#DynemechSystems

Explore tagged Tumblr posts

Text

Dynemech DRAS Series – High-Performance Rubber Air Springs for Precision Vibration Isolation

High-performance industrial applications are supported by the Dynemech Anti-Vibration Technology DRAS Series, which is comprised of Rubber Air Springs High-Precision Vibration Isolation Technology solutions.

The purpose of the Dynemech Anti-Vibration Technology DRAS Series Rubber Air Springs is to provide an exceptional capacity for Vibration Isolation in both dynamic (active) and static (passive) industrial applications. For the purpose of providing improved durability, increased service life, and superior damping, the Vibration Control components are manufactured using elastomeric materials of the highest quality. The DRAS Series is designed to remove low-frequency shock and vibration, which can hinder the accuracy of machines, lower the quality of products, and shorten the lifespan of precision equipment. DRAS Rubber Air Springs are able to provide precise isolation in high-stress applications where traditional mounts are insufficient. These springs have vertical natural frequencies that range from 2.5 Hz to 6.0 Hz*. The Absolute Pinnacle of Technical Accomplishment The natural frequency range is from 2.5 Hz to 6.0 Hz*, and it effectively isolates low-frequency disturbances that are not reduced by typical rubber or metal mounts.

The vertical-to-horizontal stiffness ratio is about equal to one. Maintains a consistent level of performance in all directions, which is an essential quality for dynamically loaded equipment that is loaded in many directions.

• Elastomeric Design for air chambers that are compressed The effectiveness of Vibration Isolation and shock absorption is significantly improved as a result of the synergistic interplay between rubber resilience and air damping.

The High Load Carrying Capacity A is a feature. In particular, it is ideal for a wide range of equipment, ranging from light laboratory equipment to heavy industrial presses.

• Operations That Require No Maintenance DRAS air springs, in contrast to metal springs or hydraulic dampers, do not need to be adjusted or serviced on a regular basis, which considerably reduces the amount of time that the system is offline.

In addition to being easy to install, space-saving, and modular, plug-and-play adaptability enables retrofitting into existing equipment as well as integration into new equipment designs. These applications are designed to accommodate a wider variety of industrial use cases. In situations when the equipment in question generates vibrations that need to be separated from the ground, active Vibration Isolation is utilized. • High-Speed Mechanical Power Presses

• Vibration Testing Equipment

• Rotating or Reciprocating Compressors

• Engine and Gearbox Test Beds

• High RPM Textile Machinery

• Industrial Blowers and Pumps

• Industrial Blowers and Pumps

Passive Vibration Isolation In situations when vibration-sensitive equipment needs to be protected from vibrations in the surrounding environment: Surface Plates and Metrology Instruments, Coordinate Measuring Machines (CMMs), Laser Interferometers and Optical Systems, Superfinishing and Precision Grinding Machines, Sensitive Laboratory Equipment, Spectrometers, and Microscopes, and 3D Scanning, Polishing, and Calibration Platforms are some of the products that we provide. There are benefits that you can rely on, including improved machine accuracy. Reduces the inconsistencies and inaccuracies that are caused by vibrations in the product.

• Improved Equipment Life Reduces the amount of wear and tear caused by friction, which results in a smoother operation of the machine and can extend its lifespan.

• The Comfort and Safety of the Operator The presence of low vibration levels in the workplace is associated with decreased levels of fatigue and noise.

• Reduced amount of downtime and maintenance Strong structure and passive damping both help to reduce the amount of intervention that is required.

• Enhanced Performance Across All Sectors of the Economy Established in a variety of industries, including automotive, aerospace, textile, testing and calibration, research and development labs, and more.

To learn more about our products https://www.vibrationmountsindia.com/products/

#DynemechDRAS, #RubberAirSprings, #VibrationIsolation, #MachineDamping, #PrecisionEngineering, #AntiVibrationMounts, #IndustrialVibrationControl, #LowFrequencyIsolation, #PassiveIsolation, #ActiveVibrationControl, #ShockAbsorption, #PrecisionMachineSupport, #MetrologyMounts, #IndustrialStability, #MadeInIndia, #DynemechSystems, #VibrationFreeOperations

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#DynemechDRAS#RubberAirSprings#VibrationIsolation#MachineDamping#PrecisionEngineering#AntiVibrationMounts#IndustrialVibrationControl#LowFrequencyIsolation#PassiveIsolation#ActiveVibrationControl#ShockAbsorption#PrecisionMachineSupport#MetrologyMounts#IndustrialStability#MadeInIndia#DynemechSystems#VibrationFreeOperations

0 notes

Text

VHS-LA Series Precision Levelling Mounts | Dynemech Systems – Post-Grouting Adjustable Machine Mounts for Long-Bed Machinery

Dynemech Systems Pvt. Ltd. is responsible for the meticulous design and construction of the Dynemech Precision Levelling Mounts VHS-LA Series – Accuracy Levelling Mounts.

These Dynemech Precision Levelling mounts are designed to ensure that your machine remains entirely accurate even after it has been set up.

Dynemech Precision Levelling Mounts from the VHS-LA series provide the machine with precision Levelling. Even after grouting the outside body of this mount, it is still possible to achieve and achieve the levelling. Through the use of this mount, it is possible to achieve a small horizontal alignment of long-established machinery.

Dynemech Precision Levelling Mounts VHS-LA Series is the name of the most recent series of precision Machine Levelling Solutions that have been provided by Dynemech Systems Pvt. Ltd., which has recently introduced this series.

They are able to demonstrate that they are capable of meeting the rigorous criteria that are present in modern manufacturing and high-performance machining facilities. In order to provide exceptional levelling precision, stability, and flexibility, Dynemech Precision Levelling Mounts VHS-LA mounting posts have been designed. These mounting posts are constructed from a sturdy and environmentally friendly construction. Heavy-duty, long-bedded, and high-precision machines were the target audience for the mounting posts that were built specifically for them.

It is possible to provide dependable levelling without causing any delays. The ability of the Dynemech Precision levelling Mounts VHS-LA series to perform delicate, Dynemech high-precision levelling changes is at the core of this series. It is especially important for industrial equipment to maintain correct geometric tolerances, and this series is designed to meet this requirement. When the issue at hand is the long-term retention of top-of-the-line machine performance, Dynemech Precision Levelling Mounts Series VHS-LA provide the precise control you require. This is true regardless of whether you are installing a new CNC lathe or rebuilding a surface grinder from the ground up.

When it comes to engineering, one of the unique advantages of levelling after grouting positioning the grouting One of the most notable characteristics that sets the Dynemech Precision levelling Mounts VHS-LA mounts apart from other versions of the mounts is the fact that they come equipped with the capability to permit levelling changes even after grouting has been completed. Following the grouting of the mount into the machine foundation in a permanent position, the mechanism that is contained within the mount can be utilized for the purpose of making extra fine adjustments.

This is something that can be accomplished without the need to disassemble the machine or interfere with the installation.

This is especially helpful for large installations, where it is impossible to make even the most basic alterations once the installation has been completed with the current configuration. When it comes to machinery that has long beds, having a slight horizontal adjustment could be considered appropriate. By virtue of the fact that their frames are very lengthy, long-bed machines will have very few instances of misalignment. Due to the fact that it is a horizontal alignment that is extremely minimal, the Dynemech Precision Levelling Mounts Series VHS-LA is an essential solution for the following

Applications of Dynemech Precision Levelling Mounts Series VHS-LA: Machining centers that are controlled by computer numerical control (CNC), surface and cylindrical grinders, bed-type milling machines, horizontal boring machines, gantry and bridge-type cutting machines

In order to minimize tool wear, improve component precision, and guarantee high-quality machining across the whole work surface, it is vital to have the capability to provide continuous linear accuracy along the machine bed. Performance-oriented and constructed to last for a long time The Dynemech Precision Levelling Mounts Series VHS-LA range is constructed to withstand huge loads as well as dynamic loads. It is developed in such a way that it is able to keep its structure even when it is subjected to tremendous loads.

It is not possible for vibrations to be communicated due to its structure, and it offers a sturdy platform that not only helps the machine to function properly but also makes the situation more comfortable for the user. Important Advantages in a Nutshell- Dynemech Precision Levelling Mounts Series VHS-LA • Micrometric accuracy with precision vertical levelling

• Adjustment after grouting for long-term flexibility of alignment

• Limited horizontal adjustability for long-bed uses

• Excellent Vibration Isolation, extending machine life and product finish

• Easy installation and maintenance, reducing downtime

• Customized solutions for diverse load capacities and machines Various Requests The Dynemech Precision Levelling Mounts VHS-LA line has a wide range of applications across a multitude of industries, including but not limited to the following: aerospace and defense; automobile manufacturing; heavy engineering and fabrication; tool rooms and die-making; precision component production; and more.

You should consider Dynemech Systems Pvt. Ltd. for a number of reasons. In addition to designing, engineering, and developing the most comprehensive line of Precision Levelling Mounts Series VHS-LA, noiseless blocks, shock and noise control products, Dynemech Systems Pvt. Ltd. has also completed the development of these goods.

In addition to that, we are experts in the development of Dynemech Precision Levelling Mounts Series VHS-LA, machinery mounts, spring mounts, and a variety of Dynemech Precision Leveling Mounts. The Dynemech Precision Levelling Mounts that Dynemech Systems Pvt. Ltd. manufactures are known all over the world.

The Precision Levelling Mounts offered by Dynemech Systems are the ideal solution for this problem. It is constructed from a combination of high-quality rubber polymers and cork, which ultimately results in the creation of a product that boasts exceptional resistance to the effects of natural aging, compression set, water, and oil.

Dynemech’s Precision Levelling Mounts Series VHS-LA are widely used in: Refrigeration Plants, Compressors, Conveyors, Air Conditioning Plants, Diesel Generators, Business Machines, Fans, Motors, Power / Impact Presses, Pumps, CNC Machines etc. Our range of silent block are ideal for controlling machine vibration. Our rubber based products are ideal in controlling both active and passive vibrations coming from various industrial machines.

In the field of precision engineering, Dynemech Systems Pvt. Ltd. is a name that is renowned all over the world for its dependability.

The company has decades of experience in vibration control and machine mounting solutions. Our Dynemech Precision Levelling Mounts VHS-LA Series is a prime example of our commitment to innovation, quality, and solutions that are driven by the needs of our customers. Using Dynemech's VHS-LA Precision Levelling Mounts, you can ensure that your machining investment remains accurate over the long run, reduce the amount of time that it is offline, and protect yourself.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#DynemechSystems, #PrecisionLevellingMounts, #MachineMounts, #VHSLASeries, #CNCAlignment, #LongBedMachines, #IndustrialMachinery, #MachineLevelling, #VibrationIsolation, #PostGroutingLevelling, #CNCStability, #HeavyMachinerySuppor,t #EngineeringSolutions, #MachineToolAccessories, #ManufacturingExcellence,

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#DynemechSystems#PrecisionLevellingMounts#MachineMounts#VHSLASeries#CNCAlignment#LongBedMachines#IndustrialMachinery#MachineLevelling#VibrationIsolation#PostGroutingLevelling#CNCStability#HeavyMachinerySuppor#t#EngineeringSolutions#MachineToolAccessories#ManufacturingExcellence

0 notes

Text

Dynemech Anti-Vibration Metrology Tables Applications requiring correct estimation depend much on a strong and disturbance-free stage. The accuracy and steadfastness of metrology can be affected by any little mechanical vibration. Outlined particularly for correct metrology tables and fragile measuring apparatuses, the Dynemech Anti-Vibration Innovation offers the finest execution in requesting mechanical and research facility uses. In a estimation setting, vibrations can begin from a few sources counting adjacent buildings and apparatus. These vibrations, but small, have a incredible affect on very correct gadgets. Amazingly touchy to relocation, perusing floats or estimation botches in arrange measuring machines (CMMs), vision frameworks, interferometric, and surface analyzers can be created indeed from miniature vibrations. Dynemech fathoms these issues by advertising uncommonly made Vibration Separation Arrangements that effectively isolated hardware execution from exterior unsettling influences. Dynemech gives separation stages, levelling instruments, and anti-vibration mounts to fit a extend of metrology gear. Now and then these frameworks make utilize of progressed elastomeric materials, steel springs, and pneumatic mechanics. Each component is chosen and put to maximize vibration damping proficiency considering auxiliary limitations of the hardware. This produces a steady single premise ensuring framework exactness and estimation keenness. Relative flexibility of Dynemech frameworks is one of their fundamental preferences. Dynemech gives customizing depending on stack capacity, machine measure, and vibration behavior whether combined with a modern metrology workstation or an ancient one. Utilizing on-site studies, their specialized specialists can offer the perfect blend of isolators for a given environment. This custom-made procedure ensures that vibration levels are diminished to sensible levels, hence empowering gear to run as accurately as it may conceivably do. Dynemech Anti-Vibration Innovation too benefits long term. Devices that are not continually vibrated keep their mechanical solidness, in this manner expanding their lifetime and bringing down their wear. Less calibration intrusions and lower support costs take after from this. High-precision divisions counting hardware fabricate, toolmaking, car, and aviation depend on dimensional precision; Dynemech Separation Frameworks can offer assistance these segments to make strides execution and steadfastness. Dynemech Anti-Vibration fundamentally offers exceptionally correct fabricated anti-vibration arrangements required to guarantee the constancy and quality of modern metrology. Their approach makes a difference to reach the primary destinations of precision, reproducibility, and certainty in each estimation by disposing of vibration at the source and location of measurement.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #Antivibration, #MetrologySolutions, #PrecisionEngineering, #VibrationIsolation, #DynemechSystems, #CoordinateMeasuringMachine, #IndustrialAutomation, #ManufacturingExcellence, #VibrationControl, #MeasurementAccuracy, #EngineeringInnovation,

Contact: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#Dynemech#Antivibration#MetrologySolutions#PrecisionEngineering#VibrationIsolation#DynemechSystems#CoordinateMeasuringMachine#IndustrialAutomation#ManufacturingExcellence#VibrationControl#MeasurementAccuracy#EngineeringInnovation

0 notes

Text

Vibration-Free Machinery Starts with Dynemech Anti-Vibration Technology"

The Dynemech Anti-Vibration Technology developed by Technocloy Dynemech has shown satisfactory results.

Accuracy, Efficiency, and Machine Stability

High-quality Dynemech Anti-Vibration Mounts and accessories for a range of industrial applications are the specialty of Dynemech Anti-Vibration Technology, a renowned Anti-Vibration Solutions Specialist.

Dynemech, which has a strong local presence in India and a global presence in places like Europe, Australia, and the Asia-Pacific area, is dedicated to providing top-notch machine performance improvement.

With the aid of sophisticated Anti-Vibration Mounts and Accessories, #operationsafety and Precision Manufacturing are achieved.

Best Engineering Solutions Provide by Dynemech Anti-Vibration Solutions.

Companies looking for Precise, detailed Machinery installation with long-term stability and performance may consider Dynemech's Solutions.

Wide Variety of Items

Every type of machine and Vibration profile can be mounted with one of Dynemech's several Anti-Vibration Systems.

Wedge Mounts

A three-piece Wedge Mechanism provides strong Vibration Isolation and Precise Machine Leveling with Wedge Mounts. Heavy Precision Machines like CNCs and VMCs are Especially Well-suited for Wedge Mounts.

Mounts for Screw Supports

These mounts are affordable, simple to install, and appropriate for equipment weighing between a few and several hundred pounds.

Both machine life and product quality are enhanced by their ability to properly isolate vibrations transmitted by the floor.

Mounts in the Dynemech TPM Series

IMTMA guidelines TPM mounts position equipment at the ideal height to facilitate cleaning and preventative maintenance. They also offer Superior Vibration Isolation.

Dynemech Spring Isolator’s With Best Quality

For dynamically loaded machinery like large compressors or forging hammers, spring supports provide efficient low-frequency vibration dampening. Viscosity oil dampers can be used in addition to spring supports and we Provide best quality Open Spring Isolator as required by cust. For customized Solutions.

Springs made of rubber

For passive Vibration management, Rubber Air Springs work well in delicate environments like labs. High-precision testing and measuring apparatuses might benefit from their equal leveling and damping capabilities.

Mounts for Compression and Shear

There are many industries that use these all-purpose mounts to absorb shocks and vibrations. A rubber component found in them offers isolation in both shear and compression modes.

Tables to Reduce Vibration

These tables, which are designed for R&D and quality testing facilities, have a high damping capacity and multi-layer insulation. For leveling delicate equipment like CMM machines and microscopes, they are ideal.

The Principal Advantages of Dynemech Anti-Vibration Technology.

Planned Installation of Precision Equipment: For long-term machine stability, Dynemech makes it possible to properly level, anchor (or provide free support), and isolate vibrations.

Reduced Maintenance Costs: Increases machine life significantly by reducing wear on critical components like spindles and bearings.

Reduces operator fatigue and exposure to hazardous vibrations, improving operator convenience and safety.

Lean production setups are made possible by simpler factory setups, which save time by allowing machines to be moved with ease and repainted rather than re-grouted or re-anchored.

Dynemech is Provide best customized solutions provide Their engineers examine vibration issues, provide appropriate advice, and carry out hassle-free installations in close collaboration with customers.

Dynemech offers flexible and effective customized Vibration Control systems, whether retrofits are carried out on an existing machine or for a new production line.

Served Industries: Oil & Gas; Plastics & Chemicals; Machine Tools & Metalworking; Automotive & Aerospace; Textiles & Packaging; Power Generation; Research Labs & Electronics

Contact Us

The tested line of Anti-Vibration Mounts from Dynemech may boost output, lessen vibration damage, and ensure accurate, reliable operations. Find out more about their entire product line or request a customized solution right now.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#DynemechSystems, #AntiVibrationSolutions, #VibrationControl, #VibrationIsolation, #IndustrialEfficiency, #PrecisionEngineering, #EquipmentStability, #MakeInIndia, #ManufacturingExcellence, #EngineeringSolutions, #MachineryMounts, #MachineVibrationMounts

Contact: +91-9810760131

Website: www.vibrationmountsindia.com

Email: [email protected]

#DynemechSystems#AntiVibrationSolutions#VibrationControl#VibrationIsolation#IndustrialEfficiency#PrecisionEngineering#EquipmentStability#MakeInIndia#ManufacturingExcellence#EngineeringSolutions#MachineryMounts#MachineVibrationMounts

0 notes

Text

"Dynemech Anti-Vibration Mount Upgrade Your Machine Stability with Dynemech Wedge Mounts for VMC" Machine performance is important in the industrial manufacturing sector. However, what are some ways to improve accuracy, decrease downtime, and extend tool life?

The solution can be simpler than you think: It starts at the very beginning.

By mounting our Vertical Machining Center on Dynemech Systems Pvt Ltd Wedge Mounts, we have successfully raised it to a new level, and the results have been nothing short of revolutionary.

Why Use Wedge Mounts from Dynemech Systems Pvt Ltd?

A machine mount might not seem like much at first. However, it is clear that choosing the right foundation is the difference between maximizing the potential of any industrial machine and settling for mediocrity, especially since vibrations are a major contributor to problems with surface finishes, tool deterioration, misalignment, and Dynemech Pvt. Ltd. Without the need for foundation anchoring, wedge mounts are precise levelling solutions that offer superior stability, faultless alignment, and high-performance vibration isolation. It's the best foundation-free option for the modern, high-tech manufacturing environment.

Superior Accuracy & Performance: important Components of an Advanced Three-Piece Wedge Design

Even on uneven floors or with flawed foundations, machine levelling can be easily adjusted and accurate alignment ensured with a central wedge and sliding top plate. This flexibility is essential for high-speed, high-accuracy operations like CNC machining, milling, and turning to obtain precise tolerances.

Adaptable Anchor Bolt

During fitting, accurate and simple alignment is made possible by the provided adjustable bolt. These bases make it easy to make quick changes that maintain the machine at the right angles for optimal efficiency, whether you're installing a new machine or retrofitting an old one.

Non-Slip Base Plate Material

All undesired movement and shifting are eliminated when your machine is secured for high-speed operations with the anti-skid, high-friction plate. Because of its design, which maintains your machine in the precise position you desire without the need for a floor anchor, it is ideal for both freestanding and fixed machine mounts in high-vibration environments.

Flexibility Without a Foundation

Long-term foundation alterations are not necessary with Dynemech mounting.

You can easily move your machines without compromising accuracy or performance, whether you're moving your business or installing new equipment. It's the ideal option for portable plant equipment or flexible manufacturing concepts.

✅ What We Have: Unprecedented Efficiency, Accuracy, and Efficiency Results?

Our VMC machine's performance and efficiency have significantly improved when we mounted it on Dynemech Wedge Mounts.

Here's how:

Vibration Isolation: Better Tool Wear & Surface Finish Dynamech Systems Pvt Ltd mounts' anti-vibration properties significantly reduce micro-vibrations, which are unnoticeable yet significantly impact machine wear, tool life, and component quality. Less vibration results in smoother surfaces for components, higher overall machining quality, and longer tool life.

Stable and Accurate Levelling: Increasing Geometric Accuracy Levelling has emerged as a major priority. Our machines can be correctly aligned thanks to Dynemech Systems Pvt Ltd mounts' precise, adjustable levelling, which increases tolerances and reduces scrap rates. Our machines maintain the intended orientation even during the most demanding milling operations.

Shorter setup and downtime

Installation of Dynemech Systems Pvt Ltd mounts is quick and easy because they don't require complex grouting or foundation work. The mount approach helps us get up and running more quickly, reducing downtime and maintaining production, whether we're transferring an old computer or installing a new one.

Operating Without Maintenance and Reusability

After installation, the mounts don't require any maintenance. We are certain that the mounts will provide us with steady, long-term positioning even if we replace our machines or rearrange our floor plan because they are reusable.

Superiority in the Industry Developed to Support a Range of Applications

Dynemech Pvt. Ltd. Wedge mounts are made especially to accommodate the following dynamic industrial uses:

CNC Machining Centers; Injection Moulding Machines; Presses & Automation Systems; Sheet Metal & Fabrication Equipment; Milling, Drilling, and Turning Machines; Mobile Plant & Retrofit Systems

Dynemech Wedge Mounts offer a sturdy, vibration-free base to increase productivity and extend machine life, regardless of the kind of machine or its intended usage.

Why This Is Important: Does the Foundation Determine Machine Precision?

It's simple to get sucked by the shiny production enhancements, such as faster spindles, new software, or sophisticated technology. However, stability is a prerequisite for machine performance. Even the best machinery cannot function at its peak efficiency without it. The right foundation is therefore crucial. The precise alignment, vibration isolation, and stability of Dynemech Wedge Mounts eliminate the need for a base and enable your machines to improve surface polish, reduce wear, and boost productivity.

Conclusion: Dynemech Systems Pvt Ltd's Benefits

We can attest to the fact that Dynemech Wedge Mounts have transformed our shop floor. We have observed an improvement in machine performance and shop flexibility due to its precise levelling, improved vibration control, and foundation-free installation. Start with the ground if you want to maximize the performance of your machinery. The stability is provided by Dynemech Systems Pvt Ltd.

Are you developed to improve the functionality of your machine?

For the best vibration control and precise levelling solutions, select Dynemech Systems Pvt. Ltd. For better result, let's remodel the foundation of your machine.

To learn more about our products:

https://www.vibrationmountsindia.com/products/

#Dynemech, #VMCmachine, #MachineMounts, #PrecisionLevelling, #AntiVibration, #FoundationFree, #SmartManufacturing, #CNCmachines, #EngineeringExcellence, #WedgeMounts, #MachineTools #PrecisionEngineering #IndustrialSolutions #VibrationControl #ManufacturingInnovation, #FactoryUpgrade, #DynemechSystems, #PerformanceWithoutLimits

Contact Us: +91-9810760131; +91-9911145131

Email: [email protected]

Explore Our Solutions: vibrationmountsindia.com

#Dynemech#VMCmachine#MachineMounts#PrecisionLevelling#AntiVibration#FoundationFree#SmartManufacturing#CNCmachines#EngineeringExcellence#WedgeMounts#MachineTools#PrecisionEngineering#IndustrialSolutions#VibrationControl#ManufacturingInnovation#FactoryUpgrade#DynemechSystems#PerformanceWithoutLimits

0 notes

Text

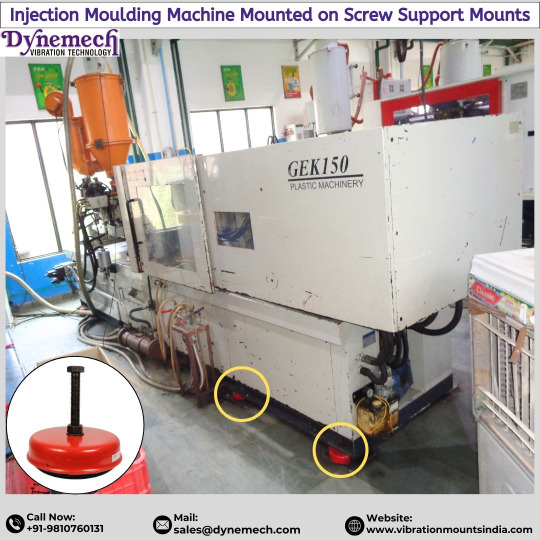

Enhance Injection Moulding Performance with Premium Screw Support Mounts

Dynemech Systems Pvt. Ltd., a leading name in industrial vibration control and machine mounting solutions.

The high-performance Screw Support Mounts for Injection Moulding Machines from Dynemech Systems is a top provider of industrial vibration control and machine mounting solutions, offer unparalleled stability, accuracy, and vibration dampening for high-speed manufacturing processes.

For all sectors to produce high-quality plastic components, injection molding machines are essential. However, the kind of mounting mechanism that is employed has a big influence on how well these machines work. Dynemech Screw Support Mounts can help with that.

Are uncontrolled vibrations endangering the precision of your injection molding and the longevity of your equipment?

Leading screw support mounts designed especially for injection molding machines are offered by Dynemech Systems, guaranteeing peak performance, lower maintenance costs, and longer equipment life.

Our Screw Support Mounts' Main Advantages:

Significant Vibration Reduction - Minimizes machine movement and improves part quality

Enhanced Precision - Maintains tight tolerances in manufactured components

Extended Machine Lifespan - Reduces mechanical wear and prevents premature failures

Quick Installation - Designed for easy integration with minimal downtime

Custom Load Ratings - Available for machines of all sizes and specifications

Industries Served:

Automotive component manufacturing

Consumer electronics production

Packaging industry

Household appliance manufacturing

Construction materials

Telecommunications equipment

Why Choose Dynemech Systems?

With over 20 years of experience in vibration isolation technology, Dynemech Systems is the top provider of anti-vibration solutions in India. Our technical staff works directly with clients to understand specific demands and recommend the best mounting alternatives for your injection moulding processes.

Injection moulding machines are the backbone of plastic part manufacturing, and even minor vibrations or misalignments can impact product quality and operational efficiency. Dynemech's screw support mounts are the ideal solution to optimize your machine’s performance without requiring any foundation work.

The Dynemech Commitment: Excellence in Engineering and Service

As India's premier provider of specialized vibration control solutions, Dynemech Systems combines technical expertise with dedicated customer service.

Our company values include:

Engineering Innovation: Continuous improvement and development of new solutions

Manufacturing Quality: Rigorous testing and quality control at every production stage

Customer Partnership: Close collaboration to ensure optimal results

Technical Support: Responsive assistance from knowledgeable professionals

Request a Site Visit and Vibration Analysis

Our engineers can perform an on-site assessment for larger installations or complicated vibration issues in order to create a comprehensive solution that meets your unique requirements.

Contact Us Today for Expert Consultation

Explore our full product range here: https://vibrationmountsindia.com/elastomeric-machines/

#dynemech, #antivibration, #VibrationControl, #InjectionMouldingEquipment, #VibrationIsolation, #ManufacturingEfficiency, #QualityControl, #DynemechSystems, #MadeInIndia, #EngineeringExcellence, #PrecisionManufacturing, #IndustrialEquipment,

Email: [email protected] Phone: +91-9810760131 Website: www.vibrationmountsindia.com

#dynemech#antivibration#VibrationControl#InjectionMouldingEquipment#VibrationIsolation#ManufacturingEfficiency#QualityControl#DynemechSystems#MadeInIndia#EngineeringExcellence#PrecisionManufacturing#IndustrialEquipment

0 notes