Teknoflow is the Preferred and Trusted Manufacturing Partner in the Acoustic, Air, Water, Oil & Gas, Energy, Recovery, Mining, and Water Industries. We provide a wide range of services and products from designing to custom development, Prototyping to the manufacturing of Equipment like Pressure Vessel (Coded & Non-Coded), Heat exchangers, Boilers, Industrial Silencers, Filter houses, Oxidizers, Exhaust and Intake Systems, and Ventilation systems.

Don't wanna be here? Send us removal request.

Text

Rto Thermal Oxidizer

Teknoflow Green Equipments Private Limited specializes in the design and manufacturing of RTO (Regenerative Thermal Oxidizer) systems, which are crucial for controlling volatile organic compounds (VOCs) and minimizing air pollution in industrial processes. Our RTOs utilize advanced thermal oxidation technology to efficiently convert harmful emissions into harmless byproducts, ensuring compliance with environmental regulations. With a focus on sustainability and innovation, Teknoflow is dedicated to providing customized solutions that enhance operational efficiency while safeguarding the environment.

0 notes

Text

This article outlines the top 5 benefits of installing a Regenerative Thermal Oxidizer (RTO) in your facility. It explains how RTOs significantly improve air quality by efficiently destroying volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), while reducing operational costs through energy recovery. The article also highlights the environmental advantages, regulatory compliance, and enhanced operational safety provided by these systems, making them an essential investment for industries looking to improve efficiency and meet stringent emissions standards.

0 notes

Text

This article highlights the critical role of safety standards in the design and manufacturing of air receiver tanks, emphasizing the steps Indian manufacturers are taking to ensure compliance and reliability. It explores how stringent quality controls, adherence to international safety regulations, and the use of advanced materials and technologies are helping to reduce risks in industries that rely on air receiver tanks. By focusing on these practices, Indian manufacturers are setting benchmarks in safety and quality, ensuring long-lasting and secure solutions for their customers.

0 notes

Text

The Role of Advanced Technology in Modern Pressure Vessel Tank Manufacturing

In today’s industrial landscape, the manufacturing of pressure vessels has evolved significantly, thanks to advancements in technology. Pressure vessels are critical components used across various industries, from oil and gas to chemical processing, power generation, and even food manufacturing. As industrial requirements grow more complex, modern pressure vessel tank manufacturers are leveraging cutting-edge technology to ensure safety, efficiency, and durability.

In this blog, we will explore how advanced technology is transforming the world of pressure vessel manufacturing and why working with experienced pressure vessel suppliers in India like Teknoflow Green Equipments Private Limited is crucial to ensuring top-quality products.

Precision in Pressure Vessel Design

The foundation of any successful pressure vessel begins with its design. Modern pressure vessel manufacturers now use advanced software tools like Computer-Aided Design (CAD) and Finite Element Analysis (FEA) to create highly accurate and optimized designs. These technologies allow engineers to simulate different operating conditions, ensuring that the pressure vessel design can withstand extreme pressures, temperatures, and chemical exposure.

At Teknoflow Green Equipments Private Limited, the integration of advanced design tools ensures that every vessel meets the specific requirements of its application while adhering to strict safety standards. This high level of precision results in improved product performance and longevity.

Material Selection and Innovation

With the help of technology, pressure vessel tank manufacturers can now better evaluate and select materials based on the unique requirements of each application. High-performance materials like carbon steel, stainless steel, and specialized alloys are tested using advanced simulation tools to ensure they can withstand the pressure, corrosion, and temperature fluctuations in various industrial environments.

By leveraging advanced material science, pressure vessel suppliers in India such as Teknoflow Green Equipments Private Limited can manufacture vessels that are not only durable but also cost-effective and energy-efficient.

Automated Fabrication and Welding

In the past, fabricating a pressure vessel required highly manual processes, which could result in human error and inconsistencies. Today, automated fabrication techniques have revolutionized the manufacturing process. Automated welding systems, for instance, ensure that welds are of uniform quality, reducing the chances of defects or leaks in the vessel.

Pressure vessel manufacturers in India like Teknoflow Green Equipments Private Limited utilize state-of-the-art welding robots and fabrication technologies, improving production speed and accuracy. These advancements contribute to stronger, more reliable pressure vessels that require less maintenance over time.

Advanced Testing and Quality Assurance

Safety is a top priority in pressure vessel design and manufacturing. To ensure each vessel meets regulatory standards, modern manufacturers employ advanced testing methods such as radiographic testing, ultrasonic testing, and hydrostatic pressure testing. These non-destructive testing (NDT) techniques allow manufacturers to inspect every aspect of a pressure vessel without causing damage.

By utilizing these advanced quality control methods, Teknoflow Green Equipments Private Limited ensures that each pressure vessel meets both international and local safety standards. This commitment to quality makes them one of the most reliable pressure vessel suppliers in India.

Customization and Flexibility

One of the most significant benefits of advanced technology in the pressure vessel industry is the ability to offer customized solutions. Using 3D modeling software, pressure vessel manufacturers can create tailored designs that meet specific operational needs, such as unique size requirements, pressure ratings, or material specifications.

At Teknoflow Green Equipments Private Limited, customization is at the core of their service offerings. They work closely with clients to design and manufacture pressure vessels that meet the precise needs of each project, ensuring safety and operational efficiency.

Sustainability and Efficiency

As industries shift towards more sustainable practices, pressure vessel tank manufacturers are increasingly adopting green technologies to reduce their environmental impact. From energy-efficient fabrication processes to the use of eco-friendly materials, modern manufacturers are innovating to meet global sustainability goals.

Companies like Teknoflow Green Equipments Private Limited are at the forefront of this trend, implementing sustainable practices in their production processes. Their commitment to eco-friendly manufacturing positions them as leaders among pressure vessel manufacturers in India.

Conclusion

The role of advanced technology in pressure vessel manufacturing cannot be overstated. From precision design to automated fabrication and stringent testing, these innovations are helping manufacturers create safer, more reliable, and efficient pressure vessels. By working with leading pressure vessel suppliers in India like Teknoflow Green Equipments Private Limited, industries can benefit from high-quality, customized solutions that meet their specific operational needs.

As technology continues to evolve, the future of pressure vessel design and manufacturing will likely bring even more improvements in safety, efficiency, and sustainability.

0 notes

Text

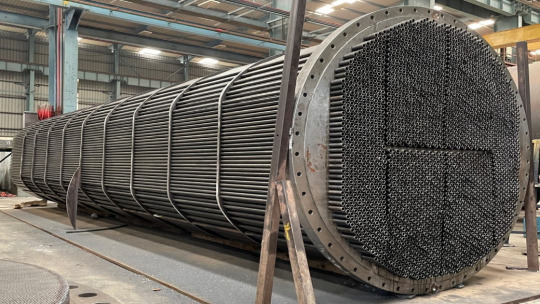

The Role of Heat Exchangers in Modern HVAC Systems: Key Insights

Heat exchangers are pivotal in modern HVAC systems, enabling efficient heat transfer between fluids. They help regulate indoor temperatures by transferring heat from hot to cold fluids or vice versa, enhancing energy efficiency and reducing operational costs. Their design and performance are crucial for maintaining optimal climate control and improving overall system effectiveness.

0 notes

Text

Top 5 Common Problems with Heat Exchangers and How to Fix Them

Heat exchangers are vital components in many industrial processes, but they can encounter common issues that affect performance. This guide highlights the top five problems: fouling, leakage, corrosion, inadequate heat transfer, and improper flow distribution. Each issue is accompanied by effective solutions to restore efficiency and ensure reliable operation. By addressing these challenges promptly, you can enhance the longevity and effectiveness of your heat exchanger systems.

0 notes

Text

Safety Considerations When Installing and Using Air Receiver Tanks

Air receiver tanks are crucial components in compressed air systems, serving as storage vessels that help regulate air pressure and improve system efficiency. However, the installation and use of air receiver tanks come with significant safety considerations. This blog will explore these safety aspects, focusing on best practices to ensure safe operation. Additionally, we will highlight the role of a reliable air receiver tank manufacturer in India in providing quality products that meet safety standards.

Understanding Air Receiver Tanks

Air receiver tanks act as buffers between the air compressor and the demand side of the system. They store compressed air and help stabilize pressure fluctuations, ensuring a consistent supply of air. The importance of these tanks cannot be overstated, as they play a vital role in maintaining the efficiency and reliability of compressed air systems.

Safety Considerations for Air Receiver Tanks

1. Proper Sizing and Selection

Selecting the right size of an air receiver tank is crucial for safety and efficiency. An undersized tank may lead to excessive cycling of the compressor, while an oversized tank can be unnecessarily costly and occupy valuable space. Consulting with an experienced air receiver tank manufacturer in India can help ensure you choose the appropriate tank for your specific needs.

2. Quality and Compliance

When purchasing an air receiver tank, it's essential to ensure that the product complies with industry standards and regulations. In India, tanks should adhere to standards such as IS 2825, which governs the design and manufacture of pressure vessels. A reputable air receiver tank manufacturer in India will provide tanks that meet these stringent standards, ensuring safety and reliability.

3. Installation Location

The location of the air receiver tank is another critical safety consideration. The tank should be installed in a well-ventilated area, away from direct sunlight, heat sources, and flammable materials. Adequate space should be provided around the tank for maintenance and inspection activities.

4. Pressure Relief Devices

Air receiver tanks must be equipped with pressure relief devices, such as safety valves, to prevent over-pressurization. These devices should be properly sized and set to activate at the tank's maximum allowable working pressure. Regular testing and maintenance of pressure relief devices are essential to ensure their proper functioning.

5. Regular Inspections and Maintenance

Routine inspections and maintenance are crucial for the safe operation of air receiver tanks. Inspections should include checking for signs of corrosion, leaks, and damage. Internal inspections should be conducted periodically to assess the condition of the tank's interior surfaces. Maintenance activities, such as draining condensate and testing safety valves, should be performed according to the manufacturer's recommendations.

6. Proper Drainage

Condensate accumulation in air receiver tanks can lead to corrosion and reduced storage capacity. Installing automatic or manual drain valves helps remove condensate and prevent moisture-related issues. Regularly draining the tank is a simple yet effective way to maintain its integrity and safety.

7. Pressure Monitoring

Installing pressure gauges on air receiver tanks allows for continuous monitoring of internal pressure levels. This helps operators detect abnormal pressure variations that could indicate potential issues. Maintaining pressure within the recommended range is essential for safe operation.

8. Training and Education

Ensuring that personnel responsible for operating and maintaining air receiver tanks are adequately trained is vital for safety. Training should cover proper operating procedures, emergency response, and routine maintenance tasks. An informed workforce can significantly reduce the risk of accidents and ensure the safe use of air receiver tanks.

The Role of Air Receiver Tank Manufacturers in India

A reliable air receiver tank manufacturer in India plays a crucial role in ensuring the safety and efficiency of compressed air systems. These manufacturers provide high-quality tanks that meet industry standards and offer technical support to assist with proper selection, installation, and maintenance. Here are a few ways they contribute to safety:

Quality Assurance: Reputable manufacturers adhere to strict quality control processes, ensuring that each tank meets safety and performance standards.

Custom Solutions: Manufacturers can provide customized air receiver tanks tailored to specific requirements, ensuring optimal performance and safety.

Technical Support: Expert advice and support from manufacturers help customers make informed decisions about tank selection, installation, and maintenance.

Compliance: Leading manufacturers ensure their products comply with national and international standards, providing peace of mind regarding safety and reliability.

Conclusion

Safety is paramount when installing and using air receiver tanks in compressed air systems. Proper sizing, quality assurance, pressure relief devices, regular inspections, and training are critical aspects of ensuring safe operation. Partnering with a reputable air receiver tank manufacturer in India can provide the necessary expertise and high-quality products to meet these safety requirements. By prioritizing safety, businesses can ensure the reliable and efficient performance of their compressed air systems, protecting both personnel and equipment.

0 notes

Text

How to Evaluate the Best Air Receiver Tank Manufacturer for Your Needs

When it comes to selecting an air receiver tank manufacturer, making the right choice is crucial for ensuring efficiency, reliability, and safety in your industrial operations. Air receiver tanks play a vital role in various applications, from storing compressed air to stabilizing pressure fluctuations. Here’s a comprehensive guide to help you evaluate and choose the best air receiver tank manufacturer tailored to your specific requirements.

Define Your Requirements

Begin by clearly defining your operational requirements and specifications. Consider factors such as the volume of compressed air needed, operating pressure, ambient conditions, and any specific regulatory standards or certifications required for your industry.

Assess Industry Experience and Reputation

Look for manufacturers with a proven track record in designing and manufacturing air receiver tanks. A reputable manufacturer with years of experience is likely to offer products that meet high-quality standards and comply with industry regulations. Check customer reviews, testimonials, and industry certifications to gauge their reputation.

Quality Standards and Certifications

Verify if the manufacturer adheres to international quality standards such as ASME (American Society of Mechanical Engineers) standards for pressure vessels. Compliance ensures that the tanks are designed, fabricated, inspected, and tested to meet rigorous safety and performance criteria.

Customization Capabilities

Evaluate the manufacturer's ability to customize air receiver tanks according to your specific needs. Whether you require a particular size, material, or additional features such as special coatings or instrumentation, ensure that the manufacturer can accommodate customization without compromising quality.

Product Range and Innovation

Consider the manufacturer's range of products and technological innovations. A manufacturer that invests in research and development to enhance product efficiency, durability, and energy savings can offer you cutting-edge solutions that align with industry trends and advancements.

Manufacturing Processes and Facilities

Visit or inquire about the manufacturer's production facilities and processes. Modern manufacturing facilities equipped with advanced machinery and quality control systems contribute to consistent product quality and reliability. Ask about their manufacturing capabilities and quality assurance protocols.

Support and Service

Evaluate the manufacturer's customer support capabilities, including after-sales service, technical assistance, and warranty terms. A responsive and supportive manufacturer can provide timely assistance, maintenance, and troubleshooting solutions throughout the lifespan of your air receiver tank.

Cost Considerations

While cost shouldn’t be the sole deciding factor, compare pricing structures among different manufacturers. Consider the overall value proposition, including product quality, customization options, warranty coverage, and ongoing support services, to determine the best investment for your budget.

Sustainability and Environmental Responsibility

Assess the manufacturer's commitment to sustainability practices and environmental responsibility. Look for eco-friendly manufacturing processes, energy-efficient designs, and recyclable materials that align with your organization's sustainability goals and regulatory requirements.

References and Case Studies

Request references or case studies from the manufacturer showcasing successful projects similar to yours. Insights from other customers can provide valuable perspectives on the manufacturer's reliability, performance, and ability to deliver solutions that meet specific industrial needs.

Conclusion

Choosing the best air receiver tank manufacturer involves thorough research, careful evaluation of capabilities, and alignment with your operational requirements and industry standards. By focusing on quality, customization, support, and sustainability, you can make an informed decision that enhances efficiency, reliability, and safety in your industrial applications.

Remember, investing in a reputable and reliable manufacturer ensures that your air receiver tank not only meets but exceeds your expectations for performance and longevity.

FAQ’S

What is an air receiver tank, and why is it important?

An air receiver tank is a crucial component in compressed air systems, used to store compressed air and stabilize pressure fluctuations. It helps enhance system efficiency, reduce energy costs, and protect downstream equipment from pressure variations.

How do I choose the right air receiver tank manufacturer?

When selecting a manufacturer, consider factors such as their industry experience, reputation for quality and reliability, adherence to safety standards like ASME, customization capabilities, and customer support services. Evaluating these aspects ensures you find a manufacturer that meets your specific operational needs.

What certifications should I look for in an air receiver tank manufacturer?

Look for manufacturers certified by organizations such as ASME (American Society of Mechanical Engineers) for pressure vessel design and manufacturing. These certifications ensure that the tanks are built to rigorous standards, tested for safety, and compliant with industry regulations.

Can air receiver tanks be customized to specific requirements?

Yes, reputable manufacturers often offer customization options to tailor air receiver tanks to your specific needs. This includes adjustments in size, material selection (such as stainless steel for corrosion resistance), special coatings for environmental conditions, and additional features like instrumentation or insulation.

What support services should I expect from an air receiver tank manufacturer?

A reliable manufacturer should provide comprehensive support services, including technical assistance during installation and operation, maintenance guidelines, warranty coverage, and responsive customer support for any inquiries or issues that may arise with the tank.

0 notes

Text

Mining Ventilation Equipment in India: Ensuring Safety and Efficiency Underground

Overview of Mining Ventilation

Definition and Importance

Mining ventilation equipment in India involves the process of supplying fresh air to underground mines and removing contaminated air. This is essential to ensure the safety and health of miners by controlling the levels of dust, gases, and heat in the mining environment.

Historical Background

The need for proper ventilation in mines has been recognized for centuries. Early mining operations relied on natural ventilation, but technological advancements have led to the development of sophisticated mechanical ventilation systems.

Current Scenario in India

India's mining industry is diverse, covering coal, metal, and non-metal mining. The demand for efficient ventilation systems has increased with the expansion of mining activities, driven by regulatory requirements and the need for improved worker safety.

Types of Mining Ventilation Equipment

Primary Ventilation Systems

Primary ventilation systems are responsible for the overall supply and exhaust of air in the mine. These systems are usually large-scale and form the backbone of the mine's ventilation strategy.

Secondary Ventilation Systems

Secondary systems are used to manage air distribution in specific sections of the mine. They ensure that adequate airflow reaches all working areas, complementing the primary system.

Auxiliary Ventilation Systems

Auxiliary ventilation systems are portable units used for localized ventilation, often in areas where temporary work is being carried out or in smaller, less accessible parts of the mine.

Natural vs. Mechanical Ventilation

Natural ventilation relies on natural forces such as wind and thermal gradients, whereas mechanical ventilation uses fans and ducts to control airflow. Mechanical systems are more common in modern mining operations due to their reliability and control.

Components of Ventilation Systems

Fans

Fans are the heart of any mechanical ventilation system. They create the necessary airflow to ventilate the mine and are available in various types and sizes to suit different requirements.

Ducts

Ducts are used to transport air from the fans to different parts of the mine. Proper duct design and maintenance are crucial for efficient air distribution.

Regulators

Regulators control the flow of air within the ventilation system. They can adjust the volume and direction of airflow to optimize ventilation.

Airflow Measurement Devices

These devices are essential for monitoring and managing the ventilation system. They provide real-time data on airflow rates, helping to ensure that the system is functioning correctly.

Applications in Different Mining Operations

Coal Mines

Ventilation in coal mines is critical due to the presence of methane and other explosive gases. Effective ventilation helps prevent gas buildup and reduces the risk of explosions.

Metal Mines

Metal mines require ventilation to control dust and toxic fumes generated during mining and processing activities. Proper ventilation also helps maintain comfortable working temperatures.

Non-metal Mines

Non-metal mines, such as those extracting gypsum or limestone, also need adequate ventilation to control dust and maintain air quality.

Benefits of Proper Ventilation

Safety Enhancements

Adequate ventilation significantly improves safety by reducing the risk of explosions, fires, and exposure to harmful gases and dust.

Productivity Improvements

Good ventilation improves working conditions, leading to higher productivity and efficiency. Miners can work longer and more comfortably in well-ventilated environments.

Environmental Impact

Proper ventilation reduces the environmental impact of mining by controlling emissions and improving air quality in and around mining sites.

Challenges in Implementing Ventilation Systems

Cost Factors

Implementing and maintaining advanced ventilation systems can be expensive. This includes the initial investment in equipment and ongoing operational costs.

Technological Barriers

Technological challenges, such as integrating modern ventilation systems with existing mine infrastructure, can hinder implementation.

Regulatory Issues

Compliance with stringent safety and environmental regulations can be challenging. Mines must adhere to national and international standards, which often require significant investment in ventilation systems.

Innovations in Mining Ventilation

Smart Ventilation Systems

Smart ventilation systems use advanced sensors and AI to monitor and control air quality in real-time. These systems optimize airflow, reduce energy consumption, and improve safety.

Energy-efficient Technologies

Innovations in fan design and control systems have led to more energy-efficient ventilation solutions. These technologies help reduce operational costs and environmental impact.

Real-time Monitoring Solutions

Real-time monitoring systems provide continuous data on air quality and system performance. This allows for prompt adjustments and ensures optimal ventilation at all times.

Future Prospects of Mining Ventilation in India

Trends and Predictions

The future of mining ventilation in India looks promising, with increasing adoption of advanced technologies and greater emphasis on safety and environmental sustainability.

Government Initiatives

The Indian government is supporting the mining industry through various initiatives, including funding for research and development of better ventilation systems.

Industry Outlook

The mining industry's outlook in India is positive, with expected growth in mining activities and continued investment in safety and efficiency improvements.

Comparative Analysis with Global Standards

Best Practices from Leading Countries

Countries like Australia, Canada, and the United States have established best practices in mining ventilation. Learning from these countries can help India improve its own systems.

India's Position in the Global Market

India is making strides in mining ventilation but still has room for improvement to match global standards. Continued investment and innovation are key to closing this gap.

Proper ventilation is crucial for the safety, productivity, and environmental sustainability of mining operations in India. With advancements in technology and increased focus on safety, the future of mining ventilation in India looks promising.

Name: Teknoflow Green Equipments Pvt. Ltd.

Address: S. No. 19/2,Ambe Bahula, Nashik 422010,Maharashtra,INDIA

Phone No: 89567 79584

Website: www.teknoflow.co

0 notes

Text

Uncovering the Best Pressure Vessel Suppliers in India: A Comprehensive Guide

Introduction: Navigating the World of Pressure Vessels

In the realm of industrial equipment, pressure vessels stand as critical components for various applications ranging from chemical processing to oil refining. If you're in search of reliable pressure vessel suppliers in India, you're in the right place. We, as seasoned experts in the field, understand the pivotal role these vessels play in industrial operations and are dedicated to providing you with comprehensive insights into the top suppliers, manufacturers, and exporters in the country.

Exploring Pressure Vessel Suppliers, Manufacturers, and Exporters

The Essence of Reliable Suppliers

When it comes to pressure vessel suppliers, reliability is paramount. You need partners who not only deliver quality products but also ensure adherence to international standards such as ASME standards. Our curated list includes suppliers known for their commitment to excellence and customer satisfaction.

Leading Manufacturers at Your Service

In the landscape of pressure vessel manufacturers, India boasts a diverse array of companies with a proven track record of innovation and precision engineering. From reactor vessels to storage tanks, these manufacturers specialize in crafting solutions tailored to your specific needs.

Global Reach of Indian Exporters

Indian pressure vessel exporters have made significant strides in catering to international markets. With a focus on quality, efficiency, and competitive pricing, these exporters have earned a reputation for excellence worldwide.

Delving into Pressure Vessel Design and Fabrication

Design Excellence: A Prerequisite for Performance

The success of any pressure vessel project hinges upon meticulous pressure vessel design. From conceptualization to detailed engineering, every aspect must be meticulously crafted to ensure optimal performance and safety.

Mastering Fabrication Techniques

Fabricating a pressure vessel demands a blend of expertise and cutting-edge technology. Our recommended suppliers and manufacturers employ advanced fabrication techniques to deliver products that exceed expectations in terms of durability and efficiency.

Ensuring Compliance: Pressure Vessel Inspection and Safety

Navigating Regulatory Standards

Adherence to pressure vessel regulations is non-negotiable in the industry. Whether it's local regulations or international codes such as ASME, our partners prioritize compliance to safeguard both personnel and assets.

Prioritizing Safety at Every Step

Safety is at the core of everything we do. From initial design to ongoing maintenance, our recommended suppliers and manufacturers prioritize pressure vessel safety, implementing robust measures to mitigate risks and ensure peace of mind for our clients.

Beyond Pressure Vessels: Exploring Heat Exchangers

Unraveling the Role of Heat Exchangers

In addition to pressure vessels, heat exchangers play a pivotal role in various industrial processes. Our comprehensive guide covers everything from basic principles to advanced applications, empowering you to make informed decisions for your operations.

Maintenance Matters: The Key to Longevity

Proactive Maintenance Strategies

Effective pressure vessel maintenance is essential for prolonging equipment life and optimizing performance. Our experts offer insights into best practices and proactive strategies to minimize downtime and maximize productivity.

Conclusion: Your Trusted Partner in Industrial Solutions

Pressure vessel suppliers in India requires expertise and a keen eye for quality. With our curated guide, you're equipped with the knowledge and insights needed to make informed decisions and forge partnerships that drive success. Partner with us, and let's embark on a journey towards excellence together.

Name: Teknoflow Green Equipments Pvt. Ltd.

Address: S. No. 19/2,Ambe Bahula, Nashik 422010,Maharashtra,INDIA

Phone No: 89567 79584

Website: www.teknoflow.co

FAQs

What are pressure vessels, and what are their primary functions?

Pressure vessels are containers designed to hold gases or liquids at pressures substantially different from ambient pressure. They serve various industries, including chemical processing, oil and gas, pharmaceuticals, and power generation. Their primary function is to store, transport, or process fluids under pressure safely.

What are the key safety considerations when using pressure vessels?

Safety is paramount when dealing with pressure vessels. Regular inspections, maintenance, and adherence to stringent design and construction codes, such as ASME Boiler and Pressure Vessel Code, are crucial. Proper installation, operation by trained personnel, and pressure relief mechanisms are vital to prevent accidents due to overpressure.

How do pressure vessels differ from ordinary containers?

Pressure vessels are specifically engineered to withstand high internal pressures safely. Unlike ordinary containers, they undergo rigorous design calculations and material selection to ensure structural integrity. They also incorporate features like thicker walls, reinforcement ribs, and welded joints to withstand the stresses induced by pressure.

What are the common materials used in constructing pressure vessels, and how do they affect performance?

Pressure vessels are typically constructed from materials such as carbon steel, stainless steel, aluminum, and various alloys. Material selection depends on factors like the operating pressure, temperature, and the nature of the stored fluid. For instance, corrosive substances may require corrosion-resistant alloys, while high-pressure applications may demand materials with high tensile strength.

How are pressure vessels tested for safety and performance?

Pressure vessels undergo rigorous testing procedures, including hydrostatic testing, pneumatic testing, and non-destructive examination (NDE) techniques like ultrasonic testing and radiographic inspection. These tests ensure the vessel's integrity, weld quality, and absence of defects. Additionally, pressure vessels must comply with regulatory standards and obtain certifications before deployment to ensure their safe operation.

0 notes

Text

Exploring the Top Pressure Vessel Suppliers in India

Introduction:

When it comes to pressure vessels, quality, reliability, and compliance are paramount. In the dynamic landscape of industrial operations, finding the right supplier is essential for ensuring seamless operations, safety, and optimal performance. India, renowned for its burgeoning industrial sector, hosts a plethora of pressure vessel suppliers, each vying to offer the best-in-class solutions. In this comprehensive guide, we delve into the top pressure vessel suppliers in India, shedding light on their expertise, product offerings, certifications, and commitment to excellence.

Understanding Pressure Vessels: A Crucial Component in Industrial Operations

Pressure vessels play a pivotal role in various industries, including oil and gas, petrochemicals, pharmaceuticals, and power generation. These vessels are designed to store and transport fluids or gases under high pressure, making them indispensable in ensuring the efficiency and safety of industrial processes. From storing compressed air to housing volatile chemicals, pressure vessels come in diverse shapes, sizes, and materials, tailored to meet specific application requirements.

The Criteria for Selecting Pressure Vessel Suppliers

Quality Assurance and Compliance

In the realm of pressure vessels, adherence to stringent quality standards and regulatory frameworks is non-negotiable. Top pressure vessel suppliers prioritize quality assurance throughout the manufacturing process, employing advanced technologies and robust quality control measures to uphold product integrity. Additionally, compliance with international standards such as ASME, PED, and ISO certifications underscores their commitment to delivering superior and compliant solutions.

Technical Expertise and Innovation

Innovation is the cornerstone of progress in the pressure vessel industry. Leading suppliers leverage cutting-edge technologies and engineering expertise to develop innovative solutions that enhance efficiency, durability, and safety. Whether it's implementing advanced materials, optimizing designs for maximum performance, or incorporating smart features for real-time monitoring, technical prowess distinguishes the frontrunners in the competitive landscape.

Customization and Flexibility

Every industrial application has unique requirements, necessitating tailored solutions that address specific challenges and constraints. The best pressure vessel suppliers exhibit flexibility and agility in accommodating custom design requests, modifications, and specialized configurations. By collaborating closely with clients and offering personalized consultations, they ensure that each pressure vessel aligns seamlessly with the operational needs and objectives of the end-user.

Spotlight on the Top Pressure Vessel Suppliers in India

Teknoflow Green Equipments Pvt. Ltd.

With a legacy of excellence spanning decades, Teknoflow Green Equipments Pvt. Ltd. stands as a paragon of quality and reliability in the Indian pressure vessel industry. Renowned for their state-of-the-art manufacturing facilities, meticulous quality control processes, and a diverse product portfolio, Teknoflow caters to a wide spectrum of industries, including oil and gas, chemical, and pharmaceuticals. Their commitment to innovation and customer satisfaction has earned them accolades and certifications, making them a preferred choice for discerning clients seeking top-tier pressure vessel solutions.

Conclusion Pressure vessel suppliers in India play a vital role in providing essential equipment for various industries such as oil and gas, chemical, and pharmaceutical. With a focus on quality, innovation, and adherence to safety standards, these suppliers contribute significantly to India's industrial growth and ensure reliable solutions for diverse engineering needs.

Name: Teknoflow Green Equipments Pvt. Ltd.

Address: S. No. 19/2,Ambe Bahula, Nashik 422010,Maharashtra,INDIA

Phone No: 89567 79584

Website: www.teknoflow.co

FAQS

What types of pressure vessels do you supply?

We supply a wide range of pressure vessels including but not limited to cylindrical, spherical, and conical vessels suitable for various applications such as storage, processing, and transportation.

What materials are your pressure vessels made from?

Our pressure vessels are typically constructed from materials such as stainless steel, carbon steel, aluminum, and other alloys, depending on the specific requirements of the application and regulatory standards.

Do you offer custom pressure vessel designs?

Yes, we specialize in providing custom-designed pressure vessels tailored to meet the specific needs and requirements of our clients. Our engineering team works closely with customers to develop solutions that best fit their applications.

What certifications do your pressure vessels adhere to?

Our pressure vessels adhere to industry standards and are certified according to applicable regulations such as ASME, PED, CE, API, and others as required. We ensure that our products meet the highest quality and safety standards.

What is the typical lead time for manufacturing and delivery?

The lead time varies depending on the complexity of the pressure vessel and current production schedules. Generally, we strive to provide accurate lead time estimates during the quotation process and work closely with clients to meet their project timelines.

0 notes

Text

Case Study: How Indian Shell and Tube Heat Exchanger Manufacturers Are Driving Energy Efficiency

In the realm of industrial energy efficiency, shell and tube heat exchangers play a pivotal role. These devices are crucial components in various industries, facilitating heat transfer between two mediums, often liquids or gases, while keeping them separate. In India, where energy efficiency is becoming increasingly vital, manufacturers like Tekno Flow Green Equipments are spearheading initiatives to drive sustainability and reduce energy consumption through innovative shell and tube heat exchanger solutions.

Teknoflow Green Equipments: Revolutionizing Energy Efficiency

Teknoflow Green Equipments stands out among shell and tube heat exchanger manufacturers in India for its commitment to sustainability and technological innovation. The company's focus on energy-efficient solutions has made it a key player in the Indian market and beyond. By leveraging advanced engineering techniques and cutting-edge materials, Teknoflow has been able to design heat exchangers that not only enhance operational efficiency but also minimize environmental impact.

The Importance of Energy Efficiency

In a world where concerns about climate change and resource depletion are ever-present, the importance of energy efficiency cannot be overstated. Industries account for a significant portion of global energy consumption, and optimizing processes to reduce energy usage can lead to substantial benefits. Shell and tube heat exchangers offer an effective means of improving energy efficiency in industrial settings by optimizing heat transfer processes and minimizing energy losses.

Driving Energy Efficiency Through Innovation

Teknoflow Green Equipments has distinguished itself by its relentless pursuit of innovation in the field of heat exchanger technology. The company's engineers are constantly exploring new materials, design methodologies, and manufacturing techniques to develop heat exchangers that offer superior performance and energy efficiency. By incorporating features such as enhanced heat transfer surfaces, optimized flow patterns, and advanced thermal insulation, Teknoflow's heat exchangers deliver impressive efficiency gains while maintaining reliability and durability.

Case Study: Implementing Teknoflow's Heat Exchangers

Let's consider a case study of a manufacturing plant in India looking to improve the energy efficiency of its processes. By partnering with Teknoflow Green Equipments and installing their advanced shell and tube heat exchangers, the plant was able to achieve significant reductions in energy consumption and operating costs.

Enhanced Heat Transfer: Teknoflow's heat exchangers are designed to maximize heat transfer efficiency, allowing the plant to achieve the desired process temperatures with minimal energy input.

Reduced Fouling and Maintenance: The innovative design of Teknoflow's heat exchangers minimizes fouling and corrosion, reducing the need for frequent maintenance and downtime.

Customized Solutions: Teknoflow works closely with clients to develop customized heat exchanger solutions tailored to their specific requirements, ensuring optimal performance and efficiency.

Environmental Benefits: By reducing energy consumption and greenhouse gas emissions, the implementation of Teknoflow's heat exchangers contributes to a greener and more sustainable future.

Conclusion

In conclusion, Indian shell and tube heat exchanger manufacturers like Teknoflow Green Equipments are playing a crucial role in driving energy efficiency and sustainability across various industries. Through innovation, collaboration, and a commitment to excellence, these manufacturers are helping businesses reduce their environmental footprint while improving operational efficiency and competitiveness. As the demand for energy-efficient solutions continues to grow, companies like Teknoflow will undoubtedly remain at the forefront of India's efforts to build a cleaner, more sustainable future.

Name: Teknoflow Green Equipment Pvt. ltd

Address: Ven Business Centre 2,3rd Floor, Baner Pashan Link Road, Pune, Maharashtra 411021.

Contact No:+91 8956779584

0 notes

Text

The Latest Innovations in Mining Ventilation Equipment for the Indian Market

Introduction:

In the dynamic landscape of mining, ensuring a safe and efficient working environment is paramount. mining ventilation equipment manufacturers play a crucial role in maintaining air quality and managing underground conditions. As technological advancements continue to reshape the mining industry, Teknoflow Green Equipments Private Limited stands at the forefront, introducing cutting-edge solutions to meet the evolving needs of the Indian market.

Mining Ventilation Equipment: A Vital Component for Safety and Productivity

Effective ventilation is essential in mining operations to mitigate the risks associated with poor air quality, dust, and hazardous gases. Teknoflow Green Equipments, a leading player in the field, recognizes the significance of reliable ventilation systems for both safety and operational efficiency.

Key Features of Teknoflow's Mining Ventilation Equipment:

Energy-Efficient Designs:

Teknoflow prioritizes sustainability and energy efficiency in its ventilation equipment. The latest offerings are designed to optimize airflow while minimizing energy consumption, resulting in lower operational costs for mining companies.

Advanced Air Filtration Systems:

To address the challenges of airborne contaminants, Teknoflow integrates state-of-the-art air filtration systems into its ventilation equipment. These systems efficiently remove dust particles and pollutants, promoting a healthier work environment for miners.

Smart Monitoring and Control:

Leveraging the power of technology, Teknoflow incorporates smart monitoring and control features in its ventilation solutions. This allows real-time tracking of air quality, temperature, and gas levels, enabling prompt responses to potential safety concerns.

Modular and Scalable Solutions:

Recognizing the diverse needs of mining operations, Teknoflow offers modular and scalable ventilation solutions. This flexibility ensures that equipment can be tailored to suit different mine layouts and sizes, providing a customized approach for each client.

Compliance with International Standards:

Teknoflow's commitment to quality and safety is reflected in its adherence to international standards. The company's ventilation equipment complies with industry regulations, giving mining companies confidence in the reliability and safety of the solutions provided.

Mining Ventilation Equipment Manufacturers Leading the Way in India

As one of the leading mining ventilation equipment in India, Teknoflow Green Equipments Private Limited has consistently demonstrated a commitment to innovation and excellence. The company's products have become synonymous with quality and reliability, earning the trust of mining operators across the country.

Teknoflow's contributions to the mining industry extend beyond delivering high-quality equipment. The company also provides comprehensive support services, including installation, maintenance, and training, ensuring that mining operations can maximize the benefits of their ventilation systems.

Conclusion:

In the ever-evolving landscape of mining, Teknoflow Green Equipments Private Limited continues to play a pivotal role in shaping the industry's future. By offering state-of-the-art ventilation solutions, the company contributes to creating safer, more efficient, and environmentally conscious mining environments in India. As the demand for advanced mining ventilation equipment continues to rise, Teknoflow remains at the forefront, driving innovation and setting new standards for the industry.

Name: Teknoflow Green Equipment Pvt. ltd

Address: Ven Business Centre 2,3rd Floor, Baner Pashan Link Road, Pune, Maharashtra 411021.

Contact No:+91 8956779584

0 notes

Text

The Latest Innovations in Mining Ventilation Equipment for the Indian Market

Introduction:

In the dynamic landscape of mining, ensuring a safe and efficient working environment is paramount. mining ventilation equipment manufacturers play a crucial role in maintaining air quality and managing underground conditions. As technological advancements continue to reshape the mining industry, Teknoflow Green Equipments Private Limited stands at the forefront, introducing cutting-edge solutions to meet the evolving needs of the Indian market.

Mining Ventilation Equipment: A Vital Component for Safety and Productivity

Effective ventilation is essential in mining operations to mitigate the risks associated with poor air quality, dust, and hazardous gases. Teknoflow Green Equipments, a leading player in the field, recognizes the significance of reliable ventilation systems for both safety and operational efficiency.

Key Features of Teknoflow's Mining Ventilation Equipment:

Energy-Efficient Designs:

Teknoflow prioritizes sustainability and energy efficiency in its ventilation equipment. The latest offerings are designed to optimize airflow while minimizing energy consumption, resulting in lower operational costs for mining companies.

Advanced Air Filtration Systems:

To address the challenges of airborne contaminants, Teknoflow integrates state-of-the-art air filtration systems into its ventilation equipment. These systems efficiently remove dust particles and pollutants, promoting a healthier work environment for miners.

Smart Monitoring and Control:

Leveraging the power of technology, Teknoflow incorporates smart monitoring and control features in its ventilation solutions. This allows real-time tracking of air quality, temperature, and gas levels, enabling prompt responses to potential safety concerns.

Modular and Scalable Solutions:

Recognizing the diverse needs of mining operations, Teknoflow offers modular and scalable ventilation solutions. This flexibility ensures that equipment can be tailored to suit different mine layouts and sizes, providing a customized approach for each client.

Compliance with International Standards:

Teknoflow's commitment to quality and safety is reflected in its adherence to international standards. The company's ventilation equipment complies with industry regulations, giving mining companies confidence in the reliability and safety of the solutions provided.

Mining Ventilation Equipment Manufacturers Leading the Way in India

As one of the leading mining ventilation equipment in India, Teknoflow Green Equipments Private Limited has consistently demonstrated a commitment to innovation and excellence. The company's products have become synonymous with quality and reliability, earning the trust of mining operators across the country.

Teknoflow's contributions to the mining industry extend beyond delivering high-quality equipment. The company also provides comprehensive support services, including installation, maintenance, and training, ensuring that mining operations can maximize the benefits of their ventilation systems.

Conclusion:

In the ever-evolving landscape of mining, Teknoflow Green Equipments Private Limited continues to play a pivotal role in shaping the industry's future. By offering state-of-the-art ventilation solutions, the company contributes to creating safer, more efficient, and environmentally conscious mining environments in India. As the demand for advanced mining ventilation equipment continues to rise, Teknoflow remains at the forefront, driving innovation and setting new standards for the industry.

Name: Teknoflow Green Equipment Pvt. ltd

Address: Ven Business Centre 2,3rd Floor, Baner Pashan Link Road, Pune, Maharashtra 411021.

Contact No:+91 8956779584

0 notes