Don't wanna be here? Send us removal request.

Text

Day 4 - 26.08.2024

On the fourth visit to Singla Rice Mill, we aimed to observe the mill functioning around the time of closing which was 8- 9 pm.

We observed chemical polishing agents being poured into a tank which connects to the Silky Master machine responsible for making the texture of rice grains smoother.

They were collecting all the spilled rice grains to have a clean floor to work on the next day and we observed their clever approach of doing so using sacks rolled up. We observed the relationship of the workers with inanimate objects such as sacks, tools , etc.

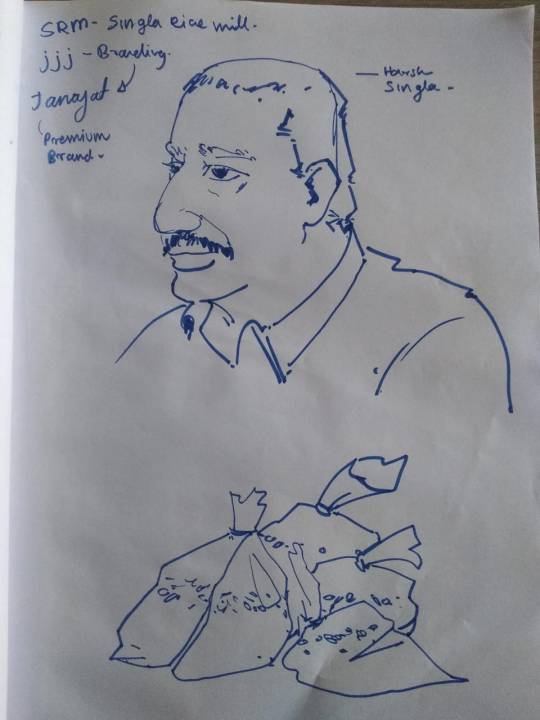

We did not expect to see a busy environment considering the fact that it was off-season and the day was ending. The CEO was present there and we came to realize that it was a moment of crisis for the mill. A government-bound rice stock was left unattended outside the Food Corporation of India (FCI) warehouse, risking exposure to rain.

Harsh, along with 4 laborers was planning to leave to attend to the situation at the FCI warehouse. We requested him to take us with him to observe the activities over there and followed him there in our auto rickshaw.

Harsh explained that while government-related work can be swift, it often requires additional spending. The process involves transporting rice to the warehouse, getting FCI approval, and then stacking it inside. However, FCI’s lack of proper storage facilities means the mill must ensure the rice remains unspoiled until they receive the official acceptance note (A note).

Despite FCI being responsible on paper, the mill has to manage the logistics, including paying for labor to load and stack the rice, as FCI is often short on workers, especially after hours. Bad weather exacerbates these issues, sometimes requiring the mill to bring in their own laborers. The mill also handles lighting and other logistics, as the warehouse lacks basic facilities.

Harsh expressed frustration with the government's uncooperative approach but noted that competition in the industry is minimal. He also mentioned that to meet weight requirements, sacks are sometimes sprayed with water, and any spillage during loading is collected and sold.

1 note

·

View note

Text

Day 3 - 23.08.2024

On the third day, our discussions with Rajesh continued, focusing on the chemical testing process used to determine starch presence in the rice sample. Rajesh demonstrated how samples are tested using a red chemical solution, which turns green after shaking when starch is present.

We also spoke with other staff at the mill to learn about their roles. Budhsen Yadav and Ramsundar Yadav, both laborers, work on a contract basis and split their time between the mill and farming in their home regions. Paramanand, another laborer, is more regular and also takes breaks to farm.

Jasbir described the role of Ashok, the fourth supervisor, who handles tasks that require leaving the mill, such as bank work, purchasing machinery parts, and personal errands for the owner.

The conversations revealed the daily routine and dynamics among the laborers. They live in quarters behind the factory and have a Bhandari who cooks for them. The laborers work long hours, especially during the busy season, but despite being provided with decent living quarters, the conditions have deteriorated.

The mill employs around 18-20 laborers, along with a few operators and helpers. The discussions highlighted the transient nature of labor at the mill, with workers frequently coming and going, while the operators are seen as more essential.

The mill also owns land behind the factory, where they grow their own paddy, with occasional assistance from a local farmer who previously owned that portion of the land. Paddy was also growing in regions where the husk was accumulated.

A floor plan was also made of the facility for better understanding of the space and placement of machinery. This was to track the movement of the product and staff. The facility had an office space with the CEO's cabin and a common space for Accountant's desk, Testing and Sampling, two high ceiling warehouses - one for packaging and storage and the other for processing plant. Half of the processing was happening outside beneath a shed.

We were also treated by the Supervisors with samosas for lunch, had a great time :)

1 note

·

View note

Text

Day 2 - 22.08.2024

On the second day, we delved deeper into the operations at Singla Rice Mills, guided by Rajesh, a facility supervisor. His role involves purchasing paddy, maintaining stock, managing labourers, and sorting paddy based on quality.

He described the two main types of paddy they handle: Paddy 14, which is of higher quality, longer, thicker, and pricier, and Paddy 26, which is shorter, thinner, and cheaper. He can identify the quality of paddy just by sight, which directly impacts its pricing and processing.

Rajesh mentioned that most of their produce is for government orders, and the factory works around the clock during the season.

The plant has four supervisors, each overseeing different aspects: Paddy, Rice, Operations, Laborers, and Night Shift. Rajesh, along with his colleagues Tarsem, Ashok, and Jasbir, has been with the company for 10-12 years, previously working at their Mathana mill.

Rajesh also spoke about the logistical aspects, including the use of trucks for transportation, the process for checking the quality of paddy using tools like the "Parkhi" and "Kundi," and the lab’s role in manual quality checks.

The mill processes 4-5 tons of rice per hour, with paddy bulk purchases in October. He also shared insights on the different types of rice, such as steamed, boiled, and Sela rice, and how the mill manages broken rice, either selling it cheaply or using it as poultry feed.

that’s it for today, see you tomorrow!

#rice#manufacturing#processing#industrial design#communication design#textile design#research#business#systems thinking#system design#day 2

1 note

·

View note

Text

Systems Thinking

Singla Rice Mills

Hello from Group 3 - The Huskies B)

This is a blog to document the everyday progress of our Systems Thinking Research and you are welcome to give your valuable feedbacks every step of the way!

The group includes Akriti, Akshaya, Gautham, Karthik, Ketaki, Madhumanti and Prerna.

Day 1 - 21.08.2024

First day started with brainstorming for the domain. The group decided to focus on a topic within the agriculture sector, as Haryana is well-known for its agricultural activities.

Initially, we planned to conduct our research at a sugar mill. Upon visiting the site, we learned that the sugarcane harvest season hasn’t started yet, and the factory wouldn’t be operational until November.

After exploring other nearby agro-based industries like disposable leaf plate makers, poultry farms, wheat factories, and honey bee farms, we finally connected with Singla Rice Mills.

The CEO, Harsh Singla, was very welcoming and gave us a comprehensive overview of the business and its technical aspects. He explained the rice processing stages, discussed the factors that directly impact the business, and provided a tour of the facility.

We also saw samples of different rice categories obtained after processing. The first day was full of valuable insights that will guide our research moving forward.

Thanks, see you tomorrow :)

#business#systems thinking#design#rice#industrial design#communication design#textile design#field trip#system design#research#day 1

2 notes

·

View notes