#HDPE Packaging Market

Explore tagged Tumblr posts

Text

HDPE Packaging Market Growth, Key Players, & Industry Insights 2025

Comprehensive Analysis of the Global HDPE Packaging Market

Executive Summary

The global HDPE Packaging Markethas demonstrated substantial growth, valued at USD 17.10 billion in 2022 and projected to reach USD 17.96 billion in 2023. The market's continued expansion is expected to see it reach USD 26.25 billion by 2031, with a compound annual growth rate (CAGR) of 5.57% during the forecast period from 2024 to 2031. This growth trajectory is attributed to the increasing demand for durable, lightweight, and recyclable packaging solutions across diverse industries such as food and beverages, pharmaceuticals, personal care, and e-commerce. Additionally, the rise of eco-conscious consumer behavior and sustainability trends are likely to significantly influence the market's evolution in the coming years.

This article explores the intricate dynamics of the HDPE packaging market, including growth drivers, challenges, regional trends, and market segment analysis, with a focus on key insights that are shaping the sector's future.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40611-global-hdpe-packaging-market

HDPE Packaging Market Overview

The global HDPE packaging market is witnessing robust growth, driven by technological advancements, increasing demand for sustainable solutions, and a shift toward more efficient packaging alternatives. As industries across the world look to optimize their packaging systems, HDPE offers several compelling advantages—lightweight, durable, resistant to chemicals, and recyclable. These attributes make it highly favored for a wide range of packaging applications, particularly in industries where product safety and durability are paramount, such as food and beverage, healthcare, and consumer goods.

The market's expansion is further propelled by innovations in HDPE production technologies, including blow molding, extrusion processes, and the increasing shift toward post-consumer recycled (PCR) content. Moreover, the regulatory landscape is evolving to favor recyclable and sustainable materials, which positions HDPE as a preferred choice for manufacturers looking to comply with stringent environmental regulations.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40611-global-hdpe-packaging-market

Key HDPE Packaging Market Drivers:

Sustainability Trends: Increasing consumer preference for eco-friendly packaging options.

Advancements in Manufacturing: Technological innovations leading to more efficient and cost-effective production of HDPE packaging.

E-commerce Growth: The rising demand for packaging solutions due to the exponential growth of the e-commerce industry.

Regulatory Pressure: Government initiatives and policies promoting the adoption of recyclable and reusable packaging solutions.

HDPE Packaging Market Dynamics

Drivers of Market Growth

Durability and Lightweight Nature HDPE’s inherent strength and low weight make it an ideal material for packaging, especially for liquid and solid products that require long shelf lives or need protection from external factors like moisture and contaminants. Its resilience ensures that it remains one of the most sought-after materials for both primary and secondary packaging in various sectors.

Rising Demand for Sustainable Packaging Solutions A significant shift toward sustainable packaging solutions is reshaping the industry. With heightened concerns over plastic pollution and environmental impact, manufacturers are increasingly turning to recyclable HDPE alternatives. This trend is particularly prevalent in consumer goods, food and beverage, and pharmaceuticals, where eco-friendly packaging is now a key demand driver.

Technological Advancements Breakthroughs in HDPE production technologies—such as advancements in blow molding, extrusion, and thermoforming—have improved the material’s versatility, strength, and customization options. These innovations enable manufacturers to create lightweight, high-performance packaging that meets consumer expectations for both functionality and sustainability.

Regulatory Push for Recyclable Packaging Governments around the world are enacting stricter regulations on plastic waste and non-recyclable packaging. As part of the global initiative to combat plastic pollution, many jurisdictions are mandating the use of recyclable materials in packaging. HDPE's ability to be easily recycled makes it a highly attractive material for companies striving to comply with these policies.

HDPE Packaging Market Challenges

Fluctuating Raw Material Prices One of the significant challenges impacting the HDPE packaging market is the volatility in raw material prices. The price of crude oil, which is a key input in HDPE production, can be unstable, which in turn affects the cost of HDPE-based packaging solutions.

Plastic Waste Management Concerns Despite being recyclable, HDPE is still plastic, and its widespread use has contributed to mounting concerns about plastic waste. Many companies in the packaging sector are under pressure to adopt sustainable alternatives, and there is an ongoing push for innovations in biodegradable blends and circular economy initiatives.

HDPE Packaging Market Segmental Analysis

By Product Type

Bottles & Containers

The bottles and containers segment dominated the global HDPE packaging market in 2023 and is expected to maintain its leading position through 2031. HDPE bottles and containers are used extensively in the food and beverage, pharmaceutical, and household chemicals industries, where strength, moisture resistance, and durability are crucial. The growing demand for dairy products, juices, edible oils, and cleaning agents is expected to continue to drive growth in this segment.

The segment's projected CAGR from 2024 to 2031 is 5.2% as manufacturers increasingly incorporate post-consumer recycled (PCR) materials into bottle production to meet sustainability targets.

Films & Sheets

The films and sheets segment is gaining significant traction in packaging applications, especially in flexible packaging formats. HDPE films are lightweight, cost-effective, and capable of providing an excellent moisture barrier. This makes them highly suitable for applications in the food industry, such as packaging for fresh produce, meat, and dairy products. Additionally, the growing demand for e-commerce packaging, where flexible packaging is often preferred due to its efficiency, is driving the expansion of this segment.

By Material

Virgin HDPE

The virgin HDPE segment has historically commanded the largest share of the market due to its superior mechanical properties, such as higher strength, rigidity, and purity. These attributes make it particularly valuable in food and pharmaceutical packaging, where material safety is paramount. Despite the growing trend toward sustainable packaging, the reliability and performance of virgin HDPE continue to make it the material of choice in various applications.

Recycled HDPE

With increased environmental awareness and regulatory pressure, recycled HDPE is expected to experience robust growth. The transition toward using recycled content in HDPE packaging is driven by both consumer demand for sustainable packaging and the adoption of circular economy principles by companies in the packaging sector.

By End-Use Industry

Food & Beverage

The food and beverage sector remains the largest end-use industry for HDPE packaging, driven by the need for safe, durable, and lightweight packaging for perishable goods. The market for HDPE packaging in this sector is expected to grow at a CAGR of 5.5% from 2024 to 2031, bolstered by the increasing demand for convenient packaging formats such as bottles, containers, and pouches.

Pharmaceuticals & Healthcare

The pharmaceutical sector is another significant contributor to HDPE packaging demand. The need for tamper-evident, contamination-free packaging for medicines, supplements, and medical devices positions HDPE as a preferred material due to its high barrier properties.

HDPE Packaging Market Regional Analysis

Asia-Pacific

The Asia-Pacific region is poised for the highest growth rate in the global HDPE packaging market, with a projected CAGR of 5.8%. The growth is largely driven by the rapid industrialization and urbanization in countries like China and India, where there is increasing demand for HDPE packaging solutions in the food, beverage, and pharmaceutical sectors. The rise in disposable incomes and the booming e-commerce industry are further contributing to this growth.

North America & Europe

In North America and Europe, the demand for HDPE packaging is being fueled by stringent environmental regulations and a growing emphasis on sustainable packaging solutions. Both regions are expected to experience steady growth rates, with North America projected to grow at 5.2% CAGR and Europe at 4.9% CAGR.

Competitive Landscape

The HDPE packaging market is highly competitive, with several leading players striving for innovation and market share. Amcor, Berry Global, Sealed Air, Mondi, and Huhtamaki are some of the major companies dominating the market. These companies are investing heavily in sustainable packaging solutions, including biodegradable HDPE blends and recycled materials, to meet evolving consumer preferences and regulatory requirements.

Strategic mergers and acquisitions are also a key growth strategy in the industry. For instance, Amcor’s recent merger with Berry Global enhances its position as a global leader in packaging, particularly in the healthcare and foodservice sectors.

Conclusion

The HDPE packaging market is set to experience robust growth over the next decade, driven by technological innovations, the increasing demand for sustainable packaging, and the expanding reach of industries like food and beverage, pharmaceuticals, and e-commerce. Companies that focus on recycling, biodegradable materials, and cost-effective solutions will likely gain a competitive edge in this rapidly evolving market. As consumer preferences shift toward eco-friendly

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40611-global-hdpe-packaging-market

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#HDPE Packaging Market#Global HDPE Packaging#Packaging Industry Trends#HDPE Packaging Growth#HDPE Packaging Forecast#Packaging Market 2025#Sustainable Packaging#HDPE Packaging Insights#Market Trends in Packaging#Plastic Packaging Industry#Eco-friendly Packaging#Market Share HDPE Packaging

1 note

·

View note

Text

REVOLUTIONIZING RETAIL: THE ROLE OF OPEN ITEMS PACKAGING SOLUTIONS IN MODERN MARKETING

The retail landscape doubles open solutions like product packaging for brands, making an impression on consumers that lasts a long time. With this revolutionary packaging concept, brands can showcase their products effectively and also offer the target audience a perhaps unique opportunity to interact with them on a more personal level. In this article, we will be reviewing the importance of marketing open-item packaging in front of current customers and what drastic changes it is about to bring to the retail industry.

Exploring Open Items Packaging Solutions: A Comprehensive Insight

The type of packaging that uses design to lure consumers to look at how the product is on the inside is called open-item packaging. In contrast, bulky packaging is a conventional method that covers a product with plastic and cardboard, but open packaging displays the product at the front line, where the customer can identify the product to induce their decision to buy.

The Appeal of Transparency

Transparency is a crucial high point of the open-item packaging. Thanks to that, consumers can see the product, and therefore the brand represents itself as a trustworthy and reliable company that does not have any hidden secrets or deceit, which would disappoint the client after opening the package. This transparency, therefore, gives rise to a feeling of sincerity and honesty, which are greatly valued due to the competitiveness of the market.

Enhancing the shopping experience

In addition, the open-item package brings a new aspect to consumers’ shopping experiences. It is indirectly through their physical interaction with the product that they develop a perception of the product, which greatly changes their point of purchase. Studies have proven that information technology is nowadays an integral tool in marketing since buyers and consumers have become more likely to purchase a product at a physical store instead of online when they can touch, feel, and experience it firsthand. In the same way, a tactile experience creates one’s personal connection with the audience, brands can have a deep emotional connection with the audience, leading to loyalty and repeat business.

Visual Impact

For starters, shelf impact, or visual impact, arises when products are open in packaging. By emphasizing and presenting the product in its most glorious form, the brand can attract the attention of potential consumers and avoid other brands vying for their attention, thus giving it a competitive advantage. When it comes to visual appeal, open-item packaging allows brands to advertise the product in an attention-grabbing manner that speaks to their specific audience. It could be either bright colours, modern design, or simply innovative features that leave a memorable impression.

Storytelling Opportunity

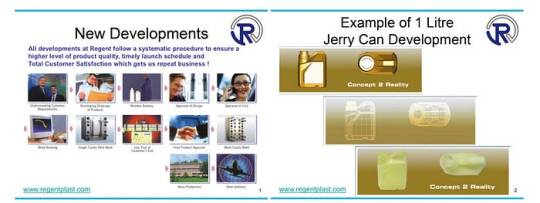

https://regentplast.com/wp-content/uploads/2024/05/image.png

In addition, the presentation of the brand story becomes possible on the packaging of unwrapped items, which holds exciting potential for the brands. Branding, messaging, and visual components are, thus, key components of packaging design that should be included to connect a brand with its target audience and establish unique experiences for consumers. It’s the storytelling bit that bridges consumers more deeply into the brand beyond superficial levels and gives the brand an advantage over others in an increasingly busy market.

Read More- https://regentplast.com/revolutionizing-retail-the-role-of-open-items-packaging-solutions-in-modern-marketing/

#packaging#manufacturing#hdpebottles#sustainability#environment#plastic#recycling#hdpe plastic container manufacturer#brand identity#branding#business#marketing

0 notes

Text

Plastic Protective Packaging Market Analysis, Business Growing Strategies, Segmentation and Forecast 2033

According to Fact.MR, the global plastic protective packaging market is projected to reach US$ 17.7 billion in 2023 and grow at a compound annual growth rate (CAGR) of 6.6% from 2023 to 2033.

Plastic remains one of the most widely used materials for protective packaging across various industries. The retail sector, in particular, heavily relies on plastic packaging, with applications ranging from weather protection to damage prevention. Compared to other packaging materials, plastic is more versatile and cost-effective. Recent advancements in plastic formulations have further expanded its use in the packaging industry. Plastic's flexibility, lightweight, and durability make it especially valuable in the food and beverage sector, driving increased demand for plastic protective packaging.

Get FREE Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=3277

The e-commerce industry has evolved significantly over the years, with nearly every manufacturing sector now utilizing online platforms and last-mile delivery services. Plastic protective packaging plays a vital role in this industry, contributing to the rising demand for protective packaging solutions. Widely used packaging types in e-commerce include bubble wrap, plastic mailers, and air cushions. Beyond e-commerce, industries like automotive, electronics, and aerospace also rely on plastic protective packaging for both primary and secondary applications.

Key Takeaways from the Market Study:

The plastic protective packaging market is valued at US$ 17.7 billion in 2023 and is projected to grow at a CAGR of 6.6% from 2023 to 2033.

By 2033, the market is expected to reach a valuation of US$ 33.5 billion.

North America is a key region, holding a 23.2% market share in 2023.

Leading players in the market include Berry Global Group, Sealed Air Corporation, and Smurfit Kappa Group.

Tier-1 manufacturers account for 17-19% of the global plastic protective packaging market share.

“Advancements in Materials and Technology: Driving Plastic Protective Packaging Market During the Forecast Period” says a Fact.MR analyst.

Key Players of Plastic Protective Packaging Market

AEP Industries Inc.

Berry Global Group

Coveris Holdings S.A.

Kureha Corporation

PREMIUM PACK GmbH

Schur Flexibles Group

Sealed Air

Get Customization on this Report for Specific Research Solutions: https://www.factmr.com/connectus/sample?flag=RC&rep_id=3277

Market Growth Strategies

Leading manufacturers and suppliers in the plastic protective packaging market include Sealed Air, Berry Global Group, Kureha Corporation, and Coveris Holdings S.A.

To stay competitive, these companies are offering customizable packaging solutions tailored to meet specific customer requirements. This strategy enhances customer loyalty, encourages repeat business, and provides a competitive edge. Additionally, many companies are investing in new materials and technologies to improve the quality, durability, and sustainability of plastic protective packaging. By focusing on eco-friendly solutions, they are responding to the growing demand for sustainable packaging while differentiating themselves in a highly competitive market.

Segmentation of Plastic Protective Packaging Industry Research

By Material :

Air Cushion

PP

HDPE

LDPE

LLDPE

Plastic Mailer

PP

HDPE

LDPE

LLDPE

Bubble

PP

HDPE

LDPE

LLDPE

Dunnage Bags

PP

HDPE

LDPE

PVC

Sleeves

PP

HDPE

LDPE

PVC

Shrink Wrap

PP

HDPE

LDPE

LLDPE

PVC

Stretch Wrap

PP

HDPE

LDPE

LLDPE

PVC

Stretch Hood

HDPE

LDPE

LLDPE

By Region :

North America

Latin America

Europe

East Asia

South Asia & Oceania

Middle East & Africa

Read More: https://www.factmr.com/report/3277/plastic-protective-packaging-market

More Valuable Insights on Offer

Fact.MR, in its new offering, presents an unbiased analysis of the plastic protective packaging market, presenting historical market data (2018-2022) and forecast statistics for the period of 2023-2033.

The study reveals essential insights on the basis of material, (air cushion, plastic mailer, bubble, dunnage bags, sleeves, shrink wrap, stretch wrap, stretch hood), and across major regions of the world (North America, Latin America, Europe, East Asia, South Asia, and Oceania, Middle East & Africa).

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Know About The Potential of Plastic Extrusion Process

A manufacturing technique called plastic extrusion is used to make products with a predetermined cross-sectional profile. To form molten plastic into a continuous profile that can be cut to specified lengths, it is pushed through a die. Numerous items may be produced with this technique, ranging from straightforward pipes and tubes to intricate profiles utilized in packaging, automotive, construction, and other industries.

Flexibility in Utilization

Building: Plastic extrusion plays a key role in the building sector by creating pipes, profiles, and other parts that go into drainage systems, windows, doors, roofing, and plumbing. For example, extrusion is frequently used in the manufacturing of PVC and HDPE pipes because of its robustness and resistance to corrosion.

Consumer Products: The production of toys, furniture, and home appliances has benefited from the usage of the Plastic Extrusion Process. Custom profiles and complex designs may be produced with this technology, meeting the practical and aesthetic needs of many items.

Medical: Tubing, catheters, and other medical equipment are produced in the medical industry via plastic extrusion. The capacity to produce accurate, sterile parts guarantees adherence to strict legal requirements while satisfying the needs of medical practitioners and patients.

Benefits of Plastic Extrusion:

Cost-Effectiveness: Plastic extrusion provides affordable options for producing a variety of goods. Compared to alternative approaches, the process lowers material waste and needs less expensive tooling, making it a financially feasible option for large-scale manufacturing.

Design Flexibility: Manufacturers may design unique profiles and forms using plastic extrusion to satisfy certain specifications. In markets with intense competition, this flexibility promotes innovation and product differentiation.

Efficiency: The production of consistent profiles in continuous lengths with little downtime is possible through the very efficient process of plastic extrusion. This efficacy adds to overall operational effectiveness by translating into increased production and quicker turnaround times.

Material Versatility: PVC, HDPE, LDPE, PP, and ABS are just a few of the thermoplastic materials that may be used with plastic extrusion. Because of its adaptability, plastic extrusion manufacturer may choose the material that best suits their needs by weighing characteristics like strength, flexibility, and chemical resistance.

2 notes

·

View notes

Text

Inverted Squeeze Bottle Market Insight | Outlook | Growth Analysis Report 2030

Inverted Squeeze Bottle Market Report has recently added by Value Market Research, this surveillance report establishing the facts based on current scenarios, historical records from 2022 to future forecast upto 2030. This report explicit data of various outlook such as market share, size, growth rates, and industry opportunities and offering an economical advantage for business success. It furnish the 360-degree overview of the competitive landscape of the global industries. Porter’s Five Forces Model analysis has been used to understand the industry’s structure, strength, weaknesses, opportunities, threats and challenges in front of the businesses. Moreover, the report also highlights a sudden occurrence of COVID 19 impact on Inverted Squeeze Bottle market to improve future capacities and other developments.

The research report also covers the comprehensive profiles of the key players in the market and an in-depth view of the competitive landscape worldwide. The major players in the inverted squeeze bottle market include Genesis Industries, Inc., IonWays, LLC, Midland Manufacturing Company, Inc., Kyoraku Co., Ltd., The Original Squeeze Company, Suzhou Innovation Packaging Materials Co.,Ltd, Illing Company, Inc., Kaufman Container Company etc. This section consists of a holistic view of the competitive landscape that includes various strategic developments such as key mergers & acquisitions, future capacities, partnerships, financial overviews, collaborations, new product developments, new product launches, and other developments.

Get more information on "Global Inverted Squeeze Bottle Market Research Report" by requesting FREE Sample Copy at https://www.valuemarketresearch.com/contact/inverted-squeeze-bottle-market/download-sample

Market Dynamics

The growing utilization of squeeze bottles in several industries such as food, drinks, healthcare, and personal care, pharmaceuticals, and so on is the major factor driving the inverted squeeze bottle market. The huge benefits are associated with squeeze bottles, such as it leaves less waste, Better control of food quantity, Easy fit into refrigerator door shelves, and require less space in the refrigerator, which might create high market demand in the coming years across the food industry. The rising popularity of fast food and Italian food like pasta and pizza among consumers across the globe is positively impacting the inverted squeeze bottle market’s growth. Moreover, the rapidly growing food and beverage industry across the globe is likely to create lucrative growth opportunities for key players of the Inverted squeeze bottle market in the coming years.

The research report covers Porter’s Five Forces Model, Market Attractiveness Analysis, and Value Chain analysis. These tools help to get a clear picture of the industry’s structure and evaluate the competition attractiveness at a global level. Additionally, these tools also give an inclusive assessment of each segment in the global market of inverted squeeze bottle. The growth and trends of inverted squeeze bottle industry provide a holistic approach to this study.

Browse Global Inverted Squeeze Bottle Market Research Report with detailed TOC at https://www.valuemarketresearch.com/report/inverted-squeeze-bottle-market

Market Segmentation

This section of the inverted squeeze bottle market report provides detailed data on the segments at country and regional level, thereby assisting the strategist in identifying the target demographics for the respective product or services with the upcoming opportunities.

By Closure Type

Flip Top Cap

Plug Orifice Cap

Screw Cap

Others

By Material Type

Polyethylene Terephthalate (Pet)

Polypropylene (Pp)

High Density Polyethylene (Hdpe)

Others

By Capacity

Up To 100 Ml

100 Ml To 250 Ml

250 Ml To 500 Ml

500 Ml To 750 Ml

Above 750 Ml

By End Use Industry

Food & Beverages

Automobile

Personal Care & Hygiene

Healthcare & Pharmaceutical

Chemicals

Others

Regional Analysis

This section covers the regional outlook, which accentuates current and future demand for the Inverted Squeeze Bottle market across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Further, the report focuses on demand, estimation, and forecast for individual application segments across all the prominent regions.

Purchase Complete Global Inverted Squeeze Bottle Market Research Report at https://www.valuemarketresearch.com/contact/inverted-squeeze-bottle-market/buy-now

About Us:

Value Market Research was established with the vision to ease decision making and empower the strategists by providing them with holistic market information.

We facilitate clients with syndicate research reports and customized research reports on 25+ industries with global as well as regional coverage.

Contact:

Value Market Research

401/402, TFM, Nagras Road, Aundh, Pune-7.

Maharashtra, INDIA.

Tel: +1-888-294-1147

Email: [email protected]

Website: https://www.valuemarketresearch.com

#Inverted Squeeze Bottle Market#Inverted Squeeze Bottle Market Report#Inverted Squeeze Bottle Industry#Inverted Squeeze Bottle Industry Report

2 notes

·

View notes

Text

How to Improve the Purity of Recycled PET Flakes: Best Practices

Recycled PET flakes are a crucial resource in the circular economy. They are used in packaging, textiles, and other industries. However, the quality and purity of these flakes affect their usability and market value. Impurities such as labels, adhesives, dirt, and mixed plastics can reduce performance and limit applications.

Improving the purity of recycled PET flakes is crucial for manufacturers seeking to meet industry standards and produce high-quality products. This article shares best practices for enhancing flake purity, from collection to final processing.

Start with Clean and Sorted Input Materials

The first step in producing high-quality recycled PET flakes is ensuring that the input materials, which are PET bottles, are clean and properly sorted.

Best practices:

Source from reliable collection systems: Bottles collected through organized recycling programs tend to be cleaner and better sorted.

Remove caps and labels early: These are often made from different plastics and can contaminate the flakes.

Avoid mixing with other plastics: Keep PET separate from HDPE, PVC, and other materials to prevent cross-contamination.

Proper sorting at the beginning reduces the burden on downstream cleaning and separation processes.

Use Advanced Washing and Cleaning Systems

Washing is a critical stage in improving the purity of recycled PET flakes. It removes dirt, glue, food residues, and other contaminants.

Recommended washing techniques:

Hot water washing: Helps dissolve adhesives and remove stubborn residues.

Friction washers: Scrub the flakes to eliminate surface contaminants.

Chemical cleaning: In some cases, mild detergents or alkali solutions are used to enhance cleaning.

Multiple rinse cycles: Ensure thorough removal of cleaning agents and residues.

A well-designed washing line can boost the quality of recycled PET flakes.

Invest in Optical and Density-Based Sorting

Even after washing, some impurities may remain. Advanced sorting technologies help separate PET flakes from unwanted materials based on colour, density, and composition.

Sorting technologies to consider:

Optical sorters: Use cameras and sensors to detect and remove coloured or contaminated flakes.

Air classifiers: Separate light contaminants such as paper or film.

Float-sink tanks: Separate PET from other plastics based on density differences.

These systems are useful in large-scale recycling operations where manual sorting is not feasible.

Monitor and Control Contamination Levels

To maintain consistent quality, it’s important to test and monitor the purity of recycled PET flakes. This helps identify issues early and adjust processes accordingly.

Quality control measures:

Visual inspection: Check for colour consistency and visible contaminants.

Intrinsic viscosity (IV) testing: Measures polymer strength and degradation.

Contaminant analysis: Use lab tests to detect non-PET materials or chemical residues.

Batch tracking: Keep records of input sources and processing conditions.

Regular monitoring ensures that recycled PET flakes meet industry standards and customer expectations.

Train Staff and Maintain Equipment

Human error and poorly maintained equipment can lead to contamination. Training and maintenance are key to ensuring high-purity output.

Operational best practices:

Train workers on sorting and handling procedures

Schedule regular equipment cleaning and maintenance

Calibrate sensors and sorting machines periodically

Enforce safety and hygiene protocols in the facility

A well-managed recycling plant produces cleaner and better quality recycled PET flakes.

Conclusion: Clean flakes ensure better products

Improving the purity of recycled PET flakes is not just about meeting technical standards; it’s about creating better products, reducing waste, and supporting sustainability. By following best practices in sorting, washing, and quality control, manufacturers can produce flakes that are suitable for high-end applications, such as food-grade packaging and premium textiles.

0 notes

Text

Top Closure Bottle Caps Manufacturer Delhi India Precision Meets Quality

Delhi, India is home to some of the most reliable and innovative closure bottle caps manufacturers, catering to industries such as beverages, pharmaceuticals, cosmetics, and food packaging. These manufacturers offer a wide range of high-quality plastic and metal caps, including screw caps, flip-tops, and tamper-evident closures, designed for durability, leak-proof sealing, and aesthetic appeal. Using advanced molding technology and food-grade materials, they ensure safety, functionality, and regulatory compliance. Whether for mass production or customized packaging needs, bottle cap manufacturers in Delhi provide scalable, cost-effective solutions that meet both domestic and international standards making them a preferred choice for brands seeking reliable packaging components.

Diverse Range of Bottle Cap Solutions for Every Industry

Closure bottle caps manufacturer Delhi India offer a comprehensive range of products to meet the specific needs of various industries. From standard screw caps and flip-top closures to tamper-evident and child-resistant designs, these manufacturers produce caps suitable for beverages, pharmaceuticals, cosmetics, chemicals, and more. With the ability to handle high-volume production and specialized orders, they cater to small-scale brands as well as large enterprises. Their wide product portfolio ensures compatibility with glass, PET, and HDPE bottles, making them a one-stop solution for diverse packaging requirements.

Use of High-Quality, Food-Grade Materials

Delhi-based closure cap manufacturers prioritize safety and compliance by using only premium, food-grade raw materials such as HDPE, PP, and LDPE. These materials are non-toxic, durable, and capable of withstanding extreme temperatures, making them ideal for both food and pharmaceutical packaging. Additionally, manufacturers conduct stringent quality checks to ensure material integrity, minimizing contamination risks. By following global safety standards, these manufacturers ensure that their bottle caps are not only functional but also safe for consumer use—making them a dependable choice for industries where hygiene and compliance are non-negotiable.

Advanced Manufacturing Techniques and Infrastructure

Equipped with state-of-the-art facilities, closure bottle cap manufacturers in Delhi utilize high-speed injection molding, compression molding, and automated assembly lines to deliver consistent product quality. These technologies enable precision engineering, tight tolerance control, and high production efficiency. With the ability to produce both standard and custom designs at scale, manufacturers can meet urgent and bulk orders without compromising on quality. Modern infrastructure and skilled technicians ensure that every cap meets the required specifications in terms of size, sealing strength, and finish.

Customization and Branding Capabilities

In today’s competitive market, packaging plays a crucial role in brand identity. Closure bottle caps manufacturers in Delhi offer full customization options, including logo embossing, color matching, printing, and special finishes. Whether it’s a unique design for a cosmetic product or color-coded caps for pharmaceuticals, manufacturers work closely with clients to develop closures that enhance visual appeal while maintaining performance. These customized solutions help brands stand out on the shelves and build trust with consumers. Manufacturers also offer design consultations to ensure that the cap complements the bottle and the product's intended use.

Focus on Leak-Proof and Tamper-Evident Designs

Ensuring product integrity is a top priority for closure bottle caps manufacturers in Delhi. Many suppliers specialize in leak-proof and tamper-evident closures, which provide added safety and consumer confidence. These features are particularly important for pharmaceuticals, food, and beverages where contamination or tampering can lead to serious consequences. By incorporating sealing liners, security bands, and advanced locking mechanisms, manufacturers ensure their caps provide airtight sealing, spill prevention, and visible proof of product safety aligning with both regulatory standards and market expectations.

Eco-Friendly and Sustainable Manufacturing Options

With growing awareness around environmental sustainability, many Delhi-based bottle cap manufacturers are adopting eco-friendly practices. They offer biodegradable, recyclable, and reusable caps made from sustainable polymers. Some manufacturers also use energy-efficient machines and implement waste-reduction strategies during production. These green initiatives not only reduce the environmental footprint but also align with the eco-conscious values of modern consumers and global brands. By choosing manufacturers that prioritize sustainability, businesses can contribute to circular economy goals while maintaining packaging quality and aesthetics.

Strategic Location and Efficient Distribution Networks

Being located in the national capital, closure bottle caps manufacturers in Delhi benefit from excellent connectivity, making it easy to serve clients across India and export globally. Their strategic location near major logistics hubs allows for fast, reliable shipping and reduced lead times. Many manufacturers maintain well-managed inventory systems and dedicated distribution channels to fulfill orders on time, even in bulk. This logistical advantage, combined with consistent product quality, makes Delhi-based manufacturers ideal partners for businesses that need dependable packaging solutions delivered with speed and efficiency.

Conclusion

Closure bottle caps manufacturers in Delhi, India, play a vital role in delivering reliable, high-quality packaging solutions for a wide range of industries. With advanced production facilities, food-grade materials, customizable designs, and eco-friendly practices, they meet both functional and aesthetic demands of modern packaging. Their commitment to precision, safety, and timely delivery makes them trusted partners for businesses across India and around the globe. Whether you're in the beverage, pharmaceutical, cosmetic, or chemical sector, these manufacturers provide secure, leak-proof, and tamper-evident closures tailored to your needs. Choosing a Delhi-based bottle cap manufacturer ensures performance, compliance, and competitive pricing all in one place.

0 notes

Text

Top Closure Bottle Caps Manufacturer Delhi India Precision Meets Quality

Delhi, India is home to some of the most reliable and innovative closure bottle caps manufacturers, catering to industries such as beverages, pharmaceuticals, cosmetics, and food packaging. These manufacturers offer a wide range of high-quality plastic and metal caps, including screw caps, flip-tops, and tamper-evident closures, designed for durability, leak-proof sealing, and aesthetic appeal. Using advanced molding technology and food-grade materials, they ensure safety, functionality, and regulatory compliance. Whether for mass production or customized packaging needs, bottle cap manufacturers in Delhi provide scalable, cost-effective solutions that meet both domestic and international standards making them a preferred choice for brands seeking reliable packaging components.

Diverse Range of Bottle Cap Solutions for Every Industry

Closure bottle caps manufacturer Delhi India offer a comprehensive range of products to meet the specific needs of various industries. From standard screw caps and flip-top closures to tamper-evident and child-resistant designs, these manufacturers produce caps suitable for beverages, pharmaceuticals, cosmetics, chemicals, and more. With the ability to handle high-volume production and specialized orders, they cater to small-scale brands as well as large enterprises. Their wide product portfolio ensures compatibility with glass, PET, and HDPE bottles, making them a one-stop solution for diverse packaging requirements.

Use of High-Quality, Food-Grade Materials

Delhi-based closure cap manufacturers prioritize safety and compliance by using only premium, food-grade raw materials such as HDPE, PP, and LDPE. These materials are non-toxic, durable, and capable of withstanding extreme temperatures, making them ideal for both food and pharmaceutical packaging. Additionally, manufacturers conduct stringent quality checks to ensure material integrity, minimizing contamination risks. By following global safety standards, these manufacturers ensure that their bottle caps are not only functional but also safe for consumer use—making them a dependable choice for industries where hygiene and compliance are non-negotiable.

Advanced Manufacturing Techniques and Infrastructure

Equipped with state-of-the-art facilities, closure bottle cap manufacturers in Delhi utilize high-speed injection molding, compression molding, and automated assembly lines to deliver consistent product quality. These technologies enable precision engineering, tight tolerance control, and high production efficiency. With the ability to produce both standard and custom designs at scale, manufacturers can meet urgent and bulk orders without compromising on quality. Modern infrastructure and skilled technicians ensure that every cap meets the required specifications in terms of size, sealing strength, and finish.

Customization and Branding Capabilities

In today’s competitive market, packaging plays a crucial role in brand identity. Closure bottle caps manufacturers in Delhi offer full customization options, including logo embossing, color matching, printing, and special finishes. Whether it’s a unique design for a cosmetic product or color-coded caps for pharmaceuticals, manufacturers work closely with clients to develop closures that enhance visual appeal while maintaining performance. These customized solutions help brands stand out on the shelves and build trust with consumers. Manufacturers also offer design consultations to ensure that the cap complements the bottle and the product's intended use.

Focus on Leak-Proof and Tamper-Evident Designs

Ensuring product integrity is a top priority for closure bottle caps manufacturers in Delhi. Many suppliers specialize in leak-proof and tamper-evident closures, which provide added safety and consumer confidence. These features are particularly important for pharmaceuticals, food, and beverages where contamination or tampering can lead to serious consequences. By incorporating sealing liners, security bands, and advanced locking mechanisms, manufacturers ensure their caps provide airtight sealing, spill prevention, and visible proof of product safety aligning with both regulatory standards and market expectations.

Eco-Friendly and Sustainable Manufacturing Options

With growing awareness around environmental sustainability, many Delhi-based bottle cap manufacturers are adopting eco-friendly practices. They offer biodegradable, recyclable, and reusable caps made from sustainable polymers. Some manufacturers also use energy-efficient machines and implement waste-reduction strategies during production. These green initiatives not only reduce the environmental footprint but also align with the eco-conscious values of modern consumers and global brands. By choosing manufacturers that prioritize sustainability, businesses can contribute to circular economy goals while maintaining packaging quality and aesthetics.

Strategic Location and Efficient Distribution Networks

Being located in the national capital, closure bottle caps manufacturers in Delhi benefit from excellent connectivity, making it easy to serve clients across India and export globally. Their strategic location near major logistics hubs allows for fast, reliable shipping and reduced lead times. Many manufacturers maintain well-managed inventory systems and dedicated distribution channels to fulfill orders on time, even in bulk. This logistical advantage, combined with consistent product quality, makes Delhi-based manufacturers ideal partners for businesses that need dependable packaging solutions delivered with speed and efficiency.

Conclusion

Closure bottle caps manufacturers in Delhi, India, play a vital role in delivering reliable, high-quality packaging solutions for a wide range of industries. With advanced production facilities, food-grade materials, customizable designs, and eco-friendly practices, they meet both functional and aesthetic demands of modern packaging. Their commitment to precision, safety, and timely delivery makes them trusted partners for businesses across India and around the globe. Whether you're in the beverage, pharmaceutical, cosmetic, or chemical sector, these manufacturers provide secure, leak-proof, and tamper-evident closures tailored to your needs. Choosing a Delhi-based bottle cap manufacturer ensures performance, compliance, and competitive pricing all in one place.

0 notes

Text

Polyethylene Market

Polyethylene Market Poised for Growth Amidst Rising Demand Across Industries

The Polyethylene market is witnessing significant momentum as global demand for versatile plastic materials continues to surge. As a cornerstone of modern industrial applications, Polyethylene—the most widely produced plastic globally—plays a vital role in packaging, construction, automotive, electronics, and healthcare sectors. The expanding applications of polyethylene are fueling an uptick in market volume, prompting stakeholders to assess opportunities and challenges more strategically.

Global Polyethylene Market Size: Analysis By Type (High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE)), By Industry (Packaging Industry, Construction Industry, Automotive Industry, Electrical and Electronics Industry, Consumer Goods Industry, Agriculture Industry, Healthcare Industry): Global and Regional Demand Supply Trends and Forecast-2025-2030

Growing Industry Segments Fuel Market Expansion

The polyethylene industry is categorized primarily into HDPE, LDPE, and LLDPE—each with distinct characteristics and industry use cases. HDPE, known for its high tensile strength and rigidity, is extensively used in construction and automotive applications. LDPE and LLDPE, with their flexibility and toughness, dominate the packaging and consumer goods segments. The polyethylene market report shows an increase in demand from emerging economies, particularly in Asia-Pacific, where rapid industrialization and urbanization drive consumption.

Packaging Industry Dominates Demand

According to recent polyethylene market analysis, the packaging industry continues to be the largest consumer of polyethylene, driven by the growth of e-commerce, FMCG sectors, and increasing demand for food-safe materials. Flexible and rigid packaging solutions are seeing innovation, contributing to rising polyethylene market share. The polyethylene market forecast suggests packaging applications will continue to dominate through 2030, especially for HDPE and LLDPE variants.

Sustainability Trends and Market Drivers

One of the most notable polyethylene market trends is the rising demand for sustainable and recyclable materials. As regulatory pressures mount and consumer preferences shift toward eco-friendly solutions, manufacturers are investing in circular economy strategies and chemical recycling techniques. This sustainability shift is both a polyethylene market opportunity and a challenge, requiring innovation and capital investments.

Key polyethylene market drivers include growing urban infrastructure, increased automotive production, and the proliferation of electronic devices requiring durable and insulating materials. However, polyethylene market restraints such as fluctuating crude oil prices, environmental concerns, and stringent regulations in some regions may impact production and profitability.

Outlook and Strategic Insights

The global polyethylene market is expected to grow steadily from 2025 to 2030, backed by technological advancements and robust demand from diverse sectors. A comprehensive polyethylene market study reveals strong potential in the Asia-Pacific and Middle East regions, while North America and Europe continue to focus on recycling technologies and high-performance polymers.

In conclusion, strategic investments in research, recycling infrastructure, and regional expansions are critical for tapping into the evolving polyethylene market size and capturing long-term growth. Stakeholders across the value chain must remain agile to navigate the fast-changing landscape of the polyethylene industry.

For more detailed polyethylene market insights, keep an eye on industry reports and forecasts that highlight granular polyethylene market statistics and segmentation opportunities.

0 notes

Text

MDO FILMS Market| Where Film Deals, Art, and Innovation Meet

United States of America – The Insight Partners is pleased to introduce its newest research report, "MDO FILMS Market: An In-depth Analysis of Market Trends, Growth Drivers, and Future Opportunities". This all-encompassing market research report provides an in-depth analysis of the market with regard to present trends and future projections so that stakeholders are able to comprehend where the market is moving.

Overview

The MDO FILMS market has witnessed a number of developments over the past few years. From fluctuating growth rates to changing market forces, this report highlights the driving forces behind these changes most significantly, technological innovations, changing regulatory landscapes, and changing consumer preferences. These drivers have not only transformed the existing landscape but have also created new opportunities for market participants.

Key Findings and Insights

Market Size and Growth

Historical Data & Forecast: The MDO Films Market is anticipated to grow at a CAGR of 5% from forecast period.

Key Growth Drivers:

Growing demand for sustainable and recyclable packagings

Growing use in food & beverages, personal care, and medical packaging

E-commerce and retail industries growth, fueling flexible packaging demand

Technology advancement enhancing performance and productivity of films

Get Sample Report: https://www.theinsightpartners.com/sample/TIPRE00020339

Market Segmentation

By Material

Polypropylene

HDPE

LLDPE

Polyamide

EVOH

PET

By Film Type

Cast Film

Blown Film

By Application

Pouches and Sachets

Bags

Films

Labels

Identification of Emerging Trends

Technological Developments

Advancements in film orientation technology enhancing strength and barrier properties

Use of biodegradable materials for environmentally friendly packaging

Application of AI and IoT in the manufacturing of films to increase process control and limit waste

Evolution of Consumer Preferences

Increasing consumer preference towards green and lightweight packaging

Increasing demand for hassle-free, single-use food and healthcare packaging formats

Transition to appearance-based and clear packaging to exhibit improved visibility of the product

Regulatory Developments

Implementation of plastic waste management regulations across many countries

Increased compliance needs around food-grade safety and recyclability

Implementation of Extended Producer Responsibility (EPR) regulations affecting packaging decisions

Growth Opportunities

Sustainability Initiatives: With sustainability emerging as a major corporate objective, firms are undertaking investments in recyclable.

Emerging Markets: Expansion in emerging markets, particularly in Asia-Pacific and Latin America, is fueling demand for flexible packaging.

Customization Trends: Need for customized film thickness, coating, and printing opens up opportunities for innovation.

Strategic Partnerships: Strategic alliances and joint ventures among film producers and FMCG players are assisting in co-creating next-generation packaging solutions.

Conclusion

The MDO FILMS Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Period report offers valuable information for companies seeking to create or grow their business in this changing market. With a comprehensive analysis of market dynamics, competition, and new opportunities, this report supports evidence-based decision-making and strategic planning to achieve long-term success.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

HDPE Prices in India

The domestic petrochemical market in Ahmedabad witnessed a notable price adjustment today, with HDPE (High-Density Polyethylene), grade F5400, recording a decline in rates. As per market data tracked by Indianpetrochem, HDPE prices dropped by Re.1/Kg on July 11, 2025, sliding from Rs.97/Kg to Rs.96/Kg. This subtle yet significant movement reflects evolving market dynamics that deserve closer scrutiny. This price revision is not just a number on the charts—it is a signal of broader undercurrents in the petrochemical ecosystem. Industry analysts at Indianpetrochem observe that the fall in HDPE prices could be attributed to a variety of domestic and international influences, ranging from production consistency to changing demand cycles. Domestic Market Insights: Stable Production, Softer Demand: India’s top petrochemical producers—Reliance Industries Ltd., Indian Oil Corporation, and Haldia Petrochemicals—have maintained consistent production levels. Supply remains sufficient to meet the current market requirements. Yet, the dip in HDPE price points towards inventory pressures. According to Indianpetrochem market observers, the current pricing may reflect an attempt by suppliers to clear excess stock amidst a slightly sluggish demand from downstream sectors. Even though production is stable, downstream industries seem to be purchasing more conservatively, especially in the packaging and construction segments. The automotive industry, another key HDPE consumer, has also witnessed a temporary dip in raw material intake, possibly due to fluctuating production schedules and seasonal shifts. HDPE remains a cornerstone material in the Indian petrochemical landscape. From plastic containers, piping, geomembranes to construction applications, its durability, rigidity, and resistance to chemicals make it indispensable across multiple industries, HDPE Prices in India, Indian HDPE Prices, Indian Prices HDPE, IndianPetrochem.

0 notes

Text

1 note

·

View note

Text

Secure and Stylish Shipping with Poly Bags

Quapri provides high-quality Custom Courier Poly Bags that deliver secure, functional, and stylish solutions to your shipping requirements. It is perfect for e-commerce, retail, and logistics business purposes, ensuring durability and functionality while also creating opportunities for branding on packaging.

Durable and Functional Custom Courier Poly Bags

We make our courier poly bags from tough HDPE material to ensure durability and tamper-proof security during transit. These bags protect your products from exterior damage while providing a professional appearance. You can safely add shipping information or invoices in the accompanying transparent pocket.

Branding Personalization with Custom Plastic Carry Bags

Elevate your brand identity by creating custom plastic bags with single-color screen printing up to eight vibrant colors. Add your logo, business name, or design to create packaging that acts as a marketing tool and leads your brand to shine through on every shipment.

#customcourierpolybags#courierbagsprinting#brandedpolybags#printedcourierbags#ecommercepolybags#tamperproofpolybags#personalizedcourierbags#customshippingbags#logocourierbags#mailerpolybags#businesscourierbags#polybagswithlogo#bulkcourierbags#custompackagingbags#deliverypolybags#packagingcourierbags#plasticmailerbags#polybagprinting#retailcourierbags#securecourierbags#waterproofpolybags#expresscourierbags#custommailbags#quapripolybags#sustainablepolybags

0 notes

Text

How Regent Plast Partners with Customers for Custom Moulding & Packaging

At Regent Plast, we believe that true innovation stems not just from manufacturing excellence but from collaborative partnerships built on trust, shared vision, and mutual creativity. We don’t simply deliver bottles, jars, or packaging components — we co-create solutions that align with your brand’s identity and market goals.

We’re not just a plastic packaging manufacturer. We’re your strategic partner in custom moulding and packaging development, committed to delivering products that meet technical specifications while embodying your brand’s essence.

Collaboration at the Core of Custom Moulding

The process of custom plastic moulding is much more than crafting a unique bottle shape or lid. It’s an ongoing dialogue between our team and yours — a blend of expertise and imagination.

Here’s how we ensure every custom moulding project becomes a shared success:

1. Understanding the ‘Why’ Behind Your Product

We begin by listening. Our first goal is to understand your objectives:

What are your target markets?

What values does your brand stand for?

What experience should your packaging deliver to the end user?

This early discovery phase allows us to align with your core brand values — be it sustainability, luxury, simplicity, or functionality.

We don’t just ask what you want; we ask why you want it. That’s how we transform functional packaging into a powerful branding tool.

2. Design Thinking Meets Engineering Precision

Once your goals are understood, our in-house R&D and design team steps in. Combining design thinking with industry experience, we prototype innovative, cost-effective, and market-ready packaging solutions.

Whether you need a custom HDPE shampoo bottle, a dual-tone lotion pump, or an ergonomic jerry can, we integrate:

Aesthetic appeal

Brand consistency

Technical feasibility

Consumer usability

Our design process is iterative and collaborative. With 3D renders, sample moulds, and rapid prototyping, we keep you involved at each step, ensuring the final design is a true reflection of your vision.

3. Custom Tooling with Precision

Once a design is approved, we move into tooling. At Regent Plast, we invest in high-precision mould development using advanced CNC and EDM technologies. Every tool is built to meet:

Dimensional accuracy

Durability for mass production

Efficient cycle times

Seamless integration with your production needs

By managing mould creation in-house, we ensure cost control, quality assurance, and faster turnaround times, without compromising on design complexity or product integrity.

4. Flexible Production Capabilities

Our custom moulding partnerships benefit from flexible manufacturing lines and state-of-the-art equipment, including:

Injection moulding machines

Blow moulding machines

Decoration such as Silk Screen Printing, Pad Printing, Labelling

Assembly such as Blister Sealing

This enables us to produce a wide range of packaging formats — bottles, jars, caps, closures, dispensers, and more — in various volumes and materials like HDPE, PP, and PET.

Whether it’s a small-batch custom launch or large-volume export orders, we scale to match your supply chain demands while ensuring consistent quality control.

5. Brand Enhancement Through Packaging

At Regent Plast, we know packaging is more than containment. It’s about enhancing your brand story. Through our custom moulding service, we help you:

Stand out on shelves

Create memorable unboxing experiences

Communicate value through design

Build consumer trust through quality packaging

We assist in color matching, surface texturing, embossing, debossing, and custom labeling — ensuring every product that leaves our facility reflects the premium image you want your consumers to experience.

6. Sustainable Packaging Solutions

Sustainability isn’t a trend. It’s a responsibility we share with our clients.

We offer options for:

Recycled HDPE packaging

Lightweighting to reduce plastic usage

Refillable bottle designs

Biodegradable material integration (on request)

Our sustainability experts work with you to align packaging with your eco-conscious values — without sacrificing functionality or aesthetics.

7. End-to-End Project Management

Every custom packaging project at Regent Plast is handled by a dedicated team of project managers, engineers, and quality specialists. We ensure:

Clear timelines

Transparent communication

Regular progress updates

Rapid response to design tweaks or supply needs

This streamlined approach removes bottlenecks, reduces time-to-market, and ensures you stay competitive in dynamic industries like personal care, agrochemicals, pharma, and nutraceuticals.

READ MORE- https://regentplast.com/how-regent-plast-partners-with-customers-for-custom-moulding-packaging/

#packaging#manufacturing#sustainability#hdpebottles#environment#recycling#plastic#eco friendly#lifestyle

0 notes

Text

Rotomolding Market Size, Share, Key Growth Drivers, Trends, Challenges and Competitive Landscape

"Executive Summary Rotomolding Market :

CAGR Value : Global rotomolding market size was valued at USD 1.90 billion in 2024 and is projected to reach USD 3.03 billion by 2032, growing with a CAGR of 6.1% during the forecast period of 2025 to 2032.

Rotomolding Market report has been designed by keeping in mind the customer requirements which assist them in increasing their return on investment (ROI). The report also endows with the information, statistics, facts and figures which are very helpful for the companies to maximize or minimize the production of goods depending on the states of demand. This market research report is formulated with the most excellent and superior tools of collecting, recording, estimating and analysing market data of industry. The insights provided in this market research report are based upon SWOT analysis on which businesses can rely confidently. The Rotomolding Market business report describes CAGR (compound annual growth rate) values and its fluctuations for the specific forecast period.

This Rotomolding Market report underlines the consumption of market, key players involved, sales, price, revenue and market share with volume and value for each region. Significant industry trends, estimations of market size and market share are analysed and discussed in this report. It presents top to bottom examination of the market for estimating income, return on investment (ROI) and developing business strategies. Furthermore, competitive analysis gives a clear idea about the strategies used by the major competitors in the market that perks up their penetration in the market. The data collected to structure this Rotomolding Market report is based on the data collection modules with large sample sizes.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Rotomolding Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-rotomolding-market

Rotomolding Market Overview

**Segments**

- By Type: Based on type, the rotomolding market is segmented into linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), polyvinyl chloride (PVC), cross-linked polyethylene (PEX), nylon, polycarbonate, and others. The LLDPE segment is expected to witness significant growth due to its superior properties such as high tensile strength and resistance to chemicals. - By Application: In terms of application, the market is categorized into construction, automotive, packaging, agriculture, furniture, and others. The automotive segment is likely to dominate the market owing to the increasing demand for lightweight and durable automotive components. - By End-Use Industry: Based on end-use industry, the rotomolding market is segmented into automotive, construction, agriculture, chemical, food and beverage, and others. The construction sector is anticipated to exhibit substantial growth due to the rising construction activities worldwide.

**Market Players**

- The major players operating in the global rotomolding market include Exxon Mobil Corporation, LyondellBasell Industries Holdings B.V., Chevron Corporation, Dow, SABIC, INEOS, and Green Age. These companies are focusing on strategic initiatives such as mergers and acquisitions, partnerships, and product launches to enhance their market presence and expand their product offerings. - Some other key players in the market are Rotoplas S.A. de C.V., Elkhart Plastics, Inc., Selroth Plastics, Inc., The Plastic Forming Company, Inc., Rotational Molding, Inc., and Granger Plastics Company. These players are investing in research and development activities to introduce innovative products and gain a competitive edge in the market.

The global rotomolding market is poised for significant growth in the coming years, driven by various factors such as the increasing demand for durable and lightweight products across industries like automotive, construction, packaging, and agriculture. One of the key trends shaping the market is the adoption of advanced materials like linear low-density polyethylene (LLDPE) and high-density polyethylene (HDPE) due to their superior properties such as high tensile strength and chemical resistance. The construction sector, in particular, is expected to witness substantial growth, supported by the ongoing construction activities worldwide and the need for high-quality construction materials.

Market players in the rotomolding industry are constantly striving to strengthen their market position through strategic initiatives like mergers, acquisitions, partnerships, and product launches. Companies such as Exxon Mobil Corporation, LyondellBasell Industries Holdings B.V., and SABIC are investing in expanding their product offerings and enhancing their global presence. These industry giants are leveraging their technological expertise and innovation capabilities to cater to the evolving demands of end-use industries and gain a competitive edge in the market.

Furthermore, smaller players like Rotoplas S.A. de C.V., Elkhart Plastics, Inc., and Granger Plastics Company are also making significant investments in research and development activities to introduce innovative products and differentiate themselves in the market. These companies are focusing on product customization, quality enhancement, and cost-effective solutions to meet the diverse needs of customers across different industries. By aligning their strategies with market trends and consumer preferences, these key players are well-positioned to capitalize on the opportunities in the growing rotomolding market.

Overall, the global rotomolding market is witnessing steady growth, driven by key factors such as material advancements, increasing demand from end-use industries, and strategic efforts by market players to innovate and expand their market presence. With a strong focus on sustainability, product quality, and customer satisfaction, companies in the rotomolding industry are poised to unlock new avenues for growth and success in the foreseeable future.The global rotomolding market is experiencing robust growth driven by a confluence of factors that are shaping the industry landscape. The adoption of advanced materials such as LLDPE and HDPE is a key trend that is revolutionizing the market dynamics. These materials offer superior properties like high tensile strength and chemical resistance, making them ideal for various applications across industries. The construction sector, in particular, is poised for significant growth propelled by the increasing construction activities worldwide and the escalating demand for high-quality construction materials.

Market players in the rotomolding industry are actively engaging in strategic initiatives to enhance their market position and expand their product portfolios. Major players like Exxon Mobil Corporation, LyondellBasell Industries Holdings B.V., and SABIC are focusing on mergers, acquisitions, partnerships, and product launches to strengthen their global presence and cater to the evolving needs of end-use industries. By leveraging their technological expertise and innovation capabilities, these industry giants are staying ahead of the competition and tapping into new growth opportunities.

Additionally, smaller players in the market such as Rotoplas S.A. de C.V., Elkhart Plastics, Inc., and Granger Plastics Company are investing in research and development to introduce innovative products and differentiate themselves in the market. These companies are prioritizing product customization, quality enhancement, and cost-effective solutions to meet the diverse requirements of customers across different sectors. By aligning their strategies with market trends and consumer preferences, these key players are positioning themselves for success in the dynamic rotomolding market landscape.

Overall, the global rotomolding market is set for steady growth driven by material advancements, increasing demand from end-use industries, and strategic efforts by market players to innovate and expand their market reach. With a strong emphasis on sustainability, product quality, and customer satisfaction, companies in the rotomolding industry are well-positioned to unlock new growth avenues and excel in the competitive market environment. The continuous evolution of the industry driven by innovation and strategic collaborations will further propel the growth of the global rotomolding market in the coming years.

The Rotomolding Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-rotomolding-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key Benefits of the Report:

This study presents the analytical depiction of the global Rotomolding Marketindustry along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global Rotomolding Market share.

The current market is quantitatively analyzed from to highlight the Global Rotomolding Market growth scenario.

Porter's five forces analysis illustrates the potency of buyers & suppliers in the market.

The report provides a detailed global Rotomolding Market analysis based on competitive intensity and how the competition will take shape in coming years

Browse More Reports:

Global Mastitis Market Global Glucocorticoid Agonist Market Global Ultra-High Barrier Shrink Films Market North America Sustainable Aviation Fuel Market North America Lung Cancer Diagnostics Market Global Cannabidiol (CBD) Infused Edible Market Global Garage and Service Station Market Global Physiotherapy Examination Tables Market Global Composite Bearings Market Europe Ostomy Devices Market U.S. Diet and Nutrition Apps Market Asia- Pacific Plant Based Protein Market Global Atomic Force Microscope (AFM) Market Global Sailing Jackets Market U.S. Electric Enclosure Market Global Long Fiber Thermoplastics Market Global Cocoa Processing Equipment Market Global Medical Tuning Fork Market Global Modified Bitumen Market Global Medical Device Cleaning Market Global Biodetectors and Accessories Market Global Heavy Metals Testing Market Global Glucaric Acid Market Global Ruminant Feed Antibiotics Market Global Aircraft Thrust Reverser Market Asia-Pacific Frozen Ready Meals Market Middle East and Africa Laminated Busbar Market Global Train Signalling System Market Global Heat Stabilizers Market Asia-Pacific Surgical Power Tools Market North America Frozen Ready Meals Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

"

0 notes

Text

Sealing the Future Innovative Plastic Cap Manufacturer Delhi

In today’s fast-paced packaging industry, reliable sealing solutions are crucial and Delhi’s innovative plastic cap manufacturer delhi is leading the way. Known for combining cutting-edge technology with precision engineering, this manufacturer delivers high-quality plastic caps that meet the diverse needs of industries such as food & beverage, pharmaceuticals, cosmetics, and household goods. With a strong focus on durability, functionality, and customization, they offer caps that not only protect the product but also enhance its visual appeal. Their commitment to innovation, sustainability, and customer satisfaction makes them a trusted partner for businesses looking to seal their products with confidence and quality.

Precision Engineering for Leak-Proof Protection

Delhi’s leading plastic cap manufacturer delhi specializes in creating leak-proof caps designed with exacting precision. Each cap is crafted using advanced molding techniques that ensure a perfect fit, preventing spills, contamination, and product degradation. From liquid beverages to pharmaceutical solutions, these caps maintain airtight seals under various storage and transportation conditions. The company adheres to strict quality control standards, inspecting every batch to guarantee performance and reliability. Whether for PET bottles, jars, or specialty containers, their precision-engineered caps provide consistent sealing that businesses can trust ensuring both safety and customer satisfaction in every use.

Wide Range of Cap Designs for Multiple Industries

Offering versatility across sectors, this Delhi-based manufacturer produces plastic caps tailored to the needs of industries like food & beverage, pharmaceuticals, cosmetics, personal care, and more. Their extensive catalog includes flip-top caps, screw caps, snap-on closures, dispensing caps, and child-resistant designs. Each product is available in a variety of sizes, shapes, and colors to meet specific brand and functional requirements. The team also collaborates with clients for customized solutions that reflect branding goals while enhancing usability. This wide selection ensures that every product—no matter its contents is securely sealed and presented with professional, functional packaging.

High-Quality, Food-Grade Materials for Safety and Durability

Material matters, especially in industries where hygiene and safety are paramount. This plastic cap manufacturer uses only premium, food-grade polymers like PP, HDPE, and LDPE to ensure caps are durable, non-toxic, and compliant with global safety standards. These materials are resistant to chemicals, temperature fluctuations, and wear, making them ideal for long-term use. Each cap is tested for structural integrity, flexibility, and seal strength before leaving the factory. For products like edible oils, syrups, cosmetics, and medicines, customers can count on caps that uphold product quality while reflecting a commitment to safety and reliability.

Customization to Match Your Brand Identity

In today’s competitive market, packaging is a crucial brand touchpoint. Delhi’s top plastic cap manufacturer offers full customization options from cap shape and size to color, embossing, and printed logos allowing brands to stand out on shelves. Whether you want a sleek, minimalist look or vibrant, brand-specific colors, the design team works closely with clients to bring their vision to life. Customization not only enhances visual appeal but also improves user experience with ergonomic or easy-pour features. This focus on tailored design ensures every cap is both practical and an extension of the brand it represents.

Sustainable Practices for an Eco-Friendly Future