#FDM 3D Printing

Explore tagged Tumblr posts

Text

Posted this tiny zen duck pond, this one is a Patreon exclusive so head there to check it out!

20 notes

·

View notes

Text

"The familiar graveyard, a shortcut you've taken countless times, feels wrong tonight. The air is heavy, tinged with the sharp tang of brine, though the sea lies miles away. A mist creeps unnaturally close to the ground, swirling as if alive.

As you step forward, the faint sound of sloshing echoes-like footsteps mirroring your own."

*Roll for Perception*

1 note

·

View note

Text

High-Quality FDM 3D Printing Service at Metamorph

Metamorph specializes in FDM 3D Printing service, providing affordable and precise 3D models. FDM technology is ideal for rapid prototyping and functional parts, offering simplicity and versatility. Whether for industrial or creative projects, Metamorph ensures superior results at competitive prices.

Contact Us :- Phone:-+91 88840 52777 Email :[email protected] Website :-https://metamorph3dprint.com/technologies/

0 notes

Text

The Prusa Printer’s crazy, man.

It’s one step closer to a self replicating machine, as most of its upholstery and bulk can be printed on another Prusa.

Have you seen pictures of the insides of their factories? It’s wild! Rows on rows of their OWN printers printing even more printers. Look it up, it’s bonkers.

Just got certified on one today in my University’s maker lab. Made a little thingy.

1 note

·

View note

Text

What's The Differences Between SLA and SLS in Rapid Prototyping?

Rapid Prototyping(RP) is a manufacturing technology that quickly generates models or parts. There are more than ten different processes, such as stereolithography (SLA), laminated object manufacturing (LOM), selective laser sintering (SLS), fused deposition modeling (FDM), solid ground curing (SGC), three dimensional printing (3DP_Binder Jetting), ballistic particle manufacturing (BPM), etc. Among them, SLA is the earliest and most widely used technology, accounting for about 70% of all rapid prototyping equipment.

Today we'll discuss the differences between SLA and SLS from four aspects.

The principle of SLA: use laser of a specific wavelength to solidify the resin.

The material of SLA is the category of resin.

The characteristics of SLA:

1. Stereolithography is the earliest rapid prototyping process, with high maturity and time-tested. 2. The prototype is made directly from the CAD digital model, with fast processing speed, short production cycle, and no need for cutting tools and molds. 3. It can process prototypes and molds with complex structures or difficult to form using traditional means. 4. Make CAD digital models intuitive and reduce the cost of error repair. 5. Provide samples for experiments can verify and check the results of computer simulation calculations. 6. It can be operated online and remotely controlled, which is conducive to production automation.

The disadvantages of SLA:

1. The SLA system is expensive to build, use and maintain. 2. The SLA system is a precision device that operates liquids and has strict requirements on the working environment. 3. Most molded parts are made of resin, which has limited strength, rigidity and heat resistance, and is not conducive to long-term storage.

The principle of SLS: heat the powder sintered to near melting point of the material and then add laser energy to sinter it.

The material of SLS is nylon and various materials and mixed materials.

The characteristics of SLS:

1. A variety of materials can be used. In principle, this method can use any powder material that reduces viscosity when heated, and can produce any shape through materials or various types of coated particles containing binders to meet different needs. 2. The manufacturing process is relatively simple. Since a variety of materials can be used, the selective laser sintering process can directly produce complex-shaped prototypes, cavity mold three-dimensional components or parts and tools according to the raw materials used. 3. No support structure is required. The overhanging layers that appear during the lamination process can be supported directly by the unsintered powder. 4. High material utilization rate. Since the process does not require a support structure, most of the powders used in the SLS process are relatively cheap, so the cost of the SLS model is relatively low. 5. Short production cycle. It only takes a few hours to dozens of hours from CAD design to the completion of parts processing. The entire production process is digitalized and can be modified and manufactured at any time. This feature makes it particularly suitable for the development of new products. 6. Combined with traditional process methods, it can realize functions such as rapid die casting, rapid molding and small batch manufacturing, injecting new vitality into traditional manufacturing methods. 7. Wide application. Due to the diversity of molding materials, the SLS process is suitable for a variety of application fields, such as prototype design verification, mold master, precision casting investment, casting shell and core, etc.

The disadvantages of SLS:

1. Rough surface. Since the raw material of SLS process are in powder form, the prototype is built by melting the powder layer by layer through heating. Therefore, strictly speaking, the surface quality of the prototype is not good enough as in powder form. 2. Polymer materials or powder particles generally emit odorous gases during laser sintering and melting. 3. Sometimes more complicated auxiliary processes are required. SLS technology varies depending on the materials used, and sometimes more complicated auxiliary processes are required, such as preheating the raw materials for a long time, cleaning the surface powder of the model after the modeling is completed, etc.

The advantage of RP prototype is its rapidity, but it is mainly formed by stacking technology, so RP prototype is generally relatively rough, and has centain requirements on the wall thickness of the product. For example, if the wall thickness is too thin, it cannot be produced.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#rp#sla#sls#3d printing#3d printed#additive manufacturing#stereolithography#selective laser sintering#fdm#fdm 3d printing

1 note

·

View note

Text

#FDM 3D Printing#3D Printing Technology#Fused Deposition Modeling#Rapid Prototyping#3D Printing Materials#Custom Manufacturing#3D Printing Benefits#Additive Manufacturing#Maadhu Creatives#3D Printing Process

1 note

·

View note

Text

3D printing is literally magic don't let anyone else tell you otherwise. You can make literally anything.

Flow rate testing time because I wanna get it super dialed in after updating it

2 notes

·

View notes

Text

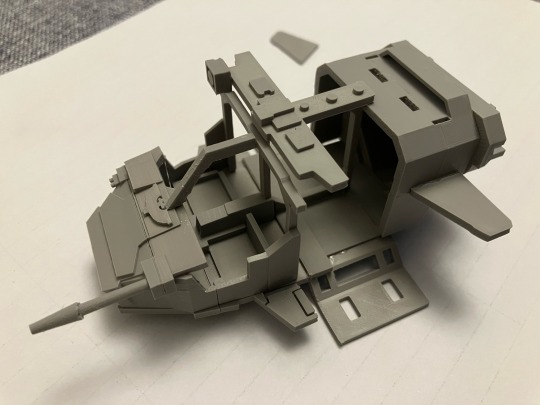

Fdm printed this bad boy, and I think it turned out great. Only problem is I have no idea what wargame I can use him for. One page rules I guess? Maybe a Tau army?

8 notes

·

View notes

Text

Unicorns live even after death! Meet our next Halloween design - Skeleton Unicorn. It's a print-in-place toy, it has articulated legs and a moveable head. The unicorn is available as a STL file that you can print at home with your FDM or Resin 3d printer. The toy design by Svetlana Germanova (the Happy Flexi pets project) Check the Skeleton Unicorn on Cults3d You also can support us on Patreon

#skeleton#halloween#skeleton unicorn#unicron#halloween decoration#unicorn toy#3d printed toy#unicorn figurine#cults 3d#articulated toy#cute animal#fantasy#spooky design#print in place#fdm toy

36 notes

·

View notes

Text

Armor and paints ready! Time to give this knight a soul. ⚔️✨

Same miniature as before, but with a another paint job, it takes on a whole new personality!" 🎨🛡️

2 notes

·

View notes

Text

I have 3d printed some very special dice

It's a D1. It only has one possibility.

For when things are certain.

Although, thinking about it, usually 1 is the number people don't want to get, what they want is a 20.

So I also made this

(Also here are a bunch of earlier prototypes)

#joke dice#3d printing#3d printing adventures#dice#this was based on the one advertised on curiosity box which are all out of stock and i didn't want to wait#hand painted and a bit rough but they work#my machine is an fdm printer which is less suitable for the smaller end of things and i wanded these to be small#so they could blend in with other dice#i carefully adjusted the number size and position for balance and clarity#but imperfections in my printing means a little cleaning up was still needed#i kinda want to try more weird dice shapes#this was part of a present for a friend so this has been scheduled for after the party in the odd chance that she visits Tumblr before then#the only practical use i think is for expressing certainty (with perhaps just a bit of sarcasm).#'for that i need you to roll a D1'#'I'm going to roll D1 to see if they attack you'#etc

33 notes

·

View notes

Text

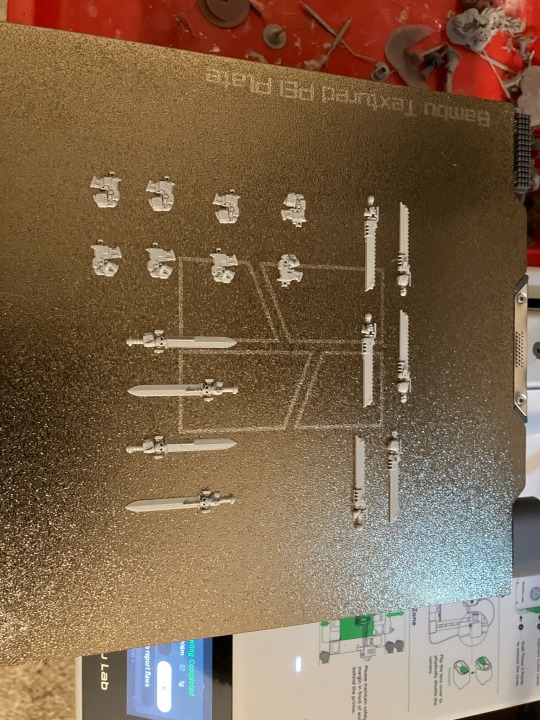

After a week of getting my hands on the A1 mini, I've printed more than I imagined!

My current project is building an army of Firstborn space marines. Previously I've relied on eBay rescues, but the hassle of finding the exact models/wargear and having to strip paint have been really daunting. (Plus they're not always that cheap!)

Now I can print the exact parts I want and not worry about play mental gymnastics while staring at my bits box!

I was skeptical of 3D printing, so I didn't think the day would come when it's my turn to say "3D printer goes BRRRR!"

3 notes

·

View notes

Text

1 note

·

View note