#CFS Design Software

Explore tagged Tumblr posts

Text

Steel Smart System offers innovative CFS Software for cold-formed steel design. Our CFS Design Software enhances efficiency and accuracy, streamlining the design process for construction projects. Empower your team with tools that drive exceptional results in CFS design.

0 notes

Text

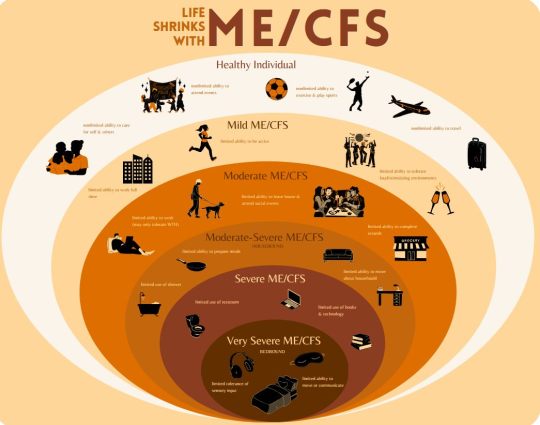

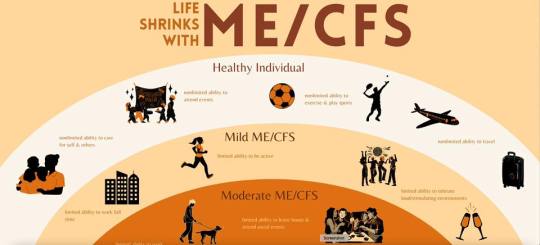

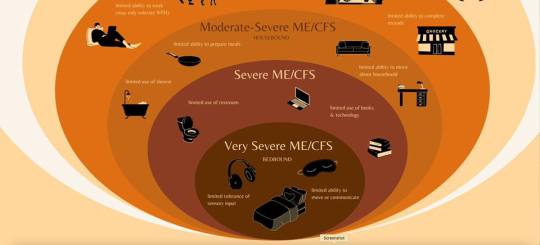

It may be easier to read it this way

Thanks to Laura Scheepers who has written out the text:

The white ring, with 'healthy individual' has - nonlimited ability to care for self and others - nonlimited ability to attend events - nonlimited ability to exercise and play sports - nonlimited ability to traven The yellowish ring with 'mild ME/cfs' say: - limited ability to work full time - limited abilty to be active - limited ability to tolerate loud/stimulating environments The orange ring, with 'moderate ME/cfs' says: - limited ability to work (may only tolerate WFH) - limited ability to leave house and attend social events - limited ability to complete errands The dark orange ring with 'moderate-severe ME/cfs'has housebound as subtitle and says: - limited use of shower - limited ability to prepare meals - limited ability to move about household The red ring with 'severe ME/cfs' says: - limited use of restroom - limited use of books and technology The poopbrown ring with 'very severe ME/cfs' has bedbound as subtitle and says: - limited tolerance of sensory input - limited ability to move and communicate.

36 notes

·

View notes

Text

I’ve been thinking about this for a little while — something I’d want to do if I had the time and money would be to design a Motorola 68000-powered tiny (10” or smaller) laptop. Modern CMOS 68K implementations are very power-efficient and decently well-suited to handheld and portable devices (see: TI-92 series), and if combined with a crisp, modern monochrome OLED display, could get you days of continuous usage without needing a recharge! Add a few megabytes of RAM, some peripherals (IDE/CF controller, ISA or S-100 slots, DMA controller, SPI bus, RS-232 port, SD or CF slot, PS/2 port for a mouse, text mode + hires monochrome video card, etc…), and you have a nice, flexible system that can be rarely charged, doesn’t require ventilation, and can be just thick enough to fit the widest port or slot on it.

The main issue would be software support: nearly all existing operating systems that ran on a 68K were either intended for very specific hardware (Classic Mac OS, AmigaOS) or required more than a flat 68000 (NetBSD, Linux, or any other UNIX requiring MMU paging). So, it would probably end up being a custom DOS with some multitasking and priv level capability, or perhaps CP/M-68K (but I don’t know how much software was ever written for that — also, it provides a “bare minimum” hardware abstraction of a text-mode console and disk drive). A custom DOS, with a nice, standard C library capable of running compiled software, would probably be the way to go.

The software question perhaps raises another, harder question: What would I use this for? Programming? Then I’d want a text editor, maybe vi(m) or something like that. OK. Vim just needs termcap/(n)curses or whatever to draw the text, and not much else. That’s doable! You’d just need to provide text-mode VT100 emulation and termcap/curses should “just work” without too much issue. I like writing C, so I’d need a compiler. Now, I’m assuming this simplistic operating system would be entirely written in a combination of assembly language (to talk to hardware and handle specific tasks such as switching processes and privilege management and whatnot) and C (to handle most of the logic and ABI). I could probably cross-compile GCC and be good to go, aside from handling library paths and executable formats that don’t comply with POSIX (I have no intention of making yet another UNIX-like system). Hopefully, most other command-line software (that I actually use) will follow suit without too much trouble. I don’t know how much work it is to get Python or Lua to a new platform (though NetBSD on the 68K already supports both), but Python (or Lua) support would bring a lot of flexibility to the platform. Despite me being a Python hater, I must admit it’s quite an attractive addition.

What about graphics? All the software I’ve mentioned so far is text-mode only, yet historical 68K-based systems like the Mac and Amiga had beautiful graphics! Implementing X11 would be a massive pain in the ass, considering how much it relies on UNIXy features like sockets (not to mention the memory usage), and I really don’t want Wayland to have anything to do with this. I guess I’d have to roll my own graphics stack and window manager to support a WIMP interface. I could copy Apple’s homework there: they also made a monochrome graphics interface for a M68K configured with a handful of MiB of RAM. I could probably get a simple compositing window manager (perhaps make it tiling for a modern vibe ;3). Overall, outside of very simple and custom applications, functionality with real software would be problematic. Is that a big problem? Maybe I want an underpowered notebook I can put ideas and simple scripts down on, then flesh them out more fully later on. An operating system allowing more direct access to the hardware, plus direct framebuffer access, could yield some pretty cool graphing/basic design utility.

I’d need a way to communicate with the outside world. An RS-232 UART interface, similar to the HP-48 calculator (or the TI-92’s GraphLink, only less proprietary) would help for providing a remote machine language monitor in the early stages, and a real link to a more powerful (and networked) machine later on. I think real networking would defeat the purpose of the machine — to provide a way to remove yourself from modern technology and hardware, while retaining portability, reliability, and efficiency of modern semiconductor manufacturing techniques. Giving it a CF or SD slot could provide a nice way to move files around between it and a computer, maybe providing software patches. A floppy drive would be amazing: it would provide a way to store code and text, and would be just about the right storage size for what I want to do. Unfortunately, there’s not really a good way to maintain the size of the laptop while sticking a 3.5” (or worse, 5.25”) floppy drive in the middle of it. To my knowledge, 3.5” floppy drives never got thin enough to properly fit with all the other expansion slots, socketed components, and user-modifiable parts I’d want. A completely solid-state design would likely be the best option.

Anyway, uhh… I hope this made some semblance of sense and I don’t sound insane for going on a rant about building a modern computer with a 1979 CPU.

5 notes

·

View notes

Text

youtube

Yesterday I saw a few people interested in 3D printers, and then I just saw this video explaining the issues with really cheap 3D printers, and how you can upgrade them with lots of time and money to work properly. That absolutely matches my experience. My first 3D printer was a 150€ machine, not quite as crappy as the one in this video, but still full of flaws and issues and things that didn't work well. I later bought the Bambu Lab A1 mini, also recommended in this video, and it's been problem-free. I don't like recommending a single product like that, but in my experience it really does work that well. I'm sure you can get others that aren't bad as well, but when it comes to price and performance and ease of use, it genuinely seems to be the best option right now.

So a quick buyer's guide if you're interested in that particular model.

First up, watch out for sales. The official price is like 320€ for an A1 mini, but in practice there are usually sales that drop the price to 199€. Don't pay more than that.

Second, they sell multiple printers, but for beginners the interesting ones are the A1 and A1 mini. The A1 is bigger and can print bigger parts, for around 150€ more; apart from that they're basically identical. I got the smaller one and am perfectly happy with it. Instead you can put that money into…

The AMS (Automated Material System), a thing you put next to the printer that can feed it material in different colours. It's included in several bundles, on the Bambu Lab website you specifically need to deselect it to not get it. This is the printer's main party trick, because it can print multiple colours (up to four) at once. This feature isn't actually that great, because on every layer it dumps a bit of the old material and then sucks in new ones, so multicolour prints take forever and produce a lot of scrap material. But you can do them at all, which is great. It's how I printed this D20 for my sister. Can you spot the special feature that she hasn't yet?

And it's useful to swap materials between different prints quickly. E.g. you want to print a gearbox and it takes several tries, but you can change the colours between each iteration so you don't get confused which is the new and old part. I've bought the AMS, I'm happy with it, but if money were tight this would be the first thing I'd get rid of. Note that for the A1 printers, you need the AMS lite, that's the one included in the bundles.

Print material (filament). Bambu Lab sells some, it's good. Lots of other companies sell some and those are also good, there's basically no advantage here, but Bambu Lab sells it for relatively cheaply if you order it with the printer. If you don't know material what you want or need (yet), you'll want PLA in different colours. Note that silk PLA needs to be treated differently (your printer and its software know about that, but you need to tell them you're using silk PLA). PLA-CF or glow-in-the-dark PLA also have special properties that require special handling.

Other additions: A smooth build plate is a nice thing to have for either very small things or things that need to be smooth. Different hot-ends can be useful; you need the hardened ones for PLA-CF or glow-in-the-dark PLA and some other materials; ones with a higher diameter print faster, ones with a lower diameter print more precisely. Glue: I've never used that for anything. These aren't things you need right away, but you do get a bit of a discount if you do order them with the printer.

Obviously I do need to tell you that this is literally a machine for producing plastic trash, there's no way around that. And while you can use the printer offline (or so I heard, I haven't tried it), it's mostly designed to be used with the Chinese manufacturer's cloud service, which does not make me super-happy. Also, the resolution for really tiny stuff is limited; if you want to build e.g. model trains, then you should really get a resin printer, but everything I heard about the chemicals and post-processing and so on there scares me, so I haven't yet. But if you are interested in 3D printing and want to get one for yourself, this is, as of right now, the thing I'd recommend.

15 notes

·

View notes

Text

Three-phase Independent Adjustable RCD Nonlinear Load Bank

The three-phase independent adjustable RCD nonlinear load bank is designed to accurately test and evaluate power systems under diverse load conditions. Its ability to independently adjust each phase ensures precise simulation of real-world scenarios, enhancing the reliability and performance of generators and UPS systems. This advanced load bank accommodates nonlinear loads, making it ideal for testing modern power equipment and ensuring compliance with industry standards.

Product Description:

Ensure your power systems meet peak performance with the three-phase independent adjustable RCD nonlinear load bank. Whether testing inverters or conducting UPS load tests, its comprehensive capabilities provide unparalleled reliability and data accuracy. Ideal for both lab and field applications, this load bank is your trusted partner in safeguarding critical power infrastructure, offering precise control and robust performance for demanding testing requirements.

Product Features&Advantage:

1.Suitable for testing inverters and UPS loads.

2.Includes upper computer operating software, compatible with ATE special envoy.

3.Equipped with RS485, Ethernet, CAN, and other communication ports.

4.Features programmable test steps, ideal for automatic testing of photovoltaic and energy storage inverters.

5.Capable of loading any power within the full power range.

6.Power adjustment precision: as low as 10W.

7.Power factor adjustment: as low as 0.45.

8.Peak factor CF: up to 3.

9.Customizable for a wide voltage range.

10.Utilizes PC data management software to control load operations and save test data.

EMAX load bank stands at the forefront of the power testing industry, providing high-quality load banks designed to meet various industrial needs. Delivered worldwide to ensure that global customers can use our advanced solutions

2 notes

·

View notes

Text

Revolutionizing Terminal Efficiency with Envision CTOS: The Future of Smart Container Terminal Operations

In the hyper connected economy of today, the seamless functioning of container terminals is crucial for economic momentum, trade, and logistics. From inland depots to giant international ports, cargo movement both in terms of quantity and complexity has grown manifold.

In the midst of these issues, Envision Enterprise Solutions brings forth a revolution in products: Envision CTOS — a next-generation Container Terminal Operating System (CTOS) designed to integrate intelligent automation, real-time visibility of containers, and automated terminal orchestration.

@EnvisionEnterpriseSolutions

This blog explores the full potential of Envision CTOS, explains its technological framework, breaks down core features, and offers a comprehensive competitor analysis. It also answers the most common questions about terminal operations and highlights why Envision CTOS stands out in the market.

What is a Container Terminal Operating System (CTOS)?

A Container Terminal Operating System (CTOS) is an electronic system that controls and automates the complex processes in seaports, inland terminals, and depots. Its function extends to scheduling, container transport, resource allocation, documentation, and performance monitoring.

The key subsystems of a modern CTOS include:

Container Yard Management System

Depot Management System (DMS)

Container Freight Station (CFS) Software

Automated Gate System

Yard Truck Management System

Vessel Planning and Optimization

Container Tracking Software

Without a central CTOS, terminals will experience congestion, manual mistakes, poor resource utilization, and low profitability. Real-time visibility, intelligent scheduling, and active exception handling are no longer discretionary items in today's logistics universe; they are essential for survival in competition.

What is Envision CTOS?

Envision CTOS is a next-generation Container Terminal Operating System developed by Envision Enterprise Solutions. Created for the changing needs of container logistics, Envision CTOS combines real-time visibility, smart automation, and mobile-first design into one powerful platform.

With modular flexibility, it can serve both large global ports and small inland container depots (ICDs), allowing for fast digital transformation without regard to terminal size or complexity. With an emphasis on configuration over customization, the solution enables faster deployments and significantly reduces the total cost of ownership.

Core Features of Envision CTOS

1. Container Yard Management System

The container yard management system in Envision CTOS utilizes AI and rule-based automation to manage yard storage space and container allocation. It optimizes space usage and positions containers in a way that reduces rehandling and dwell time.

Yard visualization technology offers a heatmap view of container density, enabling planners to make informed decisions based on data.Real-time updates also allow for rapid response to vessel schedule changes and truck arrival fluctuations.

2. Depot Management System (DMS)

The integrated depot management system (DMS) simplifies operations for empty container depots, managing inspection, repair, release, and repositioning. Real-time inventory updates improve coordination with carriers and leasing companies.

It also provides mobile functionality for surveyors to capture repair images and upload damage reports directly from their handheld devices.

3. Container Freight Station (CFS) Software

The CFS software in Envision CTOS streamlines operations for both LCL and FCL cargo. Automated invoicing, electronic documentation, and cargo tracking reduce paperwork, delays, and customer complaints.

It also integrates with customs clearance systems to ensure faster regulatory processing, thus reducing detention charges and improving cargo turnover.

4. Automated Gate System

Envision’s automated gate system uses OCR and RFID to reduce gate wait times and eliminate manual checks. Integration with weighbridges and container scanners ensures compliance and security.

Self-service kiosks and appointment scheduling features help reduce congestion and improve customer satisfaction.

5. Container Tracking Software

Live dashboards powered by GPS and IoT form the backbone of Envision’s container tracking software, helping operators trace containers across their journey—from vessel to yard, depot, or consignee.

Alerts, geofencing, and ETA predictions ensure better coordination among stakeholders.

6. Yard Truck Management System

The yard truck management system in Envision CTOS optimizes internal truck movements with real-time task assignments, reducing idle time and fuel usage. It includes performance metrics and geofencing alerts.

Fleet operators receive detailed insights into driver productivity, turnaround times, and equipment maintenance schedules.

7. Vessel Planning and Optimization

Terminal efficiency begins with smart vessel planning. Envision CTOS ensures optimal crane split, berth scheduling, and stowage planning, powered by analytics for continuous improvement.

The module supports real-time updates on vessel ETAs and prioritizes container discharging and loading based on delivery windows and truck arrivals.

Mobile Accessibility: Work from Anywhere

Envision CTOS is built with mobile-first architecture. Supervisors, truck drivers, equipment operators, and depot staff can access real-time updates, assign or accept tasks, and monitor KPIs on smartphones or tablets.

Mobile Highlights:

Mobile dashboards for yard operations

Task approvals, maintenance logs, and checklists

E-token generation for gate-in/out processes

Offline support for operations in low-connectivity zones

Whether in the yard, on a crane, or at a remote depot, Envision’s mobile capability ensures no user is disconnected from operations.

Integration Capabilities of Envision CTOS

Envision CTOS is designed to integrate effortlessly into your terminal’s digital ecosystem.

Supported Integrations:

ERP Systems: SAP, Oracle, Microsoft Dynamics

PCS Systems: Port Community Systems for stakeholder coordination

Customs Portals: Auto-submission of import/export documents

Shipping Line Interfaces: EDI/API-based communications

IoT Sensors: Temperature, weight, GPS, vibration, and tamper sensors

These integrations help terminals eliminate silos, accelerate customs clearance, and improve transparency across the logistics chain.

Frequently Asked Questions About Envision CTOS

Q1: Is Envision CTOS cost-effective for mid-sized operators?

Yes. Envision CTOS offers modular deployment and competitive pricing. It can be tailored to your terminal’s size and complexity without incurring excessive costs.

Q2: How long does implementation take?

Typical implementation takes 8–12 weeks for mid-sized terminals. Larger, more complex environments may require phased rollouts.

Q3: What technologies power Envision CTOS?

The platform is powered by cloud-native architecture, AI-driven algorithms, microservices, and real-time analytics. It’s designed for high availability, redundancy, and global scalability.

Real-World Use Cases of Envision CTOS

Inland Container Depot (ICD) Transformation

A leading ICD in South Asia adopted Envision CTOS and witnessed a 38% improvement in gate throughput and 25% increase in yard utilization. The depot management system (DMS) module automated container maintenance scheduling, eliminating paper-based workflows.

Coastal Port Automation

A regional coastal port implemented Envision’s full CTOS suite, integrating vessel planning and optimization, yard truck management, and automated gate system modules. Result: a 40% reduction in vessel turnaround time and 50% faster gate processing.

Dry Port Efficiency Boost

A dry port handling over 300,000 TEUs per year deployed Envision CTOS and reduced container misplacements by 70% using the container tracking software and real-time yard mapping. Stakeholders praised the improvement in turnaround and transparency.

Competitor Analysis: Where Envision CTOS Stands Out

1. Navis N4

Strengths: Feature-rich, widely adopted.

Weaknesses: High licensing costs, slower deployment.

Envision CTOS Advantage: Lower TCO, faster go-live, better for hybrid cloud.

2. Tideworks Technology

Strengths: Modular tools.

Weaknesses: Limited flexibility in emerging markets.

Envision CTOS Advantage: Agile customization and mobile-enabled workflows.

3. CyberLogitec OPUS Terminal

Strengths: Strong documentation workflows.

Weaknesses: Limited support in South America, Africa.

Envision CTOS Advantage: Global 24/7 support and adaptable localization.

4. RBS TOPS

Strengths: Good for small terminals.

Weaknesses: Outdated UX, scaling issues.

Envision CTOS Advantage: Intuitive interface, scalable cloud deployment.

Envision CTOS is purpose-built for terminals seeking enterprise-grade functionality with startup-like agility.

Why Choose Envision CTOS?

Envision CTOS is more than a system—it’s a growth enabler.

Key Benefits:

Unified Platform: Integrates yard, gate, vessel, and depot operations.

Mobile and Cloud-First: Built for modern workflows.

Data-Driven Decision-Making: Advanced reporting and predictive analytics.

AI-Powered Automation: From crane scheduling to truck routing.

Enterprise-Grade Security: GDPR, ISO, and SOC compliance.

Faster ROI: Deploy, train, and gain within weeks—not months.

The Future of Container Terminal Automation

As the maritime logistics landscape embraces container terminal automation, stakeholders demand smarter, faster, and leaner solutions. Terminals must transition from fragmented software environments to integrated ecosystems. Envision CTOS helps operators do just that—by unifying key terminal processes in a future-ready platform.

The push toward sustainable, green port operations also underscores the value of digital solutions like Envision CTOS. Fewer truck idling times, better resource utilization, and paperless documentation contribute to environmental targets and regulatory compliance.

Conclusion: Embrace the Intelligent Terminal with Envision CTOS

Whether you manage a container freight station (CFS), operate a busy inland container depot (ICD), or run a complex coastal port, Envision CTOS transforms operations from reactive to proactive. It offers unmatched functionality across container yard management, vessel planning, tracking, and terminal automation — all while being scalable, secure, and mobile-ready.

If your goal is to modernize operations, increase throughput, reduce delays, and gain full control of terminal logistics, Envision CTOS is the strategic solution for you.

Take the Next Step Toward Terminal Excellence

Contact Envision Enterprise Solutions today to book a demo, schedule a consultation, or explore how Envision CTOS can become the foundation of your digital terminal transformation.

Envision CTOS – Automate Intelligently. Operate Efficiently. Grow Sustainably.

#ai powered port management#artificial intelligence#ports#ai powered automation#management#maritime#logistics#container#smartports#envision#CTOS#envision CTOS

0 notes

Text

Envision CTOS: The Future of Smart Container Terminal Operations

In the hyper connected economy of today, the seamless functioning of container terminals is crucial for economic momentum, trade, and logistics. From inland depots to giant international ports, cargo movement both in terms of quantity and complexity has grown manifold.

In the midst of these issues, Envision Enterprise Solutions brings forth a revolution in products: Envision CTOS — a next-generation Container Terminal Operating System (CTOS) designed to integrate intelligent automation, real-time visibility of containers, and automated terminal orchestration.

This blog explores the full potential of Envision CTOS, explains its technological framework, breaks down core features, and offers a comprehensive competitor analysis. It also answers the most common questions about terminal operations and highlights why Envision CTOS stands out in the market.

What is a Container Terminal Operating System (CTOS)?

A Container Terminal Operating System (CTOS) is an electronic system that controls and automates the complex processes in seaports, inland terminals, and depots. Its function extends to scheduling, container transport, resource allocation, documentation, and performance monitoring.

The key subsystems of a modern CTOS include:

Container Yard Management System

Depot Management System (DMS)

Container Freight Station (CFS) Software

Automated Gate System

Yard Truck Management System

Vessel Planning and Optimization

Container Tracking Software

Without a central CTOS, terminals will experience congestion, manual mistakes, poor resource utilization, and low profitability. Real-time visibility, intelligent scheduling, and active exception handling are no longer discretionary items in today's logistics universe; they are essential for survival in competition.

What is Envision CTOS?

Envision CTOS is a next-generation Container Terminal Operating System developed by Envision Enterprise Solutions. Created for the changing needs of container logistics, Envision CTOS combines real-time visibility, smart automation, and mobile-first design into one powerful platform.

With modular flexibility, it can serve both large global ports and small inland container depots (ICDs), allowing for fast digital transformation without regard to terminal size or complexity. With an emphasis on configuration over customization, the solution enables faster deployments and significantly reduces the total cost of ownership.

Core Features of Envision CTOS

1. Container Yard Management System

The container yard management system in Envision CTOS utilizes AI and rule-based automation to manage yard storage space and container allocation. It optimizes space usage and positions containers in a way that reduces rehandling and dwell time.

Yard visualization technology offers a heatmap view of container density, enabling planners to make informed decisions based on data.Real-time updates also allow for rapid response to vessel schedule changes and truck arrival fluctuations.

2. Depot Management System (DMS)

The integrated depot management system (DMS) simplifies operations for empty container depots, managing inspection, repair, release, and repositioning. Real-time inventory updates improve coordination with carriers and leasing companies.

It also provides mobile functionality for surveyors to capture repair images and upload damage reports directly from their handheld devices.

3. Container Freight Station (CFS) Software

The CFS software in Envision CTOS streamlines operations for both LCL and FCL cargo. Automated invoicing, electronic documentation, and cargo tracking reduce paperwork, delays, and customer complaints.

It also integrates with customs clearance systems to ensure faster regulatory processing, thus reducing detention charges and improving cargo turnover.

4. Automated Gate System

Envision’s automated gate system uses OCR and RFID to reduce gate wait times and eliminate manual checks. Integration with weighbridges and container scanners ensures compliance and security.

Self-service kiosks and appointment scheduling features help reduce congestion and improve customer satisfaction.

5. Container Tracking Software

Live dashboards powered by GPS and IoT form the backbone of Envision’s container tracking software, helping operators trace containers across their journey—from vessel to yard, depot, or consignee.

Alerts, geofencing, and ETA predictions ensure better coordination among stakeholders.

6. Yard Truck Management System

The yard truck management system in Envision CTOS optimizes internal truck movements with real-time task assignments, reducing idle time and fuel usage. It includes performance metrics and geofencing alerts.

Fleet operators receive detailed insights into driver productivity, turnaround times, and equipment maintenance schedules.

7. Vessel Planning and Optimization

Terminal efficiency begins with smart vessel planning. Envision CTOS ensures optimal crane split, berth scheduling, and stowage planning, powered by analytics for continuous improvement.

The module supports real-time updates on vessel ETAs and prioritizes container discharging and loading based on delivery windows and truck arrivals.

Mobile Accessibility: Work from Anywhere

Envision CTOS is built with mobile-first architecture. Supervisors, truck drivers, equipment operators, and depot staff can access real-time updates, assign or accept tasks, and monitor KPIs on smartphones or tablets.

Mobile Highlights:

Mobile dashboards for yard operations

Task approvals, maintenance logs, and checklists

E-token generation for gate-in/out processes

Offline support for operations in low-connectivity zones

Whether in the yard, on a crane, or at a remote depot, Envision’s mobile capability ensures no user is disconnected from operations.

Integration Capabilities of Envision CTOS

Envision CTOS is designed to integrate effortlessly into your terminal’s digital ecosystem.

Supported Integrations:

ERP Systems: SAP, Oracle, Microsoft Dynamics

PCS Systems: Port Community Systems for stakeholder coordination

Customs Portals: Auto-submission of import/export documents

Shipping Line Interfaces: EDI/API-based communications

IoT Sensors: Temperature, weight, GPS, vibration, and tamper sensors

These integrations help terminals eliminate silos, accelerate customs clearance, and improve transparency across the logistics chain.

Frequently Asked Questions About Envision CTOS

Q1: Is Envision CTOS cost-effective for mid-sized operators?

Yes. Envision CTOS offers modular deployment and competitive pricing. It can be tailored to your terminal’s size and complexity without incurring excessive costs.

Q2: How long does implementation take?

Typical implementation takes 8–12 weeks for mid-sized terminals. Larger, more complex environments may require phased rollouts.

Q3: What technologies power Envision CTOS?

The platform is powered by cloud-native architecture, AI-driven algorithms, microservices, and real-time analytics. It’s designed for high availability, redundancy, and global scalability.

Real-World Use Cases of Envision CTOS

Inland Container Depot (ICD) Transformation

A leading ICD in South Asia adopted Envision CTOS and witnessed a 38% improvement in gate throughput and 25% increase in yard utilization. The depot management system (DMS) module automated container maintenance scheduling, eliminating paper-based workflows.

Coastal Port Automation

A regional coastal port implemented Envision’s full CTOS suite, integrating vessel planning and optimization, yard truck management, and automated gate system modules. Result: a 40% reduction in vessel turnaround time and 50% faster gate processing.

Dry Port Efficiency Boost

A dry port handling over 300,000 TEUs per year deployed Envision CTOS and reduced container misplacements by 70% using the container tracking software and real-time yard mapping. Stakeholders praised the improvement in turnaround and transparency.

Competitor Analysis: Where Envision CTOS Stands Out

1. Navis N4

Strengths: Feature-rich, widely adopted.

Weaknesses: High licensing costs, slower deployment.

Envision CTOS Advantage: Lower TCO, faster go-live, better for hybrid cloud.

2. Tideworks Technology

Strengths: Modular tools.

Weaknesses: Limited flexibility in emerging markets.

Envision CTOS Advantage: Agile customization and mobile-enabled workflows.

3. CyberLogitec OPUS Terminal

Strengths: Strong documentation workflows.

Weaknesses: Limited support in South America, Africa.

Envision CTOS Advantage: Global 24/7 support and adaptable localization.

4. RBS TOPS

Strengths: Good for small terminals.

Weaknesses: Outdated UX, scaling issues.

Envision CTOS Advantage: Intuitive interface, scalable cloud deployment.

Envision CTOS is purpose-built for terminals seeking enterprise-grade functionality with startup-like agility.

Why Choose Envision CTOS?

Envision CTOS is more than a system—it’s a growth enabler.

Key Benefits:

Unified Platform: Integrates yard, gate, vessel, and depot operations.

Mobile and Cloud-First: Built for modern workflows.

Data-Driven Decision-Making: Advanced reporting and predictive analytics.

AI-Powered Automation: From crane scheduling to truck routing.

Enterprise-Grade Security: GDPR, ISO, and SOC compliance.

Faster ROI: Deploy, train, and gain within weeks—not months.

The Future of Container Terminal Automation

As the maritime logistics landscape embraces container terminal automation, stakeholders demand smarter, faster, and leaner solutions. Terminals must transition from fragmented software environments to integrated ecosystems. Envision CTOS helps operators do just that—by unifying key terminal processes in a future-ready platform.

The push toward sustainable, green port operations also underscores the value of digital solutions like Envision CTOS. Fewer truck idling times, better resource utilization, and paperless documentation contribute to environmental targets and regulatory compliance.

Conclusion: Embrace the Intelligent Terminal with Envision CTOS

Whether you manage a container freight station (CFS), operate a busy inland container depot (ICD), or run a complex coastal port, Envision CTOS transforms operations from reactive to proactive. It offers unmatched functionality across container yard management, vessel planning, tracking, and terminal automation — all while being scalable, secure, and mobile-ready.

If your goal is to modernize operations, increase throughput, reduce delays, and gain full control of terminal logistics, Envision CTOS is the strategic solution for you.

Take the Next Step Toward Terminal Excellence

Contact Envision Enterprise Solutions today to book a demo, schedule a consultation, or explore how Envision CTOS can become the foundation of your digital terminal transformation.

Envision CTOS – Automate Intelligently. Operate Efficiently. Grow Sustainably.

#ai powered solutions#container#ctos#envision#operating systems#terminals#artificial intelligence#envision CTOS

0 notes

Text

Nagra V Upgrade package

For the users that are bold enough to do this upgrade I am offering packages that include everything you need to make it into reality.

For the working audio professional, it will save you a little height and weight in your cart or bag. Thanks to the CF media, there will be no moving parts inside the machine, and it will simplify your workflow. You can mount wireless receivers on top of the unit to take up the extra space of the previous cover in the original bag.

For the hi-fi enthusiast, the new lid and backpack design complement the look of other Nagra components while still keeping its road-ready tough look.

To order any of these packages, please contact me.

To know more about this upgrade visit these links:

Go to Part 1

Go to Part 2

Go to Part 3. [Coming Soon]

Nagra V product page

Download Nagra V product documentation and the NavCom software here

Manufacturing and lead times

The lid, backpack, and handle parts will be CNC machined by XY Global and are made-to-order. The machining will take about 2 weeks.

The good thing about made-to-order parts is that it allows the customers to choose the materials, color, and logo placement/ removal for each of these components. Some processes may need to have an extra charge. Contact me for any inquiries.

I will personally check each part for quality and test each part on my own unit before I ship to you and photos will be taken and sent to you at every step.

Here are the options:

Option 1- CF Upgrade (no Twin Drive) US$500

Package contents:

1- Lid with CF reader

1- Backpack assembly

2- Custom white POM washers

1- Custom hand-made IDE cable

1- Low profile 90 degree 15-pin (DB15) connector

1- Low profile 4-pin connector and coiled cable with pigtail end (power cable)

1- Plastic spudger

1- Utek UT-890A USB to RS422 adapter

1- DB9 custom cable 30cm

Option 2- Twin Drive Upgrade US$550

**This option is only for units with V3.0 or higher

1- Lid (with CF reader)

1- Backpack assembly

2- Custom white POM washers

1- Custom hand-made IDE cable

1- FR4 board with CF reader

4- Screw stands

1- Low profile 90 degree 15-pin (DB15) connector

1- Low profile 4-pin connector and coiled cable with pigtail end (power cable)

1- Plastic spudger

1- Utek UT-890A USB to RS422 adapter

1- DB9 custom cable 30cm

---

Options

Handle -- US$200

The handle is machined with tight tolerances and can be totally disassembled. It fits your Nagra V like a glove. You can loosen or tighten the screws as needed with the included Allen wrenches.

The heat-shrunk athletic grip is really nice to touch.

The knurled thumb screws have an extra knurled nut that can be removed if you are not using it with the bag.

1- Handle Assembly

4- Hand-tighten screws

2- Allen wrenches

Extra POM washers

---

Accessories

These accessories are only available to add on to your package order. The shipping is just not worth it for these small items and should be available wherever you live.

Of course, if you don't mind paying the shipping, I don't mind shipping it.

Connector cover set US$25

I noticed that the connectors on the unit get really dusty over time. Also, the banana line outputs and headphone TRS directly expose the interior of the unit to the elements.

These covers give me peace of mind when travelling or working in dusty, dirty locations.

(You will still need to tape up the holes at each switch when working in sandy environments.)

3- Neutrik XLR male connector cover

2- Neutrik XLR female connector cover

1- Canare BNC cover

1- 3.5mm TRS plug

1- 6.35mm TRS plug

2- VGA connector cover.

3- 3.8mm plug for banana plug line out.

1- Lemo cover

HD15 (15 Pin) 90-degree low profile connector US$6

These are pretty cool and very low profile. They can be easily reversed so that the cables are pointing up or down in the bag. Solder your own cables to have custom connectors and lengths.

Purchase more for different setups in your cart or bag so you can just unplug from one setup and quickly plug into another.

Comes with different radiused cable strain relief parts that you can use depending on how thick your cable is.

---

Returns

All components go through very strict quality control and testing by me on my own Nagra V before shipping.

I will verify general dimensions and configurations with each buyer to make sure everything is compatible with their unit. Each part will be carefully wrapped and padded for shipping.

If the machined parts do not fit your unit, then they can be returned at the buyer's expense.

All of the shipped goods will be insured so any damage can be claimed with the shipping company.

Payment

Payment will be made through Paypal in USD$. If you cannot open a Paypal account, we can find an alternate payment service.

China orders can be paid with 支付宝 or 微信.

To order any of these packages, please contact me.

0 notes

Text

The Steel Smart System utilizes advanced CFS software to streamline cold-formed steel design. It enhances efficiency through integrated design tools, automates repetitive tasks, and supports real-time collaboration. This system ensures accurate modeling, compliance with standards, and customizable solutions for optimal project outcomes.

0 notes

Text

What Should You Consider When Choosing Metal Stud and CFS Design Software?

When choosing Metal Stud Design Software, it’s important to consider the software’s compatibility with your current tools and systems. The software should seamlessly integrate with other design programs you use, ensuring a smooth workflow and reducing the risk of errors. Another key factor is the ease of use. A user-friendly interface can save you time and effort, allowing you to focus on design rather than grappling with complex software features. Look for software that offers clear instructions and support resources, which can be incredibly helpful.

For those working with CFS Design Software, consider the software's ability to handle various design parameters specific to cold-formed steel. The software should offer precise calculations and comply with relevant codes and standards. Additionally, evaluate whether it provides useful features such as detailed reporting and simulation capabilities.

Steel Smart System offers specialized solutions in the industry, with a focus on advanced software for both metal stud and CFS design needs. Their tools are designed to enhance your design process with accuracy and efficiency. Explore their offerings in cold-formed steel design software. For more information, visit their website.

0 notes

Text

Envision's Success in Maritime Digitization

Envision Enterprise Solutions has successfully deployed its CTOS in top global terminals, converting conventional operations into completely digitized, automated smart terminals. Some of the achievements include:

Installation of full-scale container terminal automation systems in high-volume ports

Industry analyst recognition for innovation in design of container yard management system and yard truck management system

Smooth integration of depot management system (DMS) and container freight station (CFS) software to harmonize terminal and inland operations

Exceptional ROI for terminal operators via turnaround time and operating cost reductions

Excellent relationships with port authorities, logistics providers, and technology suppliers worldwide

With global trade continuing to expand in both volume and complexity, the need for state-of-the-art digital systems such as Envision CTOS becomes ever more indispensable. By providing greater control over operations, automation, visibility, and compliance, CTOS enables terminals to keep pace with the requirements of contemporary commerce.

Whether you're expanding your current terminal infrastructure or building a smart port from scratch, investing in a future-proof container terminal operating system such as Envision CTOS guarantees long-term success in the changing maritime environment.

0 notes

Text

Expert Memory Card Recovery Services in San Antonio

One of the sinking feelings is when you plug in your memory card to save your important files, photos, or your child's first steps only to face error messages such as "Card needs formatting," "Card unreadable," or even worse, a complete absence of any message.

It appears that you might have accidentally selected the wrong card for formatting or unintentionally pressed the "delete all" option. The essential photos, videos, and crucial documents appear to be lost beyond recovery.

At JET Data Recovery in San Antonio, we understand the intense panic and frustration people experience when they lose data from their memory cards. That is why we offer memory card recovery services in San Antonio to bring you back your lost data.

Why Do Memory Cards Fail?

Data loss on memory cards can happen for various reasons, including

Logical Errors: File system corruption, often caused by improperly removing the card from a device, power surges during read/write operations, or software glitches. Such errors can make the card appear empty or unreadable, even though the data might still be physically present.

Accidental Deletion or Formatting: Accidentally deleting files or formatting the entire card, especially when managing multiple cards or transferring files quickly, is common.

Physical Damage: Memory cards can be fragile. Bending, cracking, water damage, or static electricity can physically damage the card's internal components, making data access impossible through standard means.

Card Wear and Tear: Like all storage media, memory cards have a finite lifespan. Frequent read/write can eventually lead to wear and controller failure.

JET Data Recovery: Your Local San Antonio Experts

This is where JET Data Recovery comes into play. As San Antonio's dedicated data recovery specialists, we have the advanced technology, expertise, and secure lab environment required to tackle complex memory card recovery cases.

Our process involves

Professional Evaluation: We carefully check the memory card condition in order to determine the nature of the data loss and the best recovery strategy.

Advanced Techniques: Using our proprietary hardware and software designed specifically for recovering data from flash media, we include techniques like chip-off recovery for severely damaged cards.

Secure Handling: We treat your data with the utmost confidentiality and security throughout the recovery process in our San Antonio facility.

Whether it's cherished family photos, vital project videos, or crucial documents stored on an SD, microSD, CF, or other memory card formats, don't assume they're lost forever. Stop using the card immediately to prevent further data overwriting. If you are seeking memory card recovery services in San Antonio, contact the experienced professionals at JET Data Recovery.

0 notes

Text

How a Container Terminal Operations System (CTOS) Enhances Port Efficiency

Table of Contents

Introduction

The Evolution of Vessel and Terminal Operations

The Role of a Container Terminal Operating System (CTOS) in Efficiency

Key Factors Influencing Port Efficiency

The Strategic Importance of a CTOS

Envision (iPortman) CTOS: The Future of Port Management

Conclusion

The Evolution of Vessel and Terminal Operations

Hence, it is necessary to invest in new container terminal operating systems (CTOS) and new infrastructure for improved efficiency as well as dock reduction time.

The Role of a Container Terminal Operating System (CTOS) in Efficiency :

With the highly competitive environment, effective terminal operations are essential to retain a competitive advantage. Though capacity expansion of the terminal has been the focus, terminal management software tends to get neglected. A robust container terminal operating system (CTOS) is essential to automate processes and improve service levels.

The primary features of a CTOS are:

Optimized Container Movement Management: Accurate placement of containers within the terminal.

Automated Loading/Unloading Scheduling: Optimizing the utilization of container yard management systems based on real-time shipping data.

Seamless Multi-Modal Integration: Enabling unproblematic road, rail, and sea transportation mode transfers through automated gate system support.

Improved Communication: Providing stakeholders with precise container tracking software updates.

Key Factors Influencing Port Efficiency

Container terminals play a critical role in international logistics by managing cargo handling and intermodal transfers. Several factors impact port efficiency, including:

Yard Size & Layout: Directly influencing storage capacity and movement optimization.

Maritime, Road, and Rail Connectivity: Ensuring efficient cargo transfers between transport networks.

Advanced Machinery: Boosting operational productivity and enhancing automated gate system performance.

Container Terminal Operating System (CTOS): A foundational tool that streamlines operations, from vessel planning and optimization to yard truck management system implementation.

The Strategic Importance of a CTOS

Maximizing efficiency and minimizing costs are key issues for terminal operators. Container terminal operating system (CTOS) simplifies container handling, making cargo flow smooth.

The key benefits of CTOS implementation include:

Reduced Vessel Turnaround Time: Faster cargo handling increases port calls and enhances throughput.

Revenue Optimization: Efficient asset utilization and automated invoice processing improve financial performance.

Lower Operating Costs: Reducing manual operations and leveraging container terminal automation minimizes expenses.

Maximized Resource Utilization: Optimizing asset allocation across yard truck management systems and depot management system (DMS).

Enhanced Transparency & Collaboration: Real-time reporting strengthens stakeholder communication, improving customer satisfaction.

Envision (iPortman) CTOS: The Future of Port Management

Envision’s iPortman CTOS is designed to meet today’s operational needs while future-proofing port efficiency.

Key advantages include:

Modular Architecture: Adaptive module-based deployment for scalable container terminal operating system expansion.

Comprehensive Cargo Handling: Supporting imports, exports, and container freight station (CFS) software integration.

All-in-One Port Management: Unifying all operations under a single platform, including vessel planning and optimization.

Mobile App Support: Enhancing real-time data collection and reducing back-office delays.

Customer Portal Integration: Increasing transparency, stakeholder collaboration, and satisfaction.

Advanced Planning & Optimization: Strengthening efficiency in depot management system (DMS) and yard truck management system deployment.

High-Level Reporting Features: Enabling key information about cargo activities, gate transactions, and performance of automated gate systems.

Conclusion

The use of an advanced container terminal operating system (CTOS) is necessary for maximizing port efficiency, lowering costs, and fueling revenue growth. Envision’s iPortman CTOS presents a comprehensive, future-proof solution that enhances transparency, productivity, and terminal operations.

In today’s competitive global logistics environment, investing in a sophisticated CTOS, along with container yard management system and container freight station (CFS) software, is no longer optional — it’s a necessity.

0 notes

Text

The Intersection of Applied Science, Demolition Engineering, and Cold Formed Steel Software

Applied science is the backbone of modern engineering, enabling professionals to tackle real-world challenges with precision and innovation. Among its diverse applications, demolition engineer and the use of cold formed steel (CFS) software stand out as transformative areas reshaping the construction landscape.

Demolition engineering is a critical discipline focused on the safe and efficient dismantling of structures. It demands a deep understanding of material properties, structural behavior, and environmental considerations. Demolition engineers utilize advanced techniques such as controlled implosions, robotic tools, and data-driven safety protocols to execute projects with minimal risk. Applied science plays a key role in enhancing these processes, ensuring that every step is informed by scientific principles and technological advancements.

Cold formed steel has become a popular choice in construction due to its strength, lightweight nature, and recyclability. Specialized CFS software enables engineers to model, analyze, and optimize designs for structural efficiency and compliance with building codes. By simulating real-world conditions like wind or seismic loads, this software ensures structures can withstand environmental stresses while minimizing material waste.

The synergy between demolition engineering and CFS software is revolutionizing both fields. During demolition, CFS software helps engineers assess the viability of salvaged materials, promoting sustainable practices. This approach not only reduces construction waste but also supports green building initiatives, aligning with global sustainability goals.

Looking forward, advancements in artificial intelligence and augmented reality promise to further integrate applied science into these domains. Real-time simulations and predictive analytics will empower engineers to design and dismantle structures more safely and efficiently.

Learn more about this subject on our blog - https://appliedscienceint09.medium.com/applied-science-in-engineering-exploring-the-role-of-demolition-engineers-and-cold-formed-steel-33846b70751a

0 notes

Text

Intellect eWarehouse: Optimizing Warehouse and Freight Operations

Intellect eWarehouse is a robust ERP-integrated Warehouse Management System (WMS) designed to streamline operations for warehouse, distribution, and CFS (Container Freight Station) companies. The software features advanced functionalities such as customizable configurations, real-time inventory management, barcode scanning, and seamless integration with US Customs for smooth transportation processes. It supports e-commerce shipments, automates billing, and offers a customer access portal for efficient management. Whether you're handling domestic or international shipments, this solution offers scalable capabilities to manage complex logistics needs.

0 notes