#Future of Manufacturing with AI

Explore tagged Tumblr posts

Text

AI in Manufacturing Operational Efficiency 2025

Artificial intelligence (AI) is revolutionizing the manufacturing sector by driving operational efficiency to new heights. From automating repetitive tasks to enabling real-time decision-making, AI is reshaping how manufacturing processes are executed. With the demand for smarter factories and leaner operations, companies are turning to AI to stay competitive. In this article, we explore how AI in manufacturing operational efficiency in 2025, key use cases, and the transformative benefits it offers.

The Role of AI in Manufacturing Operational Efficiency 2025

AI-powered solutions are pivotal in addressing the complexities of modern manufacturing. By integrating AI into operations, manufacturers can achieve predictive maintenance, improve quality control, and streamline supply chain processes. This leads to cost reduction, enhanced productivity, and minimized downtime.

Benefits of AI in Manufacturing 2025

Predictive Maintenance: AI algorithms analyze machine data to predict failures before they occur, reducing unplanned downtime.

Quality Control: Machine learning models detect defects in real-time, ensuring consistent product quality.

Supply Chain Optimization: AI enhances inventory management, demand forecasting, and supplier coordination.

Energy Efficiency: AI optimizes energy consumption by adjusting processes to real-time demands.

Human-Machine Collaboration: AI-powered tools empower workers with actionable insights, enhancing productivity and safety.

Key AI Applications in Manufacturing 2025

1. Predictive Maintenance

Predictive maintenance uses AI to monitor equipment performance and anticipate potential failures. Sensors embedded in machines collect real-time data, which AI models analyze to identify anomalies and predict when maintenance is needed. This reduces unexpected breakdowns and maintenance costs.

2. Quality Assurance

AI-powered computer vision systems inspect products for defects with greater accuracy than human inspectors. These systems can process thousands of images per second, identifying flaws invisible to the naked eye and ensuring consistent quality standards.

3. Supply Chain Management

AI streamlines supply chain operations by predicting demand, managing inventory, and optimizing logistics. This reduces lead times and ensures the availability of materials, enhancing operational efficiency.

4. Robotics and Automation

AI-driven robots handle complex tasks such as assembly, welding, and material handling. These robots adapt to changing conditions and learn from their environment, boosting flexibility and precision in manufacturing.

5. Energy Optimization

AI analyzes energy consumption patterns to identify inefficiencies. By adjusting machine operations and production schedules, manufacturers can significantly reduce energy usage and costs.

The Impact of AI on Operational Efficiency 2025

Enhanced Decision-Making

AI provides real-time insights that enable manufacturers to make informed decisions quickly. By analyzing vast amounts of data, AI identifies trends and patterns that humans might overlook.

Reduced Waste

AI optimizes resource utilization, reducing waste and lowering production costs. Smart systems adjust processes dynamically to minimize material wastage.

Improved Customer Satisfaction

By ensuring consistent product quality and timely deliveries, AI helps manufacturers meet customer expectations. Predictive analytics also enable personalized customer solutions.

Scalability

AI enables manufacturers to scale operations efficiently by automating repetitive tasks and optimizing workflows. This allows companies to meet growing demand without compromising quality or increasing costs.

Challenges and Solutions in Implementing AI

Data Management

AI systems require vast amounts of high-quality data for training. Manufacturers must invest in data collection and management systems to ensure reliable outcomes.

Integration with Legacy Systems

Integrating AI with existing infrastructure can be challenging. Partnering with experienced AI solution providers helps ensure seamless integration.

Workforce Training

Adopting AI requires upskilling employees to work alongside AI tools. Offering training programs ensures a smooth transition to AI-driven workflows.

The Future of AI in Manufacturing 2025

The adoption of AI in manufacturing is expected to grow exponentially. Emerging technologies such as generative AI, digital twins, and edge computing will further enhance operational efficiency. Companies that embrace AI will gain a competitive edge, driving innovation and sustainability in the manufacturing sector.

Challenges include data management, integration with legacy systems, and workforce training. Addressing these issues requires strategic planning and partnering with AI solution providers.

AI is transforming manufacturing by unlocking new levels of operational efficiency in 2025. From predictive maintenance to energy optimization, the possibilities are vast. By embracing AI, manufacturers can future-proof their operations and drive sustainable growth.

Content Source - https://tagbinnews.blogspot.com/2025/01/ai-in-manufacturing-operational.html

#tagbin#writers on tumblr#artificial intelligence#AI in Manufacturing Operational Efficiency 2025#AI in Manufacturing#Manufacturing Operational Efficiency#Artificial Intelligence in Manufacturing 2025#Predictive Maintenance with AI#AI-powered Quality Control#AI for Supply Chain Management#Robotics in Manufacturing 2025#Future of Manufacturing with AI#AI and Manufacturing Trends 2025#tumblr

0 notes

Text

The Unseen Driver: Merck KGaA’s Behind-the-Scenes Impact on the Semiconductor World

Merck KGaA, a venerable company with a history spanning over 350 years, occupies a critical position in the semiconductor industry through its Electronics Business, led by CEO Kai Beckmann. With a background in Computer Science and Microelectronics, Beckmann's over 35 years of leadership within the company have equipped him with a deep understanding of the industry's intricacies. Merck KGaA's role in providing specialized materials and technologies for semiconductor manufacturing is foundational, supporting all top 100 semiconductor companies, including those with fabrication plants and fabless entities, as well as tool companies offering integrated solutions.

The company's contributions are not merely supplementary but constitute the building blocks of semiconductor architecture, including crucial layers on silicon substrates for insulation, conduction, and more. This multifaceted support underscores Merck KGaA's indispensable position in the industry. The current AI-driven surge in demand for sophisticated chips, particularly evident in data center applications and the training of large language models, has significantly boosted the company's growth trajectory. As AI's influence expands beyond data centers to edge devices, such as smartphones, in the form of Edge AI, the demand for Merck KGaA's advanced materials and technologies is expected to escalate further.

Navigating the semiconductor industry's complex dynamics, characterized by a historically cyclical nature now complicated by asynchronous technology cycles, requires foresight and adaptability. Merck KGaA is well-positioned to meet these challenges, leveraging its extensive experience and commitment to innovation. The integration of AI into material science, to accelerate the discovery of new materials, exemplifies the company's proactive approach. This strategic deployment of AI, both as a driver of demand and a tool for innovation, highlights Merck KGaA's pivotal role in shaping the industry's future.

As the industry evolves, with Edge AI poised to potentially redefine production and research paradigms, Merck KGaA's expertise will be crucial in addressing the heightened need for sophisticated materials. The company's ability to balance the stability afforded by its 70% family ownership with the agility of a publicly traded entity, listed on the German DAX index, further enhances its capacity to respond effectively to emerging trends. Through its innovative spirit, deep industry knowledge, and strategic adaptability, Merck KGaA is not only navigating the transformative impact of AI on the semiconductor industry but also playing a defining role in its future trajectory.

Kai Beckmann: Why Next-Gen Chips Are Critical for AI's Future (Eye on AI, December 2024)

youtube

Thursday, December 5, 2024

#semiconductor industry#artificial intelligence#ai applications#technology innovation#material science#electronics manufacturing#industry trends#future tech#corporate leadership#interview#ai assisted writing#machine art#Youtube

5 notes

·

View notes

Text

#robotic arm#industrial robot#automation robot#Peribott arm robot#AI robotic arm#collaborative robot#smart manufacturing solutions#robotic automation for industry#future of robotics#robot for repetitive tasks#ai#ai generated#ai model#tech#technology#smart tech#robot#robotics#robots

0 notes

Text

Generative AI: Changing Manufacturing for the Better

In today’s world, technology is changing how things are made. One exciting tech tool is Generative Artificial Intelligence (AI). It’s making a big difference in Manufacturing, helping companies work smarter and better. From designing products to fixing machines before they break, Generative AI in manufacturing is helping factories run smoothly and make cool stuff.

What is Generative AI?Generative AI is a smart tool that learns from lots of information and uses it to make new things. Unlike older tech that follows strict rules, Generative AI gets creative. It can make new designs based on what it learned from past ones. This makes it perfect for manufacturing, where new ideas are always needed.

Making Designs Better and FasterIn manufacturing, creating designs is super important. With Generative AI in manufacturing, designers can quickly make lots of versions of a product. They just tell the AI what they need, like it needs to be strong or cheap. Then, the AI gets to work and comes up with new designs that fit those needs. It’s like having a super-fast design assistant!

Keeping Machines Running SmoothlyGenerative AI in manufacturing isn’t just for making things. It’s also great at fixing stuff before it breaks. For example, let’s say a machine in a factory is acting weird. Generative AI can look at its data and figure out if something’s wrong. It can even predict when the machine might break and tell workers to fix it before that happens. This saves time and money because it keeps everything running smoothly.

Adaptive Assessment and FeedbackAssessment is an integral component of the learning process, serving as a measure of understanding, progress, and mastery. Generative AI enables the development of adaptive assessment systems that offer personalized feedback and evaluation tailored to each learner’s strengths and weaknesses.By leveraging machine learning algorithms, these systems can analyze learner responses, identify patterns, and adaptively adjust the difficulty and type of assessment items in real-time. Additionally, Generative AI can generate constructive feedback and explanations based on common misconceptions and errors, helping learners develop a deeper understanding of the subject matter.

Making Customized StuffAnother cool thing about Generative AI in manufacturing is that it can make things just for you. Imagine going to a store and picking out a product. With Generative AI, that product could be customized just for you. Maybe it’s a pair of shoes with your favorite colors, or a phone case with your name on it. Generative AI makes it possible to have things that are uniquely yours.

Challenges and Things to Think AboutBut using Generative AI isn’t always easy. Sometimes, there’s not enough good information for the AI to learn from. Also, it’s important to make sure that AI is used in fair and safe ways. People need to understand how it works and trust that it’s making good decisions.

Conclusion

Generative AI in manufacturing is changing the industry for the better. It’s helping companies design better products, keep machines running smoothly, and even make things just for you. But we need to think about how to use it in the right way. With the right care and attention, Generative AI can help us make amazing things and make the world a better place.

Click the link below to learn more about the blog Generative AI : https://tudip.com/blog-post/generative-ai-changing-manufacturing-for-the-better/.

1 note

·

View note

Text

Digital Turnaround: How Tech Transforms Legacy Companies | Kunal Chopra on Shift AI

In this episode of the Shift AI Podcast, Certivo CEO Kunal Chopra joins Boaz Ashkenazy (CEO of Augmented AI Labs) to explore how legacy, “pen-and-paper” companies can undergo complete digital transformation. From eliminating manual processes to embedding AI agents directly into workflows, Kunal shares how he led old-school organizations into the future using technology and operational redesign.

At Certivo, AI isn’t just a tool — it’s a team member. CORA, our AI compliance agent, collaborates with human teams to automate the tedious, surface what matters, and help manufacturers stay always compliant and always market-ready.

This episode is a must-watch for anyone leading change in traditional industries, compliance management, or AI-driven operations.

🎧 Watch the full podcast: https://www.youtube.com/watch?v=KDTCN5Jyjfw

🌐 Learn more about Certivo: https://www.certivo.com/

#Digital transformation in legacy companies#AI-powered compliance solutions#AI in manufacturing compliance#Shift AI Podcast Kunal Chopra#Compliance tech for enterprises#Operational redesign with AI#Future of work with AI agents#How to digitize old-school businesses#Certivo AI compliance software#Compliance automation for manufacturers

0 notes

Text

How AI Is Shaping the Future of ERP & CRM Solutions

AI Is Changing the Game for ERP & CRM — Are You Ready?

From smarter decision-making to automating daily tasks, AI in ERP & CRM systems is helping businesses work faster, better, and smarter.

In our latest blog at JRS Dynamics, we explore how AI is: ✅ Automating routine business processes ✅ Enhancing customer experiences ✅ Improving forecasting and inventory planning ✅ Powering tools like Microsoft Copilot in Dynamics 365

Whether you're in manufacturing, distribution, or services — AI is no longer a “future tech.” It’s already transforming how modern ERP & CRM systems work.

Read the full blog here: https://jrsdynamics.com/how-ai-is-shaping-the-future-of-erp-crm-solutions/

#AI in ERP#AI in CRM#Microsoft Dynamics 365#ERP#CRM#AI Future#Copilot#SMB Tech#Artificial Intelligence in ERP#AI in Manufacturing ERP#AI in ERP and CRM

1 note

·

View note

Text

Exploring Automation Design Services: Innovations and Opportunities

Automation has become a driving force behind the modernization of industries worldwide. In India, the surge in demand for efficient and intelligent manufacturing processes has propelled automation design services India into the spotlight. These services, led by skilled automation designers in India, are creating new opportunities for businesses to innovate, reduce costs, and improve quality.

The Innovation Landscape in Automation Design Services

The core of industrial automation design services India lies in innovation bringing together mechanical engineering, electronics, software, and data analytics to create machines and systems that work smarter. New technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) are increasingly integrated into automation designs, offering unprecedented levels of control and flexibility.

For example, automated systems today can self-diagnose faults, adjust operations in real time, and communicate seamlessly with other equipment on the factory floor. This level of sophistication is reshaping traditional manufacturing into a connected, adaptive ecosystem.

How Automation Designers in India Are Leading the Charge

Automation designers in India play a critical role in translating these technological advances into practical solutions tailored to the unique needs of Indian industries. By combining global best practices with local insights, they design systems that not only improve productivity but also align with cost and operational constraints.

Their work involves conceptualizing custom machinery, integrating robotics, developing control systems, and ensuring that each solution is scalable and maintainable.

Opportunities Created by Automation Design Services India

Increased Competitiveness: Automation enables Indian manufacturers to meet global standards of quality and efficiency, helping them compete in international markets.

Skilled Workforce Development: As automation evolves, there is growing demand for professionals trained in designing, operating, and maintaining automated systems, fostering new career opportunities.

Sustainability Gains: Automated processes often reduce waste and energy consumption, aligning with global sustainability goals.

Customization and Flexibility: Modern automation design allows for greater customization, enabling manufacturers to quickly adapt to changing product designs and market demands.

The Growing Scope of Industrial Automation Design Services India

With sectors such as automotive, pharmaceuticals, FMCG, and electronics embracing automation, the scope for industrial automation design services India continues to expand. These services cover everything from initial design and simulation to prototyping, installation, and after-sales support.

The collaborative approach taken by automation designers in India ensures that solutions are practical, effective, and future-ready.

Why Partner with Experts in Automation Design Services

Navigating the complex world of automation requires expertise. Working with experienced providers of automation design services India ensures your project benefits from:

End-to-end project management

Latest design tools and technologies

Compliance with safety and industry standards

Ongoing support and system optimization

Pure Machine Design’s Role in Driving Innovation

At Pure Machine Design, we harness the latest advancements in automation to deliver cutting-edge automation design services India. Our dedicated team of automation designers in India focuses on creating innovative, reliable, and scalable solutions that empower businesses to transform their manufacturing processes.

Conclusion

The landscape of automation design is rich with innovation and opportunity. As industrial automation design services India evolve, they unlock new potential for efficiency, quality, and sustainability. Forward-thinking companies that engage expert automation designers in India can seize these opportunities to lead in their industries.

Up next: Meet the Leading Automation Designers in India

#Automation Design Services India#Industrial Automation Design Services India#Automation Designers in India#Innovations in Automation India#Smart Manufacturing India#AI in Industrial Automation#IoT in Indian Manufacturing#Intelligent Automation Solutions#Custom Machine Design India#Manufacturing Automation India#Future of Automation in India

0 notes

Text

#AI Tools#Entrepreneur#Business Growth#Future of Work#Technology#Local Business#Startup Strategy#Automation#manufacturer in mumbai

0 notes

Text

AI in Cosmetic Manufacturing: What��s Changing in the Industry? | Ayo Labs

The beauty industry has always been at the forefront of creativity and innovation, constantly adapting to new trends, ingredients, and technology. As we look into 2025 and beyond, one revolutionary force is changing the industry: artificial intelligence (AI). But what does it mean for cosmetics manufacturing? How is AI shaping the future of beauty production? Let’s explore how this technology is reshaping the industry and what it means for businesses and consumers alike.

The Rise of AI in Cosmetic Manufacturing

Artificial intelligence is already making a significant impact across industries, and the beauty sector is no exception. By the end of 2025, AI is expected to play an even bigger role in cosmetic manufacturing, with the adoption rates projected to soar by over 50%.

For cosmetic brands, AI offers transformative benefits, enhancing efficiency and improving product quality. Whether it’s personalised formulations, refining consumer testing, or streamlining supply chains, AI empowers manufacturers to create better products faster and more efficiently.

How AI is Changing the Cosmetic Industry?

The benefits of incorporating AI into cosmetic manufacturing are numerous, and they extend beyond just improving the efficiency of production lines. Some of the most notable pros of artificial intelligence include:

Personalised products: Beauty Tailored to You

Personalisation has become a cornerstone of the modern beauty industry. The days of generic skincare and one-size-fits-all products are fading fast. With AI in the beauty industry, brands can now develop products tailored to each individual’s unique and specific needs.

By analysing data like skin type, hair texture, and personal preferences, AI can recommend ingredients or even design entirely new formulations. This kind of customisation would be impossible without AI’s ability to process vast amounts of data in real-time. As a result, more beauty brands are embracing AI to deliver highly personalised and effective solutions.

2. Faster product development

Creating new cosmetic products has traditionally been a lengthy process, often taking months or even years. However, with artificial intelligence in manufacturing, the timeline is shrinking. By running simulations, AI can predict how ingredients interact with each other, how a product will perform in various conditions, and how consumers might react.

This accelerates research and development, enabling brands to bring products to market much faster. In an industry where trends evolve rapidly, this speed is a game-changer.

3. Smarter consumer insights

Understanding consumer preference is crucial for any beauty brand, but traditional methods of gathering feedback can be slow and limited. AI changes the game by analysing thousands of reviews, social media content, and surveys in minutes.

Through sentiment analysis, brands can gain deep insights into what customers love — or don’t love — about a product. This allows the manufacturer to fine-tune formulations and marketing strategies before launching on a larger scale.

4. Optimised production process

AI isn’t just revolutionizing product development, it’s also transforming production. By predicting demand patterns, AI helps manufacturers optimise production schedules and minimise waste.

For example, AI can analyse historical sales data to forecast demand, ensuring products are made in the right quantities at the right time. This reduces overproduction, saving resources and cutting costs.

5. Sustainability: Greener manufacturing

Sustainability is no longer optional — it’s a must. AI is helping beauty brands reduce their carbon footprints by optimising ingredient sourcing, improving package design, and making it easier to create functional yet sustainable solutions that consumers appreciate.

AI can identify eco-friendly ingredients and predict the environmental impact of different formulations. It can also streamline packaging design.

What’s Next for AI in Cosmetic Manufacturing?

As AI continues to evolve, its role in the beauty industry will only grow. Here are some trends to watch:

Automation: A machine powered by AI will take on more tasks, from mixing ingredients to packaging production, making production faster and more precise.

Personalised marketing: AI will help brands predict consumer preferences and offer tailored product recommendations based on past behaviour.

Real-time insights: With AI, brands can adjust strategies and products instantly based on dynamic consumer feedback.

Leading the way: AYO Labs and AI

At AYO Labs, we’re leveraging AI to transform every aspect of cosmetic manufacturing. From custom formulations to R&D to packaging and quality assurance, our AI-driven tools streamline production while maintaining the highest standards of quality.

Whether you’re a small brand launching your first product or establishing a company looking to scale, our flexible, AI-powered solutions are designed to meet your needs. We can handle orders ranging from 250 units to millions, ensuring efficiency and precision at every step.

Conclusion: Embracing the Future of AI in Cosmetic Manufacturing

AI is ushering in a new era for the beauty industry, recolonising everything from product development to sustainability. At AYO Labs, we are embracing this innovation in cosmetics by integrating AI into our contract manufacturing processes, ensuring that we remain at the forefront of industry advancements.

Ready to bring your formulation to life? Contact us at [email protected]. With AI on your side, the possibilities are endless.

#AI in Cosmetic Manufacturing#The Rise of AI in Cosmetic Manufacturing#How AI is Changing the Cosmetic Industry?#benefits of AI in Cosmetics Manufacturing#pros of artificial intelligence#AI in the beauty industry#artificial intelligence in manufacturing#AYO Labs and AI#Future of AI in Cosmetic Manufacturing#innovation in cosmetics#Ayo Labs

0 notes

Text

What are the Top Examples, Use Cases, And Benefits of AI in Manufacturing

The rapid evolution of technology has ushered in a new era for industries worldwide, with artificial intelligence in manufacturing leading the charge. These revolutions are revolutionizing the methods of product development and delivery and go to unheard-of levels of automation, precision and added value. Manufacturers are now integrating AI to solve problems, to foresee a breakdown, and enhance workflows.

From advanced robots to predictive maintenance, artificial intelligence-powered solutions are transforming established procedures. Examining useful applications, prominent use cases, and the many advantages AI presents to firms negotiating a more competitive market, this article explores how this technology is changing the manufacturing sector.

How does AI enhance efficiency in manufacturing?

Organization and productivity have always been the key elements in the structure of manufacturing, and AI cannot be further helpful in the process. AI harnesses significant amounts of data from machine constructs, the production line and the marketplace to discover more efficient ways of functioning.

The global AI in manufacturing market size was valued at USD 8.14 billion in 2019 and is projected to reach USD 695.16 billion by 2032. One main area where the use of AI increases productivity is in the area of predictive maintenance.

Originally, the manufacturers used only a mechanical type of preventive or corrective maintenance, which means that they could only guess when their products were going to fail or could plan for periodic maintenance checks in a timetable that might be unconnected with the actual need.

AI-based systems, on the other hand, provide constant supervision through sensor and analytics and can predict when perhaps a part in the machinery might fail. This means that damages can be effected and sorted early enough without much time being lost to equipment breakdowns hence improving on its durability.

Automation by AI Robotics also adds to efficiency through removing hardworking and repetitive tasks. For example, robots that are incorporated with AI can either build, bond, or even package products with high efficiency and accuracy.

Collaborative robots, or cobots,are designed for joint operation with employees; the concept significantly applies human creativity with robotic precision. This synergy makes it possible for manufacturers to improve productivity by enhancing quality production.

What are real-world examples of AI in manufacturing?

AI is already showing positive returns within diverse manufacturing industries. Here are some noteworthy examples:

1. Predictive maintenance

Companies like GE and Siemens are pioneers in leveraging AI for predictive maintenance. In this way, with the help of data from sensors, their AI systems can predict device failures in advance, days or even weeks. It reduces incidences of a halt on production and allows what has been planned to go on as calendar and time dictate.

2. Quality control

Nowadays, firms like BMW have implemented the use of AI-based computer vision in the production processes. These systems use some form of image recognition to pick up on abnormalities such as scratches, dents, or seemingly off alignments in most instances within milliseconds. This not only improves the quality of the product but also does away with wastages and rework charges.

3. Demand forecasting

AI is useful in demand forecasts, the foundations of which are currently being set. For instance, Unilever recently revealed it uses Artificial Intelligence Algorithms to forecast customers’ demand of their products based on previous sales records, conditions and trends. This makes it possible to achieve the right stock, to accommodate the right stock without some vices such as overstock or out of stock problems.

4. Supply chain optimization

Amazon’s supply chain success is a testament to the power of AI. The mechanisms of algorithms based on machine learning allow the e-commerce giant to enhance the control over stock, storage facilities, and delivery. This level of optimization helps to minimize operational cost whilst at the same time ensuring short order turnaround.

5. Generative design

Many aerospace companies including Airbus are now using AI in generative design. Specific requirements, including weight, strength and necessity of materials, are entered by engineers and multiple design solutions are provided by an AI. Researchers defined that an AI-optimized design is much lighter yet stronger and cheaper as compared to original designs.

How does AI improve quality and precision?

AI’s assure high quality, and its precision makes the difference for the manufacturer. The previous tools used in quality control were based on the ability of the human eye to inspect the products, this was disadvantageous because the human eye may miss some defects due to tiredness or even carelessness.

AI however is superior when it comes to checking for discrepancies compared to human beings in this case. Within the manufacturing industry, most respondents (59 percent) state that quality control is the most important use case for artificial intelligence.

Examples of AI-driven quality enhancement:

Automotive industry: Tesla has implemented AI surveillance on welds and assemblies that need accuracy as small as micrometers. This gives both structural and product qualities and hence the company’s reputation.

Pharmaceutical manufacturing: It keeps necessary checks upon the medicine production and management of dosages of various medicines so there can be no compromise on the issues of safety and effectiveness.

Apart from the elimination of defective and, therefore, non-saleable products, AI contributes effectively to the achievement of sustainable objectives by cutting unnecessary use of raw materials and energy. For instance, AI control can allow a flexible management of material consumption, guaranteeing that every amount is used optimally without any compromise of quality.

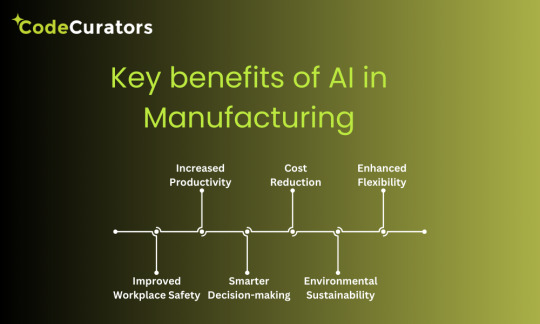

What are the key benefits of AI in manufacturing?

1. Increased productivity

AI automates repetitive procedures and thereby increases the manufacturing rate among the manufacturers. Through continuous functioning without being weary, the use of robots under the AI operations’ umbrella can help increase throughput.

2. Cost reduction

Predictive maintenance minimizes that time as well as the frequency of repairs. AI is projected to increase productivity by 40% or more in the manufacturing industry by 2035. Moreover, AI helps to save material consumption and energy as well these strategies also help in reducing expenses.

3. Enhanced flexibility

Production lines powered by artificial intelligence are incredibly flexible so the same line can produce different variations of a product and changes in market trends can easily be handled as well.

4. Improved workplace safety

AI relieves human workers of dangerous tasks that they used to perform. Hazardous work can be done by robots, and AI systems track the state of the workplace concerning safety in real-time.

5. Smarter decision-making

Real-time analytics and predictive insights let companies decide with knowledge. AI ensures optimal efficiency by helping to maximize everything from inventory levels to manufacturing schedules.

6. Environmental sustainability

Manufacturing sustainability goals are met because AI helps cut down on energy consumption and wastage. For example, skills can be used in the identification of chances of reclaiming raw materials or reducing energy use in the production process.

What challenges exist when implementing AI in manufacturing?

While the benefits are significant, implementing AI is not without challenges:

1. High initial costs

Both complex AI and the environments that support such systems are not inexpensive. The high initial cost is one of the chief concerns many manufacturing companies feel.

2. Data dependency

AI has more dependence on quality data and needs a significant quantity of data for the workspace. To provide the wrong recommendations or forecast, you need to feed the algorithm with inconsistent or inferior data quality.

3. Integration issues

Technologies based on AI can sometimes integrate with existing legacy systems with some level of difficulty and with much necessary reorganization.

4. Workforce adaptation

Workers may need retraining to collaborate with artificial intelligence systems, and change may face opposition.

To overcome these hurdles, manufacturers should consider phased AI implementation, invest in employee training, and prioritize data management.

What Is the Future of AI in Manufacturing?

The future of manufacturing will likely be defined by even deeper AI integration. Emerging trends include:

1. Collaborative robots (Cobots)

These robots will complement man in that they bring into the equation, the mechanical accuracy of a robot and the flexibility of man.

2. Edge AI

AI processing at the edges of networks will be a boon for decision making mechanisms because it will help in the localization of data processing.

3. Sustainability-Focused AI

AI will be responsible for further contributing to the right utilization of energy so as to minimize wastage in the manufacturing firms to meet environmental objectives.

4. Personalized manufacturing

AI will improve the production capacity of manufactures so as to meet the consumers’ demand for personalisation.As AI technologies evolve, their integration with other innovations like IoT, 5G, and blockchain will further revolutionize the manufacturing sector, making it more efficient, innovative, and sustainable.

Conclusion

Artificial intelligence in manufacturing has become instrumental in solving some of the oldest problems facing the industry while providing new opportunities for expansion. From improving speed and accuracy to transforming growth trajectories and enabling more sustainable practices, AI offers endless possibilities. However, despite barriers such as high costs and integration challenges, the advantages significantly outweigh the disadvantages.

The automotive sector, in particular, is gearing up to become smarter, more flexible, and better prepared for the global market as manufacturers increasingly adopt AI technology. For organizations aiming to remain at the forefront of the competitive landscape, leveraging AI in Manufacturing is no longer a luxury but an absolute necessity.

We can assist you if you are prepared to use AI to improve your manufacturing processes. For a consultation on how advanced AI technologies may boost your business’s operations, increase productivity, and promote long-term success, get in touch with us. Together, we can overcome obstacles, take advantage of fresh chances, and establish your company as a leader in the field. Are you prepared to welcome the AI-powered manufacturing of the future? Contact us right now, and together, let us make it happen.

#Evolution of technology#AI in manufacturing#AI powered solutions#benefits of AI in manufacturing#Future of AI in Manufacturing#manufacturer#software engineering

1 note

·

View note

Text

AI in Automotive Manufacturing 2025: Driving the Future of Smart Production

Introduction

The automotive industry is undergoing a paradigm shift, with artificial intelligence (AI) playing a crucial role in transforming manufacturing processes. AI in automotive manufacturing 2025 is set to revolutionize production efficiency, quality control, and supply chain optimization. From predictive maintenance to autonomous quality inspection, AI is enhancing every aspect of car production, making factories smarter and more efficient. In this article, we explore how AI is reshaping the automotive manufacturing landscape, its benefits, and the future it holds.

The Role of AI in Automotive Manufacturing

AI is bringing unprecedented efficiency and precision to car manufacturing by enabling automation, predictive analytics, and intelligent decision-making. Key areas where AI is making a significant impact include:

1. Smart Robotics & Automation

AI-driven robotic arms are streamlining manufacturing processes by executing tasks such as welding, painting, and assembly with extreme accuracy. Unlike traditional robots, AI-powered machines adapt to new tasks through machine learning algorithms, reducing downtime and improving productivity.

2. Predictive Maintenance

Predictive maintenance powered by AI helps automotive manufacturers prevent unexpected equipment failures. By analyzing data from IoT sensors, AI can predict machinery breakdowns and recommend timely maintenance, reducing downtime and costs.

3. AI-Powered Quality Control

Traditional quality control methods are being replaced by AI-driven vision inspection systems that detect even the smallest defects in car components. AI ensures consistency and precision, minimizing recalls and warranty claims.

4. Supply Chain Optimization

AI is optimizing the automotive supply chain by predicting demand, managing inventory, and identifying disruptions before they occur. This helps manufacturers maintain a steady production flow while reducing costs and improving efficiency.

5. Autonomous Vehicles in Manufacturing Plants

Automakers are integrating AI-powered autonomous vehicles within factories to transport materials, enhancing efficiency and reducing human intervention in logistics.

Benefits of AI in Automotive Manufacturing

The integration of AI in car manufacturing offers numerous advantages, including:

• Enhanced Efficiency: AI automates repetitive tasks, reducing manual labor and increasing production speed.

• Cost Savings: Predictive analytics minimize operational costs by preventing breakdowns and optimizing resource allocation.

• Improved Product Quality: AI-driven quality control ensures defect-free components, leading to higher customer satisfaction.

• Sustainability: AI helps reduce waste and energy consumption, making manufacturing more environmentally friendly.

• Workforce Safety: AI-powered robots take over hazardous tasks, improving workplace safety for employees.

Challenges in Implementing AI in Automotive Manufacturing

Despite its benefits, AI adoption in automotive manufacturing faces several challenges:

• High Initial Investment: Implementing AI-driven systems requires significant investment in technology and infrastructure.

• Skilled Workforce: Companies need trained professionals who can manage AI systems effectively.

• Data Privacy & Security: Protecting sensitive manufacturing data from cyber threats remains a critical concern.

• Integration Complexity: AI systems must be seamlessly integrated into existing manufacturing processes, requiring careful planning.

The Future of AI in Automotive Manufacturing

By 2025, AI is expected to become an integral part of every automotive production process. Key future trends include:

• Fully Automated Factories: AI will lead to the development of smart factories with minimal human intervention.

• AI-Driven Customization: Personalized car manufacturing will be possible, allowing customers to customize vehicle features in real time.

• Sustainable Manufacturing: AI will enhance sustainability by optimizing resource usage and reducing emissions.

• Collaboration Between AI & Humans: AI will complement human workers, enabling them to focus on high-value tasks while AI handles repetitive processes.

Conclusion

The AI in automotive manufacturing 2025 revolution is transforming the industry by improving efficiency, quality, and sustainability. As automakers embrace AI-driven technologies, they will unlock new opportunities for growth and innovation. While challenges exist, the benefits of AI far outweigh the hurdles, making it a game-changer for the future of car manufacturing.

#tagbin#writers on tumblr#artificial intelligence#technology#ai trends 2025#AI in automotive manufacturing 2025#AI in car production#artificial intelligence in auto industry#AI-driven vehicle manufacturing#smart factories in automotive#AI-powered car assembly#robotics in automobile production#future of AI in automotive#AI automation in car factories#machine learning in automotive industry

0 notes

Text

The Future of Humanoid Robots in Manufacturing

In recent years, artificial intelligence and robotics have become integral parts of production processes. Jensen Huang, the CEO of Nvidia, recently highlighted the prospects of widespread adoption of humanoid robots during his speech, revealing new horizons in high technology and the economy.

Jensen Huang’s Predictions

During his keynote address at the annual developers’ conference in San Jose, Jensen Huang stated that it is less than five years until humanoid robots become commonplace in manufacturing. His talk focused on several key aspects:

Advancement of artificial intelligence technologies

Software tools for better interaction of robots with their environment

Potential applications across various industries

According to Huang, these factors create a solid foundation for the mass integration of humanoid robots, which could fundamentally transform production processes.

Software Tools for Robots

In his presentation, Huang introduced a variety of software tools designed to improve the navigation and interaction of humanoid robots with the real world. These technologies will enable robots to adapt to changing conditions and perform complex tasks effectively. Notable innovations include:

Enhanced machine learning algorithms

Computer vision technologies

Innovative real-time data processing methods

These tools aim to provide a higher degree of autonomy and independence for robotic systems.

Signs of Ubiquitous AI

Jensen Huang also discussed key indicators that will signify the widespread presence of artificial intelligence:

Integration of AI in everyday business processes

An increase in the number of people working alongside AI systems

A significant reduction in the time required to complete routine tasks

Development of user-friendly interfaces for engaging with AI

Recognition of innovations at the governmental and industrial levels

These signs could serve as markers of technological maturity and its acceptance in mainstream practices.

Conclusion

The future of humanoid robots and their impact on manufacturing processes represents one of the most compelling topics in the technology landscape today. Jensen Huang’s predictions illustrate that significant changes may occur in the coming years. The development of new software tools and artificial intelligence technologies provides a robust foundation for this transition, where humanoid robots could potentially play crucial roles across various sectors of the economy.

Our website: https://goldriders-robot.com/

Follow us on Facebook: https://www.facebook.com/groups/goldridersfb

Follow us on Pinterest: https://ru.pinterest.com/goldridersrobot/

Follow us on X: https://x.com/goldridersx?s=21

Follow us on Telegram: https://t.me/+QtMMmyyVhJExZThi

0 notes

Text

Peribott: Pioneering the Future of Robotics and Automation

In today’s fast-evolving industrial landscape, automation is no longer a luxury—it’s a necessity. Peribott’s Arm Robot is leading this transformation by bringing speed, precision, and intelligence to industries ranging from manufacturing to healthcare.

Designed with advanced AI integration and multi-axis motion, Peribott’s robotic arm can perform repetitive, hazardous, and high-precision tasks without fatigue. Whether it’s welding in factories, assisting in surgeries, or handling fragile materials in electronics assembly—this robot adapts seamlessly to the needs of modern operations.

Unlike traditional automation tools, the Peribott Arm Robot is built for flexibility. With programmable functions, real-time feedback, and a compact design, it enhances efficiency while maintaining safety and consistency. The result? Lower operational costs, improved product quality, and a safer work environment.

Adopting Peribott’s robotic arm means embracing the future—where humans and machines collaborate to unlock new possibilities.

Explore more at www.peribott.com

#robotic arm#industrial robot#automation robot#Peribott arm robot#AI robotic arm#collaborative robot#smart manufacturing solutions#robotic automation for industry#future of robotics#robot for repetitive tasks#ai#ai generated#ai model#tech#robot#robotics#robots#smart tech#technology

1 note

·

View note

Text

Digital Turnaround: How Tech Transforms Legacy Companies | Kunal Chopra on Shift AI

In this episode of the Shift AI Podcast, Certivo CEO Kunal Chopra joins Boaz Ashkenazy (CEO of Augmented AI Labs) to explore how legacy, “pen-and-paper” companies can undergo complete digital transformation. From eliminating manual processes to embedding AI agents directly into workflows, Kunal shares how he led old-school organizations into the future using technology and operational redesign.

At Certivo, AI isn’t just a tool — it’s a team member. CORA, our AI compliance agent, collaborates with human teams to automate the tedious, surface what matters, and help manufacturers stay always compliant and always market-ready.

This episode is a must-watch for anyone leading change in traditional industries, compliance management, or AI-driven operations.

🎧 Watch the full podcast: https://www.youtube.com/watch?v=KDTCN5Jyjfw 🌐 Learn more about Certivo: https://www.certivo.com/

#Digital transformation in legacy companies#AI-powered compliance solutions#AI in manufacturing compliance#Shift AI Podcast Kunal Chopra#Compliance tech for enterprises#Operational redesign with AI#Future of work with AI agents#How to digitize old-school businesses#Certivo AI compliance software#Compliance automation for manufacturers

0 notes

Text

Revolutionize Your Enterprise with Simulanis VR & AR

The future of business is immersive, interactive, and driven by technology. Enterprises that embrace Virtual Reality (VR) and Augmented Reality (AR) are unlocking new levels of efficiency, engagement, and innovation. At Simulanis, we are revolutionizing industries with cutting-edge VR and AR solutions that transform workforce training, customer experiences, and operational workflows.

Why VR & AR Are Essential for Enterprise Growth?

🔹 Next-Generation Employee Training Traditional training methods are no longer enough. Simulanis VR training solutions create realistic, hands-on virtual simulations, allowing employees to practice in a risk-free environment. AR-assisted learning further enhances training by providing real-time digital overlays and interactive guidance.

🔹 Enhanced Customer Engagement & Product Visualization Enterprises can showcase products and services in 3D, offering customers an immersive and interactive buying experience. VR-powered virtual showrooms and AR product visualization tools help businesses boost sales and brand loyalty.

🔹 Operational Efficiency & Safety Improvements From industrial safety training to real-time AR-powered remote assistance, immersive technologies help enterprises reduce risks, improve accuracy, and enhance productivity. AR smart glasses and VR simulations empower teams to perform complex tasks with greater precision.

🔹 Immersive Collaboration & Remote Work Solutions With VR-powered virtual workspaces, businesses can conduct meetings, training sessions, and brainstorming workshops in a realistic, collaborative digital environment. This is the future of hybrid work models and global enterprise connectivity.

🔹 Seamless Integration with the Metaverse The Metaverse is redefining business interaction, allowing enterprises to build virtual spaces, host digital events, and create next-level customer experiences. Simulanis provides tailored Metaverse solutions that help businesses stand out in the digital landscape.

Industries Benefiting from Simulanis VR & AR Solutions

✅ Manufacturing & Industrial Training – VR-based process training, equipment simulations, and AR maintenance guides. ✅ Healthcare & Medical Training – Surgical simulations, medical procedures training, and AR-assisted diagnostics. ✅ Retail & E-Commerce – Virtual try-ons, 3D product showcases, and interactive shopping experiences. ✅ Education & Corporate Learning – Engaging VR classrooms, AR-based learning modules, and enterprise e-learning solutions. ✅ Real Estate & Architecture – Immersive virtual property tours, 3D architectural visualizations, and interactive design planning. ✅ Automotive & Engineering – VR for vehicle prototyping, driver training, and AR-powered repair assistance.

Why Choose Simulanis?

At Simulanis, we are pioneers in VR, AR, and Metaverse technology, helping businesses unlock the full potential of immersive solutions. Our expertise in Extended Reality (XR) solutions ensures that enterprises can streamline operations, enhance customer engagement, and train employees more effectively.

🚀 The future of enterprise innovation starts now! 🚀

�� Get in touch with Simulanis today and explore how VR & AR can transform your business!

Visit Website: simulanis.com

#Virtual Reality (VR)#Augmented Reality (AR)#Mixed Reality (MR)#Metaverse Solutions#Extended Reality (XR)#Enterprise VR Solutions#AR for Business#Immersive Technology#Future of Work#Digital Transformation#VR Training Programs#AR Training Modules#Industrial VR Training#Corporate Learning with XR#3D Virtual Simulations#AR Product Visualization#Workforce Training Solutions#Metaverse for Enterprises#Remote Work with VR#AI-Powered AR/VR#Smart Manufacturing with XR#VR for Employee Development#Augmented Reality for Retail#Virtual Showrooms#AR Maintenance & Support#VR in Healthcare & Medical Training#Immersive Learning Solutions#AR/VR for Real Estate#Enterprise Innovation with XR

0 notes

Text

#Artificial Intelligence#Global Control#Humanity’s Downfall#Machine Messiah#Manufactured Consent#Mass Manipulation#Orwellian Future#Psychological Warfare#Silicon Enslavement#Social Engineering#straight forward#Surveillance State#The Art of Deception#The Illusion of Freedom#The Rise of AI

0 notes