Don't wanna be here? Send us removal request.

Text

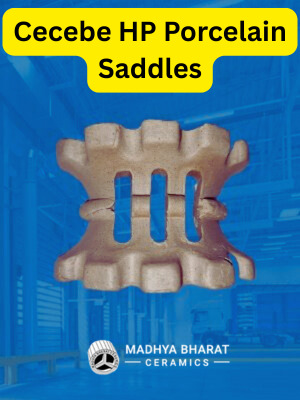

Cecebe HP Porcelain Saddles by Experts – Fast Delivery

Madhya Bharat Ceramics is your trusted source for Cecebe HP Porcelain Saddles, engineered for high-efficiency tower packing applications across diverse industries. As a recognized Cecebe HP Porcelain Saddles manufacturer, we deliver performance, consistency, and speed—exactly what industries need in high-temperature and chemical processing environments.

With a focus on both quality and logistics, we ensure rapid dispatch and global availability to meet urgent and bulk industrial demands.

What Are Cecebe HP Porcelain Saddles?

Cecebe HP Porcelain Saddles are high-performance ceramic tower packing materials used in distillation, absorption, and stripping columns. Their unique saddle shape maximizes surface area while minimizing pressure drop—making them a top choice for chemical, petrochemical, and environmental industries.

These saddles offer:

Excellent acid and heat resistance

Optimized flow dynamics

High mechanical strength

Low fouling and scaling tendencies

Why Choose Us as Your Cecebe HP Porcelain Saddles Manufacturer?

Madhya Bharat Ceramics has positioned itself as a leading Cecebe HP Porcelain Saddles manufacturer in India by leveraging superior ceramic technology and stringent quality controls.

Here’s what sets us apart:

ISO-compliant production processes

Precision-engineered designs for consistent performance

Custom sizing options to meet client specifications

In-house R&D and testing for quality assurance

Our in-depth knowledge of ceramic materials ensures every product we deliver meets or exceeds industry standards.

Leading Cecebe HP Porcelain Saddles Supplier for Global Needs

As a professional Cecebe HP Porcelain Saddles supplier, we serve clients across various regions including the Middle East, Europe, Southeast Asia, and Africa. Our product is widely appreciated for:

Bulk availability with ready-to-dispatch stock

Strong packaging for secure international transit

Technical documentation and client support

Competitive pricing without quality compromise

We work with industries ranging from petrochemicals to pharmaceuticals and environmental engineering.

Cecebe HP Porcelain Saddles Exporter with Proven Track Record

Madhya Bharat Ceramics is a reliable Cecebe HP Porcelain Saddles exporter that complies with all international shipping standards and customs documentation. Our export services include:

Efficient supply chain management

Multi-modal logistics (air, sea, road)

Real-time tracking and updates

End-to-end export compliance

Whether your project is based in India or across borders, our global footprint ensures your saddles reach you on time.

Applications of Cecebe HP Porcelain Saddles

Our saddles are widely used in:

Packed columns for gas-liquid contact

Waste gas treatment towers

Desulfurization systems

Distillation and separation units

Thanks to their thermal shock resistance and chemical inertness, Cecebe HP saddles are ideal for both new installations and replacement needs.

Key Benefits at a Glance

High resistance to thermal and chemical stress

Low pressure drop for improved efficiency

Wide surface area for mass transfer

Easy installation and maintenance

Durable, long-lasting structure

Whether you’re operating in a corrosive or high-temperature environment, our porcelain saddles provide unmatched reliability.

Why Madhya Bharat Ceramics?

✔ Over two decades of ceramic expertise ✔ Fast delivery and competitive pricing ✔ Flexible bulk order handling ✔ Strong customer support and technical guidance

We work closely with plant engineers, EPC contractors, and procurement managers to deliver the right solution—on time, every time.

Final Thoughts

When industrial performance and timely delivery matter, trust the experts at Madhya Bharat Ceramics—your go-to Cecebe HP Porcelain Saddles supplier. From local supply to international export, we provide a seamless experience from quote to delivery.

Contact us :

Phone:

+91-8827697111 (Siddharth Jain)

+91-9425105256 (Sushil Jain)

Email:

Address:

Chandapura Road, Pashupatinath Mandir Road

Mandsaur, Madhya Pradesh 458001

India

📞 Get in touch today for pricing, samples, or technical specs. Let’s work together to elevate your tower packing performance.

Madhya Bharat Ceramics – Precision You Can Rely On.

#Cecebe HP Porcelain Saddles#Cecebe HP Porcelain Saddles Manufacturer#cecebe hp porcelain saddles supplier#cecebe hp porcelain saddles exporter

0 notes

Text

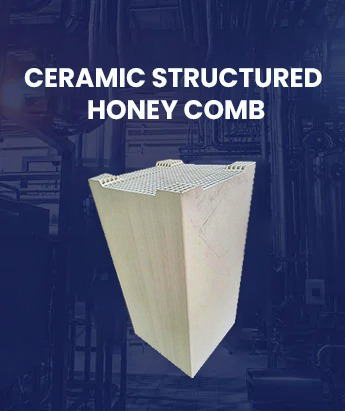

India’s Leading Ceramic Honeycomb Structure Supplier

When it comes to precision, durability, and efficiency in high-temperature industrial processes, ceramic honeycomb structures play a vital role. As India’s trusted ceramic honeycomb structure supplier, Madhya Bharat Ceramics is proud to deliver top-grade solutions for industries that demand performance, consistency, and fast delivery.

Whether you're managing an RTO (Regenerative Thermal Oxidizer), SCR system, or industrial heat exchanger, our honeycomb structures are engineered to meet your operational demands.

What is a Ceramic Honeycomb Structure?

A ceramic honeycomb structure is a ceramic-based component with a honeycomb-shaped geometry. This unique structure offers high surface area and low pressure drop, making it ideal for filtration, gas flow control, and heat exchange processes in industries like chemical, pharmaceutical, automotive, and environmental treatment.

Key Features:

High thermal stability

Corrosion and chemical resistance

Uniform cell distribution

Excellent heat and mass transfer performance

Energy-efficient performance in RTO/SCR systems

Why Choose Madhya Bharat Ceramics?

Based in Mandsaur, Madhya Pradesh, Madhya Bharat Ceramics is a renowned ceramic honeycomb structure manufacturer with a legacy of quality and commitment. We use high-purity ceramic materials, advanced forming technology, and a strict quality control process to ensure our products perform even in the most demanding industrial environments.

As a leading supplier, we provide:

Standard and customized cell densities (e.g. 100, 200, 400 CPSI)

Multiple size and shape options (round, square, custom)

OEM and bulk order capabilities

Quick dispatch from our Mandsaur facility

Applications of Ceramic Honeycomb Structures

Our honeycomb ceramics serve a broad range of industries and functions:

RTO Units: Enhances heat recovery and VOC destruction efficiency

Catalytic Converters: Used in SCR systems for NOx removal

Heat Exchange Media: Improves thermal cycling in furnaces

Gas Filtration: Removes particulate matter and harmful gases

Madhya Bharat Ceramics – Your Go-To Supplier in Mandsaur

Being a reputed ceramic honeycomb structure supplier in Mandsaur, we take pride in fulfilling the needs of industries across India and abroad. Our location enables easy transport logistics and cost-effective supply for Indian industries as well as export markets.

As a ceramic honeycomb structure manufacturer, we maintain high-volume production capacity without compromising on quality. From prototype development to full-scale manufacturing, we cater to clients with precision-engineered solutions.

Industries We Serve

Our honeycomb ceramics are trusted by:

Pollution Control Units

Chemical Processing Plants

Automotive Exhaust Systems

Metal Smelting Operations

Power and Energy Facilities

Each unit is tested for dimensional accuracy, thermal resistance, and performance output, ensuring peace of mind for engineers and plant operators.

Benefits of Partnering with Madhya Bharat Ceramics

✅ Experienced Manufacturer – Decades of experience in ceramic engineering ✅ Bulk Supply Ready – Large-volume availability for urgent requirements ✅ Export-Quality Products – Serving both domestic and international markets ✅ On-Time Delivery – Efficient dispatch processes from Mandsaur

Get in Touch with the Ceramic Honeycomb Structure Experts

If you're searching for a reliable ceramic honeycomb structure supplier, look no further than Madhya Bharat Ceramics. Our industry-grade honeycomb solutions are engineered to deliver long-term efficiency, safety, and savings.

📞 Call us now for a quote or sample request 📦 Bulk orders and custom sizes available 🌐 Serving across India and international markets

Contact us : Phone:

+91-8827697111 (Siddharth Jain)

+91-9425105256 (Sushil Jain)

Email:

Address:

Chandapura Road, Pashupatinath Mandir Road

Mandsaur, Madhya Pradesh 458001

India

Madhya Bharat Ceramics – Your Partner for High-Performance Ceramic Honeycomb Structures, Manufactured in Mandsaur, Delivered Globally.

#ceramic honeycomb structure#ceramic honeycomb structure supplier#ceramic honeycomb structure manufacturer#ceramic honeycomb structure in mandsaur

0 notes

Text

Buy from Top High Alumina Ceramic Balls Exporters in India

In industrial operations where extreme temperatures and corrosive environments are common, High Alumina Ceramic Balls are the preferred support and packing media. Known for their durability, chemical resistance, and high thermal stability, these balls ensure consistent performance and long service life in challenging conditions.

Madhya Bharat Ceramics stands among the leading High Alumina Ceramic Balls exporters, offering reliable supply, competitive pricing, and consistent quality to industries across the globe.

What Are High Alumina Ceramic Balls?

High Alumina Ceramic Balls are spherical support media made using high-purity alumina oxide. These balls are used to support catalysts, absorb shock, and distribute gas or liquid flow uniformly in packed beds.

Key Features:

High alumina content (92–99%)

Excellent resistance to wear and corrosion

High mechanical strength

Low water absorption

Suitable for temperatures up to 1600°C

These features make them ideal for thermal, catalytic, and mechanical support in industrial reactors and towers.

Applications of High Alumina Ceramic Balls

As a seasoned high alumina ceramic balls manufacturer, Madhya Bharat Ceramics produces balls suitable for various industrial applications, offering flexibility in sizes and performance grades.

Common Applications:

Catalyst bed support in refining and petrochemical plants

Grinding media for ceramic and mineral industries

Heat insulation and thermal buffering in kilns and furnaces

Water and gas filtration

Drying and adsorption towers

Their low reactivity and high load-bearing capacity make them essential in continuous process environments.

Why Madhya Bharat Ceramics?

With years of manufacturing expertise and a global distribution network, Madhya Bharat Ceramics has emerged as a trusted high alumina ceramic balls supplier in India and beyond.

What Sets Us Apart:

State-of-the-art manufacturing and quality control

Custom sizing options from 3mm to 50mm

Strong global logistics for on-time delivery

ISO-compliant processes

Dedicated support team for technical assistance

We are committed to supplying products that meet international standards and client-specific requirements.

Benefits of Buying from High Alumina Ceramic Balls Exporters

As experienced High Alumina Ceramic Balls exporters, we understand what industries expect—reliability, long-term performance, and competitive pricing. Our products are packaged securely for international shipping and are trusted by EPC contractors, OEMs, and direct industries.

With Us, You Get:

Cost-effective and durable ceramic solutions

Fast turnaround for large-scale projects

Industry-standard compliance and testing reports

Direct manufacturer support for bulk inquiries

By partnering with a trusted exporter, you ensure quality and performance without compromise.

Frequently Asked Questions (FAQs)

1. What is the difference between high alumina ceramic balls and other ceramic balls?

High alumina ceramic balls have a greater alumina content (92–99%), making them more resistant to high temperatures, corrosion, and mechanical wear compared to standard ceramic or porcelain balls.

2. What sizes do high alumina ceramic balls come in?

We offer sizes ranging from 3mm to 50mm, depending on your application. Our team can guide you to choose the right size based on your industrial setup.

3. Are you a direct high alumina ceramic balls manufacturer?

Yes, Madhya Bharat Ceramics is a direct manufacturer of high alumina ceramic balls. We handle everything from raw material sourcing to finished product export under strict quality protocols.

Let’s Work Together

Whether you need support media for a new project or want to replace old packing materials, trust Madhya Bharat Ceramics—the name behind reliable high alumina ceramic balls suppliers in India. We serve industries worldwide with consistency, commitment, and customized solutions.

📞 Contact us now for bulk orders, samples, or custom specifications.

Phone:

+91-8827697111 (Siddharth Jain)

+91-9425105256 (Sushil Jain)

Email:

Address:

Chandapura Road, Pashupatinath Mandir Road

Mandsaur, Madhya Pradesh 458001

India

Performance You Can Measure. Quality You Can Trust. Delivered Worldwide.

#High Alumina Ceramic Balls#High Alumina Ceramic Balls exporters#high alumina ceramic balls manufacturer#high alumina ceramic balls suppliers

0 notes

Text

High-Performance Ceramic Honeycomb Structure by Experts

The demand for durable, energy-efficient, and high-performing ceramic honeycomb structures continues to grow in industries that rely on heat recovery, pollution control, and catalytic processing. Designed for excellent thermal resistance and maximum surface area, these structures play a key role in increasing operational efficiency across a wide range of applications.

At Madhya Bharat Ceramics, we specialize in manufacturing and supplying top-grade ceramic honeycomb structures built for performance and longevity. As a trusted ceramic honeycomb structure supplier in Mandsaur, we serve clients across India and export globally.

What Is a Ceramic Honeycomb Structure?

A ceramic honeycomb structure is a block or tile made of ceramic material, engineered with multiple uniform channels in a honeycomb pattern. These structures allow maximum exposure to air or gas flow while maintaining high mechanical strength and thermal shock resistance.

Common Applications:

Regenerative Thermal Oxidizers (RTOs)

Heat exchangers and air heaters

Exhaust filtration systems

Catalytic converters

Gas treatment and emission control units

By offering low-pressure drop and high surface area, these units are essential in industries such as chemicals, pharmaceuticals, refineries, and electronics.

Why Choose Madhya Bharat Ceramics?

As a leading ceramic honeycomb structure manufacturer, Madhya Bharat Ceramics combines technical expertise with strict quality standards. Our honeycombs are manufactured using advanced ceramic formulations, making them resistant to high temperatures, corrosion, and mechanical stress.

What Sets Us Apart:

State-of-the-art manufacturing unit in Mandsaur, MP

Available in multiple cell densities (cpsi) and dimensions

ISO-compliant quality control

Fast turnaround on bulk orders

Expert support and consultation for custom applications

We have earned a reputation as a dependable ceramic honeycomb structure supplier to major industries in India and abroad.

Benefits of Using Ceramic Honeycomb Structures

Using ceramic honeycomb blocks in your industrial systems can lead to:

✅ Improved energy efficiency

✅ Reduced emissions

✅ Longer equipment life

✅ Lower maintenance costs

✅ Enhanced thermal performance

They are also lightweight and easy to install, making them a preferred choice for new installations and retrofitting older systems.

Proudly Manufactured in Mandsaur

Madhya Bharat Ceramics is based in Mandsaur, Madhya Pradesh — a growing industrial hub for advanced ceramic materials. Our facility is equipped to meet the growing demand for ceramic honeycomb structure in Mandsaur and nationwide.

We cater to:

OEMs and EPC contractors

Pollution control equipment manufacturers

Process industries and refineries

International buyers needing bulk export

FAQs – Ceramic Honeycomb Structure

1. What is the purpose of ceramic honeycomb in industrial systems?

Ceramic honeycomb structures are used to maximize heat exchange, improve air filtration, and support chemical reactions in high-temperature environments like RTOs, furnaces, and exhaust systems.

2. How durable are ceramic honeycomb structures?

They are highly durable due to their thermal shock resistance, chemical inertness, and mechanical strength. When installed properly, they can last for several years with minimal maintenance.

3. Can ceramic honeycomb structures be customized?

Yes. As a leading ceramic honeycomb structure manufacturer, Madhya Bharat Ceramics offers custom cell sizes, shapes, and dimensions to meet your specific application requirements.

Partner with the Experts in Ceramic Honeycomb Solutions

If you're looking for a ceramic honeycomb structure supplier you can trust, Madhya Bharat Ceramics delivers quality, consistency, and value. From Mandsaur to across the globe, we supply performance-driven ceramic solutions tailored to your industrial needs.

📞 Contact us today for a quote, sample request, or consultation.

Phone:

+91-8827697111 (Siddharth Jain)

+91-9425105256 (Sushil Jain)

Email:

Address:

Chandapura Road, Pashupatinath Mandir Road

Mandsaur, Madhya Pradesh 458001

India

Madhya Bharat Ceramics – Powering industrial performance with smart ceramic engineering.

#ceramic#ceramic honeycomb structure#ceramic honeycomb structure supplier#ceramic honeycomb structure manufacturer#ceramic honeycomb structure in mandsaur#Ceramic Honeycomb supplier#ceramic honeycomb exporters#Ceramic Honeycomb

0 notes

Text

Ceramic Ultra Solutions by Madhya Bharat Ceramics

Madhya Bharat Ceramics is a trusted leader among ceramic ultra manufacturers, ceramic ultra suppliers, and ceramic ultra exporters in India. Our Ceramic Ultra products are engineered to meet the highest industry standards, offering durability, chemical resistance, and superior performance for various industrial applications.

What is Ceramic Ultra?

Ceramic Ultra refers to an advanced class of ceramic materials specially designed for high-performance industrial uses. These ceramics combine excellent thermal stability, chemical inertness, and mechanical strength. They are widely used in filtration, catalyst support, heat exchange, and pollution control systems.

Ceramic Ultra products by Madhya Bharat Ceramics ensure:

Long-lasting performance even in harsh environments

Resistance to acids, alkalis, and extreme temperatures

Low maintenance requirements, reducing overall operational costs

Why Choose Madhya Bharat Ceramics as Your Ceramic Ultra Supplier?

As one of the premier ceramic ultra manufacturers in India, Madhya Bharat Ceramics offers:

Quality Assurance: Our Ceramic Ultra products undergo rigorous quality checks and meet international standards.

Customization: We tailor our products to specific client requirements for optimal performance.

Wide Product Range: Including ceramic filters, honeycombs, saddles, and other industrial components.

Export Expertise: Efficient global logistics and export support enable us to serve international markets reliably.

Our expertise and commitment to quality have earned us a strong reputation as a leading ceramic ultra exporter globally.

Applications of Ceramic Ultra Products

Ceramic Ultra solutions are vital in industries such as:

Environmental Technology: For air and water filtration, pollution control, and emission reduction.

Chemical Processing: Catalyst carriers and packing materials withstand corrosive environments.

Automotive & Energy: Used in catalytic converters and heat exchangers for efficiency and durability.

Manufacturing: Support for high-temperature operations in furnaces and reactors.

Benefits of Using Ceramic Ultra from Madhya Bharat Ceramics

Choosing Ceramic Ultra solutions from Madhya Bharat Ceramics provides:

Enhanced Efficiency: Optimized designs improve reaction rates and filtration efficiency.

Durability: Our ceramics resist cracking, erosion, and chemical degradation over long service lives.

Cost Savings: Reduced downtime and maintenance expenses thanks to robust materials.

Eco-Friendly: Ceramic Ultra supports cleaner industrial processes by enabling better emission controls.

Frequently Asked Questions

Q1: What industries use Ceramic Ultra products? Ceramic Ultra is widely used in environmental tech, chemical processing, automotive, and manufacturing industries due to its resistance to heat and chemicals.

Q2: How does Ceramic Ultra differ from regular ceramics? Ceramic Ultra materials feature enhanced thermal and chemical resistance with superior mechanical strength, making them suitable for demanding industrial applications.

Q3: Can Madhya Bharat Ceramics customize Ceramic Ultra products? Yes, Madhya Bharat Ceramics offers customized ceramic ultra solutions tailored to specific process requirements and industry standards.

📞 Conatct Us

🏢 Address Chandapura Road (Pashupatinath Mandir Road) Mandsaur, Madhya Pradesh 458001, India

📧 Email

📱 Phone

+91‑88276 97111 (Siddharth Jain)

+91‑94251 05256 (Sushil Jain)

🌐 Website www.mbctower.in

0 notes

Text

Inert Ceramic Balls – Reliable Support Media for Industrial Applications

Inert Ceramic Balls are essential components in various industrial processes, especially in chemical, petrochemical, and refining plants. Known for their excellent mechanical strength, chemical stability, and thermal resistance, these balls serve as the foundation layer in packed columns and catalyst beds. At MBC Tower, a reputed inert ceramic balls manufacturer and exporter in mandsaur, we offer precision-engineered ceramic support media trusted by industries worldwide.

What Are Inert Ceramic Balls?

Inert Ceramic Balls are spherical, non-reactive ceramic support materials used as bed support in reactors and columns. These balls help in distributing gases or liquids evenly while protecting catalyst layers from damage and contamination.

They are manufactured using refined kaolin, alumina, and other ceramic materials that provide excellent resistance to high temperatures and corrosive environments.

Benefits of Using Inert Ceramic Balls

High Thermal Stability

Withstand temperatures up to 1,300°C, making them ideal for high-temperature applications in gas treatment and refining.

Chemical Inertness

Non-reactive with acids, alkalis, and other harsh chemicals used in processing industries.

Uniform Size and Shape

Ensures even flow distribution and minimizes pressure drop within the packed bed.

Long Service Life

Resistant to wear, mechanical stress, and thermal cycling, reducing maintenance costs over time.

Industrial Applications of Inert Ceramic Balls

MBC Tower’s inert ceramic balls are widely used in:

Petrochemical refineries

Sulfuric acid and ammonia plants

Natural gas processing units

Fertilizer manufacturing towers

Environmental emission control systems

They also complement advanced packing systems like:

Ceramic Super Intalox Saddle

Cecebe HP Porcelain Saddles

Ceramic Ring Partitioned

PP Pall Ring

Ceramic Honeycomb structures

Why Choose MBC Tower?

As a trusted inert ceramic balls exporter and supplier near me, MBC Tower is known for quality, consistency, and timely delivery. Located among leading ceramic manufacturers in Mandsaur, we provide:

ISO-certified production standards

Custom sizing and packing solutions

Compatibility with other ceramic materials like alumina balls, grid blocks, and ceramic ultra

Our products are ideal for integration into high-performance tower packing systems where strength and reliability are essential.

Related Products Offered

High Alumina Ceramic Balls

Ceramic Saddles Manufacturer & Exporter

Ceramic Honeycomb Supplier

Ceramic Ferrule Manufacturer in Mandsaur

Ceramic Grid Block Exporter

Ceramic Ring Partitioned Supplier

MBC Tower ensures compatibility across your plant’s entire mass transfer and support media system.

Click here :-

Frequently Asked Questions (FAQs)

1. What is the purpose of inert ceramic balls?

Inert ceramic balls serve as protective support media at the bottom of packed beds. They ensure uniform flow distribution and protect catalysts from direct contact with process fluids.

2. Are inert ceramic balls reusable?

Yes, if not physically or chemically damaged, inert ceramic balls can be reused after cleaning. Their durability allows multiple life cycles in non-extreme environments.

3. How are inert ceramic balls different from high alumina balls?

While both offer thermal and chemical stability, high alumina ceramic balls are harder and used in more demanding environments. Inert ceramic balls are more economical and suitable for general support functions.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Top Ceramic Ultra Manufacturers – Premium Industrial Solutions from MBC Tower

MBC Tower stands out as one of the most reliable ceramic ultra manufacturers in mandsaur in the industrial ceramics space, delivering cutting-edge ceramic components with unmatched thermal and chemical resistance. Designed for use in high-performance applications, our Ceramic Ultra range includes advanced formulations that exceed traditional ceramics in durability, heat stability, and efficiency.

From ceramic ring partitioned systems to Cecebe HP Porcelain Saddles supplier in mandsaur and Ceramic Super Intalox Saddles, we serve a wide array of industries with premium-quality ceramic products engineered to meet today’s toughest operational demands.

What Is Ceramic Ultra?

Ceramic Ultra is a next-generation ceramic material designed for extreme environments, offering:

High mechanical strength

Excellent resistance to corrosion and thermal shock

Low thermal expansion

Long operating life in acidic, basic, or high-temperature systems

This material is widely used in reactors, distillation columns, heat exchangers, and other critical components in the chemical, petrochemical, fertilizer, and power generation industries.

Key Benefits of Choosing MBC Tower’s Ceramic Ultra Products

As leading ceramic ultra suppliers, we focus on performance, longevity, and cost-efficiency. Our ceramic materials are produced using high-purity raw materials and modern sintering techniques.

Why MBC Tower?

ISO-compliant production processes

Custom designs and sizing

Fast lead times for domestic and international orders

Wide export network across Asia, Europe, and the Middle East

Our other offerings include High Alumina Ceramic Balls, Inert Ceramic Balls, Ceramic Grid Block, Ceramic Honeycomb, and PP Pall Rings—all from a single trusted manufacturer.

Applications Across Industrial Sectors

Our Ceramic Ultra materials are essential for operations involving:

High-temperature reactors

Catalytic and thermal reforming systems

Tower packing and gas-liquid contactors

Abrasive and corrosive fluid environments

MBC Tower is also a top ceramic saddles manufacturer near me, ceramic ferrule manufacturer in Mandsaur, and ceramic grid block exporter, making us a one-stop solution for industrial ceramic needs.

Committed to Global Quality Standards

As certified ceramic ultra exporters, we ensure our products meet the highest international specifications. Whether you're sourcing from India or abroad, our ceramics are tested for density, porosity, compressive strength, and resistance to heat and chemicals.

We also serve as a:

Ceramic Ring Partitioned Exporter

Ceramic Ring Manufacturer in India

Ceramic Honeycomb Structure Supplier

Cecebe HP Porcelain Saddles Supplier

PP Saddles Exporter

This makes us the preferred choice for buyers looking for reliability and innovation.

Click here :-

Frequently Asked Questions (FAQs)

1. What is Ceramic Ultra used for?

Ceramic Ultra is used in industrial applications that require high thermal resistance, strength, and corrosion resistance. Common applications include reactors, tower packing, heat exchangers, and scrubbers.

2. How is Ceramic Ultra different from regular ceramic materials?

Ceramic Ultra offers superior durability, lower thermal expansion, and higher resistance to acids and alkalis compared to conventional ceramics, making it ideal for harsh environments.

3. Can Ceramic Ultra products be customized for my application?

Yes. MBC Tower offers custom-sized Ceramic Ultra components based on your process requirements, including geometry, thickness, and material properties.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Top Ceramic Ultra Manufacturers – Premium Industrial Solutions from MBC Tower

MBC Tower stands out as one of the most reliable ceramic ultra manufacturers in mandsaur in the industrial ceramics space, delivering cutting-edge ceramic components with unmatched thermal and chemical resistance. Designed for use in high-performance applications, our Ceramic Ultra range includes advanced formulations that exceed traditional ceramics in durability, heat stability, and efficiency.

From ceramic ring partitioned systems to Cecebe HP Porcelain Saddles in mandsaur and Ceramic Super Intalox Saddles, we serve a wide array of industries with premium-quality ceramic products engineered to meet today’s toughest operational demands.

What Is Ceramic Ultra?

Ceramic Ultra is a next-generation ceramic material designed for extreme environments, offering:

High mechanical strength

Excellent resistance to corrosion and thermal shock

Low thermal expansion

Long operating life in acidic, basic, or high-temperature systems

This material is widely used in reactors, distillation columns, heat exchangers, and other critical components in the chemical, petrochemical, fertilizer, and power generation industries.

Key Benefits of Choosing MBC Tower’s Ceramic Ultra Products

As leading ceramic ultra suppliers near me, we focus on performance, longevity, and cost-efficiency. Our ceramic materials are produced using high-purity raw materials and modern sintering techniques.

Why MBC Tower?

ISO-compliant production processes

Custom designs and sizing

Fast lead times for domestic and international orders

Wide export network across Asia, Europe, and the Middle East

Our other offerings include High Alumina Ceramic Balls, Inert Ceramic Balls, Ceramic Grid Block, Ceramic Honeycomb, and PP Pall Rings—all from a single trusted manufacturer.

Applications Across Industrial Sectors

Our Ceramic Ultra materials are essential for operations involving:

High-temperature reactors

Catalytic and thermal reforming systems

Tower packing and gas-liquid contactors

Abrasive and corrosive fluid environments

MBC Tower is also a top ceramic saddles manufacturer, ceramic ferrule manufacturer in Mandsaur, and ceramic grid block exporter, making us a one-stop solution for industrial ceramic needs.

Committed to Global Quality Standards

As certified ceramic ultra exporters, we ensure our products meet the highest international specifications. Whether you're sourcing from India or abroad, our ceramics are tested for density, porosity, compressive strength, and resistance to heat and chemicals.

We also serve as a:

Ceramic Ring Partitioned Exporter

Ceramic Ring Manufacturer in India

Ceramic Honeycomb Structure Supplier

Cecebe HP Porcelain Saddles Supplier

PP Saddles Exporter

This makes us the preferred choice for buyers looking for reliability and innovation.

Click here :-

Frequently Asked Questions (FAQs)

1. What is Ceramic Ultra used for?

Ceramic Ultra is used in industrial applications that require high thermal resistance, strength, and corrosion resistance. Common applications include reactors, tower packing, heat exchangers, and scrubbers.

2. How is Ceramic Ultra different from regular ceramic materials?

Ceramic Ultra offers superior durability, lower thermal expansion, and higher resistance to acids and alkalis compared to conventional ceramics, making it ideal for harsh environments.

3. Can Ceramic Ultra products be customized for my application?

Yes. MBC Tower offers custom-sized Ceramic Ultra components based on your process requirements, including geometry, thickness, and material properties.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Ceramic Structured Honeycomb: Advanced Ceramic Solutions by MBC Tower

Ceramic structured honeycomb in mandsaur technology has transformed the way industries manage thermal energy, chemical filtration, and emission control. These high-performance ceramic structures are designed for maximum durability, thermal efficiency, and chemical resistance—ideal for a wide range of applications in environmental engineering, chemical processing, and energy recovery systems.

At MBC Tower, a leading ceramic honeycomb structure manufacturer in Mandsaur, we deliver precision-engineered ceramic honeycomb solutions trusted by global industries for consistent performance and long service life.

What is a Ceramic Structured Honeycomb?

Ceramic structured honeycomb refers to a block-shaped material composed of many parallel channels that resemble a honeycomb pattern. These channels allow fluids or gases to pass through with minimal resistance while maximizing contact surface area.

Manufactured from materials such as cordierite, mullite, or high alumina, honeycomb ceramics are engineered for:

High-temperature resistance

Chemical inertness

Excellent mechanical strength

They are widely used in catalytic converters, regenerative thermal oxidizers (RTOs), air pollution control systems, and heat recovery units.

Key Benefits of Ceramic Honeycomb Structures

Exceptional Thermal Performance

Ceramic honeycombs can withstand temperatures up to 1400°C, making them suitable for high-temperature processes.

High Chemical Resistance

Ideal for harsh environments involving acids, solvents, or other corrosive agents.

Lightweight Design

Despite their strength, these structures are lightweight and easy to handle and install.

Optimized Gas and Fluid Flow

The structured channels minimize pressure drop while increasing mass and heat transfer efficiency.

Applications Across Industrial Sectors

MBC Tower’s ceramic structured honeycomb manufactural products serve industries such as:

Environmental Engineering – Used in scrubbers and emission control systems.

Chemical Processing – Enhances catalytic reactions and thermal management.

Energy Recovery – Improves efficiency in heat exchangers and RTOs.

Automotive and Marine – Integral in exhaust purification systems.

These products are often installed with Ceramic Ring Partitioned, Ceramic Super Intalox Saddles, Cecebe HP Porcelain Saddles, and PP Pall Rings for optimized tower performance.

Why Choose MBC Tower?

As one of the top ceramic manufacturers in Mandsaur, MBC Tower offers:

ISO-certified ceramic honeycomb structure manufacturer services

Full-spectrum solutions as a ceramic honeycomb supplier and exporter

Custom designs based on your system needs

Competitive pricing with on-time delivery

We also manufacture and export related components such as:

Ceramic Grid Block

High Alumina Ceramic Balls Exporters

Inert Ceramic Balls Manufacturer

Alumina Balls

Ceramic Ferrule Manufacturer in Mandsaur

Related Ceramic Solutions

We offer an extensive range of high-performance ceramic tower packing materials:

Ceramic Ring Partitioned Exporter

Ceramic Saddles Manufacturer & Exporter

Ceramic Ultra Exporters

Ceramic Super Intalox Saddle Manufacturer

Cecebe HP Porcelain Saddles Supplier

PP Pall Ring Exporter

These products are engineered for seamless integration with ceramic honeycomb systems in both existing and new industrial setups.

Click here :-

Frequently Asked Questions

1. What is a ceramic structured honeycomb used for?

It’s used in high-temperature and high-chemical load environments for heat exchange, catalytic reactions, and emission control. Common industries include automotive, chemical processing, and air purification systems.

2. What are the advantages of ceramic honeycomb over metal alternatives?

Ceramic honeycombs offer higher thermal resistance, better chemical inertness, and longer lifespan in harsh environments compared to metal or plastic structures.

3. Can ceramic honeycomb structures be customized for specific applications?

Yes. MBC Tower offers customizable sizes, cell densities, and materials to meet specific application and performance requirements.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Ceramic Structured Honeycomb for Industrial Applications – MBC Tower

At MBC Tower, we specialize in advanced ceramic engineering to support industrial efficiency, and one of our most trusted products is the ceramic structured honeycomb. With its high surface area, low thermal expansion, and excellent mechanical strength, this structure has become indispensable in sectors such as environmental engineering, petrochemical refining, and automotive exhaust treatment.

Designed for high-temperature and corrosive environments, ceramic honeycomb structures significantly improve energy efficiency and process reliability.

What Is a Ceramic Structured Honeycomb?

A ceramic structured honeycomb is a solid, porous block designed with a honeycomb lattice that maximizes surface area while minimizing flow resistance. These structures are manufactured using heat-resistant ceramic materials, including high alumina ceramic balls, inert ceramic balls, and ceramic ultra grades for various applications.

Key Benefits:

High thermal resistance up to 1400°C

Low pressure drop and energy consumption

High geometric surface area for excellent heat transfer

Effective pollutant filtration and gas distribution

Lightweight and structurally stable

Applications of Ceramic Honeycomb in Industry

Ceramic honeycomb structures are used in multiple industrial operations, including:

Regenerative Thermal Oxidizers (RTOs)

Catalytic converters

Air and gas filtration systems

Heat exchange processes

Desulfurization and denitrification reactors

Many of our clients from Ceramic Manufacturers in Mandsaur rely on these for high-efficiency pollution control systems and catalytic support beds.

Why Choose MBC Tower?

As a trusted ceramic honeycomb structure supplier near me and manufacturer in Mandsaur, MBC Tower brings quality, performance, and precision manufacturing to the forefront.

We also offer:

Cecebe HP Porcelain Saddles Manufacturer

Ceramic Super Intalox Saddle Supplier

PP Pall Ring Exporter

Ceramic Saddles Manufacturer & Exporter

Our commitment to consistency and reliability has made us one of the leading ceramic grid block exporters and ceramic ring partitioned suppliers.

Quality Materials Backed by Innovation

All honeycomb structures are made using premium ceramics, such as:

High Alumina Ceramic Balls – For thermal durability

Alumina Balls – Providing high surface contact

Ceramic Ultra – Ensuring advanced chemical resistance

Inert Ceramic Balls – Used for catalyst support and uniform distribution

These materials ensure long-lasting performance in demanding conditions.

Trusted Worldwide

MBC Tower serves industries globally, with expertise as a:

Ceramic Honeycomb Exporters

Ceramic Saddles Supplier

Inert Ceramic Balls Exporters

Ceramic Ferrule Manufacturer in Mandsaur

Frequently Asked Questions

1. What is ceramic structured honeycomb used for?

It’s used in air purification, heat exchangers, and pollution control systems due to its high surface area and thermal durability.

2. What materials are used in ceramic honeycomb structures?

They are commonly made from cordierite, alumina, or mullite, known for their strength and heat resistance.

3. Are ceramic honeycombs customizable?

Yes, at MBC Tower, we offer custom dimensions, cell densities, and materials based on the client's application requirements. Click here :-

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Understanding PP Pall Rings and PP Saddles

PP Pall Rings and PP Saddles are lightweight, low-cost plastic packing media commonly used for mass transfer in towers. They are appreciated for:

Low pressure drop and easy handling

Cost efficiency and corrosion resistance

Lightweight design facilitating quick installation

Why Ceramic Grid Blocks are Preferred

Ceramic Grid Blocks stand out as durable alternatives thanks to superior material properties:

Exceptional compressive strength for load-bearing towers

Thermal stability up to 800–1,400 °C, far above plastic options

Chemical resistance to acids, alkalis, and solvents

Higher porosity and controlled flow for optimal gas–liquid contact

These blocks are favored where load-bearing capacity, temperature, and chemical exposure exceed plastic media limits.

Ideal Use Cases for Ceramic Grid Blocks

Madhya Bharat Ceramics' ceramic grid block supplier services fit industries requiring both mechanical resilience and chemical resistance:

High-temperature towers, such as thermal reactors and furnaces

Catalyst bed support, integrated with ceramic saddles or grid packing

Enhanced flow media, complementing inert ceramic balls and ceramic honeycomb Google My Business :-

These blocks blend load-bearing strength with operational efficiency.

Madhya Bharat Ceramics: Your Ceramic Packing Experts

As leading Ceramic Manufacturers in Mandsaur, Madhya Bharat Ceramics offers:

Customizable grid block dimensions and bar configurations

Rigorous quality control—including thermal tolerance and load-bearing tests

Integrated solutions with Ceramic Super Intalox Saddles, Ceramic Honeycomb, and Ceramic Ultra

Bulk export capacity as a trusted ceramic grid block exporter Click Here :-

Frequently Asked Questions

1. Can PP packing be used in high-temperature towers?

Answer: No. PP Pall Rings and Saddles degrade quickly above ~80–100 °C, making them unsuitable for high-temperature processes.

2. Why are ceramic grid blocks preferred in corrosive environments?

Answer: They resist a wide range of chemicals and maintain structural integrity where plastics would dissolve or weaken.

3. Do ceramic grid blocks reduce pressure drop?

Answer: They provide controlled pressure drop suitable for tall or complex towers while supporting heavy loads and maintaining uniform flow.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Grid Block: Premium Ceramic Packing Solutions by Madhya Bharat Ceramics

In modern industrial applications, the choice of packing material significantly impacts process efficiency and operational stability. Madhya Bharat Ceramics, a reputed name among Ceramic Manufacturers in Mandsaur, specializes in high-quality Grid Blocks that optimize flow distribution, support catalyst beds, and improve overall performance in towers and reactors.

What is a Grid Block?

A Grid Block is a structured ceramic packing used primarily in chemical reactors, catalytic converters, and absorption towers. These blocks support catalyst beds and help evenly distribute gas or liquid flows, reducing channeling and pressure drops.

Manufactured from high-grade ceramic materials, grid blocks offer excellent thermal and chemical resistance, making them ideal for harsh industrial environments. Google My Business :-

Key Advantages of Ceramic Grid Blocks

Madhya Bharat Ceramics, recognized as a reliable ceramic grid block manufacturer, supplies grid blocks designed for superior durability and functionality:

High Thermal Resistance: Operate efficiently at elevated temperatures without degradation.

Chemical Stability: Resistant to acids, alkalis, and corrosive gases.

Mechanical Strength: Able to withstand heavy loads and pressure in tower packing.

Improved Flow Distribution: Reduces channeling, ensuring uniform contact between phases.

Long Service Life: Minimal wear and tear increase maintenance intervals.

Applications of Grid Blocks

Grid blocks are widely used in industries including:

Petrochemical processing

Oil refining

Gas treatment plants

Environmental engineering

Fertilizer manufacturing

They often work alongside other ceramic packing materials such as Ceramic Ring Partitioned, Ceramic Super Intalox Saddle, and Ceramic Honeycomb Structure for optimized performance.

Why Choose Madhya Bharat Ceramics for Grid Blocks?

As a trusted ceramic grid block exporter and supplier, Madhya Bharat Ceramics offers:

Customized grid block sizes and shapes to meet specific process requirements

Bulk supply capability to meet large industrial demands

Comprehensive quality checks ensuring product integrity and performance

Expertise in delivering ceramic packing solutions such as Cecebe HP Porcelain Saddles and High Alumina Ceramic Balls

Click here :-

Frequently Asked Questions

Q1: What is the purpose of a grid block in industrial applications? A: Grid blocks support catalyst beds and promote even flow distribution, reducing channeling and pressure drops in reactors and towers.

Q2: How does a ceramic grid block differ from other packing materials? A: Ceramic grid blocks offer superior thermal and chemical resistance compared to metal or plastic packings, making them ideal for harsh environments.

Q3: Can grid blocks be customized for specific industrial needs? A: Yes, Madhya Bharat Ceramics offers customized sizes and shapes of grid blocks to fit various process requirements and tower dimensions.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Grid Block: A Reliable Solution for High-Performance Industrial Applications

In demanding industrial environments where durability, heat resistance, and chemical stability are essential, Grid Blocks have proven to be an effective solution. Known for their strength, thermal stability, and superior airflow characteristics, Grid Blocks are widely used in a variety of chemical, petrochemical, and environmental engineering applications.

At Madhya Bharat Ceramics, a leading ceramic grid block manufacturer and ceramic grid block exporter, we provide high-performance grid blocks that help enhance operational efficiency in complex processing systems.

What Is a Grid Block?

A Grid Block is a ceramic structural element with a lattice-like design that promotes even gas distribution and enhances heat and mass transfer. These blocks are installed at the bottom of packed towers, reactors, and scrubbers to support packing media and promote uniform fluid flow.

As a reliable ceramic grid block supplier, we engineer our grid blocks using premium materials such as ceramic ultra, alumina balls, and high alumina ceramic balls to ensure long-lasting performance under high-stress conditions.

Benefits of Using Ceramic Grid Blocks

1. Superior Load-Bearing Strength

Grid Blocks offer excellent mechanical strength, enabling them to support heavy tower packing components like ceramic saddles, ceramic super intalox saddles, and PP pall rings.

2. Enhanced Air and Gas Flow

Their open structure allows unrestricted gas and fluid passage, reducing pressure drop and improving process efficiency.

3. Thermal and Chemical Resistance

Made with advanced ceramic materials, grid blocks withstand temperatures above 1000°C and resist corrosion from acids, alkalis, and other chemicals.

4. Support for Packing and Catalyst Beds

Grid Blocks ensure even distribution and secure placement of inert ceramic balls, alumina balls, and other catalyst support media.

Industrial Applications of Grid Blocks

Grid Blocks are commonly used in:

Packed towers and distillation columns

Chemical reactors and scrubbers

Environmental gas treatment systems

Heat exchangers and waste incinerators

They are an essential component in systems that use ceramic saddles tower packing, ceramic honeycomb structures, and Cecebe HP porcelain saddles.

Google my business :-

Why Choose Madhya Bharat Ceramics?

As one of the top ceramic manufacturers in Mandsaur, we offer:

High-quality ceramic grid blocks with precise dimensions

Custom designs and sizes to match your process needs

Consistent quality and global export capabilities

Trusted by industries across India and worldwide

Our product range also includes ceramic ring partitioned, ceramic ferrule, inert ceramic balls exporters, and ceramic honeycomb exporters to meet all your mass transfer and catalyst support needs.

Frequently Asked Questions (FAQs)

1. What is the purpose of grid blocks in packed towers?

Grid blocks serve as support structures that evenly distribute fluids and hold packing materials in place. They help reduce pressure drop and enhance flow uniformity.

2. Are ceramic grid blocks suitable for high-temperature operations?

Yes, ceramic grid blocks are thermally stable up to 1000°C or more and are ideal for high-temperature reactors and gas treatment systems.

3. How do ceramic grid blocks compare to metal or plastic alternatives?

Ceramic grid blocks offer superior thermal stability and corrosion resistance compared to metal or plastic, making them better suited for harsh industrial environments.

Get in Touch with Madhya Bharat Ceramics

Boost your industrial system’s performance with durable and efficient ceramic grid blocks from Madhya Bharat Ceramics. As a trusted ceramic grid block exporter, we are ready to support your operations with top-tier products and expert solutions.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Inert Ceramic Balls: Reliable Catalyst Support Solutions from Madhya Bharat Ceramics

Inert ceramic balls are essential components used in various industrial processes, particularly in the chemical and petrochemical industries. These high-performance ceramic spheres are primarily utilized as catalyst bed support media. Designed to withstand extreme temperatures, mechanical stress, and chemical exposure, inert ceramic balls play a critical role in enhancing the efficiency and longevity of industrial reactors.

At Madhya Bharat Ceramics, a trusted inert ceramic balls manufacturer and exporter in Mandsaur, we deliver premium-quality products that meet global standards for performance and durability.

Key Benefits of Using Inert Ceramic Balls

The high utility of inert ceramic balls lies in their durability, thermal stability, and low reactivity. Here are their core advantages:

Excellent Chemical Stability: Resistant to acids, alkalis, and most organic solvents.

High Thermal Resistance: Suitable for temperatures exceeding 1000°C.

Superior Mechanical Strength: Withstand high-pressure environments without cracking.

Low Water Absorption: Ensures minimal interference in gas-liquid processes.

Extended Catalyst Life: Protects active catalyst components from mechanical abrasion.

These features make them ideal for use in fixed-bed reactors, desulfurization systems, ammonia converters, and other packed bed applications.

Industrial Applications of Inert Ceramic Balls

Inert ceramic balls are widely used across industries due to their versatile properties. Common application areas include:

Petrochemical Processing: Act as protective agents and supports for active catalysts.

Gas and Liquid Filtration Systems: Improve the efficiency of separation processes.

Water Treatment Plants: Facilitate efficient filtration and removal of impurities.

Refinery Towers and Columns: Enhance the distribution of gas and liquid in packed beds.

Our products also complement other ceramic media such as ceramic ring partitioned, high alumina ceramic balls, and ceramic saddles, which we also manufacture and supply.

GOOGLE MY BUSINESS :-

Why Choose Madhya Bharat Ceramics?

As one of the leading ceramic manufacturers in Mandsaur, Madhya Bharat Ceramics is committed to delivering excellence in every product. Here's what sets us apart:

Customized Solutions: Available in various sizes from 1/8" to 2.5" to suit different industrial needs.

Global Exports: Trusted inert ceramic balls exporters to international markets.

Stringent Quality Checks: Each batch tested for strength, absorption, and purity.

Comprehensive Product Range: Including ceramic super intalox saddles, alumina balls, ceramic honeycomb, and PP pall rings.

FAQs About Inert Ceramic Balls

Q1: What is the purpose of inert ceramic balls in chemical processes? A: Inert ceramic balls serve as support and protective layers for catalysts. They evenly distribute gases or liquids and prevent catalyst damage.

Q2: Can inert ceramic balls be reused after a process cycle? A: Yes, if they remain structurally intact and chemically unaffected. However, routine inspection is recommended.

Q3: What sizes are available for inert ceramic balls? A: Sizes typically range from 1/8" to 2.5", and custom sizes are available depending on application requirements.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Grid Block | Industrial Solutions by Madhya Bharat Ceramics

Madhya Bharat Ceramics is a top-tier ceramic grid block manufacturer, offering durable and efficient solutions for various industrial applications. Our grid blocks are designed to provide mechanical support and promote uniform gas-liquid distribution in packed bed systems. As a trusted ceramic grid block exporter and supplier, we serve a global clientele across chemical processing, petrochemical, refining, and environmental sectors.

Our facility in Mandsaur is equipped with advanced ceramic manufacturing technologies, ensuring high-quality products tailored to meet international standards.

What Are Ceramic Grid Blocks?

Ceramic grid blocks are structured ceramic components placed at the bottom or between packing beds in columns or towers. They ensure even flow distribution and provide mechanical strength to prevent channeling and improve efficiency.

Common applications include:

Mass transfer columns

Scrubbing towers

Catalyst support beds

Distillation and absorption systems

These blocks offer thermal stability and corrosion resistance, making them essential in high-temperature and chemically aggressive environments.

Benefits of Using Our Ceramic Grid Blocks

Madhya Bharat Ceramics' ceramic grid block supplier solutions stand out due to:

High Mechanical Strength: Supports heavy loads and maintains structural integrity

Corrosion Resistance: Ideal for acidic and alkaline environments

Thermal Stability: Performs well under extreme temperatures

Improved Flow Distribution: Reduces pressure drop and enhances mass transfer

We also supply:

Inert Ceramic Balls

Ceramic Super Intalox Saddles

Alumina Balls

High Alumina Ceramic Balls

Ceramic Ring Partitioned Google My business :-

Industries We Serve

As a premier ceramic grid block manufacturer, we serve diverse industries such as:

Chemical Processing

Petroleum Refining

Environmental Engineering

Pharmaceuticals

Wastewater Treatment Plants

Our ceramic grid block exporter services ensure timely delivery, quality assurance, and reliable support worldwide.

Why Madhya Bharat Ceramics?

We are a reputed name among ceramic manufacturers in Mandsaur, with advantages that include:

Custom designs to meet exact specifications

Quality assurance through ISO-certified processes

Competitive pricing and scalable production

Experienced technical team for support and consultation

Our products are also used by customers looking for:

Ceramic Honeycomb Structures

Cecebe HP Porcelain Saddles

PP Pall Rings and PP Saddles Click here :-

Frequently Asked Questions

Q1: What is the function of a ceramic grid block? A: Ceramic grid blocks provide mechanical support and help in distributing fluids evenly in packed bed towers, improving system efficiency.

Q2: Are ceramic grid blocks resistant to chemicals? A: Yes, they are highly resistant to acids, alkalis, and other corrosive chemicals, making them suitable for harsh processing environments.

Q3: Can grid blocks be customized for different applications? A: Absolutely. We offer customized sizes, shapes, and configurations based on your specific requirements.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Grid Block Manufacturer & Supplier with Global Reach

Madhya Bharat Ceramics, a trusted name among ceramic grid block manufacturers, stands out for delivering high-performance solutions tailored to meet the needs of global industries. Based in Mandsaur, Madhya Pradesh, we specialize in crafting reliable grid blocks that support efficient heat distribution, energy saving, and structural integrity in various high-temperature and chemical processing environments.

As a grid block supplier with a global reach, we ensure our products meet international quality standards, offering durable and long-lasting performance.

What is a Ceramic Grid Block?

A ceramic grid block is a structured ceramic component designed to improve airflow and heat transfer in thermal systems. It is widely used in regenerative thermal oxidizers (RTOs), kilns, and furnaces where high temperature and corrosion resistance are crucial.

These blocks are typically made from high-purity materials like alumina balls and inert ceramic balls, which offer:

Excellent thermal shock resistance

High surface area for optimized performance

Structural stability under extreme conditions

Key Benefits of Our Ceramic Grid Blocks

As a leading ceramic grid block manufacturer, we provide products that offer a range of benefits:

High Heat Resistance: Withstands temperatures over 1200°C, ideal for industrial furnaces and kilns.

Optimized Gas Distribution: Promotes even airflow and enhances combustion efficiency.

Corrosion Resistance: Withstands exposure to acidic and basic gases.

Customizable Design: Available in various sizes and patterns for industry-specific applications.

Industries We Serve Globally

Our ceramic grid block supplier network supports clients across various sectors:

Petrochemical and Chemical Processing

Environmental Engineering

Power Generation

Metallurgical Industry

Ceramic Tile and Refractory Manufacturing

Madhya Bharat Ceramics also offers complementary products like:

Ceramic Super Intalox Saddles

High Alumina Ceramic Balls

PP Pall Ring and Cecebe HP Porcelain Saddles

Why Choose Madhya Bharat Ceramics?

Global Export Network: We are a trusted ceramic grid block exporter serving clients across Asia, Europe, and the Middle East.

ISO-Certified Quality: Adherence to stringent international quality and testing protocols.

Experienced Team: Decades of experience in designing custom ceramic solutions for unique industrial needs.

Sustainability Focus: Our manufacturing practices align with global energy-efficiency goals.

We are also a prominent name among Ceramic Manufacturers in Mandsaur, delivering excellence in ceramic ultra, ceramic ring partitioned, and ceramic saddles tower packing.

Frequently Asked Questions (FAQs)

Q1: What is the primary use of a ceramic grid block in industry? A: Grid blocks are mainly used in thermal applications to optimize airflow and heat distribution in kilns, regenerators, and oxidizers.

Q2: How do ceramic grid blocks compare with traditional refractory bricks? A: Unlike traditional bricks, ceramic grid blocks provide enhanced heat retention, reduced thermal mass, and better resistance to thermal cycling.

Q3: Can I request a custom grid block design for my specific application? A: Yes. As a seasoned ceramic grid block manufacturer, we provide custom sizes and configurations to meet your exact requirements.

Ready to Optimize Your Industrial Process?

Partner with Madhya Bharat Ceramics, the trusted grid block supplier and ceramic grid block exporter from Mandsaur. Whether you need bulk supply, customized design, or consultation, we’re here to help you improve performance and reliability in high-temperature operations.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes

Text

Durable Ceramic Grid Blocks for Chemical and Petrochemical Industries

In high-demand sectors like chemical and petrochemical industries, reliability and durability are essential. Ceramic grid blocks serve a vital role in structured packing systems, ensuring thermal resistance, chemical stability, and long-term operational performance. At Madhya Bharat Ceramics, we specialize in manufacturing durable ceramic grid blocks tailored for harsh industrial environments.

Why Ceramic Grid Blocks Are Essential for Industrial Applications

Ceramic grid blocks are widely used in high-temperature towers, distillation units, and chemical reactors due to their unique physical properties. They are engineered to deliver:

High mechanical strength

Superior heat resistance

Exceptional resistance to corrosive chemicals

Long operational life

These attributes make ceramic grid blocks ideal for chemical processing, oil refineries, and other petrochemical operations.

Key Benefits of Using Ceramic Grid Blocks in Chemical Industries

Choosing ceramic grid blocks from trusted ceramic grid block manufacturers ensures performance stability in critical systems. Benefits include:

Improved Thermal Efficiency: With low thermal expansion, they withstand extreme heat cycles.

Low Pressure Drop: Their open structure enables efficient gas-liquid contact, improving processing efficiency.

Minimal Fouling: The smooth surface reduces the risk of blockage or scaling over time.

Environmentally Safe: Made from inert ceramic materials that do not react with hazardous chemicals.

Madhya Bharat Ceramics – Trusted Ceramic Grid Block Manufacturer

As a leading ceramic grid block manufacturer and ceramic grid block supplier, Madhya Bharat Ceramics delivers products that meet international quality standards. Our grid blocks are manufactured in Mandsaur, a hub of ceramic excellence.

We also offer a complete range of complementary products for your tower packing needs, including:

Ceramic Ring Partitioned

Ceramic Ultra

High Alumina Ceramic Balls

Inert Ceramic Balls

Ceramic Super Intalox Saddle

PP Pall Ring

Cecebe HP Porcelain Saddles

Applications of Ceramic Grid Blocks in Petrochemical Systems

Ceramic grid blocks are vital in:

Absorption and desorption columns

Distillation towers

Scrubbing systems

Thermal reactors

Their chemical inertness makes them particularly suited for handling acids, alkalis, and high-purity chemical processes.

Why Choose Madhya Bharat Ceramics?

Our products are trusted by industries across India and globally due to:

ISO-certified manufacturing processes

Decades of experience as ceramic grid block exporters

Advanced R&D and testing facilities

Personalized support and on-time delivery

Frequently Asked Questions (FAQs)

1. What are ceramic grid blocks used for in chemical industries? Ceramic grid blocks are used as structured packing materials in columns and reactors to improve heat and mass transfer, reduce pressure drop, and resist chemical corrosion.

2. How do ceramic grid blocks differ from random packing? Unlike random packing, grid blocks are structured and provide uniform gas-liquid distribution, resulting in higher efficiency and better performance in controlled environments.

3. What is the lifespan of ceramic grid blocks in industrial use? With proper installation and maintenance, ceramic grid blocks can last 5–10 years or more, depending on the operating environment and exposure to chemicals or thermal stress.

Get in Touch with Madhya Bharat Ceramics

Looking for a reliable ceramic grid block supplier or ceramic grid block exporter? Contact Madhya Bharat Ceramics for high-quality, custom-engineered ceramic grid blocks. Let’s elevate your industrial operations with products built for performance and durability.

CONTACT :- MADHYA BHARAT CERAMICS :- Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India Email us : [email protected] [email protected] us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain) Call us on : +91-8827697111 (Siddharth Jain) +91-9425105256 (Sushil Jain)

0 notes