#Expanded polystyrene (EPS)

Explore tagged Tumblr posts

Text

Unraveling the Growth Potential of the Geofoams Market: Global Outlook

The global geofoams market size is expected to reach USD 972.6 million by 2027, expanding at a CAGR of 2.7%, according to a new report by Grand View Research, Inc. Factors such as availability of geofoams at low cost coupled with its superior strength and durability are projected to fuel the market growth. Expansion of the construction industry across the globe coupled with the infrastructural developments in economies such as India, China, Brazil, Mexico, Saudi Arabia, and others is expected to propel the demand for geofoams over the forecast period. In addition, maintenance of the existing infrastructure in developed nations is likely to drive the growth of the market.

Geofoams Market Report Highlights

The expanded polystyrene geofoams segment accounted for USD 508.2 million in 2019 and is projected to expand at a CAGR of 3.1% from 2020 to 2027. The compatibility of the product has resulted in its increasing adoption for applications including roads and highway construction, building and infrastructure, and others

The road and highway construction application segment accounted for 38.07% of the total market and is projected to expand at a CAGR of 3.4% from 2020 to 2027 on account of the rising infrastructural growth across the developing economies including China, India, Brazil, UAE, Saudi Arabia, and others

Asia-Pacific accounted for USD 278.5 million in 2019 and is estimated to expand at a CAGR of 3.2% from 2020 to 2027 owing to the rising demand for road pavement, which is anticipated to further benefit the growth

China accounted for the highest market share in Asia Pacific on account of the rapidly expanding construction industry in the country

Europe market is estimated to expand at a CAGR of 2.8% owing to the rising number of construction and infrastructural activities in economies including Spain, Italy, and others

For More Details or Sample Copy please visit link @: Geofoams Market Report

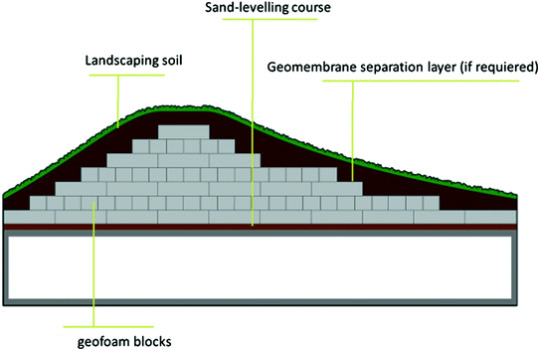

Geofoams are increasingly used in the construction industry as it helps in suppressing the noise and vibrations. In addition, it is easy to handle and does not require any special equipment for installation. The product is increasingly used in the railway track systems, below the refrigerated storage buildings, storage tanks, and others to avoid ground freezing.

The geofoams undergo chemical changes when it comes in contact with petroleum solvents. It turns into a glue-type substance, thereby losing its strength. This factor is projected to limit the use of geofoams in the construction industry which is projected to restrict the industry growth over the forecast period.

#Geofoam#Expanded polystyrene (EPS)#Geofoam blocks#Construction materials#Road and highway construction#Retaining walls#Geotechnical engineering#Soil stabilization#Environmental protection#Earthquake resistance#Noise and vibration control#Water management#Hydrostatic pressure#Thermal insulation#Structural stability

12 notes

·

View notes

Text

Expanded Polystyrene Panel: The Lightest Way to Build Big

Want strong walls without the extra load? EPS panels are changing the way modern structures rise—fast, efficient, and built to last. Curious? Step in.

0 notes

Text

Discover Top-Quality Foam Solutions in Florida, USA

When it comes to versatile building and creative materials, Expanded Polystyrene (EPS) in Florida, USA stands out for its lightweight, durable, and cost-effective nature. Ideal for insulation, packaging, and architectural detailing, EPS is a favorite among construction companies and designers across the Sunshine State. Its excellent thermal resistance and shock absorption make it an eco-friendly choice for many commercial and industrial applications.

0 notes

Text

Expanded Polystyrene (EPS) Packaging Market: Growth, Trends, and Future Outlook

Expanded Polystyrene (EPS) packaging has become a cornerstone in various industries due to its lightweight, cost-effectiveness, and excellent protective properties. As the global demand for efficient packaging solutions rises, the EPS packaging market is poised for significant growth. This article delves into the current market landscape, key drivers, segmentation, regional insights, and future prospects of the EPS packaging industry.

Market Overview

As of 2023, the global EPS packaging market was valued at approximately USD 10.05 billion. Projections indicate that this market will reach around USD 13.58 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 4.40% during the forecast period.

Request Sample Report

Key Market Drivers

E-commerce Expansion: The surge in online shopping has heightened the need for reliable packaging solutions that ensure product safety during transit. EPS packaging, with its shock-absorbing properties, has become a preferred choice for protecting goods in the e-commerce sector.

Growth in the Retail Sector: The expanding retail industry demands efficient packaging to preserve product integrity and extend shelf life. EPS packaging offers insulation and protection, making it suitable for a wide range of retail products.

Sustainability Initiatives: EPS is recyclable and contributes to reducing environmental impact. Advancements in recycling technologies have enhanced the sustainability profile of EPS packaging, aligning with global environmental goals.

Market Segmentation

The EPS packaging market can be segmented based on density, application, and region.

By Density:

15.0-19.9 kg/m³: Suitable for lightweight applications requiring moderate protection.

20.0-29.9 kg/m³: Ideal for general-purpose packaging with balanced strength and cushioning.

30-34.9 kg/m³ and above: Used for heavy-duty applications demanding high durability and impact resistance.

By Application:

Food and Beverage: EPS packaging maintains temperature and protects perishable items, ensuring food safety and quality.

Electronic Appliances: Provides cushioning and protection for delicate electronic devices during shipping and handling.

Healthcare: Ensures the safe transport of medical equipment and temperature-sensitive pharmaceuticals.

Others: Includes applications in automotive parts, consumer goods, and industrial products.

Regional Insights

North America: A mature market with steady demand, driven by the robust e-commerce and electronics sectors.

Asia Pacific: Expected to witness the highest growth rate due to rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India.

Europe: Focuses on sustainable packaging solutions, with stringent regulations promoting the use of recyclable materials like EPS.

Middle East & Africa: Emerging markets with growing demand for efficient packaging solutions in the food and construction industries.

Competitive Landscape

Key players in the EPS packaging market include BASF, Ineos, Kaneka, Sabic, Synthos, Total SA, Nova Chemicals, ACH Foam Technologies, Alpek SAB de CV, Jackon, Knauf, and Monotez. These companies focus on product innovation, strategic partnerships, and expanding their geographical presence to maintain a competitive edge in the market.

Future Prospects

The EPS packaging market is poised for continued growth, with several trends shaping its future trajectory:

Technological Advancements: Ongoing research and development efforts are leading to the creation of EPS variants with enhanced properties, such as improved thermal insulation and fire resistance, broadening their application scope.

Regulatory Compliance: Adherence to evolving global regulations regarding packaging materials and sustainability will be crucial for market players to ensure compliance and consumer trust.

Customization and Aesthetics: Brands are likely to invest in customizable EPS packaging designs to enhance product differentiation and appeal to diverse consumer preferences.

Conclusion

The Expanded Polystyrene Packaging market presents a dynamic landscape with significant growth opportunities across various industries. Driven by consumer demand for product integrity, sustainability, and technological advancements, EPS packaging solutions are set to become increasingly prevalent. Stakeholders in this market must stay attuned to emerging trends and consumer preferences to capitalize on the potential that EPS packaging offers in the evolving global market.

0 notes

Text

Explore our range of EPS panels at Vishay Porta Cabins Enterprises. Discover energy-efficient and versatile solutions for insulation, construction, and temperature control.

#eps panels#expanded polystyrene panels#energy-efficient panels#temperature control panels#customizable eps solutions#eps panel manufacturer#eps panel supplier

0 notes

Text

2032, Expanded Polystyrene (EPS) Recycling Market Growth and Research 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Expanded Polystyrene (EPS) Recycling Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Expanded Polystyrene (EPS) Recycling Market Size share, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Expanded Polystyrene (EPS) Recycling Market?

The expanded polystyrene (EPS) recycling market size reached US$ 19.7 Billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 36.5 Billion by 2032, exhibiting a growth rate (CAGR) of 6.7% during 2024-2032.

What are Expanded Polystyrene (EPS) Recycling?

EPS recycling is the practice of collecting, sorting, and processing EPS foam products to reclaim the material for reuse. EPS, also known as Styrofoam, is a lightweight and rigid plastic material utilized in packaging and insulation. The recycling process involves compressing the foam to reduce its size and then melting it down to create dense blocks or pellets suitable for manufacturing new products. EPS recycling contributes to environmental sustainability by diverting EPS waste from landfills and reducing the demand for new plastic production.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1775

What are the growth prospects and trends in the Expanded Polystyrene (EPS) Recycling industry?

The expanded polystyrene (EPS) recycling market growth is driven by various factors. The market for recycling expanded polystyrene (EPS) is expanding, fueled by growing environmental consciousness and regulatory measures promoting recycling practices. EPS, widely utilized in packaging and construction, significantly contributes to plastic waste. Recycling EPS involves collecting, cleaning, and processing it into reusable material for diverse applications. Market growth is propelled by increasing demand for recycled EPS in the construction and packaging sectors, driven by sustainability objectives and economic advantages. Moreover, technological advancements in EPS recycling and government support for recycling initiatives are further driving market growth. Hence, all these factors contribute to expanded polystyrene (EPS) recycling market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By EPS Waste Type:

Post-consumer EPS waste

Pre-consumer EPS waste

By EPS Recycling Process:

Mechanical recycling

Chemical recycling

Other recycling processes

By End-Use Industry:

Packaging

Construction

Electrical and Electronics

Automotive

Others

By Recycled EPS Product:

Packaging materials

Insulation boards

Molded products

Composite materials

Others

By Source of Collection:

Municipal recycling programs

Industrial and commercial collection

Retail collection

Other

By Recycling Equipment:

Shredders

Granulators

Densifiers

Extruders

Others

By Application:

Packaging

Building and construction

Insulation

Consumer goods

Others

By Distribution Channel:

Direct sales

Distributor sales

E-commerce

By Market Type:

Business to Business (B2B)

Business to Consumer (B2C)

Segmentation By Region:

North America:

United States

Canad

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Dart Container Corporation

NOVA Chemicals Corporation

ACH Foam Technologies, LLC

Ravago Recycling Group

Styro Recycle LLC

Total, Petrochemicals & Refining USA, Inc.

Alpek Polyester

Repsol S.A.

Vanden Recycling

Plasti-Fab Ltd.

NexKemia Petrochemicals Inc.

EPS Industry Alliance

Vita Group

FPC Foam Plastics Corporation

Winco Foam Industries Limited

View Full Report: https://www.reportsandinsights.com/report/Expanded Polystyrene (EPS) Recycling-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Expanded Polystyrene (EPS) Recycling Market share#Expanded Polystyrene (EPS) Recycling Market size#Expanded Polystyrene (EPS) Recycling Market trends

0 notes

Text

#Expanded Polystyrene (EPS) Market#Expanded Polystyrene (EPS) Market size#Expanded Polystyrene (EPS) Market share#Expanded Polystyrene (EPS) Market trends#Expanded Polystyrene (EPS) Market analysis#Expanded Polystyrene (EPS) Market forecast

0 notes

Text

Custom EPS Room Model by Maadhu Creatives

Maadhu Creatives designed a tailored EPS (Expanded Polystyrene) room model according to the client's specifications. With dimensions of 279mm (length) x 263mm (width) x 368mm (height), the model perfectly met the client's needs. The client is fully satisfied with the final design. Watch the full video to explore the details of the project and see the model in action!

#3dmodel#customdesign#roomdesign#epsfoam#epsmodel#architecturalmodel#3dmodeling#customroommodel#maadhucreatives

2 notes

·

View notes

Text

Global Insulated Concrete Form Market Report: Industry Forecast & Competitive Landscape

Unveiling the Future of Sustainable Construction with Insulated Concrete Forms

The global insulated concrete form market is entering a pivotal growth phase, propelled by the escalating demand for energy-efficient construction, green building standards, and resilient infrastructure. As of 2023, the insulated concrete form market is undergoing a dynamic transformation with a projected Compound Annual Growth Rate (CAGR) of 5.65% from 2024 to 2031, driven by both residential and non-residential construction booms across key global regions.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40387-insulated-concrete-form-market

Insulated Concrete Form Market Overview: A Rapidly Growing Sector

Accelerating Adoption Across Developed and Emerging Economies

With urbanization, climate-responsive construction, and sustainable housing solutions becoming imperatives, ICFs have emerged as a core component of modern building practices. These modular formwork systems—typically comprising expanded polystyrene or polyurethane foam blocks—are reshaping construction dynamics by offering enhanced thermal insulation, seismic resistance, and reduced environmental footprint.

The global Insulated Concrete Form Market, valued at USD XX million in 2022, is expected to surpass USD XX million by 2031, marking a robust uptrend in demand across North America, Europe, Asia-Pacific, and beyond.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40387-insulated-concrete-form-market

Key Insulated Concrete Form Market Segments and Growth Catalysts

By Type: Flat Wall and Grid Wall Systems Lead

Flat Wall Systems

Flat wall systems dominate the ICF architecture, favored for their seamless integration into standard building frameworks and superior load-bearing capacity.

Grid Wall Systems (Screen, Waffle, Post & Lintel)

Screen grid and waffle grid systems provide high flexibility for architectural customization. These systems are gaining popularity in earthquake-prone regions due to their capacity to dissipate structural stress effectively.

By Material: Expanded Polystyrene Foam Remains the Cornerstone

Expanded Polystyrene Foam (EPS)

EPS continues to lead the materials segment due to its light weight, moisture resistance, and high insulation value (R-value), making it the preferred choice for energy-conscious construction.

Polyurethane Foam

Polyurethane foam is anticipated to witness the second-highest growth rate, gaining traction for applications requiring superior thermal resistance and minimal wall thickness.

Others (Cement-Bonded Wood Fiber, Cellular Concrete)

Innovative eco-materials like cement-bonded wood fiber are emerging as sustainable alternatives, particularly in markets with stringent green building codes.

By End-Use Industry: Residential Segment to Experience Unprecedented Expansion

The residential sector is forecasted to witness the highest growth rate during the forecast period. This momentum is driven by:

Consumer preference for net-zero and passive homes

Government subsidies promoting sustainable construction

Rising awareness of long-term energy savings

Meanwhile, the non-residential sector, including hospitals, schools, and commercial offices, is also adopting ICFs for their durability, sound insulation, and lower lifecycle costs.

Regional Outlook: North America Maintains Dominance

North America

North America, particularly the United States and Canada, remains at the forefront of ICF adoption. This is underpinned by:

Advanced building codes promoting energy-efficient structures

High labor costs driving preference for modular, time-saving systems

Growing focus on disaster-resilient infrastructure in hurricane and wildfire-prone areas

Europe

The European market is witnessing significant uptake in countries such as Germany, France, and the UK, spurred by the EU’s regulatory push for near-zero-energy buildings (nZEBs).

Asia-Pacific

China, India, Japan, and ASEAN nations represent high-potential markets driven by rapid urbanization, infrastructural upgrades, and a growing middle-class demand for smart housing.

Middle East & Africa / South America

These regions are gradually integrating ICF technologies into urban master plans and sustainable city frameworks, particularly within the UAE, Saudi Arabia, Brazil, and South Africa.

Competitive Landscape: Strategic Focus on Innovation and Market Expansion

The global Insulated Concrete Form Market is moderately consolidated, with leading players continuously investing in product innovation, strategic alliances, and regional expansions. Key players include:

Airlite Plastics Company

Amvic Inc.

BASF SE

Beco Products Ltd.

Durisol UK

Nudura Corporation

Quad-Lock Building Systems, Ltd.

BuildBlock Building Systems, LLC

Logix Insulated Concrete Forms Ltd.

Standard ICF Corporation

These companies are shaping the industry through R&D in fire resistance, structural integrity, and biodegradable material options, aiming to align with LEED and BREEAM certifications.

Strategic Forecast: Opportunities and Challenges Through 2031

Insulated Concrete Form Market Growth Opportunities

Integration with smart home technologies

Expansion in disaster-prone and energy-scarce regions

Government incentives for net-zero building adoption

Development of recyclable and reusable ICF systems

Key Challenges

High initial construction costs compared to traditional methods

Limited awareness in low-income markets

Need for skilled labor familiar with ICF installation

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40387-insulated-concrete-form-market

Conclusion

The global Insulated Concrete Form market is at the crossroads of sustainability, efficiency, and resilience. As governments, builders, and homeowners pivot toward future-ready construction methods, ICFs stand out as a transformative solution. With technological advancements and policy support, the industry is well-positioned to surpass its current growth trajectory and redefine global construction standards through 2031.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Photo

https://it-recycle.uk/understanding-polystyrene-recycling-is-it-possible/ Polystyrene, also known as Styrofoam, is everywhere. It's used in food packaging and insulation. But, its impact on the environment is a big worry. This has led to a need for better recycling solutions.In this article, we'll look into the challenges of recycling polystyrene. We'll see if it's a good way to tackle the plastic waste problem.Key Takeaways Polystyrene, including expanded polystyrene (EPS) and extruded polystyrene (XPS), is a common plastic material with low recyclability. Manufactur

0 notes

Text

0 notes

Text

Durability and Material Choices for Custom Packaging Boxes

The Critical Role of Material Selection in Packaging Longevity Industrial buyers prioritizing protective packaging solutions must evaluate materials through the lens of supply chain realities. The relationship between substrate composition and container resilience directly impacts product safety during transcontinental shipping, warehouse storage cycles, and last-mile delivery challenges. Corrugated fiberboard remains the cornerstone for balance between structural integrity and weight optimization, with flute configurations (B-flute vs E-flute) offering customizable compression resistance. For electronics or precision instruments, rigid paperboard with laminated coatings provides anti-static protection while maintaining recyclability – a key consideration as global e-waste regulations tighten.

Balancing Cost and Performance in Protective Packaging Procurement teams increasingly demand packaging that withstands ISTA 3A testing protocols without inflating per-unit costs. Advanced kraft paper blends now incorporate hemp fibers to achieve 22% greater tear resistance compared to standard options, enabling thinner material profiles that reduce shipping weight. Injection-molded pulp packaging emerges as a cost-competitive alternative for fragile items, absorbing 34% more impact energy than expanded polystyrene (EPS) according to ASTM D4169 testing. Forward-thinking manufacturers now offer hybrid solutions pairing recycled PET internal cushioning with corrugated exteriors, achieving 18% better damage protection than traditional double-wall boxes at comparable price points.

Packaging Boxes

Environmental Compliance Meets Structural Requirements The convergence of circular economy mandates and packaging performance needs drives innovation in plant-based polymers and cellulose nanocomposites. Water-based barrier coatings now replace traditional polyethylene laminates, enabling 100% curbside-recyclable moisture-resistant boxes – a critical advantage for perishables shipping. Mushroom-based mycelium packaging, while currently niche, demonstrates comparable compressive strength to polypropylene containers in controlled humidity environments. Industrial buyers should prioritize suppliers offering life cycle assessment (LCA) documentation to validate sustainability claims against mechanical performance metrics.

Climate-Specific Material Engineering Strategies Globalized distribution networks require packaging solutions adaptable to diverse climatic conditions. For high-humidity corridors, silica gel-infused paperboard maintains 92% dry strength retention after 72-hour humidity chamber testing (ASTM E104). Arctic shipping routes benefit from ethylene-vinyl acetate (EVA) foam laminates that retain flexibility at -40°C, preventing brittle fracture risks. Pharmaceutical companies now adopt phase-change material (PCM) inserts in corrugated boxes, maintaining 2-8°C temperature ranges for 96+ hours without external refrigeration – a breakthrough validated through WHO PQS certification protocols.

Optimizing Packaging for Automated Logistics Systems The rise of robotic warehouse systems demands packaging materials with consistent friction coefficients and edge crush resistance. Corrugated boxes treated with nano-ceramic coatings demonstrate 40% better conveyor belt compatibility compared to standard finishes, reducing jams in high-speed sorting facilities. Anti-abrasion varnishes now protect offset-printed surfaces from scuffing during automated palletizing, maintaining brand presentation through extended supply chains. Advanced die-cutting technologies enable precise ventilation patterns in storage boxes, preventing condensation buildup during temperature-controlled海运运输 while meeting automated handling system requirements.

Future-Proofing Packaging Investments Strategic material selection now incorporates predictive analytics for evolving regulatory landscapes and consumer trends. Conductive graphene inks embedded in packaging surfaces enable real-time shock monitoring through IoT integration, providing logistics teams with actionable data to improve handling practices. Self-healing polymer coatings under development promise to automatically repair surface abrasions during transit, potentially extending container reuse cycles by 300%. Forward-looking procurement specialists are partnering with material engineers to develop adaptive packaging systems that learn from supply chain stressors, ensuring long-term ROI as market conditions evolve.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description "Strength & longevity:-The helmet also incorporates a black inner shell, which adds an extra layer of protection and durability to the design. This inner shell helps to reinforce the structure of the helmet, increasing its overall strength and longevity. " Material:-The inner shell of the helmet is made of expanded polystyrene (EPS) foam, a lightweight material known for its high energy absorption capabilities. This EPS foam lining is strategically placed throughout the helmet to effectively cushion and distribute the force of impacts, reducing the risk of head injuries. "Safety:-Plastic shell cover for additional durability and protection and Lightweight construction for enhanced comfort during rides. " "Ventilation:-Air Vents for improved airflow and breathability. Available in multiple colors and Sizes. " [ad_2]

0 notes

Text

0 notes