#BCM Repair

Explore tagged Tumblr posts

Text

0 notes

Text

BCM Cloning Experts Fixing Electrical Issues Efficiently

When it comes to modern automotive systems, one of the most complex and vital components is the Body Control Module (BCM). This essential unit oversees a wide range of electronic functions in vehicles, from power windows and mirrors to interior lighting, remote keyless entry, and even security systems. As vehicles become increasingly reliant on electronic systems, any malfunction within the BCM can lead to frustrating and potentially dangerous issues. That’s where skilled cloning experts come in, offering specialized services to efficiently address electrical problems without the need for costly full replacements. These professionals use advanced diagnostic tools and cloning techniques to transfer data from a faulty module to a new or refurbished one, preserving the vehicle’s original configurations and avoiding compatibility issues.

Cloning a BCM requires not only technical knowledge but also precision and experience. Experts in this field are adept at handling sensitive electronic components and interpreting complex vehicle wiring diagrams. By carefully replicating the original module’s firmware and data, they ensure the new unit functions exactly as the old one did, restoring the vehicle’s full electrical capabilities. This method is particularly beneficial in situations where replacement modules are hard to find or prohibitively expensive. Rather than replacing the entire system or reprogramming everything from scratch, cloning offers a faster and more cost-effective alternative that minimizes downtime and maintains the car’s factory settings.

Electrical problems related to the BCM can manifest in many ways—flickering lights, malfunctioning door locks, unresponsive dashboard displays, or issues starting the engine. Without proper diagnosis, these symptoms can lead to unnecessary part replacements and high repair bills. Cloning experts are trained to identify the root cause of the problem, distinguishing between software corruption and hardware failure. Once diagnosed, they use high-end equipment to perform secure and accurate data transfers, often within hours. Their efficiency not only saves time but also provides peace of mind, knowing that the vehicle’s functions are being restored with the utmost care.

In today’s era of sophisticated electronics, relying on BCM Cloning & Repairs experts for electrical repairs is a smart decision. Their deep understanding of automotive electronics, combined with hands-on experience and cutting-edge tools, allows them to fix complex issues with precision and reliability. By choosing cloning over traditional replacement methods, vehicle owner’s benefit from a more efficient, less invasive, and often more affordable solution to electrical problems.

0 notes

Text

Beyond the Bulge The Hidden Impact of Inguinal Hernias on Your Quality of Life #qualityoflife #livin

#herniaawareness #fixhernia #hernialife #herniaproblems #inguinalhernia #hiatalhernia #umbilicalhernia #herniarepair #postoplife #healthychoices source

View On WordPress

#abdominal wall reconstruction#Baylor College of Medicine#BCM#complex hernia#complex hernia repair#Dr. David Farley#Dr. Michele Loor#Health Care (Issue)#Healthcare Science (Field Of Study)#hernia#hernia mesh#hernia repair#hernia surgery#hiatal hernia#Houston#incarcerated hernia#incisional hernia#inguinal hernia#laparoscopic#Mayo Clinic#mesh#Saving Lives With Gus#Texas Medical Center#TX#usa#ventral hernia

0 notes

Text

Why do my headlights keep going out?

The following is a systematic analysis and solution based on the problem of frequent headlight extinguishing of your vehicle:

I. Core fault causes 1. Circuit overload causes fuse to blow

Short circuit or overload: Damage to the insulation layer of the wiring harness (such as friction between the wiring harness and metal parts in the engine compartment) will cause a short circuit, or the modification of high-power LED bulbs (such as 100W) exceeds the original circuit design capacity.

Detection method: Use a multimeter to measure the resistance at both ends of the fuse. If it is close to 0Ω, there is a short circuit; if the resistance value is normal but the fuse blows repeatedly, it is necessary to check whether the load exceeds the standard.

2. Relay/switch aging failure

Relay contact adhesion: Long-term current shock causes contact oxidation, and the circuit cannot be disconnected normally, which may cause intermittent power outage of the headlight.

Carbonization of the combination switch: The internal contacts of the headlight switch form high resistance (>5Ω) due to arc erosion, resulting in voltage fluctuations that cause the light to flicker or go out.

3. Poor connector contact

Plug oxidation: When the headlight socket is damp, the metal contacts generate copper oxide (especially in rainy areas), the resistance increases to more than 10Ω, and the current transmission is unstable.

Wiring harness is not connected: The terminal is not tightened during maintenance or the vehicle vibration causes the connector to loosen (common in off-road vehicles), and the measured voltage fluctuation can reach ±3V.

4. Bulb and circuit compatibility issues

Poor quality LED modification: Non-automotive grade LED driver EMC is unqualified, generating high-frequency harmonics to interfere with BCM control signals.

Halogen filament breakage: After the filament is partially melted, it may be briefly overlapped, showing random extinguishing (typical symptoms at the end of life).

II. Diagnostic process and tools Step-by-step troubleshooting table: Step Operation Tool/parameter Normal value range 1 Check fuse specifications and blown state Visual inspection + multimeter Original rated current (usually 10-20A) 2 Measure headlight socket voltage (ignition switch ON) Digital multimeter 11.5-14.2V 3 Shake the wiring harness to observe light changes (simulate vibration interference) Manual test Voltage fluctuation should be <0.5V 4 Replace relay test Relay of the same model Contact resistance <0.1Ω 5 Read BCM fault code OBD-II diagnostic instrument (such as Autel) No U0100/U0155 code

III. Targeted solutions 1. Circuit protection upgrade

Replace slow-blow fuses (such as ATO series), which have a surge current resistance 300% higher than fast-blow fuses.

Install ceramic insulation sleeves to protect the wiring harness in the engine compartment, which can withstand temperatures up to 1000℃.

2. Connection reliability optimization

Replace the original tin-plated plugs with gold-plated terminals, and the contact resistance is reduced to below 0.02Ω.

Apply conductive silicone grease (such as Dow Corning DC-4) in the socket to prevent oxidation and enhance sealing.

3. Control module reset

Perform a hard reset on the BCM: disconnect the negative pole of the battery for 10 minutes to clear the historical fault memory.

Update BCM firmware: Some models (such as Volkswagen after 2018) need to be upgraded to SW026 or above to fix the lighting control BUG.

Fourth, repair costs and suggestions Fault type Typical repair solution Cost range (RMB) Fuse/relay replacement Original spare parts + labor ¥80-200 Wiring harness repair Partial wiring + heat shrink tube insulation ¥300-600 BCM programming 4S shop special equipment matching ¥500-1,200 Full vehicle lighting system detection Diagnostic instrument + load test ¥200-400

Operation warning:

Do not use copper wire instead of fuse, which may cause the wiring harness to melt (case: a car owner caused a cabin fire).

LED modification requires simultaneous upgrade of the cooling system, and it is recommended to choose an integrated assembly with IP67 protection level.

If self-diagnosis fails, it is recommended to use an infrared thermal imager to scan the circuit (abnormal heating points are often the source of the fault), or contact a professional technician to perform oscilloscope waveform analysis (capture power ripple and relay control signals).

#led lights#car lights#led car light#youtube#led auto light#led light#led headlights#led headlight bulbs#ledlighting#young artist#car culture#race cars#classic cars#car#cars#coupe#suv#chevrolet#convertible#supercar#car light#headlight extinguishing#headlight bulb#headlight restoration#headlight#headlamp#car lamp#lamp#lighting#repair

2 notes

·

View notes

Text

How to Fix a Rear Belt Monitor Fault in Your Ford: DIY Solutions That Work

https://autorepairlebanontn.com/?p=3888 How to Fix a Rear Belt Monitor Fault in Your Ford: DIY Solutions That Work Dealing with a rear belt monitor fault in your Ford vehicle can be frustrating and concerning. This warning light typically indicates an issue with your vehicle’s seat belt system, potentially compromising safety features designed to protect you and your passengers. We’ve helped thousands of Ford owners troubleshoot this common problem, and understand how alarming these dashboard warnings can be. Whether you’re experiencing this issue in your F-150, Explorer, or any other Ford model, the good news is that many rear belt monitor faults can be resolved without expensive dealer visits. In this comprehensive guide, we’ll walk you through the causes, diagnostic steps, and proven answers to get your Ford back to optimal safety performance. Table of Contents Toggle Understanding the Rear Belt Monitor System in Ford VehiclesCommon Symptoms of a Rear Belt Monitor FaultWarning Light IndicatorsAudible Alert IssuesCauses of Rear Belt Monitor Failures in Ford ModelsSeat Belt Buckle IssuesElectrical Connection ProblemsSensor MalfunctionsOther Potential CausesDiagnosing a Rear Belt Monitor Fault in Your FordUsing OBD ScannersVisual Inspection MethodsHow to Fix Rear Belt Monitor FaultsDIY Repair OptionsWhen to Seek Professional HelpCost Implications of Rear Belt Monitor RepairsDIY and Basic RepairsProfessional Repair ServicesDiagnostic ToolsComprehensive RepairsFord Models Most Affected by Rear Belt Monitor IssuesConclusionFrequently Asked QuestionsWhat is a rear belt monitor fault in Ford vehicles?What causes rear belt monitor faults in Ford vehicles?How can I diagnose a rear belt monitor fault myself?Can I fix a rear belt monitor fault without going to a dealer?When should I seek professional help for a rear belt monitor fault?How much does it cost to fix a rear belt monitor fault?Which Ford models are most affected by rear belt monitor issues?Is it safe to drive with a rear belt monitor fault warning? Understanding the Rear Belt Monitor System in Ford Vehicles Ford’s rear seat belt monitoring system serves as a crucial safety feature that helps protect passengers by alerting drivers when rear seat belts aren’t properly fastened. This advanced technology forms part of Ford’s comprehensive safety suite, introduced to enhance passenger protection and reduce potential injuries during accidents. The system uses sensors strategically placed throughout the vehicle to detect whether rear seat occupants are properly buckled up. These sensors connect to your vehicle’s main computer system, triggering dashboard alerts when they identify unfastened seat belts. Common alert indicators include a warning light on the instrument panel, chimes, or messages displayed on the information center screen. Most modern Ford models manufactured after 2015 come equipped with this technology, including popular vehicles like the F-150, Explorer, Escape, and Fusion. Ford designed this feature to comply with safety regulations while providing drivers with real-time information about their passengers’ safety status. The rear belt monitor works by: Detecting the presence of passengers in rear seats through weight sensors Monitoring the engagement status of seat belt buckles Sending signals to the vehicle’s Body Control Module (BCM) Displaying appropriate warnings when safety requirements aren’t met Understanding how this system functions helps diagnose potential issues when fault warnings appear. The monitor continuously checks seat belt status and communicates with multiple vehicle systems, making it susceptible to various electronic and mechanical failures that can trigger warning messages. Common Symptoms of a Rear Belt Monitor Fault Ford owners experiencing a rear belt monitor fault typically encounter exact warning signs that indicate issues with the seat belt monitoring system. These symptoms often appear consistently and require attention to ensure proper safety system functionality. Warning Light Indicators Dashboard display warnings constitute the primary visual alert when a rear belt monitor fault occurs. The most common indication is a exact message reading “rear belt monitor fault” or “rear belt monitor fault – service required” prominently displayed on your instrument panel. This warning message usually requires manually pressing an “OK” button to dismiss temporarily, though it frequently reappears shortly afterward, indicating an ongoing issue rather than a one-time glitch. A yellow airbag warning light often accompanies this fault message, further signaling potential problems with the seat belt monitoring system. These visual alerts persist until the underlying issue is addressed, with only temporary relief after acknowledgment. Audible Alert Issues While the primary notification method for rear belt monitor faults is visual, your Ford may produce accompanying audio signals to draw attention to the problem. Though exact audible alerts aren’t extensively documented for this particular fault, Ford vehicles typically emit a beep or chime when dashboard warning messages appear. In some instances, the fault affects additional vehicle systems, such as automatically disengaging cruise control when a driver’s seat belt monitor fault is detected. The underlying cause often relates to problems with the rear seat belt buckles themselves or loose/faulty connectors in the seat belt wiring system. Checking or replacing these components resolves the fault in many cases, restoring proper functionality to your vehicle’s safety monitoring systems. Causes of Rear Belt Monitor Failures in Ford Models The “Rear Belt Monitor Fault” warning in Ford vehicles stems from several key issues within the safety monitoring system. Understanding these common causes helps Ford owners troubleshoot the problem effectively before seeking professional assistance. Seat Belt Buckle Issues Faulty seat belt buckles represent the most frequent cause of rear belt monitor failures in Ford models. Both rear passenger and driver’s seat buckles can trigger this warning when they malfunction. The internal mechanisms within these buckles contain sensors that communicate with the vehicle’s safety system, and when they fail, the system registers an error. Replacing the defective buckle typically resolves the issue completely, restoring proper functionality to the monitoring system. Electrical Connection Problems Electrical connection failures frequently trigger the rear belt monitor fault in Ford vehicles. These problems commonly occur when rear seats are removed for cleaning or modification without properly reconnecting the seat belt plugs. Damaged wiring harnesses or loose connectors can interrupt the signal between the seat belt sensors and the vehicle’s Body Control Module. Inspecting all seat belt connectors for secure connections and signs of physical damage often provides a quick fix for this issue. Sensor Malfunctions Seat belt monitoring systems rely on sophisticated sensors that detect whether belts are fastened correctly. These sensors can deteriorate over time or experience electronic failures that trigger fault warnings. Ford models sometimes exhibit false readings when sensors in the buckles become contaminated with debris or moisture. The driver’s seat buckle sensor occasionally causes system-wide alerts that mistakenly appear as rear belt issues. Diagnosing sensor problems typically requires testing each component individually to identify the exact malfunctioning unit. Other Potential Causes Several additional factors can contribute to rear belt monitor faults in Ford vehicles. Recent software or system updates sometimes create compatibility issues within the safety monitoring network. Physical obstructions preventing seat belts from locking properly might trick sensors into detecting an error condition. Ensuring rear seatbelts remain properly secured when not in use helps prevent unnecessary warnings. BCM (Body Control Module) programming errors occasionally require professional diagnostic equipment to resolve persistent fault messages. Diagnosing a Rear Belt Monitor Fault in Your Ford Diagnosing a rear belt monitor fault in your Ford vehicle requires a systematic approach to identify the root cause. We’ve compiled effective methods to help you troubleshoot this common safety system issue before heading to the dealership. Using OBD Scanners OBD scanners provide valuable diagnostic information when troubleshooting rear belt monitor faults. These tools can help identify general fault codes, though they may not always pinpoint the exact seat belt system issue directly. Standard OBD scanners access basic vehicle information, but for more detailed analysis, Ford-exact diagnostic tools like ForScan offer comprehensive insights into the seat belt monitoring system’s functionality. ForScan can reveal exact fault codes related to the seat belt sensors and connections that generic scanners might miss. Professional diagnosis at a Ford dealership remains beneficial for persistent issues, as dealers have access to advanced diagnostic equipment designed specifically for identifying seat belt monitoring system problems. Visual Inspection Methods Visual inspection serves as the first line of diagnosis for rear belt monitor faults in Ford vehicles. Start by checking if all rear seat belts are properly buckled and locked securely in place—improperly secured belts frequently trigger warning messages. Examine the seat belt buckles carefully, looking for physical damage or debris that might interfere with the sensor contacts. The fault commonly originates from defective buckles, including both rear seat and driver’s seat buckles. Inspect all electrical connectors associated with the rear seat belts, especially if seats have been previously removed or adjusted. Even with seats removed, disconnected wiring can trigger fault messages in the monitoring system. Reconnecting loose wiring or replacing damaged buckles often resolves the issue without requiring dealer intervention. How to Fix Rear Belt Monitor Faults Resolving rear belt monitor faults in Ford vehicles is often achievable through straightforward repairs. Most issues relate to malfunctioning seat belt buckles or incorrect connections that trigger the system warnings. DIY Repair Options Replacing faulty seat belt buckles offers the most effective solution for rear belt monitor faults. Many Ford owners report successfully eliminating the warning by installing a new driver’s seat belt buckle or rear seat buckles. Checking all seat belt connectors ensures they’re properly plugged in, especially if you’ve previously removed or modified rear seats. Disconnected or improperly seated electrical connections commonly trigger these fault messages. Temporary relief might come from simply buckling all rear seatbelts and acknowledging the warning on your dashboard. This method, while not a permanent fix, can temporarily clear the alert until you carry out a more lasting solution. Remember to inspect each buckle for visible damage, debris, or signs of malfunction before replacing components. When to Seek Professional Help Professional assistance becomes necessary when DIY answers don’t resolve persistent rear belt monitor faults. Ford dealerships or certified mechanics possess specialized diagnostic equipment to identify complex issues within the seat belt monitoring system. Vehicles exhibiting recurring faults after buckle replacement likely have deeper electrical or module-related problems requiring expert attention. Diagnostic tools like Forscan allow technicians to access the Restraint Control Module (RCM) for exact error codes. These specialized tools provide detailed information unavailable through basic inspection methods. Parts availability also influences repair approaches – if required components like exact seat belt buckles are on national backorder, dealership service departments can better navigate the procurement process. Software-related issues sometimes emerge after vehicle updates, potentially requiring dealer re-diagnosis to address underlying system incompatibilities. Ford owners who’ve made physical modifications to their vehicles should consult professionals to ensure all electrical connections related to the safety systems remain properly integrated to prevent recurring fault messages. Cost Implications of Rear Belt Monitor Repairs Fixing a rear belt monitor fault in Ford vehicles ranges from affordable DIY answers to more expensive professional repairs. The final cost depends largely on the exact issue causing the fault and your chosen repair approach. DIY and Basic Repairs Basic repairs often present the most economical option for Ford owners. Replacing a faulty seatbelt buckle typically costs around $30 for the part itself, making it an affordable fix if you’re comfortable with simple vehicle maintenance. Minor electrical problems like loose wire connections might cost even less if you already own basic tools and have some technical knowledge. Professional Repair Services Specialized repair services offer a middle-ground option for more complex issues. Companies like Safety Restore provide dedicated seat belt repair services for Ford vehicles at fixed rates between $65-$79.99. These services handle exact problems such as locked or blown retractors without requiring complete replacement of the entire system. Diagnostic Tools Accurate diagnosis forms an essential part of addressing rear belt monitor faults efficiently. An OBD scanner helps identify the exact nature of the problem, with basic models available from $20 while advanced scanners with enhanced capabilities cost $100 or more. This investment often pays for itself by preventing unnecessary repairs and pinpointing the exact issue. Comprehensive Repairs Complex problems involving the vehicle’s airbag system or integrated safety features generally incur higher costs. These situations typically require professional intervention from a Ford dealership or certified mechanic. Labor charges combined with replacement of major components can significantly increase the total repair expense, potentially reaching several hundred dollars for comprehensive answers. Ford Models Most Affected by Rear Belt Monitor Issues The Ford Maverick lineup, particularly 2022 and newer models, frequently experiences rear belt monitor faults. These issues often stem from problematic seat belt buckles or system malfunctions in the rear seat monitoring components. Many Maverick owners report dashboard warnings even though all belts being properly fastened. Ford Bronco Sport vehicles, especially the 2021 Outer Banks trim, commonly display this error message. Interestingly, some Bronco Sport owners discovered the fault originated from the driver’s seat belt buckle rather than the rear belts indicated by the warning. This suggests potential communication issues within the vehicle’s safety monitoring network. Various Ford truck models across different production years share susceptibility to rear belt monitor faults. The problem transcends exact models, indicating a broader issue with Ford’s implementation of safety monitoring systems in their truck lineup. Forum discussions reveal similar experiences among owners of different Ford truck variants. Several consistent causes appear across affected Ford models: Malfunctioning sensors within the seat belt assembly Damaged or loose wiring connections Faulty control modules requiring recalibration Mechanical failures in the seat belt buckle components The prevalence of these issues across multiple Ford models suggests a potential pattern in component sourcing or system design that creates vulnerability to monitoring faults. Identifying your exact Ford model helps in narrowing down the most likely cause and appropriate repair approach. Conclusion Addressing rear belt monitor faults in your Ford vehicle doesn’t have to be intimidating or expensive. With proper diagnosis using OBD scanners or visual inspection techniques we’ve outlined you can often identify the issue yourself. Whether it’s a simple fix like replacing a seat belt buckle or reconnecting loose wiring most problems can be resolved without dealer intervention. For more complex issues involving the RCM or system programming professional help may be necessary. Remember that your vehicle’s safety systems are designed to protect you and your passengers. Taking care of these alerts promptly ensures your Ford continues to provide the protection you expect. By understanding the common causes and answers exact to your model you’ll save time money and maintain your vehicle’s critical safety features. Frequently Asked Questions What is a rear belt monitor fault in Ford vehicles? A rear belt monitor fault is a warning that appears in Ford vehicles when the system that monitors rear seat belt usage detects a problem. This safety feature, present in most Ford models manufactured after 2015, is designed to alert drivers when rear seat belts aren’t properly fastened. When malfunctioning, it typically displays a dashboard warning message and may be accompanied by a yellow airbag warning light. What causes rear belt monitor faults in Ford vehicles? The most common causes include faulty seat belt buckles with malfunctioning sensors, electrical connection problems (often after seat removal), sensor contamination or deterioration, software compatibility issues, physical obstructions affecting seat belt locking, and Body Control Module (BCM) programming errors. The issue is frequently related to problems in the buckles or wiring connectors of the safety monitoring system. How can I diagnose a rear belt monitor fault myself? Start with a visual inspection of rear seat belts to ensure they’re properly buckled. Check buckles and electrical connectors for visible damage or debris. For deeper diagnosis, use an OBD scanner, preferably Ford-specific tools like ForScan, to retrieve error codes related to the seat belt monitoring system. This systematic approach helps identify the root cause before attempting repairs. Can I fix a rear belt monitor fault without going to a dealer? Yes, many rear belt monitor faults can be resolved without a dealer visit. Common DIY repairs include replacing malfunctioning seat belt buckles and ensuring connectors are properly seated. A temporary fix involves buckling all rear seatbelts, though this isn’t a permanent solution. Basic repairs are often straightforward and can be completed with minimal tools. When should I seek professional help for a rear belt monitor fault? Seek professional help if DIY solutions don’t resolve the issue, if the fault is accompanied by multiple warning lights, or if you suspect complex wiring or software problems. Professionals have specialized diagnostic equipment to access the Restraint Control Module (RCM) for precise error codes and can address issues that arise after vehicle updates or those involving integrated safety systems. How much does it cost to fix a rear belt monitor fault? Repair costs vary widely based on the issue. DIY repairs like replacing a faulty seatbelt buckle cost around $30 for parts. Specialized repair services charge fixed rates between $65-$80. Comprehensive repairs involving the airbag system or integrated safety features typically cost several hundred dollars and require professional intervention. Accurate diagnosis is crucial to avoid unnecessary expenses. Which Ford models are most affected by rear belt monitor issues? The 2022+ Ford Maverick and 2021 Bronco Sport are particularly prone to these issues, often due to problematic seat belt buckles or system malfunctions. Various Ford truck models also frequently experience these faults. Common causes across affected models include malfunctioning sensors, damaged wiring, faulty control modules, and mechanical failures in seat belt components. Is it safe to drive with a rear belt monitor fault warning? While you can technically drive with this warning, it indicates a compromised safety system. The vehicle’s ability to monitor rear passenger safety is impaired, which could be critical in an accident. It’s advisable to address the issue promptly, especially if you regularly transport passengers in rear seats. In the interim, ensure all passengers manually buckle up. https://autorepairlebanontn.com/?p=3888 Absolute Auto Repair

0 notes

Text

Emergency Locksmith Encinitas: Why Modern Cars Need Specialized Locksmiths?

If you have been locked out of your car or lost the key fob, your first thought would be to call the emergency locksmith Encinitas. However, calling any locksmith may not help you. In some cases, you might need locksmith to help with advanced vehicles while for other cases you need someone who can reach you immediately. The modern cars possess complex security systems that require professional training to ensure they can work with cutting-edge vehicle technology. Let’s take a look at all the reasons modern cars would require specialized locksmiths and why they provide different services. This will also help you understand why getting in touch with a professional can get you the best service. 1. In case of traditional car keys, you need to consider the mechanical lock alone. However, if you are looking at cars that were manufactured after 2000, you might be working with transponder keys or smart key fobs. These devices communicate with your car’s computer using the radio frequency signals or encrypted chip. In case the communication doesn’t work, the car would not start or unlock. If such a key fob is lost or broken, you cannot get it repaired at the hardware store. You need commercial locksmith Encinitas CA who can program the new transponder keys or replace the smart key fobs. You should also look for a locksmith who is trained to work with the vehicle’s onboard diagnostics system. The professionals have the necessary diagnostic equipment with programming tools that you generally find at the dealerships at an affordable rate. 2. The modern vehicles are very secure, which means you can ensure they are not stolen. However, it becomes a challenge when you are locked out. In some cars, they also provide encrypted immobilizer system that is designed to prevent unauthorized access and hotwiring. These encryptions are designed specific for the brand, and this simply means that every brand has a separate encryption. The professional and specialized locksmiths are updated with the variations and constantly evolve with the software. So, you need someone who is well-versed with accessing or reprograming the encrypted systems without putting your car electronics at risk. 3. A lot of modern cars rely on push-button start or keyless entry that use proximity sensors. You need a trained emergency locksmith Encinitas that can help you when the push start mechanism malfunctions or your key fob doesn’t work. They can diagnose the system failures or reprogram the fob. They can easily reset and replace the onboard security modules as well. In this case, the locksmith will not just help unlock the door, but also ensure the ignition of the vehicle is functioning properly and safely. 4. The different brands work differently and their security protocols are also different. They have their own security protocols, chip technology and programming requirements. In some cases, the professional locksmith would also need manufacturer-specific authorization code. The specialized locksmiths have full authority to the databases, security portals and diagnostic networks. This allows them to access the vehicle PIN and key codes. The locksmiths can also interface with the car’s ECU or BCM.

The commercial locksmith Encinitas CA can help you unlock the door manually and they can ensure speed and cost efficiency as compared to the dealerships.

0 notes

Text

What Makes A2 Cow Milk Better Than Regular Milk?

Milk is an essential part of our daily diet, providing us with calcium, protein, and essential vitamins. However, not all milk is created equal. With growing awareness of health and nutrition, many people are switching from regular milk to A2 cow milk. But what makes A2 cow milk better than regular milk? Let’s dive into the details and explore the differences, focusing on the benefits of A2 milk.

Understanding A2 Milk vs Regular Milk

The primary difference between A2 cow milk and regular milk lies in the type of beta-casein protein they contain. Beta-casein is one of the main proteins found in milk, and it comes in two forms: A1 and A2.

A1 Beta-Casein: Found in regular milk (from Holstein, Jersey, and other hybrid cows), A1 protein has been linked to digestive discomfort and inflammation in some individuals.

A2 Beta-Casein: A2 cow milk, derived from indigenous breeds like Gir cows, contains only the A2 protein, which is easier to digest and considered healthier.

A2 Milk Benefits

1. Easier Digestion

One of the most significant advantages of A2 cow milk is its superior digestibility. Regular milk with A1 protein can produce BCM-7 (Beta-Casomorphin-7) during digestion, which may cause bloating, discomfort, or even lactose intolerance-like symptoms. A2 milk, free from A1 protein, eliminates these issues, making it gentler on the stomach.

2. Nutrient-Rich Composition

A2 milk is packed with essential nutrients like calcium, potassium, and vitamins A, D, and B12. These nutrients promote stronger bones, improved immunity, and better overall health. Additionally, the high protein content supports muscle repair and growth.

3. Improved Heart Health

Studies suggest that A2 milk may reduce the risk of heart-related issues. Unlike A1 milk, which can contribute to inflammation, A2 milk is believed to have anti-inflammatory properties, making it a healthier choice for long-term cardiovascular health.

4. Allergy-Friendly

Many people avoid regular milk due to lactose intolerance or milk allergies. While A2 milk is not lactose-free, it is often better tolerated by those with mild lactose sensitivity due to its natural structure, which closely resembles human milk.

5. Pure and Natural

A2 milk is often sourced from desi (native) cow breeds, ensuring that it is free from harmful additives or chemicals. Brands like Ksheerdham prioritize purity by providing raw, unpasteurized A2 cow milk directly from their farms, preserving its natural nutrients.

Why Should You Switch to A2 Cow Milk?

Switching to A2 cow milk is not just a trend but a step toward better health. If you’ve been experiencing digestion issues, bloating, or discomfort after consuming regular milk, A2 milk might be the solution. Moreover, it’s an excellent choice for families who want to prioritize natural and wholesome nutrition for their loved ones.

Choose Ksheerdham for Pure A2 Milk

At Ksheerdham, we believe in delivering the best of nature to your doorstep. Our A2 Gir cow milk is sourced from happy, healthy cows raised on our own farms. With a commitment to purity, freshness, and quality, we ensure that you and your family receive milk that’s both nutritious and delicious.

Make the switch today and experience the difference of A2 cow milk for yourself. Your health deserves nothing less!

0 notes

Text

CGDI CG100/ CG100X Repair BMW FRM3 Module

How to use CG100 Prog III or CGDI CG100X Programmer to repair BMW FRM3 Footwell module?

Check the details below.

The FRM3 Footwell Module is commonly found in the following vehicles:

BMW: E81, E82, E84, E87, E89, E90, E91, E92, E93, E70, E71, E72 series.

Mini: R55, R56, R57, R58, R59, R60, R61 series.

If the FRM module is faulty, you may encounter these issues:

Light switches do not respond.

Windows fail to go up or down.

Some lights, such as parking lights, remain constantly on.

Indicators stop working.

Interior lights fail to turn on.

How to repair FRM Module by CG100/CG100X?

CG100 and CG100X are excellent tools for repairing BMW FRM modules. While other programmers like VVDI Prog can read and write data, CG100 is specifically designed to repair the module.

Here’s a step-by-step guide:

Open the FRM module and remove the circuit board.

Use a special FRM clip adapter to connect the FRM module to the CG100 programmer.

Alternatively, you can use a CG BMW FRM Solder-free Adapter (recommended) or solder wires manually.

Connect the FRM module to the CG100 using the BDM4 adapter.

In the software, navigate to:

BCM>> BMW>> FRM>> E Series>> 9S12XEQ384 (3M25J)

Confirm the connection and press Start to read the data.

Connect a reliable power supply.

Ensure the voltage remains stable and does not drop.

Successfully read the chip’s D-Flash data.

Save and Repair

Turn off the power supply after reading.

Save the data file when prompted.

The CG100 will ask if you want to repair the FRM module—press “Yes”.

The repair process will begin automatically.

Wait for the process to complete. Do not disconnect during the repair.

Write the repaired EEPROM data back to the FRM module.

The FRM3 module will be successfully repaired and ready to reinstall in the vehicle.

Done!

UK Professional OBD2 Tools Online Shop

0 notes

Text

ECM repair train in India

ECM repair train in India specializes in giving hands-on training in ECM Repair Course In India, vehicle electricals/electronics, key coding, automobile wiring, and all diagnostic methods using cutting-edge oscilloscope and simulator technologies. Our knowledgeable instructors will walk you through the most recent techniques and tools to help you become a proficient specialist in the field of automotive diagnostics and repairs. Join our course and begin your path to a rewarding career in the automotive sector!

Hitech Automotive Skills Developments Academy provides hands-on, in-depth training on the most recent procedures for repairing and diagnosing engine control modules (ECM). Our professional instructors will show you how to utilize oscilloscopes and simulators to diagnose and repair automotive electrical and electronic systems, such as key coding and car wiring. Our course curriculum covers diagnostic methods for all sorts of automobiles, making it necessary training for anybody wishing to develop a career in the automotive business.

ECM Repair Course:

• Sensor Knowledge. • Wiring Checking Sensor Testing. • Scanner Training. • ECM-ECU Component Checking. • Soldering / Desoldering. • ECM-ECU Fault Diagnose. • ECM-ECU On Table. • Practical of ECM. • Fault Code In ECM. • Immobilizer Checking. • ECM Programming/ Software.

Our Training course duration is 60 days and it covers all company ECM modules:

• Car Scanning/Fault code reading & solving the problem case for a clear problem. • Preparing datasheets for ECU output & input voltage pin. • ECM tuning using KTAG for reading and writing. • Training on EPS-BCM-SRS-ABS-Immobilizer-Meter. • Airbag crash programming / Resetting Airbag control unit. • Sensor signal testing using a Digital Oscilloscope. • Complete Soldering Training on the SMD chip level. • Fuel Injection Coding and Testing using a simulator. • Key Programming for ECU/BCM/IMMO. • Testing Power Regulator IC / Driver IC using voltage data sheets. • Basic training skills for the datasheet marketing process. • Providing datasheets for cars ECU. • Car & Commercial ECU / ECM Repair Course Training.

Assured Quality Training & Technical Support for the students who are willing to take the ECM Repair Course Training from Hitech Automotive Skills Developments Academy will get lifetime technical Support

FUTURE SCOPE:- Students who complete our institute's Hitech Automotive Skills Developments Academy training can start their businesses in the Automobile/Car Repair Department, ECM Repair Course, Electrical Repair, Meter Repair Training, BS-6 Car & Truck Repair, and other fields. After training, anyone can be successful in the vehicle field, depending on their firm, region, work profile, and experience.

1 note

·

View note

Text

Achieving ISO 22301 Certification in Australia: A Guide to Workplace Safety

What is ISO 22301 Certification?

ISO 22301 Certification in Australia is the internationally recognized standard for Business Continuity Management Systems (BCMS). It provides a framework to help organizations manage potential disruptions to their operations, ensuring that they can maintain critical functions during unexpected events such as natural disasters, cyber-attacks, or supply chain disruptions. The standard enables businesses to assess potential risks, develop response strategies, and implement recovery plans that minimize operational impact and downtime.

For Australian organizations, ISO 22301 certification is highly valuable due to the country’s susceptibility to natural hazards, economic volatility, and the increasing importance of digital security. ISO 22301 helps businesses ensure resilience, compliance with regulations, and protection for stakeholders and assets, which is essential in today’s dynamic and often unpredictable business landscape.

What are the Benefits of ISO 22301 Certification?

Enhanced Resilience: ISO 22301 Implementation in Australia helps organizations identify risks and develop response strategies that enable them to adapt quickly to disruptions. With a BCMS in place, organizations can protect their operations, maintain critical functions, and reduce the time it takes to recover after a disruption.

Improved Stakeholder Confidence: ISO 22301 certification demonstrates a commitment to business continuity, which reassures clients, partners, and stakeholders that the organization has measures in place to handle unforeseen challenges. This enhances trust and strengthens business relationships.

Regulatory Compliance: Many industries in Australia have regulatory requirements related to business continuity. ISO 22301 certification helps companies meet these regulatory standards, ensuring that they comply with legal obligations and avoid potential fines or penalties.

Competitive Advantage: Certification gives businesses a competitive edge in the market by showcasing their commitment to risk management and continuity. It can make a significant difference when tendering for contracts, particularly with government bodies or larger organizations that value resilience.

Operational Efficiency: Through the development and maintenance of a BCMS, organizations can improve overall operational efficiency. ISO 22301 encourages a proactive approach to identifying potential threats, reducing downtime, and streamlining processes, which contributes to smoother operations.

Reduced Financial Losses: Effective business continuity planning minimizes disruptions that could result in significant financial losses. By preparing for and mitigating risks, businesses can avoid costly shutdowns, repair expenses, and other financial impacts associated with operational downtime.

Cost of ISO 22301 Certification

ISO 22301 Cost in Australia varies depending on factors such as organization size, complexity, and the current level of business continuity preparedness. Generally, the main cost components for achieving ISO 22301 certification include:

Gap Analysis: An initial assessment to determine where the current business continuity practices fall short of ISO 22301 requirements. This stage helps establish a roadmap for achieving compliance.

Consulting Fees: Many organizations engage consultants to guide them through the certification process, which includes designing the BCMS, creating policies, and training staff.

Internal Resource Allocation: The organization may need to assign internal resources for document preparation, training, and the development of new processes.

Audit Fees: Accredited certification bodies charge fees for the certification audit. The audit duration and cost will depend on the complexity of the business operations and size of the organization.

For a small or medium-sized organization in Australia, the overall cost might range from AUD $5,000 to AUD $15,000. Larger companies may incur higher costs, especially if they have complex operations that require extensive planning and support.

ISO 22301 Certification Audit

ISO 22301 Audit in Australia process consists of several stages, typically conducted by an accredited certification body, to evaluate an organization’s compliance with ISO 22301 requirements. Here’s an overview of the audit stages:

Stage 1 – Documentation Review: The auditors review the organization’s business continuity plans, policies, and procedures to assess their alignment with ISO 22301. This stage helps to identify any areas that may require improvement before the onsite audit.

Stage 2 – Onsite Audit: During this phase, auditors visit the organization’s premises to observe the implementation of the BCMS. They interview employees, assess readiness, and verify that business continuity measures are actively maintained and effective.

Audit Report and Non-Conformity Resolution: After the onsite assessment, the auditors provide a report detailing any non-conformities found. The organization must address these areas and provide evidence of corrective actions within a specified timeframe.

Certification Decision: If the organization meets all ISO 22301 requirements, the certification body issues an ISO 22301 certificate, valid for three years. The organization will also undergo annual surveillance audits to ensure continued compliance.

How to Get ISO 22301 Consultants for Certification

Engaging ISO 22301 consultants can streamline the certification process by providing the expertise needed to establish a robust BCMS. Consultants assist with every stage of the certification journey, from initial planning to post-certification support. Here’s how consultants can help:

Conducting Gap Analysis: Consultants perform an initial assessment to identify areas that need improvement. This analysis helps the organization focus on key areas of compliance.

Developing Policies and Procedures: Consultants assist in developing customized business continuity policies, procedures, and response plans that align with ISO 22301.

Training and Awareness: They provide training for employees to ensure they understand the importance of business continuity and their roles in maintaining an effective BCMS.

Audit Preparation: Consultants help organizations prepare for the certification audit by conducting mock audits and ensuring all documentation is complete and aligned with ISO 22301.

To find a qualified ISO 22301 consultant in Australia:

Research and Recommendations: Look for consultants with proven expertise in business continuity and ISO standards. Client testimonials and referrals from industry professionals can be helpful indicators of quality.

Accreditation and Experience: Verify the consultant’s credentials, including experience with ISO 22301 implementation in Australia. Look for consultants with knowledge of local regulations and business continuity practices.

Cost and Scope of Services: Obtain detailed quotes from multiple consultants, and compare their offerings. Some consulting firms offer end-to-end support, from policy development to audit preparation, which may be beneficial for first-time certification seekers.

ISO 22301 Certification Consultants in Australia is a strategic investment for organizations in Australia, helping them build resilience, safeguard operations, and enhance their reputation in business continuity. With the right support from skilled ISO 22301 consultants, businesses can achieve certification efficiently, ensuring they are well-prepared to face unexpected challenges and maintain stability in a rapidly changing environment.

0 notes

Text

HUNGARY’S PIPE FITTING INDUSTRY: NAVIGATING OPPORTUNITIES IN CSŐSZERELŐ ÁLLÁS

Pipefitters [csőszerelő Allás] in Hungary earn an average of HUF 6,985,744 per year and HUF 3,359 per hour. The typical wage range for a Pipefitters [csőszerelő Allás] is HUF 4,980,836 to HUF 8,431,793. This compensation analysis is based on salary survey data obtained directly from employers and anonymous employees in Hungary.

In the heart of Central Europe lies Hungary, a country with a vibrant pipe fitting [Csőszerelő Állás] industry that plays a pivotal role in sectors like construction, manufacturing, and energy. This article aims to explore the intricacies of pipe fitting jobs (Csőszerelő Állás) in Hungary, shedding light on the market dynamics and essential skills required pipe fittier jobs (Csőszerelő Állás) for success.

The Essence of Pipe Fitting [csőszerelő Állás]

Pipe fitting [csőszerelő Allás] is a crucial profession responsible for the installation, maintenance, and repair of piping systems. These systems are the lifelines of various industries, facilitating the seamless transport of fluids, gases, and materials essential for everyday operations. Pipe fitters [csőszerelő Allás ] are the unsung heroes behind these systems, ensuring they function efficiently and reliably.

The Hungarian Pipe Fitting Job [csőszerelő Állás] Market:

Pipe Fitting Job [csőszerelő Allás] Requirements :

To enter the pipe fitting industry [csőszerelő állás] in Hungary, individuals typically require formal qualifications. Vocational training in pipe fitting [csőszerelő állás] or related trades serves as the preferred pathway into this profession. Additionally, technical skills such as blueprint reading, tool usage, and sometimes welding are essential. Physical abilities like strength, stamina, and hand-eye coordination are also crucial, along with soft skills like problem-solving and effective communication.

Pipe fitter [csőszerelő Allás] Qualifications and Skills:

Always pay attention to detail and stay vigilant to ensure safety.

Proficiency in following directions and communicating with coworkers, as well as reading safety warnings and rules.

Ability to master basic computer skills for communicating via email, documenting daily work and progress, and tracking procurements and status.

Education, experience, and license requirements:

Minimum four years of experience in mechanical systems.

Journeyman gas fitting and/or HVAC licenses are desirable.

extensive grasp of codes.

Expertise in pipes for cooling towers, chillers, boilers, and huge rooftop equipment, as well as hydronic and refrigeration operations.

BCM Group Recruitment Services for Pipe fitters [csőszerelő Allás ] in Hungary

BCM Group Recruitment Services specializes in sourcing skilled pipe fitters for a range of industries in Hungary. Whether you’re in need of qualified pipe fitters, we possess the expertise to match you with the perfect talent. Our dedication to excellence guarantees access to top-tier professionals tailored to your precise requirements. We facilitate the recruitment of experienced and proficient workers. Explore our services by visiting our homepage and completing the necessary details. Alternatively, reach out to us via phone or email, and our team will promptly assist you in meeting your recruitment needs.

0 notes

Text

Inguinal vs Femoral Hernias Sorting Out the Similarities and Differences Between Two Groin Troublem

#herniaawareness #fixhernia #hernialife #herniaproblems #inguinalhernia #hiatalhernia #umbilicalhernia #herniarepair #postoplife #healthychoices source

View On WordPress

#abdominal wall reconstruction#Baylor College of Medicine#BCM#complex hernia#complex hernia repair#Dr. David Farley#Dr. Michele Loor#Health Care (Issue)#Healthcare Science (Field Of Study)#hernia#hernia mesh#hernia repair#hernia surgery#hiatal hernia#Houston#incarcerated hernia#incisional hernia#inguinal hernia#laparoscopic#Mayo Clinic#mesh#Saving Lives With Gus#Texas Medical Center#TX#usa#ventral hernia

0 notes

Text

Why would the headlights of your car remain on after the ignition is switched off?

If your car’s headlights remain on after switching off the ignition, it could be due to several factors. Here’s a breakdown of common causes and solutions:

1. Manual Headlight Switch Left "On" • Cause: If the headlight control is set to "On" (not "Auto"), lights may stay on even when the car is off.

• Fix: Turn the switch to "Off" or "Auto." Many modern cars (e.g., Toyota, Honda) have automatic headlights that shut off with the ignition.

2. Delayed Shut-Off (Follow-Me-Home Lights) • Cause: Some cars (e.g., GM, Ford) have a "lighting delay" feature that keeps headlights on for 30–60 seconds after locking the car.

• Fix: Disable this feature via the infotainment settings (e.g., Settings → Lighting → Exit Delay).

3. Faulty Light Sensor (Automatic Headlights) • Cause: A malfunctioning ambient light sensor (e.g., dirty, damaged) may fail to detect darkness and keep lights on.

• Fix: Clean the sensor (usually on the dashboard) or have it recalibrated.

4. Stuck Relay or Wiring Short • Cause: A stuck relay or corroded wiring can keep the headlight circuit energized.

• Test: Swap the headlight relay with another identical one (e.g., horn relay) to see if the issue persists.

• Fix: Replace the relay (cost: $10–$30) or repair damaged wiring.

5. Ignition Switch Failure • Cause: A worn ignition switch may not send a "power off" signal to the headlight circuit.

• Clue: Other systems (radio, power windows) also stay active when the key is removed.

• Fix: Replace the ignition switch (cost: $150–$400).

6. Aftermarket Modifications • Cause: Poorly installed LED kits, alarms, or wiring harnesses can backfeed power to the headlights.

• Example: A miswired trailer hitch or dashcam might keep the circuit live.

• Fix: Inspect aftermarket components and consult an auto electrician.

7. Battery Saver Mode • Cause: Some cars (e.g., Ford, Hyundai) keep lights on temporarily if the battery is critically low.

• Fix: Charge or replace the battery.

8. Software Glitch • Cause: A bug in the Body Control Module (BCM) or firmware can disrupt lighting logic.

• Fix: Update the vehicle’s software at a dealership (e.g., Tesla, BMW).

Troubleshooting Steps

Check the headlight switch position.

Lock the car (many systems shut off lights upon locking).

Disconnect the battery temporarily to reset the system.

Scan for error codes with an OBD2 scanner (look for BCM codes like U0231).

Critical Risks

Dead Battery: Headlights left on overnight can drain the battery (e.g., 55W halogens draw ~5A/hour).

Legal Issues: Some states (e.g., California) prohibit leaving headlights on in parked vehicles.

When to Visit a Mechanic If basic fixes fail, suspect:

Faulty BCM ($500–$1,200 to replace).

Parasitic Drain (use a multimeter to test for >50mA draw after shutdown).

Let me know your car’s make/model for tailored advice! 🚗💡

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car culture#race cars#classic cars#car#cartoon#cars#suv#vehicle#automobile#muscle car#car light#headlight bulb#headlamp#headlight#car lamp#lamp#lights

2 notes

·

View notes

Text

Understanding and Fixing BMW Car Computer Issues: Must-Know Updates and Maintenance Tips

Modern BMW vehicles are marvels of engineering, integrating advanced computer systems that manage everything from engine performance to navigation and safety features. These onboard computers, also known as Electronic Control Units (ECUs), are essential for the smooth operation of your car. However, like any complex system, they can encounter issues that may affect your vehicle's performance, safety, and overall driving experience. This article explores common BMW car computer problems, how to fix them, and essential maintenance tips to keep your vehicle's software up to date.

The Role of Computers in BMW Vehicles

BMW vehicles rely on a network of ECUs, each responsible for controlling specific systems within the car. These include:

Engine Control Module (ECM): Manages engine functions, including fuel injection, ignition timing, and emissions control.

Transmission Control Module (TCM): Controls gear shifts, ensuring smooth and efficient transmission performance.

Body Control Module (BCM): Manages electrical systems like lighting, windows, and locks.

Infotainment System: Handles multimedia functions, navigation, and connectivity features.

Safety Systems: Includes airbags, ABS, and stability control systems, ensuring driver and passenger safety.

Given their integral role, any malfunction in these computer systems can lead to significant issues, ranging from minor inconveniences to serious safety concerns.

Common BMW Car Computer Problems

BMW car computers can develop issues for various reasons, including software bugs, hardware failures, or external factors like voltage fluctuations. Here are some of the most common problems:

Software Glitches and Bugs

Software glitches are a frequent cause of computer problems in BMW vehicles. These can manifest as erratic behavior in the infotainment system, unexpected warning lights, or unresponsive control modules. Often, these issues arise from outdated software or bugs in the current version.

Faulty Sensors

BMW vehicles rely on numerous sensors to monitor everything from engine temperature to wheel speed. If a sensor fails or sends incorrect data, it can cause the associated ECU to malfunction. For example, a faulty oxygen sensor can lead to poor fuel efficiency and increased emissions, while a malfunctioning ABS sensor may compromise braking performance.

Communication Errors

The various ECUs in a BMW communicate with each other through a network called the CAN bus (Controller Area Network). If there’s a communication error, it can cause multiple systems to fail or behave unpredictably. This might manifest as warning lights on the dashboard, malfunctioning electronics, or even engine stalling.

Battery and Power Issues

The ECUs in your BMW require a stable power supply to function correctly. If the battery is weak or there are issues with the alternator, it can cause the computers to behave erratically. Symptoms may include flickering lights, intermittent system failures, or even a complete shutdown of electronic systems.

Hardware Failures

Over time, the hardware components of ECUs can wear out or fail. This could be due to age, exposure to extreme temperatures, or moisture ingress. Hardware failures can lead to permanent loss of functionality in affected systems, requiring repair or replacement of the ECU.

Diagnosing BMW Car Computer Issues

Diagnosing computer problems in a BMW requires specialized equipment and knowledge. Here’s how you can approach the diagnosis:

Use an OBD-II Scanner

An OBD-II (On-Board Diagnostics) scanner is a vital tool for diagnosing computer-related issues. When a problem occurs, the ECU stores a fault code that can be read using a scanner. These codes provide valuable insight into the nature of the issue, allowing for targeted troubleshooting.

Check for Software Updates

BMW regularly releases software updates to fix bugs, improve system stability, and enhance performance. If you’re experiencing issues, checking for and installing any available updates should be one of the first steps. This can often resolve software-related glitches.

Inspect Sensors and Wiring

Faulty sensors or damaged wiring can cause a range of issues. A visual inspection of the sensors and wiring harnesses can help identify any obvious damage or disconnections. In some cases, further testing with a multimeter may be necessary to confirm the sensor’s functionality.

Battery and Alternator Testing

Ensure that your BMW’s battery and alternator are functioning correctly. A weak battery or faulty alternator can cause voltage drops, leading to erratic behavior in the vehicle’s computer systems. A simple battery test or alternator check can help rule out these issues.

Consult a Professional

If you’re unable to diagnose the issue yourself, or if the problem seems complex, it’s advisable to consult a BMW specialist. They have the expertise, tools, and access to BMW-specific diagnostic software to accurately diagnose and repair any computer-related problems.

Fixing BMW Car Computer Issues

Once the issue has been diagnosed, the next step is to address it. Here’s how to fix common BMW car computer problems:

Software Updates

Installing the latest software updates is often the easiest way to resolve glitches and bugs. BMW offers updates through their dealerships, and in some cases, they can be installed via a USB drive or over-the-air (OTA) if your vehicle supports it. Regular updates help ensure that your car’s software remains stable and secure.

Sensor Replacement

If a faulty sensor is identified, replacing it with a new one is essential. Genuine BMW parts are recommended to ensure compatibility and reliability. After replacement, the system may need to be recalibrated to ensure the new sensor functions correctly.

Repairing or Replacing Wiring

Damaged wiring should be repaired or replaced to restore proper communication between ECUs. This might involve soldering broken connections, replacing corroded wires, or installing new wiring harnesses.

Battery and Alternator Replacement

If the battery or alternator is found to be faulty, replacing it with a new unit will restore stable power to the vehicle’s computer systems. It’s essential to choose a battery with the correct specifications for your BMW model to avoid further issues.

ECU Repair or Replacement

In cases where the ECU itself has failed, repair or replacement may be necessary. Some specialized shops can repair ECUs, while in other cases, replacing the unit with a new or refurbished one may be required. After installation, the ECU will need to be programmed to match your vehicle’s specific configuration.

Maintenance Tips to Prevent BMW Car Computer Issues

Preventing computer-related issues in your BMW involves regular maintenance and care. Here are some tips to keep your vehicle’s systems running smoothly:

Regular Software Updates

Keep your BMW’s software up to date by regularly checking for updates. This not only prevents issues but also ensures your vehicle benefits from the latest features and improvements.

Routine Inspections

Regularly inspect the sensors, wiring, and battery to catch potential problems early. Addressing minor issues before they escalate can prevent major system failures.

Proper Battery Maintenance

Maintain your battery’s health by keeping it clean and ensuring the terminals are free from corrosion. If your vehicle is not driven frequently, consider using a battery maintainer to keep it charged.

Use Genuine BMW Parts

When replacing sensors, wiring, or ECUs, always use genuine BMW parts. These parts are designed to work seamlessly with your vehicle’s systems, ensuring reliability and longevity.

Professional Service

Regularly service your BMW at a reputable workshop or dealership. Professional technicians can identify and address issues before they become serious, keeping your car’s computer systems in optimal condition.

Conclusion

BMW vehicles are equipped with sophisticated computer systems that require proper care and attention to function correctly. By understanding common computer-related issues, knowing how to diagnose and fix them, and following essential maintenance tips, you can ensure your BMW continues to deliver the performance and driving experience you expect. Regular updates, timely repairs, and the use of genuine parts are key to keeping your vehicle’s systems running smoothly, allowing you to enjoy the luxury and innovation that BMW is known for.

0 notes

Text

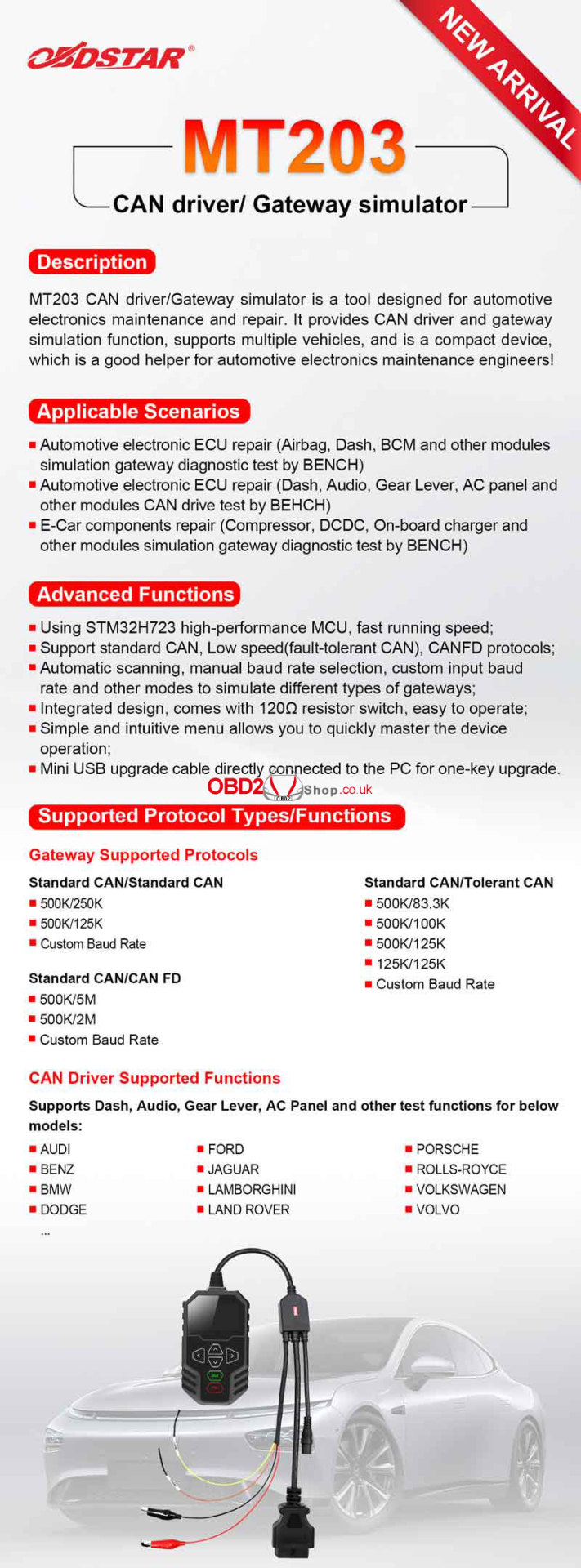

OBDSTAR MT203 CAN Driver/Gateway Simulator Is Coming!

Good news! OBDSTAR MT203 CAN Driver/Gateway Simulator will arrive next month and can accept pre-orders now. It's an automotive electronics maintenance and repair tool to support the dash, audio, gear lever, AC panel, and other test functions. It provides CAN driver and gateway simulation functions for multiple vehicles.

Application Automotive electronic ECU repair(airbag, dash, BCM, and other modules simulation gateway diagnostic test by BENCH) Automotive electronic ECU repair(dash, audio, gear lever, AC panel, and other modules CAN drive test by BENCH) E-Car components repair(compressor, DCDC, on-board charger, and other modules simulation gateway diagnostic test by BENCH)

Advanced Functions Using STM32H723 high-performance MCU, fast running speed; Support standard CAN, low speed(fault-tolerant CAN), CANFD protocols; Automatic scanning, manual baud rate selection, custom input baud rate, and other modes to simulate different types of gateways; Integrated design, comes with 120Ʊ resistor switch, easy to operate; A simple and intuitive menu allows you to master the device operation quickly; Mini USB upgrade cable directly connected to the PC for one-key upgrade.

Supported Protocol Types/Functions Gateway Supported Protocols Standard CAN/Standard CAN 500K/250K 500K/125K Custom Baud Rate

Standard CAN/CAN FD 500K/5M 500K/2M Custom Baud Rate

Standard CAN/Tolerant CAN 500K/83.3K 500K/100K 500K/125K 125K/125K Custom Baud Rate

CAN Driver-Supported Functions Supports dash, audio gear lever, AC panel, and other test functions for the below models: AUDI, FORD, PORSCHE, BENZ, JAGUAR, ROLLS-ROYCE, BMW, LAMBORGHINI, VOLKSWAGEN, DODGE, LAND ROVER, VOLVO...

www.obd2shop.co.uk

0 notes

Text

What is the meaning of PCM in Cars & How it Works?

A Powertrain Control Module (PCM) is a critical electronic component in modern vehicles that manages and controls the powertrain system, which includes the engine and the transmission. The PCM integrates the functions of both the Engine Control Unit (ECU) and the Transmission Control Unit (TCU), ensuring that the engine and transmission work together efficiently to optimize performance, fuel economy, and emissions.

Here are the key functions and features of a PCM:

Engine Control: The PCM monitors and regulates various engine parameters such as air-fuel mixture, ignition timing, idle speed, and emission controls. It uses sensors to collect data on engine conditions and adjusts these parameters to ensure optimal engine performance and compliance with emission standards.

Transmission Control: The PCM controls the shifting of the transmission, ensuring smooth gear changes and proper torque conversion. It adjusts transmission operations based on driving conditions, engine load, and speed to improve vehicle efficiency and performance.

Diagnostic Functions: The PCM continuously monitors the powertrain system for any issues or malfunctions. It stores diagnostic trouble codes (DTCs) that can be read using a scan tool, aiding in the diagnosis and repair of powertrain problems.

Communication: The PCM communicates with other control modules in the vehicle, such as the Body Control Module (BCM) and the Anti-lock Braking System (ABS) module, through a network of sensors and actuators. This communication ensures coordinated operation of various vehicle systems.

Adaptability and Learning: Many PCMs have adaptive learning capabilities, allowing them to adjust to changes in the engine and transmission over time. This helps maintain optimal performance and efficiency as components wear or as driving conditions change.

How the PCM Works

The PCM's operation involves several key processes:

Data Collection:

Sensors: The PCM receives input from various sensors located throughout the vehicle. These sensors monitor a wide range of parameters, including:

Engine temperature

Air-fuel ratio

Throttle position

Oxygen levels in the exhaust

Vehicle speed

Transmission fluid temperature

Knock (detonation) sensor

Manifold Absolute Pressure (MAP) sensor

Mass Air Flow (MAF) sensor

Processing:

Microcontroller: Inside the PCM, a microcontroller processes the incoming data. Using pre-programmed algorithms and real-time inputs, it calculates the optimal settings for both the engine and the transmission.

Lookup Tables: The PCM uses lookup tables and maps stored in its memory to determine the best operational parameters based on the current conditions.

Control Actions:

Engine Management: The PCM adjusts fuel injection timing, ignition timing, and air intake to maintain the ideal air-fuel mixture, ensuring efficient combustion and minimal emissions. It also controls idle speed and variable valve timing if the vehicle is equipped with these features.

Transmission Management: The PCM controls gear shifting, torque converter lockup, and shift timing to provide smooth and efficient power delivery. It adapts shift patterns based on driving conditions and driver behavior to optimize performance and fuel economy.

Feedback Loop:

Continuous Monitoring: The PCM continuously monitors sensor data to ensure the vehicle operates within its optimal parameters. If any readings fall outside of the expected range, the PCM can make immediate adjustments to correct the issue.

Adaptive Learning: Many PCMs have adaptive learning capabilities, which allow them to adjust their control strategies over time based on the wear and tear of components, driving habits, and environmental conditions.

Diagnostics:

Error Detection: The PCM performs self-diagnostic checks and can detect malfunctions or abnormalities in the powertrain system. When it identifies a problem, it stores diagnostic trouble codes (DTCs) in its memory.

Warning Indicators: If a significant issue is detected, the PCM can illuminate warning lights on the dashboard (such as the Check Engine Light) to alert the driver. Technicians can use a diagnostic scanner to read the stored DTCs and pinpoint the source of the problem.

Importance of the PCM

The PCM is crucial for several reasons:

Efficiency: By precisely controlling engine and transmission operations, the PCM helps maximize fuel efficiency.

Performance: It ensures that the engine and transmission work together seamlessly to provide smooth and responsive performance.

Emissions Control: The PCM helps the vehicle comply with emissions regulations by optimizing combustion and controlling exhaust outputs.

Reliability: Continuous monitoring and adaptive learning help maintain the vehicle’s reliability and performance over time.

Overall, the PCM is a sophisticated component that plays a vital role in the modern vehicle's functionality, contributing significantly to the driving experience, vehicle longevity, and environmental compliance.

0 notes