#Geofoam blocks

Explore tagged Tumblr posts

Text

Unraveling the Growth Potential of the Geofoams Market: Global Outlook

The global geofoams market size is expected to reach USD 972.6 million by 2027, expanding at a CAGR of 2.7%, according to a new report by Grand View Research, Inc. Factors such as availability of geofoams at low cost coupled with its superior strength and durability are projected to fuel the market growth. Expansion of the construction industry across the globe coupled with the infrastructural developments in economies such as India, China, Brazil, Mexico, Saudi Arabia, and others is expected to propel the demand for geofoams over the forecast period. In addition, maintenance of the existing infrastructure in developed nations is likely to drive the growth of the market.

Geofoams Market Report Highlights

The expanded polystyrene geofoams segment accounted for USD 508.2 million in 2019 and is projected to expand at a CAGR of 3.1% from 2020 to 2027. The compatibility of the product has resulted in its increasing adoption for applications including roads and highway construction, building and infrastructure, and others

The road and highway construction application segment accounted for 38.07% of the total market and is projected to expand at a CAGR of 3.4% from 2020 to 2027 on account of the rising infrastructural growth across the developing economies including China, India, Brazil, UAE, Saudi Arabia, and others

Asia-Pacific accounted for USD 278.5 million in 2019 and is estimated to expand at a CAGR of 3.2% from 2020 to 2027 owing to the rising demand for road pavement, which is anticipated to further benefit the growth

China accounted for the highest market share in Asia Pacific on account of the rapidly expanding construction industry in the country

Europe market is estimated to expand at a CAGR of 2.8% owing to the rising number of construction and infrastructural activities in economies including Spain, Italy, and others

For More Details or Sample Copy please visit link @: Geofoams Market Report

Geofoams are increasingly used in the construction industry as it helps in suppressing the noise and vibrations. In addition, it is easy to handle and does not require any special equipment for installation. The product is increasingly used in the railway track systems, below the refrigerated storage buildings, storage tanks, and others to avoid ground freezing.

The geofoams undergo chemical changes when it comes in contact with petroleum solvents. It turns into a glue-type substance, thereby losing its strength. This factor is projected to limit the use of geofoams in the construction industry which is projected to restrict the industry growth over the forecast period.

#Geofoam#Expanded polystyrene (EPS)#Geofoam blocks#Construction materials#Road and highway construction#Retaining walls#Geotechnical engineering#Soil stabilization#Environmental protection#Earthquake resistance#Noise and vibration control#Water management#Hydrostatic pressure#Thermal insulation#Structural stability

12 notes

·

View notes

Text

Foam Cutters LLC

youtube

hot wire foam cutter

Hot Wire Foam Cutters is the #1 Hand-Held Tool for cutting GeoFoam, EPS, Polystyrene, and Foam Blocks.

Foam Cutter Tool Features

Precision Cutting

Shape Foam with Unmatched Accuracy

Ultra Portable

Take It Anywhere for On-Site Foam Cutting

Adjustable Heating

Control the Heat Control the Cut

All Skill Levels

User-Friendly for seasoned contractors or first-time user

Safe & Efficient

Advanced Safety Features for Maximum Protection

Fast & Clean

No Mess, No Waste Just Perfect Cuts

Durable & Reliable

Crafted with high-quality materials & built to last

Large & Small

Cuts effortlessly through small or large foam blocks

hot wire foam cutting tool

See Our Tool in Action

Discover the ultimate solution for cutting foam with precision and ease. Our Hot Wire Foam Cutter is designed for fast, mess-free cutting of EPS, Geofoam, and more. Whether you’re shaping foam for construction or creative projects, this tool delivers professional results every time. Watch it in action and see how it can transform your workflow.

About Foam Cutters LLC

Proudly Designed and Manufactured in the USA

At Foam Cutters, LLC, we’ve spent over a decade perfecting foam cutting tools for the EPS industry. Based on prototypes introduced years ago, our team refined the design and functionality to create the most reliable, portable, and cost-effective hand-held hot wire foam cutters available today.

Our mission is to empower construction professionals with tools that offer precision, efficiency, and ease of use on any job site. Whether you’re cutting EPS blocks or shaping intricate foam designs, our tools are crafted to meet the highest industry standards. We proudly manufacture in the USA and distribute to leading EPS manufacturers, block molders, and contractors across North America.

Hot Wire Foam Cutter Pricing

We understand that every project has different needs, which is why we offer flexible pricing options for our Hot Wire Foam Cutter tool. Whether you’re purchasing a single unit for small projects or need bulk pricing for your entire team, we’ve got you covered. Contact us directly to discuss your requirements, and we’ll provide competitive rates.

hot wire foam cutter wire

contact us

Foam Cutters LLC https://foamcuttersllc.com/ Phone number: 817-447-8674

Facebook

Instagram

X

2 notes

·

View notes

Photo

https://galaxy-poly.com/geofoam-blocks/

0 notes

Photo

Extruded polystyrene Geofoam blocks is ideal for buildings, efficient, easy to install, and lightweight.

0 notes

Text

Geofoam Market To Grow at a CAGR of 6.3% by 2028 | Industry Share, Size, Scope, Growth, Company & Application

Geofoam Market is expected to reach a value of USD 1,156 million by 2028, with a CAGR of around 6.3%.

Geofoam is a product manufactured by expanding polymeric polystyrene into a "foam" made up of many closed yet gas-filled cells.

Geofoam market is a multi-purpose building material that may be used in a variety of ways owing to its unique physical qualities, flexibility, and high value, it is a preferred material for constructing various structures, foundations, and buildings. It has a wide range of uses, including highways, landscaping, and thermal insulation, as well as stadiums and movie theatres.

Regulatory Framework

The Building Materials Regulation establishes uniform marketing regulations for building items in the European Union. The Regulation establishes an uniform technical vocabulary for evaluating construction product performance. It guarantees that experts, government officials, and customers have trustworthy data to compare the performance of products from different manufacturers in different nations.

ASTM International specifies the minimum characteristics of EPS geofoam. The appropriate ASTM specification for EPS geofoam is ASTM D6817 Standard Specification for Rigid Cellular Polystyrene Geofoam. Two further ASTM standards are D7180 Standard Guide for the Use of EPS Geofoam in Geotechnical Projects and D7557 Standard Practice for Sampling of EPS Geofoam Specimens.

Impact of Coronavirus Outbreak

Operations at industrial factories and construction sites came to a standstill due to global lockdowns to prevent the spread of the virus, resulting in a drastic decline in cement production and consumption. Even in countries where construction was not on the list of banned economic activities during the lockdown, the economic slump and low consumer confidence led to a reduction in cement demand in the first quarter of 2020. According to a CK Birla Group analysis, building output in North America fell down by 6.6% in 2020, resulting in a loss of USD 122.4 billion in projects.

Segmentation

By Type

On the basis of type, the global geofoam market has been bifurcated into expanded polystyrene and extruded polystyrene.

Expandable polystyrene is used for slope stabilization, compensating foundations, roofing and rooftop gardens, bridge underfill, pavement insulation, and road embankments, among other things. The ability of EPS geofoam to be used in a wide range of applications is expected to move the product forward in the construction sector by the end of the projection period.

Extruded polystyrene foam is a rigid insulating material created from extruded polystyrene polymers. It's a strong foam block with a rough surface that conducts heat poorly. Extruded polystyrene is more commonly utilised for below-grade waterproofing and roofing systems that need insulation to be put atop a roof membrane.

By End Use

Based on end use, the global geofoam market has been segmented into road & railways, building & construction, and others.

Road infrastructure refers to land that is utilized for the transportation of products and passengers by road, and includes national, provincial, and municipal roadways, as well as parking and stopping facilities, road reserves, maintenance, and manoeuvring facilities.

In building & construction, it is used in a variety of applications, including landscaping, slope stabilization, insulation, and foundations. Geofoam is a great thermal insulator resulting in lower heating and cooling expenditures. It is often used to fill building walls, as well as roofing and ground structures, for all types of residential and commercial buildings.

Others segment include utilities, marine, loading docks, tanks, refrigerated storage among many others.

By Region

North America: The substantial expenditure in repairing and reconstructing damaged infrastructure is driving regional geofoam growth in North America. A vast network of infrastructure, ranging from roads and bridges to freight rail and ports, as well as electricity grids and internet connectivity, supports the US economy, and drives the geofoam market.

Asia-Pacific: Asia-Pacific emerged as the fastest-growing regional market. Factors such as improving economic conditions along with fast-paced urbanization and industrialization are driving the global market growth. Domestic demand is strong as a result of healthy labour markets, significant increases in disposable income, and persistent governmental support. Furthermore, in most economies, low inflation continues to boost real earnings.

Europe: The construction industry is vital to the European Union's economy. The sector employs 18 million people directly and accounts for about 9% of the EU's GDP. It also generates new jobs, stimulates economic growth, and addresses social, environmental, and energy issues.

Access full report @ https://www.marketresearchfuture.com/reports/geofoam-market-10754

Competitor Analysis

Some of the key companies profiled in the global geofoam market include Carlisle (US), Amvic Building Systems (Canada), Atlas Roofing Corporation (US), Insulation Company of America (US), Foam Products Corporation (US), Jablite (UK), ThermaFoam, LLC (US), Expol (New Zealand), Pacific Allied Products, Ltd. (US), Airfoam (Canada), Harbor Foam (US), Groupe Legerlite Inc. (Canada), Drew Foam (US), Plasti-Fab Ltd. (Canada), Benchmark Foam Inc. (US), Mega Packaging Corporation (Philippines), StarRFoam (US), Poly Molding LLC (US), Beaver Plastics Ltd. (Canada), Foamex (Australia), Universal Foam Products (US), Polyfoam XPS (UK), Galaxy Polystyrene LLC (UAE), Styro Insulations Mat. Ind. LCC. (UAE), and Technopol SA (South Africa).

Atlas Roofing Corporation is a customer-focused, creative manufacturer of residential and commercial roofing products. Atlas has expanded from a single shingle manufacturing factory to a North American industry leader with 24 locations. The Environmental Protection Agency has recognised Atlas for its efforts to reduce greenhouse gas emissions, industry trade organisations have recognised Atlas for its efforts in safety across its many facilities, and several national building materials supply chains have recognised Atlas for its growth and partnerships that have led to banner growth.

Contact Data

Market Research Future (Part of Wantstats Research and Media Private Limited)

99 Hudson Street, 5Th Floor

New York, NY 10013

United States of America

+1 628 258 0071 (US)

+44 2035 002 764 (UK)

Email: [email protected]

Website: https://www.marketresearchfuture.com

#Geofoam Market Size#Geofoam Market Share#Geofoam Market Type#Geofoam Market Application#Geofoam Market Region#Geofoam Market Research#Geofoam Industry

0 notes

Text

Why Geofoam Is One Of The Best-Selling Lightweight Fill Materials

Geofoam is an incredibly durable and cost-effective material used in a variety of construction projects, from retaining walls, to rooftop garden boxes, to tiered stadium seating. It is commonly made from expanded polystyrene (EPS) foam, which makes it lightweight and ideal for projects where a reduction of material weight is essential.

How Is Geofoam Used?

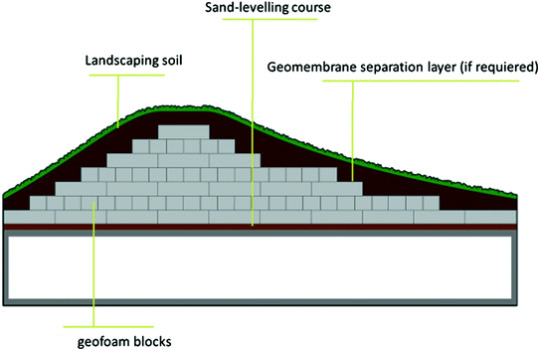

Geofoam can be used in a number of construction applications. Since the density of geofoam is 50 to 100 times lower than soil, it is an ideal lightweight fill material in soil and road embankment projects. It can be used as backfill behind retaining structures, as it reduces lateral pressure, provides better waterproofing, and reduces ground settling, all without adding significant load.

When used for slope stabilisation, the existing soil is removed and replaced with EPS geofoam. Since it significantly reducing stress to underlying sub-grades, it can be used on both soil and rocky slopes.

Geofoam is also an excellent choice as pavement insulation for both highway and airport roadways, and provides a lightweight, stable base in construction over utility lines.

Where weight reduction is vital, geofoam is an ideal material choice. When used to make roof-top planters for urban gardens, it provides a water-resistance medium that does not add significant load to the roof structure. A popular material in stadiums, theatres, and gymnasiums, geofoam is the fill material of choice for places where tiered seating is needed.

Geofoam is easy to use and can be installed without the special lifting equipment usually needed with steel, wood, concrete and other heavy materials. Its high compressive resistance and low weight make it effective for both new construction and renovation projects.

Why Use Geofoam?

Saving time and money is always important on any construction project. Using EPS geofoam blocks accomplishes this in several ways:

First, and perhaps the most significant, is reduced labour and equipment costs. Since geofoam is so light and easy to install, it can quickly be carried to the work site and set in place by a labourer. If alterations are needed for blocks to fit properly, there is no need to send them back to the factory or to arrange for special on-site equipment. EPS geofoam can easily be trimmed using a hot wire cutter or hand saw.

Geofoam can be installed in most weather conditions and there is no need for soil compaction and stabilisation before blocks can be set into place.

Safety of employees and the environment is a top priority on the construction site. Geofoam is lightweight and does not require heavy lifting to set it place, reducing on-the-job injuries.

The blocks are non-toxic and do not attract animals or insects. Since EPS geofoam does not provide nutrients, plant roots will not infiltrate the foam blocks and compromise structural integrity. In addition, there are no negative effects on soil and groundwater quality, and geofoam reduces runoff to site-adjacent water sources.

When it comes to customisation, geofoam is beyond comparison. Companies like Foam Technologies make expanded polystyrene (EPS) geofoam blocks that come in standard block sizes, or that can be factory cut into custom shapes and sizes depending on the specific needs of the project. When you consider all its advantages, it’s easy to see why geofoam is one of the best-selling lightweight fill materials for new and remodelling of landscape features in construction projects. If you are looking for polystyrene (EPS) foam in perth contact Foam Technologies

1 note

·

View note

Photo

Geofoam blocks provides stability to unstable soil conditions

Call Us ☎+971 2 5511166 WhatsApp 📲 052 10 20 30 0 Website 🌐https://www.styrene-uae.com/polystyrene-products/geofoam/

#Styrene#styrofoam#polystyrene#manufacturingindustry#lightweight#safe#ecofriendly#environment#recyclable#recycling#geofoam#abudhabi#uae

0 notes

Link

0 notes

Text

Geofoam Market Growth, Industry Forecast 2021-2027

A study recently conducted by the strategic consulting and market research firm BlueWeave Consulting revealed that global geofoam market was worth USD 698.3 million in 2020 and is further projected to reach USD 1,105.4 million by 2027, at a CAGR of 6.9 % during the forecast period (2021-2027). Growth in the geofoam market can be attributed to increasing demand for geofoam from end-user industries due to their excellent and superior properties. Additionally, geofoams are an easy alternative to traditional land stabilization materials due to their cost-effective nature. During the forecast period, the development of infrastructure and the adoption of modern technology will likely generate new opportunities for the geofoams market.

Geofoams' cost-effectiveness is propelling the market growth.

Geofoams' familiarity, pervasiveness, and low cost have made them the favored option for the construction industry. Geofoam's strength and flexibility make it the ideal material for construction projects. It may be installed using basic hand tools, reducing construction labor, investment, and operating costs. For instance, Foamshield, a new product from Airfoam launched in June 2021, can significantly reduce the cost of insulating a home. FoamShield is a rigid EPS insulation that can be installed around an uninsulated wood-frame wall with a sheathing membrane. Hence, geofoams' benefits as an alternative to traditional materials for land stabilization contribute to the market’s growth.

Growing infrastructural activities and technological advancement are expected to drive the geofoam market.

The large-scale growth of infrastructure in emerging countries and the upkeep and maintenance of existing infrastructure in developed countries drive demand for geofoam. According to the Department for Promotion of Industry and Internal Trade, FDIs (Foreign Direct Investments) in the construction development sector (townships, housing, built-up infrastructure, and construction development projects) and construction (infrastructure) activities totaled USD 26.08 billion and USD 24.72 billion, respectively, in India between April 2000 and March 2021. (DPI). In FY21, FDI inflows totaled USD 81.72 billion, or 13% of the overall inflows. Expanded polystyrene also has various advantages over conventional earthen dams, including quick construction and the use of prefabricated bridge and bridge support components. These advancements are expected to help grow the geofoam industry in the upcoming years.

Request For Free Sample Report @ https://www.blueweaveconsulting.com/report/global-geofoam-market/report-sample

Global Geofoam Market: By Type

Based on types, the global geofoam market is categorized as expanded polystyrene geofoams (EPS) and extruded polystyrene geofoam (XPS). Out of these, the extruded polystyrene geofoam segment accounted for a significant market share in 2020 and is likely to dominate the segment during the forecast period. The segment’s growth can be attributed to its properties as it provides insulation and protection to the structures. Furthermore, the product is made of recycled materials and can be shaped into various forms, including sheets and blocks. Additionally, it has higher insulation properties than extruded polystyrene geofoams, which encourages its use in areas such as walls, basements, and attics.

On the other hand, due to its multi-functionality, diverse applications for soft ground construction, greater strength, flexibility, and low cost compared to extruded polystyrene geofoam, expanded polystyrene is likely to grow at the fastest CAGR throughout the forecast period.

Impact of COVID-19

The pandemic affected several aspects of the geofoam value chain. COVID-19 significantly impacted several financial and industrial sectors, including travel and tourism, manufacturing, construction, and aviation. Geofoam end-use industries such as road building and paving and airport construction were also severely affected. The construction industry was one of the most severely affected industries as most nations imposed strict lockdowns and curfews to prevent the spread of Coronavirus, which led to construction activities being halted. Airports worldwide have also been affected by the global ban on international and domestic flights, which has negatively impacted the global geofoam market.

North America Leads the Global Geofoam Market

North America held a significant market share in 2020 and is likely to dominate during the forecast period. Geofoams are becoming increasingly popular in North America due to growing awareness among civil engineers regarding their use in infrastructure and construction. Additionally, the region has seen a growth in the use of geofoams in maintaining and rehabilitating existing roads, highways, and flyovers. For instance, between 2016 and 2020, the Fixing America's Surface Transportation (FAST) Act and the Highway Trust Fund approved a fund of more than USD 300 billion, emphasizing infrastructure safety and structural highway programs.

Competitive Landscape

Due to the presence of numerous players in the market, the global geofoam market is moderately fragmented. Developing new products, expanding, and acquiring enable companies to remain competitive. Some of the leading players are increasing their global footprint by acquiring overseas companies. Some key players in the global geofoam market are Carlisle, Amvic Inc., Atlas Roofing Corporation, Insulation Company of America, LLC, Foam Products Corporation, Jablite, Thermafoam, LLC, Expol, Pacific Allied Products, Ltd., Airfoam, Harbor Foam, Groupe Legerlite Inc., Drew Foam, Plasti-Fab Ltd., and other prominent players.

About Us

BlueWeave Consulting provides all-inclusive Market Intelligence (MI) Solutions to businesses regarding various products and services online & offline. We offer comprehensive market research reports by analyzing both qualitative and quantitative data to boost up the performance of your business solution. BWC has built its reputation from the scratches by delivering quality inputs and nourishing long-lasting relationships with its clients. We are one of the promising digital MI solutions companies providing agile assistance to make your business endeavors successful.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

GREENMAX machines can recycle waste EPS into new foam products

The quality of EPS material is useful in packaging-cheap, light, and able to fill space in boxes, but this makes recycling and transportation uneconomical.

Actually, 100% of the EPS can be recycled, but most municipalities don’t want to spend money to collect it. Philadelphia and Baltimore provide EPS recycling for materials provided by municipal recycling centers, do not provide roadside pick-up foam.

Because of its labor-intensive characteristics, high cost and lack of proper recycling channels, the EPS recycling rate in the world accounts for only about 15% of the total consumption of plastics so far. However, due to the limitation of petroleum resources in the world, it is of great significance to consider the conservation of earth resources and the recovery of plastic foam. To recycle more plastic waste, many countries are now working to develop new technologies to recycle plastic solid waste to reduce the cost of recycling EPS waste.

GREENMAX has several machines for waste EPS recycling, including an EPS compactor or EPS Melting Machine. These machines can handle different types of EPS waste, which will be a good helper for waste plastic recycling. GREENMAX Polystyrene Compactors can crush large foams, and compress crushed foam into blocks at a ratio of 50:1. The EPS Melting Machine works with melting technology to make foam ingots up to a ratio of 90:1. Both of the two machines are efficient.

The recycled EPS can be used for household insulation, plastic clothes hanger, and photo frame, and other products. Flynn said the foam could eventually be used in building materials, including molds for concrete and “geofoam” for stabilizing and building ground under foundations or road embankments.

0 notes

Text

Different Types of Geotextile

If we talk about Geotextile, then one cannot ignore the fact that Rajdhani Syntex is the best Geobag manufacturer in India. They are famous when it comes to the manufacturing of geotextile and Geobags as they have years of experience in this field. However, let's continue to discuss different types of geotextiles. One can classify geotextile in two ways, and they are according to the manufacture and time of use.

Types of Geotextile Based on Manufacture

One can manufacture by weaving or by knitting it or by using the nonwoven technologies. One can classify geotextile in the following ways:

✔ Woven Geotextiles

With the interlacement of the two sets of yarns that too at the right angle through the knitting process, then woven geotextiles are produced. These textiles have higher modulus and strength in the weft and warp direction, and at rupture, they have low elongation.

✔ Non-woven Geotextiles

These geotextiles are made from continuous filaments or the staple fibers and are thicker than the woven geotextile. These can be produced in various bonding techniques like needle punching, chemical and thermal bonding.

✔ Knitted Geotextiles

When the interloping of one or more yarn is done in the knitting process, then knitted geotextile is produced. These have high extensibility and low strength as compared to woven geotextiles.

✔ Stitch Bonded Geotextile

When the interlocking of yarns or fibers or both is done either through sewing or stitching is called as the stitch-bonded geotextiles. You can produce the heavyweight and strong geotextile rapidly through this bonding process. Manufactured tubular geotextiles can be in cylindrical and tubular fashion without any longitudinal seam.

✔ Geonets

The open grid-like material that is formed by two sets of the parallel, coarse and extruded polymeric strands that are intersecting at an acute angle is geonets. This network will form a sheet with the in-plane porosity so that it can be used for carrying the relatively large fluid or gas flow.

✔ Geogrids

The material which has open grid-like material is called geogrids, and they are mainly used in the reinforcement of the soil.

✔ Geomembranes

The continuous flexible sheets that are manufactured from synthetic materials are geomembranes. These are impermeable and can be used as the liner for the gas and fluid containment as well as vapor barriers.

✔ Geocomposites

These are made from the combination of two or more geosynthetic types such as geotextile-geogrid; geotextile-geonet; or geonet-geomembrane.

✔ GCLs

These are Geocomposites which are prefabricated along with the bentonite clay layer. It is typically incorporated between the top, and bottom layer of the geotextile or the geotextile bentonite is bonded to the geomembrane.

✔ Geocells

These are thick 3-D networks that are constructed from the strips of the polymeric sheet, and then for forming the interconnected cell, the strips are joined together. These are then filled with concrete or soil.

✔ Geopipes

These are the perforated or the solid-wall polymeric pipes which are used for drainage of gas and liquids.

✔ Geofoam

For creating the geofoam slabs or the blocks, expansion of polystyrene foam is used in the low-density network.

Types of Geotextile Based on Time of Use

✔ 1st Generation

Earlier geotextiles were manufactured for the carpet, and industrial sacking bit later they were used for manufacturing geo technical purposes and were called as the 1st generation geotextile.

✔ 2nd Generation

These are the geotextiles that were manufactured for specific geo-technical purposes but without adopting modern manufacturing technology.

✔ 3rd Generation

These are the geotextiles that were manufactured, produced and designed for meeting the end-use of the client and were actual geo-textile.

You may be thinking from where can you get all these types of geotextile that too at affordable rates then the answer is Rajdhani Syntex. They are the best geotextile and Geobag Supplier in Bihar which can help you in meeting your requirement of the geotextiles and other geo fabrics.

Source URL:

https://penzu.com/public/cfb0662b

#Geobag Supplier in Assam#Geobag Supplier in Bihar#Geobag Manufacturer in India#Geobag Supplier in India#Nonwoven Geofabric Supplier in India#Geotextile Manufacturer in India

0 notes

Text

What is Cellular Concrete?

Cellular concrete is a low-density fill material. It is in geotechnical applications. To make cellular concrete, pre-formed stable foam blends with a slurry made of cement. Cellular concrete is a foam cement or lightweight flowable fill.

There are many types of lightweight cementitious materials, but the significant difference between those materials and cellular concrete is the external foam used on cellular cement to reduce its density.

Uses of Cellular Cement

Cellular concrete has numerous uses. One primary application throughout the world is in construction jobs, where the concrete is used to build things like the roof deck and floor deck. For roof decks, it is meant to reduce the possible weight and provide thermal and sound insulation. Cellular concrete floor decks reduce weight and help maintain the quality of the floor.

Cellular concrete can replace gypsum-based mixes or level them. It is in geotechnical applications such as void fill abandonments. Besides construction jobs, cellular concrete can be used in architecture applications and so much more.

Other Uses

Cellular concrete is used in many other applications, including:

Fencing panels along highways. It's used because of its ability to minimize sounds coming from outside in addition to blocking outsiders from viewing. You can also save on its weight because of its light.

It was filling culvert trenches. Cellular concrete is the best for culvert trench fills because it does not allow the soil to settle later or cause dips inroads.

It's an excellent choice for the construction of interior walls. It reduces weight and is more affordable. It is also more soundproof and fire-resistant.

Cellular concrete is the best for patios, porch decks, and sidewalks because it is lesser in weight and more affordable.

It is an excellent option for any applications that need a flowable fill or geofoam.

Why Use Cellular Concrete from Kilgore Companies?

Cellular concrete from Kilgore Companies is the most preferred fill material because:

It has better insulative properties.

Its more pumpable

It flows smoothly, which makes it ideal for construction jobs.

It's lightweight and therefore easy to handle

For more information on cellular concrete, do not hesitate to contact Kilgore Companies today.

0 notes

Photo

⚡️🤘🏼🤠ain’t no party like an @sgpropmke @geofffitzharris geo foam block party! 🤠🤘🏼⚡️ #bayview #geofoam #party #hotsummer #geterdone #buildshit #sgpropmke (at Bay View, Wisconsin) https://www.instagram.com/p/CCwOLC3HRUL/?igshid=vqoqktxr0skt

0 notes

Photo

EPACK is a leading EPS geofoam manufacturer and geofoam blocks supplier, eps thermocol blocks in India. EPACK is the largest EPS Geofoam blocks manufacturer for the construction of highways, bridges, Rail Embankment, and road construction in India.

0 notes

Text

Product Spotlight: StarRFoam Stadium Seating-EPS GeoFoam.

One of EPS Geofoam's increasingly popular applications is the construction of stadium seating for commercial movie theaters and lecture halls etc. Geofoam is an ideal solution for building stadium seating. It was used throughout a variety of nationwide projects, ranging in size from a small home theater to a 22,000 seat sports stadium. In precut blocks, geofoam is supplied with each block labeled by tier and row. A drawing accompanies the foam blocks, which shows the installation crew where each block should be placed. StarRFoam pre-fabricate geofoam blocks to the specified size and shape so that they are instantly ready to be placed after arrival. StarRFoam's Stadium Seating geofoam is available in a wide range of densities to guarantee the reliability and integrity of the structures. The steel gripper plate is placed between layers that lock it together. All the pieces are precut, requiring little, if any, on-site modification. The project is ready for concrete after the final tier has been installed. Is it cheaper and better possible? If StarRFoam's Stadium Seating Geofoam is used for stadium seating, it is! Geofoam is much faster to install than steel metal framing and much cheaper.

Not sure what your project needs?

StarRFoam Stadium Seating is a lightweight, closed-cell, rigid insulation manufactured from expanded polystyrene (EPS). It is a cost-effective, durable, and time-saving solution. Stadium Seating meets or exceeds ASTM C578, Standard Specification for Rigid, Cellular, Polystyrene Thermal Insulation. Contact us today at 800-722-6218, and speak to StarRFoam's professional foam associate. We'll give you a FREE quote and answer any questions you have about selecting the right EPS product for your construction project. Log onto our website www.starrfoam.com for more information.

0 notes

Text

Unknown Facts About Geotextile

Summary

Picture Courtesy: Comsyn

The application of Geotextile is changing rapidly as research shows results and manufacturing processes improve. Fundamental considerations in design and installation are also to be discussed. India is a large producer of jute, jute is a low cost, renewable, biodegradable and eco-friendly product for making geotextile.

History of Geotextile Application Textiles were first applied to roadways long back, in the days of the Pharaohs. Even they struggled with unstable soils that rutted or washed away. They found that natural fibers, improved road quality when mixed with soils, particularly unstable soils. In the 1920s it is said that the state of South Carolina used a cotton textile to reinforce the underlying materials on a road with poor quality soils. Several years later it is found that the textile in good workable condition. In the 1960s, when synthetic fibers became more available, textiles were considered more seriously for roadway construction and maintenance.

Different Categories of Geosynthetics

Geotextiles- These are flexible textile fabrics used to provide filtration, separation or reinforcement in soil, rock and waste material. Geomembranes- These are impermeable polymeric sheets used as a carrier for liquid or solid waste.

Geogrids- Stiff or flexible polymer grid-like sheets used primarily as reinforcement of unusable soil.

Geonets- stiff polymer nets like sheets with an in-plane opening used primarily as a drainage material within landfills or soil and rock masses. Geosynthetic clay liners- Clay layers incorporated between geotextile and geomembrane and used as a barrier for liquid or solid waste containment.

Geopipes- Perforated or solid wall polymeric pipes used for the drainage of various liquids.

Geofoam- A newer category of product is geofoam. Geofoam is manufactured into large blocks which are stacked to form a lightweight thermally insulating mass buried within a soil or pavement structure.

Conclusion Certain fundamental considerations are necessary for success in any application of Geotextiles. We must know the soils to select the proper geotextile in road construction and maintenance. In many installations, permeability may override concern for durability and resistance to bursting, puncturing and tearing.

0 notes