Text

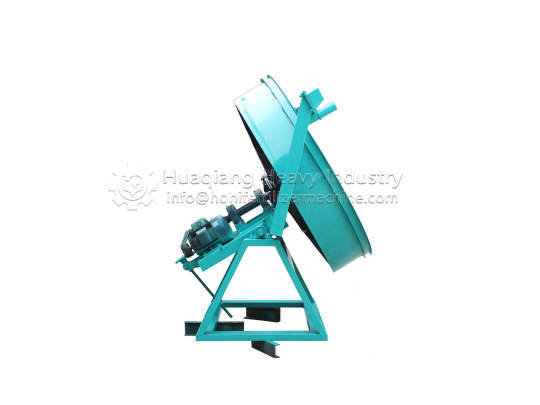

What are the technical advantages of organic fertilizer granulator in improving product quality

The technical advantages of organic fertilizer granulator in improving product quality are mainly reflected in the following aspects:

1. Ball pellet production: organic fertilizer granulator can process raw materials into ball pellets, which is conducive to the uniform application of fertilizer and the absorption of crops.

2. Pure organic granulation: organic fertilizer granulation machine can achieve 100% organic content of granulation, without adding binder, to ensure the purity and quality of organic fertilizer.

3. Solid particles: The produced particles have a solid structure, which helps to maintain the integrity of the particles during storage and transportation, reducing the generation of crushing and dust.

4. Energy saving and consumption reduction: The design of organic fertilizer granulator pays attention to energy saving, the organic matter after fermentation can be granulated without drying, and the water content of raw materials can be 20-40%, which can reduce the drying energy consumption.

5. Strong adaptability: The new organic fertilizer granulator is suitable for a variety of raw materials, including livestock manure, crop straw, food waste, etc., which can convert these wastes into valuable organic fertilizers.

6. Improve fertilization effect: the organic fertilizer after granulation is easier to store, transport and apply, improving the utilization rate of fertilizer and fertilization effect.

7. Environmental protection design: Pay attention to environmental protection in the production process of organic fertilizer equipment, and use advanced dust removal and purification equipment to reduce environmental pollution.

Through these technical advantages, organic fertilizer granulator not only improves the quality of organic fertilizer, but also helps promote the sustainable development of agriculture and environmental protection.

0 notes

Text

How do organic fertilizer production lines adjust to meet demand in different agricultural production

The adjustment of organic fertilizer production lines in different scales of agricultural production to meet the needs can mainly be carried out from the following aspects:

1. Raw material pretreatment: According to the specific scale of agricultural production and available raw materials, adjust the pretreatment method of raw materials, such as the use of solid-liquid separator or crushing equipment to adapt to different raw material water content and particle size requirements.

2. Selection of fermentation equipment: according to the size of the production scale, choose the right fermentation equipment, such as fermentation compost turning machine or high temperature aerobic fermenter, the latter is more suitable in areas with more stringent environmental requirements.

3. Deep processing capacity: For large-scale production, it can be equipped with deep processing equipment such as mixing machine, granulation drying and cooling equipment to produce more diversified organic fertilizer products and improve market competitiveness.

4. Degree of automation: according to the size and capital of the farm, choose the appropriate automated production line to reduce labor costs and improve production efficiency.

5. Service-led management: For small-scale farms, it is possible to achieve service-led scale management through agricultural production custody services, such as providing farming, harvest prevention and other operations.

6. Environmental protection measures: In the design and operation of the production line, environmental protection factors should be considered, such as the use of dust collectors, dehydrators and other auxiliary equipment to reduce pollutant emissions in the production process.

7. Technology upgrade and innovation: constantly explore and apply new technologies, such as intelligent management systems, to improve the scientific and technological content and production efficiency of organic fertilizer equipment.

Through the above measures, organic fertilizer production lines can be flexibly adjusted to meet the needs of different scale agricultural production, while improving product quality and market competitiveness.

#organic fertilizer equipment#organic fertilizer production line#fermentation compost turning machine

0 notes

Text

What are the possible paths for the green transformation of NPK fertilizer production lines

With the support of environmental protection policies, the green transformation of NPK fertilizer production lines can be achieved through the following possible paths:

1. Improve fertilizer utilization rate: Through technological innovation, such as precision agriculture technology, nitrogen, phosphorus and potassium fertilizers can be applied more targeted and more effectively, reducing environmental pollution and resource waste caused by excessive use.

2. Optimize fertilizer structure: adjust the ratio of nitrogen, phosphorus and potassium, as well as the nutrient form, to promote more efficient absorption of crops and reduce the burden on the environment.

3. Develop new fertilizers: promote organic and inorganic fertilizer products, such as organic fertilizers, microbial fertilizers, etc., which can improve soil quality, improve crop disease resistance and product quality.

4. Improve fertilization methods: efficient fertilization technologies such as water and fertilizer integration and leaf fertilization are adopted to reduce fertilizer loss and environmental impact.

5. Environmental policy support: National policies encourage fertilizer reduction and efficiency, providing policy support and direction for the green transformation of nitrogen, phosphorus and potassium fertilizer production lines.

6. Scientific and technological innovation: Through scientific and technological innovation, such as the improvement of the production process of organic fertilizer equipment, the research and development of new fertilizers, etc., to improve the environmental performance and market competitiveness of fertilizers.

7. Market demand: With the increasing demand of consumers for healthy food and environmentally friendly products, the market potential of organic fertilizers and environmentally friendly NPK fertilizers is huge.

8. International cooperation and exchange: Through international cooperation, the introduction of advanced fertilizer production technology and management experience to enhance the environmental protection level and international competitiveness of domestic nitrogen, phosphorus and potassium fertilizer production lines.

0 notes

Text

How to improve production efficiency by automating organic fertilizer equipment

Automated organic fertilizer equipment has significant advantages in improving production efficiency, and here are some key points:

1. Automatic control system: Through the integration of advanced automatic control system, the centralized management of organic fertilizer production line can be realized, including temperature monitoring, equipment operating status monitoring, etc., so as to improve production efficiency and product quality.

2. Accurate metering and dosing: Automatic equipment can accurately control the ratio of raw materials to ensure the accurate ratio of various nutrients in organic fertilizers to meet the needs of different crops.

3. Reduce manual operation: Automation equipment reduces the need for manual operation, reduces labor costs, reduces human error, and improves the consistency and repeatability of the production process.

4. Improve production continuity: automation equipment can continuously produce, reduce the production interruption caused by manual operation, and improve the overall production efficiency.

5. Energy saving and consumption reduction: Automation equipment effectively reduces energy consumption and production costs by optimizing energy use and reducing waste in the production process.

6. Environmental control: Automation equipment can operate in a controlled environment to reduce the impact of environmental factors on the production process and ensure stable production conditions.

7. Data management: Automated systems can collect and analyze production data to help managers optimize production processes, predict and solve potential problems, and improve the operation efficiency of production lines.

Through the application of these automation technologies, organic fertilizer equipment can improve production efficiency and reduce costs, while ensuring product quality and meeting market demand.

0 notes

Text

How to ensure the stable operation of organic fertilizer granulator in different seasons

To ensure the stable operation of organic fertilizer granulator in different seasons, corresponding maintenance measures need to be taken according to seasonal changes:

1. Seasonal lubrication: Different types of lubricating oil should be used in different seasons. For example, it may be necessary to use a thicker lubricant in the winter, and a thinner oil in the summer. Each time the lubricating oil should be replaced, the old oil should be completely discharged and cleaned before adding new oil.

2. Insulation measures: In the cold season, it should be ensured that the workplace of the granulator or the organic fertilizer equipment itself has sufficient insulation measures to prevent the difficulty or inability to start due to low temperature.

3. Antifreeze treatment: For organic fertilizer raw materials, especially those with high moisture content, antifreeze treatment should be carried out to avoid affecting production due to freezing.

4. Regular inspection: No matter what season, you should regularly check the key components of the granulator, such as motors, bearings, gears, etc., to ensure that there is no wear or damage, and replace the damaged parts in time.

5. Cleaning and maintenance: After each use, the residual materials inside and outside the granulator should be removed, especially the die and roll to prevent rust. For other parts, appropriate anti-rust treatment should also be carried out, such as coating anti-rust grease.

6. Moisture and corrosion protection: In the wet season, special attention should be paid to the moisture and corrosion protection of the equipment to ensure that the equipment will not fail due to high humidity.

Through the above measures, we can ensure that the organic fertilizer granulator can run stably in different seasons, improve the production efficiency of the organic fertilizer production line, and extend the service life of the equipment.

0 notes

Text

What are the operation skills that can improve the efficiency of the large wheel compost turning machine?

When using the large wheel compost turning machine, the following operation techniques can be adopted to improve the efficiency of the heap turning:

1. Ensure the normal operation of the equipment: Before operation, check whether the screws of each part of the stacking machine are loose, whether the chain and belt are fastened, and whether the diesel engine, hydraulic cylinder, water tank, etc., are added to ensure that the equipment is in good condition.

2. Materials: Before turning the pile, ensure that there are no debris such as bricks, stones, iron, and glass in the materials to avoid damaging the equipment or affecting the effect of turning the pile.

3. Control the stacking speed: During the stacking process, control the forward speed of the organic fertilizer equipment to avoid being too fast or too slow to ensure that the stacking is uniform.

4. Regular maintenance: Regular maintenance and maintenance of the stacking machine to ensure long-term stable operation of the organic fertilizer production line.

5. Optimize the stacking frequency: according to the fermentation situation and environmental conditions of the material, arrange the stacking frequency reasonably to promote the uniform fermentation of the material.

6. The use of technological innovation: the use of film overturning technology and other innovative methods can be carried out without uncovering the film of the covered material, reducing greenhouse gas and odor gas emissions, and improving the efficiency of overturning.

7. Train operators: Ensure that operators receive appropriate training and are familiar with the operating procedures and maintenance methods of the equipment.

Through the above techniques, the efficiency of the large wheel composting machine can be effectively improved, and the efficient production of organic fertilizer can be promoted.

#organic fertilizer equipment#organic fertilizer production line#large wheel compost turning machine

0 notes

Text

How much cost savings can organic fertilizer equipment bring in reducing fertilizer use

The cost savings that organic fertilizer equipment can bring in reducing fertilizer use are mainly reflected in the following aspects:

1. Improve the utilization rate of fertilizers: the reasonable allocation of organic fertilizers and fertilizers can improve the utilization efficiency of fertilizers and reduce the waste of fertilizers. According to relevant studies, improving the utilization rate of fertilizer can significantly reduce the purchase cost of fertilizer.

2. Reduce additional transportation and labor costs: Although the application amount of organic fertilizer is larger, its nutrient rich advantage can offset the additional increase in transportation and labor costs. By using organic fertilizer equipment, agricultural waste can be converted into organic fertilizer on the spot, reducing transportation distances and costs.

3. Energy saving and emission reduction: Compared with fertilizer production, the production process of organic fertilizer has lower energy consumption and less pollution. By increasing the market share of organic fertilizers, energy consumption and pollutant emissions in the process of fertilizer production can be reduced, thereby reducing related costs and environmental governance costs.

4. Long-term soil fertility maintenance: organic fertilizer can improve soil structure and increase soil organic matter content. Long-term application helps to maintain and improve soil fertility and reduce dependence on fertilizer, thus saving costs in the long run.

In summary, organic fertilizer equipment can bring certain cost savings in reducing fertilizer use, but the specific amount of savings will be affected by various factors such as the region, crop type, and production scale of organic fertilizer production lines. Through the rational use of organic fertilizer equipment, it can not only save costs, but also bring environmental and social benefits.

0 notes

Text

How to store and maintain organic fertilizer equipment when idle

The maintenance and storage of organic fertilizer equipment when idle is very important, and the correct maintenance method can extend the service life of the equipment and keep it in good working condition. Here are some key points:

1. Clean the equipment: Before the equipment is idle, thoroughly clean the inside and outside of the equipment to remove residual fertilizers and impurities to prevent corrosion and rust.

2. Lubrication parts: lubricate the bearing, gear and other friction parts of the equipment to prevent rust and wear.

3. Storage environment: Store the device in a dry, ventilated, non-corrosive gas environment, away from direct sunlight and rain wet.

4. Cover protection: If conditions permit, you can use a dust cover or similar cover to protect the equipment.

5. Regular inspection: Even if the equipment is idle, it should be checked regularly to ensure that no small animals or other factors cause damage to the equipment.

6. Electrical parts maintenance: For the electrical parts of the equipment, such as the motor, should be stored in a dry and clean environment, and ensure that it is not affected by moisture.

7. Regular start: If the equipment will be idle for a long time, the equipment should be regularly started for idling to ensure that its mechanical components will not fail due to long-term rest.

8. Follow the manufacturer's guidelines: Finally, follow the maintenance and storage guidelines provided by the manufacturer of the device, as different devices may have different maintenance requirements.

Through the above measures, you can ensure that organic fertilizer equipment is properly maintained during idle period, reducing the risk of equipment failure, and can quickly resume the fertilizer production lines when needed.

0 notes

Text

It is a long way to achieve harmless treatment of organic fertilizer production line

Organic fertilizer production line to achieve harmless treatment is indeed a long-term and complex process, but through the efforts of the following aspects, you can gradually achieve this goal:

1. Technological innovation: Using advanced fermentation technology and organic fertilizer equipment, such as high temperature composting system, to convert organic waste into organic fertilizer in a relatively short time through microbial fermentation. At the same time, rapid detection technology is developed to ensure that the quality of organic fertilizer products meets the standards.

2. Raw material pretreatment: Proper pretreatment of raw materials such as livestock manure and straw, such as crushing and drying, in order to facilitate the subsequent mixing and fermentation process.

3. Process optimization: Optimize the compost fermentation process, control the aerobic conditions, avoid the anaerobic environment to produce odor gas, reduce environmental pollution.

4. Environmental management: In the production process, strictly control the temperature, humidity and ventilation conditions to reduce the production and emission of odor. Policy support and regulation: Referring to the experience of developed countries, formulate strict standards for the production and use of organic fertilizers, and provide policy support and subsidies to encourage farmers to use organic fertilizers.

5. Market promotion: Through education and publicity, to improve farmers' awareness of organic fertilizers, promote the use of organic fertilizers, so as to reduce the dependence on chemical fertilizers.

6. Quality control: Establish a strict quality control system to ensure the safety and effectiveness of organic fertilizer products and meet the needs of sustainable agricultural development.

Through these measures, we can gradually improve the level of harmless treatment of organic fertilizer production lines, promote the resource utilization of agricultural waste, protect and improve the environment.

0 notes

Text

How to make fertilizer granulating production line achieve leapfrog development

To achieve the leapfrog development of fertilizer granulating produciton line, you can start from the following aspects:

1. Technological innovation: The use of advanced granulation technology, such as melt urea carrier tower granulation technology, this technology can produce a smooth appearance, uniform particles of fertilizer products, while having its own anti-counterfeiting characteristics.

2. Product upgrade: Develop new fertilizers, such as bio-organic fertilizers, which not only provide nutrients, but also improve soil structure and increase crop resistance to pests and diseases.

3. Equipment optimization: Use efficient fertilizer granulator to optimize production line layout, reduce production cycle and improve production efficiency.

4. Environmental protection and energy saving: Pay attention to the environmental protection and energy saving design of organic fertilizer equipment, reduce waste and emissions in the production process, reduce energy consumption, and meet environmental protection standards.

5. Market orientation: Pay attention to market demand, produce fertilizer products that adapt to the development of modern agriculture, such as high concentration urine-based compound fertilizer, etc., to meet the needs of the market and consumers.

6. Service upgrade: Provide comprehensive services, including agrochemical services and technical support, to enhance the brand's market competitiveness.

7. Industrial chain integration: Strengthen the integration of upstream and downstream industrial chains to ensure the stability and cost-effectiveness of raw material supply, while improving product market competitiveness.

Through the above measures, the fertilizer granulation production line can improve production efficiency and market competitiveness on the basis of ensuring product quality, and achieve leapfrog development.

0 notes

Text

How do senior enterprises sell organic fertilizer production lines

Senior companies, when selling organic fertilizer production lines, usually employ a series of strategies and tactics to ensure successful and sustained market growth. Here are some effective sales strategies and methods:

1. Market research and analysis: research and identify potential customer groups, such as large agricultural enterprises, cooperatives, horticultural companies, etc. Understand their needs and purchasing decision factors. Understand competitors' products, prices, services and market positioning in order to develop differentiated sales strategies.

2. Customization of customer needs: In-depth communication with customers to understand their specific needs, production scale and budget. Provide customized solutions based on these requirements. According to customer needs, provide personalized production line configuration advice, including organic fertilizer equipment selection, technical support and after-sales service.

3. Price strategy: Make reasonable price strategy according to market research and cost analysis. Consider offering flexible payment options, preferential policies, or long-term discounts. Emphasize the value brought by the production line, such as improving production efficiency, reducing operating costs, increasing product quality, etc., to support price positioning.

4. Continuous innovation and improvement: continue to invest in technology research and development and innovation to maintain the advanced nature and competitiveness of products. Constantly improve products and services based on market feedback to ensure that changing market needs are met.

Through these strategies, senior enterprises can effectively promote and sell organic fertilizer production lines, win market share and customer trust.

0 notes

Text

Safe operation of compost crushers

During the use of the compost crusher, it is very important to ensure its safe operation and good maintenance. Here are some key safe operation and maintenance methods:

1. Safe operation: Train operators to ensure that all operators have been professionally trained to understand the operating procedures and safety precautions of organic fertilizer equipment. Conduct regular safety training and emergency drills.

2. Personal Protective Equipment: Operators must wear appropriate personal protective equipment, such as hard hats, goggles, ear muffs, gloves and protective shoes.

3. Equipment inspection: Before each use, check whether the various components of the equipment are normal, especially the scraper, blade, hydraulic system and electrical system. Ensure that all safety devices (e.g. shields, emergency shutdown devices) are working properly.

4. Check before starting: Ensure that all personnel are away from the equipment operation area before starting. Verify that all operating controls are in the correct position.

5. Safe operation: When operating, keep the smooth operation of the organic fertilizer production line, do not overload operation. Do not put your hands or other body parts near the moving parts of the equipment. Avoid tilting and sudden acceleration during the tipping process to prevent equipment loss of control.

6. Stop and clean up: Stop the equipment completely before stopping, and then maintain or clean up. During the cleaning process, power off the device and use hand tools to clean the device.

0 notes

Text

Why does the tool of organic fertilizer crusher wear

Tool wear in organic fertilizer crushers is usually caused by the following factors:

1. Raw material hardness: If the raw material is hard or contains more minerals, such as stones or nut shells, it will accelerate the wear of the tool.

2. Foreign body mixing: If the raw material is mixed with hard objects or metal fragments, it will cause additional wear and tear to the tool, and may even damage the tool.

3. Improper operation: overload operation, too fast or too slow operation speed, or inappropriate operating procedures may lead to excessive tool wear.

4. Humidity and viscosity of raw materials: raw materials with higher humidity will increase the friction of the tool, resulting in increased wear; Sticky raw materials may accumulate on the tool, affecting the cutting effect.

5. Tool material: The material and hardness of the tool will also affect its wear resistance. High quality tool materials usually have better wear resistance.

6. Improper maintenance: Lack of regular inspection and maintenance, not timely replacement or repair tool, will lead to the normal wear of the tool is not treated, and then affect the service life of organic fertilizer equipment.

7. Equipment design and manufacturing quality: poor equipment design and manufacturing quality may also lead to accelerated tool wear, and unreasonable tools may not be able to effectively cope with various conditions in actual use.

Regular maintenance, reasonable operation and proper raw material handling help to slow tool wear and improve its service life and crushing efficiency.

0 notes

Text

Cattle manure organic fertilizer granulator to reduce environmental pollution methods

Cow manure organic fertilizer granulator has the following methods in reducing environmental pollution:

1. Reduce gas emissions: Modern cattle manure pelleting machines usually use a closed operating system to reduce the release of harmful gases.

2. Reduce solid waste: Through efficient pelletizing technology to convert cow manure into granular fertilizer, reduce the production of solid waste. Dust control systems during the granulation process reduce dust emissions.

3. Optimize the utilization of resources: by controlling the treatment of raw materials and the granulation process, fertilizers with higher nutrient content and stronger effectiveness are produced, reducing the dependence on chemical fertilizers, thus reducing the environmental burden caused by the use of chemical fertilizers. The use of energy-saving organic fertilizer equipment and processes to reduce energy consumption, thereby reducing the environmental impact of organic fertilizer production lines.

4. Control water pollution: By controlling the humidity in the granulation process, avoid excessive liquid discharge and reduce the pollution of water resources. Effective treatment and recycling of potential waste water to prevent its pollution to the environment.

5. Improve the production process: Use high temperature treatment technology (such as high temperature fermentation) to kill pathogens and eggs in cow manure and reduce potential threats to the environment. By optimizing the treatment process and adding the appropriate deodorant, the odor in the fertilizer production process is reduced and the impact on the surrounding environment is reduced.

Through these methods, cow manure organic fertilizer granulator not only improves the production efficiency of fertilizer, but also effectively reduces environmental pollution in the production process and helps achieve sustainable agricultural development.

0 notes

Text

The far-reaching impact of cow manure organic fertilizer crusher

Cow manure organic fertilizer crusher plays an important role in the production of organic fertilizer, and its far-reaching impact on organic fertilizer is reflected in the following aspects:

1. Improve the uniformity of fertilizer: The crusher can refine organic raw materials such as cow manure to make its particles more uniform. This uniformity helps the fertilizer to be applied more evenly, thereby improving the effectiveness of the fertilizer and reducing the uneven growth problem caused by the uneven distribution of fertilizer during the fertilization process.

2. Reduce the transportation and storage costs of fertilizers: the volume of refined organic fertilizers is reduced and the density is increased, thus reducing the transportation and storage costs. In addition, the pulverized fertilizer is easier to load and handle, reducing logistics costs and storage space requirements.

3. Improve environmental friendliness: By crushing cow manure, this waste can be used more effectively and its negative impact on the environment can be reduced. Pulverized fertilizer can be better transformed into soil fertility, increase soil organic matter content, improve soil structure, and promote soil health.

4. Promote the recycling of resources: cow manure organic fertilizer crusher promotes the recycling of agricultural waste, reducing the dependence on fertilizer, thereby reducing the environmental burden. Through the effective use of cow manure, the pollution of waste to the environment is reduced, and the utilization efficiency of resources is improved.

In summary, the cow manure organic fertilizer crusher not only optimizes the production process of the organic fertilizer production line, but also improves the overall quality and efficiency of the fertilizer, which has a far-reaching positive impact on agricultural production and environmental protection.

0 notes

Text

The reason why the water should not be too much when the organic fertilizer granulator is producing

In the production process of organic fertilizer granulator, it is very important to control the water content of raw materials, and too much water will cause the following problems:

1. Granulation difficulty: too much water will make the raw material too wet, easy to form caking in the granulation process, affecting the granulation effect. High humidity increases the adhesion of raw materials, which can lead to blockage of the pelletizer feed system and pelletizing components.

2. Particle quality decline: The particles formed in the granulation process of raw materials with too much water may be too soft, insufficient strength, and easy to be broken in subsequent treatment and transportation. Too much water will lead to uneven particle formation, affecting the overall quality of the fertilizer.

3. Drying problem: too much water will make the particles need more time to remove water during the drying process, thus extending the drying time and increasing energy consumption. High moisture will lead to uneven moisture distribution in the drying process, affecting the drying quality of the particles.

4. Increased energy consumption: Processing high-moisture raw materials requires more energy to complete the drying process, increasing production costs.

5. Equipment loss: high moisture raw materials may increase the wear and tear of organic fertilizer equipment and shorten the service life of equipment. Equipment clogging and failure due to excessive moisture may require more frequent maintenance and overhaul.

Therefore, in order to ensure the smooth progress of organic fertilizer granulation and product quality, it is usually necessary to control the moisture of raw materials within the appropriate range.

0 notes

Text

In the era of commodities, organic fertilizer granulators need to be carefully selected

In the era of commodities, the choice of organic fertilizer granulator does need to be careful, mainly because of the following considerations:

1. Raw material adaptability: Different organic fertilizer granulators are suitable for different types of raw materials (such as chicken manure, cow manure, compost, etc.). Choosing a granulator suitable for your raw material type can ensure the production efficiency and fertilizer quality of the organic fertilizer production line.

2. Production capacity: According to your production scale, choose the appropriate capacity and specifications of the granulator. A device that is too small may not be able to meet the demand, while a device that is too large may lead to a waste of resources.

3. Equipment quality: The quality of organic fertilizer equipment directly affects the stability of production and product quality. Choosing reputable manufacturers and proven equipment can reduce failure rates and ensure smooth production.

4. Technical support and after-sales service: The technical support and after-sales service of the equipment is very important, including installation and commissioning, maintenance and troubleshooting. Choosing a provider that provides a complete service can avoid problems in subsequent operations.

5. Environmental performance: organic fertilizer production process may produce a certain odor and dust, choose environmental performance of good equipment to help reduce the impact on the environment, in line with environmental standards.

6. Equipment flexibility: Choose those with high flexibility equipment, can adapt to different formulations and production needs, increase the diversity and flexibility of the production line.

In the selection of organic fertilizer granulator, a comprehensive consideration of the above factors, and sufficient market research and equipment comparison, can help you make wise investment decisions to ensure the efficient operation of the production line and long-term profitability.

0 notes