Text

Best Jib Crane Manufacturers in India

When it comes to buying a jib crane, a lot of factors need to be taken into account. First, you should choose a manufacturer who has a good market reputation. You can ask around from people in the business or read online reviews and testimonials. Always ask questions and make sure you select a manufacturer that has a good track record and is experienced in the field.

A jib crane manufacturers is a multipurpose crane that is not as large as a tower crane but is very powerful. These cranes are fixed to the ground or free-standing and are capable of lifting heavy loads up to 15 tons. They are manufactured with many features that improve productivity and workplace safety.

Jib cranes are used in many industries to move and lift materials. They are also used in construction sites. They normally have fixed jibs, although there are also developments available. These developments make it easier to move heavier loads. If you need to lift a heavy load, a jib crane is the way to go.

The jib crane is one of the most important pieces of machinery in any factory or warehouse. It helps employees in handling heavy loads and increases productivity by reducing labor costs. It also eliminates the need for manual operation.

0 notes

Text

Types of Overhead Cranes for Sale

There are several types of overhead cranes for sale on the market. If you are in need of a crane for your business, there are several types available, including the single-girder type. This type of crane is widely used in numerous industries, including steel plants, steel product manufacturers, oil and gas, plastic, and cement plants, mines, construction, and car/truck industries. It is also widely used in the installation and maintenance work.

AQ-LX

The AQ-LX overhead crane is a single-girder crane that confirms the design standards of India. Its single-girder structure is light and can be easily operated, while its high-speed travel can accommodate a load up to 10 tons. It is suitable for factories, warehouses, and machinery assembling sites. In addition, it can move from 20 to 30 meters per minute and can reach up to 16 meters away from the wall. This crane is similar to its predecessor, the AQ-LD. It is a single-girder crane that have a similar lifting mechanism, and it can be integrated into the design of the building where it is used.

If you're a business owner looking for overhead crane manufacturers to increase productivity and efficiency, you'll want to invest in the latest equipment available. Purchasing a reputable crane will ensure that you're using the best equipment available for your needs. It will increase the speed of your work, allowing you to get more things done in less time.

AQ-NLH

The AQ-NLH electric double girder overhead crane is designed in line with European FEM standards. Its steel structure is optimized to meet the required strength and service life. Its smooth operation and low cost make it an ideal choice for general lifting applications. Whether you need a small or large crane, the AQ-NLH overhead crane will provide an excellent solution.

This low-headroom overhead crane is ideal for low-height manufacturing and assembling workshops. Its low-height design reduces the construction height of the building and saves construction costs. Its high lifting capacity makes it widely used in general machinery production workshops and assembling workshops. In addition, it incorporates national industry standards to ensure quality. This low-headroom overhead crane for sale is equipped with ground control and dual-speed motor.

AQ-QDX

AQ-QDX overhead crane is designed with several innovative features. It has a new generation of electrical motor, hoisting limiter and electrical control box. It also has a stair to connect the platform and the main part and uses a low-speed shaft. Its design adheres to the concept of maximization of the smallest parts to achieve a high degree of efficiency. In addition, this crane is maintenance-free. Its track is made of special cold-drawn steel with high straightness and flatness, which reduce wheel pressure and extend wheel life.

Its rigidity, tight structure, and aesthetic appearance to help it work in tough environments. It is also durable and can work under temperatures ranging from -20°F to 40°F.

AQ-QZ

The AQ-QZ overhead crane for sale is used in a variety of industrial settings. Its wide application range includes power plants, warehouses, freight yards, and docks. It is also used for a wide variety of materials, including scrap metal, sheet steel, and profile steel. Its rated lifting capacity ranges from five to fifty tons. It is equipped with an electromagnetic chuck, which can be removed easily for maintenance.

AQ-QZ overhead crane for sale comes with an advanced design that offers a number of advantages over its competitors. Its self-weight and roller pressure is lighter than those of its predecessors, making it a practical choice for heavy-duty applications. It also features a short limit size, which allows it to run faster and save lighting and heating equipment costs. Furthermore, it is highly durable, ensuring low maintenance costs.

UDZWG

If you're in the market for an Overhead Crane, then you have come to the right place. GovPlanet has a wide selection of Overhead Cranes from a variety of manufacturers, including Abus, Anchor, Deal, and OCMA. Browse through the inventory to find the perfect equipment for your next project.

0 notes

Text

Portable Power Winch Machine For Sale

Portable power winch machines are made to provide high pulling force. They are designed as per the IS-9507-1979 standard and are suitable for heavy duty applications. They are available with left-hand and right-hand operation and have various capacities. They are fitted with electromagnetic brakes or Double Shoe type brakes.

Portable power winch machine manufacturers are typically equipped with synthetic rope or steel cable for added durability and long-lasting performance. They are also ideal for use on rugged terrain and sharp rocks. Nonetheless, it is recommended to wear protective gloves when using these machines to avoid getting injured. Another advantage of steel cables is that they cost less than synthetic ropes, but they are much more dangerous in case of breakage.

Another advantage of an electric portable power winch is its zero-emission and maintenance-free operation. This type of portable winch is the ideal machine for pulling logs, brush, and other heavy objects. It is also useful for off-roading and hunting excursions. The battery-operated portable power winch is available in a wide range of speeds and features.

Portable power winches come with wireless or remote controls to control the operation of the machine. These winches have similar capacities to water-driven machines but they are faster and easier to use. While purchasing an electric power winch, be sure to choose a reliable manufacturer with a warranty. Also, consider how easy the machine is to install.

0 notes

Text

Electric Crab Trolley Supplier in India

An electric crab trolley is a great tool to use when handling crabs in open areas. They are made of quality materials and utilize the latest technology. They are designed by engineers who have vast experience in the industry. Electric crab trolleys are designed to avoid stooping and tipping, and they are safe to use. They can lift up to six meters and can carry up to fifty kilograms.

There are many electric crab trollely manufacturers that produce superior quality crab trolleys. They use the best quality materials and engineers. They are committed to the quality of their product and receive excellent feedbacks from clients. In addition, they are designed with advanced features to help the crabmen get the most out of their work. The electrical motor in these crab trolleys increases the strength of the product, which is a great benefit.

A good electric crab manufacturer in India will have several models available, allowing the user to pick a style that best suits the needs of their facility. There are single lift trolleys and double lift trolleys available, as well as battery-powered models. Some models have remote control capabilities. In addition to these features, an electric crab trolley can also be customized to accommodate different lifting applications.

The drums used in crab trolleys are made from high-quality materials that are designed to withstand a high load. They are also designed to be lightweight and anti-wear. They also come with an up/down limit switch. They are also modular and offer easy maintenance. A crab trolley's components include a motor, reducing gear box, wheel set, and brake.

0 notes

Text

Monorail Hoist Manufacturers

Monorail Hoist Manufacturers

Monorail hoist manufacturers are responsible for providing monorail hoists. These hoists are not required to comply with specific regulations governing cranes. However, some requirements may be applicable to these equipments. For example, the safety features of monorail hoists should be considered. Also, a monorail hoist is not required to have load charts or load weighing devices.

Monorail hoists have two different modes of movement: vertically and horizontally. The former is used for localized lifting and the latter is used for point-to-point transport. Both types of monorail hoists offer different features and benefits. The former has advantages such as curved sections, while the latter has the advantage of being motorised. They can be installed close to or on the ceiling.

Electric monorail hoists are widely used in industrial settings for their high safety and efficiency. These hoists are widely used on jib cranes, gantry cranes and single-girder overhead cranes. They are available in single-speed and double-speed versions. In addition, you can customize them to meet your specific requirements.

Monorail cranes are available in a variety of models, including freestanding, wall-mounted and floor-mounted versions. They are available in different capacities ranging from 150 to 4,000 pounds. The track can be made of steel or aluminum. Many models also feature switches and other options, such as custom paint colors. Some models can even be used for palletizing.

0 notes

Text

Electric Power Winch Machine

Electric power winches are a great option for lifting and moving materials. These power winches are electric motor powered machines that are available in right and left handed versions. They are highly reliable and have a long service life. They are also available with an extended warranty. Electric power winches are extremely versatile and can be used for many applications.

They can be used in a variety of industries and are ideal for lifting and pulling heavy loads quickly and safely. Whether you're working on a construction site or offshore, an electric winch can meet your needs. There are even marine duty models that are designed to operate in harsh marine or offshore environments. This means that you can use them for everything from handling anchors to moor a ship or towing large boats. These machines are usually IP56-protected, so they won't rust or get wet.

To find the best electric power winch machine manufacturers for your needs, begin your search by searching for a machine that has the features and quality you need. Choose an electric power winch with high starting torque, good insulation, and a durable brake system. Electro hydraulic thrusters, double-shoe type brakes, and electromagnetic brakes are all reliable options for power winches. Also, look for an electric power winch that includes an optional hand brake provision for emergency situations. Many of these machines also have extended warranties.

Besides the high-quality electric power winch machine, there are manual power winches for lighter-weight loads. Manual winches are less expensive and can be operated by a human. They are also safer and more affordable.

0 notes

Text

Circular Crane Suppliers in India

The circular crane manufacturers provide design was initially used as a military emblem during the Warring States period and was later adapted for use in garments and pottery. Today, circular cranes are used for construction and other industrial purposes. They are highly efficient and easy to maintain.

This type of crane is ideal for handling large loads or in places with low ceilings. It is also safer than conventional cranes because of its precision movements. The high precision movements of circular cranes significantly reduce the risks of injury to the operators and damage to bulk material handling equipment. It is also an excellent choice for applications that require a small footprint.

The advantages of a circular crane include high hoisting capacity, large operating radius, and large hoisting moment. It is also suitable for lifting nuclear power, petrochemical complexes, and ocean engineering modules. Its size allows it to lift heavy objects without compromising stability. It is the most common type of crane used in construction and maintenance projects.

A circular crane's control panel contains several components for safe operation and maintenance. For example, it has an automatic switch and a limit switch. All the components are designed to protect the crane from overheating and damage.

0 notes

Text

Best Electric Chain Hoist Manufacturers in India

Electric chain hoist manufacturers produce a variety of electric chain hoist models that meet varying needs. These models are designed for fast, smooth lifting and have a high load carrying capacity. They also require little maintenance, and can function at a high level for many years. In addition, electric chain hoists are durable and easy to use, which makes them an excellent choice for many industrial applications.

Depending on the requirements of an industrial facility, electric chain hoists are available in capacities ranging from 1/8 to three tons. Many of these hoists are used in steel mills, plating operations, and food processing facilities. Some even come with hygienic pharmaceutical designs. These types of electric chain hoists are electrically or manually operated.

The electric chain hoist works by placing the lifting chain on several gears. The motor then turns the gears, which raise or lower the chain. Most electric chain hoists also feature a lifting hook, which can be connected to the object being lifted. Electric chain hoists are available from leading manufacturers like Venus Crane, which has been manufacturing these products for over a century. The company also offers maintenance and service worldwide.

Electric chain hoists are widely used in light lifting applications. The HMI classifies electric chain hoists as H3 or H4 services, depending on the weight capacity. They can range from 250 pounds to five tons. They are ideal for small machine shops and industrial production lines. Because they are electric, they are extremely easy to operate and can be serviced easily. Furthermore, the ease of use makes electric hoists a cost-effective choice for many applications.

0 notes

Text

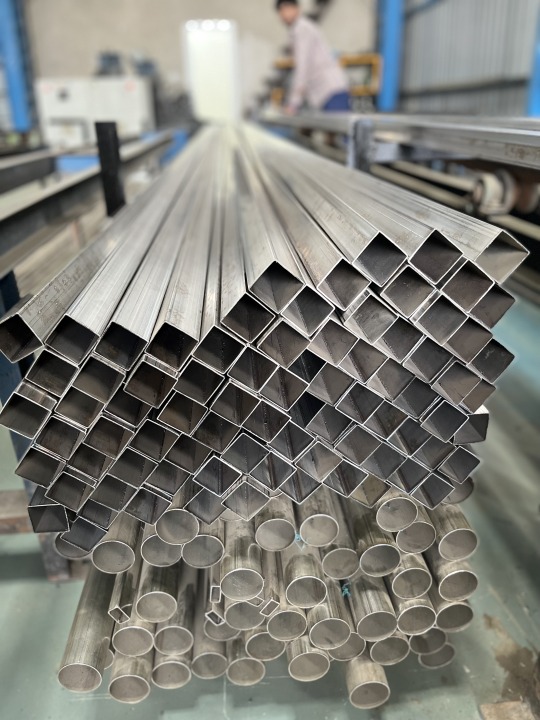

One of the leading Stainless Steel Pipes Manufacturers

Venus Pipes is a specialized producer of stainless steel pipes and tubes. It has been awarded ALL INDIA FIRST (AIF) manufacturer status and received the BIS approval for stainless steel pipes. The company is planning to raise Rs165 crore through its IPO. It is priced at 21 times FY22 annualized earnings per share (EPS).

It plans to increase its production capacity by 24,000 MTPA

The expansion project will double the company's current manufacturing capacity. The company currently produces welded and seamless pipes with a total capacity of 10,800 MTPA. In the next three years, the company intends to increase its total production capacity to 24,000 MTPA. It also plans to set up a piercing line.

The company has approved an investment of Rs. 50 crores for the expansion. This expansion is expected to double its current production capacity of 10,800 MTPA and increase its range of welded pipes up to SCH80s. The project is expected to start commercial production in Q1 FY24. The company plans to invest the proceeds from the IPO in the new facility.

It is looking to raise Rs165 crore through the IPO

Stainless steel pipe manufacturers and exporter of stainless steel pipes and tubes, is looking to raise Rs165 crore through an initial public offering (IPO). The company is planning to sell shares at a price band of Rs310-326 per equity share. The subscription period will end on May 13, and the shares will be listed on stock exchanges on May 24. The company plans to use the money to finance capacity expansion, backward integration, and general corporate purposes.

Venus Pipes & Tubes has decided to raise Rs165 crore through an initial public offering (IPO) on May 11. The offer is expected to close on May 13, and investors can apply for a minimum of one lot. Retail investors can purchase up to 13 lots (598 shares).

It is priced at a PE ratio of 21 times FY22 annualized EPS

Venus Pipes is a supplier of stainless steel pipes. The company sells its products under the brand name "Venus" to various industries including food processing, engineering and chemicals. The company has a PE ratio of 21 times FY22 annualized EPS, making it a relatively inexpensive stock for a long-term investor.

Venus Pipes' is expected to raise Rs165 crore, with a price band of Rs310-325 per share. The IPO comprises a fresh issue of shares and does not include the promoters' equity shares. The company plans to use the proceeds to finance capacity expansion and meet long-term working capital requirements. Given the recent success of Data Patterns' IPO, Venus Pipes' IPO may receive good traction. The company sells its products in the domestic market and exports to over 18 countries.

#sspipes#stainlesssteelpipe#sstubes#ss304pipe#304stainlesssteelpipes#stainlesssteelpipesmanufacturers

0 notes

Text

Discover Best Electric Crab Trolley Manufacturers in India

The electric crab trolley is an efficient and safe way of moving stock. It uses the latest technology to move your stock at a speed of two meters per moment. This mechanical device has several advantages over the other means of moving stock. For instance, it is safe to operate as there is no risk of accidents.

Electric Crab Trolleys are an efficient and safe means of moving your stock

Electric Crab Trolley manufacturers are an excellent way of transporting stock. They are extremely effective for transporting heavy loads, and are an economical way of transferring large quantities of product. These trolleys are available in various capacities, ranging from a few hundred kilograms to six or fifty meters. In addition, they are very safe and efficient, resulting in a significant reduction in the risk of tripping or dropping cargo.

Electric crab trolleys are electric devices that help in moving your crabs from a near-bottom position to the surface. You can choose from a single or twin-hoist design. You can also get dual-speed cranes for maximum control over speed.

They eliminate the risk of accidents

Crab trolleys are electric powered, and their capacity varies from a few hundred kilograms to up to fifty meters. The electric engine, with 40% CDF, is used to propel the trolley. A drum is used to deliver the trolley's contents. These trolleys are safe and efficient, minimizing the risks of accidents.

Electric chain hoist manufacturers provide hoists for different industries, including the crab industry. These hoists are made of stainless steel so that they are safe and won't harm the crabs. Another key component of a crab trolley is a drum. Most companies require a drum that has certain specifications, which is necessary to keep the crabs safe. Some of these drums have double flanges and rope anchors for increased security and safety.

They are manufactured using the latest technology

There are many firms that manufacture and sell superior quality electric crab trolleys and streetcars. Many of these firms also produce portable power winch machines, which are useful for moving and lifting heavy objects. These electric trolleys are a convenient and efficient way to move stock. They are used in a wide variety of applications and processes in industries such as construction, manufacturing, and engineering.

These crab trolleys are capable of lifting materials at speeds of two to twelve meters per minute. They are designed for heavy-duty applications and are easy to maintain. Their unique features help them to reduce the labor workforce and eliminate the risk of accidents.

They give a speed of 2 meter/moment

Venus Crane Electric Crab Trolley is one of the most advanced crab trolleys on the market. It is designed with the latest technology and made from the best materials. Besides that, it employs experienced and talented engineers and employees. These people are dedicated to providing the best quality crab trolleys to their clients. These mechanical devices have increased the efficiency of the industrial sector.

Venus Crane Electric Crab Trolley has the capability to lift materials from 6 meters to 50 meters at speeds ranging from 2 meter/moment to 12 meter/moment. It is suitable for heavy-duty lifting applications and has low maintenance costs. It also minimizes labor workforce and reduces accidents. Its unique features allow it to work with a wide range of materials.

They are available in Yellow colors

Electric crab trolley is the best choice for moving goods and stock from one place to another. These vehicles are manufactured using high-quality materials to avoid any damages. They are available in single and twin crane units. In addition, these vehicles are environmentally friendly as they do not produce any noise and exhaust fumes.

The electric crab trolley manufacturers in India provide trolleys in different capacities and sizes. Their construction is stainless steel to avoid any damage to the crabs. The drum that a crab trolley is made of is one of the main raw materials. Most firms look for drums that meet certain specifications. Other features of crab trolleys include breaks, double flanges, and rope anchors.

0 notes

Text

Jib Crane Suppliers in India

Jib Crane manufacturers in India provides high-quality cranes for moving and lifting heavy material. However, a good crane must be durable and able to meet the user's needs. This is where the importance of buying from a reputable manufacturer comes into play. Venus Engineer is one such manufacturer and a leading JIB Crane Supplier in India. Apart from Jib Cranes, this company also offers Overhead EOT Single Girder Cranes, Overhead Hot Cranes, Electric Chain Hoist, Geared Motors and Chain Pulley Block.

SMJC-1

Venus Crane SMJC-1 Jib crane is a versatile machine that can be used for various lifting and lowering purposes. It has a four-way articulation that allows it to be positioned as per the needs of the job site. Its heavy-section I beam and gusset plate give it additional rigidity. Its double-roller self-aligning type bearings can withstand both vertical and horizontal loads. The jib arm can be swivelled manually or electrically. These jib cranes are designed with a high level of specification and are suitable for a variety of applications.

When used for lifting large objects, jib cranes are ideal for indoor and small-space environments. They can easily reach objects that are too high for laborers to reach. These cranes can be used to transfer materials and parts between workstations or production lines. They can also be used to lift heavy apparatuses from one office to another.

Goliath Gantry Crane

If you are looking for a reliable supplier of Goliath gantry cranes, you have come to the right place. The Goliath crane from Sparkline is a versatile, heavy-duty building crane, and is used in construction sites, steel stockyards, and pre-cast segment yards.

The crane features a control panel which can be installed in a cabin, pendant, or radio remote. The control panel has standard contactors, overload relays, timers, transformers, and other components. The crane can be fitted with a VVFD drive for short or long travel.

One of the leading manufacturers of Goliath cranes in India is Meeka Machinery. This company offers a wide range of cranes, which are classified into four major categories. They include: Overhead cranes, Flame Proof Cranes, Jib Cranes, and Goliath Cranes.

Hoist HOT Crane

If you're looking for Hoist HOT Crane suppliers in India, you've come to the right place. Venus Crane is one of the leading manufacturers of this type of crane. The company has years of experience and is backed by quality and reliability. They offer several types of cranes and provide quality raw materials.

These cranes are a popular choice in industries requiring heavy lifting capacity. They're equipped with an operator cabin and control pendant and are operated electrically. You can choose from single or double girder EOT cranes. In order to find the right crane for your business, you'll need to find a reputable supplier. When shopping around for a crane, ask about their certification and quality assurance policies.

Hoist HOT Crane suppliers in India can provide you with a variety of options when it comes to sizing and installation. The company's expertise can help you determine what you need and help you decide which model is best for your needs.

0 notes

Text

Safety Devices Included With Electric Chain Hoists

An electric chain hoist is a machine that lifts a heavy object with a chain. The lifting and positioning parameters can be controlled from a remote location. It can be configured with end trucks or a bridge. Safety devices are included with electric hoists. These devices protect the worker and the work area from injury.

Duty cycle of an electric chain hoist

Duty cycle is a measure of how long a piece of electrically operated equipment can operate without needing to be shut down. Many pieces of equipment operate with a 25 percent duty cycle, meaning that their power can be used for an hour without needing to be shut down. Similarly, an electric chain hoist with a 25 percent duty cycle can only operate for 15 minutes before it needs to be shut down and cooled down.

While the duty cycle is important in determining how many times a hoist can start and stop, it is not the only factor to consider. Other factors can affect the duty cycle, including temperature and load. Generally, the higher the temperature, the lower the duty cycle.

Lifting speed

When a worker wants to lift something from one level to another, they use an electric chain hoist. The hoist is suspended over the object to be lifted and is mounted on a rigid structural frame. The worker switches the electric motor on to start the hoist. The hoist also has a brake integrated into the motor. The brake releases power supply as the load is displaced vertically.

When choosing an electric chain hoist manufacturers, it is important to consider its rated capacity. This is the maximum weight that the hoist can safely lift without buckling. It depends on several factors, including the strength of the wire rope or load chain. In addition, the operating environment and the duty cycle must be considered. For short lifts and low capacities, a manual hand chain hoist may be sufficient. For longer lifts and higher capacities, an electric hoist is a better choice.

Travel speed

There are various factors that determine the speed of an electric chain hoist. The hoist's lifting capacity is a key consideration. It is important to remember that not all materials are the same weight, so the speed should be adapted accordingly. For example, a higher speed might be more appropriate for lifting a delicate load, while a slower one is more appropriate for handling heavy objects. A lower speed is more comfortable for the operator, and it reduces the risk of a mishap.

Electric chain hoists are available in various models and configurations. Some are stationary, while others can be used with trolleys. Electric chain hoists are also available with radio remote controls for increased safety. They are also cheaper to run and take up less space than conveying systems. Moreover, electric chain hoists are ideal for production areas that have high safety requirements. They can be equipped with safety load hooks to prevent accidental unhooking of a load. The safety load hooks automatically close when the load is under load and can be opened by pressing a locking release.

Safety devices

There are two basic types of safety devices for electric chain hoists. One type is the limit switch, which cuts off the hoist when the load exceeds the maximum travel limit. The other type is the paddle limit switch, which operates by contacting a paddle on the chain. Both types of safety devices provide redundant protection.

In addition to safety devices, the hoist should be used with proper training. Proper training includes following the instructions in the operator's manual and other safety procedures. In addition, workers should physically inspect the hoist and safety devices before they are used. For example, the chain pulley block must be certified, and any lifting accessories should be marked with SWLs. It is also important to ensure the correct shackle pins are in place before a load is swung.

Cost

If you are shopping for a new electric chain hoist, there are many things to consider. One of the most important factors is the warranty. Many electric chain hoists are covered by a warranty, but some are not. This is important if you want to avoid costly repairs. It is important to read the fine print on any warranty so you understand what it covers. Some manufacturers offer lifetime warranties, but the warranty is often limited to certain components and may not cover every type of damage.

Another factor to consider is the capacity. An electric chain hoist will be most efficient if the capacity being lifted is three tons or less. However, if you need to lift heavier items, you might want to invest in a more expensive model. You can find models that lift up to 5 tons, so you can choose the right one for your needs.

0 notes

Text

What Is HOT Crane?

Hot Crane is a heavy-duty crane that helps in lifting heavy loads safely and easily. This crane can operate in any direction, and it offers excellent performance and durability. It is manufactured with the latest techniques, which ensure smooth operations. It also provides high reliability. It is a must-have piece of equipment for any construction site. It can easily handle a range of loads, including construction waste. To find out more about this crane, read on.

Single Beam

Single Beam HOT Crane manufacturers provide widely used machine for transporting materials and lifting goods to various places. Its unique features allow it to be used in many industrial settings. Aicrane, a leading single girder overhead crane manufacturer, offers a wide variety of overhead cranes, electric hoists, and winches. Its comprehensive services include designing, development, manufacturing, and sales. The company also provides installation, service, and training.

Jib Cranes

Jib cranes are versatile construction equipment that can be used for a variety of purposes. They are available in wall-mounted or free-standing configurations. Typical applications include handling bulk bags, lifting and shifting covers, motor servicing, and ingredient pouring.

Manual Crab Winch

A manual crab winch is an excellent choice for lifting massive loads. It has a low noise level and easy operation. It is a basic requirement in machine shops and motor garages.

Stationery design

The Crane Stationery collection is an example of how the best of the classics can be updated for the 21st century. The stationery is still based on traditional calligraphy, but the new look is more modern. For example, the Crane card set now features a hot pink envelope liner and lowercase monogram.

Lifting capacity

When selecting a new crane, it is important to understand its lifting capacity. This capacity can be determined from its operating manual. The manual contains detailed charts, showing lifting limits at various angles and extensions. Exceeding these limits may result in problems. It is also important to take note of weather conditions and the load being lifted.

Maintenance

Performing regular inspections on a crane is essential to ensure it is safe to use and prevent costly problems. Regular inspections are also a good way to spot issues before they become major, so that the crane operator or owner is aware of any problems before they cause problems. Regular inspections can also save your company from costly downtime.

0 notes

Text

Get Grab bucket Crane at Reasonable Price

To get a grip on the current market scenario, you need to acquire a market research report. This report provides in-depth analysis of the market with its growth prospects and competitive landscape. It provides insights based on the key players in the market, their primary growth strategies, new product innovations, and geographical expansion. It also contains sales statistics of various manufacturers.

Benefits of open loop control method

The present embodiment enables the grab bucket crane to be automated. The process can be accomplished by a simple configuration and entirely through software processing. This method significantly enhances the open lowering operation of the bucket crane. It can also reduce the downtime associated with the crane. Furthermore, the method provides improved control stability and reduced setting errors.

The present embodiment provides five alignment speed control circuits PI on the grab bucket. Circuit 5 calculates the difference between the motors 12 and 22 and feeds the result to the command circuit of the opening and closing speed control circuit. The present invention also includes six feedforward speed compensation circuits to minimize performance degradation as the speed increases.

Types of crane grab buckets

There are various types of crane grab buckets available in the market. Some of them are specifically designed to handle sand and gravel. Some are open while others have closed claws. There are several different configurations for each type to meet the needs of different industries. The types of crane grab buckets also differ in bulk density.

The report also contains detailed information on the market competition, development policies, manufacturing processes, and cost structures. The study also includes the key players operating in the global crane grab bucket market, along with their product offerings and contact details. In addition, it contains detailed information about the supply chain, revenue, and price, and includes information about the market's growth potential.

Control method

The control method for a Grab bucket crane manufacturers provide control the speed of the machine. It uses the speed difference between the motors to determine the operating speed. It also uses a feedforward method to calculate the compensation amount using the design data. This control method has more advantages than the conventional method. It offers more stable operation, which decreases the risk of setting error. Moreover, it eliminates the need for re-opening the bucket after landing, improving the efficiency of the crane.

The control method for a Grab bucket crane has three important aspects. The first aspect of load balance control includes at least one trial operation. In the trial operation, mechanical rigidity of the load balance is detected and the proportional gain for the control is selected.

Applications

The shell-type grab bucket crane has a broad range of applications in construction sites. It is particularly suitable for loading bulk cargoes such as sand and minerals. Its other uses include trench excavation, road construction, railroad track laying, and foundation excavation. Its hydraulic system is also capable of operating in harsh environments.

Its hoisting mechanism can raise and lower the bucket in an open position, and the automatic closing mechanism is operated by one crank.

Cost

The cost of a Grab bucket crane will depend on several factors, including its size, capacity, and features. A typical model will cost between $30k and $180,000. However, these prices will vary widely depending on size and capacity. For this reason, it is important to know the exact specifications of your crane before purchasing it.

The lifting capacity of a Grab bucket crane will depend on the weight of the material to be lifted. These cranes can handle a weight of up to 20 tons and can be used for a variety of different tasks. They are suitable for a variety of industries, including mining and construction.

0 notes

Text

What Is a High Efficiency Circular Crane?

A High Efficiency Circular Crane is an industrial lifting device that can lift materials at a high rate. Its input line voltage is 380 V and output line voltage is 220 V or 36 V. These voltages supply illumination and signal power. The crane also has a repair socket. All the cables and wires are arranged in a raceway, and the repair socket is installed on the crane. Cables are temperature-proof and are made of copper wire or copper bars.

Workstation cranes

High Efficiency circular crane manufacturers have multiple benefits for your company. First, they are easy to install. Second, their modular design makes them adaptable and expandable. Third, they help to reduce the risk of repetitive stress injuries and workers compensation claims. Lastly, they can help you save money.

High Efficiency circular workstation cranes can be used in a wide variety of applications. They are especially useful in situations where a traditional jib cannot reach. These cranes have multiple attachments and are capable of positioning loads in awkward places. They are lightweight and have a high level of precision. Moreover, they are easily maneuverable and can support up to 1,000 lbs.

Telescopic boom cranes

A telescopic boom is a mobile crane that consists of an upper inverted U-shaped longitudinal section and a lower convexo-concave section. The upper and lower sections are welded together along their longitudinal edges and form a hollow cavity. The lower section consists of several arcuate segments disposed in sequential order across the concave surface. These sections are formed with a cold roll die.

The boom section of a telescopic boom is preferably composed of two sections - a base section and an upper fly section. These two sections are interconnected by an intermediate section. The two sections can be hollow or solid, and are preferably formed from steel plates. The base and fly sections may be connected at one or both ends with stiffeners that add additional shear carrying capacity.

Monorail cranes

Monorail cranes follow a single path and are perfect for lifting jobs that don't require side-to-side trolley movement. Their simple design makes them an affordable, versatile option. These cranes are also a great choice for production lines or assembly lines. You can find them in a variety of sizes, shapes, and styles, depending on your needs.

Festoon systems are another option for a high-efficiency circular crane. They allow multiple layers of cable to be stacked without twisting or tangling. Festoon systems are easy to install and maintain. They are also hard-wired for extreme environments. These cranes are available in basic economic designs or complex cable packages for more robust applications.

Overhead bridge cranes

High Efficiency circular overhead bridge cranes have a number of advantages over conventional overhead cranes. These cranes are capable of reaching spans of 30 feet or longer, and their steel truss construction keeps the bridge's weight to a minimum. In addition, their long spans allow them to be installed where supporting assemblies are rare, allowing for greater flexibility in layout. And, the cranes are available in four distinct sizes, making them a flexible and cost-effective solution for a variety of lifting applications.

There are two main types of overhead cranes: bridge cranes and jib cranes. The former can be mounted to the building's structure, while the latter requires multiple support columns which can take up valuable floorspace. The latter type is best for repetitive movement in small areas.

Goliath cranes

Goliath circular high efficiency cranes are used for heavy lifting and transportation applications. They are particularly useful in shipyards, as they can safely lift and transport bulky ship segments and trolleys. The cranes' travel distances are the longest in the industry, and they use energy chains to reduce drive energy. The energy chains also contribute to safety, as they are exceptionally robust and able to withstand the weight of heavy loads.

Goliath cranes are known for their durability, performance, and low operating cost. They are available in different styles and capacities, and can lift and move objects up to 100 tons. The Goliath circular high efficiency cranes are made from high quality materials and are designed to work with the needs of various industries.

0 notes

Text

Portable Power Winch Machine Supplier in India

If you are looking for a portable power winch machine supplier in India, you need to consider a few features. These include the capacity, reliability, and raw material used in the manufacturing process. The next step is to find the right supplier. You can do this by looking at reviews of the products in your area.

Features of a portable power winch machine

A portable power winch machine from Venus crane is equipped with a series of advanced features that make the job of pulling heavy loads easier. These machines are available in manual and automatic modes. They can be operated by either a right-hand or left-hand operator. The machine also features a high-quality steel fabrication. In addition, it is equipped with several built-in safety systems to avoid any accident.

An electric portable power winch machine is able to hold a wire rope with a capacity of up to 100 meters. The strength of the wire rope can range from 1-2 tons. If you need to lift larger objects, you can also purchase a 220-meter portable power winch machine. It is important to check out the features of the product to make sure that it will meet your requirements.

Reliability of a power winch machine

Reliability is important in a power winch machine. A well-designed power winch machine will work efficiently for a long period of time. The main components of the winch machine are a control panel, push button station, double-shoe type thruster, electro-hydraulic motor and a reversing triple-pole. The machine also includes a hand brake arrangement for emergency use.

A power winch machine from Venus crane has a proven track record of reliability and high quality. Its five-fold safety factor means that it will not fail to lift heavy objects. The winch gearbox converts the power of the motor to large force. The two main types of winch gearboxes are worm gearbox and spur gearbox. The winch controls can be accessed by a push button control box or by remote control. Other features include reversing switches and a cam control.

Maximum capacity of a power winch machine

Portable power winch machines have different capacities. The capacity of a portable power winch depends on its reduction capacity and rope drum. Electric chain hoist manufacturers provide different types of power winches. They differ in their weight, capacity and speed. The power motor in a portable power winch machine should be rated for 150 starts per hour. Higher capacities can cause the machine to stall. Another important factor is the number of flanges on the drum shaft. If the drum is made of steel with spines at two ends, the capacity is higher.

The capacity of a portable power winch machine can range from 2,000 to 6,000 pounds. Some machines also feature a helical reduction gearbox to reduce the cost of power. Others offer trolley hoists and linear motors. A portable power winch machine supplier in India such as Venus crane offers a wide range of power winch machines. These machines are equipped with several advanced innovations and features, including safety systems.

Raw material used to manufacture a power winch machine

A portable power winch machine is a portable device that is used for lifting heavy objects. Its main components include the rope drum, the motor, the control panel and the controls. These components are used to control the speed and force of the winch. These machines can be purchased from reputed manufacturers such as BCH and ABB. They also come with a set of brakes.

Depending on the power and performance requirements, industrial power winches are manufactured with a precision design. They are available in a range of capacities, ranging from half to 100 tons. In addition, their cable drums are sized to accommodate the rope storage requirements and fleet angle restrictions.

Manufacturers of a power winch machine

Portable power winch machine manufacturers are available in India through manufacturers and distributors. These machines are designed for heavy-duty work and are equipped with a wide range of features. They are operated by a push button station or a control panel with 110V power. The control panel of these machines is made from reputed make and is housed in a dust-proof steel panel box. They also come with a step-down transformer and overload relay with single phasing protection. In addition, a limit switch is also installed to prevent over-travelling and hoisting.

These machines can pull loads up to 3000 pounds. They can be either right-handed or left-handed depending on the user's preference. Electric portable power winches are ideal for heavy-duty work and are convenient to transport. Their compact design makes them ideal for both indoor and outdoor usage. These machines also feature a self-made helical reduction gearbox to further reduce their weight.

0 notes

Text

What Is a Grab Bucket Overhead Crane?

A Grab Bucket Overhead Crane is a type of crane that is used for lifting and loading bulk materials. It has a side or top entrance and can be used indoors or outdoors. Its structure is simple and reliable and it can operate at any height. It is designed to be easy to operate and can load bulk materials of various sizes.

Overview of a Grab Bucket Overhead Crane

Unlike other overhead cranes, grab buckets can be operated on an open air site. However, this requires rainproof facilities. Therefore, make sure that you specify this requirement in your contract. Additionally, when using an overhead crane in the open air, the overall weight of the crane will increase by about 5%.

This type of crane can be operated by an electric motor or a cable winder. The latter is more suitable for lifting material that has a loose accumulation. The main advantages of this type of crane are its ease of use and high efficiency in load. However, the drawback of this crane is that it cannot be used for lifting loads from the sea.

Grab bucket crane manufacturers provide a variety of applications. Typically, they are used for direct loading of bulk material. This crane is particularly useful for handling material that cannot be handled manually. This type of crane is especially useful for bridge ships that need to be unloaded from the ship.

Types of Grab Buckets

The types of grab buckets available for overhead cranes vary in bulk density and size. There are four basic types: single-rope grabs, four-rope grabs, and electric hydraulic grabs. These grabs are commonly used for removing heavy loads. Each type is best suited to a particular job and can be classified by bulk density.

Electric motor-driven grabs: Generally used for grabbing loose accumulations, these grabs are easy to operate and have high efficiency in a load. They are also able to carry energy during lifting a large load. One important drawback is that they cannot be operated underwater.

Electric hydraulic-powered grab buckets: Electric hydraulic grab buckets are designed according to DIN/FEM standards. The main hydraulic components are imported. Electric hydraulic crane buckets are further divided into orange peel crane buckets and clamshell crane buckets. Electric-powered grab buckets are more powerful and have higher levels of automation. They are often the preferred choice for crane buckets in industries such as steel and iron, forest farms, and coal mines.

Maintenance of a Grab Bucket Overhead Crane

It is very important to properly maintain grab buckets. A daily inspection of easy-wearing parts is crucial to prolong the service life of a grab bucket and maximize productivity. The most common cause of breakdowns in a grab bucket is abrasive wear, which accounts for 30% of the overall loss in performance. To improve service life, grabs can be designed with anti-wear properties. There are many factors that contribute to wear and tear, including external elements, loads, and the geometry of the bucket.

The first thing to do is change the oil in the grab bucket. The oil should be changed after 500 hours of usage. Thereafter, it should be changed after every 10,000 hours of usage. It is also advisable to inspect the electrical equipment and hoses regularly. It is also necessary to check the operation of the brake motors.

0 notes