#Modular PLC Design

Explore tagged Tumblr posts

Text

Future-Proof Building Operations with NX-ERA Premium PLC Redundant Systems

In the domain of intelligent infrastructure, building intelligence is no longer a privilege but has become a requirement. Modern buildings, be it skyscraper business complexes, advanced healthcare institutions, or high-end hospitality centres function as living, breathing ecosystems. These types of buildings heavily depend on a Building Management System (BMS) to regulate HVAC, lighting, elevators, energy, and security systems.

Yet a single failure within the control system will bring these systems to a grinding halt, leading to operational disruption, safety hazard, tenant dissatisfaction, and regulatory non-compliance. This is where Messung's NX-ERA Premium PLC Redundant Systems, our state-of-the-art control solution for future-proofed infrastructure, come into play with their reliability, accuracy, and scalability.

Let us explore how NX-ERA provides intelligence, continuity, and scalability to your buildings through this blog.

The Evolution of Building Control Systems

Traditional relay-based control panels were able to handle building services in the past. Nowadays, buildings are far more advanced. Real-time data, multi-zone control, preventative maintenance, energy optimisation, and safety systems all require more intelligence.

Programmable Logic Controllers (PLCs) are the cornerstones of such a revolution. Although not all PLCs are alike.

The NX-ERA Premium PLC transforms building automation with a fail-safe, redundant design architecture that maintains your operations no matter what, and scales beautifully with your growing infrastructure.

Why Choose NX-ERA Premium PLCs?

Our NX-ERA platform is more than a PLC; it is an architecture that enables smart building management with unparalleled reliability.

Key Features:

Redundant Architecture: Two CPUs, two power supplies, and two communications modules offer zero downtime.

High-Speed Data Processing: Facilitates prompt decision-making between various sub-systems.

Remote Access PLC: Control, monitor, and troubleshoot anywhere.

Modular PLC Design: Flexible and scalable to project size and future requirements.

Intelligent PLC Capabilities: Sophisticated analytics, alarms, and diagnostics.

Built-in SCADA Integration: Integrated central control and visibility of the whole facility.

We have designed NX-ERA for round-the-clock use in the most demanding scenarios, starting from hospitals and IT parks to shopping malls and industrial clusters.

Application-Centric Design for Mission-Critical Infrastructure

In today's high-performance buildings, every system, air conditioning, lighting, fire detection, or security, has an important function to provide comfort, safety, and efficiency. Our NX-ERA Premium PLC is designed keeping this in mind. It is specifically made for use in mission-critical environments and allows for precise, continuous control of all major building services.

1.HVAC & Climate Control - NX-ERA provides advanced control of HVAC systems, controlling air conditioning, humidity, and ventilation with multi-zone precision. With open sensor integration, it provides condition-based automation, modulating airflow, temperature, and filtration in real time. This provides maximised indoor air quality and major energy savings, particularly in variable-occupancy buildings.

2. Lighting Automation - From programmed schedules to daylight-responsive dimming, NX-ERA regulates lighting between corridors and floors. It allows daylight harvesting by adjusting artificial lighting based on ambient conditions, saving energy without sacrificing occupant comfort. Smart lighting control also minimises operating costs and maximises fixture life.

3. Fire and Life Safety Systems - As a Safety PLC certified to operate, NX-ERA provides life-critical system support. It integrates with fire alarms, smoke detectors, and smoke extraction fans safely and reliably, with a timely response in case of emergencies. Redundant architecture ensures system availability even in the event of component failure.

4. Security & Access Control - NX-ERA controls security functions such as CCTV feeds, access readers, intruder alarms, and emergency lockdowns. It is fault-tolerant for access control and surveillance, even in the case of faults, with its dual-CPU design. Third-party system support provides seamless and scalable integration.

NX-ERA brings precision, resilience, and intelligent automation to every corner of your infrastructure, ensuring your building operates flawlessly, around the clock.

Constructing a Strong Framework with Redundant Design

NX-ERA’s architecture is designed around fail-safe principles:

Redundant CPUs are in hot standby, providing instant takeover if the primary CPU fails.

Duplicate Power Supplies provide a continuous power supply, avoiding shutdowns caused by voltage instability or failure.

Dual Communication Modules remove the threat of being disconnected from field devices or SCADA.

Programmable Logic Controllers provide deterministic behaviour and quick response times for real-time control.

This is the level of redundancy that must ensure the PLC Control Systems are single-point failure-proof and properly compliant with safety standards.

Smooth Integration with Building Ecosystems

NX-ERA is specifically designed for comprehensive, integrated control of building operations. Interoperability is its basis.

Native MODBUS TCP/IP communication for easy integration with third-party devices such as energy meters, smart sensors, HVAC devices, lighting panels, and fire safety devices.

It aggregates independent systems onto a single SCADA dashboard, providing a live view of all building services operating.

Remote diagnostics and centralised control enable facility managers to observe, investigate, and react to inefficiencies or faults from a central command centre—or any other location with secure access.

NX-ERA also supports seamless interaction with modern IoT systems like occupancy analytics, air quality monitoring, and asset tracking, making conventional buildings responsive, adaptive spaces.

Whether you are installing new infrastructure or expanding existing installations, NX-ERA keeps your architecture flexible, networked, and future-proof.

Real-Time Intelligence for Smarter Facilities

NX-ERA is not just a control system—it's a smart decision-making platform. Its data-driven performance offers real-time insights that raise operational effectiveness:

Offers high-resolution data logs for all parameters—temperature, voltage, energy consumption, etc.

Fully integrated with Energy Management Systems, supporting predictive load balancing, peak demand management, and actionable energy intelligence.

Generates predictive alerts for anomalies such as HVAC inefficiencies, equipment fatigue, or sensor deviations, helping prevent breakdowns before they occur.

Stores complete, tamper-proof logs that support regulatory audits and compliance with ISO standards, LEED guidelines, and other sustainability certifications.

With NX-ERA, facility managers can depart from reactive repair towards proactive, data-driven facility management.

Built to Scale, Built to Last

Growth and sustainability are the major pillars of the existence of any building. NX-ERA guarantees your automation system grows with your building while meeting environmental goals:

Modular structure allows you to add I/O points, add new subsystems, or accommodate newer technologies without redesigning the system.

Fully supports IoT-enabled smart metering, leak detection for water, predictive HVAC control, and occupancy analytics.

Facilitates LEED and green building certifications by maintaining constant energy audits, performance benchmarking, and real-time carbon footprint tracking.

Perfectly complements digital transformation initiatives, setting the stage for cloud analytics, AI, and automation-ready.

NX-ERA is your control companion, not just for today’s needs, but for tomorrow’s smart infrastructure vision.

Messung: Reliable Across Industries

For more than four decades, Messung has spearheaded India's industrial automation process with high-performance, dependable PLC solutions. NX-ERA Premium PLC is used in a broad range of mission-critical industries:

Data centres need constant uptime and exact environmental control.

Hospitals where life-saving equipment has to work without any failure.

Office towers with intricate lighting, HVAC, and elevator systems.

Residential high-rise buildings require energy efficiency and safety.

Plant operations where lost time equates to high operating costs.

Every NX-ERA deployment is backed by thorough testing, sophisticated lifecycle support, and intimate customer knowledge to deliver performance with confidence.

When to Upgrade to NX-ERA

Use NX-ERA if:

Your business requires no interruption of business.

You are grappling with legacy PLC failures or integration issues.

You're targeting PLC Automation for mission-critical sub-systems.

You need audit-quality logs to achieve ISO or LEED certification.

You're growing and require Remote Access PLC functionality.

NX-ERA is designed to fulfil your current requirements and long-term ambitions.

Conclusion: Join Messung for Uninterrupted Brilliance

In a world where building systems are designed to work flawlessly, learn intelligently, and expand seamlessly, your automation partner can be the difference-maker. At Messung Industrial Automation, we realise that infrastructure today requires more than control; it demands resilience, precision, and vision.

Our NX-ERA Premium PLC Redundant Systems reflect these principles. Not only do they provide fault-tolerant automation, but they also provide a complete platform for smart building management, enabling your infrastructure to react in real time, recover immediately, and adapt continuously.

Whether your business is a hospital, data centre, office complex, or intelligent residential complex, NX-ERA is your command centre that makes you never miss a beat.

Let's redefine what's possible, together.

Contact Messung Industrial Automation to see how NX-ERA can future-proof your plant with zero downtime, maximum intelligence, and permanent peace of mind.

Select NX-ERA. Select uninterrupted brilliance.

Frequently Asked Questions (FAQs)

Why would NX-ERA Premium PLCs be ideal for mission-critical buildings?

NX-ERA Premium PLCs are designed with two CPUs, power supplies, and communications modules, which render them zero downtime in case of failure. They are ideal for units where continuous operation is crucial, including hospitals, data centres, and business complexes.

Is NX-ERA compatible with existing building systems and legacy infrastructure?

Yes. NX-ERA is an open protocol-based based, such as MODBUS TCP/IP, and is capable of being integrated with third-party equipment, legacy control panels, and contemporary IoT-based systems and is extremely flexible for new and retrofit applications.

In what ways does NX-ERA support energy efficiency and green building goals?

NX-ERA includes integration with Energy Management Systems, daylight harvesting, and advanced energy analytics that minimise energy use and support the needs of green building certifications such as LEED.

For which industries and applications is NX-ERA best suited?

NX-ERA is tailored for various industries such as healthcare, manufacturing, commercial real estate, residential townships, and mission-critical infrastructure that need smart, high-availability automation.

Can NX-ERA be remotely monitored and remotely troubleshot?

Yes. NX-ERA allows secure remote access, with real-time monitoring, diagnostics, and command execution from remote locations, reducing response time and maintenance cost.

#NX-ERA Premium PLC#Building Management System (BMS)#Programmable Logic Controllers (PLCs)#Modular PLC Design#SCADA Integration#HVAC systems#Smart lighting control#Safety PLC#Duplicate Power Supplies#MODBUS TCP/IP#HVAC devices#modern IoT systems#Energy Management Systems#IoT-enabled#PLC solutions#NX-ERA Premium PLC Redundant Systems#MODBUS#healthcare#manufacturing#commercial real estate#residential townships#mission-critical infrastructure

0 notes

Text

What is the installation space requirement and power consumption?

Planning for both production capacity and practical installation needs—namely, power consumption and floor space—is crucial when thinking about buying a square-bottom paper bag maker. Your factory layout, monthly operating expenses, and long-term scalability are all directly impacted by these two variables.

At Prakash Machineries Pvt. Ltd., we design our square-bottom paper bag machines to be Whether you’re running a large industrial setup or launching a small startup, our machines are built to integrate smoothly into your workspace without demanding major infrastructure upgrades.

In this guide, we explain the power and space requirements of our square-bottom paper bag machines and how you can prepare your facility for successful installation and operation.

⚡ Power Consumption: Designed for Energy Efficiency

Our machine is equipped with servo-driven motors, automated PLC controls, and energy-optimized components to ensure high productivity with minimal energy use. On average, the power consumption of our square-bottom paper bag-making machine falls between

✅ 10 kW to 14 kW per hour

(Depending on the machine model, size range, and optional attachments)

🔋 Breakdown of Power Usage:

Component Approximate Load Main motor (servo drive) 5–7 kW Vacuum pump 2–3 kW Gluing system & heater (if any) 1–2 kW Control panel and sensors 0.5–1 kW Optional attachments (printer, handle unit) 1–2 kW

This efficient power profile means that you won’t need industrial-scale electricity infrastructure to run the machine. Even for startups or medium-scale units, a standard 3-phase connection with a 20–25 HP (horsepower) supply is typically sufficient.

✅ Monthly Cost Estimate:

Assuming 8 hours/day of operation at an average of 12 kW/hr:

12 kW × 8 hours × 30 days = 2,880 kWh/month

At ₹8/kWh (approx. industrial rate in India), monthly electricity cost = ₹23,000

This makes our machine a cost-effective production solution, especially when you compare the high output capacity (up to 192,000 bags/day) with the low operational expense.

��� Required Space for Installation

Our square-bottom paper bag machines are compact, modular, and engineered to occupy minimal floor space while still offering full production capabilities.

✅ Recommended Installation Area:

20 feet (L) × 8 feet (W) for standard machines 25 feet (L) × 10 feet (W) if optional units (e.g., printer, handle pasting) are included

🏭 Ideal Layout Plan Includes:

Machine footprint—main operational unit

Paper roll loading area—space for jumbo rolls (up to 1 m wide)

Bag collection table—output stacking and packing zone

Operator movement zone—minimum 3 ft clearance on each side

Electrical control cabinet—attached or wall-mounted

Optional space—for printer unit, handle applicator, or lamination feeder (if installed)

Our machines can be installed in a production unit as small as 500–600 sq. ft. You do not need a massive industrial hall. Even a startup with a moderate factory space can begin production seamlessly.

🛠️ Site Preparation Checklist

Before installation, ensure the following infrastructure is in place:

✔️ Electrical Requirements:

3-phase power connection (415V)

A stabilizer or UPS recommended for voltage fluctuation zones

Isolated circuit breaker and control panel for machine safety

✔️ Space & Foundation:

Flat, concrete floor surface (leveling required)

Dust-free, dry environment for optimal performance

Space for operators to safely move around machine

✔️ Ventilation & Safety:

Basic ventilation or exhaust fans (especially in hot climates)

Fire safety measures as per industrial compliance

Proper lighting for operator visibility

💡 Why This Matters to Your Business

Understanding your power and space needs in advance helps you

Avoid delays in installation

Ensure uninterrupted production

Optimize your floor plan for raw material, output, and manpower

Control operational costs with energy-efficient planning

This is especially crucial for startups, small businesses, or factories expanding capacity, where space and energy planning affect both short-term efficiency and long-term profitability.

🔧 Our Support Includes:

At Prakash Machineries Pvt Ltd, we don’t just deliver machines—we offer end-to-end installation support, including:

Pre-installation guidance (electrical, civil layout)

Custom floor plans for your site

On-site machine setup and calibration

Operator training and troubleshooting

Maintenance and after-sales service

🏁 Conclusion: Compact. Efficient. Installation-Ready.

Our square-bottom paper bag-making machines are designed to be energy-efficient and space-friendly—ideal for both high-output factories and compact manufacturing setups. With low power consumption (10–14 kW) and a compact footprint (under 250 sq. ft.), you can begin or scale up your paper bag production with minimal infrastructure investment.

📞 Plan Your Factory Setup With Us

Want help designing your factory layout? Need a customized installation guide for your plant? We’re here to help.

👉 Contact Prakash Machineries Pvt Ltd to get a personalized site layout, electrical requirement checklist, or expert consultation to prepare your facility for high-speed, efficient paper bag production.

#manufacturer#paper bag manufacturer#paper bag#paper#machines#flexo#v bottom#square bottom#alien stage#baking#bags#cake#chris sturniolo#cooking#critical role#dan and phil#delicious#breakfast#chocolate

1 note

·

View note

Text

Sand Washer Market Size, Anticipating Growth Prospects from 2033

According to recent analysis by Fact.MR, the global sand washer market is expected to grow from USD 1 billion in 2023 to USD 1.65 billion by 2033, at a compound annual growth rate (CAGR) of 5%.

Sand washers improve sand quality by removing contaminants like clay and silt. They work by separating dirt and debris from the water and sand mixture. Typically used alongside a filter for additional water purification, sand washers come in manual and electric varieties. Manual models use a brush to agitate the water, while electric machines use an impeller to mechanically spin the water in a drum.

For more insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=3177

Globally, the demand for sand washers is rising due to their diverse applications across industries like construction, mining, and electronics. Sand washers are employed alongside sand-making equipment to remove stone powder and other impurities from the sand produced.

The increasing need for clean building materials in civil construction projects and the widespread use of sand washers in wet process mining are key drivers of market growth. These devices are used to wash a variety of materials, including concrete, sand, manganese ore, and gold ore.

Key Takeaways from Market Study

The global sand washer market stands at a value of US$ 1 billion in 2023.

Global demand for sand washers is set to increase at a CAGR of 5% from 2023 to 2033.

Use of sand washers in quarry washing applications is predicted to increase at a CAGR of 5.1% over the decade.

Worldwide sales of sand washers are forecasted to reach US$ 1.65 billion by 2033.

The market in China is predicted to rise at 5.6% CAGR over the next ten years.

“Sand and stones produced from large-scale manufactured sand and stone crushing units have to be segregated and washed to produce highly marketable materials to be used in construction, for which, sand washers are required. For manufacturers of quarry washing sand washers, major profits are generated through aftermarket spares, services, and technical support,” says a Fact.MR analyst

Winning Strategy

Leading sand washer manufacturers are focusing on quality control, advanced technology integration, and adherence to product standards to boost revenue. They are heavily investing in R&D to develop innovative products and strengthen their market position. Key players are also emphasizing new developments, strategic collaborations, and efficient supply chain management to meet rising product demand.

To reduce environmental impact, many companies are introducing eco-friendly sand washers. This approach not only attracts new customers but also encourages existing ones to switch to more sustainable solutions.

Prominent producers are expanding their market share by prioritizing product innovation and strengthening partnerships, distribution networks, and regional presence.

For example:

In 2019, McLanahan launched the Modular Ultra-Wash, which has a capacity of 365 TPH and can produce two types of sand products.

In 2020, at CONEXPO-CON/AGG in Las Vegas, CDE Global introduced the 500 TPH ComboTM X900, specifically designed for the material processing industries in North and Latin America.

Key Companies Profiled

CDE Global Ltd.

Dernaseer Engineering Ltd.

Hydria Water

McLanahan

Powertrac Inc.

Propel Industries

Superior Industries, Inc.

The Weir Group PLC

Zhengzhou Unique Industrial Equipment Co., Ltd.

Key Segments of Sand Washer Industry Research

By Type:

Wheel

Spiral

By Capacity:

Below 50 T/H

50 to 100 T/H

101 to 150 T/H

151 to 200 T/H

201 to 300 T/H

Above 300 T/H

By Portability:

Stationary

Mobile

By Power Consumption:

Below 10 kW

10 to 25 kW

26 to 50 kW

51 to 100 kW

Above 100 kW

By End Use:

Quarry Washing

Ore Washing

Sand & Gravel Washing

Others

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

More Valuable Insights on Offer

Fact.MR, in its new offering, presents an unbiased analysis of the global sand washer market, presenting historical demand data (2018 to 2022) and forecast statistics for the period (2023 to 2033).

The study divulges essential insights on the market based on type (wheel, spiral), capacity (below 50 T/H, 50 to 100 T/H, 101 to 150 T/H, 151 to 200 T/H, 201 to 300 T/H, above 300 T/H), portability (stationary, mobile), power consumption (below 10 kW, 10 to 25 kW, 26 to 50 kW, 51 to 100 kW, ABOVE 100 kW), and end use (quarry washing, ore washing, sand & gravel washing), across five major regions of the world (North America, Europe, Asia Pacific, Latin America, and MEA).

𝐂𝐨𝐧𝐭𝐚𝐜𝐭: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

PLC Programming Using CODESYS: Powering Industrial Automation

Programmable Logic Controllers (PLCs) are the backbone of industrial automation, and programming them effectively is crucial for efficient manufacturing and process control. CODESYS (Controller Development System) is a leading IEC 61131-3 compliant software platform that simplifies PLC programming, offering a versatile environment for engineers. Widely used across industries like manufacturing, energy, and robotics, CODESYS enables the creation of robust, scalable control solutions. This article explores the fundamentals, features, programming process, applications, benefits, challenges, and future of PLC programming using CODESYS as of July 28, 2025.

What is PLC Programming Using CODESYS?

PLC programming involves writing code to control machinery and processes through a PLC, a ruggedized computer designed for industrial environments. CODESYS is an integrated development environment (IDE) that supports multiple programming languages as defined by the IEC 61131-3 standard, including Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Instruction List (IL), and Sequential Function Chart (SFC). This flexibility allows engineers to tailor solutions to specific needs, from simple relay logic to complex algorithms, using a single platform.

Key Features of CODESYS

CODESYS stands out with its comprehensive features:

Multi-Language Support: Offers five IEC 61131-3 languages, catering to diverse programming preferences.

Real-Time Capabilities: Ensures precise timing for time-critical applications.

Integrated Debugging: Provides tools for simulation, tracing, and error detection.

Hardware Independence: Supports a wide range of PLC hardware from different manufacturers.

Object-Oriented Programming (OOP): Enhances code reusability and modularity in newer versions.

Programming Process with CODESYS

The PLC programming process using CODESYS follows a structured approach:

Project Setup: Define the hardware configuration and create a new project in CODESYS.

Code Development: Write programs using chosen IEC 61131-3 languages, such as ST for complex logic or LD for traditional relay-based control.

Simulation: Use the integrated simulator to test code offline before deployment.

Download and Debugging: Transfer the program to the PLC and use debugging tools to monitor and adjust performance.

Maintenance: Update and optimize code as process requirements evolve.

For example, programming a conveyor system might involve using FBD to define motor control logic and ST to handle variable speed adjustments, all tested within CODESYS.

Benefits of Using CODESYS for PLC Programming

CODESYS offers several advantages:

Standardization: Adherence to IEC 61131-3 ensures compatibility and portability across platforms.

Efficiency: Reduces development time with reusable libraries and templates.

Flexibility: Supports diverse applications, from small machines to large production lines.

Cost-Effectiveness: Eliminates the need for multiple proprietary software tools.

Scalability: Easily adapts to expanding or changing industrial needs.

Applications Across Industries

CODESYS-powered PLC programming is vital in various sectors:

Manufacturing: Controls assembly lines, robotic arms, and packaging systems with precision.

Energy: Manages power distribution and renewable energy systems like wind turbines.

Automotive: Automates testing rigs and production processes in vehicle manufacturing.

Water Treatment: Regulates pumps, valves, and filtration systems for efficient operation.

Building Management: Oversees HVAC systems and lighting controls in smart buildings.

Challenges in PLC Programming with CODESYS

Despite its benefits, challenges exist:

Learning Curve: Mastering multiple languages and the IDE requires significant training.

Hardware Compatibility: Ensuring seamless integration with specific PLC hardware can be complex.

Real-Time Constraints: Meeting strict timing requirements demands optimized code.

Maintenance Issues: Updating legacy systems programmed in older versions can be difficult.

Security Risks: Network-connected PLCs are vulnerable to cyberattacks, necessitating robust safeguards.

Future Trends in CODESYS PLC Programming

The future of CODESYS is shaped by technological advancements:

Industry 4.0 Integration: Supports IoT and data exchange for smart factories.

Artificial Intelligence: AI-driven optimization of control logic enhances efficiency.

Cloud Connectivity: Enables remote monitoring and programming via cloud platforms.

Enhanced Security: Incorporates advanced encryption and cybersecurity features.

Edge Computing: Processes data locally on PLCs, reducing latency.

As of July 28, 2025, these trends align with the global shift toward intelligent automation, making CODESYS a forward-looking solution.

Role in the Automation Lifecycle

CODESYS plays a key role throughout the automation process:

Design Phase: Facilitates initial control strategy development.

Implementation Phase: Deploys and tests code on PLC hardware.

Operation Phase: Monitors and adjusts system performance in real time.

Upgradation Phase: Supports seamless updates to meet new requirements.

Career Opportunities

Professionals skilled in CODESYS PLC programming are in high demand. Roles include automation engineer, control systems designer, and PLC programmer, with opportunities in manufacturing, energy, and tech sectors. Certifications in CODESYS, combined with hands-on experience, lead to competitive salaries and career growth as automation expands.

Conclusion

PLC programming using CODESYS empowers engineers to build efficient, reliable, and scalable industrial automation solutions. Its adherence to international standards, versatility, and evolving features make it a preferred choice across industries. Despite challenges like complexity and security, advancements in AI and IoT promise to enhance its capabilities. As of July 28, 2025, CODESYS remains a cornerstone of modern automation, driving innovation and productivity in the industrial world.

0 notes

Text

Buy Refurbished Danfoss Automation Products in Switzerland

The quest for high performance in automated systems is growing quickly in the market today. Advanced manufacturing and energy-efficient building systems are examples of industries where automation is the basis for modern advancements. For companies in Switzerland looking for solutions that also make sense economically, the refurbished route has emerged as a thoughtful and sustainable choice. Danfoss is one of the most trusted brands in the industry and a world leader in automated technologies that promote high performance and energy conservation. And now, for companies in Switzerland using platforms like `Automation-Warehouse,` Danfoss is offering Swiss industry access to extremely high-quality Danfoss automation products at greatly reduced prices.

The Growing Value of Industrial Automation

In Switzerland, we are known for being precise, innovative, and industrious—and not just in the watch or chocolate industry! Automation in many industries, such as pharmaceutical, food processing, mechanical engineering, and energy, has become an ingrained necessity rather than a luxury. Automated solutions create productive and scalable solutions while yielding fewer human errors in processes. But the upfront cost to outfit a facility with new technology can be significant, especially for small to medium-sized businesses.

Refurbished automation technology fills these gaps. Refurbished automation technology allows for access to high-quality technology at a fraction of the price while being more sustainable by extending product life cycles and reducing electronic waste. Refurbished Danfoss components provide plenty of opportunities through refurbished automation technology and components!

Why Choose Danfoss Automation Products?

Danfoss is a name synonymous with reliability, efficiency and high engineering quality. Danfoss’ automation portfolio includes numerous drives, controllers, sensors and soft starters designed to improve efficiencies in many applications in the industrial space. Danfoss components are designed to robust standards intended for long life expectancy, even beyond refurbishment.

Danfoss’ most commonly used automation products are:

VLT Drives: Used for energy efficiency and tight control of motors

Soft Starters: Creates an easier spike of mechanical stress on physical equipment and the power networks

Pressure & Temperature Sensors: Provide accurate data in critical systems

PLC Modules and Controllers: Provide thoughts around reliable process control and logic execution

The Danfoss automation products maintain a steady presence in HVAC, water treatment, manufacturing and heavy industries. Due to their durable physical build and modular design, these automation products are very suitable for refurbishment and ensure strong performance well beyond their first lifecycle.

Understanding Refurbished Automation Equipment

The word "refurbished" can be a troublesome word for many people. However, in the world of industrial automation, "refurbished" typically refers to used or previously owned equipment that has been inspected, repaired, tested, and cleaned by a professional inspection company. Many refurbished products are functionally and aesthetically just like new. Quality refurbished items are often just as good as brand new, particularly from reliable sources, like Automation-Warehouse. Each refurbished product is inspected for functioning and compatibility and has been checked for safety. For example, the refurbished Danfoss drive we have consistently tested for power output, programming, and motor control. All we are doing is assessing it to make sure it will function in the real world and if it will meet expectation levels. In Switzerland, where precision is paramount, having access to expertly refurbished automation parts provides an excellent opportunity for industries to expand or maintain operations without compromise.

Why Switzerland’s Industries Are Turning to Refurbished Solutions

Swiss industry is promoting the benefits of both cost and resource efficiencies. Refurbished automation equipment will enable businesses to: 1. Reduce CapEx costs with the same level of reliability 2. Provide sustainability by minimizing waste and the use of resources 3. Acknowledge compatibility with legacy systems which are still in operation 4. Affordably obtain obsolete or rare parts which enhance business continuity Businesses operating in environments which are heavily regulated, such as in pharmaceuticals or food processing, require that their control systems are consistent and reliable. All Danfoss automation products (products include obsolete versions of legacy products) provide this need, and refurbished versions continue to extend these products at affordable levels to a wider range of users. Automation-Warehouse: Your Trusted Source in Switzerland

Automation-Warehouse is a dominant source for surplus and refurbished industrial automation equipment. We are not authorized distributors for Danfoss; however, we have procured, with independent and verifiable sources, quality Danfoss products to sell to customers at a fair price. Their inventory includes hundreds of Danfoss automation products, from discontinued legacy models to current-generation systems, many of which are difficult to find elsewhere. Every product listed is marked for stock status, pricing, and technical specifications, ensuring transparency and ease of selection. Additionally, Automation-Warehouse ships worldwide from Switzerland and Hong Kong, making it an efficient and accessible partner for industries in Zürich, Basel, Bern, and beyond.

Benefits of Buying from Automation-Warehouse

When it comes to buying refurbished automation products, trust and service are as important as price. Here's how and why Swiss customers keep returning to Automation-Warehouse:

1. Full Testing and Quality Control

Every Danfoss unit is fully tested before it is available for sale. You can be assured of the quality of your investment, and the performance will last.

2. Competitive Price Including Warranty

Price points are often the driver of the selection, but also assurance. Automation-Warehouse offers up to a 3-year warranty on selected refurbished products, similar to warranties available with new equipment. That is assurance and a level of confidence that speaks volumes for their quality.

3. Global Express Delivery

Express delivery service and commitments are key attributes of our Swiss customers' selection. With FedEx and DHL services around the world, Swiss clients get their products when, where and how they want, with real-time order and delivery process updates. It is all about service.

4. Safe and Secure Payment Options

All payment processing is handled and completed through third-party gateway systems in compliance with PCI and ISO 27001 standards, which ensures that customer data is safe and secure when processing customer data.

5. Support and Customer Care

With trained staff available by email, Swiss customers get fast and accurate answers to business process, technical questions or supply chain clarification.

Tips for Buying Refurbished Danfoss Products

When making a purchase, it is important to remember this statement: 1. Determine your specifications: Make sure you are clear on the model number, voltage rating, firmware version, and connection type you require. 2. Ask for any documentation: Many refurbished units come with product manuals, wiring diagrams or tools used for configuration. In the case of automation-warehouse, it will include it if possible! 3. Verify compatibility; be sure that if you are integrating a refurbished unit into an older system, it is compatible with other components and software with it. 4. Understand warranty terms: make sure you know what is covered and how you claim the warranty or support if needed. 5. Remember your spare parts: Having critical spare parts will minimize downtime in case there are any issues in the future.

Industries That Benefit the Most

While almost any industrial operation can benefit from Danfoss automation products, some sectors in Switzerland are particularly suited for refurbished solutions: Pharmaceutical Manufacturing: High precision and process control Food & Beverage Processing: Consistency, hygiene, and compliance Renewable Energy Plants: Wind and hydro control systems Water & Wastewater Management: Sensor-driven process automation HVAC & Building Automation: Energy-efficient system optimisation For these applications, using high-grade yet affordable automation systems can make a significant impact on both performance and profit margins.

The Sustainability Advantage

With its dedication to sustainability, Switzerland makes upgraded automation products a green environmental choice because when companies reuse high-quality materials, they are hitting both green goals and circular economy markers, and are reducing their operational waste and carbon footprint. When companies can save Danfoss components from the landfill, they reduce the energy and materials needed to make new versions, while getting very good performance and reliability in the replacement components. Final Thoughts

Refurbished Danfoss automation equipment gives teams in the Swiss industry a practical, economical and environmentally friendly alternative to purchasing new equipment. Whether you are replacing older products, expanding existing systems, or looking for a more intelligent way to reduce automation costs, high-quality refurbished components should be considered. For example, if you choose Automation-Warehouse as your supplier, you will benefit from a deep inventory of tested Danfoss parts (some are even "tested to destruction"), industry-leading warranties, and worldwide shipping! A hassle-free way to add uncompromising automation technology to your portfolio, without the heavy price tag.

0 notes

Text

Investment Surge in Oil Infrastructure Drives Heat Tracing Market

The global electric heat tracing systems market was valued at US$ 2.8 Bn in 2022 and is projected to reach US$ 5.7 Bn by the end of 2031, expanding at a CAGR of 8.3% from 2023 to 2031. This robust growth is fueled by increasing investments in oil and gas infrastructure and rising global energy consumption. As industries seek reliable and energy-efficient thermal management systems, electric heat tracing is rapidly emerging as a preferred solution over conventional steam tracing.

Market Dynamics

1. Surge in Oil & Gas Infrastructure Development

One of the primary drivers of market expansion is the ongoing investment in oil and gas infrastructure, particularly in pipelines, tanks, and offshore facilities. The global demand for crude oil, as highlighted by the International Energy Agency, rose to 99.5 million barrels per day in 2022, a figure expected to rise further.

Electric heat tracing systems play a vital role in maintaining optimal temperature during hydrocarbon transportation and refining. These systems prevent pipelines from freezing or overheating, ensuring uninterrupted operations even in extreme environmental conditions, such as those found in arctic and polar regions.

2. Preference Over Steam Tracing

Electric systems are gaining ground over traditional steam tracing owing to their lower maintenance costs, superior energy efficiency, and advanced monitoring features. According to industry estimates, the installation cost of electric heat tracing can be up to 25% less than that of steam tracing.

Moreover, electric solutions offer precise control, automation, and integration with digital monitoring platforms, enabling users to detect faults, reduce energy wastage, and enhance safety. These benefits are unavailable in steam-based systems, which are bulkier and harder to regulate.

3. Technological Advancements and Product Innovation

Ongoing technological innovation is a key enabler of market growth. Self-regulating heating cables, for example, adjust their output based on ambient temperature. This dynamic wattage adjustment ensures consistent heating while preventing overheating—making the systems safer for use with flammable liquids and gases.

The April 2022 launch of the nVent RAYCHEM STS-HV cable is a testament to this trend. Designed for high-voltage, longline heating applications, it adds to the resilience and adaptability of electric tracing in large-scale industrial projects.

Regional Market Overview

North America dominated the electric heat tracing systems market in 2022, supported by an expansive oil and gas pipeline network. According to the U.S. Energy Information Administration, the country hosts more than 200 oil pipelines, surpassing Russia and China combined. This vast infrastructure demands efficient temperature maintenance solutions, creating a thriving market for heat tracing systems.

In Asia Pacific, the market is witnessing steady growth, driven by rapid urbanization and expanding energy networks in countries such as India and China. India, for instance, has over 17,000 kilometers of natural gas pipelines, and the government is investing in further network expansion.

Industry Outlook and Competitive Landscape

Key players in the electric heat tracing systems market are focusing on product development, mergers, and strategic collaborations to strengthen their market position. Companies such as Pentair PLC, Thermon Inc., Emerson Electric Co., Danfoss, Parker Hannifin Corp., BARTEC, and eltherm GmbH are leading the innovation curve.

Their strategies include the integration of IoT and smart monitoring, development of longer and more durable heating cables, and the creation of modular systems for easy scalability. These efforts aim to cater to both industrial heavyweights and emerging applications in commercial and residential segments.

Conclusion

The global electric heat tracing systems market is undergoing a transformative phase, fueled by the rising demand for energy, need for efficient thermal management, and the growing complexity of oil and gas operations. With advancements such as self-regulating cables and intelligent monitoring systems, electric heat tracing offers unmatched reliability, safety, and cost-effectiveness.As industries shift toward sustainable and digitally enabled infrastructure, electric heat tracing systems are expected to become an integral part of thermal process control, across sectors and geographies. With a projected value of US$ 5.7 Bn by 2031, the market holds significant promise for stakeholders looking to invest in the future of industrial efficiency.

0 notes

Text

Boost Storage Strength and Efficiency with JUGMUG’s Shelf Stiffener Roll Forming Machine

In the world of storage, logistics, and retail display, the strength and durability of shelving systems are paramount. A crucial element that adds structural rigidity and load-bearing capacity to shelves is the shelf stiffener. JUGMUG RollForming, a pioneer in roll forming technology, introduces its advanced Shelf Stiffener Roll Forming Machine—a high-performance, automated solution designed to manufacture stiffeners with unmatched accuracy, speed, and consistency. Whether you're producing heavy-duty warehouse racks or elegant retail shelves, JUGMUG’s roll forming technology is engineered to meet the demands of today’s industrial standards.

What is a Shelf Stiffener Roll Forming Machine

A Shelf Stiffener Roll Forming Machine is a specialized industrial system used to fabricate long, narrow metal profiles that are fixed underneath shelving panels to improve strength and load resistance. These machines work by feeding a coil of steel or galvanized sheet through a series of rollers that gradually shape the metal into a precise cross-section, without heat or welding. These stiffeners can have multiple shapes such as hat channels, omega profiles, or custom geometries depending on the shelf design and load requirements. JUGMUG’s machine ensures exact repeatability in every profile even in high-volume production environments.

Stiffener Rollforming Machine.

Key Features of JUGMUG’s Shelf Stiffener Roll Forming Machine

Precision Roll Tooling JUGMUG engineers the roller dies with high-grade alloy steel using CNC machines for perfect shaping. Each station progressively bends the metal to achieve the desired profile without any cracks or deformities.

Robust Frame Design The machine is built on a solid steel base frame with side walls and column supports that withstand continuous vibrations and ensure long-term structural integrity.

High-Speed Operation JUGMUG’s shelf stiffener line is capable of producing profiles at speeds up to 20–30 meters per minute depending on the profile shape and material thickness.

Servo-Based Cutting System Equipped with a servo-controlled flying shear or hydraulic post-cutting unit the machine ensures accurate length cutting without halting the production process.

User-Friendly Control Panel The PLC-based touchscreen HMI allows operators to control all machine parameters set product lengths batch sizes and adjust operational speeds. Real-time monitoring and diagnostics ensure zero downtime.

Coil Handling and Decoiling Unit The decoiler unit handles large coils up to 5 tons and feeds the strip with auto-tension control for smooth operation reducing material wastage and manual error.

Applications of Shelf Stiffeners in Industrial and Commercial Spaces

Warehouse Racking Systems Shelf stiffeners provide support for storing heavy pallets boxes and inventory items. These stiffeners are essential for high-load industrial storage.

Supermarket Shelving Retail stores and supermarkets use decorative yet strong shelving systems. Stiffeners manufactured using roll forming enhance the aesthetic as well as the structural performance.

Modular Office Furniture In office storage cabinets and lockers shelf stiffeners improve weight-bearing performance while keeping the design slim and minimal.

Library and Archive Storage Long-span shelving in libraries or record rooms uses stiffened shelves to hold heavy stacks of books or files safely over time.

Why Choose JUGMUG RollForming for Shelf Stiffener Manufacturing

Customizable Design Every client has specific requirements based on profile size material and production capacity. JUGMUG offers custom roll tooling and machine configurations tailored to your business.

Turnkey Solution From coil loading to final profile cutting and stacking JUGMUG delivers a complete automated line with minimal human intervention.

Low Maintenance Long Life JUGMUG’s machines are designed for long-term use with minimal downtime. Bearings rollers and gears are easy to replace and lubricate.

Local Support and Training After installation JUGMUG provides on-site operator training and long-term service support across India and global markets.

Energy Efficiency Modern roll forming uses low power compared to stamping or welding processes. JUGMUG’s machines are optimized to minimize energy consumption while maximizing output.

Technical Specifications Typical Range

Material CR Steel GI PPGI Stainless Steel

Thickness 0.5 mm to 2.0 mm

Width Up to 300 mm

Profile Types Hat Channel Box Channel Omega Custom

Line Speed 15–30 m/min

Roll Stations 12–20 varies by profile

Control System Siemens or Delta PLC with HMI

Cutting System Hydraulic or Servo Flying Shear

Power 10–25 HP depending on configuration

Future of Roll Forming in Storage Infrastructure

As warehousing e-commerce and retail infrastructure expand rapidly in India and across the globe the demand for robust yet lightweight shelving systems is expected to rise. With innovations in metal alloys digital controls and smart automation roll forming technology will play a vital role in the next generation of smart warehouse construction. JUGMUG is already preparing for this future by developing IoT-enabled roll forming lines that offer predictive maintenance remote diagnostics and cloud integration for large-scale manufacturers.

Conclusion:

If your business depends on high-quality high-volume shelf stiffener production there’s no better partner than JUGMUG RollForming. With a legacy of engineering excellence JUGMUG offers a durable efficient and scalable solution that transforms how shelf components are manufactured. From precision roll design to robust automation every machine is built to perform last and deliver maximum ROI. Join the many satisfied clients who trust JUGMUG for their stiffener roll forming machine needs and bring unmatched strength to every shelf you produce.

#roll forming machine#custom roll forming machine#roll forming machine suppliers#power press machine

0 notes

Text

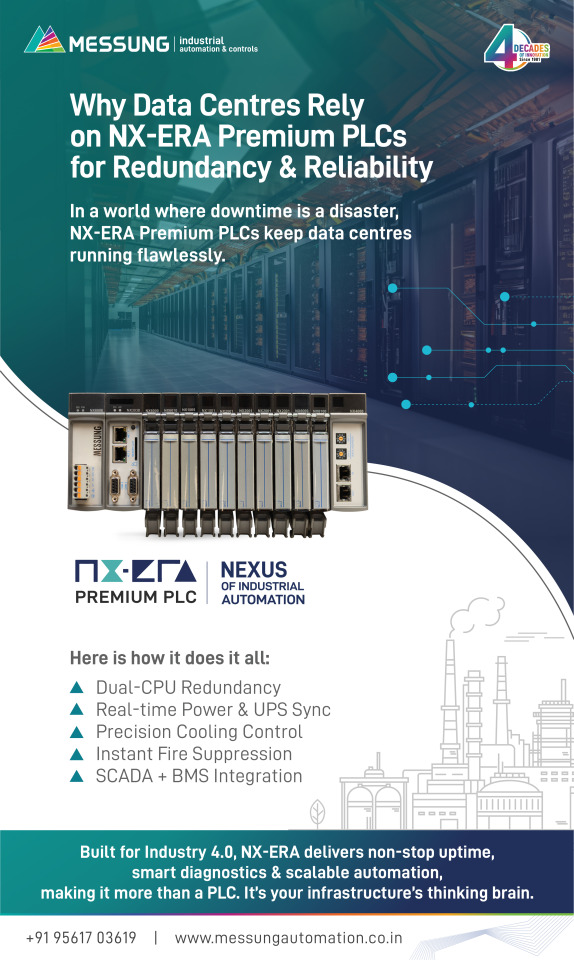

Why Data Centres Rely On NX-ERA Premium PLCs For Redundancy & Reliability

Data centres are the online headquarters of businesses today. Every click, transaction, login, or query is responded to via a data centre. In this hyper-connected world, downtime is more than a slowdown; it's a disaster.

Whether it is hosting cloud applications, running finance systems, or managing mission-critical enterprise data, data centres simply can't afford failure of control. That's why businesses often spend money on layers of redundancy, not merely power or cooling, but even on the thinking brain of their infrastructure: the Programmable Logic Controller (PLC).This is where Messung Industrial Automation's NX-ERA Premium PLCs come in as a strategic benefit, designed to provide unparalleled modular scalability, PLC redundancy, and seamless SCADA integration for control that's future-proof. For more information about NX-ERA Premium Plc visit us https://www.messungautomation.co.in/why-data-centres-rely-on-nx-era-premium-plcs-for-redundancy-reliability/

#data centres#Programmable Logic Controller (PLC)#PLC redundancy#SCADA integration#mini PLCs#Premium PLC#PLC controller#data centre automation#redundant PLC#high-speed PLC#modular PLC design#MODBUS TCP/IP#NX-ERA Premium PLCs#PLC architecture#PLC systems#Industry 4.0 PLC#AI-based decision systems

0 notes

Text

Understanding Load Cells and Their Importance in Precision Measurement: A Focus on Star EMBSYS Solutions

In the world of industrial automation, manufacturing, and precision instrumentation, accurate force measurement is a critical requirement. This is where load cell come into play. A load cell is a transducer that converts a mechanical force—such as tension, compression, pressure, or torque—into a measurable electrical signal. These devices are vital in applications that demand high accuracy, repeatability, and reliability. Companies like Star EMBSYS have carved a niche in the design and development of high-quality load cell systems, serving various industries with innovative and robust solutions.

What is a Load Cell?

A load cell works on the principle of strain gauge technology, where strain gauges are bonded to a structure that deforms under load. This deformation causes a change in electrical resistance, which is then converted into a voltage output. That voltage is proportional to the force applied to the load cell. There are different types of load cells such as compression load cells, tension load cells, shear beam load cells, and single-point load cells, each suited to different applications and environments.

Applications of Load Cells

Load cells are used in diverse fields such as aerospace, automotive testing, industrial automation, material testing, medical devices, and even in consumer-grade weighing scales. In large-scale manufacturing units, they help maintain quality control by ensuring machines apply the correct amount of force. In civil engineering, load cells monitor stress on structures like bridges or buildings. In healthcare, they are integrated into medical beds and physiotherapy equipment to monitor patient weight and force distribution.

Star EMBSYS and Load Cell Innovation

Star EMBSYS, a forward-thinking company in the embedded systems and sensor integration sector, plays a crucial role in enhancing load cell technology. Their approach is rooted in precision engineering, custom-designed solutions, and user-friendly interfaces. By combining advanced microcontroller-based systems with accurate sensor inputs, Star EMBSYS has developed load cell modules that are not only reliable but also easily integrable into broader automation systems.

Their offerings typically include both the load cell hardware and the supporting electronics like amplifiers, analog-to-digital converters (ADCs), and display systems. This ensures end-to-end control and quality, from force sensing to data output.

Key Features in Star EMBSYS Load Cell Solutions

Star EMBSYS distinguishes itself with a few critical advantages:

High Accuracy and Stability: Their systems are designed to minimize error, drift, and noise, ensuring precise readings even in harsh industrial environments.

Modular Integration: Star EMBSYS load cell solutions are compatible with various microcontrollers and industrial PLCs, making them ideal for smart manufacturing systems.

Custom Solutions: The company often works closely with clients to develop tailor-made solutions that fit specific industrial requirements, including custom calibration, mechanical design, and communication protocols.

Robust Construction: The load cells and associated electronics are built to withstand tough usage conditions—whether it's high temperature, moisture, or vibration—ensuring long operational life.

Future of Load Cells with Star EMBSYS

As industries continue to move toward Industry 4.0, smart sensing and data analytics become more important than ever. Load cells are transitioning from standalone sensors to being part of intelligent systems that communicate real-time data to cloud platforms. Star EMBSYS is aligning its product development in this direction, incorporating features like wireless communication, remote diagnostics, and IoT compatibility into its load cell systems.

In conclusion, load cells remain a cornerstone of accurate force measurement across industries. With companies like Star EMBSYS leading innovation in sensor technology and embedded systems, the future holds exciting possibilities for smarter, more connected, and more efficient industrial processes. Their commitment to quality, precision, and customization makes them a reliable partner in applications that demand uncompromised accuracy.

Visit:- https://www.starembsys.com/master-load-cell.html

0 notes

Text

What Innovations Are Chennai Crane Manufacturers Bringing to the Industry?

Crane manufacturers in the region are redefining material handling by introducing advanced features, sustainable technologies, and industry-specific solutions.

Key Innovations from Chennai Manufacturers

Smart and Automated Cranes Chennai-based crane companies are integrating automation technologies like PLC controls, IoT sensors, and remote operation systems in EOT (Electric Overhead Travelling) cranes. These innovations enable real-time monitoring, predictive maintenance, and reduced human error, which greatly enhance workplace safety and efficiency.

Modular Crane Design Many manufacturers are now offering modular and customizable crane systems. These allow industries to install, dismantle, and relocate cranes with ease, reducing downtime. Modular cranes are widely used in facilities where operations change frequently, such as automotive assembly lines or logistics warehouses.

Energy-Efficient Motors Energy consumption is a major concern in heavy machinery. To address this, crane manufacturers in Chennai have adopted energy-efficient motors and regenerative drives. These systems recover energy during braking and reduce overall power usage—ideal for large-scale applications such as steel plants and infrastructure projects.

Compact & Low Headroom Cranes For industries with space constraints, especially in urban setups, low headroom single-girder EOT cranes and wall-mounted jib cranes are being developed. These cranes offer powerful lifting within limited vertical and horizontal space, making them suitable for light manufacturing, workshops, and repair units.

High-Temperature & Hazard-Resistant Cranes Manufacturers like Gearcon Engineering are producing hot metal cranes for use in steel mills and foundries.

Applications and Uses

Steel and Foundry Industries: Use high-capacity, heat-resistant cranes for handling molten metal and heavy ingots.

Automotive Sector: Employ modular and precision-controlled EOT cranes in assembly lines and component storage.

Warehousing and Logistics: Utilize automated and remote-controlled cranes for material movement, reducing manual labor.

Construction: Depend on tower and gantry cranes for lifting large materials to heights safely and efficiently.

Textile and Food Industries: Use compact cranes for gentle handling of lightweight materials in confined spaces.

Conclusion

Chennai crane manufacturers are not only meeting industry demands but pushing boundaries with innovation, adaptability, and technology integration. Their cranes are now smarter, safer, more energy-efficient, and application-specific—making Chennai a pivotal contributor to India’s modern industrial infrastructure.

#cranemanufacturers#craneindustry#heavyequipment#constructionmachinery#materialhandling#engineeringexcellence#liftingsolutions#eotcranemanufacturers

0 notes

Text

Top Hydraulic Power Pack and Hydraulic Cylinder Manufacturers in India

Top Hydraulic Power Pack and Hydraulic Cylinder Manufacturers in India – New Delhi, Mumbai, and Pune

In the evolving world of industrial automation and heavy machinery, hydraulic systems have become the backbone of operations across multiple sectors. Be it construction, manufacturing, agriculture, or automotive industries, reliable hydraulic power packs and hydraulic cylinders are indispensable. As leading manufacturers across New Delhi, Mumbai, and Pune continue to push innovation forward, the demand for precision-engineered hydraulic components is on a sharp rise.

Hydraulic Power Pack Manufacturers in New Delhi – Power and Performance You Can Trust

The capital city, New Delhi, is home to some of the most prominent hydraulic power pack manufacturers in India. These companies specialize in crafting compact, robust, and highly efficient hydraulic power packs that are custom-built to meet various industrial needs.

A hydraulic power pack is a self-contained unit that includes a motor, fluid reservoir, and pump. These units are capable of delivering consistent power to hydraulic machinery, ensuring seamless operations even in the most demanding environments.

Top features offered by New Delhi manufacturers:

Custom-built configurations to meet client-specific needs

High-efficiency motors and low-noise operations

Integration with advanced control systems

Durable construction for extended service life

Compact designs suitable for mobile and industrial machinery

These manufacturers cater to sectors such as aerospace, defense, civil engineering, and automobile production, positioning themselves as pioneers in hydraulic technology in India.

Hydraulic Power Pack Manufacturers in Mumbai – Innovation at Its Best

Mumbai, India's financial and industrial hub, is also a major center for hydraulic power pack production. The city's top manufacturers are renowned for their engineering excellence, state-of-the-art manufacturing facilities, and strict adherence to international quality standards.

Key advantages of hydraulic power packs manufactured in Mumbai:

Incorporation of advanced filtration systems

Energy-saving motors and minimal heat generation

Modular design for ease of maintenance

High-pressure capacity for heavy-duty applications

Integrated PLC-based control units

Many of Mumbai’s top hydraulic manufacturers have ISO certifications and export their products globally, establishing India’s reputation in international markets.

Hydraulic Cylinder Manufacturers in Pune – Precision Redefined

Known as the Detroit of India, Pune is a powerhouse for hydraulic cylinder manufacturing. These manufacturers specialize in high-pressure, double-acting, single-acting, and telescopic hydraulic cylinders. Whether for presses, injection molding machines, cranes, or agricultural implements, hydraulic cylinders from Pune ensure smooth, leak-free, and reliable performance.

Why choose hydraulic cylinders manufactured in Pune?

Use of high-grade alloy steels and surface treatments

Superior seal technology to prevent leakage

Precision-machined hydraulic cylinder pistons and barrels

Heavy-duty designs for extended service life

Custom bore sizes and stroke lengths available

These manufacturers provide cost-effective solutions without compromising on quality, which has made Pune-based companies the preferred suppliers for OEMs across India and abroad.

Understanding Hydraulic Cylinders and Their Core Components

A hydraulic cylinder converts fluid energy into linear mechanical force and motion. To better understand its role and performance, let’s look into its major components:

Hydraulic Cylinder Components:

Cylinder Barrel: Houses the piston and holds hydraulic pressure

Piston: Separates pressure zones inside the barrel

Piston Rod: Transfers the force from the piston to the machinery

Rod Gland/End Cap: Ensures sealing and guides the rod

Seals: Prevent fluid leakage and contamination

Ports: Inlet and outlet for hydraulic fluid

Proper configuration and manufacturing precision in these components ensure a long service life and minimal maintenance.

Hydraulic Cylinder and Piston – The Perfect Duo

The hydraulic piston is the heart of the cylinder. Its design and material play a crucial role in handling pressure and ensuring smooth operation. Manufacturers in India are now using CNC machining and advanced thermal treatments to manufacture pistons that resist wear, corrosion, and fatigue.

Features of modern hydraulic cylinder pistons:

Hardened and chromed surfaces

High dimensional accuracy

Optimized weight-to-strength ratio

Resistance to pressure surges

Compatibility with multiple hydraulic fluids

Hydraulic Cylinder Price – What Factors Affect the Cost?

The price of a hydraulic cylinder depends on several factors. Understanding these elements can help buyers make informed purchasing decisions:

Bore size and stroke length

Operating pressure capacity

Materials used (e.g., steel grade, chromed rods)

Type of seals and coatings

Customization and quantity ordered

Import/export duties and logistics

Typically, standard cylinders are more affordable, whereas custom-engineered cylinders carry a higher price tag due to specialized components and testing.

Hydraulic Power Pack – Essential for Modern Industry

Whether it’s powering a hydraulic press, lift system, or automated equipment, the hydraulic power pack plays a pivotal role in modern industry. Indian manufacturers are increasingly offering:

Skid-mounted mobile units

Weather-proof enclosures for outdoor applications

AC and DC motor-based options

Remote monitoring capabilities

These innovations are vital for applications in marine, mining, construction, and material handling sectors, delivering consistent power with optimized energy consumption.

Why Choose Indian Manufacturers for Hydraulic Solutions?

India’s hydraulic equipment manufacturing sector has matured into a globally competitive industry. Manufacturers in New Delhi, Mumbai, and Pune offer:

High-quality engineering

Compliance with ISO, CE, and BIS standards

Fast delivery timelines

After-sales support and technical service

Competitive pricing with zero compromise on quality

These manufacturers also provide technical documentation, CAD drawings, load testing reports, and custom fabrication options, making them an ideal choice for large-scale and niche hydraulic applications.

Conclusion – Your Trusted Hydraulic Partners Across India

Whether you're seeking a rugged hydraulic cylinder for earth-moving machinery or a customized hydraulic power pack for precision automation, the manufacturers based in New Delhi, Mumbai, and Pune offer unmatched expertise and quality. Their commitment to innovation, reliability, and performance ensures your machinery operates efficiently, safely, and cost-effectively.

hydraulic cylinder in mumbai

Hydraulic Power Pack Manufacturers in Hyderabad

Hydraulic Power Pack Manufacturers in Gujarat

Hydraulic Cylinder Manufacturers in Maharashtra

Centrifuge Bag Lifting Device

Hydraulic Cylinder Manufacturers in New Delhi

Hydraulic Power Pack Manufacturers in New Delhi

Hydraulic Power Pack Manufacturers in Mumbai

Hydraulic Cylinder Manufacturers in Pune

Hydraulic Power Pack Manufacturers in Pune

hydraulic power pack

hydraulic cylinder

power pack

hyd cylinder

hydraulic cylinder price

hydraulic cylinder components

hydraulic cylinder piston

hyd cyl

hydraulic cy

hydraulic cylinder and piston

hydraulic piston cylinder price

hydraulic cylinder

hyd cylinder

hydraulic cy

#hydraulic cylinder in mumbai#Hydraulic Power Pack Manufacturers in Hyderabad#Hydraulic Power Pack Manufacturers in Gujarat#Hydraulic Cylinder Manufacturers in Maharashtra#Centrifuge Bag Lifting Device#Hydraulic Cylinder Manufacturers in New Delhi#Hydraulic Power Pack Manufacturers in New Delhi#Hydraulic Power Pack Manufacturers in Mumbai#Hydraulic Cylinder Manufacturers in Pune#Hydraulic Power Pack Manufacturers in Pune#hydraulic power pack#hydraulic cylinder#power pack#hyd cylinder#hydraulic cylinder price#hydraulic cylinder components#hydraulic cylinder piston#hyd cyl#hydraulic cy#hydraulic cylinder and piston#hydraulic piston cylinder price

0 notes

Text

Windrow Compost Turning Machine: 6 Advantages Redefining Composting Efficiency

The Windrow Compost Turning Machine plays a critical role in the organic fertilizer production process by accelerating decomposition through efficient aeration and mixing of organic materials. As essential fertilizer manufacturing equipment, it ensures uniform composting, pathogen elimination, and moisture control, transforming raw waste into high-quality organic fertilizer while optimizing production efficiency and output consistency.

All-Terrain Adaptability

Imagine when traditional wheeled equipment struggles in muddy conditions after heavy rain, the crawler compost turner operates with ease. Its unique track design distributes ground pressure to just 1/3 of conventional equipment, maintaining excellent stability whether on soft soil, uneven ground or slopes. Test data shows 200% better mobility in extreme conditions compared to wheeled machines.

"No more rainy season downtime" is consistent user feedback

Deep and Uniform Turning

The patented spiral turning mechanism penetrates 2-meter-deep piles, precisely bringing under-fermented bottom materials to the surface. Specially angled blades create a "tornado effect" during rotation, ensuring thorough aeration while maintaining ideal particle size. Practical applications show this design improves fermentation uniformity by 45%, completely eliminating "partially cooked" materials.

Intelligent Automation

Equipped with advanced PLC control systems, operators only need to set basic parameters for the machine to automatically handle complex operations like speed adjustment and turning depth control. Newer models support remote monitoring via mobile apps, enabling efficient "one-operator-multiple-machines" management. One large organic fertilizer plant reported 60% labor cost reduction after adoption.

Flexible Site Adaptation

Unlike bulky traditional turners, modern crawler models feature modular designs with minimum turning radius of just 3 meters, easily handling irregularly shaped windrows. Foldable designs make transportation more convenient, especially suitable for distributed composting sites.

Eco-Friendly Design

The hybrid power system reduces energy consumption by 35% compared to conventional equipment. Unique noise reduction design keeps operational noise below 75dB, meeting environmental requirements for residential areas. Every ton of organic waste processed reduces carbon emissions by approximately 15kg.

Military-Grade Durability

Critical components use special wear-resistant steel, passing 100,000-cycle fatigue tests without deformation. Track service life reaches 8,000 working hours, double the industry standard. Sealed bearing design and automatic lubrication ensure long-term stable operation even in dusty environments.

From all-terrain performance to intelligent control, from eco-design to exceptional durability, crawler compost turners are redefining modern composting equipment standards with their comprehensive excellence, becoming the preferred solution for organic waste recycling.

0 notes

Text

Breaking Into the Beer Industry: Start Your Beer Brand with Prodeb’s Brewing Technology

Let’s Be Honest: Starting a Beer Brand Isn’t Just About Brewing Beer

It’s about culture, ambition, identity — and yes, a lot of stainless steel. If you’re thinking of how to start a beer brand, you’re not just entering a market — you’re entering a lifestyle-driven, experience-hungry space that rewards authenticity and quality. At Prodeb, we don’t just sell beer brewing machines — we engineer bold beginnings.

You’re Not Starting a Business. You’re Starting a Movement.

Craft beer is booming, and today’s drinkers crave more than just alcohol content — they want a story. What does your beer stand for? Is it rebellious? Is it rooted in heritage? Does it blend art and science? We’re here to make sure your equipment, processes, and product match the spirit behind your brand.

The Blueprint: From Beer Dreamer to Brand Owner

Let’s skip the textbook model. This is the real-world flow we’ve seen work best:

1. Start With Your Signature

Before you even touch hops or yeast, know your flagship style:

Crisp summer lager for the heat?

Punchy IPA with a local twist?

Dark stout brewed with cocoa nibs?

Prodeb helps you design recipes that suit both palate and production feasibility.

2. Scale Without Compromise

Most beginners ask: “Can I start small and grow later?” Absolutely — if you’ve got the right system. Our modular beer brewing machine setups grow with your brand. Start with 500L and scale up to 5000L without rebuilding your entire plant.

Why the Beer Brewing Machine You Choose Matters (More Than You Think)

A brewery is only as good as its gear. Period.

What Sets Prodeb Apart?

Automated Precision: You don’t need 20 brewers watching temperature — let our PLC-based automation do the heavy lifting.

Energy Smart: Our systems use optimized heating and chilling to reduce energy waste.

Consistency-First Design: You need every batch to taste like the last one that made customers fall in love.

This isn’t a home kit. This is industrial-grade brewing intelligence — simplified.

Licensing Isn’t Glamorous, But It’s Game-Changing

Let’s be real: Indian alcohol regulations are a maze. That’s why Prodeb partners with experts in every major state to handle:

Brewery and excise licensing

Water, pollution, and safety clearances

Custom labeling and GST compliance

You focus on your craft. We’ll handle the bureaucratic brew.

From Tank to Tap — Or Bottle, Or Can

Whatever your format, we’ve got the full line:

Kegging stations for taprooms

Filling & crowning machines for bottles

Can seamers with nitrogen purging

Labelers, cappers, conveyors — all synced to reduce human error

Plus, all machines are pre-tested at our facility before dispatch — zero surprises.

Marketing the Brew: Make It Loud, Make It Local

A killer beer without a voice is just another drink. Build your brand with:

Collaborations with cafes and chefs

QR-code storytelling on your packaging

Beer-and-food pairing events

Interactive brewery tours

Prodeb clients often become local legends before becoming national brands.

You Brew It. We Power It.

There’s something wildly satisfying about watching your first batch bubble in a fermenter. That “it’s real now” moment hits differently. Our clients tell us it’s not just about making beer — it’s about creating pride in something that’s yours.

And Prodeb? We’re right there from your first grain to your 10,000th bottle.

Why Brands Choose Prodeb — and Never Look Back

💡 Brewery Layout & Civil Guidance

🔧 Tailor-Made Brewing Systems

🌍 Global-Grade Stainless Steel

🎓 Training for You & Your Team

🛠️ 24x7 Technical Support

We don’t just build machines. We build breweries that last.

Conclusion: The Real Secret to Starting a Beer Brand

It’s not luck. It’s not just a good idea. It’s execution — backed by the right technology, right team, and right intent.

And that’s where Prodeb steps in. From helping you refine your recipe to installing India’s most reliable beer brewing machines, we’re your end-to-end brewing partner.

Whether you’re pouring pints in a hilltop brewpub or bottling for supermarket shelves, Prodeb helps you brew with purpose and pride.

Ready to Brew Your Legacy? Let’s Talk.

Your beer is waiting to be brewed. The only thing missing? The machine that makes it happen. And the team that helps you grow it.

👉 Contact Prodeb Today for:

Personalized brewery consultation

Tailored equipment quotes

Site layout and installation plan

Full-scale training & support

📞 Don’t wait. Start your beer brand now — the Prodeb way.

FAQs

1. What is the cost of setting up a beer factory in India? The cost can vary based on your capacity. A microbrewery starts around ₹60–80 lakhs for a 500L setup with automation. A larger packaging unit can go beyond ₹2 crores. Prodeb offers turnkey solutions tailored to your budget and business model.

2. Is the brewery business profitable in India? Yes, the brewery business can be highly profitable when done right. Profit margins depend on location, licensing, and marketing. Prodeb’s energy-efficient equipment and scalable solutions ensure your operations stay lean and profitable from day one.

3. How long does it take to install a brewery from Prodeb? Typically, 6 to 10 weeks from the date of order confirmation, including custom manufacturing, pre-dispatch testing, shipping, and installation.

4. Can Prodeb help me with beer recipe development? Absolutely. Prodeb has an in-house team of brewing technologists and access to pilot brewing labs to help you develop and perfect your signature recipes.

5. Are beer brewing machines from Prodeb suitable for export markets? Yes. Prodeb’s beer brewing machines are CE-certified and designed to meet international standards, making them suitable for breweries across Asia, Africa, Europe, and the America.

0 notes

Text

Unlocking the dilemma of scrap steel processing: How can a [Xrido] shredder reshape your profit chain?

In the scrap steel recycling industry, efficiency is the lifeline and cost is competitiveness. Are traditional processing methods trapping you in these quagmires?

"Eat" slowly: Pre-processing of large pieces of scrap steel is time-consuming and labor-intensive, and the equipment idle rate is high?

"Spit" scattered: The output materials are of different sizes and low density, and the transportation is lost tons, and the selling price is suppressed?

"Sick" a lot: The equipment wears quickly, maintenance is frequent, and the downtime loss is unbearable?

"People" are difficult to manage: It relies heavily on manual labor, has great safety hazards, and has high management costs?

[Xrido] Heavy-duty scrap steel shredder, a tailor-made breakthrough weapon for you!

We are not just a crushing machine, but also your "profit accelerator":

"Giant mouth" swallows, efficiency revolution:

The uniquely designed wide feed inlet can easily "swallow" "big guys" such as car shells, oil drums, I-beams, and home appliance shells.