#Structural stability

Explore tagged Tumblr posts

Text

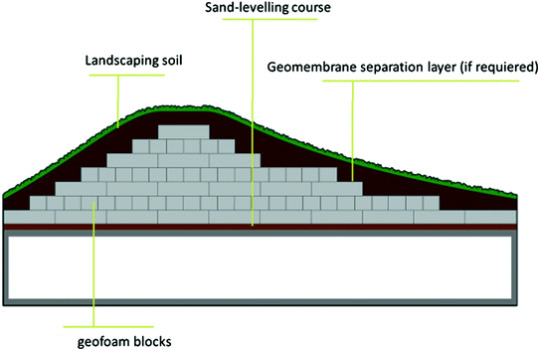

Unraveling the Growth Potential of the Geofoams Market: Global Outlook

The global geofoams market size is expected to reach USD 972.6 million by 2027, expanding at a CAGR of 2.7%, according to a new report by Grand View Research, Inc. Factors such as availability of geofoams at low cost coupled with its superior strength and durability are projected to fuel the market growth. Expansion of the construction industry across the globe coupled with the infrastructural developments in economies such as India, China, Brazil, Mexico, Saudi Arabia, and others is expected to propel the demand for geofoams over the forecast period. In addition, maintenance of the existing infrastructure in developed nations is likely to drive the growth of the market.

Geofoams Market Report Highlights

The expanded polystyrene geofoams segment accounted for USD 508.2 million in 2019 and is projected to expand at a CAGR of 3.1% from 2020 to 2027. The compatibility of the product has resulted in its increasing adoption for applications including roads and highway construction, building and infrastructure, and others

The road and highway construction application segment accounted for 38.07% of the total market and is projected to expand at a CAGR of 3.4% from 2020 to 2027 on account of the rising infrastructural growth across the developing economies including China, India, Brazil, UAE, Saudi Arabia, and others

Asia-Pacific accounted for USD 278.5 million in 2019 and is estimated to expand at a CAGR of 3.2% from 2020 to 2027 owing to the rising demand for road pavement, which is anticipated to further benefit the growth

China accounted for the highest market share in Asia Pacific on account of the rapidly expanding construction industry in the country

Europe market is estimated to expand at a CAGR of 2.8% owing to the rising number of construction and infrastructural activities in economies including Spain, Italy, and others

For More Details or Sample Copy please visit link @: Geofoams Market Report

Geofoams are increasingly used in the construction industry as it helps in suppressing the noise and vibrations. In addition, it is easy to handle and does not require any special equipment for installation. The product is increasingly used in the railway track systems, below the refrigerated storage buildings, storage tanks, and others to avoid ground freezing.

The geofoams undergo chemical changes when it comes in contact with petroleum solvents. It turns into a glue-type substance, thereby losing its strength. This factor is projected to limit the use of geofoams in the construction industry which is projected to restrict the industry growth over the forecast period.

#Geofoam#Expanded polystyrene (EPS)#Geofoam blocks#Construction materials#Road and highway construction#Retaining walls#Geotechnical engineering#Soil stabilization#Environmental protection#Earthquake resistance#Noise and vibration control#Water management#Hydrostatic pressure#Thermal insulation#Structural stability

12 notes

·

View notes

Text

How the Right Dowel Bars Improve the Performance of Concrete

Concrete systems depend closely on excellent reinforcement substances for durability and energy. The combination of well-decided-on dowel bars with excessive-grade TMT Saria creates construction answers that face up to immense pressure and demanding environmental situations. Leading TMT Saria manufacturers recognize that reinforcement systems require strategic integration of multiple components to achieve optimal structural integrity.

Understanding the Synergy Between TMT Saria and Dowel Bars

TMT (Thermo-Mechanically Treated) Saria presents the primary tensile electricity in strengthened concrete, serving as the spine of structural integrity. However, while concrete sections meet—consisting of highways, business floors, or constructing foundations—dowel bars turn out to be crucial connecting elements. These specialized bars transfer loads across concrete joints while allowing necessary horizontal movement.

The relationship between these components isn't merely additive but synergistic. Quality dowel bars complement TMT Saria by preventing differential settlement and minimizing stress concentration at critical junctures. This partnership dramatically extends the functional lifespan of concrete structures, particularly those exposed to heavy traffic or shifting loads.

Key Factors Affecting Dowel Bar Performance

Several characteristics determine how effectively dowel bars enhance TMT reinforcement systems:

Material Composition: Premium dowel bars feature consistent carbon content and precise microstructure that align with TMT Saria specifications, ensuring compatible expansion rates and corrosion resistance.

Surface Treatment: Epoxy-coated or stainless-steel dowel bars dramatically lessen corrosion capacity while used along with corrosion-resistant TMT Saria, especially in moisture-inclined packages.

Dimensional Precision: Properly sized dowel bars distribute loads calmly throughout concrete sections, stopping localized stress on TMT reinforcement networks.

Installation Alignment: Even the highest-grade materials from a TMT Saria manufacturer will underperform if dowel bars aren't perfectly horizontal and parallel to traffic direction.

The Hidden Role of Binding Wire in Reinforcement Systems

While focus often centers on dowel bars and TMT Saria, binding wire plays a crucial supporting role that affects overall structural performance. Quality binding wire secures reinforcement components during concrete placement, maintaining precise spacing and alignment. The interaction between binding wire, dowel bars, and TMT Saria creates a comprehensive reinforcement system greater than the sum of its parts.

Construction teams should select binding wire that resists corrosion and maintains tensile strength compatible with both TMT Saria and dowel bars. Inadequate binding wire can compromise positioning during concrete pouring, negating the benefits of even premium-grade reinforcement materials.

Optimizing Construction Projects Through Integrated Solutions

Construction professionals increasingly recognize that sourcing TMT Saria, dowel bars, and binding wire as an integrated package improves project outcomes. Selecting materials from a reputable TMT Saria manufacturer that also provides compatible dowel bars ensures dimensional tolerance matching and consistent material properties across all reinforcement components.

Modern construction specifications now frequently require documented compatibility testing between dowel bars and TMT Saria, particularly for infrastructure projects with expected lifespans exceeding 50 years. This evolving standard acknowledges the critical relationship between these reinforcement elements.

Making Informed Reinforcement Decisions

When evaluating reinforcement options, construction teams should:

Consider the specific load transfer requirements at concrete joints.

Match dowel bar specifications with TMT Saria grade and dimensions.

Select appropriate binding wire that maintains positioning integrity.

Consult with specialized TMT Saria manufacturers about compatibility assurance.

The modest additional investment in properly specified dowel bars yields substantial returns through extended service life and reduced maintenance requirements. Projects utilizing integrated reinforcement solutions typically demonstrate superior crack resistance and load distribution characteristics compared to those using mismatched components.

The construction industry continues moving toward system-based reinforcement approaches rather than treating dowel bars, binding wire, and TMT Saria as separate considerations. This holistic perspective recognizes that structural performance depends on how successfully these elements work together to create durable, resilient concrete structures designed for generations.

#dowel bars#concrete performance#construction strength#concrete durability#structural stability#concrete reinforcement#concrete joints#dowel bar placement#dowel bar use#concrete quality#concrete cracks#reinforced concrete#construction materials#concrete design#road construction#dowel bar benefits#concrete roads#concrete repair#dowel bar installation#construction tips#concrete solutions.

0 notes

Text

Column Jacketing: Types and Benefits Explained

Column jacketing strengthens columns and improves their load-carrying capacity. Engineers add materials around existing columns to boost their strength, stiffness, and durability. This method helps repair and upgrade structures to meet modern safety standards. Jacketing of columns increases their resistance to seismic forces, making buildings safer during earthquakes. It also improves the…

#building rehabilitation#building renovation#civil engineering#column jacketing#column strengthening#composite jacketing#concrete jacketing#construction repair#FRP jacketing#infrastructure upgrade#load-bearing capacity#reinforced concrete#retrofitting columns#seismic retrofitting#steel jacketing#Structural Engineering#Structural Integrity#structural reinforcement#structural stability#structural strengthening

0 notes

Text

The Role of Binding Wire in Structural Stability: A Deep Dive into Construction's Essential Component

Structural stability forms the backbone of every construction project, and binding wire plays a pivotal role in this critical aspect. From towering skyscrapers to robust bridges, this humble yet essential component ensures the integrity of reinforced concrete structures worldwide.

Understanding the Foundation of Structural Stability

Binding wire serves as the invisible force that holds reinforcement bars together, creating a stable framework within concrete structures. This seemingly simple element becomes the cornerstone of structural integrity, ensuring that reinforcement bars maintain their designed positions during concrete placement and throughout the structure's lifetime.

Critical Functions in Construction

Reinforcement Assembly

The primary function of binding wire in construction involves:

Securing reinforcement bars at intersections

Maintaining precise spacing between bars

Ensuring proper alignment during concrete pouring

Preventing displacement under construction loads

Load Distribution

Proper binding wire installation contributes to:

Even distribution of structural loads

Prevention of stress concentration

Enhanced structural performance

Improved seismic resistance

Durability Factors

Material Properties

High-quality binding wire exhibits essential characteristics:

Superior tensile strength

Optimal ductility

Resistance to corrosion

Consistent diameter throughout

Environmental Considerations

Binding wire must withstand various environmental challenges:

Temperature fluctuations

Moisture exposure

Chemical reactions

Physical stress

Technical Specifications and Performance

Strength Requirements

Different construction applications demand specific strength characteristics:

Breaking force tolerance

Elongation capacity

Yield strength

Fatigue resistance

Quality Standards

Industry standards ensure reliable performance through:

Material grade specifications

Dimensional accuracy

Surface finish requirements

Coating integrity

Applications in Different Structures

Building Construction

Binding wire proves essential in:

Column reinforcement

Beam assemblies

Slab construction

Foundation work

Infrastructure Projects

Large-scale applications include:

Bridge construction

Highway structures

Underground facilities

Retaining walls

Impact on Long-Term Stability

Structural Integrity

Proper binding wire selection and installation ensure:

Maintained reinforcement positioning

Enhanced concrete bonding

Reduced crack propagation

Extended structure lifespan

Performance Factors

Key considerations include:

Load-bearing capacity

Stress distribution

Movement accommodation

Structural flexibility

Selection Criteria for Projects

Material Grade

Choose binding wire based on:

Project specifications

Load requirements

Environmental exposure

Budget constraints

Application Requirements

Consider specific needs like:

Ease of installation

Accessibility

Maintenance requirements

Safety factors

Best Practices in Installation

Proper Techniques

Ensure optimal performance through:

Correct tying methods

Appropriate tension application

Clean surface preparation

Regular inspection

Quality Control

Maintain standards by:

Checking wire specifications

Verifying proper installation

Documenting procedures

Conducting regular inspections

Future Considerations

Innovation in Materials

Advancing technology brings:

Enhanced coating systems

Improved strength characteristics

Better corrosion resistance

Sustainable options

Industry Trends

Stay informed about:

New application methods

Updated safety standards

Environmental regulations

Performance requirements

Making Informed Decisions

Selection Process

Consider these factors when choosing binding wire:

Structure type and size

Environmental conditions

Loading requirements

Installation conditions

Professional Guidance

Seek expert advice regarding:

Material specifications

Installation methods

Quality control measures

Maintenance requirements

The Path Forward

Understanding the crucial role of binding wire in structural stability helps ensure successful construction outcomes. Careful consideration of material properties, installation techniques, and quality control measures leads to durable, stable structures that stand the test of time.

For optimal results, work with reputable suppliers who provide high-quality binding wire meeting project specifications. Remember that investing in quality materials and proper installation techniques pays dividends through enhanced structural stability and reduced maintenance needs.

Proper selection and installation of binding wire significantly impact overall structural performance. Base decisions on thorough evaluation of technical requirements, environmental conditions, and quality standards to achieve optimal results in every construction project.

#binding wire#structural stability#reinforcement#concrete bars#construction#wire strength#load distribution#stability#construction wire#binding wire use#construction bars#concrete wire#wire materials#wire installation#durability#binding wire quality#wire performance#structural wire#wire manufacturing#binding bars#construction safety

0 notes

Text

Excavation is a fundamental step in construction, laying the groundwork for a stable and secure structure. This blog delves into the importance of excavation, the techniques involved, and its impact on overall construction quality. Learn how proper excavation practices ensure the longevity and safety of buildings. Visit ShreeTMT to explore more about the role of excavation in construction.

#Excavation#Construction#Building Foundation#ShreeTMT#Construction Techniques#Excavation Practices#Structural Stability#Construction Quality#Building Longevity#Construction Safety

0 notes

Text

Structural Engineers Group & Third-Party Testing, Inspection, Verification & Certification services provider

NDT testing:

Non-Destructive Testing (NDT), provided by Geocontech, encompasses a range of techniques crucial for assessing materials and structures without causing harm. These methods, including Ultrasonic Pulse Velocity testing, Rebound Hammer testing, and Core Cutting testing, allow for thorough inspections to detect flaws, discontinuities, or weaknesses that could compromise structural integrity. By employing NDT services, industries can ensure the reliability and safety of their assets while minimizing downtime and costly repairs. Geocontech offers comprehensive NDT consultancy and inspection services tailored to meet the specific needs of clients across various sectors, maintaining high standards of quality and accuracy in every evaluation.

For businesses seeking Non-Destructive Testing and Inspection Services, Geocontech provides expertise in utilizing advanced techniques like Ultrasonic Pulse Velocity testing, Rebound Hammer testing, and Core Cutting testing. These methods are instrumental in identifying defects and evaluating material properties without causing damage, ensuring the integrity and longevity of critical structures and components. With a commitment to precision and reliability, Geocontech delivers NDT solutions that meet industry standards and regulatory requirements, supporting clients in maintaining operational efficiency and safety across their projects.

structural engineers:

When considering the best companies for structural engineers, Geocontech emerges as a leader in the field of structural stability and testing services. Specializing in Structural Stability Certificate Consultancy, Geocontech provides thorough and reliable structural stability checking services tailored to meet the needs of building owners, developers, and construction firms. Their expertise extends to Building Structural Stability Testing Service, ensuring compliance with rigorous inspection, verification, and certification standards for both new constructions and existing structures.

Geocontech excels in Construction Testing Inspection verification and certification, offering specialized services that guarantee the structural integrity and safety of buildings, factories, and other infrastructure projects. Their commitment to excellence in Building Testing and Factory Testing Inspection further solidifies their reputation as a trusted partner in ensuring structural stability across diverse sectors. By leveraging advanced engineering techniques and adhering to industry best practices, Geocontech delivers comprehensive solutions that prioritize safety, efficiency, and compliance with regulatory requirements.

best concrete repairs and restoration:

When seeking the best concrete repairs and restoration solutions, Geocontech excels in offering comprehensive Structural Rehabilitation Services. Specializing in Structural Repairs and Rehabilitation Services, Geocontech provides tailored solutions to address concrete deterioration, cracks, and structural weaknesses effectively. Their expertise extends to Structural Repairing Service & Rehabilitation, where they utilize advanced techniques and materials to restore the integrity and longevity of concrete structures.

Geocontech's commitment to excellence in Structural Repair Services ensures thorough assessment, precise repair methodologies, and adherence to industry standards. Whether it's repairing structural elements in buildings, bridges, or other infrastructure, Geocontech's skilled team delivers reliable solutions that enhance durability and structural stability. By prioritizing quality craftsmanship and innovative repair techniques, Geocontech stands out as a trusted partner for clients seeking robust concrete repairs and restoration services.

project management consulting:

Project management consulting involves specialized advisory services provided by experts to help organizations effectively plan, execute, and control their projects. Geocontech, a leading name in this field, offers top-tier Project Management Consultants (PMCs) who assist clients in Chennai and beyond with comprehensive PMC Services. These services encompass strategic planning, resource allocation, risk management, and quality control to ensure projects are delivered on time, within budget, and to the highest standards.

Geocontech's PMC Project Management Consultancy includes tailored solutions that cater to the unique needs of each project. Their team of experienced Project Management Consultants brings expertise in overseeing project lifecycles from inception to completion, ensuring efficient coordination among stakeholders and adherence to project goals. By leveraging industry best practices and innovative methodologies, Geocontech enhances project efficiency and minimizes risks, making them a trusted partner for organizations seeking reliable project management consulting services.

Soil Testing & Mix Design Services:

Conducting a Marshall mix design test is essential for determining the optimal asphalt binder content in asphalt mixtures, ensuring durability and performance in road construction. At Geocontech, we specialize in providing comprehensive Soil Test & Concrete Design Mix services, including precise Soil Testing & Mix Design Services and Concrete Mix Design Test Services. The Marshall mix design test begins with careful selection of aggregates and asphalt binders based on project specifications and environmental conditions. Samples are then prepared and compacted using a Marshall compactor to simulate real-world conditions, followed by testing to measure stability, flow, air voids, and density. Through meticulous analysis of these results, our expert team ensures that asphalt mixtures meet stringent quality standards and performance requirements, offering tailored solutions that enhance the longevity and resilience of infrastructure projects.

0 notes

Text

Carefully testing the floor beneath his feet, the kender stepped out into the hall.

"DragonLance Chronicles: Dragons of Autumn Twilight" - Margaret Weis and Tracy Hickman

#book quote#dragonlance chronicles#dragons of autumn twilight#margaret weis#tracy hickman#tasslehoff burrfoot#careful#testing#floor#structural stability#kender#hall of the ancestors

0 notes

Text

Little P.Eng. Engineering for Structural and Piping Design in Hydrogen Pilot Plant for Green Energy

In the race to counteract climate change, green energy solutions are imperative. Hydrogen, known as the universe's most abundant element, offers a promising pathway. Pilot plants are experimental setups designed to understand and optimize large-scale industrial processes. Little P.Eng. Engineering has emerged as a pivotal player in realizing this potential by specializing in the structural and piping design for hydrogen pilot plants.

Hydrogen's Role in Green Energy

Hydrogen is not just another energy source; it's a powerful, clean fuel that, when consumed, emits only water as a byproduct. Green hydrogen, especially, is produced using renewable energy sources, ensuring a low-carbon footprint. As governments and industries realize its potential, pilot plants that can produce, store, and utilize hydrogen efficiently are in demand.

Little P.Eng. Engineering’s Expertise

Little P.Eng. Engineering's team specializes in addressing the unique challenges posed by hydrogen in pilot plants. Their structural and piping designs consider factors such as hydrogen's low density, its propensity to embrittle metals, and the safety requirements necessary when working with the element.

Structural Design Considerations

Hydrogen Embrittlement: Hydrogen can make metals brittle, especially under high-pressure conditions. The structural components must be designed with materials resistant to this phenomenon.

Safety Measures: Hydrogen is flammable. Incorporating explosion-proof structures, safe zones, and preventive measures against accidental leaks is paramount.

Modularity: As pilot plants are often experimental setups, flexibility and modularity in design allow for changes based on the evolving understanding of the process.

Piping Design Considerations

Material Selection: Given hydrogen's small molecule size, it can easily leak through many materials. Piping must be constructed with materials that prevent leakage and are resistant to embrittlement.

Pressure Challenges: Hydrogen storage and transport require high-pressure conditions. The piping system must handle these pressures, ensuring safety and efficiency.

Temperature Factors: Liquid hydrogen storage needs extremely low temperatures. This necessitates designs that can handle thermal stresses and expansion-contraction challenges.

Safety Valves and Monitoring Systems: Real-time monitoring of the hydrogen flow, pressure, and potential leaks are essential. Incorporating advanced monitoring systems and safety valves ensures timely detection and mitigation of any risks.

Applications in Green Energy

Hydrogen pilot plants are not just limited to producing hydrogen. They also focus on:

Storage: Efficiently storing hydrogen is a challenge. Pilot plants explore solutions like high-pressure gas storage or cryogenic liquid storage.

Power Generation: Pilot plants test fuel cells and other means to convert hydrogen back into electricity.

Integration with Other Renewable Sources: Connecting hydrogen production with wind, solar, and hydroelectric power sources ensures a continuous energy supply, even when these sources aren't generating power.

Green Mobility: Hydrogen fuel cell vehicles (FCVs) are on the rise. Pilot plants play a pivotal role in researching and optimizing hydrogen production, storage, and refueling stations for these vehicles.

Advancing the Future

Little P.Eng. Engineering's commitment to green energy is evident in its consistent research and innovation in structural and piping designs. By regularly updating their designs based on feedback from pilot plants, they ensure safety, efficiency, and scalability for large-scale hydrogen production.

The company also collaborates with universities, research institutions, and industries to stay at the forefront of technology. Such partnerships help in the exchange of ideas and the rapid adoption of best practices.

Challenges and Opportunities Ahead

While the potential of hydrogen as a green energy source is immense, there are challenges:

Economic Feasibility: Bringing down the costs associated with hydrogen production, storage, and usage is essential for its mainstream adoption.

Scalability: While pilot plants offer invaluable insights, scaling these solutions to meet global energy demands requires further research and innovations.

Public Awareness and Acceptance: For hydrogen to be widely adopted, both as an energy storage medium and a fuel, public understanding and acceptance of its benefits and safety are crucial.

Little P.Eng. Engineering, with its expertise and dedication, is poised to address these challenges, turning them into opportunities for a greener future.

Conclusion

As we grapple with the urgency of transitioning to green energy solutions, hydrogen emerges as a beacon of hope. With its abundant availability and potential for clean energy generation, it can revolutionize the energy landscape. Companies like Little P.Eng. Engineering, through their specialized structural and piping designs, play a pivotal role in this transition. As the world moves towards a sustainable future, the role of such innovators becomes even more significant.

Tags:

Meena Rezkallah

Little P.Eng. Engineering

Structural design

Energy efficiency

Engineering expertise

Hydrogen pilot plant

Green energy

Piping design

Sustainable energy sources

Hydrogen storage

Hydrogen transportation

Structural stability

Pressure-relief systems

Safety mechanisms

Hydrogen production

Electrolysis

Advanced simulations

Material embrittlement

Leak prevention

Optimal hydrogen flow

Seismic resilience

Weather-resistant structures

Modular designs

Renewable energy

Zero carbon emissions

Advanced safety

North American energy transition

Environmental consciousness

Hydrogen infrastructure

Hydrogen diffusivity

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng. Engineering#Structural design#Energy efficiency#Engineering expertise#Hydrogen pilot plant#Green energy#Piping design#Sustainable energy sources#Hydrogen storage#Hydrogen transportation#Structural stability#Pressure-relief systems#Safety mechanisms#Hydrogen production#Electrolysis#Advanced simulations#Material embrittlement#Leak prevention#Optimal hydrogen flow#Seismic resilience#Weather-resistant structures#Modular designs#Renewable energy#Zero carbon emissions#Advanced safety#North American energy transition#Environmental consciousness#Hydrogen infrastructure#Hydrogen diffusivity

0 notes

Text

one of my favourite ot3 dynamics is like these two people who are entangled by fate and revenge and honour and the guy who got caught up in it because of unceasing, unflinching devotion to one of them

#ot3#hanwenzhou#also zhanchengxian but not in the way you would expect#definitely whatever jo yeong lee gon and jeong tae-eul have got going on#and one day ill tell you all about how this is also about kundavai poonkuzhali and vanathi#i like to this the kebab ki haddi dynamic#the haddi provides stability and maintains the structural integrity of the kebab

442 notes

·

View notes

Text

The moon will sing a song for me

I loved you like the sun

Doomed lovers,,, star crossed lovers,,, maybe in another world they will have the chance meet again as Capitano/Thrain won’t be reborn in this one

#she was the sun and he was the moon#Mavuika prepared to go out in a final fiery blast but instead it was the cold that froze and stabilized her world#leaving her to blaze a new path for the future as the sacrificial structure he left behind allows her to move on when he can’t#mavuika#capitano#mavuitano#genshin impact#genshin 5.3#genshin 5.3 spoilers#genshin spoilers#my stuff#genshin#my post#genshin impact screenshots#I didn’t have her sig weapon so a 3 star one was the best one I had aesthetically 😢

143 notes

·

View notes

Note

So make the sub-heirs fight to put the heirs on the throne?

Took me a hot minute to realize you were talking about The Next Prince!

It kind of makes sense though, it would mean the king didn't have anything to fear from his own blood if they decided they wanted his throne. Instead of looking up at the aging monarch, it keeps the next in line looking down at their own heirs. Seems like historically it would leave a trail of dead sub-heirs, sure, but the king himself is sitting safer than you usually see in like the typical western monarch structure.

It wouldn't incentivize regicide unless you are super damn sure of your kid's skills against all the others, and keep the potential next monarch busy either trying to kill or protect certain sub-heirs.

#the next prince#ask#it would be interesting if it existed historically just to see if it is just another flavor of monarchy#or if it does something to stabilize the monarchy compared to what you see in the more traditionally thought-of structure#where a crown prince gets tired of waiting and rebels against the king#i mean it is a wider pool of candidates already by not limiting it to a specific bloodline but 4 main houses

21 notes

·

View notes

Text

The Advantages of Using Super Rings and TMT Steel for Structural Reinforcement

TMT Steel has revolutionized the development industry with its amazing power-to-weight ratio and advanced sturdiness in comparison to traditional reinforcement alternatives. When paired with modern accessories like Super Rings, structural initiatives gain great blessings in balance, longevity, and fee-effectiveness. Understanding these substances and their synergistic benefits helps developers make informed choices that affect creation pleasantly for decades to return.

The Evolution of Reinforcement Technology

Construction experts face consistent strain on stability mission prices with structural integrity necessities. Traditional mild steel reinforcement served its motive for generations; however, cutting-edge construction demands have shifted toward materials presenting stronger performance traits. TMT Steel emerged as a game-changer with the aid of introducing thermo-mechanical treatment procedures that essentially regulate steel's microstructure.

Key Performance Advantages of TMT Steel

Beyond primary power metrics, TMT Steel delivers precise benefits that translate to real-world creation benefits:

Superior Ductility: TMT steel's potential to bend without breaking proves crucial at some stage in seismic occasions, permitting systems to flex instead of failing catastrophically.

Weldability: Unlike some excessive-power alternatives, TMT Steel keeps tremendous weldability, simplifying on-site adjustments and connections.

Corrosion Resistance: The subtle grain structure of TMT Steel increases resistance to environmental degradation, extending provider lifespans in aggressive environments.

Fatigue Resistance: Cyclic loading—commonplace in bridges and business systems—causes less cumulative harm in TMT steel compared to conventional options.

For fee-conscious developers, the preliminary 8mm rod price per piece might appear slightly higher than fundamental reinforcement. However, calculations typically reveal average project savings through decreased material portions and lower labor fees. When the 8mm rod charge according to the piece is analyzed towards lifetime performance metrics, TMT Steel consistently demonstrates superior performance.

Complementary Role of Super Rings

While TMT Steel gives the primary reinforcement backbone, Super Rings function as essential spacing and positioning factors that maximize structural performance. These precision-manufactured additives preserve the right concrete cover and make certain reinforcement positioning all through concrete placement—elements that immediately affect structural overall performance.

Super Rings are available in various configurations designed for precise programs. The standard designs keep steady spacing between primary and secondary reinforcement layers, while specialized Super Rings include capabilities for difficult setup situations or particular structural requirements.

Selection Criteria for Quality Materials

When evaluating TMT Steel alternatives, shoppers must verify:

Manufacturing Certification: Legitimate TMT steel manufacturers observe standardized production protocols and exceptional management measures.

Grade Appropriateness: Different structural elements require precise TMT steel grades based on load conditions.

Surface Condition: Quality TMT steel exhibits regular surface traits without considerable defects.

Dimensional Accuracy: Precise rod diameters immediately affect structural calculations and overall performance.

Similarly, while sourcing Super Rings, key quality indicators include:

Material Composition: Premium Super Rings make use of corrosion-resistant substances with appropriate tensile residences.

Dimensional Consistency: Variations in Super Ring dimensions can compromise reinforcement positioning.

Load Capacity: Quality Super Rings keep functioning even beneath the weight of employees and wet concrete.

Compatibility: The best Super Rings work seamlessly with standard TMT steel dimensions.

Implementation Best Practices

Maximizing the advantages of those materials requires proper handling and setup:

Storage Protocol: TMT Steel should remain elevated from ground contact and be protected from excessive moisture.

Cutting Methods: Appropriate cutting techniques preserve TMT Steel's engineered properties.

Super Rings Placement: Systematic setup at specific intervals ensures consistent concrete cover.

Inspection Protocols: Quality assurance ought to verify each material and setup before concrete placement.

By combining top-class TMT steel with suitable Super Rings in accordance with engineering specs, builders create structures that outperform traditional creation strategies while optimizing cloth utilization and long-term sturdiness. This effective aggregate represents the destiny of structural reinforcement technology—turning in advanced overall performance metrics that translate to lasting cost for stakeholders.

#Super Rings#TMT Steel#structural reinforcement#construction strength#building materials#TMT bars#durable steel#construction tech#reinforcement bars#steel advantages#earthquake resistance#cost-effective#high tensile#building safety#strong foundation#concrete reinforcement#structural stability#superior strength#TMT bars uses#reinforcement benefits#TMT steel features.

0 notes

Note

hey. Never apologize for dogbuckposting ✊

youre right. dogbuck is always the correct lens to view buckposts through

#hes literally so neurotic dog coded#he just needs an owner who can keep up with his tendencies and give him structure#oliver saying buck needs a relationship with structure and stability? 👀#what was i saying#🐕🦺#asks

11 notes

·

View notes

Text

Bar Dowels And Their Role in Concrete Reinforcement

Picture a massive highway stretching across rugged terrain, or a bridge withstanding the relentless pressure of heavy traffic and changing weather conditions. Behind these engineering marvels lies an unsung hero of construction: bar dowels, the critical components that breathe strength and stability into concrete structures.

Understanding Bar Dowels: The Backbone of Structural Integrity

Bar dowels are more than just metal rods. They are precision-engineered connectors that transform ordinary concrete into a robust, flexible, and long-lasting material. These unassuming steel bars play a crucial role in transferring loads, controlling cracking, and maintaining structural continuity across construction joints.

The Science Behind Structural Reinforcement

Concrete, despite its impressive compressive strength, has a fundamental weakness—it struggles with tension and can crack under stress. Bar dowels emerge as the perfect solution, bridging concrete sections and providing critical load transfer mechanisms that prevent structural failures.

Types of Bar Dowels: Engineered for Specific Challenges

Not all bar dowels are created equal. Construction professionals can choose from various types, each designed to address specific engineering requirements:

Smooth Round Dowels: Ideal for minimal load transfer and allowing slight movement

Deformed Bar Dowels: Provide superior bonding with concrete and enhanced load-bearing capacity

Epoxy-Coated Dowels: Offer exceptional corrosion resistance in challenging environmental conditions

Stainless Steel Dowels: Deliver maximum durability in aggressive chemical environments

Critical Applications Across Construction Sectors

Bar dowels prove invaluable in multiple construction domains:

Road Construction

Distribute heavy vehicle loads evenly

Minimize pavement cracking

Enable smooth joint transitions

Enhance overall road durability

Bridge Engineering

Absorb dynamic loads from traffic

Provide structural flexibility

Manage expansion and contraction

Prevent catastrophic structural failures

Building Foundations

Control concrete shrinkage

Maintain structural alignment

Enhance seismic resistance

Improve overall building stability

Technical Advantages of Bar Dowels

Modern bar dowels represent a pinnacle of metallurgical and engineering innovation. Their sophisticated design offers remarkable benefits:

Load Transfer Efficiency: Seamlessly distribute stress across concrete sections

Crack Prevention: Minimize concrete deterioration

Structural Flexibility: Allow controlled movement without compromising integrity

Long-Term Performance: Resist corrosion and maintain structural strength

Economic Benefits: More Than Just a Construction Component

Investing in high-quality bar dowels translates into significant long-term economic advantages:

Reduced maintenance costs

Extended infrastructure lifespan

Minimized repair and replacement expenses

Enhanced structural reliability

Selecting the Right Bar Dowels: A Strategic Decision

Choosing bar dowels isn't just a technical choice—it's a commitment to quality, safety, and durability. Key considerations include:

Project-specific load requirements

Environmental conditions

Corrosion resistance needs

Budget constraints

Long-term performance expectations

Installation: Precision Matters

Proper bar dowel installation is as critical as selecting the right product. Factors like:

Correct spacing

Proper alignment

Adequate concrete coverage

Precise joint preparation

Can dramatically influence the overall performance of concrete structures.

The Future of Structural Reinforcement

As construction technologies evolve, bar dowels continue to advance. Emerging trends include:

Advanced metallurgical compositions

Smart coating technologies

Enhanced corrosion-resistant materials

Improved load transfer mechanisms

Making the Optimal Choice

Bar dowels represent more than a technical component—they are the silent guardians of structural integrity. Every bridge that withstands heavy traffic, every road that endures extreme weather, every building that remains standing through decades tells a story of intelligent engineering.

Why Bar Dowels Matter

Critical load transfer mechanism

Prevent structural cracking

Enhance concrete performance

Economically viable solution

Proven reliability across sectors

Your Structure, Your Legacy

Construction is about creating legacies that outlast generations. Each bar dowel carries the weight of human ambition, safety, and progress.

Considering a construction project that demands uncompromising strength and reliability? Consult structural engineering experts to understand how precisely engineered bar dowels can transform your architectural vision into an enduring reality.

Strength isn't just measured in materials—it's measured in trust, precision, and the structures that define our world.

#bar dowels#concrete reinforcement#dowel bars#structural stability#load transfer#concrete joints#reinforced concrete#slab connection#durable construction#construction dowels

0 notes

Text

I have a controversial yet brave opinion about Gilmore girls

Gigi is one of the most tragic characters in the whole show

Her mother ups and leaves her when she’s a toddler, she’s left to be raised mostly by rotating nannies because her father works half the time. Then suddenly she’s 3-4 years old and her mom decides “oh right I have a daughter! I wanna be a mommy again :)” and whisks her away to a foreign country to spend a few months with her.

She comes back to a new house and her dad having suddenly been married to a woman she’s only met when she babysat her 1 time. Then like 2 months after that they divorce and she moves away again.

And worst of all. Her father? Christopher Hayden.

Like damn girl I’d be screaming too

#Gilmore girls#like yeah she was a hellspawn for a while but what can you expect from a toddler with absolutely no structure or stability or proper parenti#correction. she did meet lorelai after the babysitting but like#still#justice for Gigi

16 notes

·

View notes

Text

Noodle also wants to play A Game About Digging A Hole.

#quokka plays#a game about digging a hole#noodle doesn’t#poor opposable thumb-less wretch#I’m digging a spiral#because I vaguely understand structural stability#and enjoy having unbroken ankles

7 notes

·

View notes