#12 layer PCB

Explore tagged Tumblr posts

Text

Learn about the best practices and key considerations for designing a 12-layer PCB stack-up. Viasion provides a detailed guide on layer configuration, signal integrity, and thermal management to help you optimize the performance and reliability of your multi-layer PCBs.

0 notes

Text

ZUN's Music Collection vol. 10: Mugen Noh of Tanabatazaka ~ Taboo Japan Disentanglement.

Getting a new Hifuu CD after so long is extremely exciting, especially when the cover looks like this (Maribel's design getting ever so slightly closer to her completed Yukari appearance) and especially when one of the arranged tracks is fucking AoCF Necrofantasia. The CD was fully uploaded and translated within 24 hours of the Reitaisai release — never change, RenMerry shippers — so I immediately went to check it out.

Track 1: Dawn Breaks on Tanabatazaka (Original)

Not very much to say about this one other than that it's nice and the soft instrumentation lends it an interesting tone.

Track 2: Tinkerbell of Inequality (Original)

Surprisingly heavy percussion and bass here. Unlike the minimalist Fires of Hokkai, though, this track has a complex "mechanical"-sounding drumline that feels more like something you'd hear out of Len'en. I like this a lot.

Track 3: Does the Forbidden Door Lead to This World, or the World Beyond? (HSiFS)

A hard downgrade over the original. I get what ZUN was going for — stage-1-ifying the song makes it more of a tonal fit with the album — but making it less punchy and softening the drums in the mix makes it sound kind of generic.

Track 4: Smoking Dragon (UM)

Mostly the same as the original but with a key change and a more complicated piano harmony. Not much to write home about.

Track 5: Mugen Noh ~ Taboo Marionette (Original)

ZUN rarely writes in 3/4, so this was pretty surprising. I like this a lot; the mood is tranquil but with plenty of drive at the core, and its instrumentation gives it DiPP/PCB-era vibes while still being unmistakably modern Touhou.

Track 6: Crazy Backup Dancers (HSiFS)

Woah. I like this a lot better than the original from HSiFS, the updated arrangement does a great deal here and the new section in the second half makes the track as a whole a hell of a lot less annoying.

Track 7: Yorimashi Between Dreams and Reality ~ Necro-Fantasia (AoCF)

Opening right off the bat with an original intro (is that 12-string guitar(?) patch a new instrument???), the long-awaited AoCF cover sounds fucking awesome in the newer style! Cutting down the mix to just the ZUNpet and one or two other patches for percussion texture is a fun technique and it's cool to see it deployed so well here. My only real complaint is that it feels like it should be longer.

Track 8: The Lonely Road of Hitachi (Original)

3/4 swing melody over an unswung 3/4 beat (with occasional 4-tuplets?), neat. The heavy arpeggio delay on the piano gives the track an "asynchronized" feeling that I like a lot.

Track 9: The Lamentations Known Only by Jizo (WBaWC)

The addition of the choir layer is a good choice imo, and the tone overall is more melancholic which fits its context in this album. Feels a bit space-filler-y but it's still solid.

Track 10: The Concealed Four Seasons (HSiFS)

This sounds pretty much the same as the original. Don't get me wrong, the original was a good song (if atypical for a stage 6 boss), but it's kind of disappointing that the arrange isn't very distinctive.

Track 11: Ghosts Exist Even When It's Not Night (Original)

A slowly-building staff roll-ish track that works nicely to cap off the album. I like it.

Overall thoughts & story

Eight years since the last Hifuu CD, ZUN still has it. The worst it ever gets is "well that was disappointing" and the best it gets is fresh and exciting. The story is an interesting development while leaving plenty of room for future exploration — it explicitly connects the shared features of Okina and Yukari's abilities to Merry's use of time travel in CoSD, for one thing — and the choice to include Okina's narration stands out and has me curious what volume 11 is going to be like.

9/10 definitely worth it.

11 notes

·

View notes

Text

Common Printed Circuit Boards in New Energy Vehicles

As new energy vehicles handle high voltage and current, various PCB types are utilized to conduct and control electricity safely across functions:

Multi-layer PCBs 6-12+ layer boards employ complex internal circuitry to precisely transmit signals and power between electronic modules. More layers enable more robust connectivity.

Thick Copper PCBs Ultra-thick 2oz, 3oz and even 4oz copper reliably channels currents up to 400A+, applied for motor control and power conversion requiring stable high ampacity traces.

HDI PCBs High-density interconnect technology with microscopic vias and dense circuitry allows integrating more functionality and components in confined control units, saving space and weight.

Large-area PCBs Sprawling PCBs powering functions like body electronics and chassis controls enable more consolidated layouts and simplified connectivity.

At Hitech Circuits, we are a premier PCB manufacturer providing one-stop PCB fabrication and assembly services to meet the diverse needs across multiple industries. With years of experience and cutting-edge capabilities, we deliver high-quality, quick-turn PCB solutions tailored to each application’s unique requirements.

Our Core Expertise:

Wide range of PCB technologies: HDI, rigid-flex, RF/microwave, thermal boards, and more Advanced manufacturing processes: high-density interconnect, buried/blind vias and more Fast prototype to production cycle times Strong engineering support from quote to delivery High-reliability PCBs for demanding applications

Whether you need prototypes for new product development or high-volume PCB production, Hitech Circuits is your trusted partner.

0 notes

Text

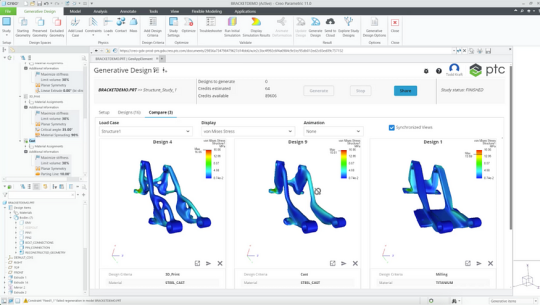

PTC Creo 12: New Tools for Smarter, Faster 3D Design

Discover what’s new in PTC Creo 12 — enhanced simulation, AI-driven design, MBD, and manufacturing tools. Upgrade now with ANH, the trusted PTC Creo reseller in the Delhi NCR region.

Top New Features in Creo 12

1. AI-Driven Design Guidance

Creo 12��takes intelligent design to the next level with built-in AI tools that offer real-time suggestions and improvements.

Get feedback during modeling

Reduce trial-and-error

Improve efficiency with every click

2. Enhanced Model-Based Definition (MBD)

Creo 12 makes MBD more practical and powerful, eliminating the need for traditional 2D drawings.

Improved PMI (Product Manufacturing Information)

Better GD&T annotation support

Clearer data for downstream users

3. Performance & Usability Upgrades

PTC has improved the overall speed, responsiveness, and ease of use:

Faster model regeneration

Smart mini toolbars

Enhanced model tree filters

Customizable dashboards for quick access

4. Creo Simulation Live — More Powerful Than Ever

Simulation Live has been expanded to cover:

Structural & thermal simulations

Better support for nonlinear materials

Real-time design feedback

5. Advanced Multi-Body Design

Creo 12 makes it easier to work with complex parts and assemblies:

Better control over multiple bodies in a single part

New body operations and organization tools

Improved part-to-part interactions

It’s ideal for high-detail engineering and intricate product development.

6. Additive and Subtractive Manufacturing Enhancements

Manufacturing has never been smoother in Creo:

More control over lattice structures

Enhanced 5-axis CAM functionality

New machine support and output formats

Whether you’re 3D printing or using CNC, Creo 12 has you covered.

7. Improved ECAD–MCAD Collaboration

With electronics becoming a bigger part of mechanical products, Creo 12 improves:

PCB visualization

Layer management

Synchronization between electrical and mechanical teams

This helps avoid costly errors during development.

Why Creo 12 is a Must-Have Upgrade

PTC Creo 12 isn’t just for big enterprises — it’s built for everyone who values smart, high-quality design. Whether you’re a design engineer, manager, or product innovator, Creo 12:

Saves time

Reduces errors

Encourages innovation

Supports industry 4.0 goals

Get Creo 12 from Delhi NCR’s Trusted PTC Reseller — ANH

Looking to upgrade your CAD tools or switch to Creo 12? ANH is a leading authorized PTC reseller in the Delhi NCR region. From licensing to training, we help businesses unlock the full potential of Creo.

Contact ANH today to get started with Creo 12!

✅ Conclusion: Welcome to the Future of Design

PTC Creo 12 is more than just an upgrade — it’s a gateway to smarter design, quicker development, and stronger innovation. With new AI tools, advanced simulations, and seamless usability, it’s built to give your team a competitive edge.

Design faster. Design smarter with Creo 12.

0 notes

Text

ASROCK AMD Radeon RX 9060 XT Challenger 16GB OC GPUs

AMD Radeon RX 9060 XT Challenger Architecture

The ASROCK AMD Radeon RX 9060 XT Challenger 16GB OC graphics card handles 1440p gameplay faster with AMD's RDNA 4 architecture.

AMD RDNA 4 and AMD Radeon RX 9060 XT GPU power it. Next-generation design boosts rendering and performance with unified computing units with advanced ray tracing and AI accelerators.

The card includes 16GB of 128-bit Memory Bus-connected GDDR6 memory. The memory clock is 20 Gbps.

A 2700 MHz game clock and a 3290 MHz boost clock are on board.

Processors and Compute Units: The GPU includes 32 compute units, including third-generation RT and second-generation AI accelerators. Also included are 28 stream processors.

Essential Features and Technologies: ASROCK AMD Radeon RX 9060 XT Challenger

It supports OpenGL 4.6 and DirectX 12 Ultimate.

It supports PCI Express 5.0 via the x16 bus specification.

This lightning-fast gaming design targets improved 1440p performance.

Used AI-powered features and tech AMD FidelityFX Super Resolution 4's ML-powered upscaling and next-generation raytracing generate AI-enhanced graphics.

Used AMD products and supported AMD FidelityFX Super Resolution 4 (FSR 4), which game developers must integrate. AMD does not support FSR on other graphics cards.

AMD HYPR-RX is on Radeon RX 7000 Series GPUs and later. This technology enables AMD Fluid Motion Frames, Radeon Super Resolution, FSR, Radeon Anti-Lag, and Radeon Boost to work together.

Compatible with AMD Smart Access Memory technology, if OEM support is available, with AMD 500 Series or later motherboards with the latest BIOS, AMD Radeon RX 5000 Series GPUs, and Ryzen 3000 Series CPUs (certain models excluded).

An upgraded media engine improves streaming clarity.

Modern ultra-high refresh monitors can employ the updated Radiance Display Engine, which features DisplayPort 2.1a and HDMI 2.1b.

Featuring Future-Ready Technology and longevity.

For optimal AM5 platform performance with AMD Ryzen 9000 Series CPUs.

ASROCK AMD Radeon RX 9060 XT Challenger Resolution and Connectivity:

One HDMI 2.1b, three DisplayPort 2.1a. With a Digital Max Resolution of 7680×4320, it enables up to three screens for multi-viewing. Use HDCP.

Power:

The card needs a 550W PSU with one 8-pin power socket. Power delivery components like Dr. MOS, an integrated power stage for synchronous buck-set down voltage applications, improve thermal performance. It can produce 50A per phase continuously. Additionally, it uses Premium 90A Power Chokes, which have three times the saturation current and greater Vcore voltage than typical chokes.

Cooling system

Dual fans increase cooling efficiency and balance performance and silence. Striped Axial Fans increase airflow with their blade stripe construction and bottom polishing surface. The 0dB Silent Cooling feature turns off the fans at low temperatures for quiet and on when the temperature rises. Cooling includes Ultra-fit and consolidated heatpipes to maximise GPU baseplate contact and heat dissipation.

High-density metal welding isolates pipes and stacked fins, improving heat dissipation. Nano Thermal Paste maximises heat transfer and closes contact gaps. Components heat the heatsink via reliable thermal pads. To protect the GPU die and maximise cooler mounting pressure for thermal efficiency, precise screw torque is employed during construction.

ASROCK AMD Radeon RX 9060 XT Challenger PCB and Hardware:

A sleek metal backplate avoids PCB bending and increases cooling using thermal pads. An LED On/Off Switch turns on or off LED indicators for decoration. The PCB architecture includes a 2 oz copper PCB for lower temperatures and energy efficiency, a matte black PCB with an intriguing colour scheme, and a high density glass fabric PCB to fill layer gaps and prevent humidity-induced electrical shorts.

AMD Radeon RX 9060 XT Challenger Software

User-friendly AMD Software Adrenaline Edition controls performance with trustworthy drivers, real-time AI-powered support, and one-click AMD HYPR-RX optimisation. This software improves gameplay with higher frame rates, less lag, and sharper graphics.

Dimensions and Weight:

Card weighs 645 g and dimensions 249 x 132 x 41 mm.

Price and Availability

The ASRock AMD Radeon RX 9060 XT Challenger 16GB OC graphics card will launch internationally on June 5, 2025, for $349 USD.

#AMDRadeonRX9060XT#AMDRadeonRX9060#RadeonRX9060XT#RX9060XTGPU#AMDRadeonRX9060XTChallenger16GBOC#ASRockAMDRadeonRX9060XT#technology#technews#technologynews#news#govindhtech

0 notes

Text

Smart Recliner Sofas in 2025: The New Standard for Living-Room Comfort

Five years ago a recliner sofa was little more than a lever-operated armchair on steroids—cushy, yes, but clunky and best kept out of sight. Fast-forward to 2025 and the category has been reborn as the most high-tech, health-centric, and style-savvy seating money can buy. If you’re sizing up a living-room upgrade that will earn its keep every single day, a smart recliner sofa deserves a place at the top of your shortlist.

1 | Why Recliner Sofas Went High-Tech

Two trends converged to push manufacturers into overdrive. First, the ‘home as wellness hub’ movement—supercharged by remote work—shifted buyer priorities from “good looks first” to “how will this help my body?” Second, the cost of compact motors, IoT chips, and heat-and-massage modules dropped fast once they’d scaled in automotive and fitness gear. Suddenly it was both possible and profitable to integrate those features into large-format furniture. The result: sofas that recline to a zero-gravity angle, remember your favorite positions, charge your devices, stream Bluetooth audio, and even warm (or cool) individual seat zones—all behind a sleek neutral fabric that fits modern décor.

2 | A Quick Anatomy of the 2025 Recliner

Frame. Kiln-dried hardwood meets laser-cut steel slide rails: lighter than the boxy pine skeletons of old but stiff enough to survive 10 000 cycles.

Mechanism. Dual or tri-motor power packs: one for the back, one for the footrest, and a third for head-tilt. Silent gearboxes move just 45 decibels—quieter than dialogue in a Netflix stream.

Padding. Sandwich construction: pocketed springs, high-density foam, and a top sheet of gel-infused memory foam that vents heat through micro-perforations.

Upholstery. Performance linen or vegan bio-leather. Both treat spills like water off a duck’s back and are certified for 35 000 double rubs on the Martindale wear test.

Smart layer. A slim PCB houses Wi-Fi/Bluetooth, two USB-C ports, Qi wireless pads in the arm tops, and an infrared seat-warm zone tuned to 38 °C—safe, soothing, and energy-efficient.

3 | Health Benefits That Justify the Floor Space

Spinal Relief. Reclining 110–120 degrees unloads the lumbar discs by up to 30 percent versus upright sitting.

Improved Circulation. Elevating the calves above heart level aids venous return, easing swollen ankles after long desk days.

Micro-Massage Recovery. Ten-minute vibration waves in the lower back can cut post-workout stiffness and accelerate muscle repair.

Stress Drop. University sleep-lab studies show a 12-point reduction in evening cortisol after thirty minutes in a zero-gravity recline with gentle heat.

4 | Choosing the Right Configuration

Compact apartments thrive on a 140 cm wall-hugger loveseat: only 6 cm clearance needed behind the sofa to fully extend. Family rooms lean toward a 220 cm three-seat with autonomous controls so one parent can nap while another helps with homework. Home-cinema addicts go L-shape or stadium row: 175-degree recline, bass shakers under each seat, and fold-out snack consoles. Multi-generation homes benefit from one lift-assist end seat—reclines back but also rises forward to help elders stand safely.

5 | Material Matchmaking

Hot climate, pets, and kids? Opt for a nanotech polyester/linen blend: cool to the touch, scratch-tolerant, and stain-repellent. Luxury look, cooler weather? Top-grain Italian leather with micro-perforation balances breathability and elegance. Eco conscience? Cactus-fiber “leather” or recycled-plastic performance fabric carries a 50–60 percent lower carbon footprint.

6 | Power vs. Battery

If the sofa can’t sit near an outlet, pick a model with a 6 000 mAh lithium pack tucked under the frame. On moderate use (ten recline cycles, two hours of heat, and device charging) it lasts 10–14 days and re-plugs overnight like your phone. Hard-wired versions are still cheaper—but watch for cord trip-hazards.

7 | Price Bands & What Changes

Budget (INR)What You Get35 k – 55 kManual lever, PU leather, plywood frame, 1-year warranty55 k – 90 kDual-motor power, performance fabric, USB-A, 3-year warranty90 k – 1.4 LTri-motor, vegan leather, app & voice, seat heat, 5-year coverage1.4 L+Full-grain leather, adaptive lumbar air cells, AI posture coach, 10-year structural warranty

8 | Sustainability Watch-List

Manufacturers responding to EU eco-design rules now make frames bolt-apart for easier recycling, publish FSC certifications, and use TCPP-free foams. Ask for an Environmental Product Declaration—many mainstream brands now have one.

9 | Maintenance in Minutes

Vacuum seams weekly; crumbs degrade fabric faster than wear.

Cycle all motors to full extension once a week to keep grease spread evenly.

Condition leather or coconut-oil performance blends twice a year; skip petroleum products.

Swap the battery after 1 000 cycles—most brands sell cartridge packs you can pop in without tools.

10 | Top Indian & Global Models to Test-Sit

The Sleep Company SmartGRID Recliner 2-Seater. Grid polymer + smartphone presets; ₹89 999. Wakefit Tango Plus. Battery wall-hugger loveseat with vegan leather; ₹64 999. IKEA VÄNDA (launch Q3 2025). Flat-pack power recliner sectional aimed at DIY crowds; ~₹1 lakh for four seats. Herman Miller Motion Sofa. Adaptive lumbar air bladders and Alexa integration; imports around ₹2.2 lakh. La-Z-Boy Slim-Arm Nordic. Top-grain leather, zero-wall, heated backrest; ₹1.5 lakh.

11 | Final Checklist Before You Click “Add to Cart”

Measure the fully open length, not just the sofa width.

Confirm at least 50 cm of seat width per person.

Plan power routing or battery capacity.

Test the headrest angle for your height—many are fixed.

Read the warranty fine print: motors should carry at least two years.

Inspect return and white-glove delivery terms—recliner sofas weigh 80–120 kg.

The Bottom Line

A smart recliner sofa in 2025 isn’t merely a plush indulgence. It’s a posture-friendly, wellness-enhancing, tech-forward anchor for any living space that doubles as home office, cinema, and family-gathering zone. Choose wisely and you gain a daily retreat that pampers the body, calms the mind, and quietly recharges every device—including you.

0 notes

Text

HDI PCB vs. Traditional Multilayer PCB: What’s the Difference?

As electronic products continue to shrink in size and increase in functionality, designers are faced with new challenges in PCB layout and integration. Two common solutions are Traditional Multilayer PCBs and HDI (High-Density Interconnect) PCBs. Though they serve similar purposes, they differ significantly in design approach, manufacturing complexity, and application scope.

What is a Traditional Multilayer PCB?

A traditional multilayer PCB consists of three or more conductive layers, typically stacked symmetrically with insulating materials (prepreg and core) in between. These boards use through-hole vias to connect all layers and are widely used in industrial, automotive, and consumer electronics.

Standard via types: Through-hole

Layer count: Usually 4–12 layers

Trace width & spacing: Limited by mechanical drilling

Common applications: Power supplies, industrial controllers, communication modules

What is an HDI PCB?

HDI (High-Density Interconnect) PCBs are a more advanced type of multilayer board designed for higher wiring density in a smaller footprint. HDI boards make use of microvias, blind/buried vias, and via-in-pad technologies to achieve compact layouts.

Advanced via types: Microvias, blind vias, buried vias

Layer count: Often 6–20+, including build-up layers

Trace width & spacing: Much finer (can be below 75μm)

Common applications: Smartphones, tablets, medical devices, aerospace electronics

Key Differences

1. Via Technology

Traditional multilayer PCBs rely mainly on mechanical drilling and through-hole vias, which limit routing density.

HDI PCBs use laser-drilled microvias that connect only adjacent layers, allowing finer routing and stacked via structures.

2. Density and Miniaturization

HDI allows more interconnections per unit area, which supports smaller components (e.g., BGAs with 0.4mm pitch).

Traditional PCBs are less suitable for extremely compact or high-pin-count layouts.

3. Manufacturing Complexity

HDI fabrication requires advanced processes like laser drilling, sequential lamination, and high-precision registration.

Traditional multilayer boards follow a simpler, more mature process and are easier to produce in volume.

4. Cost

HDI boards are generally more expensive due to complex manufacturing and tighter tolerances.

Traditional multilayer PCBs are more cost-effective for larger, less space-constrained designs.

5. Signal Integrity

HDI offers shorter trace lengths and better impedance control, making it suitable for high-speed digital and RF signals.

Traditional boards may struggle with signal integrity at very high frequencies.

When to Use HDI or Traditional Multilayer?

Choose HDI PCB when:

Space is extremely limited (e.g., wearables, smartphones)

High-speed or high-frequency signals are involved

You need finer pitch components (e.g., CPU, GPU, DDR)

You aim for thinner, lighter, more compact devices

Choose Traditional Multilayer PCB when:

Size and weight are less critical

The design uses standard components and moderate speeds

Cost is a major concern

Volume production and fast lead time are priorities

Conclusion

Both HDI and traditional multilayer PCBs play important roles in modern electronics. The right choice depends on your application’s complexity, space constraints, performance requirements, and budget. HDI pushes the limits of miniaturization and performance, while traditional multilayer PCBs remain a reliable and economical solution for many mainstream applications.

0 notes

Text

PCB Manufacturing: A Comprehensive Guide to Printed Circuit Board Production

Introduction to PCB Manufacturing

PCB Manufacturing is the process of creating Printed Circuit Boards (PCBs), which are essential components in nearly all modern electronic devices. From smartphones to industrial machinery, PCBs provide the foundation for electrical connections, enabling devices to function efficiently. This guide explores the PCB Manufacturing process, materials used, key technologies, and industry trends.

The PCB Manufacturing Process: Step by Step

The production of Printed Circuit Boards involves multiple stages, each requiring precision and expertise. Below is a detailed breakdown of the PCB Manufacturing workflow.

1. Design and Schematic Creation

Before production begins, engineers design the PCB using specialized software like Altium Designer, Eagle, or KiCad. The schematic defines the electrical connections, while the layout determines the physical placement of components.

2. Printing the PCB Design

Once the design is finalized, it is printed onto a laminate material using a photoplotter, which transfers the circuit pattern onto a film.

3. Substrate Preparation

The base material, typically FR-4 (fiberglass-reinforced epoxy laminate), is cleaned and coated with a photosensitive layer called photoresist.

4. Exposure and Developing

The photoresist-coated substrate is exposed to UV light through the printed film. The exposed areas harden, while the unexposed regions are washed away during the developing stage.

5. Etching the Copper Layers

The board is then immersed in an etching solution (usually ferric chloride or ammonium persulfate), which removes unwanted copper, leaving only the desired circuit traces.

6. Drilling Holes for Components

Precision CNC machines drill holes for through-hole components and vias (electrical connections between layers).

7. Plating and Copper Deposition

A thin layer of copper is electroplated onto the board to strengthen the connections and ensure conductivity.

8. Solder Mask Application

A solder mask (usually green, but available in other colors) is applied to protect the copper traces from oxidation and prevent solder bridges.

9. Silkscreen Printing

Component labels, logos, and reference indicators are printed onto the board using silkscreen printing for easier assembly.

10. Surface Finish Application

To prevent oxidation and improve solderability, a surface finish (such as HASL, ENIG, or OSP) is applied.

11. Electrical Testing and Quality Control

Automated AOI (Automated Optical Inspection) and flying probe testers verify electrical connectivity and detect defects.

12. Final Assembly and Shipping

Once tested, the PCBs are assembled with components (if required) and shipped to manufacturers for integration into electronic devices.

Materials Used in PCB Manufacturing

The quality of a Printed Circuit Board depends heavily on the materials used. Key materials include:

Copper Foil: Conducts electricity and forms the circuit traces.

FR-4 Substrate: Provides mechanical strength and insulation.

Solder Mask: Protects copper traces and prevents short circuits.

Silkscreen Ink: Adds labels and markings for assembly.

Surface Finishes (HASL, ENIG, OSP): Enhances solderability and durability.

Advanced PCB Manufacturing Technologies

As electronics evolve, PCB Manufacturing techniques continue to advance. Some cutting-edge technologies include:

1. High-Density Interconnect (HDI) PCBs

These boards feature microvias, finer traces, and multiple layers, enabling compact designs for smartphones and wearables.

2. Flexible and Rigid-Flex PCBs

Made from polyimide or other flexible materials, these PCBs are used in bendable electronics like foldable phones and medical devices.

3. Multilayer PCBs

With 4 to 50+ layers, these PCBs are essential for complex devices like servers and aerospace systems.

4. Embedded Components

Passive components (resistors, capacitors) are embedded within the PCB, reducing size and improving performance.

5. 3D Printed Electronics

Additive manufacturing is being explored for rapid PCB prototyping, allowing faster design iterations.

Challenges in PCB Manufacturing

Despite advancements, PCB Manufacturing faces several challenges:

Miniaturization: As devices shrink, producing ultra-fine traces becomes difficult.

Signal Integrity: High-speed circuits require precise impedance control.

Thermal Management: Dense PCBs generate heat, necessitating effective cooling solutions.

Environmental Regulations: Restrictions on hazardous materials (lead, halogen) impact manufacturing processes.

Future Trends in PCB Manufacturing

The PCB Manufacturing industry is evolving with new trends:

AI and Automation: Machine learning improves defect detection and process optimization.

Sustainable Manufacturing: Eco-friendly materials and lead-free soldering gain traction.

5G and IoT Demand: High-frequency PCBs are needed for 5G networks and IoT devices.

Additive Manufacturing: 3D printing could revolutionize prototyping and low-volume production.

Conclusion

PCB Manufacturing is a complex yet vital industry that powers modern electronics. From design to final testing, each step requires precision to ensure reliability and performance. As technology advances, Printed Circuit Boards will continue to evolve, enabling smaller, faster, and more efficient electronic devices. Understanding the PCB Manufacturing process helps engineers, designers, and manufacturers stay ahead in this rapidly changing field.

By keeping up with emerging trends and overcoming challenges, the PCB Manufacturing industry will remain at the heart of technological innovation. Whether for consumer electronics, automotive systems, or aerospace applications, high-quality PCBs are indispensable in today’s connected world.

1 note

·

View note

Text

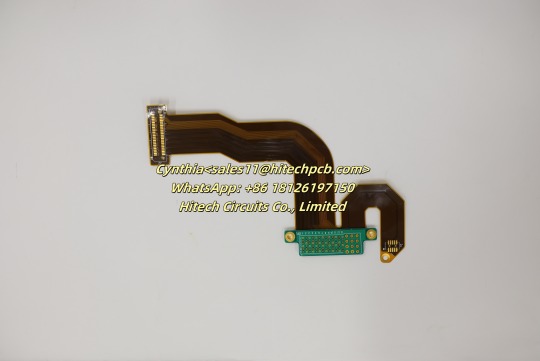

Hitech rigid flex pcb manufacturing process

After the production of FPC flexible boards is completed, the production of Hitech rigid flex pcb boards can be completed through the following processes.

1. Punching

Drill holes on FR4 and PP film, and the design on the alignment hole is not the same as the general through hole. After the punching is completed, browning is required.

2. Riveting

Laminate copper clad laminates, PP adhesives, and FPC circuit boards and place them neatly. The original old process is to laminate and pressing step by step, but it is a waste of time. After many attempts, we found that the stacking process can be completed once.

3. Laminate

This is a relatively complete step in the production of rigid-flex pcb board. Most of the materials are integrated for the first time. First, the bottom layer is copper clad laminate and PP film, above are the FPC flexible board produced in the previous process, and a PP film is placed on the FPC flexible board, then place the last layer of copper clad laminate. All materials to be laminated are placed in order and pressed together.

4. Trimming

That is to remove the part of the circuit board where there is no circuit at the edge of the circuit board currently and in the future. Afterwards, it is necessary to measure whether the material has excessive expansion and contraction. Because the PI used in the production of flexible boards is also expansion and contraction, this has a very large impact on the production of circuit boards.

5. Drilling

This step is the first step to turn on the entire circuit board, and the production parameters should be produced according to the design parameters.

6. Desmear

First, remove the scum generated by the drilling of the circuit board, and then use plasma cleaning to clean the through holes and the board surface.

7. Immersion copper

This step is the process of electroplating through holes, also known as hole metallization. Realize through-hole power conduction.

8. Plate plating

Partially electroplating copper on the upper surface of the electroplating hole makes the copper thickness above the through hole exceed a certain height of the copper clad board surface.

9. Outer dry film positive film production

The same as the production process of the anti-corrosion dry film of the FPC board, the circuit to be etched on the copper clad board is made. After the development is completed, check the circuit.

10. Graphic plating

After the initial copper sinking, pattern electroplating is performed, and the current time and copper plating wire are used according to the design requirements to reach a certain electroplating area.

11. Alkaline etching

12. Print solder mask

This step has the same effect as the FPC board protective film. We see that the PCB rigid board is generally green. This step is generally called green oil printing. After the printing is completed, the inspection is carried out.

13. Open the cover

Cover opening, which is the area where the FPC board is located, but the area not needed by the rigid board is laser cut to expose the FPC board.

14. Curing

It is also a baking process.

15. Surface treatment

Generally, at this time, a rigid-flex PCB board has been manufactured, and only the metallization treatment is required on the surface of the circuit board, which can play a role in preventing wear and oxidation. Generally, this process is to soak the circuit board in a chemical solution, and the metal elements in the solution are densely distributed on the circuit board circuit.

16. Characters printing

The positions of the parts to be assembled and some basic product information are printed on the rigid-flex board in the form of characters.

17. Test

This is a process of checking whether the circuit board is qualified. The test items are tested for electrical properties according to customer requirements. The tests generally include impedance test, open and short circuit test and so on.

18. Final inspection

19. Packaging and shipping

There are many ways to package circuit boards. Generally, Hitech use packaging bags to separate them, and then use a vacuum packaging machine to vacuum package the rigid-flex PCB boards .

If you have an inquiry for our service, please contact us, Cynthia<[email protected]>, thank you.

0 notes

Text

FPCway: Specialized manufacturer of flexible printed circuit boards

and rigid-flexible printed circuits

In today's fast-paced technology landscape, the demand for smaller, lighter, and more complex electronic devices continues to rise. Whether it's a sleek smartphone in your pocket or a sophisticated medical device in a hospital, these devices rely on cutting-edge printed circuit boards (PCBS) to run efficiently. Among the many types of printed circuit boards available, flexible printed circuits (flex PCBs) and rigid-flex printed circuits (Rigid-Flex PCBS) are increasingly favored due to their versatility and rich and diverse design possibilities.

Advantages of Flexible Printed Circuit (Flex PCB) :

Space efficiency: Very thin and lightweight, ideal for small electronic devices.

High reliability: Fewer interconnections and solder joints increase reliability and reduce points of failure.

Strong durability: Flexible printed circuits can withstand vibration, shock and extreme temperatures, making them ideal for harsh environments.

Freedom of design: The flexibility of the substrate allows for creative and innovative designs that may not be possible with rigid printed circuits.

Advantages of rigid-flex PCBs:

Space optimization: Flexible printed circuit (Flex PCB) components allow the integration of multiple PCBS and connectors, saving valuable space.

High reliability: Fewer connectors and solder joints reduce the risk of connection failure and signal loss.

Complex geometry: Rigid-flexible printed circuits can be designed to fit non-standard and irregular shaped enclosures.

Reduce weight: Reduce connectors and cables to reduce the overall weight of the device.

FPCway is a PCB manufacturing company located in Shenzhen, China, specializing in the manufacture of flexible printed circuit boards and rigid-flexible printed circuits. The circuit boards produced have been widely used in mobile communication, Internet of Things, optoelectronics, industrial control, medical equipment, consumer electronics and other high-tech industries. The products produced by FPCway are exported to all over the world. At present, FPCway has more than 5000 square meters of FPC workshop, which has 12 SMT production lines and 2 THT production lines. FPCway has more than 200 employees, with more than 20 senior executives with decades of industry experience. With this experience and advanced equipment, we have maintained excellent technical capabilities and strong competitiveness in the Flex PCB industry.

FPCway: From prototype to assembly to product

FPCway provides Flex PCB and rigid-flex PCBs from prototype design to assembly to product, while more than 200 professionals ensure zero defects and the fastest delivery time. The company sources materials from well-known brands and maintains ISO 9001, IATF16949 quality systems and UL certification, facilitating customers' access to commercial products.

Flexible PCB prototype: The production process of FPCB products usually starts from making prototypes, FPCWay almost does not limit the appearance size of FPCB, and can adjust the substrate, thickness and layer number of products according to customer needs.

Flexible PCB assembly: Bring goodness to life

Designing and manufacturing flexible printed circuits (flex PCBs) and rigid-flex PCBS is a highly specialized process that requires specialized knowledge and advanced equipment. Flexible printed circuit (Flex PCB) components are a key step in translating these innovative designs into functional electronic devices. FPCway's engineers consider the flexibility and form factor required by the customer to create a suitable flexible printed circuit (Flex PCB) layout choice; Secondly, the appropriate substrate material is selected based on factors such as flexibility, temperature resistance and intended application. The manufacturer then uses a combination of addition and subtraction processes to create the flexible circuit, which involves etching, drilling, and laminating together. FPCway uses advanced automatic pickers to precisely place components on manufacturing flexible printed circuits (flex PCBs) or rigid-flex PCBS, then apply solder paste to the component pads, heat the components to melt the solder and establish electrical connections. Finally, engineers ensure that flexible printed circuit (Flex PCB) or rigid-flex PCBs components meet quality and functional standards through rigorous testing to ensure that the product has zero defects.

FPCway through the construction of a strong talent team and increase capital investment in the purchase of new equipment, and from prototype design to assembly to the entire process of product accurate control, to ensure product quality, FPCway at a very competitive price to provide first-class service. The company stands out in the flexible printed circuit board industry for its superior technical capabilities, excellent product quality and timely delivery of products.

0 notes

Video

youtube

Rigid flex PCB board China -- Hitech Circuits

https://www.hitechpcba.com/rigid-flex-pcb-manufacturer

Rigid Flex Printed Circuit Board Manufacturer

Rigid flex printed circuit boards (PCBs) are manufactured by combining rigid and flexible board technologies. These circuit boards are made up of multiple flexible circuit inner layers. An epoxy pre-preg bonding film is used to attach together these inner layers. The key benefit of these boards is that they are a combination of the best quality of flexible and rigid circuit boards. This can have several further benefits as far as stability, assembly, signal transmission, and overall size of the circuit are concerned. Hitechpcb provides a number of variants in rigid flex PCBs, which include 4 layer rigid flex with ENIG finish, 10 layer rigid flex with 4 layer flex, 12 layer rigid flex with heat sink, 14 layer rigid flex circuit boards, and many more. It is one of the leading rigid flex PCB manufacturers.

0 notes

Text

Asus ROG Strix B660 A Gaming WIFI D4 Features: Intel LGA 1700 Socket: Ready for 12th Gen Intel Core, Pentium Gold and Celeron processors Optimal Power Solution: 12+1 power stages with ProCool power connectors, high-quality alloy chokes and durable capacitors to support multi-core processors Optimized Thermal Design: Integrated I/O cover, VRM heatsinks with high conductivity thermal pads, and three onboard M.2 heatsinks High-performance Networking: On-board Intel WiFi 6 (802.11ax) and Intel 2.5 Gb Ethernet with ASUS LANGuard Best Gaming Connectivity: Supports HDMI 2.1 and DisplayPort 1.4 output, three M.2 slots, as well as USB 3.2 Gen 2×2 Type-C Intelligent Control: ASUS-exclusive AI Cooling, AI Networking and Two-Way AI Noise Cancelation to simplify setup and improve performance DIY Friendly Design: M.2 Q-Latch, pre-mounted I/O shield, BIOS FlashBack button and Q-LED Unmatched Personalization: ASUS-exclusive Aura Sync RGB lighting, including one RGB header and three addressable Gen 2 headers Industry-leading Gaming Audio: ALC4080 with Savitech SV3H712 amplifier, along with DTS Sound Unbound and Sonic Studio III Renowned Software: Bundled 60-day free trial of AIDA64 Extreme, and an intuitive UEFI BIOS dashboard ROG Strix B660-A Gaming WiFi D4 offers premium power delivery and optimized cooling to unleash the full force of the latest 12th Gen Intel Core processors. Onboard PCIe 5.0, WiFi 6 and three PCIe 4.0 M.2 slots provide lightning-fast data transfers for an endless variety of scenarios, and ASUS-exclusive intelligent controls to help optimize PC settings. On top of all that, DIY-friendly innovations help simplify the PC building process to get to you up and running smoothly. TEAMED POWER STAGES 12+1 power stages combine high-side and low-side MOSFETS and drivers into a single package, delivering the power and efficiency that the latest Intel processors can take full advantage of. ALLOY CHOKES AND CAPACITORS High-end chokes and durable capacitors are engineered to resist extreme temperatures, enabling performance that exceeds industry standards. PROCOOL POWER CONNECTOR The ASUS ProCool socket is built to exacting specifications to ensure flush contact with the PSU power lines, enabling lower impedance and better heat dissipation. DIGI+ POWER CONTROL The Digi+ voltage regulator module (VRM) is one of the finest in the industry, ensuring ultra-smooth and clean power delivery to the CPU. SIX-LAYER PCB A multi-layered printed circuit board design quickly dissipates heat around the voltage regulators to improve overall system stability and provide the CPU with more overclocking headroom. Two-Way AI Noise Cancelation This powerful ASUS-exclusive utility leverages a massive deep-learning database to reduce background noise from the microphone* and incoming audio while preserving voices. Distracting keyboard clatter, mouse clicks and other ambient noises are removed so you can hear and be heard with perfect clarity while gaming or during calls. Asus ROG Strix B660 A Gaming WIFI D4 AI Cooling ASUS AI Cooling technology automatically manages and controls motherboard-connected fans to ensure optimal settings based on current system load and temperature. AI Networking The proprietary ROG GameFirst VI utility is designed to help all users beginners, experts, and everyone in between optimize network settings to ensure smooth online gameplay. New to this generation, GameFirst VI features AI-enhanced identification and boost technologies to ensure faster and smarter network optimization. Adaptive Intelligence GameFirst VI notes what you’re currently doing and adjusts bandwidth accordingly to ensure smooth online experiences, even when multitasking. OptiMem II OptiMem II technology offers higher clock speeds through trace layout optimizations that significantly reduce signal distance and crosstalk while enhancing memory stability and compatibility. ROG Strix B660-A Gaming WiFi D4 supports up to 128 GB of DDR4 memory across four slots.

WiFi 6 (802.11 ax) Onboard WiFi 6 (802.11ax) supports ultrafast wireless-networking speeds, improved capacity and better performance in dense wireless environments, providing exceptional online gaming experiences. Pair your motherboard with ASUS WiFi 6 routers to fully experience the networking potential of WiFi 6. Intel 2.5 Gb Ethernet Onboard 2.5 Gb Ethernet gives your wired connection a boost, with up to a 2.5x improvement over standard Ethernet connections for faster file transfers, smoother lag-free gaming and high-res video streaming. SupremeFX ROG SupremeFX is a unique blend of hardware and software that provides superior audio. In ROG Strix B660-A Gaming WiFi D4, SupremeFX features the ALC4080 codec to increase playback resolution from 192 kHz to 384 kHz across all channels. The front-panel output is streamed through a highly integrated Savitech amplifier thatands capable of driving of a wide variety of gaming headsets and high-fidelity headphones. Undeniably ROG Strix The ROG Strix B660-A Gaming WiFi D4 will turn heads with a striking silver-white finish that contrasts with a bold Aura RGB-illuminated glitch-effect logo. Meanwhile, parallel strakes and dotted text on the aluminum I/O shroud, M.2 and PCH heatsinks tie the whole aesthetic together and underline the ROG Strix fundamentals of speed, diversity and attitude. M.2 Q-LATCH The innovative Q-Latch makes it easy to install or remove an M.2 SSD without the need for specific tools. The design employs a simple locking mechanism to secure the drive and neatly eliminate traditional screws. CERTIFIED COMPATIBILITY ROG Strix motherboards undergo an extensive certification program to ensure compatibility with the widest range of components and devices. Our Qualified Vendor List (QVL) provides a reference for identifying guaranteed-compatible components and memory. ASUS AIO coolers are also compatible with a wide variety of CPUs, up to and including 12th Gen Intel processors, giving you ultimate flexibility to cool the CPU that fits your needs. THE ROG STRIX ECOSYSTEM AWAITS Level up your game with ROG Strix. Enjoy complementary aesthetics, control and compatibility across AIO coolers, cases, peripherals, and much more. ROG offers more choices than any other brand. UEFI BIOS The renowned ROG UEFI (BIOS) provides everything you need to configure, tweak, and tune your rig. It offers intelligently simplified options for newcomers to PC DIY and more comprehensive features for seasoned veterans. Sonic Studio III ROG Sonic Studio supports HRTF-based (head-related transfer function*) virtual surround for VR headsets, casting an immersive aural landscape that draws you deeper into the action. The intuitive Sonic Studio interface also offers a range of EQ options and one-click presets, allowing you to tailor acoustics to suit personal preferences or the characteristics of your headset. DTS: Sound Unbound dts ROG Strix B660 motherboards are pre-loaded with the DTS Sound Unbound app that envelops you in audio as never before, conjuring whole new levels of immersion for extraordinary gaming and entertainment experiences. By leveraging Windows Sonic spatial technology, DTS Sound Unbound delivers audio in a virtual 3D space putting you right in the middle of the soundscape, where you can sense the location and direction of every gunshot, footstep or other sound in your virtual environment. Stereo Sound: Discrete left and right audio channels enable headphone or two-speaker setup. Surround Sound: Audio is split and served over multiple speaker channels e.g., 5.1 or 7.1 to create an enveloping experience on a single, logical plane. Spatial Sound: A virtual audio sphereand effect creates astonishing 360° immersion with you at the center, where sounds seem to travel in all directions. AIDA64 EXTREME ROG Strix B660 motherboards include an AIDA64 Extreme 60 days free trial. This industry-leading system information tool provides detailed information about installed hardware

and software, and it also provides benchmarks for measuring performance of the entire system or individual components. AIDA64 Extreme includes a monitoring and diagnostics feature to detect and prevent hardware issues. All vital system sensors can be tracked in real time, allowing voltage readings, fan speeds, and temperature information to be displayed on the desktop or sent to dedicated displays or to the OLED panels of ROG AIO liquid coolers*. Armoury Crate Armoury Crate is a software utility designed to give you centralized control of supported gaming products, making it easy to tune the look and feel of your system. From a single intuitive interface, Armoury Crate helps you customize RGB lighting and effects for compatible devices and synchronize them with Aura Sync to create a unified lighting scheme across your system. In addition, Armoury Crateands Fan Xpert4 tool provides comprehensive control over fans, water pumps and all-in-one (AIO) coolers. Asus ROG Strix B660 A Gaming WIFI D4

0 notes

Text

The advantages of ENIG Surface treatment

Exceptional Surface Flatness One of the standout features of ENIG (Electroless Nickel Immersion Gold) is its impressive surface flatness, making it perfect for PCBs with fine-pitch components. This flat surface ensures precise electrical contact and reliable component placement. Additionally, the uniformity of the ENIG coating boosts its solderability, allowing for the formation of strong and consistent solder joints.

Versatile Soldering Compatibility ENIG is highly versatile, as it supports both leaded and lead-free soldering processes. This flexibility makes it suitable for a wide range of applications, from consumer electronics to industrial, aerospace, and defense systems. Furthermore, its RoHS compliance adds to its appeal in industries that require environmentally friendly manufacturing solutions.

Enhanced Oxidation Resistance The ENIG finish provides excellent protection against oxidation. The nickel layer acts as a shield, preventing the copper on the PCB from oxidizing, while the thin gold coating protects the nickel itself. This dual layer of defense extends the lifespan of the PCB, making ENIG a great choice for designs where durability is critical.

Durability and Longevity

ENIG is well-known for its durability and long-lasting performance. The nickel layer offers a hard, wear-resistant surface, capable of withstanding mechanical stress, which is crucial for through-holes, vias, and components like Ball Grid Arrays (BGAs) in demanding environments. This finish offers a long shelf life, with PCBs remaining reliable for over 12 months.

Though the gold layer is thin, it provides robust protection against corrosion. Gold’s natural resistance to oxidation ensures that the PCB's electrical performance remains consistent, even in challenging environments such as industrial or outdoor settings. Moreover, the electroless deposition process ensures even coverage across complex PCB geometries, further enhancing protection and longevity.

ENIG-finished PCBs are designed to maintain optimal performance for many years, even under tough conditions. While the initial cost of ENIG is higher than some other finishes, its extended lifespan makes it a cost-effective solution in the long run, especially for high-volume production common in places like China.

Superior Electrical and Thermal Performance

ENIG offers exceptional electrical conductivity thanks to its gold layer, which is crucial for minimizing signal loss, particularly in high-frequency applications. This makes ENIG a top choice for PCBs used in telecommunications, computing, and high-speed data processing.

In terms of thermal stability, the nickel layer's high melting point allows ENIG-finished PCBs to endure the high temperatures involved in soldering and operational use. This is especially important for PCBs in power electronics and other high-heat environments.

ENIG’s surface flatness is another performance advantage, ensuring accurate component placement and assembly, especially for fine-pitch and surface mount technology (SMT) components. Combined with excellent wetting properties, ENIG allows for the creation of reliable solder joints, which are critical to the performance and longevity of electronic devices.

Wide Compatibility

ENIG is highly compatible with various materials and manufacturing processes. It works seamlessly with both leaded and lead-free solders, and it supports a variety of solder pastes and fluxes, making it versatile across different types of PCB assemblies.

Additionally, the nickel layer provides strong corrosion protection, making ENIG suitable for use in harsh environments. It also offers a smooth surface for applications like chip-scale packages (CSPs) and is ideal for wire bonding. ENIG can handle multiple reflow cycles, making it a reliable choice for projects requiring repeated assembly processes.

If you have a PCB project with ENIG applied, please don’t hesitate to contact me--Perlina, you can click my hompage to find my our company's website.

0 notes

Text

SZOROD Technology Announces Commitment to Innovation and Growth in Electronics Manufacturing

SHENZHEN, CHINA –May 2024– SZOROD Technology Co., Ltd., a leading provider of hardware outsourcing and PCBA OEM services, announced its continued dedication to innovation and growth in the electronics manufacturing industry.

Established Expertise in Chip Decryption and PCB Reverse Engineering

Founded in Hong Kong in 2003, SZOROD boasts a long history of technical expertise in high difficulty chip unlocking solution and PCB reverse engineering. They have a successful track record and provide a wide range of services, such as:

Highly Accurate PCB Reverse Engineering: SZOROD achieves a 100% success rate for PCB designs with up to 12 layers, ensuring accurate schematics and Bill of Materials (BOM) generation.

Advanced Chip Decryption: Their team possesses a 90% success rate in unlocking even the most challenging encryption protocols on various microcontrollers (MCUs) from leading manufacturers.

High-Volume Production Capabilities: SZOROD fulfils PCB cloning orders in high quantities, efficiently managing 50-60 PCB copies and 60-70 chip decryptions daily.

Reliable Delivery: They understand the importance of timeliness and consistently meet over 95% of their contracted delivery deadlines.

Global Presence and Continued Investment

SZOROD has established a strong international presence, collaborating with over 1000 partner companies in more than 100 countries across Southeast Asia, Europe, America, and beyond. They are committed to continuous improvement and plan to:

Embrace AI-powered PCB Reverse Engineering: Leveraging cutting-edge technology, SZOROD aims to streamline PCB reverse engineering processes using artificial intelligence.

Upgrade Equipment for Enhanced Precision: The company is dedicated to investing in advanced, high-precision equipment to ensure the highest quality standards.

Pursue Domestic Listing Within Five Years: SZOROD has set an ambitious goal of achieving a domestic listing within the next five years, signifying their commitment to long-term growth and industry leadership.

A One-Stop Solution for Hardware Outsourcing

SZOROD offers a comprehensive suite of services under one roof, encompassing:

PCB Copying

PCB Design

BOM Analysis

Schematic Reverse Engineering

Chip Decryption

Component Procurement

Technical Debugging

Hardware Reverse Research and Guidance

Business Development

By integrating these services with their own board factory, SZOROD provides a seamless one-stop solution for clients seeking high-quality hardware outsourcing and PCBA OEM services.

About SZOROD Technology Co., Ltd.

SZOROD Technology Co., Ltd. is a leading provider of hardware outsourcing and PCBA OEM services, dedicated to empowering innovation in the electronics manufacturing industry. With a global presence, advanced technical expertise, and a commitment to continuous improvement, SZOROD offers a comprehensive suite of services to streamline and expedite the development and production of electronic products.

0 notes

Link

A Maximus Extreme with integrated EKWB monoblock If you want a serious motherboard for Intel's next build, the ASUS ROG Z690 Maximus Extreme Glacial is the pinnacle of Z690 boards right now. The 24+1 phase power supply design on a 12-layer PCB will... bitrise.co.in

0 notes