Don't wanna be here? Send us removal request.

Text

10 Tips for Choosing Household Power Tools

Many partners who use power tools do not pay attention to the difference between home type and professional type when choosing power tools, which will cause a lot of difficulties in use. Today we will talk about how to choose when using power tools at home, and choose the right one for you. The power tools used at home are a great help for the convenience of your follow-up work!

1. The difference between professional power tools and general household power tools is in power. Professional power tools have higher power, while general household power tools have lower power and lower input power.

2. In terms of the size of power tools, small size, highly integrated power tools are more portable than large, single-function power tool products. Therefore, we try to choose some function-rich power tools when purchasing power tools. Small size, simple structure, easy to store power tools.

3. When purchasing power tools, you need to buy power tools with clear packaging patterns and no damage.

4. The appearance of the purchased power tools is normal, the plastic parts are complete, there are no obvious shadows and dents, no scratches or bump marks, the relevant paint is smooth and beautiful without defects, the surface of the whole machine is free of oil stains and stains, and the handle of the switch Flat, wire and cable length is generally not less than 2 meters.

5. Whether the relevant signs of the power tool are clear and complete, whether the parameters, manufacturers, and qualification certificates are available.

6. For hand-held power tools, turn on the power supply and frequently operate the switch to make the tool frequently start, and observe whether the on-off function of the power tool switch is reliable.

7. After the tool is powered on for a period of time, feel the vibration and observe whether the reversing spark and the air inlet are normal.

8. Select power tools with noise within the allowable range.

9. Choose household power tools with easy-to-obtain accessories.

10.When choosing a power tool, pay attention to the power supply voltage used. Generally, hand-held power tools need to provide 220V mains power as an energy drive. Do not connect to 380V industrial power, otherwise it will cause damage to the power tool.

VIDO Company is a power tool wholesale suppliers,specializing in manufacturing a wide range of professional tools and small machines, including power tools, cordless tools, garden tools, generators, pumps, welders and accessories. If you want to know more about household power tools, please call or email us, we will be happy to serve you.

Related News:

Wood Working Tools for Professional Woodworker

4 Common Drill Bits and Their Uses

0 notes

Text

Selection of Household Power Tools

For most families, the use of power tools is limited to screwing a screw, drilling a hole, and occasionally installing a small piece of furniture. We who are not professionals, how should we choose household power tools?

1. What is the difference between the commonly used household electric tools?

In fact, there are only four commonly used: screwdrivers, pistol drills, impact drills and electric hammers.

Screwdrivers, a tool specially designed for screwing, can be used for disassembly and assembly of furniture and home appliances, but it is more difficult to drill holes.

The pistol drill can both screw and drill, and the speed is higher than that of the screwdriver, but it cannot drill concrete.

Impact drill, a pistol drill with adjustable gears, has a certain impact function. When the impact gear is impacted, it can impact concrete at a high frequency to enhance the hole-opening ability. But in the case of thick concrete, the impact drill is powerless.

Electric drill, this is a tool specially designed for hitting concrete. It can both drill and hammer, and is a good hand for demolishing homes.

The above are the common power tools at home, we can choose according to the function and our own needs.

2. Select to plug in or charge?

Observing most of the products on the market, lithium-ion power tools are actually the general trend, that is, charging tools. The charging tools are not limited by the nearby power supply and can be used outdoors. But now most brands basically have their own batteries, and the battery life can be extended by replacing the batteries. Compared with charging, plug-in tools are cheap, powerful, and can work continuously for a long time, but are prone to range limitations.

3. Precautions for selecting household power tools.

First of all, be sure to confirm that the nameplate parameters of the tool are consistent with those on the CCC certificate. Secondly, when the tool is powered on and runs for one minute, you should not feel any abnormal vibration on your hand, and looking in from the air inlet of the tool, there should be no arc on the surface of the commutator, and there should be no abnormal noise during operation. You can try to operate the switch frequently to start the tool frequently, and observe whether the on-off function of the tool switch is reliable.

If there are no problems with the above, then congratulations on buying a household power tool with no problems in quality.

VIDO 3.6V Cordless Screwdriver

As mentioned above, screwdrivers are widely used in our daily life. This cordless screwdriver is characterized by its light weight and is a good helper for all kinds of manual labor. The LED light design allows users to work in dark areas. This cordless power tool features a pistol grip shape and compact size to work in tight spaces.

VIDO 18VRotary Hammer

This rotary hammer provides more power when hammering, drilling and screwing. Users can use it to drill holes in high-hardness concrete. Due to its compact design and light weight, it is suitable for drilling in tight spaces. And its design conforms to ergonomic design, it is comfortable to hold and operate for a long time without fatigue.

VIDO specializes in manufacturing a wide range of professional tools and small machines, including power tools, cordless tools, garden tools, generators, pumps, welders and accessories. If you want to know more about household power tools, please call or email us, we will be happy to serve you.

Related News:

Wood Working Tools for Professional Woodworker

4 Common Drill Bits and Their Uses

0 notes

Text

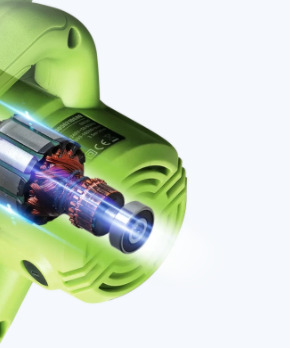

Advantages of Brushless Power Tools

As the leader of brushless tools, VIDO has its own unique technology. The coil of the stator of the motor is controlled by the control chip and the rectifier circuit group to form a magnetic field with variable phase change, and the rotor part is made of rare earth material with high magnetic energy pole to make a permanent magnet. The rotor is driven to move by continuously detecting the magnetic field direction of the rotor, applying a corresponding magnetic field to the stator and performing phase transformation.

Advantages of brushless power tools:

1. Low interference, low power loss, and low heat

Brushless power tools have no brushes, and the biggest change is that there is no electric spark generated when the brushed motor is running. As a result, the electrical energy consumed, the radio interference caused by the electric spark, and the heat generated by the electric spark all disappear. If it is a rechargeable power tool, the power saved by this item alone can increase the battery life by about 30%.

2. Low noise and smooth operation

Brushless power tools have no brushes, the friction is greatly reduced during operation, the operation is smooth, and the noise will be much lower. This advantage will be of great help to the stability of precision equipment and small equipment.

3. Long life and low maintenance cost

The main loss of the traditional motor comes from the irreparable wear of the brushes and the rotor commutator. Without the brushes, the wear of the motor itself is almost only on the bearings. From a mechanical point of view, this wear is almost negligible and can even be regarded as a maintenance-free level.

4. There is no risk of disconnection of the rotor coil

The rotating speed of the motor rotor is very high, reaching tens of thousands of revolutions per minute, so when the traditional motor encounters foreign matter intrusion, such as debris, it is easy to cause damage to the rotor winding. This is especially common in industrial-grade AC power tools. For brushless power tools, since the rotor becomes a single unit with no electricity at all and no winding, there is no electrical failure due to small damage during rotation.

5. The evolution of power tool switch function

The switch of traditional power tools often acts as a circuit breaker for the power supply of the motor, which means that the current of the entire machine needs to pass through the switch circuit. Therefore, for the electrical safety and durability of the switch, both the mechanical structure and the electrical design are very limited, and it is easy to cause many switches to be unable to be designed more ergonomically. Fatigue easily. And Japanese VIDO's brushless power tool only needs to give the corresponding weak current signal to the control chip. Therefore, the reduction of the electrical load can greatly improve the life of the switch and the comfort of use.

6. Diversification of control modes of power tools

As mentioned above, since the operation of the VIDO brushless power tool is controlled by the control chip, the detection and adjustment of the rotational speed become easier. It is also possible to provide different speeds and torque outputs for different needs by programming the chip. And most of VIDO's brushless products can provide a variety of operating modes, truly realizing a multi-purpose machine.

VIDO is an international brand specializing in the manufacture of various professional tools and small machines. We continue to pursue customer satisfaction, always providing guarantee and after-sales service to all customers, including spare parts, maintenance and technical support, dedicated to satisfying every consumer. If you want to know more about brushless power tools, please call or email us.

0 notes

Text

Differences Between Brushed and Brushless Power Tools

The biggest difference between brushed power tools and brushless power tools is the carbon brush. The main component of the carbon brush is carbon, which works like a brush on the rotating parts, so it is called a carbon brush, and the main material is graphite. Let's first understand the main material of carbon brushes: graphite. Graphite is a natural element, its main component is carbon, its color is black, opaque, with semi-metallic luster, and its hardness is not high. Both graphite and diamond are composed of carbon, but their properties are very different. Caused by different arrangement.

Carbon brushes are generally used in DC appliances. For example, refrigerators, washing machines and air conditioners used in our homes do not have carbon brushes. This is because AC motors do not need a constant magnetic field, so there is no need for a commutator, and no carbon brushes.

Brushed Power Tools

All motors are composed of electrons and rotors. In a DC motor, in order to make the rotor turn, the direction of the current needs to be changed continuously, otherwise the rotor can only turn half a circle, which is like pedaling a bicycle with one foot only half a circle. , so the DC motor needs to change the current in the rotor, that is, commutate the direction of the energized conductor when it needs to be commutated.

The commutator is composed of two semi-circular segments, and the link is separated by insulating material. The commutator at both ends is rotated and linked with the carbon brush. Turned up.

Brushless Power Tools

The brushless DC motor adopts electronic commutation, without commutator and carbon brush, but uses a position sensor, which is mainly composed of a permanent magnet rotor, a multi-stage winding stator and a position sensor. The adjacent stator coils are energized, so that the stator generates magnetic poles that attract the rotor, which can attract the rotor to rotate, so that the motor can be rotated repeatedly.

The brushed motor adopts mechanical commutation, the outer magnetic pole does not move and the inner magnetic coil moves. When the motor is working, the commutator and the coil rotate together, and the carbon brush and the magnetic steel do not move, so the commutator and the carbon brush generate friction, complete current direction switching. In the brushed motor, the coils of each group are arranged in a ring, and they are separated from each other by insulating materials to form a cylindrical shape that is integrated with the motor shaft. The power supply passes through two carbon brushes and is pressed under the pressure of the spring. On the coils, each set of coils is turned under the carbon brush to energize the set of coils. As the motor rotates, energize different coils or different stages of the same coil, so that the coils generate a magnetic field and the poles have an angle with the poles close to the permanent magnet stator.

The difference between brushed motors and brushless motors is that in addition to carbon brushes, brushed motors are controlled by gears, which will increase the repair rate of the motor. The brushless motor does not need gears, it will not be maintained frequently, the service life will be higher, and the reliability will be higher, but the control system cost of the brushless motor will be higher than that of the brushed motor; in addition, the noise of the brushed motor will be higher. Relatively large, and the brushless motor is much quieter, and the work efficiency will be higher.

Carbon brushes play a very important role in DC motors. The carbon brushes transmit current between the moving parts of the motor. This transmission is a sliding conduction, which can transmit the current from the fixed end to the rotation of the generator or motor. The part is composed of several carbon brushes to form a carbon frame, so this transmission method also causes the carbon brushes to be easily worn, and the carbon brushes also change the direction of the current, that is, commutation. Carbon brushes are also used in AC equipment. The shape and material of the AC motor carbon brushes are the same as those of the DC motor carbon brushes. The AC motor has a winding rotor and needs a variable speed. The machine also needs to change the carbon brush frequently, and its function is also very important.

VIDO specializes in manufacturing a wide range of professional tools and small machines, including power tools, cordless tools, garden tools, and more. In our constant pursuit of customer satisfaction, we always provide all customers with warranty and after-sales service, including spare parts, maintenance and technical support. If you want to know more about brushless power tools, please call or email us.

0 notes

Text

Wood Working Tools for Professional Woodworker

Much of the joy of woodworking is due to the use of various tools. For woodworking enthusiasts, for example, there is a pure joy in seeing the shavings roll up from the workpiece when operating and using a metal hand planer.Likewise, a hammer or a power drill are both charming objects. In general, tools are only pleasant and safe to use when they are well maintained, clean and sharp. At the same time, it is important to use different tools for different jobs. This article will talk about how to properly use and save tools, as well as a basic list of tools and materials.

1. Use wood working tools correctly Before you start making it, resist the temptation to order a bunch of unused tools from the manufacturer's list. When starting a woodworking job, the most important thing is to think carefully about the size and shape of your work, the materials and skills you will need, and then find a quality tool supplier and buy the minimum tools that will get the job done.

As you get started, you'll likely find that you actually need more tools. Like a different plane or a jig, but at least those extra purchases are what you actually need.

Another question to consider when buying tools is: should you choose a power tool or a hand tool? It depends on whether you want to get the job done quickly and easily, and tolerate the noise, dust, tedious commissioning during installation, and the potential risks of power tools. Of course, you may also like to work slowly and enjoy the quiet and subtle pleasures of hand tools.

2. Basic tools and materials list We divide tools into three categories: hand tools, hand-held power tools, and woodworking machinery.

Hand Tools

Take care of your hand tools, maintain them regularly and keep them neat and tidy. It is very important to keep the saw blade sharp. The range of hand tools is very wide, and there are various other hand tools besides those listed below.

Rulers and line drawing tools

pencil

Metal ruler: 300mm (12in) and 1m (39in)

Tape measure: 5m (16ft)

Scoring knife

Square or combination square

225mm (9in) protractor (use without a combined square)

Active angle ruler

Double head scriber

scriber

Dovetail scriber

Saw

Hand saw

tenon saw

Dovetail saw

hack saw

plane

rough planing

planing

short planer

Combination Oil Whetstone and Lubricant

Chisel

Tenon and chisel: 6~25mm (1/4~1in)

Slant Chisel: 6~25 (1/4~1in)

Hammer

Flat tail hammer

tip hammer

Handheld Power Tools Regarding handheld power tools, you need to make sure that your hand-held power tool meets power tool safety standards and that the saw blade or blade is installed correctly.

Jigsaws and saw blades

Hand drill and screwdriver with twist head wood drill, reamer and a set of screw head bakelite with 10mm straight cutter and bearing cutter - more cutters can be purchased On demand

Disc Sander

Circular saw

Woodworking machinery

Large tools are usually more dangerous and must be handled with care. Develop the operating habit of properly handling the workpiece with careful consideration.

band saw

Flat, press planer

Mobile dust collector (basic part connected to the planer)

Combination Crosscut Saw

Table Saw with Flat Wing Bit

table saw

3. Wood working tools save You should take the words "things go where they belong" as the golden rule of the workshop. It is very important to know the location of each tool at all times. It's as if your tools are always nearby, quickly and safely when you need them.

Careful handling of your tools will help prolong their life, making sure they are clean, well oiled, and carefully stored in dry bins or lockers, or on special storage racks. The work area must be dry, well-lit, dust-free, and clean, which is good for you and your tools. Woodworking is a healthy activity, but this benefit will only be realized if the work environment is safe, comfortable and orderly. This rule applies to all workshops, from large production plants to small balcony studios.

In general, the hand tools of woodworking have been replaced to some extent by the development of power tools and machinery. If you want to know more about handheld power woodworking tools, please contact VIDO by phone or email. We are more than happy to serve you.

1 note

·

View note

Text

Introduction to the use of heat guns

Vido produces a wide variety of professional tools, with a wide range of products, the next is to introduce you to the content of the heat gun.

The working principle of the heat gun.

According to the working principle of the heat gun, the main part of the heat gun control circuit should include the temperature signal amplification circuit, comparison circuit, silicon control circuit, sensor, wind control circuit, etc.. In addition, in order to improve the overall performance of the circuit, some auxiliary circuits should be set up, such as temperature display circuit, shutdown delay circuit and over-zero detection circuit. The temperature display circuit is set to facilitate temperature adjustment. The temperature display circuit shows the actual temperature of the circuit, and workers can manually adjust the temperature shown on the display in the process of operation.

The role of the heat gun.

Hot air gun is one of the important tools for repairing communication equipment, mainly composed of air pump, airflow stabilizer, linear circuit board, handle, shell and other basic components. Its main role is to desoldering small SMD components and SMD integrated circuits. The correct use of hot air gun can improve the efficiency of maintenance, if used improperly, the phone will be damaged by the motherboard. Such as some maintenance personnel in the removal of the amplifier or CPU, found that the cell phone circuit board off the solder joints, plastic line holders and keyboard holders were damaged, and even short-circuit phenomenon. This is actually the maintenance personnel do not understand the characteristics of the hot air gun caused. Therefore, how to correctly use the hot air gun is the key to repairing cell phones.

The use of the heat gun.

1. Clothing and shoe factory production to remove threads

About the removal of denim clothing and shoes factory joint seam thread, the traditional use of manual hand shear, slow, high cost, varying quality, and even cut bad clothing, finished shoes, this industry uses a hot air gun when the environment is too poor, more fiber thread and dust, should be regularly cleaned up the hot air gun dust network, and because the use of time lasts too long, in order to ensure the service life of the hot air gun, it is recommended to prepare more than one replacement use. (About 45 minutes to replace once) or 45 minutes after inverted upright 10 minutes and then use.

2. Remove the old paint

Use the hot air gun to remove the old paint on the metal surface, when the temperature rises, the paint on the surface of the workpiece softens, and it is easy to scrape off the old paint when it softens, without making the surface of the workpiece; some paints such as cement paint, magnetic paint, mineral paint, etc. will not be softened by heat, so the heating method cannot be used to remove paint. Use industrial special hot air gun to remove the old paint, will not make the surface of the apparatus overheating scorched.

3. Bending plastic pipe

When bending the plastic pipe with the heat gun, please put the air outlet 5~15cm from the surface of the plastic pipe and heat evenly around the part of the plastic pipe to be bent until you feel that it has started to soften, then you can start bending. Bend a little more in the bending process, because the plastic tube cools, it will spring back a little in the opposite direction.

4. Heat shrink packaging film, tube

The use of heat gun can be shrinkable plastic film, packaging film, tube heating shrinkage. In the beginning of the heating, from a distance and evenly towards the shrink film, tube heating, and then slowly approach until the shrink film, tube evenly shrink and will be packaged tightly.

5. Change the floor tile

When you want to turn over the floor tile, because the floor tile under the adhesive sticky, so you must first use the heat gun to the floor tile under the adhesive heating, so that it softened, once softened with a trowel into the gap between the floor tile and the floor will be stilted up. The first thing to note is the thickness of the floor, it may take a little time to make the heat penetrate the floor tiles, so you must use the heat gun to move back and forth in a wide range, so that the adhesive under the floor tiles can be softened evenly.

6. Stripping plastic

The hot air gun can be used to peel off the wallpaper or plastic pasted with adhesive; especially suitable for mold factory plastic factory to remove the plastic pasted on the mold;

7. Defrost and remove grease and dirt

Hot air gun can be used for defrosting and removing grease and dirt from refrigerators.

8. Auto glass film

Heat gun can be used to heat and shrink the auto glass film quickly.

9. Remove rusty or too tight nuts and metal screws.

10. Can be used in the waxing or waxing of the sled.

11. Can soften solder.

Vido is a manufacturer of professional tools, with a wide range of products exported overseas, and has been recognized by everyone. If you are interested in professional tools, you are welcome to contact our company.

0 notes

Photo

VIDO is a manufacturer of professional tools with a wide range of products, and the company describes the advantages of blowers as well as their uses.

0 notes

Text

Do you know this about blowers?

Blowers are used as specialist tools in all kinds of production, so let's get to know them together. The article describes the advantages of blowers and their uses.

Advantages of blowers.

1. Because it is a volumetric blower, it thus has the characteristic of forced air delivery. Under the condition of speed - certain, the flow rate is also certain. Even in the low flow area, there is no wheezing as in the case of centrifugal blowers, and they have relatively stable operating characteristics.

2. As a rotary machine, there is no reciprocating motion mechanism, no air valve, few wearing parts, therefore long service life, and good power balance, can run at high speed, no heavy foundation is needed. A week of operation has a number of suction and discharge, compared to the piston compressor, the airflow speed is more uniform, do not need to set up storage tanks.

3. There is a gap between the impellers, between the impellers and the casing and the wall plate, and the operation does not require oil lubrication as in the case of screw and sliding vane compressors, so it is possible to ensure that the gas delivered does not contain oil, and there is no need to use auxiliary equipment such as a gas-oil separator. Due to the clearance and the absence of valves, it is also safer to transport dusty or liquid-droplet gases.

4. No internal compression process, theoretically more compression work is consumed than those blowers with internal compression process. However, apart from the synchronous gears and bearings, there is no other mechanical friction and therefore high mechanical efficiency. In particular, large Roots blowers have high volumetric efficiency and high full adiabatic efficiency. In addition, Roots blowers also have the advantages of simple structure, easy manufacture, convenient operation and long maintenance cycles.

Uses of the blower.

The blower is mainly composed of the following six parts: motor, air filter, blower body, air chamber, base, and drip nozzle. The blower runs eccentrically on an offset rotor in the cylinder and causes the air to be drawn in, compressed and spit out by the volume change between the blades in the rotor slot. In operation the blower uses the pressure difference to automatically send lubrication to the drip nozzle, dripping into the cylinder to reduce friction and noise, while keeping the gas in the cylinder from flowing back, this type of blower is also known as a sliding blade blower. Blower conveying media to clean air, clean gas, sulphur dioxide and other inert gases. Other flammable, explosive, corrosive, toxic and special gases can also be produced on demand.

Energy saving transformation of blowers.

Nowadays, the various types of mechanical and electrical equipment in various industries in China and the blower with the motor of the motor accounts for about 60% of the installed capacity of the country, consuming about one-third of the country's total power generation. Especially worth mentioning is that most of the fans in the use of the process are large horse-drawn car phenomenon, coupled with the production, process and other aspects of change, the need to frequently adjust the flow of gas, pressure, temperature, etc.; now many units are still using the backward adjustment of the wind plate or valve opening degree to adjust the flow of gas, pressure, temperature, etc.. This is actually a way to increase the resistance artificially and to meet the requirements of the process and working conditions for gas flow regulation at the cost of wasting electricity and money. This backward regulating method not only wastes valuable energy, but also has poor regulating accuracy, which makes it difficult to meet the requirements of modern industrial production and services, etc. The negative effects are very serious. In recent years, with the rapid development of power electronics, computer technology, automatic control technology, electrical transmission technology is facing a historical revolution, that is, AC speed control instead of DC speed control and computer digital control technology instead of analogue control technology has become the development trend. Motor AC frequency control technology is a major means of saving electricity, improving processes to enhance product quality and improve the environment, and promoting technological progress today.

VIDO is a manufacturer of professional tools, with a wide range of products that are exported overseas and are unanimously recognised by everyone. If you are interested in professional tools, you are welcome to contact our company.

0 notes

Text

These are the things you must know about band saws

VIDO produces a wide range of professional tools, including band saws, circular saws and other tools, so do you know anything about band saws? You know some of the product knowledge of the band saw, then come with me to see it next.

Definition of band saw.

With the ring without end of the band saw blade for the sawing tool, around the two saw wheels for a one-way continuous linear motion to saw the wood sawing machine. Mainly by the bed, saw wheel, on the saw wheel lifting and tilting device, band saw blade tensioning device, saw blade guide device, table, guide plate and other components. The bed is made of cast iron or welded steel. The saw wheel is divided into the upper saw wheel of the amplitude type and the lower saw wheel of the amplitude plate type; the lower saw wheel is the active wheel, the upper saw wheel is the driven wheel, the weight of the upper saw wheel should be 2.5~5 times lighter than the lower saw. The cutting speed of the band saw blade is usually 30~60m/s. The upper saw wheel lifting device is used to load and unload and adjust the tension of the band saw blade; the upper saw wheel tilting device is used to prevent the band saw blade from falling off the saw wheel when sawing. The band saw blade tensioning device gives flexibility to the upper saw wheel to ensure stable tensioning of the band saw blade in operation; the old type uses a spring or lever weight mechanism, while the new type uses pneumatic and hydraulic tensioning devices. The guiding device, commonly known as the saw card, is used to prevent the band saw blade from twisting or swinging when sawing; the lower saw card is fixed at the lower end of the bed, while the upper saw card can be adjusted up and down along the vertical slide; the saw card structure has a roller type and a slider type, the slider type is made of hardwood or wear-resistant plastic. Band saws are widely used in the timber industry and are available in a wide range of models, which can be divided into: large band saws, re-cutting band saws and joinery band saws; according to the orientation of the saw wheel placement: vertical, horizontal and inclined, vertical and divided into: right and left; according to the installation of band saws: fixed and mobile; according to the number of combined tables: ordinary band saws and multi-band saws, etc.

Improvements in band saws.

1. Structural improvements

The saw wheels are the pair of wheels that realise the installation of the band saw machine and are the main component for the main movement. The lower saw wheel of the band saw machine is the active wheel, to have a large rotational inertia, and can play the role of a flywheel during work. The upper saw wheel is passive, driven by the saw blade, required to do lighter, can keep synchronized with the saw blade as far as possible, in order to reduce the start braking and sawing resistance changes caused by the saw wheel between the saw blade violent friction slippage, in order to prevent the saw blade excessive expansion and breakage.

2. Improvement of the device

The current band saw machine is mainly characterised by large feed speed, large saw specifications and poor saw blade stability. The accuracy of sawing is low, and the stability of the saw blade depends on the saw blade tension, the exposed length of the saw blade, the feeding direction and the guiding device and other factors. The saw card is the guiding device of the band saw, its role is to shorten the free length of the working side of the saw blade, improve the stiffness of the saw blade, reduce the amplitude of the saw blade lateral vibration, so as to keep the saw path straight. The saw card should be installed close to the sawn wood. The saw card has an upper and a lower card. The lower saw card is fixed to the machine base and the upper saw card is mounted on a special rail in the machine body, which can be adjusted at any time with the different heights of the saw path.

Differences between band saws and circular saws.

1. The band saw is superior to the circular saw in the performance of sawing irregular wood, large size wood, especially logs.

2. The sawing surface of the band saw is not as smooth as the sawing surface of the circular saw

3. The same reasons above plus because the band saw blade is from the top and down movement, circular saw blade is from the back of the forward rotation

Rotation, such as the occurrence of saw blade, saw blade broken, etc., the band saw is relatively safer than the circular saw.

4. Under the condition of sawing the same specification of wood, the efficiency of band sawing is not as high as circular sawing.

5. As for the straightness of the sawing that depends on the mountain, the two compared to no one has a clear advantage.

VIDO is a manufacturer of professional tools, a wide range of products, exported overseas, has been recognized by everyone, if you are interested in professional tools, you are welcome to contact our company.

0 notes

Text

Introduction to self-priming peripheral pumps

VIDO produces many professional tools, products include self-priming peripheral pumps, chainsaws, drills, etc. So do you know what the main self-priming peripheral pump is? What are its main uses? What are its main uses? Follow VIDO to learn more about it.

Definition of self-priming peripheral pump.

Self-priming peripheral pump pump is a self-priming centrifugal pump, which has the advantages of compact structure, easy operation, smooth operation, easy maintenance, high efficiency, long life, and strong self-priming ability. There is no need to install bottom valves in the pipeline, and it is only necessary to ensure that a quantitative priming liquid is stored in the pump body before work. Different liquids can be self-priming pumps with different materials.

The working principle of self-priming peripheral pumps.

The working principle of the self-priming peripheral pump is that the pump is filled with water in the pump casing (or there is water in the pump casing itself) before starting. After starting, the impeller rotates at high speed so that the water in the impeller groove flows to the volute, at which time a vacuum is formed at the entrance, so that the water inlet backstop opens and the air in the inlet pipe enters the pump and reaches the outer edge via the impeller groove.

The main uses of the self-priming peripheral pump are.

1. Fitted with a rocker type nozzle, it can also disperse water into fine raindrops for spraying after rushing into the air, and is a good machine for farms, nurseries, orchards and tea gardens.

2. Suitable for clear water, sea water and chemical medium liquid with acidity and alkalinity and slurry with general paste.

3. It can be used with any type and specification of filter press, and is the ideal pump for sending slurry to the filter press for filtering.

Product characteristics of self-priming peripheral pumps.

1. Strong discharge capacity: special impeller anti-blocking design ensures a highly efficient and non-clogging pump.

2. High efficiency and energy saving: The excellent hydraulic model is adopted, and the efficiency is 3-5% higher than that of general self-priming pumps.

3. Good self-priming performance: the self-priming height is 1 m higher than that of general self-priming pumps, and the self-priming time is shorter.

Installation of self-priming peripheral pumps.

1. Preparation and inspection work before starting

2. This series of self-priming pumps, according to the working running condition of the pump, are lubricated with high quality calcium-based grease and No.10 machine oil, if the pump with grease lubrication should be regularly filled with grease to the bearing box, and if the pump with machine oil lubrication, if the oil level is insufficient, add enough of it.

3. Check whether the reservoir in the pump casing is higher than the upper edge of the impeller, if it is insufficient, the reservoir can be injected directly into the pump body from the liquid filling port on the pump casing, and should not be started in the case of insufficient reservoir, otherwise it will not work normally and the mechanical seal will be easily damaged.

4. Check whether the rotating parts of the pump are jammed and bumped.

5. Check whether there is any loosening of the pump body foot and the nuts at each linkage.

6. Check the coaxiality and parallelism of the pump shaft and motor spindle.

7. Check whether the inlet pipeline is leaking, if there is air leakage, you must try to eliminate it.

8. Open the valve of the suction line, slightly open (not fully open) the outlet control valve.

VIDO is a manufacturer of professional tools, with a large number of products, exported overseas, and recognized by everyone. If you are interested in professional tools, you are welcome to contact our company.

0 notes

Text

Introduction to marble cutting machine knowledge

In the cutting process requires the use of many cutting tools, which must include marble cutting machine, then the working principle of marble cutting machine, features and other knowledge you know? Next we come together to understand.

The working principle of marble cutting machine.

Ultra-high pressure water jet cutting machine is the ordinary water through an ultra-high pressure pressurizer, the water pressurized to 3000bar, and then through the channel diameter of 0.3mm water nozzle to produce a water jet of about 3 times the speed of sound, under the control of the computer can easily cut any graphics of soft materials, such as paper, sponges, fibers, etc., if you add sand to increase its cutting power, it can cut almost any material,.

Features of the marble cutting machine.

1. No restriction on cutting direction, which allows various shaped processes to be completed.

2. Minimal lateral force generated by the cutter on the workpiece, which reduces set-up time and saves the cost of using fixtures

3. No thermal deformation of the cutter, no secondary machining required, saving time and manufacturing costs.

4. Fast and efficient cutting and low processing costs.

Advantages of marble cutting machine.

1. It can easily cut stainless steel plates or hard marble, granite, etc., for those who are difficult to cut due to other

For those materials that are difficult to cut by other methods such as aramid, titanium alloy and other various composite materials is very ideal or the only means of processing.

2. No cracks are produced when cutting and it is possible to cut materials with very narrow gaps. Generally speaking, the kerf of pure water cutting is about 0.1mm to 1.1mm, and the kerf of abrasive cutting is about 0.8mm to 1.8mm. As the diameter of the inner hole of the sand nozzle increases, the kerf becomes larger.

3. Can be cut in all directions, including various shapes, angles or slopes.

4. There is no need for secondary processing such as edge grinding, which also reduces flying dust during the cutting process and improves the working environment.

VIDO is a manufacturer of professional tools and exports its products overseas, which has been recognized by everyone. If you are interested in marble cutting machines or other professional tools, you are welcome to contact our company.

0 notes

Text

Introduction to the operation process of the welding machine

Welding aids include gas welding glasses to prevent the operator from being injured in the eyes by ultraviolet, infrared or other rays generated by the welding arc or other welding energy, face shields to protect the welder's eyes, face and neck during arc welding, white overalls, welder's gloves and foot protection.

Preparation of the welding machine before welding.

1. The welding machine should be placed in a ventilated and dry place and placed smoothly.

2. Check that the welding mask is free from light leaks and breakage. Welding personnel and auxiliary personnel should wear good labour protection.

3. The welding pliers, power cord and joints of the welding machine should be connected reliably and well insulated. Do not allow the junction to overheat, the power supply terminals should not be exposed and should be wrapped in electrical tape.

4. The length of the wire between the welding machine and the welding pliers should not exceed 30 meters, and in special cases should not exceed 50 meters, and the wire should be replaced immediately if it is damp or broken.

5. Welding line through the road, must be high or through the protective tube buried in the ground, such as through the track must be passed from the track below.

6. AC welding machine primary and secondary wiring should be accurate, the input current should meet the requirements of the equipment. It is strictly forbidden to touch the charged part of the primary line.

7. The copper plate of the secondary tap connection must be pressed tightly, and the terminals should have coils. Check in detail the contact bolts and other components should not be loose or damaged before closing the gate.

Welding machine welding in the notes:

1. According to the technical conditions of the work, choose a reasonable welding process, do not allow the use of overload, not allowed to use high current welding, not allowed to use the welding machine for metal cutting operations.

2. The temperature rise of the welding machine in the load welding should not exceed 60 degrees for class A and 80 degrees for class B. Otherwise, the welding machine should be stopped and cooled down before welding.

3. The welding machine should be kept dry and well ventilated at the workplace. When moving the welding machine, the power supply should be cut off and the welding machine should not be moved by dragging the power supply. If there is a sudden power failure in welding, the power supply should be cut off.

4. In welding, it is not allowed to adjust the current. It must be adjusted by using the adjustment handle when stopping welding, not too fast and too hard to avoid damaging the regulator.

5. It is forbidden to do welding work under the crane running workpiece.

6. If welding is done in an area with crane wire rope, care should be taken that the welding machine ground does not accidentally touch the lifting wire rope to avoid sparks leading to accidents.

7. When construction must be done in a wet area, the welder must stand on an insulated plank and is not allowed to touch the welding wire or use the arm to hold the charged welding pliers.

Note after welding with the welding machine.

1. After completing the welding operation, the power supply should be cut off immediately, close the welding machine switch, respectively clean up the power and ground line of the welding pliers to avoid the short circuit caused by closing the gate.

2. When welding, if you find that the automatic stopping point device is not working, you should immediately stop the power off for maintenance.

3. When clearing the weld slag, bring glasses. Pay attention to the head to avoid the direction of the welding slag splash, so as not to cause injury. Do not knock the weld slag at the people present.

4. The welding machine should be covered up after the open-air work to avoid rain.

5. When not welding (moving, repairing, adjusting, resting between jobs) the power should be cut off to avoid accidents.

6. Check once a month whether the welding machine is grounded reliably.

VIDO is a manufacturer of professional tools, with many products, exported overseas, and has been well received by everyone. If you are interested in professional tools, welcome to contact our company.

0 notes

Text

Knowledge about petrol generators

Petrol generators are very common in everyday life, so what exactly does it do? And what are its components? Let's find out together.

Definition of a petrol generator.

A petrol generator usually consists of components such as the stator, rotor, end caps and bearings. The engine is a machine that converts chemical energy into mechanical energy, its conversion process is actually the process of working cycle, simply put, it is through the burning of fuel in the cylinder, generating kinetic energy, driving the engine cylinder piston reciprocating movement, thus driving the connecting rod attached to the piston and connected to the connecting rod crank, around the centre of the crankshaft for reciprocating circular motion, and output power. The stator consists of the stator core, the wire winding, the seat and other structural parts that hold these parts in place. The rotor consists of the rotor core (or pole, choke) winding, guard ring, centre ring, slip ring, fan and the rotor shaft. The stator and rotor of the generator are connected and assembled by the bearings and end caps so that the rotor can rotate in the stator and do the movement of cutting the magnetic lines of force, thus generating the induced potential, which is led through the terminals and connected in the circuit, then the current is generated.

Advantages of petrol generators.

1. Fuel saving, excellent combustion efficiency produces high economic efficiency.

2. Quiet, low noise generator set that can be used anywhere at any time.

3. Reliable, stable automatic voltage regulation system and oil warning system for peace of mind.

4. Leading the way in internal combustion engine technology for nearly half a century, our technology and experience are reflected in each engine, ensuring that each engine is stable and reliable over a long period of time, thus greatly reducing maintenance time.

5. The automatic voltage regulator automatically maintains a stable voltage when the equipment is loaded, ensuring a smooth power supply, a unique design that is particularly important for equipment with sensitive voltage fluctuations. This is a unique feature that makes the brush motor superior to other generators and requires no maintenance.

6. When the oil level is too low, the oil warning system automatically stops the engine from running, saving it from damage.

The role of petrol generators.

1. In the event of natural disasters, such as heavy rain, flooding, etc., the huge diesel engine cannot be transported, the lightweight petrol engine is the best choice to ensure the power supply of communication equipment in the disaster area.

2. In times of utility instability or power failure, small access network rooms or stations can use gasoline generator sets as backup power.

3. In the emergency repair, if you need to emergency repair personnel to carry backup power, you can use the gasoline generator set (of course, if the power is large, you need to move the diesel generator set).

Gasoline generator maintenance methods.

1. Clean or replace the air filter.

2. Replace the engine oil.

3. Replace or wash the filter element of the lubricating oil filter.

4. Re-tighten all parts of the bolts and nuts.

5. The new generator should try to avoid a sudden increase in load or high-speed operation, as far as possible, use the manufacturer's recommended use of lubricants, different brands of lubricants should not be mixed, lubricants contain a variety of additives, different brands of lubricants mixed will make the lubrication performance decline, resulting in abnormal wear of moving parts.

6. When injecting oil into the fuel tank, there should be a filter at the injection port and it is better to put on a filter cloth; the fuel should first be left in the tank for more than 24 hours so that water and impurities can be used after precipitation; usually the drain plug of the daily fuel tank should be opened frequently to discharge the water and sediment at the bottom. Regular overhaul and planned maintenance is the key to prolonging the service life of the engine, overhaul cycle and overhaul items according to the use, use conditions and fuel, lubricant properties to make appropriate adjustments, if necessary, to overhaul in advance, as far as possible by professional technicians to complete the regular overhaul and maintenance.

7. Quality imported generator sets are often worth a lot of money, reasonable use, pay attention to routine maintenance, prevention of early wear and tear, to extend its service life, so that it is always quickly start and put into a good state of readiness, to really make the best use of it.

VIDO is a manufacturer of professional tools, producing chainsaws, petrol generators and other products. We have a wide range of products and export overseas, which have won the approval of everyone. If you are interested in petrol generators, welcome to contact our company.

0 notes