#CNCStability

Explore tagged Tumblr posts

Text

Dynemech Anti-Vibration Wedge Mounts Support Heavy Machinery

Heavy-duty machine operation, especially vibration management, is difficult.

Vibration affects machinery accuracy, lifespan, performance, and more. In this instance, Dynemech Anti-Vibration Technology Wedge Mounts help.

Our Wedge Mounts are suitable for accurate and stable heavy-duty machinery. Our mounts guarantee stable, strong, vibration-free heavy presses, CNC machines, injection molding machines, and other high-load machines.

Wedges mount:

No foundation is needed for machines placed directly on the shop floor for vibration control. Our Mounts absorb vibrations to preserve the surface. Building expensive foundations or fastening them is unnecessary.

Wedge Mount form simplifies machine levelling. After few adjustments, your machine will be balanced.

For Industrial Machinery: Used in manufacturing, plastic molding, automotive, etc.

Wedge Mounts with Dynemech Anti-Vibration Technology improve machine performance, maintenance, and operations.

Explore Our Full Range of Solutions: https://www.vibrationmountsindia.com/products/

#Dynemech, #Antivibration, #DynemechMounts, #WedgeMounts, #VibrationControl, #HeavyDutyMachinery, #MachineMounting, #IndustrialSolutions, #CNCStability, #VibrationIsolation, #MadeInIndia, #SmartFactorySetup,

📞 Need help picking the right mount? Just give us a call or drop an email. Our team is happy to guide you.

📲 +91-9810760131 📧 [email protected] 🌐 vibrationmountsindia.com

#Dynemech#Antivibration#DynemechMounts#WedgeMounts#VibrationControl#HeavyDutyMachinery#MachineMounting#IndustrialSolutions#CNCStability#VibrationIsolation#MadeInIndia#SmartFactorySetup

0 notes

Text

Dynemech Horizontal Stop Series (DHS) – Stability & Vibration Control for Precision Machines

Stable configuration of the Dynemech Horizontal Stop Series (DHS). Protected. Support for your machines that is intelligent. The concept of stability comes into play when the foundation that your equipment relies on is not as sturdy as the equipment itself. DHS, which stands for Dynemech Horizontal Stop Series, comes into play at this point. In particular, when your equipment is being subjected to severe axial loads that can bring about undesirable side-to-side motion, it is intended to offer the necessary firm support that it requires. Even if the machine bed is not extremely stiff or low in weight, the Dynemech DHS Series is able to keep everything in place, regardless of whether it is a grinder, a CNC machine, or any other high-speed, hard-working precision equipment.

Why Make Use of the DHS? It is common practice to mount machines in a flexible manner in order to Reduce Vibration. However, excessive flexibility can result in horizontal shaking, which is most noticeable in machines that contain internal parts that move back and forth across the machine. The Department of Homeland Security works to prevent that from happening. Maintaining the correct centering of your equipment while still allowing your Anti-Vibration Mounts to function is the purpose of this.

This is what it does for you: • It maintains the stability of your machine, even when subjected to high axial motion.

• It protects sensitive components by limiting unwanted lateral motion.

• When used in conjunction with Dynemech Isolators, it gives you the best of both worlds: mounting that is flexible and control that is rigid horizontally • Improves the accuracy of your machining and makes your equipment last longer

• Is easy to install and can be integrated with the majority of equipment configurations used in industrial settings • CNCs and turning centre's

• Surface and cylindrical grinders

• Injection moulding machines

• Lightly built machine beds

• Precision settings where even a small amount of movement can have a significant impact [CNCs and turning centre's]

Brief and to the point: The Dynemech DHS Series is like to an additional pair of brakes being installed on your machine; it does not slow it down in any way; rather, it merely ensures that it remains firmly on course. This method is a prudent and dependable approach to delivering stability in the areas that are most important, without compromising the Vibration Protection that your equipment require.

Explore Our Full Range of Solutions: https://www.vibrationmountsindia.com/products/

#Dynemech, #AntiVibration, #MachineStability, #HorizontalStop, #DHS, #VibrationControl, #PrecisionMachinery, #CNCStability, #IndustrialSolutions, #MachineMounts, #ManufacturingTech, #SmartFactory, #AxialForceControl, #IndustrialSupportSystems

Contact Us: +91-9810760131

Email: [email protected]

Discover Now: vibrationmountsindia.com

#Dynemech#AntiVibration#MachineStability#HorizontalStop#DHS#VibrationControl#PrecisionMachinery#CNCStability#IndustrialSolutions#MachineMounts#ManufacturingTech#SmartFactory#AxialForceControl#IndustrialSupportSystems

0 notes

Text

Dynemech Precision Levelling and Alignment Systems Manufactured by Dynemech Anti-Vibration Technology

Complete Solutions for Machine Stability and Precision are Available in the VHS, VHS-LA, and DFL Series Collections In order to provide unrivalled stability, accuracy, and flexibility for the installation of machinery in industrial applications, Dynemech Precision Levelling and Alignment Systems, such as the Dynemech VHS, VHS-LA, and DFL Series, have been developed.

Dynemech Precision Levelling Mounts Series VHS-LA series mounts provides precision levelling to the machine. The levelling is possible even after grouting the outer body of this mount. A slight horizontal alignment of long bedded machines is possible using this mount.

For the levelling, Adjustments & fixation of large machinery and other heavy equipment like boilers, turbines, generators, long-bedded lathes etc. One of the most important aspects of this technology is a wedge-based construction that enables precise vertical adjustment even when the machine is operating at its maximum capacity. Whether you are installing a small CNC or a large VTL or plano miller, Dynemech Anti-Vibration Technology solutions offer Vibration Isolation and effortless Levelling, along with optimal machine performance from the very beginning of the process.

Functionality that is centred on performance: • The ability to accurately adjust to tight tolerances, which is critical for maintaining machining accuracy and reducing tool wear.

Wide bearing surfaces and cast construction of the highest quality provide exceptional load distribution and long-term performance that is both durable and performance-oriented. There are several types that have central mounting slots that allow for post-foundation installation, which makes alignment easier even after grouting has been done.

Dynemech's VHS, VHS-LA, and DFL series offer a single, all-inclusive solution for every levelling and alignment requirement. These series cover a wide range of machine tools, from tiny machine tools to complicated, heavy-duty machining installations.

Dynemech Systems Pvt. Ltd. With high emphasis on quality, innovation and customer satisfaction, we come first in this line of business.

Products manufactured by us are used by a host of industries with much satisfaction and their demand is ever increasing. They confirm to international quality standards and their demand is high in the global market.

To learn more about our products https://www.vibrationmountsindia.com/products/

#Dynemech, #MachineLevelling, #AntiVibrationTechnology, #CNCStability, #VibrationControl, #DFLSeries, #VHSSeries, #PrecisionEngineering, #MadeInIndia, #ManufacturingSolutions, #IndustrialMachinery, #MachineryMounts, #EngineeringInnovation, #MachineAlignment, #SmartManufacturing

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#Dynemech#MachineLevelling#AntiVibrationTechnology#CNCStability#VibrationControl#DFLSeries#VHSSeries#PrecisionEngineering#MadeInIndia#ManufacturingSolutions#IndustrialMachinery#MachineryMounts#EngineeringInnovation#MachineAlignment#SmartManufacturing

0 notes

Text

Dynemech DLPM Pneumatic Anti-Vibration Mounts – Precision Levelling & Vibration Isolation

Dynemech DLPM Anti-Vibration Technology is a cutting-edge Pneumatic Levelling and Vibration Isolation System designed specifically for precision machinery.

In terms of Machine Vibration Control and Precision Levelling, the Dynemech DLPM (Dynemech Levelling Pneumatic Mount) system is considered to be the mostAadvanced Technology currently available.

The DLPM series is optimized to Isolate Vibrations, automatically level the machinery, and provide stability during dynamic working circumstances. Both of these features were specifically created for delicate machinery and high-precision applications. The Complete Levelling System with Three Points In order to achieve a standard for balancing support on equipment bases, a complete DLPM system is comprised of three master Pneumatic Isolators that operate on a three-point Precision Levelling arrangement. Because of the design, swaying is eliminated, and the accuracy of the equipment is improved, particularly in applications such as:

• Presses in high-speed mode Devices that use lasers

• Manufacturing of semiconductors and electronic components Adjustable Height and Load Compensation Automatically Additionally, each isolator is equipped with an integrated levelling valve that serves two purposes: Load-sensing is a feature that detects changes in weight while the machine is operating.

• Controlling the height: Allows for the machine to maintain a constant level through the use of automatic regulation.

This dynamic technology ensures that the machine is exactly level at all times, even when the load circumstances are fluctuating. As a result, the process quality remains consistent, and the productive capacity of the machine increases.

Installation that is Plug-and-Play Mounts for DLPM are designed to be provided as a fully assembled system that can be installed immediately. Each individual unit is outfitted with the following:

It is easy to install and does not require any specific grouting or foundation, which reduces the amount of time and money required for startup.

Principal Aspects of Performance One of the benefits of fast stabilization is that it reduces the amount of time spent in downtime and gives quick operating capability.

This feature, known as Superior Vibration Isolation, prevents the propagation of low-frequency vibrations that originate from either external sources or inside machine components. Accurate Levelling: This feature ensures that sensitive processes are aligned with the machine in a precise manner.

If there are fewer mechanical parts, there will be less wear and a longer service life. This will result in less maintenance.

The design is both compact and durable. Ideal for use in industrial applications that require both light and heavy-duty work.

Various Requests The following are some of the applications that are ideal for Dynemech DLPM systems: metrology and testing laboratories; electronic and precision component production; CNC machines and grinders; packaging machinery; and any other application that requires zero vibration and absolute stability. Opt for Dynemech DLPM Mounts instead.

Dynemech DLPM Anti-Vibration Mounts offer unparalleled performance in situations when precision, dependability, and high-end dampening are of the utmost importance. Engineered to achieve excellence, industrial sectors have faith in it.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#DynemechDLPM, #AntiVibrationMounts, #PrecisionLevelling, #PneumaticMounts, #MachineStability, #VibrationIsolation, #DLPMTechnology, #DynemechSolutions, #IndustrialAutomation, #MachinerySupport, #CNCStability, #ZeroVibration, #ManufacturingExcellence, #SmartMountingSystems

Contact Dynemech Systems Pvt. Ltd.

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#DynemechDLPM#AntiVibrationMounts#PrecisionLevelling#PneumaticMounts#MachineStability#VibrationIsolation#DLPMTechnology#DynemechSolutions#IndustrialAutomation#MachinerySupport#CNCStability#ZeroVibration#ManufacturingExcellence#SmartMountingSystems

0 notes

Text

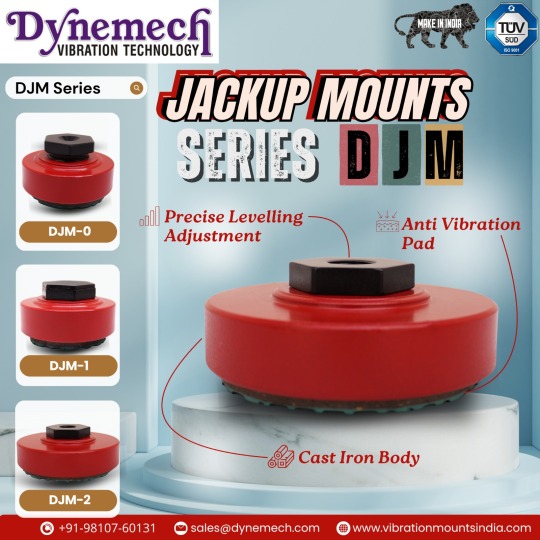

Heavy Duty Anti-Vibration and Levelling Mounts for Industrial Machinery Dynemech’s Jackup Mounts - DJM Series

Heavy Duty Levelling, Reliable Isolation and a very Smooth performance without Vibration with Dynemech Anti-Vibration Technology.

For a very accurate levelling and with the Control of Vibration of Machine in industrial environments, Dynemech's DJM Series jacks offer a smart, strong and very easy to maintain solutions. These Jackup Mountsare specially designed for a wide ranges of Machine Installation needs, including high load capacity, without any activity of Vibration and reliable anti slip support of Machine.

Main advantages of Dynemech Anti–Vibration Technology Jackup Mount Series DJM are:

Increased levelling range: The integrated lifting mechanism allows you to mark accuracy of machine levelling even with a very high operating load.

High load capacity: Designed for a very strong performance without Vibration, DJM Mounts support considerable machine weights, maintaining Alignment and Stability of the machine.

Passive vibration isolation: Thanks to the high-quality damping structure of the mounts, these Mounts Reduce Vibration transmission, improve equipment accuracy and protect sensitive components.

NON-SLIP DESIGN: The base of the Mount is designed to prevent anti slipping, ensuring a sturdy base even during a very high Vibration operations performing by machine.

EASY INSTALLATION: Designed for the user convenience, the DJM mount installs quickly and securely without complicated tools or any other equipment required.

IDEAL FOR:

Why choose the Dynemech Anti–Vibration Technology Jackup Mount Series DJM:

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #Antivibration, #JackupMounts, #SeriesDJM, #AntiVibrationSolutions, #MachineLevelling, #HeavyMachineryMounts, #CNCStability, #IndustrialMounts, #PrecisionLevelling, #MadeInIndia, #VibrationControl,

Contact Dynemech Systems Pvt. Ltd.

Phone: +91-9810760131 Email: [email protected] Website: www.vibrationmountsindia.com

#Dynemech#Antivibration#JackupMounts#SeriesDJM#AntiVibrationSolutions#MachineLevelling#HeavyMachineryMounts#CNCStability#IndustrialMounts#PrecisionLevelling#MadeInIndia#VibrationControl

0 notes

Text

VHS-LA Series Precision Levelling Mounts | Dynemech Systems – Post-Grouting Adjustable Machine Mounts for Long-Bed Machinery

Dynemech Systems Pvt. Ltd. is responsible for the meticulous design and construction of the Dynemech Precision Levelling Mounts VHS-LA Series – Accuracy Levelling Mounts.

These Dynemech Precision Levelling mounts are designed to ensure that your machine remains entirely accurate even after it has been set up.

Dynemech Precision Levelling Mounts from the VHS-LA series provide the machine with precision Levelling. Even after grouting the outside body of this mount, it is still possible to achieve and achieve the levelling. Through the use of this mount, it is possible to achieve a small horizontal alignment of long-established machinery.

Dynemech Precision Levelling Mounts VHS-LA Series is the name of the most recent series of precision Machine Levelling Solutions that have been provided by Dynemech Systems Pvt. Ltd., which has recently introduced this series.

They are able to demonstrate that they are capable of meeting the rigorous criteria that are present in modern manufacturing and high-performance machining facilities. In order to provide exceptional levelling precision, stability, and flexibility, Dynemech Precision Levelling Mounts VHS-LA mounting posts have been designed. These mounting posts are constructed from a sturdy and environmentally friendly construction. Heavy-duty, long-bedded, and high-precision machines were the target audience for the mounting posts that were built specifically for them.

It is possible to provide dependable levelling without causing any delays. The ability of the Dynemech Precision levelling Mounts VHS-LA series to perform delicate, Dynemech high-precision levelling changes is at the core of this series. It is especially important for industrial equipment to maintain correct geometric tolerances, and this series is designed to meet this requirement. When the issue at hand is the long-term retention of top-of-the-line machine performance, Dynemech Precision Levelling Mounts Series VHS-LA provide the precise control you require. This is true regardless of whether you are installing a new CNC lathe or rebuilding a surface grinder from the ground up.

When it comes to engineering, one of the unique advantages of levelling after grouting positioning the grouting One of the most notable characteristics that sets the Dynemech Precision levelling Mounts VHS-LA mounts apart from other versions of the mounts is the fact that they come equipped with the capability to permit levelling changes even after grouting has been completed. Following the grouting of the mount into the machine foundation in a permanent position, the mechanism that is contained within the mount can be utilized for the purpose of making extra fine adjustments.

This is something that can be accomplished without the need to disassemble the machine or interfere with the installation.

This is especially helpful for large installations, where it is impossible to make even the most basic alterations once the installation has been completed with the current configuration. When it comes to machinery that has long beds, having a slight horizontal adjustment could be considered appropriate. By virtue of the fact that their frames are very lengthy, long-bed machines will have very few instances of misalignment. Due to the fact that it is a horizontal alignment that is extremely minimal, the Dynemech Precision Levelling Mounts Series VHS-LA is an essential solution for the following

Applications of Dynemech Precision Levelling Mounts Series VHS-LA: Machining centers that are controlled by computer numerical control (CNC), surface and cylindrical grinders, bed-type milling machines, horizontal boring machines, gantry and bridge-type cutting machines

In order to minimize tool wear, improve component precision, and guarantee high-quality machining across the whole work surface, it is vital to have the capability to provide continuous linear accuracy along the machine bed. Performance-oriented and constructed to last for a long time The Dynemech Precision Levelling Mounts Series VHS-LA range is constructed to withstand huge loads as well as dynamic loads. It is developed in such a way that it is able to keep its structure even when it is subjected to tremendous loads.

It is not possible for vibrations to be communicated due to its structure, and it offers a sturdy platform that not only helps the machine to function properly but also makes the situation more comfortable for the user. Important Advantages in a Nutshell- Dynemech Precision Levelling Mounts Series VHS-LA • Micrometric accuracy with precision vertical levelling

• Adjustment after grouting for long-term flexibility of alignment

• Limited horizontal adjustability for long-bed uses

• Excellent Vibration Isolation, extending machine life and product finish

• Easy installation and maintenance, reducing downtime

• Customized solutions for diverse load capacities and machines Various Requests The Dynemech Precision Levelling Mounts VHS-LA line has a wide range of applications across a multitude of industries, including but not limited to the following: aerospace and defense; automobile manufacturing; heavy engineering and fabrication; tool rooms and die-making; precision component production; and more.

You should consider Dynemech Systems Pvt. Ltd. for a number of reasons. In addition to designing, engineering, and developing the most comprehensive line of Precision Levelling Mounts Series VHS-LA, noiseless blocks, shock and noise control products, Dynemech Systems Pvt. Ltd. has also completed the development of these goods.

In addition to that, we are experts in the development of Dynemech Precision Levelling Mounts Series VHS-LA, machinery mounts, spring mounts, and a variety of Dynemech Precision Leveling Mounts. The Dynemech Precision Levelling Mounts that Dynemech Systems Pvt. Ltd. manufactures are known all over the world.

The Precision Levelling Mounts offered by Dynemech Systems are the ideal solution for this problem. It is constructed from a combination of high-quality rubber polymers and cork, which ultimately results in the creation of a product that boasts exceptional resistance to the effects of natural aging, compression set, water, and oil.

Dynemech’s Precision Levelling Mounts Series VHS-LA are widely used in: Refrigeration Plants, Compressors, Conveyors, Air Conditioning Plants, Diesel Generators, Business Machines, Fans, Motors, Power / Impact Presses, Pumps, CNC Machines etc. Our range of silent block are ideal for controlling machine vibration. Our rubber based products are ideal in controlling both active and passive vibrations coming from various industrial machines.

In the field of precision engineering, Dynemech Systems Pvt. Ltd. is a name that is renowned all over the world for its dependability.

The company has decades of experience in vibration control and machine mounting solutions. Our Dynemech Precision Levelling Mounts VHS-LA Series is a prime example of our commitment to innovation, quality, and solutions that are driven by the needs of our customers. Using Dynemech's VHS-LA Precision Levelling Mounts, you can ensure that your machining investment remains accurate over the long run, reduce the amount of time that it is offline, and protect yourself.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#DynemechSystems, #PrecisionLevellingMounts, #MachineMounts, #VHSLASeries, #CNCAlignment, #LongBedMachines, #IndustrialMachinery, #MachineLevelling, #VibrationIsolation, #PostGroutingLevelling, #CNCStability, #HeavyMachinerySuppor,t #EngineeringSolutions, #MachineToolAccessories, #ManufacturingExcellence,

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#DynemechSystems#PrecisionLevellingMounts#MachineMounts#VHSLASeries#CNCAlignment#LongBedMachines#IndustrialMachinery#MachineLevelling#VibrationIsolation#PostGroutingLevelling#CNCStability#HeavyMachinerySuppor#t#EngineeringSolutions#MachineToolAccessories#ManufacturingExcellence

0 notes

Text

Dynemech Series DR – Precision Anti-Vibration Mounts for Tapped-Base Machinery

The Dynemech Anti-Vibration Technology Series DR is a collection of high-quality Anti-Vibration Damping Blocks designed for use with tapless hole machine bases. One example of the Dynemech Machinery Raiser Damping Blocks Series DR is a product that exemplifies the highest level of developed Vibration Isolation and Levelling Technology for industrial equipment. Dynemech Machinery Raiser Damping Series DR Damping Blocks are intended exclusively for applications involving tapped hole base machines. These damping blocks offer the ideal combination of improved vibration reduction, accurate load handling, and mechanical stability. Anti-Vibration Technology developed by Dynemech Systems Pvt Ltd, specifically designed for use with tap-based machinery

Machine bases that feature tapped holes for installation are found on a variety of precision machines, such as computer numerical control (CNC) machines, presses, and injection moulding systems. These kinds of combinations are specifically designed to be interfaced with by series DR mounts throughout the design process. It is possible to precisely mill a center depression on the top surface of each damping block to correspond with the diameter of the bolt that is located at the base of the machine. Enhanced axial alignment, less lateral movements, and precise bolt seating are all outcomes that can be achieved with the utilization of this cutting-edge interface. Performance and safety are both improved when dynamic loads are applied to the system. Among the most important functional advantages offered by Dynemech Machinery Raiser Damping Blocks

1. Innovative Vibration Isolation Technology

It is the high-damping elastomeric core that serves as the primary component of the Dynemech Machinery Raiser Damping Blocks Series DR mount. In addition to ensuring that the quality of surface finish is improved, tool wear and tool failure are minimized, machine and component life is increased, measurement and machining accuracy is enhanced, and a wide variety of machine-generated vibrations, both low-frequency and high-frequency, are absorbed by such a specially designed material, it also ensures that the quality of surface finish is improved.

2. Interface for Bolt Resting That Is Highly Secure

Because of the top dimple, which is meticulously created based on the size of the bolt, there is no longer a requirement for external alignment fixtures for the bolt. The following are some of the benefits that this innovation makes possible:

• Secure mounting without the possibility of sliding;

• Installation that is both quick and error-free

• Reduced stress concentration on machine bases. 3. Adjustment of the Height of the Device

The Series DR Mounts come equipped with a straightforward and durable levelling system that enables vertical adjustment in order to:

Ensure that the machine is aligned in the most effective manner Reduce the amount of grouting that is required for the foundation, make adjustments to accommodate uneven flooring, and make it simpler to move or rearrange machinery with less effort. The distribution of loads and the protection of the floor The structure not only provides long-term stability under high static or dynamic loads, but it also decreases point loading on floors and protects against floor surfaces breaking or stress damage. Also, the structure provides protection against stress damage. Applications across a Wide Range of Different Industrial Constituencies

Equipment Related to Dynemech Raiser Damping Blocks Series DR Damping Blocks have applications in a wide variety of machinery and industries, including but not limited to: CNC centers for turning, milling, grinding, and EDM; injection and blow moulding machines; hydraulic, pneumatic, and mechanical presses; spinning and textile machinery; laser cutting and sheet metal machinery; packaging, labelling, and automation systems; printing equipment and high-speed rotating equipment for printing operations There are benefits to both operations and business.

The machine's productivity and accuracy are increased, the maintenance downtime caused by vibration is reduced, the noise emission in the manufacturing area is reduced, the operator's comfort and security are increased, the machine is fully portable without the need for anchoring, and the return on investment is increased quickly due to its lifespan and reliability. It Is Possible to Customize the Technical Specifications of Dynemech Machinery Raiser Damping Blocks

Dynemech Systems Pvt. Ltd is able to modify the dimple diameter, mounting dimensions, and load of the Series DR blocks in accordance with the particular requirements of your equipment and the state of your floor. It is feasible to find specific solutions for high-tonnage and specialized vibration circumstances. Some examples of these solutions include shock and impact dampening. Using Dynemech's Anti-Vibration Technology: Why Should You Do So?

Due to the fact that Dynemech Systems Pvt. Ltd. has over twenty years of experience in Vibration Isolation and machine installation solutions, it is relied upon by some of the most prestigious manufacturers in the world.

Because Dynemech Systems Pvt Ltd is dedicated to innovation, quality, and performance, the Dynemech Machinery Raiser Damping Blocks Series DR range is a demonstration of this commitment. As a result, your machines will always be operating at their highest level of efficiency.

Dynemech Anti-Vibration Technology has produced the most extensive selection of Anti-Vibration Pads, silent blocks, shock, and noise control products available on the market and has developed them.

In addition to that, we are also involved in the production of a wide range of Anti-Vibration Pads, equipment mounts, spring mounts, and anti-vibration controlling pads.

Dynemech Anti-Vibration Technology is responsible for the production of Anti-Vibration Pads as of the highest quality.

The Dynemech Anti-Vibration Technology Anti Vibration Pad is the best possible solution to this challenge. Combining exceptional rubber polymers with cork results in the production of a product that is superior in terms of its resistance to age, compression set, water, and oil respectively.

Anti-Vibration Pads manufactured by Dynemech Systems Pvt Ltd have a wide range of applications, including but not limited to fans, motors, compressors, conveyors, air conditioning plants, diesel generators, commercial machines, power/impact presses, pumps, CNC machines, and refrigeration facilities, to name just a few examples. The elimination of machine vibration is a perfect application for our quiet blocks.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #SeriesDR, #AntiVibrationMounts, #VibrationIsolation, #MachineLeveling, #DampingBlocks, #IndustrialMounts, #MachinerySupports, #CNCStability, #InjectionMolding, #Metalworking, #PrecisionMachining, #PressMachineSupport, #ManufacturingEquipment, #MechanicalEngineering, #IndustrialAutomation, #MachineTools, #EngineeringSolutions, #VibrationControl

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#Dynemech#SeriesDR#AntiVibrationMounts#VibrationIsolation#MachineLeveling#DampingBlocks#IndustrialMounts#MachinerySupports#CNCStability#InjectionMolding#Metalworking#PrecisionMachining#PressMachineSupport#ManufacturingEquipment#MechanicalEngineering#IndustrialAutomation#MachineTools#EngineeringSolutions#VibrationControl

0 notes

Text

Dynemech Mac Level, DML Series is suitable for high speed rotating machines having small or no axial forces. Dynemech Anti-Vibration Technology provides the MAC Level Mounts-DML Series, the best Anti-Vibration Solution meant specifically for high-speed rotating machines with limited axial forces in industrial environments where accuracy, stability, and Vibration Control. Dynemech Mac Level Mounts, meant to high machine performance, lengthen lifespan, and increase output quality, were designed using modern Vibration Isolation Technologies. Created for deliberate performance - Dynemech Anti-Vibration Technology Dynemech Anti-Vibration Technology DML Series was developed especially for machines requiring extraordinary balance and little motion. Dynemech Anti-Vibration Technology offer consistent Vibration Isolation across a large frequency range with a strong iron body and premium elastomeric materials. Presses, blowers, turbine machines, CNC Machine, high-speed rotating equipment, lab spindles, and other delicate machinery.

Apart from guaranteeing better product accuracy, their capacity to lower vibrations at the source shields the machine and surrounding equipment from too much wear and damage. Important Characteristics of the DML Series Dynemech Anti-Vibration Technology MAC Level Mounts Made for High Speeds Rotating Machines Dynemech Anti-Vibration Technology-DML series performs best with machinery featuring high RPM and rotating components. Controlling undesired vibrations helps to stabilize the operational performance of the mounts and lower oscillation-related mistakes. Perfect for uses requiring small axial loads- Dynemech Anti-Vibration Technology Conventional mounts may not provide the optimum support in cases when machines generate minimal or none axial load. Designed especially to preserve performance and balance even in low axial stress environments, the Dynemech MAC Level Mounts. Levelling Mechanism- Dynemech Anti-Vibration Technology Crucially, every mount features a built-in Dynemech Anti-Vibration Mounts that lets you rapidly and precisely change height—a necessary ability to keep machine alignment on uneven surfaces. Once set, the locking mechanism guarantees rigidity and removes drift. Durable and maintenance-free - Dynemech Anti-Vibration Technology The Dynemech Mac Levelling Mounts are designed to resist in industrial conditions corrosion, wear, and chemicals. Their strong construction lets one accommodate a range of industrial weights without sacrificing vibration control. Applications in several sectors - Dynemech Anti-Vibration Technology The Dynemech Anti-Vibration Technology -DML Series offers companies trying to stabilize their equipment a flexible solution without sacrificing adaptability. The Mac Levelling Mounts enable you to keep tighter tolerances, improve production quality, and prolong the life of machinery whether your field of expertise is aerospace, automotive, electronics, or light engineering. Dynemech Anti-Vibration Technology has designed, engineered and developed the most extensive line of Anti Vibration Pads, silent blocks, shock and noise control products. We are also specializing in manufacturing of anti-vibration controlling pad, machinery mounts, spring mounts, and variety of anti-vibration pads.

Dynemech Anti-Vibration Technology manufactures world-renowned anti-vibration pads. Dynemech Systems offers an ideal solution in Anti Vibration Pad. Made from a combination of high quality rubber polymers and cork, this ideal combination ends up to make up a product that has excellent resistance to ageing, compression set, water and oil.

Dynemech’s Anti Vibration Pads are widely used in: Refrigeration Plants, Compressors, Conveyors, Air Conditioning Plants, Diesel Generators, Business Machines, Fans, Motors, Power / Impact Presses, Pumps, CNC Machines etc. Our range of silent block are ideal for controlling machine vibration. Our rubber based products are ideal in controlling both active and passive vibrations coming from various industrial machines.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#MACLevelMounts, #Dynemech, #AntiVibrationMounts, #DMLSeries, #VibrationControl, #MachineLeveling, #IndustrialMounts, #PrecisionMounting, #CNCStability, #HighSpeedMachines, #ManufacturingSolutions, #MachinerySupport, #AutomationEquipment, #FactoryEfficiency, #MachineSetup, #IndustrialSolutions, #SmartManufacturing, #MadeInIndia,

Get in Touch for Load Calculations

📞 Call Us: +91-9810760131 📧 Email: [email protected] 🌐 Website: www.vibrationmountsindia.com

#MACLevelMounts#Dynemech#AntiVibrationMounts#DMLSeries#VibrationControl#MachineLeveling#IndustrialMounts#PrecisionMounting#CNCStability#HighSpeedMachines#ManufacturingSolutions#MachinerySupport#AutomationEquipment#FactoryEfficiency#MachineSetup#IndustrialSolutions#SmartManufacturing#MadeInIndia

0 notes

Text

Maximize Machine Efficiency with Dynemech Wedge Mounts: The Smart Solution to Industrial Vibration Challenges

Vibrations are more than just a nuisance in any industrial setting—they are one of the leading causes of premature machine wear, reduced precision, higher maintenance costs, and even safety hazards on the shop floor. If your business relies on high-performance equipment, vibration control is not a choice—it's a necessity.

Dynemech Systems Pvt. Ltd. provides an effective and time-tested solution: Dynemech Wedge Mounts. Engineered to serve the most stressful industrial applications, our wedge mounts marry vibration isolation with precise levelling to enable your equipment to function at maximum efficiency—without any need for foundation anchoring or grouting.

What Sets Dynemech Wedge Mounts Apart?

1. Sophisticated Vibration Isolation

Our mounts are engineered to take up and isolate low- and high-frequency vibrations at the source, avoiding transmission to the surrounding structure and adjacent equipment.

2. Micrometric Levelling for Perfect Alignment

With a compact wedge mechanism, these mounts provide micrometric height adjustment for accurate machine levelling. This provides correct alignment, which is essential for accurate machining, minimized tool wear, and better product quality.

3. No Anchoring, No Grouting

Unlike traditional mounting systems, Dynemech Wedge Mounts do not demand permanent foundation work. This is beneficial for machines that must be relocated frequently or have changing alignments, saving considerable downtime and installation effort.

4. Stable Load Support

Each mount is designed to deliver uniform load support at all contact points, shielding machine components from stress and enhancing structural stability—even under unbalanced or dynamic loads.

5. Long-Term Reliability and Maintenance Reduction

By isolating vibration and stabilizing heavy equipment, Dynemech mounts prolong equipment life, cut breakdown frequency, and minimize maintenance costs—enabling long-term ROI for plants.

Applications by Industry:

Whether you're replacing your current setup or building a new facility, Dynemech Wedge Mounts are an economical and versatile solution for providing smoother operations, greater precision, and extended machine life.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #Antivibration, #WedgeMounts, #AntiVibrationTechnology, #MachineLeveling, #IndustrialMachinery, #ManufacturingSolutions, #CNCStability, #VibrationIsolation, #IndustrialEngineering, #MadeInIndia, #SmartManufacturing, #FactoryOptimization, #MachinePrecision, #MechanicalSolutions,

Contact Us: +91-9810760131

Email: [email protected]

Explore Our Solutions: vibrationmountsindia.com

#Dynemech#Antivibration#WedgeMounts#AntiVibrationTechnology#MachineLeveling#IndustrialMachinery#ManufacturingSolutions#CNCStability#VibrationIsolation#IndustrialEngineering#MadeInIndia#SmartManufacturing#FactoryOptimization#MachinePrecision#MechanicalSolutions

0 notes

Text

Dynemech – Complete Vibration Control & Precision Levelling Solutions for Every Industry

At Dynemech Systems Pvt. Ltd., we are dedicated to engineering precision vibration control solutions that ensure machine stability, enhanced performance, and equipment longevity. Since our inception, we have been delivering high-performance anti-vibration mounts, levelling systems, and foundation isolation technologies trusted across a wide spectrum of industries—from manufacturing and metrology to HVAC, packaging, plastics, die casting, and beyond.

With decades of expertise, Dynemech has grown to become a one-stop solution provider for machine installation and vibration-damping needs, offering not only a wide product portfolio but also custom-engineered solutions tailored to individual machine specifications and operating environments.

Our Product Range Includes:

🔹Anti-Vibration Mounts

•Wedge Mounts (DL/DLS Series) – They provide precision levelling and secure installation for CNC machines and heavy-duty equipment.

•Screw Support Mounts (DL Series) – They provide stability of dynamic machinery and precision equipment.

•Mac Level Mounts (DML Series) – They provide mounting solutions for various industrial machines.

•Stud and Compact Machinery Mounts – Designed for lightweight and compact machines.

•Jackup Mounts – Use where height adjustment and load distribution is required.

•Level Grip Mounts (DRM) – Designed for easy installation, anchoring, and levelling on uneven surfaces.

🔹Air Spring Systems

•Rubber Air Springs (DRAS, DLPM - Self Levelling) – Rubber air springs allow for load isolation of dynamic loads for sensitive applications.

•Membrane Air Springs (DMAS Series) includes the following high-performance pneumatic isolation systems and are available in series DMAS-SH, DMAS-SL, DMAS-BH, DMAS-BL.

🔹Spring Isolators

•Open Type, Closed Type, and Hammer Mount Series – Isolate vibration from HVAC, industrial fans, pumps, and heavy equipment.

•MAI-P%-TR1 Series – For dynamic machinery and shock-prone machinery.

🔹Shock and Vibration Dampers

•Spring Viscous Dampers – Hybrid design for low frequency vibration isolation and shock damping for die casting, forging and cutting machines.

•DXO Series Shock Mounts – Use for mounting compressors, pumps and any heavy industrial machinery.

🔹 Precision Leveling and Isolation Platforms

• VHS & VHS-LA Mounts – For metrology equipment and CMMs.

• DFL Series – High Precision Leveling Mounts

• VIP Anti-Vibration Platforms (AIS, VIP-E Series) – Made to support sensitive equipment and sensitive labs.

• Anti-Vibration Table (DIT-E, DIT-AHL, DIT-AM) – For microscopes, balances, or any sensitive measuring equipment.

🔹 Isolation and Support Systems

• Sandwich Mounts – Heavy-duty isolation solution for stationary and mobile machinery.

• Cradle Platforms and Machinery Raiser Damping Blocks – Load mounts that offer great damping.

• Rubber Bushes – For shock absorption in linkages and joints.

• Flexi Foot Mounts (DGF Series) – Simple installations for lightweight machinery.

Why Choose Dynemech?

Complete In-House Manufacturing – We oversee all processes from design to deliveries,

Custom Solutions – Custom Vibration Isolation and levelling solutions to suite your machinery,

Global Presence – Supporting industries across India and exporting to over 30 countries,

Proven Technical Support – Our Engineers work with customers to assess vibration issues and provide optimum outcome,

Proven Outcomes – Our products prolong the life of your machine, improve your product quality and protect your foundations.

Industries We Serve:

🏭 Automotive | 🛠️ Machine Tools | 🧪 Metrology | ❄️ HVAC | 📦 Packaging | 🧫 Pharma & Labs | 🏗️ Infrastructure | 🖨️ Printing | 🔩 Plastics & Injection Moulding

🔗 To learn more about our products: https://www.vibrationmountsindia.com/products/ 📞 Contact Us: +91-9810760131 📧 Email: [email protected] 🌐 Explore Our Solutions: vibrationmountsindia.com

#Dynemech#VibrationControl#MachineMounts#AntiVibrationSolutions#PrecisionLevelling#IndustrialSolutions#VibrationIsolation#FoundationIsolation#EngineeringSolutions#MadeInIndia#ManufacturingSupport#CNCStability#HVACMounts#MetrologySupport#IndustrialMachinery#MachineryMounting#RubberAirSprings#SpringIsolators#ShockMounts#AntiVibrationMounts

0 notes