#Metalcore PCB

Explore tagged Tumblr posts

Text

How do PCBs automatically help power with conductive pathways for non-conductive substrates?

HDI 12-layer PCBs automatically powered to help are called PWB (Printed wiring boards), PCBs (Printed Circuit Boards) come accessible to automatically help and electrically be part of electric powered-powered utilization of conductive pathways, signal strains etched from copper sheets laminated onto a non-conductive substrate. Apart from being much less high priced and reliable, PCBs are used for immoderate-volume production, even though their price is higher than wire-wrapped circuits. Generally, a Printed Circuit Board’s format is ready vaguely. Important characteristic internal PCB circuit format this is carried out to define the functionality further of mechanical and electric-powered products. This microwave PCB Prototype plays a crucial element characteristic within the format and introduction of found-out circuit boards. The technique of the PCB prototype goes via immoderate situations the whole thing is checked on the equal time because the manufacturing is in a technique including the strains and leads. However, underneath any kind of failure within the prototype, a present-day modified prototype needs to be built.

How are PCB prototypes to scrutinize efficiencies?

The prototype is saved under scrutiny until it performs as required. In case of the unavailability of a prototype of the Printed Circuit Boards, there are various uncertain risks and inefficiencies worried about the mass production of circuit boards. These revisions additionally may be time-ingesting in complex systems and may include immoderate expenses. Also, if something is determined incorrectly with a circuit, it takes a while to localize it. Different ENEPIG PCB materials are used for sort of PCB specifications and techniques in PCB prototyping and production.

What are the power outputs of rigid-flex PCB?

To get wonderful consequences and outputs, you will be capable of creating or formatting a PCB with the utilization of

Using Polyimide for flexibility – Polyimide can keep a heat temperature, which makes it most suitable for use in electric insulation applications.

Arlon for Longer Life at Higher Temperatures – Arlon materials are useful for the PCB fabrication of immoderate ordinary overall performance and frequency-mounted found-out circuit production.

Isola Range for PCB prototype – Isola range is an immoderate ordinary overall performance pre-peg system.

UTILITIES AND FUNCTIONS

Its low dielectric consistency and dissipation element permit the growth of an appropriate cloth for designing broadband circuits.

Last phrase and conclusion Storm pcb.com are expert in digital layout and PCB assembly. They remodel your circuit concept into reality, seamlessly, economically, and successfully for exceptional circuit manufacturing for men or woman demand.

#HDI PCB#RF PCB#High frequencypcb#rigid-flexpcb#Large PCB#Metalcore PCB#ENEPIG PCB#Microwave PCB#10 layer PCB#12 layer PCB

7 notes

·

View notes

Text

What is a PCB transformer and what are its applications?

This article introduces PCB-mounted transformers, so you can decide which electronic device suits your circuit best. Designers use Transformers widely in power electronics and electronics; however, in this article, we focus on PCB transformers and the essentials.

Transformers are one of the most common pieces on PCBs. This particular branch of transformers is lighter, compact, and operates under relatively light loads. Picking the proper transformer for your PCB design, on the other hand, entails some critical considerations.

Therefore, we strongly suggest you read the following titles carefully. The following passage tells what printed circuit board transformers are, how they work, transformer components, and transformer types.

What are PCB transformers?

Transformers are electrical equipment that transforms electrical energy from one circuit to another. Using an electrical transformer has several benefits and applications:

Circuit isolation: a transformer can isolate a device from the power grid and disconnect it from the earth. Therefore, it protects anyone who might touch loose wires or electrified surfaces.

Converting voltage and current without affecting overall power: you can use them in the power grid to reduce power loss.

Amplification of wave inputs

Converting the distribution wiring electricity to a suitable voltage and current for a particular device

Magnetic ferrite core transformer detail on beige printed circuit board

PCB transformers can mount on printed circuit boards as electrical components, also known as PCB-mounted transformers. Since most PCBs work below the power electronics range, most PCB transformers amplify a signal or convert electricity.

How Do Transformers Work?

As mentioned earlier, transformers transfer electricity from one circuit to another. Now, let’s see how transformers work.

A transformer has three main parts, including electronic components and magnetic components:

The primary coil

The core

The secondary coil

A simple transformer model

The steps below briefly explain how a transformer alters the output voltage.

First, when electricity passes the primary coil, it induces a magnetic flow within the metalcore.

Next, the magnetic flow reaches the secondary coil.

Finally, the magnetic flow induces an electric current in the secondary coil.

In an ideal transformer, you can calculate the voltage and current of the second circuit using the following equation:

Working of transformer

Source: Wikimedia Commons.

In the equation above, NP and NS represent how many rounds the coil wraps around the core. Those Numbers indicate how much you are amplifying the voltage.

The principles stated above apply to PCB transformers, just like any other.

PCB Transformer Composition

Inside any PCB-mounted transformer, two coils are the primary coil and the secondary coil. These coils are just coated copper wires tightly wrapped around the magnetic core. Moreover, steel or another magnetic alloy serves as the magnetic core material.

Transformer copper coil

Transformers also have terminals and an outer casing. Since you use PCB transformers on circuit boards, there are two methods to mount the transformer onto the PCB:

Surface Mounted Transformers: Manufacturers design SMT/SMD transformers so you can solder them to the PCB directly. The soldering paste might loosen up if exposed to extreme heat.

Through-hole transformers: As the name implies, you need to pass the leads through the PCB holes and solder the tips to the other side of the PCB.

PCB Transformer: Main PCB-Mount Transformer Specifications

The following types of electrical equipment are the most common circuit board transformer types:

Primary and secondary ratings: The rating indicates how much the primary and secondary voltage and current are. First, you have to check the output voltage. Then, check if the design current is below the transformer limits. Also, note that the more the power density, the more heat will discharge from the circuit.

Transformer winding formats

Source: Wikipedia

Inductance: Simply put, inductance determines how well the transformer couples the two circuits. Inductance is also a part of DC-DC converter circuits; in other cases, power efficiency indicates the coupling performance of the transformer implicitly.

Cooling mechanism: Unlike power electronic transformers, PCB-mounted transformers use much less power. Therefore, they generate less heat and don’t need a particular cooling system. However, planar PCB-mounted transformers can hold a heat sink on top of the piece.

Mounting style: Some transformers are SMT type; you have to solder these transformers to the PCB surface; hence we call them surface mount technology. On the other hand, through-hole transformers require passing the leads through PCB holes and soldering them on the opposite side of the board. The latter offers better resistance to extreme heat.

Form factor: A transformer can lay flat or stand vertical on the board. Vertical transformers save space, but they are prone to vibration.

Power rating and efficiency: Power rating determines the current type, AC or DC, and indicates how much power the transformer can handle. The voltage frequency is another important factor that you have to consider. Power efficiency tells you the direct current efficiency under a nominal load.

Transformer on a PCB detail

PCB Transformer: Types of PCB Mount Transformers

The electrical apparatus comes with different sizes of power converters and various applications.

Audio transformers: You can use these tools to convert sounds and signals from about 300Hz to 20kHz.

Autotransformers: This electrical equipment has only one winding which acts as both primary and secondary coils. Therefore, these efficient power convertors have different secondary voltage settings. You can connect other taps on the transformer for different conversion ratios. However, these transformers don’t provide isolation since there are no separate coils.

Balun transformers: This device allows balanced and unbalanced lines to be interfaced without disturbing the impedance arrangement of either stripe.

Current sense transformers: These electric transformers detect and measure current in the primary winding and produce a proportional secondary current in the secondary winding.

Flyback transformers: FBT or line output transformers (LOPT) is a special transformer that creates high voltage saw-toothed signals at relatively high voltages.

Flyback transformers

Source: Wikimedia Commons.

Interface transformers: We use these electric transformers in telecoms and communication circuits with an isolated signal.

Lighting transformers: These can generate suitable power for lightning and lumination systems.

Medical transformers: Medical equipment has strict regulations and tight safety guidelines. Therefore, medical transformers are safe-to-use in operating rooms for medical and surgical applications.

Power transformers: These transformers power up the power supply of an electric device. Manufacturers, for example, utilize power transformers to power audio systems such as speakers and amplifiers.

Power supply PCB printed circuit board.

RF transformers: Radiofrequency transformers can match impedances, isolate DC currents between circuits, and perform current or voltage step-ups or step-downs.

Resonant transformers: We use resonant transformers in radio circuits as bandpass filters and switching power supplies.

Switch mode transformers or switching transformers operate under low voltage supplies. We use them in industrial and domestic applications.

Electrical transformer

Summary

To recap the article, we defined PCB-mounted transformers, briefly explained the components, and described the underlying transformers’ electromagnetic mechanism. Furthermore, we demonstrated how you could select a suitable transformer to mount on your PCB. In addition, we distinguished different types of transformers and told their primary applications.

Bear in mind that the purpose of this article was to give you the essential information on PCB transformers. Indeed, there is much more to discover about non-PCB transformer devices and how you can use them. Anyway, we hope this article was helpful for you.

#PCBA #KFPCBA

0 notes

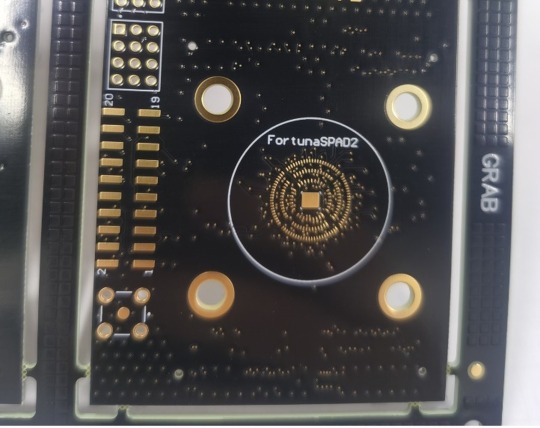

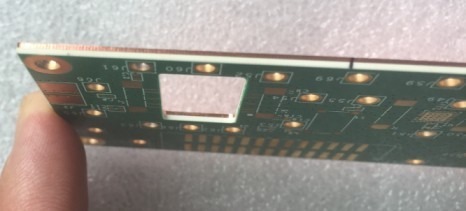

Photo

Copper base PCB with good thermalconductivity and current carrying capacity usually used in high frequency circuit and temperature with big change or precision communication equipment heat dissipation and architectural decoration filed. #copperbase #copperpcb #metalcore #MCpcb # thermalconductivity #highfrequency #circuit #equipment #pcbmanufacture #chinapcb #circuitsboard https://www.instagram.com/p/BrUlyLPntVE/?utm_source=ig_tumblr_share&igshid=12l1alj6ez9lp

#copperbase#copperpcb#metalcore#mcpcb#highfrequency#circuit#equipment#pcbmanufacture#chinapcb#circuitsboard

0 notes

Text

THE METAL CORE PCB FROM STROMPCB.COM HELPS PRODUCE BEST-LED PACKAGES

Metal Core PCB are circuit forums or MCPCB, or thermal control forums are revealed circuit forums constructed with a PCB metallic middle used to disperse warmness from the additives of the board, successfully decreasing the middle temperature of excessive warmness packages. They are used while traditional fan-cooling strategies are inadequate for cooling the whole system. Most normally observed in LED packages, MCPCBs will have a middle of one of the following materials: — aluminum (aluminum middle PCB) — copper (copper middle PCB) — a combination of unique alloys With the maximum not unusual place of the 3 indexed above being aluminum middle forums. Metal middle revealed circuit forums switch warmness many times (up to eight or nine times) quicker than FR4 forums.

Retaining warmness producing cooler additives from metal core PCBs

MCPCB laminates scatter and do away with warmness, retaining warmness and producing additives cooler that ends up in multiplied overall performance and lifestyles of the packages. Common LED packages in which metallic middle forums are observed: — Back mild unit packages — Street protection packages (streetlights, lights, etc.) — General lights packages — System car LED packages — Power converters: telecom, industrial, excessive voltage regulator, electricity supplies — Hybrid/electric powered motor manage packages — Photovoltaic

Applications The mild-emitting diode packages generate massive quantities of warmness.

With the large PCB metallic middle’s dielectric polymer layer with excessive thermal conductivity, the utility average has a decreased thermal resistance. Other packages which might be turning into an increasing number of vital metallic middle forums are solar panels and movement manage packages. As sun electricity harnessing will become an increasing number vital in regular packages together with electric powered automobiles and sun panel roofs, the warmth trapped inside them increases. Likewise, with superior movement management packages, massive quantities of processing and friction are created to create the dynamics of the motion of the superior generation robots.

PCB used in electronic items

In not unusual place pc packages today, LEDs and LED indicator lighting fixtures are regularly used. The mild warmth created via way of means of those LEDs has multiplied the middle temperature of packages significantly, making the want for thermal control more and more vital. Metal middle forums are most usually observed in LED packages and also in LED-heavy pc hardware situations. MCPCBs have nonetheless fabricated the use of preferred SMT (floor mount generation — the whole frame of the method and additives that create revealed circuit board meeting with leadless additives) meeting equipment. They are commonly multi-layered forums. They also can be constructed on a flex board or inflexible flex board for tight area regions or custom-sized packages, together with cellular phones.

#HDI PCB#RF PCB#High frequencypcb#rigid-flexpcb#Large PCB#Metalcore PCB#ENEPIG PCB#Microwave PCB#10 layer PCB#12 layer PCB

1 note

·

View note