#MODBUS TCP/IP

Explore tagged Tumblr posts

Text

Future-Proof Building Operations with NX-ERA Premium PLC Redundant Systems

In the domain of intelligent infrastructure, building intelligence is no longer a privilege but has become a requirement. Modern buildings, be it skyscraper business complexes, advanced healthcare institutions, or high-end hospitality centres function as living, breathing ecosystems. These types of buildings heavily depend on a Building Management System (BMS) to regulate HVAC, lighting, elevators, energy, and security systems.

Yet a single failure within the control system will bring these systems to a grinding halt, leading to operational disruption, safety hazard, tenant dissatisfaction, and regulatory non-compliance. This is where Messung's NX-ERA Premium PLC Redundant Systems, our state-of-the-art control solution for future-proofed infrastructure, come into play with their reliability, accuracy, and scalability.

Let us explore how NX-ERA provides intelligence, continuity, and scalability to your buildings through this blog.

The Evolution of Building Control Systems

Traditional relay-based control panels were able to handle building services in the past. Nowadays, buildings are far more advanced. Real-time data, multi-zone control, preventative maintenance, energy optimisation, and safety systems all require more intelligence.

Programmable Logic Controllers (PLCs) are the cornerstones of such a revolution. Although not all PLCs are alike.

The NX-ERA Premium PLC transforms building automation with a fail-safe, redundant design architecture that maintains your operations no matter what, and scales beautifully with your growing infrastructure.

Why Choose NX-ERA Premium PLCs?

Our NX-ERA platform is more than a PLC; it is an architecture that enables smart building management with unparalleled reliability.

Key Features:

Redundant Architecture: Two CPUs, two power supplies, and two communications modules offer zero downtime.

High-Speed Data Processing: Facilitates prompt decision-making between various sub-systems.

Remote Access PLC: Control, monitor, and troubleshoot anywhere.

Modular PLC Design: Flexible and scalable to project size and future requirements.

Intelligent PLC Capabilities: Sophisticated analytics, alarms, and diagnostics.

Built-in SCADA Integration: Integrated central control and visibility of the whole facility.

We have designed NX-ERA for round-the-clock use in the most demanding scenarios, starting from hospitals and IT parks to shopping malls and industrial clusters.

Application-Centric Design for Mission-Critical Infrastructure

In today's high-performance buildings, every system, air conditioning, lighting, fire detection, or security, has an important function to provide comfort, safety, and efficiency. Our NX-ERA Premium PLC is designed keeping this in mind. It is specifically made for use in mission-critical environments and allows for precise, continuous control of all major building services.

1.HVAC & Climate Control - NX-ERA provides advanced control of HVAC systems, controlling air conditioning, humidity, and ventilation with multi-zone precision. With open sensor integration, it provides condition-based automation, modulating airflow, temperature, and filtration in real time. This provides maximised indoor air quality and major energy savings, particularly in variable-occupancy buildings.

2. Lighting Automation - From programmed schedules to daylight-responsive dimming, NX-ERA regulates lighting between corridors and floors. It allows daylight harvesting by adjusting artificial lighting based on ambient conditions, saving energy without sacrificing occupant comfort. Smart lighting control also minimises operating costs and maximises fixture life.

3. Fire and Life Safety Systems - As a Safety PLC certified to operate, NX-ERA provides life-critical system support. It integrates with fire alarms, smoke detectors, and smoke extraction fans safely and reliably, with a timely response in case of emergencies. Redundant architecture ensures system availability even in the event of component failure.

4. Security & Access Control - NX-ERA controls security functions such as CCTV feeds, access readers, intruder alarms, and emergency lockdowns. It is fault-tolerant for access control and surveillance, even in the case of faults, with its dual-CPU design. Third-party system support provides seamless and scalable integration.

NX-ERA brings precision, resilience, and intelligent automation to every corner of your infrastructure, ensuring your building operates flawlessly, around the clock.

Constructing a Strong Framework with Redundant Design

NX-ERA’s architecture is designed around fail-safe principles:

Redundant CPUs are in hot standby, providing instant takeover if the primary CPU fails.

Duplicate Power Supplies provide a continuous power supply, avoiding shutdowns caused by voltage instability or failure.

Dual Communication Modules remove the threat of being disconnected from field devices or SCADA.

Programmable Logic Controllers provide deterministic behaviour and quick response times for real-time control.

This is the level of redundancy that must ensure the PLC Control Systems are single-point failure-proof and properly compliant with safety standards.

Smooth Integration with Building Ecosystems

NX-ERA is specifically designed for comprehensive, integrated control of building operations. Interoperability is its basis.

Native MODBUS TCP/IP communication for easy integration with third-party devices such as energy meters, smart sensors, HVAC devices, lighting panels, and fire safety devices.

It aggregates independent systems onto a single SCADA dashboard, providing a live view of all building services operating.

Remote diagnostics and centralised control enable facility managers to observe, investigate, and react to inefficiencies or faults from a central command centre—or any other location with secure access.

NX-ERA also supports seamless interaction with modern IoT systems like occupancy analytics, air quality monitoring, and asset tracking, making conventional buildings responsive, adaptive spaces.

Whether you are installing new infrastructure or expanding existing installations, NX-ERA keeps your architecture flexible, networked, and future-proof.

Real-Time Intelligence for Smarter Facilities

NX-ERA is not just a control system—it's a smart decision-making platform. Its data-driven performance offers real-time insights that raise operational effectiveness:

Offers high-resolution data logs for all parameters—temperature, voltage, energy consumption, etc.

Fully integrated with Energy Management Systems, supporting predictive load balancing, peak demand management, and actionable energy intelligence.

Generates predictive alerts for anomalies such as HVAC inefficiencies, equipment fatigue, or sensor deviations, helping prevent breakdowns before they occur.

Stores complete, tamper-proof logs that support regulatory audits and compliance with ISO standards, LEED guidelines, and other sustainability certifications.

With NX-ERA, facility managers can depart from reactive repair towards proactive, data-driven facility management.

Built to Scale, Built to Last

Growth and sustainability are the major pillars of the existence of any building. NX-ERA guarantees your automation system grows with your building while meeting environmental goals:

Modular structure allows you to add I/O points, add new subsystems, or accommodate newer technologies without redesigning the system.

Fully supports IoT-enabled smart metering, leak detection for water, predictive HVAC control, and occupancy analytics.

Facilitates LEED and green building certifications by maintaining constant energy audits, performance benchmarking, and real-time carbon footprint tracking.

Perfectly complements digital transformation initiatives, setting the stage for cloud analytics, AI, and automation-ready.

NX-ERA is your control companion, not just for today’s needs, but for tomorrow’s smart infrastructure vision.

Messung: Reliable Across Industries

For more than four decades, Messung has spearheaded India's industrial automation process with high-performance, dependable PLC solutions. NX-ERA Premium PLC is used in a broad range of mission-critical industries:

Data centres need constant uptime and exact environmental control.

Hospitals where life-saving equipment has to work without any failure.

Office towers with intricate lighting, HVAC, and elevator systems.

Residential high-rise buildings require energy efficiency and safety.

Plant operations where lost time equates to high operating costs.

Every NX-ERA deployment is backed by thorough testing, sophisticated lifecycle support, and intimate customer knowledge to deliver performance with confidence.

When to Upgrade to NX-ERA

Use NX-ERA if:

Your business requires no interruption of business.

You are grappling with legacy PLC failures or integration issues.

You're targeting PLC Automation for mission-critical sub-systems.

You need audit-quality logs to achieve ISO or LEED certification.

You're growing and require Remote Access PLC functionality.

NX-ERA is designed to fulfil your current requirements and long-term ambitions.

Conclusion: Join Messung for Uninterrupted Brilliance

In a world where building systems are designed to work flawlessly, learn intelligently, and expand seamlessly, your automation partner can be the difference-maker. At Messung Industrial Automation, we realise that infrastructure today requires more than control; it demands resilience, precision, and vision.

Our NX-ERA Premium PLC Redundant Systems reflect these principles. Not only do they provide fault-tolerant automation, but they also provide a complete platform for smart building management, enabling your infrastructure to react in real time, recover immediately, and adapt continuously.

Whether your business is a hospital, data centre, office complex, or intelligent residential complex, NX-ERA is your command centre that makes you never miss a beat.

Let's redefine what's possible, together.

Contact Messung Industrial Automation to see how NX-ERA can future-proof your plant with zero downtime, maximum intelligence, and permanent peace of mind.

Select NX-ERA. Select uninterrupted brilliance.

Frequently Asked Questions (FAQs)

Why would NX-ERA Premium PLCs be ideal for mission-critical buildings?

NX-ERA Premium PLCs are designed with two CPUs, power supplies, and communications modules, which render them zero downtime in case of failure. They are ideal for units where continuous operation is crucial, including hospitals, data centres, and business complexes.

Is NX-ERA compatible with existing building systems and legacy infrastructure?

Yes. NX-ERA is an open protocol-based based, such as MODBUS TCP/IP, and is capable of being integrated with third-party equipment, legacy control panels, and contemporary IoT-based systems and is extremely flexible for new and retrofit applications.

In what ways does NX-ERA support energy efficiency and green building goals?

NX-ERA includes integration with Energy Management Systems, daylight harvesting, and advanced energy analytics that minimise energy use and support the needs of green building certifications such as LEED.

For which industries and applications is NX-ERA best suited?

NX-ERA is tailored for various industries such as healthcare, manufacturing, commercial real estate, residential townships, and mission-critical infrastructure that need smart, high-availability automation.

Can NX-ERA be remotely monitored and remotely troubleshot?

Yes. NX-ERA allows secure remote access, with real-time monitoring, diagnostics, and command execution from remote locations, reducing response time and maintenance cost.

#NX-ERA Premium PLC#Building Management System (BMS)#Programmable Logic Controllers (PLCs)#Modular PLC Design#SCADA Integration#HVAC systems#Smart lighting control#Safety PLC#Duplicate Power Supplies#MODBUS TCP/IP#HVAC devices#modern IoT systems#Energy Management Systems#IoT-enabled#PLC solutions#NX-ERA Premium PLC Redundant Systems#MODBUS#healthcare#manufacturing#commercial real estate#residential townships#mission-critical infrastructure

0 notes

Text

AeroTrak Remote Particle Counter with Integrated Pump 6510 & 6510-VHP

AeroTrak® Remote Particle Counters with Integrated Pump are independent monitoring systems condensed into an easy-to-clean 316L stainless steel enclosure. The integrated clean pump eliminates the need for an external vacuum source. Four standard analog inputs help to reduce installation and integration costs. Vaporized Hydrogen Peroxide (VHP) resistant remote particle counter model available. Models 6510 and 6510-VHP offer 4 size channels, 0.5, 0.7, 1.0, 5.0 μm at 1 CFM (28.3 L/min) sample flow rate. The sample inlet capping auto-detect automatically stops the blower and prevents accidental damage.

Applications :

GMP Controlled Areas

Isolators

Restricted Access Barrier Systems (RABS)

Cleanrooms

Hospital Pharmacies

Laboratories

Industrial

Aerospace

Compounding Pharmacies

Features and Benefits:

Easy to Install and Maintain

Eliminates the need for centralized vacuum system

Internal blower has no carbon vanes and low heat gain

Hot-swap optical sensor and pump slide out as a single assembly for fast and easy maintenance, no tools required

Sample inlet capping auto-detect automatically stops the blower and prevents accidental damage

Standard four 4-20 mA analog inputs reduce environmental sensor integration and installation costs

Easy-to-clean passivated 316L stainless steel enclosure, sample probe and cap, which are resistant to cleaning solutions

Ethernet (TCP/IP), serial Modbus RTU, and 4-20 mA analog data outputs enable seamless integration into most software, including TSI’s FMS software.

Meets Current GMP Guidelines and International Standards :

1 CFM (28.3 L/min) flow rate, up to four channels of particle data including 0.5 μm and 5 μm per EU and US FDA Aseptic Processing Guidelines

ISO 21501-4 compliant calibration delivers consistent instrument counting and sizing performance

FMS 5 monitoring software integration enables 21 CFR Part 11-compliant data collection.

#AeroTrak#RemoteParticleCounter#IntegratedPump#CleanroomMonitoring#AirParticleMonitoring#EnvironmentalMonitoring#ContaminationControl#StainlessSteelEnclosure#🧪 Applications & Industries#GMPControlledAreas#Cleanrooms#HospitalPharmacy#CompoundingPharmacy#Laboratories#AerospaceIndustry#PharmaceuticalManufacturing#Isolators#RABS#IndustrialMonitoring#⚙️ Features & Integration#EasyMaintenance#HotSwapSensor#InternalBlower#AutoDetectCapping#AnalogInputs#ModbusRTU#EthernetTCPIP#FMS5Software#NoVacuumNeeded#✅ Compliance & Standards

0 notes

Text

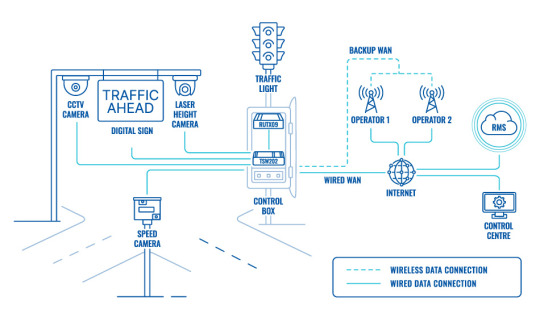

🚦 Giải pháp kết nối mạnh mẽ cho hệ thống giao thông thông minh với Teltonika

Kết nối ổn định là nền tảng cho giao thông đô thị vận hành hiệu quả. Bộ đôi Router RUTX09 + Switch PoE TSW202 mang đến giải pháp ổn định – bảo mật – dễ mở rộng:

👉 RUTX09 truyền dữ liệu từ hiện trường về trung tâm qua mạng LTE Cat 6 hoặc WAN có dây 👉 TSW202 kết nối đèn tín hiệu, camera tốc độ, biển LED… bằng 8 cổng PoE+, cấp nguồn và dữ liệu qua một sợi cáp 👉 Hệ thống hoạt động ổn định, không gián đoạn nhờ Dual SIM failover + backup WAN 👉 Quản lý toàn bộ từ xa qua nền tảng Teltonika RMS, hỗ trợ RMS Connect 👉 Bảo mật cao với VPN, firewall, xác thực nâng cao 👉 Hỗ trợ các giao thức công nghiệp: Modbus TCP, MQTT, SNMP, PROFINET, EtherNet/IP…

✅ Cấu hình linh hoạt, dễ lắp đặt tại các tủ điều khiển giao thông ✅ Giảm thiểu thời gian xử lý sự cố, nâng cao hiệu quả vận hành

👉 Xem chi tiết bài viết: https://raycom.vn/giai-phap-ket-noi-dang-tin-cay-cho-he-thong-giao-thong-thong-minh/

Raycom – đơn vị phân phối chính hãng Teltonika, tư vấn kỹ thuật & giải pháp giao thông thông minh sẵn sàng đồng hành cùng bạn.

------------------------------------------------

CÔNG TY CỔ PHẦN PHÂN PHỐI RAYCOM ☎️ Hotline: 0932 728 972 🌐Website: https://raycom.vn/ 🏫 37 Đường số 6, KDC Cityland Park Hills, Phường Gò Vấp, Thành phố Hồ Chí Minh

0 notes

Video

youtube

Custronics LED MPM PPM Metrics Display: Monitor Factory Output & KPIs in Real-Time Productivity Maximize your factory's performance with the Custronics LED Metrics Display Panel, designed to monitor MPM (Manufacturing Performance Monitoring or Meter Per Minute and PPM (Parts Per Million Defect Rate) in real-time. ✅ Display critical metrics like: • Output & Target • Rejection & Defect Rates (PPM) • OEE, Cycle Time, and Balance • Time, Shift & Line Info ⚙️ Ideal for: • Production Lines • Assembly Areas • Lean Manufacturing • Quality Control & Monitoring Zones 💡 Features: • High-brightness industrial LED display • RS485/Modbus, TCP/IP communication ready • Custom layout & multilingual support • Rugged build for 24/7 operations 🎯 Stay in control of your factory floor—monitor performance instantly, reduce downtime, and boost efficiency.

0 notes

Text

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec’d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

https://anadiautomation.com/schneider-electric/TM200CE40T

Product Overview: TM200CE40T Controller

The TM200CE40T is part of Schneider Electric’s Modicon M200 series, designed to meet the automation needs of modern industries. It features a combination of 24 digital inputs and 16 digital transistor outputs, making it ideal for various I/O-intensive applications.

🔧 Key Specifications:

Part Number: TM200CE40T

Brand: Schneider Electric

Controller Type: Programmable Logic Controller (PLC)

Digital Inputs: 24

Digital Outputs: 16 (Transistor type)

Communication Ports: Built-in Ethernet

Mounting: DIN Rail

Power Supply: 24V DC

Program Memory: Expandable

Warranty: 1 Year (provided by Anadi Automation)

Availability: In stock at Anadi Automation, Nashik, India

Top Features of Schneider Electric TM200CE40T

The TM200CE40T offers a variety of features that enhance its appeal to system integrators and OEMs alike. Here’s why it stands out:

✅ High Input/Output Capacity

With 24 digital inputs and 16 digital outputs, the controller provides ample I/O support for mid-size automation systems.

✅ Compact and Modular Design

Despite its powerful capabilities, the TM200CE40T has a compact footprint. It supports modular expansion, allowing you to scale your system as needed.

✅ Integrated Ethernet Port

The built-in Ethernet port enables high-speed communication, remote monitoring, and easy integration into industrial networks using Modbus TCP/IP protocol.

✅ High-Speed Counter and Pulse Outputs

It includes high-speed counters and pulse output functions that are essential for motion control and fast process operations.

✅ DIN Rail Mounting

Ease of installation with standard DIN rail mounting ensures a secure and accessible setup.

✅ Advanced Programming Environment

Compatible with Schneider Electric's EcoStruxure Machine Expert – Basic (SoMachine Basic) software for intuitive programming, simulation, and troubleshooting.

0 notes

Text

Industrial Ethernet Market Size, Share, Analysis, Forecast, and Growth Factors to 2032

The Industrial Ethernet Market was valued at USD 11.2 Billion in 2023 and is expected to reach USD 21.9 Billion by 2032, growing at a CAGR of 7.74% from 2024-2032.

The Industrial Ethernet market is witnessing a dynamic shift as industries increasingly prioritize automation, speed, and connectivity. From smart factories to energy grids, Industrial Ethernet provides a robust foundation for real-time communication, scalability, and interoperability. Driven by the surge in Industry 4.0 initiatives, manufacturers and infrastructure developers are rapidly deploying Ethernet solutions to replace legacy systems, aiming for higher efficiency and streamlined operations.

Industrial Ethernet Market Set to Transform Global Industrial Communication With the convergence of operational technology (OT) and information technology (IT), Industrial Ethernet has emerged as a strategic enabler for digital transformation across multiple sectors. Industries such as automotive, oil & gas, pharmaceuticals, and utilities are embracing Ethernet-based infrastructure to support high-speed data transmission, secure networking, and seamless machine-to-machine communication.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/6022

Market Keyplayers:

Siemens – SCALANCE Industrial Ethernet Switches

Cisco – Catalyst Industrial Ethernet Switches

Rockwell Automation – Allen-Bradley Stratix Switches

Belden – Hirschmann Industrial Ethernet Solutions

Moxa – Moxa EDS Series Switches

Phoenix Contact – FL SWITCH Industrial Ethernet Series

Schneider Electric – Modicon Industrial Ethernet Switches

ABB – ABB Industrial Ethernet Routers

Hewlett Packard Enterprise (HPE) – Aruba Industrial Ethernet Switches

Huawei – CloudEngine Industrial Ethernet Switches

Omron – Omron Industrial Ethernet Controllers

Advantech – Advantech Industrial Ethernet Switches

Beckhoff Automation – EtherCAT Industrial Ethernet Solutions

General Electric (GE) – GE Industrial Ethernet Switches

Honeywell – Experion Industrial Ethernet Solutions

Market Analysis The Industrial Ethernet market is characterized by robust growth due to its role in modernizing industrial networks. Factors such as the need for deterministic networking, increased use of industrial IoT (IIoT), and real-time data monitoring are fueling adoption. Major players are investing in innovative protocol technologies like PROFINET, EtherNet/IP, and Modbus TCP to gain competitive edge. Enhanced reliability and minimal downtime further position Industrial Ethernet as a superior alternative to traditional fieldbus systems.

Market Trends

Integration of cloud-based industrial systems

Rising demand for network security and cybersecurity solutions

Rapid expansion of smart manufacturing and IIoT

Development of time-sensitive networking (TSN) standards

Adoption of edge computing in industrial networks

Growth of wireless Industrial Ethernet in remote applications

Market Scope The market’s scope spans across critical verticals, offering tailored Ethernet solutions for varied applications:

Manufacturing & Automation: High-speed data exchange and real-time control

Energy & Utilities: Secure grid communication and remote monitoring

Transportation: Intelligent traffic systems and rail communication

Oil & Gas: Harsh environment networking and pipeline monitoring

Healthcare & Pharma: Precision manufacturing and compliance tracking

Industrial Ethernet's ability to offer low latency, redundancy, and scalability makes it indispensable in digitally transforming sectors. It is no longer an optional upgrade but a foundational element in building the future of industrial ecosystems.

Market Forecast The future of the Industrial Ethernet market is defined by its alignment with transformative technologies such as AI-driven automation, predictive maintenance, and 5G integration. With increasing cross-border industrial collaborations and smart infrastructure projects underway, the market is expected to experience sustained momentum. As enterprises shift towards agile and secure digital networks, Industrial Ethernet stands as the backbone of intelligent, connected industries.

Access Complete Report: https://www.snsinsider.com/reports/industrial-ethernet-market-6022

Conclusion As industrial demands evolve at an unprecedented pace, the Industrial Ethernet market emerges as a cornerstone of operational excellence and digital innovation. Its unmatched ability to connect devices, streamline operations, and foster real-time intelligence positions it as a game-changer for industries aiming to lead in the era of automation. For organizations envisioning future-ready infrastructure, embracing Industrial Ethernet isn’t just strategic—it’s essential.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Industrial Ethernet Market#Industrial Ethernet Market Scope#Industrial Ethernet Market Share#Industrial Ethernet Market Trends

0 notes

Text

AC drive ATV930D55N4

AEC switchgear provided AC drive ATV930D75N4 This Altivar Process ATV900 variable speed drive can feed 3-phase synchronous and asynchronous power motors. It is suitable for motors with power rating up to 55kW/75hp for applications requiring slight overload (up to 120%). It is suitable for motors with power rating up to 45kW/60hp for applications requiring significant overload (up to 150%). It works at a rated supply voltage from 380V to 480V AC. This variable speed / frequency drive (VSD / VFD) is specifically designed for industrial processes. In the following market segments, oil and gas, mining, minerals and metals, food and beverage water and wastewater. It offers high motor performance on any motor and total control of any kind of coupling in master/slave applications. Network services help ensure operation continuity even in case of connection breakdown. Web server and data logging help reduce downtime through fast troubleshooting and preventive maintenance. Its advanced connectivity, including EtherNet/IP and Modbus TCP, allows deep integration into automation architectures. It is designed to be mounted in vertical position (+/- 10 °) on a wall

0 notes

Text

How NX-ERA Premium PLCs Revolutionise Textile Singeing Operations

Quality has always held a high priority in the vast and ever-evolving domain of textile manufacturing, as even a single misstep in production can lead to cascading effects, starting from product rejection, leading up to brand loss and compromised customer trust. To ensure a consistent quality in textile finishing, singeing is among the first and most critical steps in the procedure. It is a seemingly sensitive operation where surface fibres are removed using gas flames.

While it may not receive the spotlight like dyeing or printing, singeing lays the foundation for almost everything that follows. It ensures that your fabric output is smooth, clean, and primed for perfection. And in this era of fast fashion, global exports, and digitised factories, managing this process with old-school tools and controls won’t simply suffice.

This is where we at Messung Industrial Automation come in. Our NX-ERA Premium PLCs are a game-changing solution that doesn’t just automate singeing but also redefines how precision, speed, safety, and intelligence come together.

Let’s explore the heart of singeing operations and discover how this Programmable Logic Controller is igniting a silent yet mighty revolution in the textile industry.

Textile Singeing: The First Touch of Refinement

Singeing is a thermal pre-treatment process where the surface fuzz or the protruding fibres on a fabric are burnt off using a controlled gas flame. This eliminates any loose threads or lint that could interfere with the dye penetration or printing clarity.

However, its benefits extend far beyond just aesthetics. They include:

Improved dye absorption and print sharpness

Premium feel through smoother fabric texture

Enhanced garment durability with reduced pilling

Less linting, critical for cleanroom or medical textiles

Compliance with international quality standards, especially in exports

When done right, singeing transforms a raw textile material into a high-value product which is ready for further treatment.

The Complexity Behind

At first glance, singeing might appear as a very straightforward flame treatment, but in practice, it is a process that juggles multiple moving parts with split-second precision. The variables in play are:

Controlling flame intensity and width based on the fabric type and speed.

Tightly monitoring the temperature to avoid scorching

Fabric speed impacts flame exposure time and must be regulated in sync with the burners

Safety systems must be in place to detect flame irregularities, gas leaks, and other emergencies

Include flexibility and minimal downtime for smooth process changeovers.

Due to all these variables, traditional relay-based systems or low-end PLC control systems often fall short, lacking the finesse, feedback loops, or integration capabilities required for modern singeing lines.

The Rise of NX-ERA Premium PLCs by Messung

Recognising the gap between process needs and available automation tools, we at Messung designed NX-ERA Premium PLCs, a high-speed, modular PLC system that is tailored for demanding applications like singeing.

What makes it “Premium”?

The reasons include:

Advanced CPU with nanosecond-level scan cycles

Real-time analogue and digital input processing

Built-in PID loops for fine-tuned temperature control

Modbus TCP/IP and other industrial protocols for easy integration

SCADA-ready architecture for centralised visibility and remote access

Modular I/O scalability for future expansion

This makes NX-ERA not just another PLC controller, but a smart, robust platform designed to thrive even in high-heat and high-stakes environments like those of textile factories.

How NX-ERA Powers Every Element of Singeing

Let’s break down how this industrial automation PLC transforms every aspect of the singeing line.

Flame Control: Precision like never before

At the heart of singeing is the burner, and controlling its intensity, width, and modulation in real time is where our NX-ERA shines.

Analogue inputs from flame sensors feed data directly to the PLC

PID Loops automatically adjust the burner valves

Real-time modulation ensures uniform heat distribution

Result? Consistent singeing with no under- or overt treated sections.

Temperature Monitoring: Accuracy that protects

Using feedback from pyrometers or infrared sensors, NX-ERA maintains a tight grip on the burner zone temperature.

Avoids fabric scorching by reacting to even minor spikes

Keeps flames within the desired thermal envelope

Enhances burner efficiency by reducing unnecessary gas usage

This level of temperature control is mission-critical for fine or synthetic fabrics

Fabric Speed Synchronisation: Seamless flow control

Singeing isn’t just about the fire; it is also about the timing. NX-ERA synchronises:

Drive Motors

Rollers

Tension Sensors

This helps in regulating the fabric speed precisely. Whether it is a slow-moving wool or a high-speed polyester line, speed and flame remain in perfect harmony.

Built-in Safety: Because lives are on the line

Working with gas burners has its risks. Therefore, to immediately halt the operations in case of abnormal conditions, NX-ERA integrates:

Flame detectors

Gas leak sensors

Emergency shutdown circuits

With redundant CPUs and power modules, the system ensures zero single-point failures, maximising safety for both the operators and the assets.

Process Optimisation: recipe for automation intelligence

Different fabrics have different treatment parameters. NX-ERA stores fabric-specific recipes that easily control:

Flame profile

Flame speed

Temperature setpoints

Operators can switch recipes with a single command, slashing changeover time and reducing manual errors.

Unified Control with SCADA Integration

The second most important thing in modern textile manufacturing is visibility. Our NX-ERA Premium PLC seamlessly integrates with SCADA (Supervisory Control and Data Acquisition) systems, transforming traditional singeing operations into fully observable, data-driven ecosystems. This fusion empowers plant managers, process engineers, and quality heads with an unprecedented ability to monitor, analyse, and optimise operations, both in real-time and retrospectively.

Here is how this synergy delivers control and clarity:

Live dashboards showing temperatures, speeds, and flame status

Historical data logs for ISO and export audits

Alarm and fault management with timestamps

Remote troubleshooting for multi-site operations

No more guesswork. Just insight-driven control.

All this precision allows for a process control that empowers smarter and faster decision-making across the board.

Tangible Benefits for Textile Businesses

Switching to NX-ERA is a leap in operational intelligence and profitability in the segment of automation segment. Here’s how your textile businesses directly benefit from this advanced PLC automation platform:

Improved Product Quality: By maintaining precise control over flame exposure and fabric speed, NX-ERA ensures singeing consistency across the entire fabric width. This leads to smoother, cleaner surfaces, superior dye penetration, and flawless prints.

Greater Efficiency: Automated control means fewer manual adjustments, faster recipe changeovers, and minimal production interruptions. That translates to shorter cycle times, maximised uptime, and increased throughput, especially critical in high-volume manufacturing environments.

Lower Rejections and Waste: Over-singeing, scorching, or uneven treatment can ruin entire fabric batches. NX-ERA’s precision-driven system minimises these risks, reducing rejections and conserving raw materials—ultimately saving both time and cost.

Enhanced Operator Safety: With built-in safety interlocks, flame detectors, and emergency shutdown protocols, NX-ERA proactively safeguards both personnel and equipment. Safety becomes predictive, not reactive.

Lower Energy and Maintenance Costs: The system fine-tunes burner performance based on real-time feedback, ensuring optimal energy usage. At the same time, it flags maintenance needs before breakdowns occur, driving down utility bills and unplanned service disruptions.

All these benefits help your products stand out in competitive export markets.

The NX-ERA Edge Over Conventional PLCs

Basic PLCs were built for basic logic, and that’s where they stop. Today’s singeing machines demand more. Here’s where NX-ERA stands apart:

Conventional PLC Limitations:

Limited scalability for complex I/O or multi-sensor integration

Poor compatibility with SCADA or MES platforms

No redundancy, leading to system crashes or halts

Inadequate processing speed for real-time adjustments

NX-ERA Delivers:

Lightning-fast logic execution for tight control over process parameters

Redundant CPU and power modules for uninterrupted operation

Modular PLC architecture for scalable, plug-and-play expansion

Open protocol support, including Modbus TCP/IP, for seamless integration with legacy and modern systems

Whether you're building a new plant or retrofitting older machinery, NX-ERA adapts effortlessly, making it a smart, long-term investment.

Conclusion: The Edge That Sets You Apart

In a market where margins are tight and expectations are sky-high, singeing can no longer be left to chance. It’s the beginning of quality. And with NX-ERA Premium PLCs, it becomes the beginning of excellence.

From smarter flame control and temperature precision to SCADA visibility and Industry 4.0 integration, NX-ERA empowers textile mills to think big, act fast, and stay ahead.

Because in the world of textiles, smooth starts lead to flawless finishes.

FAQs

What is a PLC, and how does it benefit textile operations?

A PLC (Programmable Logic Controller) is an industrial computer that automates control processes. In textile mills, it ensures consistent quality and operational safety across processes like singeing, dyeing, and finishing.

How do PID controllers improve singeing quality?

PID controllers maintain optimal burner temperature by continuously adjusting based on feedback. This prevents overheating or under singeing, resulting in uniform treatment.

Is NX-ERA Premium suitable for legacy machines?

Yes, its modular PLC architecture allows easy integration with older systems, enabling modernisation without a complete overhaul.

Can NX-ERA integrate with existing SCADA systems?

Absolutely. With Modbus and other standard protocols, NX-ERA seamlessly connects with your existing SCADA setup for real-time control and data analysis.

What makes NX-ERA a future-proof choice for Industry 4.0?

Its ability to connect with cloud systems, support for remote diagnostics, predictive maintenance, and readiness for AI make it a robust, future-proof choice for any smart textile factory.

#textile manufacturing#NX-ERA Premium PLCs#Programmable Logic Controller#smoother fabric texture#reduced pilling#Improved dye absorption#PLC control systems#modular PLC#modular PLC system#Advanced CPU#Real-time analogue and digital input processing#Modbus TCP/IP#Modular I/O scalability#PLC controller#industrial automation PLC#PID Loops#Avoids fabric scorching#redundant CPUs and power modules#NX-ERA Premium PLC#SCADA (Supervisory Control and Data Acquisition)#advanced PLC#Industry 4.0#PLC (Programmable Logic Controller)#PID controllers#SCADA systems#Modbus#SCADA

0 notes

Text

Fluke Distributor in Bangalore

The Fluke Networks Industrial Ethernet DSX CableAnalyzer™ Kit (Model: DSX2-5-IE-K1) is a comprehensive copper cable certifier designed for industrial Ethernet networks. It ensures compliance with TIA and ISO standards, supports various industrial protocols, and offers advanced troubleshooting capabilities.

🔧 Key Features

Comprehensive Certification: Validates twisted-pair copper cabling from Category 5 through 6A, ensuring adherence to TIA Level IIIe accuracy.

Rapid Testing: Provides Pass/Fail results within 10 seconds, accompanied by detailed measurement information.

Industrial Protocol Support: Compatible with cables running EtherNet/IP™, PROFINET™, Modbus TCP™, EtherCAT, and other industrial protocols.

Connector Compatibility: Supports RJ45, M12D, and M12X connectors, facilitating versatile testing options.Main Website

Advanced Troubleshooting: Identifies and locates cable issues swiftly, reducing downtime and preventing unnecessary bypass installations.

Touchscreen Interface: Features a user-friendly touchscreen with integrated project management tools for efficient operations.

Extended Battery Life: Offers up to 8 hours of continuous use on a single charge, ensuring reliability during extended testing sessions.

Comprehensive Documentation: Utilizes LinkWare™ software to document test results, supporting compliance with TIA 1005-A and ISO 11801:3 standards.

https://sapphire-tech.com/product/fluke-networks-industrial-ethernet-dsx-cableanalyzer-copper-cable-certifier-kit/

0 notes

Text

Modbus Poll Crack with serial key free Download 2025

DOWNLOAD LINK

Modbus Poll is a popular software tool designed to simulate Modbus master devices for testing and troubleshooting Modbus slave devices in industrial automation and control systems. It is widely used by engineers and technicians to monitor and troubleshoot Modbus communication, especially in the context of Modbus RTU, Modbus ASCII, and Modbus TCP/IP protocols.

Key Features of Modbus Poll:

Modbus Master Simulation:

Modbus Poll acts as a Modbus Master, enabling you to simulate communication with Modbus slave devices. You can use it to send requests (read and write operations) to connected Modbus slaves to test and verify their responses.

1 note

·

View note

Text

Ứng Dụng PLC Siemens Trong Ngành Thực Phẩm và Đồ Uống: Tối Ưu Hóa Sản Xuất và Đảm Bảo Chất Lượng

Ứng Dụng PLC Siemens Trong Ngành Thực Phẩm và Đồ Uống: Tối Ưu Hóa Sản Xuất và Đảm Bảo Chất Lượng

Ngành công nghiệp thực phẩm và đồ uống là một trong những lĩnh vực quan trọng, nơi tự động hóa đóng vai trò thiết yếu để đáp ứng các tiêu chuẩn cao về chất lượng, an toàn và hiệu suất. Trong bối cảnh đó, PLC Siemens đã trở thành giải pháp hàng đầu nhờ khả năng điều khiển linh hoạt, độ tin cậy cao và tính tích hợp vượt trội. Bài viết này sẽ khám phá cách các dòng PLC Siemens, như S7-1200 và S7-1500, được ứng dụng trong ngành thực phẩm và đồ uống, từ điều khiển quy trình chiết rót, đóng gói, đến giám sát chất lượng. Bên cạnh đó, chúng tôi sẽ cung cấp ví dụ thực tế, so sánh với các giải pháp khác và những mẹo hữu ích để triển khai hiệu quả.

1. Tổng quan về ngành thực phẩm và đồ uống Ngành thực phẩm và đồ uống không chỉ là một trong những ngành công nghiệp lớn nhất toàn cầu mà còn là lĩnh vực có yêu cầu khắt khe về quy trình sản xuất. Theo dự báo của Statista, quy mô thị trường toàn cầu của ngành này sẽ đạt 10 nghìn tỷ USD vào năm 2025, nhờ vào nhu cầu tiêu dùng ngày càng tăng. Tuy nhiên, các nhà máy trong ngành phải đối mặt với nhiều thách thức: Tiêu chuẩn an toàn thực phẩm: Tuân thủ các quy định nghiêm ngặt như HACCP, FDA và ISO 22000. Quy trình phức tạp: Bao gồm chế biến nguyên liệu, chiết rót, đóng gói và bảo quản. Sản xuất số lượng lớn: Đảm bảo chất lượng đồng đều trên quy mô lớn. Vệ sinh và bảo trì: Thiết bị cần được làm sạch thường xuyên và hoạt động ổn định. Để vượt qua những thách thức này, tự động hóa đã trở thành xu hướng tất yếu, trong đó PLC (Programmable Logic Controller) là công cụ không thể thiếu, giúp điều khiển chính xác và giám sát toàn bộ dây chuyền sản xuất. 2. Vai trò của PLC trong ngành thực phẩm và đồ uống

PLC là "bộ não" của hệ thống tự động hóa, mang lại nhiều lợi ích quan trọng cho ngành thực phẩm và đồ uống: Điều khiển chính xác: Quản lý các thông số như lưu lượng, nhiệt độ và áp suất để đảm bảo sản phẩm đạt tiêu chuẩn. Giám sát thời gian thực: Thu thập dữ liệu từ cảm biến để phát hiện lỗi và cảnh báo kịp thời. Tự động hóa vệ sinh (CIP): Điều khiển chu trình làm sạch thiết bị mà không cần tháo rời, tiết kiệm thời gian và đảm bảo vệ sinh. Tích hợp hệ thống: Kết nối với SCADA, MES và ERP để quản lý toàn diện quy trình sản xuất. Truy xuất nguồn gốc: Ghi nhận dữ liệu để đáp ứng các yêu cầu pháp lý về an toàn thực phẩm. Với hơn 50 năm kinh nghiệm, Siemens đã phát triển các dòng PLC phù hợp với mọi quy mô nhà máy trong ngành này, từ S7-1200 cho các ứng dụng nhỏ đến S7-1500 cho các dây chuyền phức tạp.

3. Tại sao chọn PLC Siemens? PLC Siemens nổi bật so với các thương hiệu khác nhờ những ưu điểm vượt trội: Ưu điểm nổi bật Độ bền cao: Hoạt động ổn định trong môi trường khắc nghiệt (nhiệt độ -20°C đến 60°C, độ ẩm cao). Hiệu suất mạnh mẽ: S7-1500 xử lý hàng nghìn điểm I/O và dữ liệu từ cảm biến với tốc độ 1 ns/lệnh. Tích hợp IoT: Hỗ trợ PROFINET, OPC UA và kết nối với MindSphere để giám sát từ xa. Dễ sử dụng: Phần mềm TIA Portal tích hợp lập trình PLC, HMI và SCADA, giảm thời gian phát triển. Hỗ trợ toàn cầu: Mạng lưới đối tác rộng khắp, như PLCSIEMENS.VN tại Việt Nam.

So sánh với đối thủ Tiêu chí Siemens S7-1500 Allen-Bradley CompactLogix Schneider Modicon M580 Tốc độ xử lý 1 ns/lệnh 2 ns/lệnh 5 ns/lệnh I/O tối đa 8192 4000 2048 Giao thức PROFINET, OPC UA EtherNet/IP Modbus TCP, EtherNet/IP Tích hợp IoT Có (MindSphere) Không Không Chi phí Trung bình-cao Cao Trung bình Siemens vượt trội về hiệu suất và khả năng tích hợp, phù hợp với các nhà máy hiện đại hóa. 4. Ứng dụng cụ thể của PLC Siemens Dưới đây là các ứng dụng phổ biến của PLC Siemens trong ngành thực phẩm và đồ uống: 4.1. Điều khiển chiết rót Mô tả: Điều chỉnh lưu lượng chất lỏng (nước, sữa, bia) khi chiết rót vào chai/lon. Ví dụ: S7-1200 điều khiển van để chiết rót 500 ml/chai với sai số ±1 ml. Công cụ: PID Control trong TIA Portal. 4.2. Quản lý đóng gói Mô tả: Điều khiển máy đóng gói để đảm bảo số lượng và chất lượng. Ví dụ: S7-1500 quản lý máy đóng gói bánh, kiểm tra trọng lượng tự động. Công cụ: Cảm biến trọng lượng và vision system. 4.3. Giám sát nhiệt độ Mô tả: Theo dõi và điều chỉnh nhiệt độ trong nấu, thanh trùng. Ví dụ: S7-1500 duy trì nhiệt độ lò nướng 180°C ±2°C. Công cụ: Module SM1231 (analog input). 4.4. Tự động hóa CIP Mô tả: Điều khiển chu trình làm sạch thiết bị. Ví dụ: S7-1200 phun dung dịch tẩy rửa theo chu kỳ. Công cụ: Chu kỳ CIP trong TIA Portal. 5. Ví dụ thực tế: Nhà máy bia Bối cảnh Nhà máy bia. Vấn đề: Chiết rót thủ công gây sai số 5-10 ml/chai, lãng phí nguyên liệu. Giải pháp: Sử dụng S7-1500 để tự động hóa. Triển khai Phần cứng: S7-1500 CPU 1516-3 PN/DP, module SM1221/SM1222, HMI TP700. Lập trình: PID Control cho van chiết rót, giao diện HMI hiển thị dữ liệu. Kết quả: Sai số giảm còn ±1 ml, năng suất tăng 20%, tiết kiệm 2% nguyên liệu.

6. Kết luận PLC Siemens là lựa chọn lý tưởng để tối ưu hóa sản xuất trong ngành thực phẩm và đồ uống. Để triển khai hiệu quả, hãy liên hệ PLCSIEMENS.VN hoặc gọi 0888-789-688 để được tư vấn chi tiết. Nguồn: https://plcsiemens.vn/ung-dung-plc-siemens-trong-nganh-thuc-pham-va-do-uong-toi-uu-hoa-san-xuat-va-dam-bao-chat-luong Read the full article

0 notes

Text

Đồng hồ đo giám sát điện năng PM5000 Series Schneider có lớp 0.2S/ 0.5S, lắp dặt dễ dàng, 4 đầu vào, ghi nhật ký dữ liệu, truyền thông Modbus RS485/ Modbus TCP/IP/ RS485 & TCP/IP, chế tạo từ vật liệu bền bỉ. Xem chi tiết tại: https://hoplongtech.com/series/pm5000

0 notes

Text

Understanding Modbus: The Universal Protocol for Industrial Communication

Modbus is a widely used communication protocol in industrial automation and control systems. Originally developed by Modicon (now Schneider Electric) in 1979, it remains one of the most popular protocols for connecting electronic devices and exchanging data in supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), and various automation applications.

How Modbus Works

Modbus operates as a master-slave (or client-server) protocol, where a master device initiates communication, and one or more slave devices respond. It is simple, reliable, and efficient, making it a preferred choice for industrial communication. The protocol is used to transmit data over serial lines (RS-232, RS-485) or via Ethernet networks (Modbus TCP/IP).

Types of Modbus Protocols

Modbus RTU (Remote Terminal Unit): A binary protocol using compact messages with cyclic redundancy check (CRC) error checking. It is ideal for real-time communication.

Modbus ASCII: Similar to RTU but uses ASCII characters, making it more readable but less efficient.

Modbus TCP/IP: Allows Modbus communication over Ethernet networks using TCP/IP protocols, making it suitable for modern industrial networks.

Key Features of Modbus

Open and Vendor-Neutral: Modbus is an open standard, meaning any manufacturer can implement it without licensing fees.

Ease of Implementation: Simple message structure and minimal processing overhead.

Interoperability: Enables different devices and systems from various vendors to communicate seamlessly.

Scalability: Supports a range of devices, from small sensors to complex industrial control systems.

Robust Error Handling: Modbus RTU uses CRC for error detection, ensuring reliable data transfer.

Applications of Modbus

Industrial Automation: Connecting PLCs, sensors, actuators, and SCADA systems.

Energy Management: Monitoring and controlling power meters and generators.

Building Automation: HVAC control, lighting systems, and access control.

Water and Wastewater Management: Supervising pumps, valves, and treatment facilities.

Oil and Gas Industry: Remote monitoring of pipelines and drilling operations.

Challenges and Limitations

Despite its advantages, Modbus has some limitations:

Limited Data Security: Traditional Modbus lacks built-in encryption, making it vulnerable to cyber threats.

Slower Speed Compared to Modern Protocols: Serial-based Modbus RTU can be slower than newer protocols like Ethernet/IP or MQTT.

Single-Master Limitation: Classic Modbus architectures typically allow only one master device, restricting flexibility.

Future of Modbus

With the advent of Industry 4.0 and Industrial IoT (IIoT), Modbus continues to evolve. Modern adaptations like Modbus TCP/IP and secure Modbus variants are making it more compatible with smart factories and cloud-based systems. Its simplicity and reliability ensure that it remains relevant in industrial automation for years to come.

Conclusion

Modbus is an essential protocol in industrial communication, providing a simple yet powerful way to connect and control devices. Its widespread adoption, open standard nature, and continuous evolution make it a critical component in modern automation and control systems. As industries transition to smart manufacturing, Modbus will likely continue to play a significant role in bridging legacy systems with modern technologies.

0 notes