#Labor Cost Estimation

Explore tagged Tumblr posts

Text

How Commercial Estimators Accurately Determine Project Costs

Accurately determining project costs is one of the most crucial responsibilities of a commercial estimator. In construction, the success of a project—whether it’s a large office building, a shopping mall, or an industrial facility—depends heavily on how well the costs are predicted before work begins. An estimator must account for a wide range of variables, including materials, labor, equipment, permits, and unforeseen challenges. This complex task requires a combination of technical knowledge, experience, and the right tools to ensure accuracy. In this blog, we’ll explore how commercial estimators accurately determine project costs and the key factors they consider during the estimating process.

1. Understanding the Scope of the Project

Before any costs can be estimated, a commercial estimator must first have a thorough understanding of the project scope. This means reviewing detailed architectural plans, drawings, and specifications that define the scope of work. It’s essential for the estimator to identify and comprehend every element of the project, including building dimensions, materials, design features, and site-specific requirements.

Estimators often meet with project owners, architects, and contractors to clarify any ambiguities in the plans. Misunderstanding or overlooking certain aspects of the project can lead to underestimation, which can be detrimental to a project’s budget. Therefore, it is critical for estimators to engage in careful discussions with all stakeholders to ensure they have all necessary information.

2. Performing a Detailed Takeoff

A critical part of determining project costs involves the takeoff process. Takeoff refers to the act of measuring quantities from the project plans, which could include the number of square feet, linear feet, or cubic yards of materials required. A takeoff essentially helps estimators calculate the quantity of each material needed for the project.

For instance, if a building requires concrete for its foundation, the estimator will determine how many cubic yards of concrete are needed based on the foundation’s dimensions. This process extends to every aspect of the construction, from the amount of steel for framing to the number of windows to be installed. Accurate takeoff is vital because it serves as the basis for all further cost estimations.

3. Material Cost Estimation

Once quantities have been determined through the takeoff, the next step is estimating the cost of materials. This is often one of the most challenging parts of commercial estimating due to the fluctuating prices of materials. Factors such as location, time of year, and market conditions can impact material costs.

Commercial estimators need to stay up to date with material prices and ensure they use accurate pricing data for every component of the project. They may consult industry databases, supplier quotes, or historical data to determine the current price of materials like steel, concrete, drywall, and roofing materials. Additionally, the estimator must consider delivery costs, potential material wastage, and storage requirements.

4. Labor Cost Estimation

Labor costs are another major factor in determining the total cost of a construction project. Estimators must calculate the amount of labor needed for each phase of the project, taking into account factors such as crew size, hourly rates, and the expected time required to complete tasks.

Labor rates can vary depending on the type of work being done, the region, and union regulations, so estimators need to ensure they account for all these variables. Additionally, they must consider factors such as overtime, the skill level of workers, and productivity rates, as they can influence overall labor costs.

Estimators may consult labor union agreements, wage surveys, or historical project data to accurately estimate the labor costs for specific tasks. Proper labor cost estimation also involves factoring in potential labor shortages or delays, which can increase costs.

5. Equipment and Tool Costs

Construction projects also require a variety of tools and equipment, ranging from cranes and bulldozers to hand tools and scaffolding. Estimators need to calculate the cost of renting or purchasing this equipment, including transportation and maintenance costs.

In some cases, estimators may need to account for equipment downtime or the wear and tear of machinery. For larger projects, specialized equipment may be needed, and estimating these costs can become more complex.

If a project requires equipment that is not readily available, the estimator may need to include additional costs for mobilization and demobilization. These costs can have a significant impact on the overall budget, especially for long-term projects.

6. Contingencies for Unforeseen Costs

No project is free from unexpected challenges or changes. A key aspect of accurate commercial estimating is accounting for these uncertainties with contingency plans. Estimators typically include a contingency percentage—often ranging from 5% to 15%—to account for unforeseen circumstances that could arise during construction.

These contingencies can cover a wide range of issues, from delays caused by weather to price fluctuations in materials or labor. Estimators must ensure that they don’t underestimate these risks, as failing to include sufficient contingencies could lead to project cost overruns.

7. Using Estimating Software and Tools

Modern commercial estimating relies heavily on specialized estimating software and tools to enhance accuracy and efficiency. Estimating software like ProEst, Buildertrend, or Procore allows estimators to input quantities, prices, and project data, and generate detailed cost breakdowns.

These tools streamline the process by automating calculations, helping to avoid human error. They can also access databases with up-to-date material costs, labor rates, and other relevant data, ensuring that the estimator has accurate pricing information. Many of these platforms also integrate with project management software, allowing for real-time updates and collaboration among all project stakeholders.

8. Accounting for Overhead and Profit Margins

Another important aspect of commercial estimating is ensuring that overhead costs and profit margins are incorporated into the estimate. Overhead costs can include things like administrative expenses, insurance, office supplies, and project management costs. These costs must be factored into the overall project estimate to ensure that the construction company remains profitable.

Similarly, estimators must add a reasonable profit margin to the estimate. This margin varies based on the type of project, the level of competition, and market conditions. Adding an appropriate profit margin ensures that the contractor can meet their financial goals while still providing a competitive bid.

9. Bid Preparation and Review

Once all costs are estimated, the final step is preparing the bid. A commercial estimator will create a detailed, organized proposal that includes a breakdown of all costs, including labor, materials, equipment, overhead, and contingencies. This bid is presented to the client for review and negotiation.

During this phase, the estimator may also need to review the bid with other team members or stakeholders to ensure that it aligns with the project’s budget and scope. Adjustments may be made if necessary, particularly if changes arise during the negotiation phase.

Conclusion

Accurately determining project costs is a complex process that requires attention to detail, industry knowledge, and the right tools. Commercial estimators must consider numerous factors, from material and labor costs to contingencies for unforeseen events. By performing a detailed takeoff, staying up to date with pricing data, and utilizing advanced estimating software, estimators can provide accurate, reliable estimates that help ensure the success of construction projects. This precise and thorough approach ultimately helps clients and contractors manage costs, avoid overruns, and complete projects on time and within budget.

#commercial estimating#commercial estimation#residential estimating#industrial estimating#cost estimation#Commercial Construction Estimator#Cost Analysis#Project Estimation#Cost Control in Construction#Unit Cost Estimation#Construction Estimating Techniques#Bid Estimating#Material Cost Estimation#Labor Cost Estimation

1 note

·

View note

Text

the best thing for an artist who works mainly in local theatre to hear

'I'm in a position to pay you what your labor is worth'

#shoutout to my friend who commissioned me for this mask project#he asked abt labor costs and i was like 'oh dude i know budgeting for theatre is usually tight. it's super negotiable lmk what you can do'#and that was his response#i still went a little sparing on the estimate (it works out to 25 an hour which is maybe a little low for high-skill maskmaking)#and i'm willing to go lower if he needs to but still. waiting to hear back from him but i'm very encouraged

8 notes

·

View notes

Text

Step-by-Step Guide: How to Estimate Construction Costs for a New Home

Accurately estimating construction costs is essential when planning to build your dream home. Understanding and calculating these expenses helps in making informed financial decisions and avoiding unexpected surprises. Here’s a detailed, step-by-step guide on how to perform a thorough construction cost estimate for your new home.

If You Need more Information about cost Estimations, visit this Website -> https://uniqueestimations.com/new-york-construction-estimating-services/

1. Understand the Types of Construction Cost Estimates

There are different methods for estimating costs depending on the stage of your construction project:

Preliminary Estimate: An early-stage estimate based on basic information.

Detailed Estimate: Involves itemized costs for materials, labor, permits, and more.

Bid Estimate: Prepared by contractors and includes detailed pricing for project execution.

Selecting the right construction cost estimator for your project depends on your project’s complexity and accuracy needs.

2. Define the Scope of Your Project

To start estimating, it’s important to clearly outline:

Square Footage: Determine the size of the home.

Design Complexity: Architectural style and special features add complexity and cost.

Quality of Materials: Decide between budget, standard, or high-end finishes.

Having a well-defined project scope ensures that your cost estimation in construction is accurate and reliable.

3. Calculate Material Costs

Material costs often constitute a significant portion of new construction estimating costs. Factors to consider include:

Foundation Materials: Concrete, steel reinforcements, and formwork.

Structural Components: Wood, steel, or concrete framing.

Exterior Finishes: Siding, roofing materials, and insulation.

Interior Finishes: Flooring, drywall, cabinetry, and paint.

Consulting local suppliers and utilizing a construction cost estimator can help you get current pricing.

4. Account for Labor Costs

Labor expenses can vary widely based on your location, the size of your project, and the expertise required. Common roles involved include:

General Contractors: Manage the entire construction project.

Specialized Contractors: Focus on plumbing, electrical work, and HVAC installation.

Skilled Laborers: Carpenters, masons, and roofers.

Make sure to factor in wages, benefits, and potential overtime when estimating construction costs for labor.

5. Include Permits and Legal Fees

Local regulations often require permits for various aspects of home construction, including:

Building permits

Plumbing and electrical permits

Environmental impact assessments

Research the requirements in your area and budget accordingly to avoid delays or fines.

6. Don’t Forget About Utility and Site Preparation Costs

These expenses cover tasks that prepare the land for construction and ensure the home is connected to essential services:

Site Clearing and Excavation: Removing vegetation and leveling the site.

Utility Hookups: Connecting water, sewer, gas, and electricity to the property.

Driveway and Landscaping: Installing access roads and outdoor spaces.

Including these in your construction estimating costs ensures you capture the full scope of expenses.

7. Estimate Plumbing and Electrical Costs

Specialty work like plumbing and electrical installations requires detailed estimates. Utilize a new construction plumbing cost estimator to calculate the expenses for:

Plumbing: Pipes, fittings, and fixtures for kitchens, bathrooms, and outdoor areas.

Electrical Systems: Wiring, outlets, switches, and lighting installations.

These components are critical to home functionality and should be accurately budgeted.

8. Factor in Contingency Costs

Unexpected expenses often arise during construction. To mitigate financial strain, allocate:

5% to 15% of Total Budget: For unanticipated changes or issues.

Price Fluctuations: For materials and labor due to market conditions.

Including a contingency buffer is essential for realistic cost estimation in construction.

9. Use Construction Cost Estimating Tools

Modern technology makes it easier to get accurate estimates with tools such as:

Online Construction Estimators: Provide quick preliminary cost insights.

Software Programs: Offer detailed and customizable reports.

Professional Services: Hiring a professional estimator can add precision and expertise.

Selecting the right tool depends on your project’s complexity and your need for accuracy.

10. Review and Adjust Your Estimate Regularly

As your project progresses, costs may change. Continuously updating your estimate ensures that your budget remains accurate and relevant. Factors to reassess include:

Changes in material prices

Design adjustments

Project delays

Regular reviews help maintain control over your estimating construction costs and prevent budget overruns.

Final Thoughts

Accurately estimating construction costs for a new home requires careful planning, detailed calculations, and regular monitoring. By following these steps, you can confidently manage your budget and make informed decisions throughout the construction process.

If you want to read more information about construction cost Estimation Website just visit --> https://uniqueestimations.com/new-york-construction-estimating-services/

#Unique Estimations#Cost Estimation#construction cost#new home cost#resturants cost#construction labor cost estimator#cost estimation for road construction

2 notes

·

View notes

Text

I got another quote for my bathroom renovation: $27.5k, by a contractor who, get this...... DID MY KITCHEN. HE RENOVATED MY WHOLE KITCHEN 12 YEARS BEFORE IT WAS MY KITCHEN. this fella walked into my place like "...... how long have you been here? I did that kitchen for the previous owner." BRUH

anyway, he's a guy that's already approved by the building, seems to know everyone and all the ways that my building needs things to be done, and says he's the guy that knows all the guys to sell us supplies for cheaper than typical contractor prices. so I'm feeling pretty good about possibly letting this guy be the guy to redo my bathroom. my kitchen is a bangin' kitchen, everything works and looks/feels delightful and solid. his portfolio shows that he knows what he's doing.

but they say to always get 3+ estimates. so the first guy quoted us between $50-70k USD, the second guy says $27.5k, we'll see what a 3rd and 4th guy says.

#one caveat to this second guys quote is that i don't think it includes the supplies/things needed#that's just the estimate for the LABOR. the demo and installing and fixing and cleaning etc#whereas the first guy's quote was an “all in one” deal including the design/supplies#so. yknow. i'm kind of preparing for his quote to be on the ''low end'' rather than the total amount this is gonna costs us

1 note

·

View note

Text

How to Get an Accurate Furnace Repair Estimate

Understanding Heating System Repair: Key Considerations for Homeowners Heating system repair is an essential aspect of maintaining a comfortable and energy-efficient home. Whether you have a furnace, heat pump, or another type of heating system, regular maintenance and timely repairs are crucial to ensure optimal performance. Understanding the common issues that can arise and the steps involved…

#blower motor issues#cost-effective furnace maintenance#energy-efficient heating#furnace breakdown prevention#furnace cleaning and tuning#furnace inspection cost#furnace lifespan#Furnace maintenance#furnace maintenance cost#furnace repair cost#furnace repair estimate#furnace repair warranty#furnace replacement factors#furnace safety#heat pump repair#heating system issues#heating system repair#Home furnace repair#home-improvement#home-maintenance#hvac#HVAC contractor#HVAC maintenance plans#HVAC repair#ignition system repair#labor cost for furnace repair#maintenance#programmable thermostat for furnace#real-estate#thermostat problems

0 notes

Text

I work at a customer service center. The leadership is a mix between 1 (outwardly) nice (seemingly) reasonable supervisor and then robots focused on productivity over people (which ig is pretty standard).

Right now they’re having an issue of basically we get fucked on call or chat becoming full of people holding whenever we have lunch times. In order to combat this they’re trying to stagger people’s lunches so that we only have like 3 people out at lunch at a time. This basically isn’t working well cause I means some folks would need to go to lunch 2-and-a-half/3 hours after arriving at work and people aren’t so happy about that plan.

It’s just so annoying cause basically the whole leadership team has decided we’re done hiring people, but we keep having this issue where we need people and they aren’t there. Like babes, better than staggering lunches to a stupid degree would just be hiring more people. But then these guys lose their minds over how we wouldn’t have them being productive or not being maxed out on work because we’d have too many people. But like that’s just how it goes???? Like we’re also having problems with this method too??

#I know they just want to not have labor costs#and like it’s stupid to tell them their goals are contradictory cause they either#know and don’t care or don’t know and still don’t care#it’s just like Jesus fuck man#the company is multi-billion dollars according to estimates I can Google#I think we can afford hiring people. but god forbid the CEO gets paid less

0 notes

Text

Green energy is in its heyday.

Renewable energy sources now account for 22% of the nation’s electricity, and solar has skyrocketed eight times over in the last decade. This spring in California, wind, water, and solar power energy sources exceeded expectations, accounting for an average of 61.5 percent of the state's electricity demand across 52 days.

But green energy has a lithium problem. Lithium batteries control more than 90% of the global grid battery storage market.

That’s not just cell phones, laptops, electric toothbrushes, and tools. Scooters, e-bikes, hybrids, and electric vehicles all rely on rechargeable lithium batteries to get going.

Fortunately, this past week, Natron Energy launched its first-ever commercial-scale production of sodium-ion batteries in the U.S.

“Sodium-ion batteries offer a unique alternative to lithium-ion, with higher power, faster recharge, longer lifecycle and a completely safe and stable chemistry,” said Colin Wessells — Natron Founder and Co-CEO — at the kick-off event in Michigan.

The new sodium-ion batteries charge and discharge at rates 10 times faster than lithium-ion, with an estimated lifespan of 50,000 cycles.

Wessells said that using sodium as a primary mineral alternative eliminates industry-wide issues of worker negligence, geopolitical disruption, and the “questionable environmental impacts” inextricably linked to lithium mining.

“The electrification of our economy is dependent on the development and production of new, innovative energy storage solutions,” Wessells said.

Why are sodium batteries a better alternative to lithium?

The birth and death cycle of lithium is shadowed in environmental destruction. The process of extracting lithium pollutes the water, air, and soil, and when it’s eventually discarded, the flammable batteries are prone to bursting into flames and burning out in landfills.

There’s also a human cost. Lithium-ion materials like cobalt and nickel are not only harder to source and procure, but their supply chains are also overwhelmingly attributed to hazardous working conditions and child labor law violations.

Sodium, on the other hand, is estimated to be 1,000 times more abundant in the earth’s crust than lithium.

“Unlike lithium, sodium can be produced from an abundant material: salt,” engineer Casey Crownhart wrote in the MIT Technology Review. “Because the raw ingredients are cheap and widely available, there’s potential for sodium-ion batteries to be significantly less expensive than their lithium-ion counterparts if more companies start making more of them.”

What will these batteries be used for?

Right now, Natron has its focus set on AI models and data storage centers, which consume hefty amounts of energy. In 2023, the MIT Technology Review reported that one AI model can emit more than 626,00 pounds of carbon dioxide equivalent.

“We expect our battery solutions will be used to power the explosive growth in data centers used for Artificial Intelligence,” said Wendell Brooks, co-CEO of Natron.

“With the start of commercial-scale production here in Michigan, we are well-positioned to capitalize on the growing demand for efficient, safe, and reliable battery energy storage.”

The fast-charging energy alternative also has limitless potential on a consumer level, and Natron is eying telecommunications and EV fast-charging once it begins servicing AI data storage centers in June.

On a larger scale, sodium-ion batteries could radically change the manufacturing and production sectors — from housing energy to lower electricity costs in warehouses, to charging backup stations and powering electric vehicles, trucks, forklifts, and so on.

“I founded Natron because we saw climate change as the defining problem of our time,” Wessells said. “We believe batteries have a role to play.”

-via GoodGoodGood, May 3, 2024

--

Note: I wanted to make sure this was legit (scientifically and in general), and I'm happy to report that it really is! x, x, x, x

#batteries#lithium#lithium ion batteries#lithium battery#sodium#clean energy#energy storage#electrochemistry#lithium mining#pollution#human rights#displacement#forced labor#child labor#mining#good news#hope

3K notes

·

View notes

Text

Please help me with my upper jaw reconstruction

I lost so much of the bone in my upper jaw that I can't even wear dentures now without reconstructive surgery. (It's been nearly 1 1/2 years now with no upper teeth--including not being able to wear dentures.)

We go in next week to discuss the next stage of my upper jaw reconstruction (involving titanium plates, something called a sinus lift, and other fun stuff) now that the initial scans are complete, and even though my surgeon is donating his labor, he estimates the surgery and recovery are going to cost at least two or three thousand dollars (100K to 150K pesos) for materials, hospital fees, other surgical personnel, etc.--maybe more. Much cheaper than it would be in the US, but still quite a bit considering we're still deep in debt from El's birth certificate fiasco despite all the help y'all gave us with that. (And thank you so much for that!)

So hey, if you can help me get a complete upper jaw again (and teeth to go in it for the first time in well over a year) without us having to go even DEEPER in debt, that'd rock! Thank you!

545 notes

·

View notes

Text

How Industrial Estimating Service Helps Control Costs in Manufacturing Plants

Cost control is a critical aspect of managing manufacturing plants. Whether you're dealing with production processes, equipment purchases, or labor management, maintaining financial discipline is essential for profitability and long-term success. One of the most effective ways to keep costs under control is through the use of industrial estimating services. These services provide accurate cost projections, which allow manufacturers to plan more effectively, avoid unnecessary expenses, and optimize resource usage.

This article explores how industrial estimating services help control costs in manufacturing plants, from production planning to resource allocation and everything in between.

1. Accurate Cost Estimation for Resource Allocation

Effective cost control starts with accurate estimates. Industrial estimating services use historical data, advanced software, and market analysis to provide precise cost forecasts for materials, labor, and overhead costs. These estimates enable manufacturing plants to allocate resources more efficiently, ensuring that production runs smoothly without overspending.

How It Helps:

Material Cost Management: Accurate estimation of raw material costs helps prevent overordering or underordering, both of which can lead to waste or shortages.

Labor Cost Planning: Estimating labor requirements allows for efficient workforce planning, ensuring that the plant has the right number of workers for each phase of production.

Overhead Cost Allocation: Estimating overheads accurately helps identify areas where expenses can be reduced, such as energy consumption or facility maintenance.

2. Budgeting and Financial Planning

Industrial estimating services provide a clear financial roadmap for manufacturing plants, offering detailed breakdowns of anticipated costs. This helps plant managers set realistic budgets and track expenses as the project progresses. A solid financial plan reduces the risk of cost overruns, allowing for better control of cash flow and working capital.

How It Helps:

Clear Budgeting: A detailed cost estimate provides an initial framework for budgeting, helping plants avoid financial surprises.

Tracking and Monitoring: With continuous tracking of actual costs against estimated costs, manufacturers can make adjustments in real-time to keep spending on track.

Contingency Planning: By including contingencies in the initial estimate, industrial estimating services help prepare plants for unforeseen costs, reducing the likelihood of financial strain.

3. Risk Mitigation and Cost Avoidance

Industrial projects often face unexpected risks such as supply chain disruptions, labor shortages, or regulatory changes that can escalate costs. Industrial estimating services can help identify and assess these risks early in the project, allowing plants to plan for potential cost increases and take preventative measures.

How It Helps:

Identifying Risks: Estimators use data analysis to foresee potential challenges, such as material price hikes or delays in supply chains, and account for these in the cost projections.

Preventative Measures: Based on risk assessments, plant managers can implement strategies to mitigate risks, such as sourcing alternative materials or adjusting production timelines.

Scenario Analysis: Estimating services can run different scenarios to show how various risks might impact costs, enabling manufacturers to develop contingency plans.

4. Optimizing Operational Efficiency

By analyzing the cost of labor, materials, and overhead, industrial estimating services can help manufacturers identify inefficiencies in their operations. Estimating tools can pinpoint areas where production processes may be too costly, helping manufacturers find ways to streamline operations and reduce waste.

How It Helps:

Process Optimization: Identifying high-cost areas in production helps manufacturers implement process improvements, such as adopting lean manufacturing principles or automation.

Waste Reduction: By analyzing material usage, estimating services can help manufacturers reduce scrap and rework, ultimately lowering production costs.

Equipment Utilization: Accurate cost estimates can also help ensure that equipment is being used effectively, reducing downtime and maximizing the return on investment in machinery.

5. Supporting Strategic Decision-Making

Industrial estimating services provide critical insights that support long-term strategic decision-making. Whether deciding to expand production capacity, invest in new technology, or make other large-scale financial commitments, having a reliable cost estimate helps ensure that decisions are made based on sound financial projections.

How It Helps:

Capital Investment Planning: When considering capital expenditures, industrial estimating services provide cost forecasts that guide investment decisions, ensuring they align with the plant’s financial capabilities.

Expansion Decisions: Cost estimates for new facilities or product lines help determine the feasibility of expansion and whether it will lead to profitable returns.

Technology Upgrades: Estimating services assess the costs and benefits of adopting new technologies, allowing manufacturers to invest in innovations that will drive long-term savings.

6. Enhancing Supply Chain Management

Effective supply chain management is essential for controlling costs in manufacturing. Industrial estimating services help evaluate the total cost of procurement, transportation, and inventory management. By analyzing supply chain variables, manufacturers can make more informed decisions about sourcing materials and managing stock levels.

How It Helps:

Supplier Evaluation: Estimating services provide insights into the cost-effectiveness of different suppliers, enabling manufacturers to choose the most cost-efficient options.

Transportation Cost Analysis: By factoring in transportation and logistics costs, industrial estimating services help manufacturers optimize supply chain routes and minimize delivery expenses.

Inventory Optimization: Accurate material cost estimation allows manufacturers to manage their inventory more effectively, ensuring that they don’t overstock or run out of essential materials.

7. Improving Project and Product Lifecycle Management

Managing the entire lifecycle of a manufacturing project, from planning to production and maintenance, requires careful cost control. Industrial estimating services help track costs throughout each phase of the project, enabling plant managers to stay on top of expenses and make adjustments as needed.

How It Helps:

Lifecycle Cost Estimation: Estimating services provide a complete cost breakdown for each phase of the project, from design to commissioning, enabling better decision-making.

Maintenance Planning: For ongoing operations, industrial estimating services help plan for the cost of maintenance and repairs, reducing the risk of unexpected downtime.

Long-Term Profitability: By accurately forecasting costs over the long term, industrial estimating services help ensure that projects and products remain financially sustainable.

Conclusion

Industrial estimating services play a vital role in controlling costs within manufacturing plants. By providing accurate cost forecasts, identifying risks, optimizing resource allocation, and supporting decision-making, estimating services help manufacturers stay within budget and maximize efficiency. With the right estimating partner, manufacturers can reduce financial risks, improve operational performance, and enhance profitability, ensuring long-term success in a competitive industry.

#Industrial estimating service#cost control in manufacturing#manufacturing cost estimation#industrial project budgeting#resource allocation in manufacturing#accurate cost estimation#industrial cost forecasting#supply chain management in manufacturing#labor cost estimation#material cost forecasting#overhead cost management#manufacturing cost analysis#cost optimization in manufacturing#production cost estimation#financial planning for industrial projects#risk mitigation in manufacturing#operational efficiency in manufacturing#manufacturing plant budget planning#contingency planning in industrial projects#supply chain cost estimation#inventory management and cost control#lean manufacturing cost estimation#manufacturing process optimization#equipment cost estimation#industrial estimating software#predictive cost analysis#manufacturing project feasibility#material price forecasting#production planning and budgeting#cost management for manufacturing plants

0 notes

Text

Anon's explanation:

I’m curious because I see a lot of people claiming to be anti-AI, and in the same post advocating for the use of Glaze and Artshield, which use DiffusionBee and Stable Diffusion, respectively. Glaze creates a noise filter using DiffusionBee; Artshield runs your image through Stable Diffusion and edits it so that it reads as AI-generated. You don’t have to take my work for it. Search for DiffusionBee and Glaze yourself if you have doubts. I’m also curious about machine translation, since Google Translate is trained on the same kinds of data as ChatGPT (social media, etc) and translation work is also skilled creative labor, but people seem to have no qualms about using it. The same goes for text to speech—a lot of the voices people use for it were trained on professional audiobook narration, and voice acting/narration is also skilled creative labor. Basically, I’m curious because people seem to regard these types of gen AI differently than text gen and image gen. Is it because they don’t know? Is it because they don’t think the work it replaces is creative? Is it because of accessibility? (and, if so, why are other types of gen AI not also regarded as accessibility? And even then, it wouldn’t explain the use of Glaze/Artshield)

Additional comments from anon:

I did some digging by infiltrating (lurking in) pro-AI spaces to see how much damage Glaze and other such programs were doing. Unfortunately, it turns out none of those programs deter people from using the ‘protected’ art. In fact, because of how AI training works, they may actually result in better output? Something about adversarial training. It was super disappointing. Nobody in those spaces considers them even a mild deterrent anywhere I looked. Hopefully people can shed some light on the contradictions for me. Even just knowing how widespread their use is would be informative. (I’m not asking about environmental impact as a factor because I read the study everybody cited, and it wasn’t even anti-AI? It was about figuring out the best time of day to train a model to balance solar power vs water use and consumption. And the way they estimated the impact of AI was super weird? They just went with 2020’s data center growth rate as the ‘normal’ growth rate and then any ‘extra’ growth was considered AI. Maybe that’s why it didn’t pass peer review... But since people are still quoting it, that’s another reason for me to wonder why they would use Glaze and Artshield and everything. That’s why running them locally has such heavy GPU requirements and why it takes so long to process an image if you don’t meet the requirements. It’s the same electricity/water cost as generating any other AI image.)

–

We ask your questions anonymously so you don’t have to! Submissions are open on the 1st and 15th of the month.

#polls#incognito polls#anonymous#tumblr polls#tumblr users#questions#polls about ethics#submitted april 15#polls about the internet#ai#gen ai#generative ai#ai tools#technology

329 notes

·

View notes

Text

Mamdani has promised to create 200,000 units of new publicly subsidized, rent-stabilized housing and to fast-track projects consisting entirely of below-market-rate units. His campaign website claims that previous administrations relied “almost entirely” on the zoning code to encourage affordable housing. This is not so. For 40 years, New York has run the nation’s most ambitious and successful affordable-housing program, which rebuilt great swaths of the city using billions of dollars in municipal investment. Zoning changes to allow more housing construction are of recent vintage.

“Zohran and his advisers don’t know history and don’t have the slightest grasp of the numbers,” a former top city housing official told me. (He asked not to be identified because he still works with the city on affordable-housing projects.) Mamdani himself has proposed to triple the amount of money spent on housing in the city’s capital plan, pushing overall costs toward $100 billion over 10 years, which overshadows the estimated cost of his rivals’ plans. And he proposes to accomplish this with union labor, which the city’s Independent Budget Office found would add 23 percent to overall costs.

Meanwhile, Mamdani’s proposal to freeze rent in rent-stabilized units ignores fundamental problems: Landlords of much of the city’s rent-stabilized housing stock—including a number of respected nonprofit groups—cannot afford maintenance costs and debt service, the watchdog Citizens Budget Commission wrote recently. Because expenses are growing faster than rents in older buildings, many are “teetering on the edge of a ‘death spiral.’”

I reached out to Mamdani’s campaign for comment on these issues and have not yet heard back. His supporters seem unbothered by the obvious holes in his proposals. His tax increases sound righteous, a socialist holding the wealthy to account. But the state legislature and governor would have to sign off, and that is a very distant possibility.

I needed to pull this section out because, as many of you may know, my job involves dealing with affordable housing and development and whatnot for the city. And Michael Powell (the writer of this Atlantic piece) and the anonymous former housing official are fully correct, and Mamdani is fully wrong.

The city's zoning plan had not received any kind of comprehensive or focused update since the 1960s, and most construction and development (for housing and otherwise) goes through rezoning through either the UDAAP or ULURP process, which involves the city council specifically designating it a certain way to exempt or change the zoning requirements for the property and the project. It's not until Adams and the City of Yes this past year that we had a comprehensive update, and one with a specific detailed housing component.

In the last budget, the city allocated $2.2 billion in capital funding to the city's housing department for funding development of new and existing affordable housing, and that was a remarkably high amount. The state also allocates funding through the state-level housing and development agency (HCR). Additionally, there's a state-established public corporation (HDC) which also provides funding and support for affordable housing development through the issuance of bonds.

With affordable housing, NYC both builds new housing but also "preserves" or rehabs existing affordable housing. The amount of space available to build new housing is limited, the amount of city-owned property is even more so (which would allow for, in theory, quicker building) and there's numerous parties to the deals both internal to the city as well as external, not limited to the developer, banks, lawyers, architects, contractors etc.

Preserving existing affordable housing involves relocating tenants, identify issues ranging from cash flow, maintenance, arrears (rent and utility, both by tenants but also by the property owner) etc. These are some of the most difficult projects to manage, and often involve a lot of financing. These projects also involve more HUD-financing, and so working with HUD is a big part of the work.

All projects involve some kind of community meeting, and often require council member approval (both the council as a whole as well as the specific council members the projects are located in).

Due to climate change, there's resiliency and environmental concerns, particularly with projects that would be located in flood zones (hello to the Rockaways).

Certain projects, if they have federal funds, trigger Davis-Bacon requirements, meaning contractors and subcontractors must be paid at the "prevailing wage", which adds to the costs (and is essentially what using union labor on all projects would do).

There are multiple oversight agencies involved which scrutinize the use of city funds for these projects, from the Comptroller to the Office of Management and Budget, and they all have lengthy review periods and rather stringent oversight and firm jurisdiction, which slows projects and causes problems.

That's not getting into what other parts of the city's housing department do, from dealing with code violations to providing Section 8 vouchers and so forth.

What Mamdani is proposing doing would require not just a fuckton of money, but also a complete overhaul of city procurement and financing processes, administrative shakeups, and intense negotiations with the city council, the state legislature, and the governor. On top of dealing with other mayors and governors in surrounding states (transportation is another area similar to housing with lots of stumbles and challenges) and with the federal government being the way it is.

182 notes

·

View notes

Text

Things Biden and the Democrats did, this week #14

April 12-19 2024

The Department of Commerce announced a deal with Samsung to help bring advanced semiconductor manufacturing and research and development to Texas. The deal will bring 45 billion dollars of investment to Texas to help build a research center in Taylor Texas and expand Samsung's Austin, Texas, semiconductor facility. The Biden Administration estimates this will create 21,000 new jobs. Since 1990 America has fallen from making nearly 40% of the world's semiconductor to just over 10% in 2020.

The Department of Energy announced it granted New York State $158 million to help support people making their homes more energy efficient. This is the first payment out of a $8.8 billion dollar program with 11 other states having already applied. The program will rebate Americans for improvements on their homes to lower energy usage. Americans could get as much as $8,000 off for installing a heat pump, as well as for improvements in insulation, wiring, and electrical panel. The program is expected to help save Americans $1 billion in electoral costs, and help create 50,000 new jobs.

The Department of Education began the formal process to make President Biden's new Student Loan Debt relief plan a reality. The Department published the first set of draft rules for the program. The rules will face 30 days of public comment before a second draft can be released. The Administration hopes the process can be finished by the Fall to bring debt relief to 30 million Americans, and totally eliminate the debt of 4 million former students. The Administration has already wiped out the debt of 4.3 million borrowers so far.

The Department of Agriculture announced a $1 billion dollar collaboration with USAID to buy American grown foods combat global hunger. Most of the money will go to traditional shelf stable goods distributed by USAID, like wheat, rice, sorghum, lentils, chickpeas, dry peas, vegetable oil, cornmeal, navy beans, pinto beans and kidney beans, while $50 million will go to a pilot program to see if USAID can expand what it normally gives to new products. The food aid will help feed people in Bangladesh, Burkina Faso, Burundi, Chad, Democratic Republic of the Congo, Djibouti, Ethiopia, Haiti, Kenya, Madagascar, Mali, Nigeria, Rwanda, South Sudan, Sudan, Tanzania, Uganda, and Yemen.

The Department of the Interior announced it's expanding four national wildlife refuges to protect 1.13 million wildlife habitat. The refuges are in New Mexico, North Carolina, and two in Texas. The Department also signed an order protecting parts of the Placitas area. The land is considered sacred by the Pueblos peoples of the area who have long lobbied for his protection. Security Deb Haaland the first Native American to serve as Interior Secretary and a Pueblo herself signed the order in her native New Mexico.

The Department of Labor announced new work place safety regulations about the safe amount of silica dust mine workers can be exposed to. The dust is known to cause scaring in the lungs often called black lung. It's estimated that the new regulations will save over 1,000 lives a year. The United Mine Workers have long fought for these changes and applauded the Biden Administration's actions.

The Biden Administration announced its progress in closing the racial wealth gap in America. Under President Biden the level of Black Unemployment is the lowest its ever been since it started being tracked in the 1970s, and the gap between white and black unemployment is the smallest its ever been as well. Black wealth is up 60% over where it was in 2019. The share of black owned businesses doubled between 2019 and 2022. New black businesses are being created at the fastest rate in 30 years. The Administration in 2021 Interagency Task Force to combat unfair house appraisals. Black homeowners regularly have their homes undervalued compared to whites who own comparable property. Since the Taskforce started the likelihood of such a gap has dropped by 40% and even disappeared in some states. 2023 represented a record breaking $76.2 billion in federal contracts going to small business owned by members of minority communities. This was 12% of federal contracts and the President aims to make it 15% for 2025.

The EPA announced (just now as I write this) that it plans to add PFAS, known as forever chemicals, to the Superfund law. This would require manufacturers to pay to clean up two PFAS, perfluorooctanoic acid and perfluorooctanesulfonic acid. This move to force manufacturers to cover the costs of PFAS clean up comes after last week's new rule on drinking water which will remove PFAS from the nation's drinking water.

Bonus:

President Biden met a Senior named Bob in Pennsylvania who is personally benefiting from The President's capping the price of insulin for Seniors at $35, and Biden let Bob know about a cap on prosecution drug payments for seniors that will cut Bob's drug bills by more than half.

#Thanks Biden#Joe Biden#jobs#Economy#student loan debt#Environment#PFAS#politics#US politics#health care

764 notes

·

View notes

Note

Amy tips for getting 30 prebuilt pcs for 1500$ each

We're going to play a game where I show tumblr what I do at work by doing it on tumblr. You can answer my questions in successive anonymous asks. My responses to you will be bracketed by dashed lines, with instructions and commentary before and after.

---------------------------

Hi Anon!

I can definitely help you with your desktop needs. Can you tell me whether you're looking minimize your costs, or get the maximum amount of computer that I can get you for a per-unit price of $1500?

Here are some details that will help me narrow down options that are a good fit for your situation:

Very generally, what will these be for? Basic office use (browsing, office suite)? Video Production? CAD? Finance? Medical providers? Educators?

What date are you looking to have these machines in place?

Is there a specific type of software that you know will be installed on these devices, and if so can you get me the hardware specs required by the software vendor?

Please let me know if you've got any questions, or if there is anything that I can do for you.

Thanks! - Ms-D

-----------------------------

The average cost of business desktops that I sell at work is $700-$900; these are devices that I would give an anticipated lifespan of 7 years, with hardware upgrades planned at 5 years. This is for a mid-range desktop with a 3-year next business day onsite warranty, no software, and does not include the cost of tax, shipping, or configuration. The cost of labor can come close to the cost of the machine for configuration. If I were *PERSONALLY* deploying these machines (pulling them out of the box, debloating, creating profiles, installing software, reboxing, transporting to the site, installing and connecting to peripherals) I'd probably charge around $200-300 per device. My work charges a lot more. Because of that, a 1500 computer is quite likely to be a 700 computer with three hours of estimated labor. If you've got an in-house IT department and aren't going to be paying through the nose for setup, you can get *a lot* of business-class computer for $1500.

If someone at work asked me for a $1500 computer, I would assume that was the cost of the machine ONLY, no peripherals, no configuration, no installation, no software, though I would try to consider both tax and our markup and would look for devices that would maximize performance while under-but-close-to the mark. If I found something that was slightly over (say by up to $70), I would drop our markup to get closer to the client's budget.

What this means for YOU, the computer consumer, is that when you're looking at a computer you need to consider the following in your budget, NOT just the sticker price.

Computer Cost

Software Cost

Setup Cost (if you're not doing it yourself)

Shipping Cost

Tax

Peripherals (computers almost all come with a mouse and a keyboard, these are usually inexpensive but very sturdy; if you want a nice keyboard and an ergonomic mouse you have to buy your own)

Whether you will LOSE peripherals when you replace your current device - do you need to buy an external optical disk drive if your old machine had a CD drive but the new machine doesn't?

Those things can add hundreds of dollars to your total cost, so figure out how much that will be so that you can figure out what your ACTUAL budget for your computer is.

(Also your computer shouldn't be plugged directly into the wall; if you're getting ready to replace a machine and you don't already own a desktop UPS, a desktop UPS should be part of the cost of your next machine!)

118 notes

·

View notes

Text

Recommendations for societies with mixed halfling/human races follow. The average halfling is assumed, from demographic estimates, to weigh 30 pounds (14 kg) and stand approximately 3 feet (1 meter) tall.

All public places where people are expected to be seated need a mix of regular/small seating. Ideally, all chairs and tables will be adjustable, but this comes with cost considerations.

All doors must be accessible for people of all sizes. This presents a challenge for doorknobs and door handles, and the recommendation is a long vertical bar accessible for both, along with low "minimum force" levels for opening and closing. Problems with locking mechanisms remain, and while floor bolts are height-neutral, they're more suited to secondary locking mechanisms.

All restaurants, cafeterias, and vending machines should stock two differently sized portions. The average halfling consumes roughly a third the amount of food as a human. Because of various frictions (packaging, labor), prices are expected to be more than one third for a halfling portion. Because of this, it's best to have systems in place that allow splitting human-sized dishes, or bringing home leftovers, or making packages resealable.

Housing presents a serious problem. A single-family dwelling for a halfling family requires roughly one fifth the volume as for a single-family human dwelling, though costs do not scale down at the same rate. However, if built to halfling scale, the interior of the dwelling will only be accessible to halflings, which presents serious problems for e.g. police, firefighters, social workers, repairmen, or anyone else who might have cause to go into the interior of the home, to say nothing of friends and coworkers. Building for halfling scale is attractive for a variety of reasons, with cost being one of the biggest, but this might result in de facto segregation, and puts considerable strain on civic infrastructure and city markets due to duplication. Another social concern is that all interactions might, by default, take place inside human homes which have worse accommodations for halflings. Special note should also be made of mixed-species couples, who suffer extra burdens within the household. These problems are intractable, as some trade-off must always be made.

Tools, household goods, and clothing are naturally split into two markets. For clothing, near-complete segregation is expected. For everything else, partial segregation is expected: a halfling cannot effectively use many human tools due to differences in grip strength and grip circumference, to say nothing of brute strength. However, many consumables can suit both species, and it's expected that cost reduction efforts will inevitably result in a single offering for both in cases where that makes remotely makes sense. Purchases using refillable containers from bulk are encouraged, as each person can determine what's best to fulfill their own needs.

Due to lower costs (housing, food, clothing), halflings can in theory work for lower wages. For certain jobs, particularly those requiring physical strength, humans are more capable on average, and for others, particularly those requiring manual dexterity, halflings are more capable on average. For jobs which do not have significant differences, wage discrimination is recommended by contentious, and is an ongoing conversation.

There are a number of "segregationist forces" in society, driven by convenience, culture, and market forces. Once segregation has become, there is every expectation that it will snowball: a neighborhood which is inaccessible to humans will have businesses that cater only to halflings, and once halfling business is concentrated, any "mixed" business has less incentive to cater to halflings. Legislation can counterbalance these forces by requiring that all businesses be able to service both humans and halflings, and accommodate both human and halfling services, but this admittedly comes at enormous cost.

Overall, there are certain recommendations that are nearly costless and can be implemented as best practices immediately, and more complicated, costly reforms that will take significant political will and budgetary consideration. Beyond that, there are questions of social engineering and the level to which it is important or preferable that these things be done.

169 notes

·

View notes

Text

Via NasAlSudan

Learn about the Sudanese revolution, the significance of December 19, and a legacy of resistance and resilience.

Join our call to action today and everyday during Sudan Action Week.

December 19 2023

Transcript:

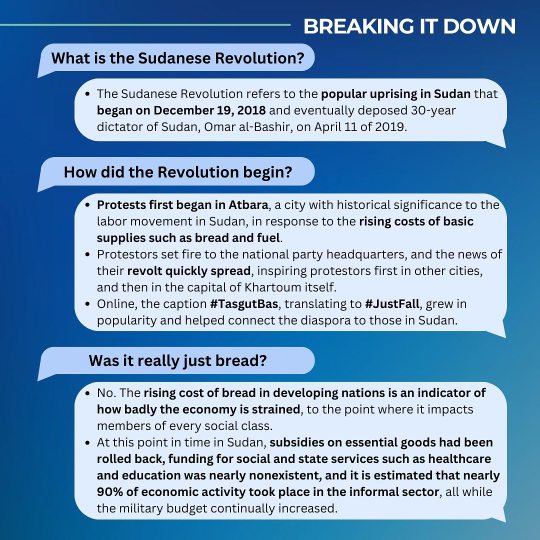

Breaking it down

What is the Sudanese Revolution?

The Sudanese Revolution refers to the popular uprising in Sudan that began on December 19, 2018 and eventually deposed 30-year dictator of Sudan, Omar al-Bashir, on April 11 of 2019.

How did the Revolution begin?

Protests first began in Atbara, a city with historical significance to the labor movement in Sudan, in response to the rising costs of basic supplies such as bread and fuel.

Protestors set fire to the national party headquarters, and the news of their revolt quickly spread, inspiring protestors first in other cities, and then in the capital of Khartoum itself.

Online, the caption #TasgutBas, translating to #JustFall, grew in popularity and helped connect the diaspora to those in Sudan.

Was it really just bread?

No. The rising cost of bread in developing nations is an indicator of how badly the economy is strained, to the point where it impacts members of every social class.

At this point in time in Sudan, subsidies on essential goods had been rolled back, funding for social and state services such as healthcare and education was nearly nonexistent, and it is estimated that nearly 90% of economic activity took place in the informal sector, all while the military budget continually increased.

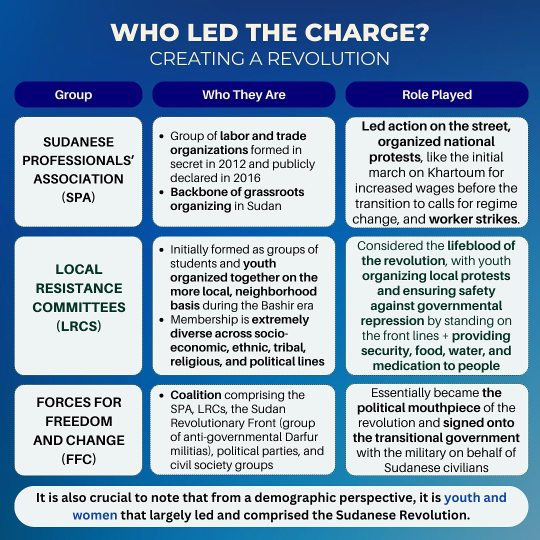

Transcript:

Who led the charge? Creating a revolution

Group: Sudanese Professional's association (SPA)

Who they are:

Group of labor and trade organizations formed in secret in 2012 and publicly declared in 2016

Backbone of grassroots organizing in Sudan

Role played:

Led action on the street, organized national protests, like the initial march on Khartoum for increased wages before the transition to calls for regime change, and worker strikes.

Group: Local Resistance Committees (LRCS)

Who they are:

Initially formed as groups of students and youth organized together on the more local, neighbourhood basis during the Bashir era

Membership is extremely diverse across socio-economic, ethnic, tribal, religious, and political lines

Role played:

Considered the lifeblood of the revolution, with youth organizing local protests and ensuring safety against governmental repression by standing on the front lines + providing security, food, water, and medication to people

Group: Forces for freedom and change (FFC)

Who they are:

Coalition comprising the SPA, LRCS, the Sudan Revolutionary Front (group of anti-governmental Darfur militias), political parties, and civil society groups

Role played:

Essentially became the political mouthpiece of the revolution and signed onto the transitional government with the military on behalf of Sudanese civilians

It is also crucial to note that from a demographic perspective, it is youth and women that largely led and comprised the Sudanese Revolution.

Trabscript:

How did the revolution succeed?

01. Learning from the Past

Following the Arab Spring wave, Sudan also attempted a revolution in September of 2013

Civilians faced violent crackdowns within the first three days of protest. 200 killed, 800+ arrested

Activists were deterred from mobilization + felt a lot of guilt at the massive loss of life and spent the next 5 years grounding themselves in the study of nonviolent theory and action

02. Building a Movement

Coalition Building and People Power

Diversification of the reach of the movement to make sure all sectors of Sudani society were represented

Decentralization of Activism

Past revolutions in 1964 and 1985 were concentrated in the labor movement and educational elites in Khartoum

This time, experienced nonviolent activists trained those in the capital and ensured ethnic, religious, and tribal diversity

Newly trained activists then taught others locally across the Sudanese states

Transcript:

Why december 19?

On December 19, 1955, the Sudanese parliament unanimously adopted a declaration of independence from the Anglo-Egyptian colonial power.

The declaration went into effect on January 1, 1956, which is why Independence Day is officially January 1, but December 19 is when the Sudanese people were truly liberated from colonial rule.

The flag shown is Sudan's independence flag. The blue is for the Nile, the yellow for the Sahara, and the green for the farmlands.

The current Sudanese flag was adopted in 1970, with the colors used being the Pan-Arab ones.

During the 2019 revolution, protestors often carried the independence flag instead as a form of resistance to the narrative of an exclusive Pan-Arab Sudanese identity.

December 19 is ultimately a tribute to Sudanese strength and resilience. It honors our independence and revolutionary martyrs - not just those of the 2019 revolution, but the democratic revolutions of 1964 and 1985 as well.

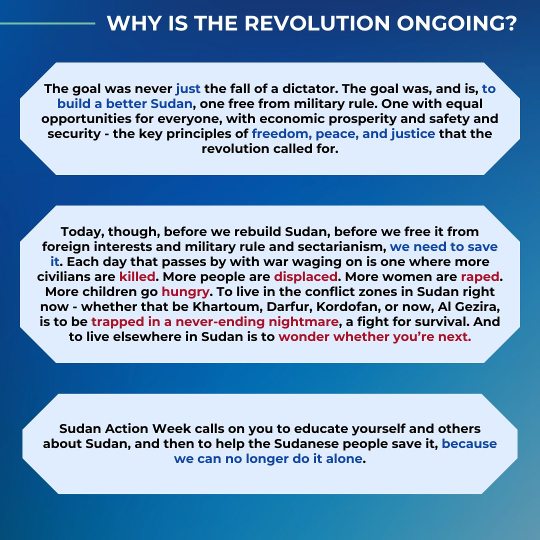

Transcript:

Why is the revolution ongoing?

The goal was never just the fall of a dictator. The goal was, and is, to build a better Sudan, one free from military rule. One with equal opportunities for everyone, with economic prosperity and safety and security - the key principles of freedom, peace, and justice that the revolution called for.

Today, though, before we rebuild Sudan, before we free it from foreign interests and military rule and sectarianism, we need to save it. Each day that passes by with war waging on is one where more civilians are killed. More people are displaced. More women are raped. More children go hungry. To live in the conflict zones in Sudan right now - whether that be Khartoum, Darfur, Kordofan, or now, Al Gezira, is to be trapped in a never-ending nightmare, a fight for survival. And to live elsewhere in Sudan is to wonder whether you're next.

Sudan Action Week calls on you to educate yourself and others about Sudan, and then to help the Sudanese people save it, because we can no longer do it alone.

Transcript:

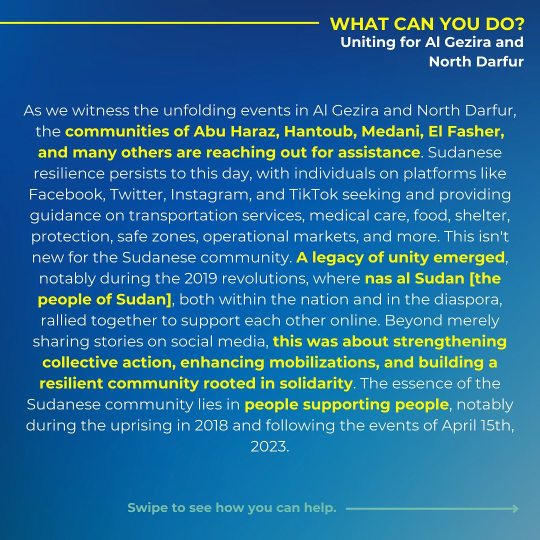

What can you do? Uniting for Al Gezira and North Darfur

As we witness the unfolding events in Al Gezira and North Darfur, the communities of Abu Haraz, Hantoub, Medani, El Fasher, and many others are reaching out for assistance. Sudanese resilience persists to this day, with individuals on platforms like Facebook, Twitter, Instagram, and TikTok seeking and providing guidance on transportation services, medical care, food, shelter, protection, safe zones, operational markets, and more. This isn't new for the Sudanese community. A legacy of unity emerged, notably during the 2019 revolutions, where nas al Sudan [the people of Sudan], both within the nation and in the diaspora, rallied together to support each other online. Beyond merely sharing stories on social media, this was about strengthening collective action, enhancing mobilizations, and building a resilient community rooted in solidarity. The essence of the Sudanese community lies in people supporting people, notably during the uprising in 2018 and following the events of April 15th, 2023

Swipe to see how you can help.

Transcript:

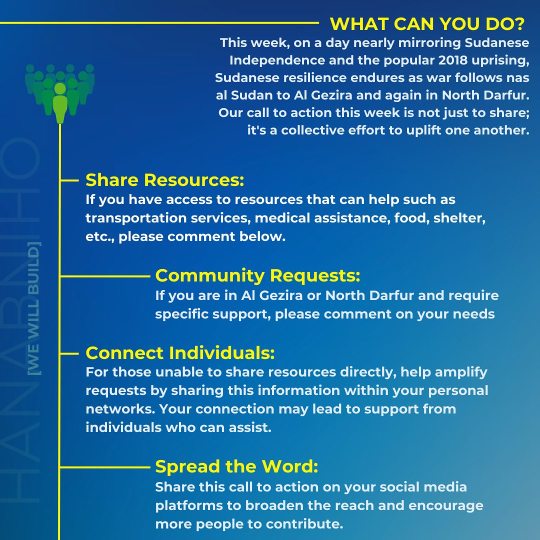

What can you do?

This week, on a day nearly mirroring Sudanese Independence and the popular 2018 uprising, Sudanese resilience endures as war follows nas al Sudan to Al Gezira and again in North Darfur. Our call to action this week is not just to share; it's a collective effort to uplift one another.

Share Resources:

If you have access to resources that can help such as transportation services, medical assistance, food, shelter, etc., please comment below.

Community Requests:

If you are in Al Gezira or North Darfur and require specific support, please comment on your needs

Connect Individuals:

For those unable to share resources directly, help amplify requests by sharing this information within your personal networks. Your connection may lead to support from individuals who can assist.

Spread the Word:

Share this call to action on your social media platforms to broaden the reach and encourage more people to contribute.

Transcript:

Hanabniho

حنبنيهوا

[We will rebuild]

#keepEyesOnSudan

#SudanActionWeek

924 notes

·

View notes

Text

"The UK government has announced that 500,000 additional children will receive a free school lunch following a major expansion in the program that provides it.

Previously, the free meal was available only to students who come from the lowest of low-income households. Following the expansion, most low and middle-class citizens will be able to qualify, and the government says it will lift 100,000 students out of poverty from the cost savings which will amount to around £500 per month, corresponding to nearly $700.

Despite having a ceiling of £7,400-per year for eligibility, last year an estimated 2.1 million students received a free school meal.

A rather arbitrary cut-off point, someone making £8,000 per year hardly possesses greater means to pay for the school meal than someone making below the cutoff point.

Under the new plan, any students from households on the UK’s universal credit will be eligible to receive one free meal a day. The universal credit replaced a number of British welfare programs, and provides a monthly cost of living assistance handout to people living in a variety of situations with a net worth of less than $20,000.

Set to begin at the outset of the 2026 scholastic year, the new expansion will also address food quality, and will be fully, rather than partially funded, to ensure there’s no delay in getting the expansion moving.

“Today’s historic step will help us to deliver excellence everywhere, for every child and give more young people the chance to get on in life,” the UK’s education secretary Bridget Phillipson said, adding “background shouldn’t mean destiny.”

The decision comes amid a record-high level of childhood poverty in one of Europe’s largest economies. The new Labor government under Prime Minister Sir Keir Starmer has vowed to drive down poverty levels in the UK, and the expansion of the student meal program was a part of that.

Free school lunches became a hot topic during the administration of Boris Johnson, when the young black Manchester United star Marcus Rashford decided to criticize Johnson for reducing the size of the free school lunch program.

While some sport pundits believed Rashford’s aim was noble, they also felt he should focus on his soccer. But he persevered and the government relented. Through this and his work with hunger charities in the city of Manchester, he was presented with an MBE, the British order of merit below a knighthood, for his advocacy work on behalf of England’s poorest students."

-via Good News Network,June 9, 2025

#uk#united kingdom#europe#england#free school lunch#poverty#food#food insecurity#childhood poverty#keir starmer#food access#good news#hope

597 notes

·

View notes