Don't wanna be here? Send us removal request.

Text

Quality is the key to purchase precise tungsten carbide mold parts

Nowadays, the competition in all walks of life is very fierce. If an enterprise wants to stand out in the competition, it must guarantee the quality of its products. Quality is benefit and the soul of the enterprise. Therefore, the purchase of precise tungsten carbide mold parts, quality is the most important.

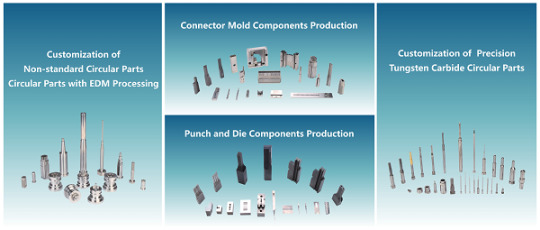

Precision tungsten steel parts are roughly divided into: punch, insert, round bar, tungsten carbide circular parts, bushing, tungsten steel drawing die, needle gauge, all kinds of precision special-shaped punch, guide post guide sleeve, etc. Dongguan Yize mould Co., Ltd. is a precision tungsten steel parts manufacturer integrating R & D, manufacturing, sales and service. After years of efforts, Yize has become an OEM manufacturer of many mold accessories at home and abroad.yizali2li

We know that quality is the foundation of everything and the cornerstone of our survival and development, so we have established a set of quality policies:

① Strictly control the quality of materials and make them controllable.

② Adopt advanced quality measurement tools to prevent trouble before it happens

③ Pay attention to customer complaints, summarize the causes of abnormal occurrence, and take this as an important basis for continuous optimization of production process, and try to prevent the recurrence of abnormal causes

④ Report to customers immediately if there is any problem, discuss the solution, treat people honestly and never cheat

Quality is the first life of an enterprise! All of our employees will do their best to control the quality of our products, never "do not accept, do not manufacture, do not flow out" of defective products!

Therefore, to purchase precise tungsten carbide mold parts, please give us an opportunity, we will guarantee the product quality, delivery time and service to the greatest extent.

yizali2ly

Above article from yize official website (https://www.yizemoulds.com/)

The original address:(http://www.yizemoulds.com/news_show_6_29_917.html)

0 notes

Text

Processing advantage of tungsten steel punch

When it comes to tungsten steel parts, we have to talk about tungsten steel punch ,it is an important part of stamping die, which is the core part of the parts needed to separate materials or plastic deformation.

The reason why tungsten steel punch is selected in industrial production is that compared with other parts, tungsten steel punch has certain processing advantages:

1. Low MC coefficient, which makes it possible to be widely used in friction parts

2. High chemical stability, resistant to alkali, alcohol, ether, hydrocarbon, weak acid, lubricating oil, detergent, water (sea water), and odorless, non-toxic, tasteless, rust free

3. Simplify the maintenance of the machine, save labor, excellent mechanical cutting performance and improve labor productivity

4. High intensity of production and processing, able to bear the load for a long time

5.Noise absorption, vibration absorption, MC nylon modulus is much smaller than metal, and the vibration attenuation is large, which provides a practical way better than metal to prevent noise

There are many characteristics of tungsten steel punches, which are not to be exemplified here. If you need to process customized tungsten steel punches or other tungsten carbide mold parts, you can choose the Yize Mould. We provide you with a series of customized products, such as special-shaped tungsten steel punch, round punch, ultra precision PG punch and so on.yizali2li

Yize's tungsten steel punch adopts imported raw materials, which is more durable; dimensional tolerance ± 0.002, we have strict requirements for each angle, diameter tolerance R angle, C angle, trimming position, etc., and our round punch has more stable quality and longer service life.

Yize, a precision mold parts manufacturer, focuses on the customized production of precision round parts, plastic mold parts, connector mold parts, tungsten steel parts and other precision mold parts. We adhere to the business principle of honesty, and look forward to cooperating with you.

yizali2ly

Above article from yize official website (https://www.yizemoulds.com/)

The original address:(http://www.yizemoulds.com/news_show_6_29_915.html)

0 notes

Text

Introduction to the processing technology of metal punch and die parts

Dongguan Yize mold is a manufacturer with more than ten years of mold parts processing experience, especially the customized processing of hardware punch and die parts.Next, Yize mould will give you a brief introduction.

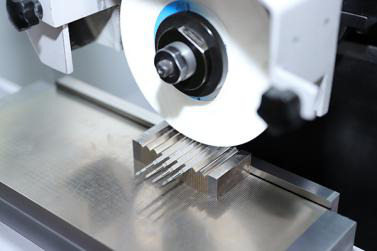

The process quantity of metal punch and die parts is determined by the dimensional accuracy and material properties of the workpiece shape. At the same time, many factors, such as stamping equipment conditions, actual mold manufacturing capacity, production batch and process stability, should also be considered. In order to ensure the quality of punch and die components and improve production efficiency, the number of processes should be as small as possible.

When processing metal punch and die parts, the following problems may be encountered, and the solutions are as follows:

1. When the section quality and dimension accuracy of the workpiece are required to be high, it can be considered to add the finishing process or directly use the precision blanking process after the blanking process.

2. The number of bending processes mainly depends on the complexity of its structure shape, which is determined by the number of bending angles, relative positions and bending directions. When the bending radius of the bending part is less than the allowable value, a shaping process will be added after bending.

3. The number of drawing process is related to material properties, drawing height, drawing steps, drawing diameter, material thickness and other conditions, which can be determined only by drawing process calculation. When the fillet radius of the drawing part is small or the dimensional accuracy is required to be high, a shaping process should be added after the drawing.yizali2li

4. In order to improve the stability of stamping process, it is sometimes necessary to increase the number of processes to ensure the quality of stamping parts. For example, the additional positioning hole punching of bending parts, the increase of deformation in the forming process and the reduction of hole punching to transfer the deformation area, etc.

5.For stamping parts with simple shape, single process die is used. Due to the limitation of the structure or strength of the die, the internal and external contour of the workpiece with complex blanking shape should be divided into several parts, and multiple stamping processes should be adopted. If necessary, continuous die can be selected. For precision metal punch and die parts with high flatness requirements, a leveling process can be added after the blanking process.

Dongguan Yize mould co., LTD., mainly engaged in precision connector mold parts, auto connector mold parts, precision plastic mold parts, precision connector mold, connector mold parts, precision mould parts, precision tungsten steel parts and precision mold parts, precision plastic mold,die casting mould parts,LED mould parts, PG optical grinding, precision stamping die parts, precision circle parts and so on, welcome to choose and buy!

yizali2ly

Above article from yize official website (https://www.yizemoulds.com/)

The original address:(http://www.yizemoulds.com/news_show_6_29_913.html)

0 notes

Text

What do you know about connector mold parts knowledge?

Now connector mold parts are widely used in automobile, electronics, medicine and other fields, and develop more and more rapidly. Yize Mould has rich experience in manufacturing connector mould parts. Next, Yize will show you more connector mold parts knowledge.

Someone might ask: is the form of connector mold parts the same? The answer is No. Its form and structure are different, with the application object, frequency, power, application environment, equipped with various forms of connector mold parts.yizali2li

The processing of connector die parts needs grinding, discharge, wire cutting and other steps in order to achieve the required accuracy, which has high requirements for connector die parts manufacturers. Only by constantly improving their own processing technology and pursuing higher product quality, can we meet the increasing product demand of customers.

If you want to know more about connector mold parts knowledge, you can pay attention to the connector mold parts manufacturer Yize mold, which provides customers with automobile connector mold parts, computer connector mold parts, tungsten steel round parts, stamping mold parts, precision tools and other mold parts. Welcome to visit the factory and discuss cooperation matters.

yizali2ly

Above article from yize official website (https://www.yizemoulds.com/)

The original address:(http://www.yizemoulds.com/news_show_6_29_902.html)

0 notes

Text

About the customization of SKD61 precision circular parts

Dongguan Yize Mould is a professional production platform of plastic mould parts, connector mould parts, tungsten steel parts, precision circular parts and other precision mould parts. Today, Yize will takes you to know about the customization of SKD61 precision circular parts.

First of all, SKD61 is a kind of hot work die steel of Japanese brand, and the brand of China (GB / T 1299-2000) is 4cr5mosi V1, which is the most widely used hot work die steel. SKD61 has good toughness and high temperature fatigue resistance, can withstand temperature fusion, and is suitable for long-term operation at high temperature with good cutting performance and polishing performance. SKD61 is smelted by electric furnace and remelted by electroslag. The steel quality is purer and toughness is better. Therefore, this material is very suitable for precision circular parts customization.yizali2li

Yize mould Co., Ltd. is a manufacturer of customized precision circular parts with EDM processing in Dongguan. It provides a series of SKD61 products, such as SKD61 thimble, SKD61 guide post, SKD61 guide sleeve, SKD61 cylinder, SKD61 punching pin, etc., as well as customized processing of other precision round parts for customers at home and abroad.

In addition to SKD61 material, Yize precision circular parts can also be customized in accordance with international industry standards such as GB, JIS, DIN, AISI, etc. the product has remarkable effect of wear resistance and corrosion resistance, which has been recognized and supported by many customers at home and abroad.

2020 precision mold components customization gives us an opportunity, we will wholeheartedly provide you with a satisfactory quality delivery time, please to map and sample customization~

yizali2ly

Above article from yize official website (https://www.yizemoulds.com/)

The original address:(https://www.yizemoulds.com/news_show_6_29_911.html)

0 notes

Text

Punch and die components processing, die heat treatment method

Dongguan Yize Mold specializes in precision mold parts processing, precision plastic mold parts, punch and die components, connector mold parts, non-standard round parts, tungsten steel parts, etc.

Heat treatment is a basic process of mold processing, which focuses on the durability and precision of the mold. Yize focuses on the processing of punch and die components. Here are the common problems and solutions encountered in the heat treatment of die:

1. Method of over quenching? Identify the material before quenching, observe whether the spark is suitable, and grasp the appropriate heating temperature and technological process; Control the heating time in real time. If the parts burn too much, normalize and anneal them again, and then go through the heat treatment process again to save them.

2. Is there any spot on the surface of die steel? Put the parts into the protection box and use dry protective agent for protection; The temperature of the salt bath should be lower than 500 ℃; Air cooling quenching is not suitable for high alloy steel; parts after quenching shall be cleaned in time.

3. How to deal with soft spots? The fiber structure of the raw material contains carbide. If the distribution is not uniform and segregation will cause soft spot phenomenon, the first thing is to choose a reasonable material; When heating, the surface of the workpiece has oxide skin and rust spots, which cause decarburization of the surface. Check carefully to remove the oxide skin and rust spots; If the quenching medium is aged or there are too many impurities, it is necessary to clean and replace the cooling medium regularly and keep the cooling medium at all times; The operation shall be carried out in accordance with the standard specifications.yizali2li

4. What should we do if the mold cracks? In case of improper material selection, attention should be paid to steel selection, management and careful selection; Control the appropriate processing temperature and select a reasonable process for processing; The stress should be removed before die quenching; In the process of graded quenching, the die should be cooled by stages and cleaned only when it is put at room temperature.

These are the problems and solutions that punch and die components manufacturer Yize Mould encountered in the heat treatment process. Yize company is a professional precision mold parts manufacturer. The earliest product is precision connector die parts manufacturing. In 2020, we hope to make progress in the whole set of precision die design, production and assembly.

yizali2ly

Above article from yize official website (https://www.yizemoulds.com/)

The original address:(https://www.yizemoulds.com/news_show_6_29_907.html)

0 notes

Text

Advantages of core pins and sleeves customization of Yize mould

We all know that the ejector sleeve plays a very good role in the manufacturing process of the mold equipment. Then, how to choose the right processing manufacturer for core pins and sleeves customization? Here, we recommend Dongguan Yize mould, a professional mold parts processing and manufacturing platform for you. So, what are the advantages of Yize mould core pins and sleeves customization?

1.Adopt better manufacturing process

The core pins is one of the main fine parts installed in the production of the guide sleeve of the die guide pillar. Because the quality of this part plays a great role in the production of the die, core pins and sleeves processing must meet the more detailed requirements, and the way to reach this standard is to improve its production process, such as the die softening and high-speed transportation adopted by the die thimble The electric spark iron cutting, pressing and other more advanced production technology.

2.Various specifications Because there are many kinds of moulds, the machines that can produce these moulds can be divided into various specifications and models. The mould thimble and cylinder on the installation machine need to be determined according to the model of the machine. Therefore, in general, there are more specifications and types for such mould machine parts to choose from. Yize mould can provide customized processing of various specifications of core pins and sleeves customization.yizali2li

3.Material selection is more attentive The production materials of Yize mould core pins and sleeves are more exquisite, because the role of this part has a great influence in the operation of the mould machinery, and the operation problems of the machine will occur in the long-term use of the mould thimble cylinder made of different materials, so generally, the key core pins and sleeves must be more careful in the selection of materials, Yize will definitely satisfy you in thisrespect.

The above is the advantages of Yize mould core pins and sleeves customization. In addition to core pins and sleeves, we also provide precision mould parts, precision plastic mould parts, hardware stamping mould parts, connector mould parts, non-standard round parts, tungsten steel parts and other customized processing.

yizali2ly

Above article from yize official website (https://www.moldpart-manufacturer.com/)

The original address:(https://www.yizemoulds.com/news_show_6_29_909.html)

0 notes

Text

High quality precision stamping mould components

Precision stamping mould components is top in any normal circumstances can reliable product from the template side ejection,and when the mold is closed its associated ejection parts to ensure that no interference with other parts of the free to return to the original position.

1、The top out mechanism:in order to make the mechanism is simplified,easy processing,generally use the round rod.

2、The precision stamping mould components jacking mechanism:pipe jacking is generally located at the bottom of the cylindrical parts.

3、Push plate mechanism used in the rectangle.Precision stamping mould components products:deep circular cavity or thin wall and core with side concave convex or annular groove.

4、Sloping roof and a swing rod ejection mechanism:used for removing products,side concave or scoliosis has the advantages of simple structure,complex processing,apex oblique top surface should be less than the core 0.05-0.1MM has anti ejection,products at the bottom on core block.Inclined sliding block should be between 5-10 degrees.Inclined sliding block should be between 5-10 degrees.The rotary demoulding mechanism:for with thread demolding,generally use the chain and gear drive with

yize80ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4398.html)

0 notes

Text

High quality plastic mould component

Plastic mold components is top in any normal circumstances can reliable product from the template side ejection,and when the mold is closed its associated ejection parts to ensure that no interference with other parts of the free to return to the original position.yize80ka

The top out mechanism:in order to make the mechanism is simplified,easy processing,generally use the round rod.The plastic mold componentsjacking mechanism:pipe jacking is generally located at the bottom of the cylindrical parts.Push plate mechanism used in the rectangle.Plastic mold components products:deep circular cavity or thin wall and core with side concave convex or annular groove.

Sloping roof and a swing rod ejection mechanism:used for removing products,side concave or scoliosis has the advantages yize67ka of simple structure,complex processing,apex oblique top surface should be less than the core 0.05-0.1MM has anti ejection,products at the bottom on core block.Inclined sliding block should be between 5-10 degrees.Inclined sliding block should be between 5-10 degrees.The rotary demoulding mechanism:for with thread demolding,generally use the chain and gear drive with.

yize80ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4397.html)

0 notes

Text

How to improve the precision mold parts processing quality

With the improvement of the domestic market economy,China has gradually become the international precision mold parts manufacturing center.In addition to the fierce competition in foreign markets,many businessman invest in the Chinese market.yize80ka

The electrical control box,machine shell,and so on are generally required for the mold parts processing.So,how to improve the precision mold parts processing quality?

Die steel material is very hard,so it’s require high reliability.

With the complexity of the workpiece shape,it is necessary to improve the design and manufacturing level.Point at some precision mould parts that have many kinds of grooves and a variety of material in a set of mold in the forming,it should be yize67ka required to pay more attention.

About improve the precision mold parts processing quality,it chould show on end products.Of cause,it has a great effect on products’ surface.Machining precision and machining error are the terms to judge the precision mold parts processing quality.Machining precision is measured by the tolerance level,it mains that the smaller the grade value is,the higher the precision is.For machining error,the numerical value is larger,and the error is larger.The machining accuracy is high,the error is small.Because the actual data by any machining method are not absolutely accurate,so base on the function of the part is can be OK that machining error is within the scope of the requirements.

The quality of the machine depends on the quality of the parts and the quality of the machine.The precision mold parts processing quality includes two parts,one is the machining precision and another is the surface quality.The main aspects which will influence processing accuracy is dimensional accuracy and the parts size tolerance.

yize80ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4396.html)

0 notes

Text

Core pin manufacturer yize quality management policy

With the rapid development of industry, all walks of life have higher and higher requirements for product quality. In order to adapt to the development of the times, Yize is also striving to improve processing technology and constantly introduce advanced equipment, aiming to provide customers with the best quality products and services. The following is the core pin manufacturer yize quality management policy:

Pay attention to details and pursue perfection.

1. Advanced quality management tools shall be used for quality management to prevent accidents in advance;

2. Strictly control the quality of materials, so that they can be traced and controlled;

3. The production process shall be in strict accordance with the production process steps. "Do not accept, manufacture or flow out" defective products;

4. The statement shall be realistic, report problems to customers immediately, discuss solutions, and never cheat customers;

5. Attach importance to customer complaints, summarize the causes of customer complaints and take them as an important basis for optimizing the production process, and prevent the yize67ka recurrence of customer complaints.

In addition, plastic mould parts manufacturer Yize also made the following detailed requirements:

All materials are purchased by a first-class agent of a brand, and all materials are strictly controlled in and out of the warehouse; parts are strictly antirust treated before baling, reusable and recyclable packaging materials are used to make contributions to the world's environmental protection; problems in processing are summarized and solutions are found in a timely manner, and quality improvement is publicized to all employees in a timely manner Guide.

The above is the core pin manufacturer yize quality management policy. We want to win the high trust of customers with the best quality and delivery time.

yize80ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4395.html)

0 notes

Text

About precision connector mold parts

Precision connector mold parts of EDM process with the development of economy,the social demand growth,complex structure and has special requirements.

A new connector mold parts material with high melting point,high hardness,high strength,high toughness are constantly emerging,the traditional mechanical cutting has been unable to meet the requirements.The direct use of electricity,electrochemical energy, sound energy and so on,up to now,have advanced equipment series, each department has been widely used in the precision connector mold parts processing customized.Precision connector mold parts of electric spark machining and mechanical processing of different nature,it does not require the tool material harder than the workpiece material,also do not need to exert obvious mechanical force in the process,But the direct use of electrical energy,chemical energy,light energy and the processing of the workpiece,in order to achieve a certain shape,size and surface roughness requirements.EDM is also called electric discharge machining processing or electric corrosion,including EDM,wire EDM,EDM hole,the outer circle and forming grinding,electrical discharge machining,synchronous rotary EDM surface strengthening and carving process.In the machining of custom precision mould are commonly used in EDM and WEDM,is currently the process connector mold parts processing surface is important.EDM refers to a certain medium,the corrosion effect between tool electrode and workpiece electrode pulse discharge,a method for processing workpiece.It can process all kinds of high melting point,high hardness,high strength,high toughness,Gao Chundu material,and shows many advantages

in production, so the arrival of the rapid development and wide application of.In a precision connector mold parts processing customization is used for machining holes and cavity.

yize62ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4395.html)

0 notes

Text

Professional precision mold part manufacturer with their products

China professional precision mold part manufacturer will be from the past mainly relied on the extensive development mode of scale expansion and an increase in the number of,to rely mainly on scientific and technological progress and improving product quality and the level of lean type development model transformation as the focus.Change from the development model with the introduction of digestion and absorption of International advanced technology to the development pattern of the introduction of digestion and absorption and improve the capability of independent innovation and transformation of industry characteristics.Some professional precision mold part manufacturer from the skill oriented industry characteristics to technology and modern enterprise management model;vigorously promote the development of innovation driven,and actively nurture and develop new growth point.We should vigorously develop modern manufacturing service industry,actively and steadily extended manufacturing as the core of the upstream and downstream industry chain to support the mold.The mold industry cluster construction should pay attention to the reasonable layout and die manufacturing industry to coordinate,gradually formed industrial pattern of complementary advantages,coordinated development. Yize mould as a professional precision mold part manufacturer is full development of more high-quality precision mold parts, efforts to promote the development of mold products!

yize62ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4394.html)

0 notes

Text

Dongguan mould part manufacturer with core pins and sleeves

Core pins and sleevs often appear in the die life,but what is the specific meaning of the thimble?yize62ka

Dongguan mould part manufacturer with core pins and sleevs can be called the push rod,pin,needle roller,needle,lathe with top is also called the core pins and sleevs,thimble is plastic mold parts,mainly used in plastic mold.Core pins and sleevs material is generally used in steel,and is an important part of the hard alloy pin.This is the specific meaning.Core pins and sleevs can be used for the mould,it can play a strong role in the mould part manufacturer.Core pins and sleevs is mainly used in the production of plastic mold parts,main types of flat thimble,dome needle,needle holder,standard thimble,thimble, thimble,non standard,materials such as SKH51.SKD61.SKD11,65Mn,lathe.It’s the standard rotary thimble JB/T3580-1998.So compared with the down,different materials have different properties of the thimble,thimble SKD61 material can resist high temperature,core pins and sleevs surface nitriding can improve the wear resistance of the thimble is very good.

Core pins and sleevs is part of a plastic mold parts processing essential,as long as we understand the specific meaning of the thimble.I believe that the precise core pins and sleevs production will become part of Yize mold thimble manufacturing yield.

yize62ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4392.html)

0 notes

Text

China precision plastic mould maker with tungsten carbide mold parts

Tungsten carbide mold parts as the polymer synthetic materials,because of its good tungsten carbide mold parts,film,insulation,acid and alkali resistance,corrosion resistance,low permeability,permeability and easy coloring,the appearance of bright features,from the beginning of the 50s,with the development of petroleum chemical tungsten carbide mold parts industry and the rapid development,become a kind of not for promoting and life are closely related to tungsten carbide mold parts material.Is widely used in many aspects of household electrical appliances,car,furniture,packaging supplies,agricultural films.So far,the world tungsten carbide mold parts annual output has reached ten million tons,China annual output of more than 5000000 tons.However,with tungsten carbide mold parts production increases,cost reduction,a large number of commodity tungsten carbide mold parts packaging bag,liquid containers and tungsten carbide mold parts sheeting,people are no longer used repeatedly.But is discarded as garbage consumer goods,even large tungsten carbide mold parts. Finally will also along with the product damage and thrown away,so that tungsten carbide mold parts is a used is on behalf of discarded products.yize62ka

Dongguan Yize mould Co. Ltd is a specialized processing factory for steel parts,we tungsten steel fittings products of good quality and affordable price received numerous customer appreciation and choice,is the support of old and new customers.We should be step by step to strong up to today's scale.In the new year wish the new and old customers together in support of the yize exhibition,a record high!

yize62ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4391.html)

0 notes

Text

Precision mold parts safety protection

Due to the specificity, precision, vulnerability and other characteristics of the mold parts, it is very important to do the precision mold parts safety protection, which is summarized as follows:

1. Rust prevention: prevent the rust caused by water leakage / condensation / rain / hand print of injection molding machine mold. 2. Anti collision: to prevent the die from being damaged due to the breakage of the thimble and the failure to return in place. 3. Deburring: prevent the mould burr caused by cloth / material punching / hand plastering / nozzle clamp / knife collision. 4. Missing parts: prevent the mold from being damaged in the use process due to the lack of pull rod / washer and other parts.yize61ka 5. Anti press: to prevent die damage caused by die locking due to product remaining in the die. 6. Undervoltage: to prevent mold from damage caused by too much low pressure protection pressure.

According to the survey, more than 85% of mold damage is caused by the lack of protection awareness, and the maintenance cost of mold is generally high, which is directly related to the interests of mould parts processing factory, so it can be seen that precision mold parts safety protection is very important.

yize62ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4831.html)

0 notes

Text

About plastic mold components technology

With China by the current economic situation of plastic mold componentshas improved,in to realize the great rejuvenation of the Chinese nation and the slogan down.China plastic mold components manufacturing becomes more and more vigorous development,and has become one of the important sign of weighing a national level of manufacturing industry.The plastic mold components industry can promote yize61ka development and quality improvement of industrial production,and can obtain great economic benefitThus caused the high attention and appreciation.In Japan,the mold is known as into the motive of rich,Germany crown as metal processing industry,the emperor in Romania is more direct:"die is gold".The important position of visible mold industry in the national economy.China also attaches great importance to the development of mould industry,promulgated in 1989 March on the national industrial policy decision points,plastic mold components technology development as the primary task of mechanical industry.

Yize adopts advanced manufacturing equipments and processing technology that from Japan.Our products are 100% exported,mainly Japan,United States,Southeast Aisa and Europe.We mainly make nonstandard parts as per drawing or supplied Grinding tolerance within 0.001mm,EDM and wire cut precision within 0.005mm,axiality within 0.002,circularity 0.0015mm,surface roughness Ra0.025,linearity 300mm within 0.002 are the production precision available.

yize62ka

Above article from yize official website (http://www.moldpart-manufacturer.com/)

The original address:(http://www.moldpart-manufacturer.com/News-Center/4390.html)

0 notes