Cable Connections Boxes) are separated by a metallic or non-metallic rigid barriers or partitions. Cable glands outside the panel and termination in its Individual Connection Box. (refer figure above) FORM-4b Type-7 This is the highest form of separation, here the main Busbar and Functional Units with its individual Cable Chambers (Cable Connections Boxes) are separated by a metallic or non-metallic rigid barriers or partitions. Cable glands are over the Individual Cable Connection Boxes inside the panels for cable termination inside it. (refer figure above) DO's Minimum IP2x level of Ingress Protection or achieve protection of ”Finger Touch Proof” in Barriers & Partitions.Epoxy/PVC Based Boots with Higher Temperature co-efficient must be used in Type 4 & 5.Busbar Covering by Insulated material must be unique and with the identification of busbars.Proper Gap should be there in between two cable terminations as all terminals come in one chamber in Type-4 & 5.Cable Chamber Boxes design must be in accordance with Cable Sizes & Arrangement w.r.t. respective current rating.Inside Cable Glanding required more space so it needs to take care of in design in Type 3 & 7.Cable chamber Gland Plates must be of a Higher thickness (Min.2.5mm or more) in Type 3 & 7.Gland Plates must use non-ferrous in the case of Single Core Cables.Except Type 3 & 7, Cable Chamber cover plates for cable entry must be cross-cut in between cable runs entry. DON'Ts Do not forget to achieve IP2x Level as well as protection of "Finger Touch Proof" in each and every partitions.Covering over the busbar must not puncher at any level to avoid any accidents.Metallic barriers should maintain minimum clearance & creepage from busbars or live part w.r.t. IEC Standards.Avoid direct termination over Switchgear, to avoid building stress and connection feasibility.Don't under design the Cable Chambers in Type 3 & 7.Boots sizes in such a way that it should cover the whole termination area.Cable Chamber Sizes should not oversizes than functional units sizes. Read the full article

#bishla#Corona#COVID19#educational#Electrical#Engineering#form4#formofseparation#manufacturing#Switchboard#Switchgear#technical#TQM#tricolite

0 notes

Text

The Luxury Of Air Conditioning: Our Homeowner’s Guide To Cost, Types, Size & Common Repairs

Just 50 years ago, air conditioning was a luxury. Today, AC is a staple of the American lifestyle. This necessary luxury has transformed the way we live, work, and play in New Albany, IN. Now we can build bigger buildings, assemble in larger groups, develop modern medicine and free ourselves from the uncertainty of the weather. Even reading this article, on a website, hosted by a server in a climate-controlled server room wouldn’t be possible without the invention of air conditioning.

In today’s world, it is inconceivable to even consider staying in a sweltering hot room without air conditioning. Can you even imagine a New Albany, IN hotel that doesn’t offer air conditioning? The sheer thought is laughable. Would you stay in a movie theatre when the AC is out? They would be better off shutting down the business completely.

So how did this need for climate control begin? How can you best take care of your current air conditioner and what does the future of AC look like? We’re so glad you asked.

WHO INVENTED AIR CONDITIONING?

People have been trying to stay cool for centuries. Even the ancient Egyptians would hang wet mats from their doorways to add a cool breeze to the hot desert. Romans circulated water through indoor pipes to cool off their stuffy villas. But it wasn’t until 1902 that real, viable air conditioning was introduced to the modern world.

The Sackett-Wilhelms Lithographing and Publishing Company in Brooklyn, NY found that excessive humidity during the summer was ruining the color register they used for their printing press. They hired a young engineer named Willis Carrier to solve this problem and that’s exactly what he did.

Willis Carrier developed a system of chilled coils that maintained a constant and comfortable humidity of 55 percent inside the printing plant and the concept of air conditioning was born. As the use of air conditioning spread to more plants and mills, Carrier continued to invent more efficient units. Eventually, movie theatres caught on to this cooling trend and realized they could pack their theatres full of patrons by offering “cool comfort” on a hot summer day. People began flocking to the theatres and Carrier installed cooling units in 30 movie theatres across the country. This was the very beginning of the “summer blockbuster” trend.

By the 1950s, those who could afford it started installing air conditioning in their homes. By 2007, 86 percent of homes had AC according to the Carrier Corporation.

PARTS OF AN AIR CONDITIONER

Today’s air conditioners are a far cry from the chilled coils of 1902, but the basic physics remain relatively the same.

Refrigerant Filled Tubing: Refrigerant is what we use now to cool the air. Initially, engineers used ammonia, which we now know to be toxic. Today’s refrigerant is a safe and reliable liquid that absorbs heat from the indoor air, changes it from gas to liquid and removes it from the air before changing back to a gas and repeats the cycle.

Compressor: The compressor pressurizes the refrigerant to heat it up and allow the heat to naturally flow towards it, which keeps everything running as it should.

Condenser Coil: This part is located in the outdoor unit. It receives the high pressure, heat-filled refrigerant and moves it to the outdoor New Albany, IN summer air.

Expansion Valve: The expansion valve removes pressure from the liquid refrigerant to allow expansion or change of state from a liquid to a vapor.

Evaporator Coil: These copper tubes receive the de-pressurized refrigerant from the expansion valve and actually absorbs the heat from the home.

Fan: The fan simply creates a current to keep the air moving throughout the system.

Filter: A filter is used to catch dust, dirt, pollen, and other allergens from recirculating in the air, keeping our air cleaner than ever before.

HOW DOES AIR CONDITIONING WORK?

All of the above components work together to make the air conditioner work all summer long without you hardly lifting a finger.

If you look around your New Albany, IN home, you’ll see return vents in each room. These suck in hot air from inside the room. The refrigerant inside your unit picks up this heat as air flows over the freezing cold evaporator coils and is absorbed by the refrigerant. Once the refrigerant has absorbed as much heat as possible, it then discharges it to the compressor. The compressor then adds pressure and heat and passes it on to the condenser coils. The big fan helps to push the air over the condenser coils to move the heat outside. The refrigerant then cycles back, and the process starts over and over again.

DIFFERENT TYPES OF AIR CONDITIONING

Window Air Conditioners: If you walk down the city street in New Albany, IN during the summer you may see white plastic boxes sticking out of windows. Those are window air conditioners. These are mounted in a window and push hot air out the back while blowing cold air through the front.

Central Air Conditioning: This is pretty common in most single family homes in New Albany, IN. It uses all the components we described above in the most effective form of air conditioning controlled by a central thermostat.

Portable Air Conditioners: Similar to a window system, a portable AC cools one small room if you don’t have another cooling option.

Through the Wall Air Conditioners: This is a self-contained unit like a window or portable AC, but it is permanently mounted and cannot be removed. It is installed in an exterior wall and should be done by a professional.

Ductless Split Air Conditioners: This is the cooling system to use if you want different “zones” within your home, or if your home doesn’t have existing duct work. However, they are typically more expensive to install than a central AC system.

Package Terminal Air Conditioners: This is a commercial air conditioning unit that is often used in hotels, hospitals, apartments, and assisted living facilities. However, you can install them in a home, and they may be a good option if you’ve added a room to your New Albany, IN home or if you have one room that is particularly warmer than the rest of the house and you need extra cooling.

Evaporative Coolers: These are most commonly known as “swamp coolers” and they aren’t as common as they used to be. They use only air and water to cool the room, without using any refrigerant. They are best in hot, dry climates because they will add humidity to the air rather than take it away. In New Albany, we have too much humidity to make evaporative coolers effective.

Geothermal Cool Systems: This is relatively new technology that uses ground temperature to heat and cool your home. It is the most energy efficient method of air conditioning, but also the most expensive to install in New Albany, IN.

Heat Pumps: A heat pump can both heat and cool your house, depending on the season. It works best in mild climates and is an energy efficient option. Sometimes a heat pump can be used in conjunction with a central air system.

HOW LONG DOES AN AIR CONDITIONER LAST?

Air conditioning is a significant investment in your home, so you want to be sure you take care of it. Typically, an air conditioner in New Albany, IN lasts between 12-15 years. Of course, this can vary between locations, and can be extended with proper maintenance and repairs.

SIGNS OF AIR CONDITIONING REPAIR

Warm Air: An air conditioner is supposed to provide cool air, never warm. If you notice that your AC unit is running, and yet the temperature is still rising, it’s time to call in a professional for an air conditioner repair in New Albany, IN. This could be due to the refrigerant, temperature sensors, thermostat, drainage, and/or dirty filters.

Low Airflow: You’re getting weak airflow, this is usually a sign that the unit is not working efficiently or that you have a blockage in the ductwork, a clogged filter, or a broken motor. An air conditioner repair technician can help you identify the issue, remove any blockages, and give your AC a boost or zoning your systems to increase efficiency. Working with a qualified technician in New Albany, IN is the best way to ensure you’re getting the best airflow where you need it most.

Frequent Cycles: Your air conditioner goes through relatively routine cooling cycles throughout the day. However, when you notice your unit turning on and off frequently and consistently throughout the day, it’s time for an air conditioner repair and checkup. This may be a simple problem with a thermostat battery or could signal that it’s time for a new system. The only way to be sure is to have your unit thoroughly inspected.

High Humidity: Part of the job of an air conditioner is to remove the humidity inside the home. If you are still feeling sticky and humid in the living room, that’s a problem. An air conditioner repair technician in New Albany, IN can diagnose humidity issues relatively quickly and determine whether you need a quick recalibration or an additional whole-house dehumidifier to support your ac unit.

Water Leaks or Pooling Water: Your air conditioner uses refrigerant to cool your home. Some level of condensation is completely normal, but no liquid should accumulate or leak out of the unit. Any time you see pooled water or an active leak around the unit, it’s a sign that something isn’t right. You need an air conditioner repair as soon as possible. Don’t wait to call as sometimes leaks can cause serious damage to your home.

Bad Odors: If you smell unpleasant odors from any part of your HVAC system, you’ll want to deal with the issue before it becomes seriously stinky. Generally, this doesn’t require an air conditioning repair. Usually it just means the unit needs a professional cleaning and tune-up of the AC unit itself. Other times, it might be something in the duct work, which can be cleared out with a thorough duct cleaning.

Weird Noises: Most air conditioners make a little bit of noise as they start up and shut down. This should sound like a low hum, and nothing more. Anything that is loud, sudden or unusual could be a sign of a big problem that likely won’t go away on its own, so it’s time to call for a New Albany, IN professional air conditioning repair.

WHEN TO REPLACE YOUR AIR CONDITIONER

Over 10 Years Old: If your unit is getting older and reaching its 10th birthday, it might be time to consider a replacement. A well-maintained unit in New Albany, IN may last up to 15 years, but after the 10 year mark it usually makes more sense to replace than pay for an air conditioner repair.

High Repair Costs: Any time the repair bill is extensive, it’s worth looking at replacing the unit completely. If the cost of an air conditioner repairs close to (or more than) 50 percent of the cost of a new system, it may be worthwhile to consider a replacement.

Frequent Repairs: No one wants to deal with an unreliable system on an ongoing basis. If you’re having to call in for an air conditioning repair every season (or multiple times per year), it might be time for an upgrade to a more reliable system.

Weird Sounds or Smells: This is often a sure sign that it’s time for a new unit. Sounds are often due to internal parts that are damaged, and odors may be caused by an internal failure that is better off to be replaced rather than attempt a repair.

Uses R-22 refrigerant: This type of Freon is being phased out by the government and is no longer sustainable. If your unit uses R-22 Freon, it will need to be replaced.

Higher Energy Bills: No one wants to pay more for less. If your energy bills are rising month after month, it’s a good indicator that your system is overworked and under-delivering. This is usually a sign that it’s time for an AC replacement.

No Longer Properly Cools Your Home: Sometimes an older unit is simply too tired, or a small unit can’t keep up with demand. In either case, if your air conditioner is not properly cooling your New Albany, IN home to keep your family comfortable, it might be time for a replacement.

WHAT SIZE AIR CONDITIONER DOES MY HOME NEED?

When it’s time to purchase a new unit, it can be tricky to determine what size to purchase for your home. A unit too big can cause drastic temperature variations from room to room and a unit too small will not be able to properly cool your New Albany, IN home. It is based on several factors:

1. BTUs: The best way to calculate the number of BTUs, or British Thermal Unit, is to use the Manual Calculation. A professional HVAC technician will look at the following things to get an accurate measurement.

Square footage

Climate zone

Ductwork

Quality & amount of insulation

Typically, warmer climates need 18-30 BTUs per square foot (this includes New Albany, IN) and cooler climates need 12-20 BTUs per square foot.

2. Age of Home: If you have an older home, it may take more power to keep it cool in the hot New Albany, IN summer

3. Number of exterior walls and windows: This can affect the energy it takes to heat or cool a home.

4. Insulation: Sometimes this goes hand in hand with the age of the home, but insulation plays a huge role in keeping your home climate controlled.

5. Existing ventilation and ductwork: The existing infrastructure of your home may determine what size of unit it can handle.

HOW MUCH DOES IT COST TO REPLACE A CENTRAL AIR CONDITIONING UNIT?

A new air conditioner can cost anywhere from $3,000 – $7,000. Larger or more complicated projects can range up to $10,000. The price is based on several factors including the unit’s quality, performance, efficiency, and size.

Quality: Just like any purchase, you get what you pay for. There are some appliance manufacturers that simply make better quality products while others are geared to be budget friendly. You have to find the balance that fits with your need and your budget.

Performance: Appliance performance is rated using the SEER rating system. SEER stands for “Seasonal Energy Efficiency Rating”. This score determines how well the unit performs. A SEER rating of 13-15 is the lowest ranked. Generally, this means they are running at full power almost all day. They will likely be louder and less energy efficient. A SEER rating of 20-24 are the best performing, quieter, more efficient, and best at creating a balanced temperature in your home.

Efficiency: Efficiency in an appliance is measured in British Thermal Units (BTUs). The BTU rating you need is determined by the area you live in. In New Albany, IN we live in Zone 4, which means you want a moderate unit with 18-22 BTU/sq.

Size: Selecting the right size ac unit is directly correlated to the square footage of your home and the climate you live in.

HOW TO INCREASE THE EFFICIENCY OF YOUR COOLING SYSTEM

While the efficiency of your air conditioning is primarily dictated by the system itself, there are some things you can do to help get the maximum efficiency from your cooling system.

Seal windows & doors: One of the biggest ways we waste energy is through windows and doors that are drafty. Seal these up and make sure to keep them closed during the summer.

Proper thermostat placement: Make sure your thermostat is placed in an area that does not receive direct sunlight, this can fool the thermostat into thinking it’s warmer than it is and affect the efficiency of your AC.

Proper temperature settings: Increase your thermostat by 5-8 degrees warmer than you’d like – this can help save a ton of money and energy and still maintain a comfortable temperature during the summer months.

Reduce the amount of added heat: If possible, cook outside, or use non-heat methods. Summer in New Albany, IN is a great time for grilling or enjoying salads for dinner. Avoid running the oven all day long or using heat-generating appliances.

Use fans & curtains: There is still something to be said for creating natural shade and moving the cool air around your home. These steps can take a load off your cooling system while keeping you comfortable.

Plant trees: The more shade you have on your property, the less your unit has to work to keep you cool.

Clean around your outdoor unit: Keeping this free and clear from leaves, branches, and debris allows it to work properly, which can increase efficiency.

Vacuum indoor vents & keep them unblocked: Sometimes your air conditioner has to work twice as hard just to get through the dirt caked on the vents. Keep these clean and let the air flow freely.

AIR CONDITIONING FAQS

What are the functions of AC filters?

The job of the air filter is to clean the air that circulated through your home. A high quality filter will trap and hold many types of particles including dust, dirt, pollen, mold, fibers, metals, hair, fur, and even bacteria.

What temperature should I set my AC to?

The temperature you choose will show up on your monthly bill, so this is an important decision. On average, it costs about a dollar an hour to heat a room that is 50 square feet. That’s $24 per day. We recommend finding a sweet spot where the temperature feels comfortable but doesn’t cost too much to maintain. Start at 78 degrees and if that’s too warm, lower by one degree each day until you hit a comfortable temperature.

What happens if you set your AC too low?

Most AC units are happiest when they are no lower than 68 degrees. Much lower than this, and you risk freezing the outside unit. When this happens, you have ice or frost form on the coils, and it can damage your compressor. When this happens, your AC will not function properly, and may even be permanently damaged.

What does the SEER rating on my AC mean?

This score determines how well the unit performs. A SEER rating of 13-15 is the lowest ranked, 20-24 is the highest.

How often should I schedule air conditioner maintenance?

We recommend servicing your air conditioner at least once a year to keep your warranty intact and increase efficiency and performance.

What is the difference between R-22 And R-410A Refrigerants?

R-22 is the old version of Freon that is now being phased out. R-410A is the new, chlorine-free version that is ozone-friendly and the standard refrigerant today.

How do I clean my air conditioner?

The best thing you can do to keep your unit clean is to ensure the outside unit is free from debris and your filters are regularly changed on the indoor unit. A yearly maintenance visit by a licensed HVAC contractor will provide a professional cleaning and inspection.

YOU CAN TRUST US TO KEEP YOU COOL

For most of us, air conditioning is an assumed benefit, an expected result, and a necessary luxury. We don’t appreciate it until it’s unavailable, and to live without it permanently is unfathomable.

As you can see, we know a thing or two about air conditioning. We make it our business to understand where it comes from, how to install it, when to repair it, and why it works the way it does. We educate ourselves on both the ancient and modern technology of air conditioning so we can provide the very best products and services to our customers.

If you’re in need of air conditioning repair, replacement, or have questions about how your system works – give us a call. We service New Albany, IN and the surrounding area to keep you and your family comfortable all summer long.

The post The Luxury Of Air Conditioning: Our Homeowner’s Guide To Cost, Types, Size & Common Repairs appeared first on AllegianceHVAC.com Allegiance Heating and Air Conditioning 7201 Highway 150 Greenville, IN 47124 812-923-4406 https://www.allegiancehvac.com/map/ https://www.allegiancehvac.com/info/

0 notes

Text

DK Eyewitness Travel Guide Walt Disney World Resort Orlando DK Publishing Google

Hmmm…check the wiring of the thermostat. The installer came out quickly, explained the entire process and installed the new system literally the very next day and we had heat! I recently moved into a new home in New York with no duct work and I am looking to install central air. Wasps and hornets, as well as the honey bee find finned coils to be comfortable nesting places.

Even though I am "guessing" based on age and sq footage its just a start. The optimal size for your home will depend on your square footage and the climate where you live. These facts and more importantly, some great tips on managing fatigue can be found in this quick read thanks to our friends at the Natonal Agricultural Aviation Association. Inspections ensure that a system is safe, will produce lower utility bills, and help the state meet energy-efficiency goals. Whole-house Zoning - With this option, you can control the temperature for each room. Since these units are located outside your home, you want a product that will not bother you or your neighbors. Packaged terminal air conditioner PTAC systems are also known as wall-split air conditioning systems. Do you want a full system with a thermostat or a specific machine for the summer like a swamp cooler? It specializes in condensing boilers, heat exchangers, indirect fired water heaters and direct fired water heaters. Access your saved products.. Keep in mind that you will be paying the fee every year regardless of whether you have a repair done. They now specialize in both residential and commercial air conditioning systems, sold at dealers nationwide. Our quieter but pricier pick, the Haier Serenity, has gone out of stock. Use the price list to select lowest price AC Repair Midway 32343 (click the following internet site) in India that best fits into your budget. Over time they can weaken. The big concern with septic tanks is to minimize the organic load on the system — table scraps go into the trash can instead of down the garbage disposal — to protect the drain field and maximize the time between visits by the honey truck. This difference has to do with the system setup, where a cooling system is usually designed to release heat generated from the energy consumed outside of the area to be cooled. You can search for and find the best schools in any area. I would never purchase anything with their name on it again and would strongly tell others to keep their money in their pockets and use someone else. Watch us on Youtube. Goodman MFG has imposedM inimumA dvertisedP ricing otherwise known as MAP. Ceiling and Wall Heaters. Normally the thermostat would control the entire system…if it works for part of it, it should be working for all of it. If you have a bigger home with multiple rooms, you will probably need to have a central air conditioner installed. Return to Top Rebates and Warranties Warranties HVAC warranties will vary from manufacturer to manufacturer. We cover this problem in detail on the following page: We have an air conditioner troubleshooting flow chart on the following page: We have a long list of problems with answers on the following page: I hope you can easily find and fix the problem. AOP HTalk Contractor Map. Subject: Air Flow Problems Chances are it is not a part problem but an airflow problem. Constant air volume CAV. See the Latest Listings in Your Area.. A steam heating system takes advantage of the high latent heat which is given off when steam condenses to liquid water. Seems more than a little high. The constant vibration of the compressor can also cause solder joints to weaken and leak. Ceramic Tile Floor Costs. Front Loader Washing Machines. Join Customer Stories: "Whenever we need appliance parts we count on your company - Repair Clinic, anything from a stove top to a freezer part.

2 notes

·

View notes

Photo

IT’S THAT TIME OF YEAR AGAIN: storm warnings, preemptive cancellations, the mist and spray of that strange heated fluid splattering off the fuselage. Airplanes and winter don’t always mix well.

The flying part is easy. Sure, low visibilities, strong crosswinds, slick runways, potential icing — all of these things are challenges for pilots and cause air traffic backlogs, but as a rule they aren’t anything that airplanes or their crews can’t handle. It’s not the in-the-air aspects of a snowstorm that cause chaos, it’s the on-the-ground aspects: Runways and taxiways need to be plowed and treated, while tarmac logistics go to hell as snow and ice accumulate. Luggage and cargo handling, fueling — everything slows to a crawl as personnel and ground equipment become bogged in the slush.

Planes, meanwhile, cannot take off with ice or snow adhering to the wings. Parked at the terminal, an aircraft collects precipitation the way your car does — via snowfall, sleet, freezing rain or frost. (Thanks to supercooled fuel in the wings, frost can form insidiously even with temps above freezing.) The delicious-looking spray (apricot-strawberry) used to remove it is a heated combination of propylene glycol alcohol and water. It melts away existing snow or ice, and prevents the buildup of more. Different fluid mixtures, varying in temperature and viscosity, are applied for different conditions.

While it seems pretty casual to the passenger, the spraying procedure is actually a regimented, step-by-step process. Procedures vary depending on the type of fluid used, ambient temperature, plus the rate and type of precipitation. The airplane needs to be configured a certain way, and pilots stay in contact with the deicing coordinator throughout the process. The deicing guide in my manual is about 20 pages long, including several checklists, graphs and charts. We keep track of something called “holdover time” to help determine if and when a second round of deicing is necessary.

With fluid costing upwards of $5 per gallon, airlines loathe snowstorms almost as much as strikes, wars, and recessions. When handling and storage costs are considered, relieving a single jet of unwanted winter white can cost tens of thousands of dollars.

It’s money well spent, however, because ice on an airplane is potentially hazardous, especially when adhering to the wings. The monster isn’t the weight of the frozen material, but the way it disrupts airflow over and around a wing’s carefully sculpted contours, robbing a plane of lift.

Icing also can occur during flight. Under the right combination moisture and temperature, it can form along the leading edges of the wings and tail, along engine intakes and propeller blades, as well as on windscreens, probes, and various other surfaces. Left unchecked, heavy icing can damage engines, throw propeller assemblies off balance, and, just as it does on the ground, steal away precious lift. Planes are most susceptible during takeoff and landing, when speed is slowest and the lift margins already slim.

The good news is that most inflight ice encounters are brief and routine, posing little if any danger. Just in case, all modern commercial aircraft are equipped with deicing equipment. The various probes, sensors and windscreens are kept clear electrically. Engine intakes and wing leading edges are heated using air bled from the engines, or are deiced through a series of pneumatically inflated “boots” that break away accumulation. On propeller-driven planes, the prop blades are electrically heated. Whether pneumatically or and electrically-run, these systems use redundant sources and are separated into independently operating zones to keep any single failure from affecting the entire plane.