#PLC-based automation

Explore tagged Tumblr posts

Text

Transform Your Water Treatment Process with Smart Automation!

0 notes

Text

CIP Panel Manufacture in India | Electropoint Automation

Experience the excellence of our high-quality Cleaning Place Control Panels as we proudly stand as a leading CIP panel manufacturer in Pune, Maharashtra. Our state-of-the-art manufacturing process ensures that each control panel is meticulously crafted using top-grade components, guaranteeing reliable and efficient performance in cleaning processes. Whether you need to control the cleaning of industrial equipment, tanks, or pipelines, our CIP panels provide seamless automation and monitoring. At Electropoint Automation, customer satisfaction is at the heart of everything we do. We strive to deliver products that exceed expectations and provide you with a competitive edge in your operations.

#CIP Panel Manufacturer#Specially Designed Panel Manufacturer#Specially Designed Panel Supplier#Separator Control Panel Manufacturer#Control Panel Manufacturer#Juice & Beverage plant turnkey automation#Dairy plant turnkey automation#PLC & SCADA Based Automation Manufacturer#Pasteurizer Panels Manufacturer

0 notes

Text

At Asteam Techno Solutions, we specialize in creating intelligent automation systems using PLC, VFD & HMI combinations.

🧠 Designed for reliability ⚙️ Engineered for control 💡 Built for efficiency Watch how this integration brings automation to life. 📩 Contact us for tailored automation solutions!

#AsteamTechno#AutomationExperts#industrialcontrol#PLCVFDHMIIntegration#PLC#SCADA#VFD#HMI#Informative#tumblr trends#trending#automation#viral#Linkedinpost

2 notes

·

View notes

Text

Fast Casual Restaurant Market Growth Projected to Reach $337.8 Billion by 2032

Fast casual restaurant offer a self-service model, often with limited table service, and place a strong emphasis on in-house dining ambiance, which features upscale decor based on various themes. Quality is a key focus, with customers expecting higher-grade ingredients at a price point between fast food and full-service dining. Customization is central to the fast-casual experience, which allow customers to customize their meals from a range of different ingredients. Some fast casual restaurants such as Chipotle and Shake Shack even include alcoholic beverage offerings.

Get a Sample PDF Report to understand our report before you purchase: https://www.alliedmarketresearch.com/request-sample/A06308

The fast casual restaurant market was valued at $124.50 billion in 2022, and is estimated to reach $337.8 billion by 2032, growing at a CAGR of 10.4% from 2023 to 2032.

The key players in the global fast casual restaurant market have implemented a range of strategic initiatives, which includes geographical expansion, product launch, innovation, and acquisitions. These key developments have significantly increased the market share, driven profitability, and strengthened their competitive position within the market. The key players operating in the fast casual restaurant market include Chipotle Mexican Grill, Wingstop Restaurants, Inc., EXKI SA, Panda Restaurant group, Inc., Five Guys Enterprises, LLC., Famous Brands Limited, Restaurant Brands International Inc., Zaxby’s Franchising LLC., Erbert & Gerbert’s Sandwich Shop, and Tortilla Mexican Grill PLC.

In addition, there are numerous fast casual restaurant chains which include Panera Bread, Sweetgreen, MOD Pizza, and Chopt Creative Salad Company. These establishments cater to a range of customer who seek the combination of convenience, quality, and customization offered by fast casual dining, making it a prominent and rapidly growing segment of the restaurant market.

The advent of cloud kitchens has brought a rapid shift in the restaurant industry by significantly reducing capital expenditure requirements, which has thereby facilitated the establishment of fast casual restaurant market growth with greater ease. This lower financial burden, coupled with the prospect of higher profit margins, has fueled significant investments in the fast-casual restaurant segment. Fast-casual restaurants typically demand lower initial capital in the beginning that effectively lowers the financial barrier to entry for entrepreneurs and investors who seeks to enter the market. Fast-casual chains are characterized by their strategic adoption of technology, which supports the businesses to streamline operations, enhance customer convenience, enable online ordering, delivery services, and engage with various customers through data-driven decision-making. This tech-driven approach contributes to increased operational efficiency and helps to provide improved overall business performance. Thus, there is a steady growth in fast casual restaurant market size in recent years, along with increased fast casual restaurant market share in different regions.

Buy Now and Get Discount Up to 50% https://www.alliedmarketresearch.com/fast-casual-restaurant-market/purchase-options

Moreover, the increase in automation within fast-casual kitchen operations and the rise of food delivery companies that specializes in door-to-door service create plenty of opportunities for further growth and expansion of these kitchen concepts on a global scale. Furthermore, many fast-casual chains offer franchise opportunities that facilitates the replication of successful business models in diverse locations all around the world. This franchising approach accelerates the proliferation of fast-casual chains, which thus contributes to rapid expansion of fast casual restaurant market. Thus, the combination of low entry barriers, the potential for robust profits, technological advancements, automation, and franchising opportunities is poised to drive the swift growth of the market during the fast casual restaurant market forecast..

Fast casual restaurants face challenges during the fast casual restaurant market analysis owing to economic uncertainties, which includes the possibility of rising unemployment and inflationary pressures globally. Fast casual restaurants, known for their fresh and health-conscious menus, come with premium prices that exclude budget-conscious consumers from the target market. The differences in prices, in comparison to more budget-friendly quick-service restaurants such as Subway or McDonald's, curtail their customer base, which thus limit their ability to serve a broader audience in the global market.

The fast casual restaurant industry recognizes the imperative role of technology in operational optimization. Integration of scheduling software, digital inventory tracking, automated procurement, and digital reservation systems offers substantial enhancements in revenue generation, inventory control, and customer satisfaction. This trend presents lucrative opportunities for fast casual restaurant stakeholders to streamline critical processes and improve efficiency. Moreover, the adoption of robot-assisted cooking technology in prominent chains such as Chipotle, White Castle, and Wing Zone presents huge market growth owing to increased convenience, reduction in labor costs, and faster food preparation, which ultimately leads to quicker customer service. Thus, fast casual restaurant market opportunities are growing owing to the advancement, which has led to fast casual restaurant market trends to flourish in recent times.

To Ask About Report Availability or Customization, Click Here: https://www.alliedmarketresearch.com/connect-to-analyst/A06308

The rapid spread of coronavirus has disrupted the smooth functioning of fast casual restaurant industry, owing to which the companies faced a downfall in the initial phase of the COVID-19 pandemic, but soon they managed to maintain their revenues after the restrictions were lifted and everything was back to normal in different regions. The outbreak started in China resulting in lockdown and ceasing of dine-in activities across the country. Moreover, recent developments in resurgence of second wave of COVID-19 in China was one of the major challenges the country faced owing to complete shutdown of all activities. Other countries in Asia were also facing the same predicament. Stringent rules across the Indian subcontinent disrupted the supply chain and interrupt the production activities. The duration of the virus outbreak remained a key factor in assessing the overall impact of the pandemic, however, lack of workers and disruption in supply chain were the major challenges for the engaged stakeholders all around the world.

The fast casual market is segmented into food type, mode of operation, nature, and region. On the basis of food type, the market is segregated into burger/sandwich, pizza/pasta, Asian/Latin American food, chicken, and others. As per mode of operation, it is divided into dine-in and takeaway. By nature, the market is bifurcated into franchised and standalone. Region wise, it is analyzed across North America (U.S., Canada, and Mexico), Europe (UK, Germany, France, Italy, Spain, and rest of Europe), Asia-Pacific (China, India, Japan, Asean, and rest of Asia-Pacific), and LAMEA (Latin America, Middle East, and Africa).

2 notes

·

View notes

Text

Need Siemens LOGO! PLC Installation Services in Dhaka?

Looking to boost your business's automation systems in Bangladesh? Apical Industrial Solution & Technology is your trusted provider for Siemens LOGO! PLC services. Our skilled engineers specialise in the installation and maintenance of Siemens LOGO! PLCs, ensuring seamless automation for your operations. Whether you're based in Dhaka, Chittagong, or anywhere across the country, we've got you covered!

Why Choose Us?

✅ Expert Siemens LOGO! PLC Installation✅ Local support across Dhaka and beyond ✅ Tailored solutions for small to medium-sized automation projects ✅ On-site troubleshooting and maintenance services

Take your business automation to the next level with our expert team!

Call Us Today to schedule your consultation or visit our website for more information. Let's transform your automation processes and elevate your productivity!

📍 Apical Industrial Solution & Technology, Dhaka, Bangladesh 📞https://maps.app.goo.gl/FnY8mTekL35zSLxT9 🌐 https://apicalindustrialsolution.com/

#DhakaAutomation #SiemensLOGOPLC #BangladeshAutomation #PLCServicesDhaka #IndustrialAutomationBangladesh #ApicalIndustrialSolutions

#DhakaAutomation#SiemensLOGOPLC#BangladeshAutomation#ApicalIndustrialSolutions#IndustrialAutomationBangladesh#PLCServicesDhaka

2 notes

·

View notes

Text

1 note

·

View note

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

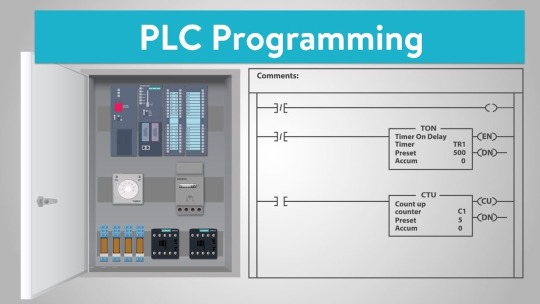

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Deployment Automation Market: Growing Popularity & Emerging Trends

According to Market Statistix, the Deployment Automation Market revenue and growth prospects are expected to grow at a significant rate during the analysis period of 2024-2032, with 2023 as the base year. Deployment Automation Market research is an ongoing process. Regularly monitor and evaluate market dynamics to stay informed and adapt your strategies accordingly. As a market research and consulting firm, we offer market research reports that focus on major parameters, including Target Market Identification, Customer Needs and Preferences, Thorough Competitor Analysis, Market Size and market Analysis, and other major factors. In the end, we provide meaningful insights and actionable recommendations that inform decision-making and strategy development.

The Deployment Automation Market is projected to experience steady growth, expanding at a CAGR of 11.3% over the forecast period.

Who are the key players operating in the industry?

Puppet Inc., Chef Software Inc., Ansible Inc., SaltStack Inc., Atlassian Corporation Plc, Red Hat Inc., Microsoft Corporation, IBM Corporation, CA Technologies (Broadcom Inc.), BMC Software Inc., Micro Focus International Plc, GitLab Inc., Flexagon LLC, CloudBees Inc., HashiCorp Inc., XebiaLabs (Digital.ai), JetBrains s.r.o., CircleCI, Octopus Deploy, Electric Cloud Inc.

Request a sample on this latest research report Deployment Automation Market spread across 100+ pages and supported with tables and figures is now available @ https://www.marketstatistix.com/sample-report/global-deployment-automation-market

Deployment Automation Market Overview and Insights:

Market Statistix is solidifying its reputation as a leading market research and consulting service provider, delivering data-driven insights that help businesses make informed strategic decisions. By focusing on detailed demand analysis, accurate market forecasts, and competitive evaluations, we equip companies with the essential tools to succeed in an increasingly competitive landscape. This comprehensive Deployment Automation market analysis offers a detailed overview of the current environment and forecasts growth trends through 2032. Our expertise enables clients to stay ahead of the curve, providing actionable insights and competitive intelligence tailored to their industries.

What is included in Deployment Automation market segmentation?

The report has segmented the market into the following categories:

Segment by Type: Type I, Type II, Type III

Segment by Application: Retail, IT and Telecommunications, BFSI, Healthcare, Manufacturing, Others

Deployment Automation market is segmented by company, region (country), by Type, and by Application. Players, stakeholders, and other participants in the Deployment Automation market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by Type and by Application in terms of revenue and forecast for the period 2019-2032.

Have a query? Market an enquiry before purchase @ https://www.marketstatistix.com/enquiry-before-buy/global-deployment-automation-market

Competitive Analysis of the market in the report identifies various key manufacturers of the market. We do company profiling for major key players. The research report includes Competitive Positioning, Investment Analysis, BCG Matrix, Heat Map Analysis, and Mergers & Acquisitions. It helps the reader understand the strategies and collaborations that players are targeting to combat competition in the market. The comprehensive report offers a significant microscopic look at the market. The reader can identify the footprints of the manufacturers by knowing about the product portfolio, the global price of manufacturers, and production by producers during the forecast period.

As market research and consulting firm we offer market research report which is focusing on major parameters including Target Market Identification, Customer Needs and Preferences, Thorough Competitor Analysis, Market Size & Market Analysis, and other major factors.

Purchase the latest edition of the Deployment Automation market report now @ https://www.marketstatistix.com/buy-now?format=1&report=46

The Deployment Automation market research study ensures the highest level of accuracy and reliability as we precisely examine the overall industry, covering all the market fundamentals. By leveraging a wide range of primary and secondary sources, we establish a strong foundation for our findings. Industry-standard tools like Porter's Five Forces Analysis, SWOT Analysis, and Price Trend Analysis further enhance the comprehensiveness of our evaluation.

A Comprehensive analysis of consumption, revenue, market share, and growth rate is provided for the following regions:

-The Middle East and Africa region, including countries such as South Africa, Saudi Arabia, UAE, Israel, Egypt, and others.

-North America, comprising the United States, Mexico, and Canada.

-South America, including countries such as Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, and others.

-Europe (including Turkey, Spain, the Netherlands, Denmark, Belgium, Switzerland, Germany, Russia, the UK, Italy, France, and others)

-The Asia-Pacific region includes Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, the Philippines, South Korea, Thailand, India, Indonesia, and Australia.

Browse Executive Summary and Complete Table of Content @ https://www.marketstatistix.com/report/global-deployment-automation-market

Table of Contents for the Deployment Automation Market includes the following points:

Chapter 01 - Deployment Automation Executive Summary

Chapter 02 - Market Overview

Chapter 03 - Key Success Factors

Chapter 04 - Deployment Automation Market – Pricing Analysis Overview

Chapter 05 - Overview of the History of the Deployment Automation Market

Chapter 06 - Deployment Automation Market Segmentation [e.g. Type (Type I, Type II, Type III), Application (Retail, IT and Telecommunications, BFSI, Healthcare, Manufacturing, Others)]

Chapter 07 - Analysis of Key and Emerging Countries in the Deployment Automation

Chapter 08 - Deployment Automation Market Structure and Value Analysis

Chapter 09 - Competitive Landscape and Key Challenges in the Deployment Automation Market

Chapter 10 - Assumptions and Abbreviations

Chapter 11 - Market Research Approach for Deployment Automation

About Market Statistix:

Market Statistix is an expert in the area of global market research consulting. With the aid of our ingenious database built by experts, we offer our clients a broad range of tailored Marketing and Business Research Solutions to choose from. We assist our clients in gaining a better understanding of the strengths and weaknesses of various markets, as well as how to capitalize on opportunities. Covering a wide variety of market applications, We are your one-stop solution for anything from data collection to investment advice, covering a wide variety of market scopes from digital goods to the food industry.

Contact Information:

Market Statistix

Media & Marketing Manager

Call: +91 9067 785 685

Email: [email protected]

Website: www.marketstatistix.com

#Deployment Automation Market#Deployment Automation Market Share#Deployment Automation Market Size#Deployment Automation Market Trends#Deployment Automation Market Growth#Deployment Automation Market Forecast Analysis

0 notes

Text

From Lab to Factory: PSA Market Grows With Industrial Standardization

The global Particle Size Analyzer Market was valued at USD 332.8 Mn in 2021 and is projected to reach USD 541.3 Mn by the end of 2031, growing at a CAGR of 5.2% from 2022 to 2031. Particle size analyzers (PSAs) play a critical role in quality control and product development across a variety of industries, including pharmaceuticals, mining, chemicals, food & beverages, and construction materials. The growing need to ensure product uniformity, performance, and safety is fueling demand for advanced particle size measurement technologies.

Market Drivers & Trends Several key factors are propelling market growth:

Increased adoption in pharmaceuticals and battery manufacturing is driving demand for PSAs to analyze powders, suspensions, and emulsions with high precision.

Technological advancements in techniques such as laser diffraction and nanoparticle tracking analysis (NTA) are enabling greater accuracy and faster analysis.

Booming lithium-ion battery market, especially due to electric vehicle (EV) proliferation, has created a need for precise control of cathode and anode material particle sizes.

Rise in nanotechnology awareness and applications has expanded PSA use in high-precision research and manufacturing.

In addition, regulatory compliance and the need for consistent product quality are driving companies to adopt particle size analysis as a standard practice.

Key Players and Industry Leaders The particle size analyzer industry is consolidated, with major players actively engaged in R&D, product innovation, and strategic partnerships to maintain their market position. Key companies include:

Anton Paar GmbH

Beckman Coulter, Inc

Bettersize Instruments Ltd.

Bühler Group

Fritsch GmbH

Horiba, Ltd.

Intertek Group plc

Mettler-Toledo International Inc.

Microtrac Retsch GmbH

Shimadzu Corporation

Sympatec GmbH

These players offer diverse portfolios spanning laser diffraction analyzers, DLS-based systems, and emerging technologies like NTA. Their market strategies include product expansion, mergers and acquisitions, and regional footprint enhancement.

Recent Developments

In February 2021, Horiba Ltd. established the HORIBA Institute for Particle Analysis in Japan to enhance development in airborne particle and nanomaterial analysis.

In June 2020, Fritsch GmbH launched the ANALYSETTE 22 NeXT Micro, a laser particle sizer with a wide measurement range (0.05–1500 µm), suitable for quality control and R&D.

Several companies are also integrating AI and automation into PSA devices for real-time monitoring and improved throughput.

Latest Market Trends

Nanoparticle Tracking Analysis (NTA) is gaining ground, especially in biotech and environmental science, due to its ability to detect nanoparticles in the 30–600 nm range.

Portable particle size analyzers are being developed for on-site analysis in sectors like mining and agriculture.

Integration with software platforms for real-time data analysis and remote monitoring is becoming common across manufacturing sectors.

The trend toward wet dispersion analysis continues due to its high accuracy in diverse liquid-based samples such as slurries and emulsions.

Market Opportunities

Rising pharmaceutical manufacturing in emerging markets, especially in India and China, presents a lucrative opportunity.

Increasing R&D in nanotechnology and biotechnology, backed by government and academic institutions, is creating demand for advanced PSA tools.

Growing investments in battery material R&D for energy storage and EVs will require reliable particle characterization solutions.

The use of PSAs in additive manufacturing (3D printing) for metal powders is also expanding rapidly.

Discover essential conclusions and data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=15773

Future Outlook The particle size analyzer market is expected to witness consistent growth through 2031, driven by expanding applications in high-growth industries and technological enhancements. As precision and quality continue to be emphasized across global supply chains, the role of PSAs will become increasingly integral. Moreover, automation and AI integration will further streamline operations and make particle analysis more accessible and efficient.

Market Segmentation The market is segmented based on technology, dispersion type, and end-use industry:

By Technology:

Dynamic Image Analysis (DIA)

Static Image Analysis

Laser Diffraction

Dynamic Light Scattering (DLS)

Nanoparticle Tracking Analysis (NTA)

Others (e.g., Sieve Analysis, Centrifugal Sedimentation)

By Dispersion Type:

Wet Particle (most dominant and growing segment)

Dry Particle

Spray Particle

By End-use Industry:

Pharmaceutical

Food & Beverage

Building & Construction

Chemical

Metals & Mining

Agriculture & Forestry

Healthcare

Industrial

Others (e.g., Academia, Semiconductors)

Regional Insights Asia Pacific leads the global market with approximately 30% market share in 2021. Factors such as rapid industrialization, increasing R&D investments, and strong presence of manufacturing industries are driving this growth. China, India, Japan, and South Korea are key contributors.

North America follows closely, driven by a strong pharmaceutical base, rising demand for nanomaterials, and technological innovation. The U.S. remains a leader in high-end PSA adoption due to a large number of pharmaceutical, biotechnology, and electronics companies.

Europe also commands a substantial share, backed by environmental regulations and advancements in life sciences.

Frequently Asked Questions

1. What is the market size of the Particle Size Analyzer industry? In 2021, the global market was valued at US$ 332.8 Mn, and it is projected to grow to US$ 541.3 Mn by 2031.

2. What is driving the growth of the PSA market? The growth is primarily driven by rising demand in pharmaceuticals, battery production, nanotechnology, and R&D across various sectors.

3. Which technology is gaining significant traction in the market? Nanoparticle Tracking Analysis (NTA) is one of the fastest-growing technologies due to its precision and applicability in advanced materials research.

4. Who are the major players in the market? Prominent companies include Anton Paar, Horiba, Mettler-Toledo, Shimadzu, and Microtrac Retsch, among others.

5. Which region dominates the market? Asia Pacific is the leading region, supported by large-scale manufacturing, R&D investments, and increasing adoption across industries.

6. What are the key applications of particle size analyzers? They are used in drug formulation, battery material analysis, food processing, construction materials, metal powders for 3D printing, and more.

7. How are particle size analyzers used in the pharmaceutical industry? They help in analyzing API particle sizes, ensuring proper drug dissolution, bioavailability, and formulation stability.

0 notes

Text

Choosing The Right PLC? Meet XMPRO-10 Built To Grow With You

#PLC#Programmable Logic Controller (PLC)#XMPRO-10 PLC series#Industry 4.0#PLC-based automation#Smart control#best PLC

0 notes

Text

Turnkey Automation Services In Maharashtra | Electropoint Automation

Electropoint Automation is a trusted provider of turnkey automation services in various process industries. We specialize in offering turnkey automation solutions for pharma plants in Pune, Maharashtra. With our expertise and experience, we ensure seamless integration of automation systems to enhance productivity, efficiency, and compliance in pharmaceutical manufacturing processes. Contact Electropoint Automation today to explore our comprehensive turnkey automation services for your pharma plant needs.

#turnkey automation services#Pasteurizer Panels Manufacturer#dairy plant turnkey automation service in Pune#dairy plant turnkey automation service in Maharashtra#MCC & PCC Panels Supplier#CIP Panel Manufacturer#PLC & SCADA Based Automation Manufacturer#Paneer Press Panels#Paneer Press Machines#Juice & Beverage plant turnkey automation#Dairy plant turnkey automation

0 notes

Text

FBG Pressure Sensor Market: Strategic Forecast for Manufacturers and Stakeholders 2025-2032

MARKET INSIGHTS

The global FBG Pressure Sensor Market size was valued at US$ 184.7 million in 2024 and is projected to reach US$ 297.3 million by 2032, at a CAGR of 7.0% during the forecast period 2025-2032. The U.S. market accounted for 32% of global revenue in 2024, while China is expected to witness the fastest growth at 6.8% CAGR through 2032.

Fiber Bragg Grating (FBG) pressure sensors are advanced photonic devices that measure pressure variations by detecting wavelength shifts in reflected light. These sensors consist of optical fibers with periodic refractive index modifications that create wavelength-specific reflection patterns. Key product variants include static pressure sensors (dominating 68% market share in 2024) and dynamic pressure sensors, with applications spanning oil storage monitoring, engine testing, and structural health assessment in harsh environments.

The market growth is driven by increasing adoption in oil & gas infrastructure monitoring, where FBG sensors outperform traditional alternatives in explosion-prone zones. Recent technological advancements include multi-point sensing arrays from Luna Innovations and high-temperature resistant designs from FBGS. However, the higher initial costs compared to electrical sensors remain a market restraint, particularly in price-sensitive emerging economies. Leading players like HBM (Spectris plc) and Technica are addressing this through hybrid sensor solutions combining FBG and conventional technologies.

MARKET DYNAMICS

MARKET DRIVERS

Rising Demand for Structural Health Monitoring Fuels FBG Pressure Sensor Adoption

The increasing emphasis on structural health monitoring across industries such as civil engineering, aerospace, and energy is significantly driving the FBG pressure sensor market. These sensors offer unparalleled advantages in harsh environments where traditional electronic sensors fail, including immunity to electromagnetic interference, corrosion resistance, and multiplexing capabilities. In the energy sector alone, deployment of FBG pressure sensors in oil & gas pipelines has grown by approximately 18% annually due to their ability to operate in explosive environments while providing real-time pressure data. The global infrastructure development boom, particularly in emerging economies, further amplifies this trend as governments implement stricter safety regulations for critical structures.

Advancements in Optical Sensing Technology Accelerate Market Expansion

Technological innovations in fiber Bragg grating (FBG) manufacturing are removing previous limitations in pressure sensing applications. Recent developments have yielded sensors with improved temperature compensation and higher pressure sensitivity, with some models now achieving measurement accuracy within ±0.1% FS. The automotive industry represents a particularly promising growth area, where FBG pressure sensors are increasingly deployed in engine monitoring systems. Manufacturers now offer compact, ruggedized sensor packages capable of withstanding extreme vibration and temperature ranges from -40°C to 300°C - a critical requirement for modern combustion engine testing and development.

Growing Industrial Automation Spurs Sensor Integration in Smart Manufacturing

Industry 4.0 implementation across manufacturing facilities worldwide is creating substantial opportunities for FBG pressure sensor adoption. These sensors play a pivotal role in predictive maintenance systems, where their ability to provide continuous pressure monitoring helps prevent equipment failures and optimize production processes. The chemicals processing sector has reported up to 30% reductions in unplanned downtime through deployment of FBG-based monitoring systems. Furthermore, the sensors' compatibility with distributed sensing networks makes them ideal for comprehensive facility monitoring, with single fiber lines often replacing dozens of traditional pressure transducers.

MARKET RESTRAINTS

High Implementation Costs Limit Widespread Industrial Adoption

Despite their advantages, FBG pressure sensors face significant market penetration challenges due to their premium pricing compared to conventional electronic sensors. A complete FBG measurement system including interrogators and specialized fiber optic cables can cost 3-5 times more than equivalent electronic solutions. This cost premium stems from complex manufacturing processes requiring precise laser systems for grating fabrication and the need for specialized installation expertise. Many small and medium-sized enterprises find these costs prohibitive, particularly for applications where the superior capabilities of FBG technology aren't absolutely necessary.

Technical Complexities in System Integration Pose Implementation Barriers

The implementation of FBG pressure sensor systems presents unique technical challenges that can deter potential adopters. Unlike conventional sensors with standardized electrical outputs, FBG systems require specialized optical interrogators and frequently need custom calibration for specific applications. The interrogation equipment alone represents a significant capital investment, with high-end units costing upwards of $20,000. Additionally, the technology requires expertise in both optical physics and instrumentation engineering - a combination of skills that remains scarce in many industrial settings. These integration complexities have slowed adoption in sectors where simpler sensor technologies can adequately meet measurement requirements.

Other Challenges

Limited Standardization The absence of universal standards for FBG sensor specifications and performance metrics creates uncertainty for potential users. This lack of standardization complicates procurement decisions and makes direct comparison between competing products challenging.

Supply Chain Vulnerabilities Reliance on specialized optical fibers and components sourced from limited suppliers creates potential supply chain risks. Disruptions in these niche supply channels could significantly impact product availability and delivery timelines.

MARKET OPPORTUNITIES

Emerging Applications in Renewable Energy Create New Growth Frontiers

The rapid expansion of renewable energy infrastructure worldwide presents significant opportunities for FBG pressure sensor manufacturers. In wind energy applications, these sensors are proving invaluable for blade pressure monitoring, with installed base growing at approximately 25% annually in this sector alone. The technology's immunity to lightning strikes - a critical advantage over electronic sensors in wind turbines - makes it particularly well-suited for these applications. Similarly, in hydrogen energy systems, FBG sensors' ability to operate safely in potentially explosive environments positions them as the preferred solution for pressure monitoring throughout the hydrogen value chain.

Miniaturization Trends Open Doors for Medical and Aerospace Applications

Recent advances in micro-optics and packaging technologies are enabling development of miniaturized FBG pressure sensors suitable for medical and aerospace applications. In the medical field, prototypes of catheter-based FBG pressure sensors have demonstrated sub-millimeter diameters while maintaining clinical-grade accuracy. The aerospace sector shows equally promising potential, with FBG sensors being evaluated for integration into composite aircraft structures and fuel systems. These emerging applications could drive significant market expansion, particularly as sensor manufacturers continue refining their fabrication techniques to meet stringent size and weight requirements.

Other Opportunities

Smart City Infrastructure Growing investments in smart city development worldwide create opportunities for FBG pressure sensors in water distribution monitoring, building structural monitoring, and traffic management systems.

Underwater Applications The sensors' corrosion resistance and ability to operate in high-pressure environments make them ideal for submarine pipeline monitoring, offshore platforms, and deep-sea exploration equipment.

MARKET CHALLENGES

Technical Limitations in Harsh Environments Constrain Market Growth

While FBG pressure sensors excel in many challenging environments, they face limitations in extremely high-temperature applications exceeding 300°C, where specialized coatings and packaging become necessary. These environmental constraints limit adoption in sectors like metallurgy and certain chemical production processes. Furthermore, maintaining sensor performance under conditions involving intense radiation or extreme mechanical shock remains technically challenging. Though recent material science advancements have improved performance limits, these technical barriers continue to restrict market expansion in some industrial segments where environmental conditions exceed current technological capabilities.

Competition from Alternative Sensing Technologies Intensifies

The FBG pressure sensor market faces growing competition from emerging sensing technologies that offer comparable benefits at lower costs. Silicon photonics-based sensors, for example, are achieving measurement performance approaching that of FBG solutions while leveraging more standardized manufacturing processes. Similarly, advances in wireless sensor networks and MEMS technology are providing viable alternatives for many industrial pressure monitoring applications. This competitive pressure forces FBG sensor manufacturers to continuously innovate while justifying their technology's premium pricing through superior performance in niche applications where alternatives fall short.

Other Challenges

Data Interpretation Complexity The specialized nature of FBG sensor data requires trained personnel for proper interpretation, creating workforce training challenges for organizations adopting the technology.

Long-Term Reliability Concerns While FBG sensors demonstrate excellent long-term stability in laboratory conditions, real-world performance data over extended periods (10+ years) remains limited for many application environments.

FBG PRESSURE SENSOR MARKET TRENDS

Increasing Adoption in Oil & Gas and Aerospace Applications to Drive Market Growth

The FBG (Fiber Bragg Grating) pressure sensor market is experiencing significant growth due to increasing utilization in critical industries such as oil & gas and aerospace. Unlike traditional sensors, FBG-based solutions offer superior performance in extreme temperatures, harsh environments, and electromagnetic interference-prone zones. The oil & gas sector, which accounts for nearly 28% of the global industrial sensor demand, particularly benefits from these sensors for pipeline monitoring and refinery pressure measurements. Their ability to withstand high-pressure conditions while delivering real-time data makes them indispensable in safety-critical operations. Furthermore, the aerospace industry leverages FBG sensors for structural health monitoring, fuel systems, and engine performance analysis due to their lightweight and corrosion-resistant properties.

Other Trends

Integration with Structural Health Monitoring Systems

The rising adoption of smart infrastructure and IoT-driven structural health monitoring systems presents a substantial opportunity for FBG pressure sensors. Governments worldwide are investing heavily in smart city projects, with structural integrity monitoring being a key focus area. FBG sensors are increasingly embedded in bridges, dams, and buildings to detect pressure anomalies or material stress in real time. Major infrastructure projects in Asia-Pacific and North America have reported a 17% year-over-year increase in the deployment of FBG-based monitoring solutions. The non-intrusive, highly sensitive nature of these sensors allows for proactive maintenance, reducing long-term operational risks and costs.

Technological Advancements Enhancing Sensor Capabilities

Recent innovations in FBG sensor technology are expanding their application scope across various sectors. Manufacturers are focusing on developing multi-parameter FBG sensors capable of measuring pressure, temperature, and strain simultaneously with micron-level precision. The emergence of miniaturized sensors with wireless data transmission capabilities has further fueled adoption in medical devices and automotive testing environments. Additionally, improvements in signal demodulation techniques have enhanced measurement accuracy by over 30%, making these sensors viable alternatives to conventional piezoresistive and capacitive pressure sensors in precision-demanding applications.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Strategic Expansion Drive Market Leadership in FBG Pressure Sensor Segment

The global FBG Pressure Sensor market demonstrates a dynamic competitive environment, characterized by both established multinational corporations and agile specialized manufacturers. HBM (Spectris plc) and Luna Innovations currently hold prominent positions, leveraging their technological expertise in fiber optic sensing and strong distribution networks across North America and Europe. Together, these top five players accounted for approximately 45% of the 2024 market revenue.

While AtGrating Technologies leads in static pressure sensor applications with its patented grating designs, Femto Sensing International has carved a niche in high-precision dynamic pressure monitoring for aerospace and defense sectors. Recent joint ventures between FBGS and Asian manufacturers highlight the growing importance of regional partnerships to access emerging markets.

Two distinct strategies are emerging among market participants: larger firms like Spectris focus on acquiring complementary technologies, while specialist players such as Optromix invest heavily in customized solutions for industrial IoT applications. This bifurcation is reshaping price competitiveness across different application segments.

Notably, Chinese manufacturers including Aunion Tech Co., Ltd. are gaining traction through government-backed R&D initiatives, particularly in oil storage monitoring systems. Their competitive pricing structures have compelled Western players to relocate portions of their manufacturing operations to maintain cost efficiency.

List of Key FBG Pressure Sensor Manufacturers Profiled

HBM (Spectris plc) (Germany)

Luna Innovations (U.S.)

AtGrating Technologies (China)

Optromix (U.S.)

FBGS (Belgium)

Technica (U.S.)

T&S Communication Co, Ltd (China)

Femto Sensing International (Singapore)

FiberStrike (Cleveland Electric Laboratories) (U.S.)

Aunion Tech Co., Ltd (China)

Segment Analysis:

By Type

Static Pressure Sensors Lead Market Due to Rising Demand in Industrial Monitoring Applications

The market is segmented based on type into:

Static Pressure Sensor

Subtypes: Absolute pressure, Gauge pressure, Differential pressure

Dynamic Pressure Sensor

Subtypes: Piezoelectric, Capacitive, MEMS-based

By Application

Oil Storage Tank Monitoring Emerges as Key Application Segment for FBG Pressure Sensors

The market is segmented based on application into:

Oil Storage Tank Monitoring

Engine Pressure Monitoring

Structural Health Monitoring

Aerospace and Defense

Others

By End User

Oil & Gas Industry Dominates End User Segment Due to Critical Pressure Monitoring Needs

The market is segmented based on end user into:

Oil & Gas Industry

Automotive

Aerospace and Defense

Energy and Power

Others

Regional Analysis: FBG Pressure Sensor Market

North America The FBG pressure sensor market in North America is characterized by strong technological adoption and significant investments in industrial automation and energy infrastructure. The U.S. dominates the region, accounting for over 65% of regional demand, driven by applications in oil & gas, aerospace, and civil engineering. Strict safety regulations and the push for smart infrastructure monitoring systems further bolster demand. Key players like Luna Innovations and HBM (Spectris plc) leverage strong R&D capabilities to maintain competitiveness. However, high production costs and supply chain complexities pose challenges for mid-sized manufacturers.

Europe Europe exhibits steady growth in FBG pressure sensor adoption, particularly in Germany and the U.K., where industrial IoT integration and renewable energy projects are prioritized. The region benefits from stringent EU directives on structural health monitoring, fueling demand in wind turbines and pipeline systems. The presence of established manufacturers such as FBGS and Technica supports localized innovation, though market fragmentation and competition from alternate sensing technologies (e.g., piezoelectric sensors) limit price flexibility. Collaborations between research institutes and industry players are common, driving advancements in high-temperature and corrosion-resistant sensor designs.

Asia-Pacific As the fastest-growing market, Asia-Pacific is propelled by China's expansive infrastructure projects and Japan’s precision manufacturing sector—”static pressure sensors” claim the largest share due to their use in hydraulic systems and aerospace testing. India’s refinery expansions and Southeast Asia’s oil storage investments present new opportunities. While cost sensitivity initially favored traditional strain gauges, FBG sensors are gaining traction for their long-term reliability in harsh environments. Local players like Aunion Tech Co., Ltd. compete aggressively on price, though technology gaps persist compared to Western offerings.

South America Market penetration in South America remains nascent but promising, with Brazil leading in oilfield applications. Economic instability and limited local manufacturing hinder scalability, but offshore exploration projects (e.g., Brazil’s pre-salt basins) drive niche demand. Most FBG sensors are imported, creating dependency on North American and European suppliers. Governments’ sporadic investments in sensor-based monitoring for dams and pipelines signal gradual growth, though political unpredictability delays large-scale deployments.

Middle East & Africa The region focuses on oil storage tanks and pipeline monitoring, leveraging FBG sensors’ explosion-proof properties. Saudi Arabia and the UAE lead adoption, supported by national oil companies’ modernization initiatives. Africa’s market is constrained by budgetary limitations, but mining sectors in South Africa and infrastructure projects in North Africa show potential. Competition from cheaper alternatives (e.g., capacitive sensors) slows FBG uptake, though partnerships with global firms like Optromix aim to address technical and cost barriers over time.

Report Scope

This market research report provides a comprehensive analysis of the global and regional FBG Pressure Sensor markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global FBG Pressure Sensor market was valued at USD 220 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 7.1% during the forecast period.

Segmentation Analysis: Detailed breakdown by product type (Static Pressure Sensor, Dynamic Pressure Sensor), application (Oil Storage Tank, Engine, Others), and end-user industry to identify high-growth segments and investment opportunities. Static Pressure Sensors accounted for 62% market share in 2024.

Regional Outlook: Insights into market performance across North America (28% market share), Europe (23%), Asia-Pacific (37%), Latin America, and the Middle East & Africa, including country-level analysis where relevant. China is expected to grow at 8.5% CAGR.

Competitive Landscape: Profiles of leading market participants including AtGrating Technologies, HBM(Spectris plc), Luna Innovations, and FBGS, covering their product offerings (15+ product lines), R&D focus, manufacturing capacity, and recent M&A activities. Top 5 players held 45% market share in 2024.

Technology Trends & Innovation: Assessment of emerging technologies including AI integration, IoT connectivity, and advanced fabrication techniques with 120+ patents filed in 2023-2024 period.

Market Drivers & Restraints: Evaluation of factors driving market growth (12% YOY increase in oil & gas applications) along with challenges (supply chain disruptions affecting 18% of manufacturers in 2024).

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators (70+ active companies), and investors regarding the evolving ecosystem and strategic opportunities in aerospace and energy sectors.

Primary and secondary research methods are employed, including interviews with 50+ industry experts, data from verified manufacturing reports, and real-time market intelligence to ensure the accuracy and reliability of the insights presented.

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global FBG Pressure Sensor Market?

-> FBG Pressure Sensor Market size was valued at US$ 184.7 million in 2024 and is projected to reach US$ 297.3 million by 2032, at a CAGR of 7.0% during the forecast period 2025-2032

Which key companies operate in Global FBG Pressure Sensor Market?

-> Key players include AtGrating Technologies, HBM(Spectris plc), Technica, Optromix, Luna Innovations, FBGS, T&S Communication Co, Ltd, Femto Sensing International, among others.

What are the key growth drivers?

-> Key growth drivers include increasing demand from oil & gas sector (35% of applications), aerospace industry modernization, and infrastructure monitoring requirements.

Which region dominates the market?

-> Asia-Pacific holds the largest market share (37%), while North America leads in technological innovation.

What are the emerging trends?

-> Emerging trends include miniaturization of sensors, multi-parameter sensing capabilities, and integration with wireless monitoring systems.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/automotive-magnetic-sensor-ics-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ellipsometry-market-supply-chain.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/online-moisture-sensor-market-end-user.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/computer-screen-market-forecasting.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/high-power-gate-drive-interface.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/strobe-overdrive-digital-controller.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/picmg-half-size-single-board-computer.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/automotive-isolated-amplifier-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/satellite-messenger-market-regional.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/sic-epi-wafer-market-innovations.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/heavy-duty-resistor-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/robotic-collision-sensor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gas-purity-analyzer-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/x-ray-high-voltage-power-supply-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/reflection-probe-market-industry-trends.html

0 notes

Text

Engineering Hiring Agencies: Bridging the Talent Gap in a Competitive Market

As global demand for engineering expertise continues to rise, companies across industries face increasing pressure to find, attract, and retain top-tier technical talent. Whether it's infrastructure, energy, manufacturing, IT, or aerospace, the success of complex projects depends heavily on skilled engineering professionals.

However, sourcing the right talent is far from easy in today's competitive labor market. That's why many organizations are turning to engineering hiring agencies to streamline their recruitment process, access specialized candidates, and ensure long-term workforce stability.

Understanding Engineering Hiring Agencies

Engineering hiring agencies are specialized recruitment firms that focus exclusively on engineering and technical roles. Their core function is to connect employers with qualified professionals across various engineering disciplines, including:

Civil Engineering

Mechanical Engineering

Electrical Engineering

Structural Engineering

Chemical Engineering

Software & IT Engineering

Instrumentation and Control

Environmental Engineering

Industrial and Manufacturing Engineering

These agencies leverage deep industry knowledge, curated candidate networks, and strategic sourcing tools to deliver talent that fits both the technical needs and organizational culture of the employer.

Why Engineering Hiring Is Increasingly Complex

Recruiting engineers involves far more than reviewing resumes and scheduling interviews. Companies today face several critical challenges:

1. Skills Shortage

Many regions report a significant gap between the number of open engineering positions and available qualified professionals. Emerging technologies and rapid industrial growth have only widened this gap.

2. Time-Consuming Hiring Processes

Technical screening, credential verification, and role-specific assessments can take weeks. For time-sensitive projects, delays in hiring can result in financial loss and project setbacks.

3. Global Competition

Engineering talent is globally mobile. High-demand professionals often have multiple offers, making it difficult for companies to secure the best candidates without expert guidance.

4. Specialization Within Fields

Modern engineering roles often require highly specific skill sets — such as CAD expertise in civil projects, PLC programming in automation, or cloud infrastructure knowledge in software engineering.

Engineering hiring agencies help address these issues by providing fast, reliable, and targeted hiring solutions.

How Engineering Hiring Agencies Add Value

Working with an engineering hiring agency offers several key benefits:

1. Access to Pre-Screened Talent Pools

These agencies maintain a robust database of qualified, vetted engineers across multiple disciplines. This allows companies to significantly reduce time-to-hire and eliminate unsuitable candidates early in the process.

2. Industry-Specific Expertise

Engineering hiring agencies understand the technical language, compliance requirements, and project needs of different industries. This ensures better role-matching and reduces turnover risk.

3. Global and Local Reach

Top agencies source candidates both locally and internationally. Whether a firm is looking for local talent for a government contract or international specialists for overseas projects, agencies can provide scalable solutions.

4. Flexible Hiring Models

Agencies offer contract staffing, permanent recruitment, project-based hiring, and executive search — allowing companies to choose a hiring model that fits their business strategy.

5. Compliance and Documentation Support

Especially for overseas hiring, engineering agencies handle visa processing, background checks, certifications, and legal compliance, easing administrative burdens on employers.

Industries That Benefit Most from Engineering Hiring Agencies

While nearly every sector today requires engineering talent, some industries heavily rely on these agencies to meet large-scale or urgent workforce demands:

Construction & Infrastructure

Oil & Gas / Energy

Manufacturing & Industrial Automation

IT & Software Engineering

Telecommunications

Aerospace & Aviation

Renewable Energy (Wind, Solar, Hydro)

Automotive & Mobility Engineering

These industries often work on high-value, deadline-driven projects where even a small talent gap can impact profitability.

Best Practices for Partnering with Engineering Hiring Agencies

To maximize the value of an agency partnership, companies should:

Clearly define technical requirements and project goals

Provide accurate timelines for hiring and onboarding

Collaborate on interviews and assessments

Give feedback on candidate quality and fit

Choose agencies with a proven track record in relevant industries

This collaborative approach fosters transparency and ensures the agency can deliver the most suitable talent.

Future Trends in Engineering Recruitment

As technology reshapes industries, engineering hiring agencies are also adapting. Key trends include:

AI and automation in candidate screening

Increased focus on soft skills and leadership potential

Remote and hybrid engineering roles

Green energy and sustainability hiring

Use of project-based and freelance engineering talent

These developments reflect a dynamic shift in both workforce expectations and employer strategies.

Conclusion: Building the Future with the Right Talent

In a world where engineering innovation drives progress, having the right professionals on board is critical. Engineering hiring agencies act as strategic partners, helping organizations navigate the complexities of modern recruitment while delivering technical excellence and workforce agility.

By leveraging specialized expertise, global networks, and flexible hiring models, these agencies ensure that companies are equipped with the talent they need — not just to meet project goals, but to lead in their industries.

#engineering staffing#engineering recruitment#engineering recruitment agency#hire engineer#engineering hiring

0 notes

Text

How a Liquid Dosing System Improves Accuracy and Efficiency in Industrial Processes ?

In many manufacturing industries like food, beverages, pharmaceuticals, and chemicals, liquid ingredients must be added in very specific amounts. If the measurement is wrong, the entire batch can be wasted. That’s where a Liquid Dosing System comes into play. It ensures that liquids are measured and added precisely, improving the quality and consistency of the final product.

Times automation, a top automation manufacturing company in India, offers advanced Liquid Dosing Systems that meet the specific needs of different industries. These systems are designed to improve production accuracy, reduce waste, and save time—all while ensuring reliable operations.

1. Ensures Accurate Measurement

A Liquid Dosing System is built to deliver precise amounts of liquid, whether it's water, chemicals, oils, or any other fluid.

This accuracy helps in maintaining the correct formulation of products.

In industries like pharma or food, even a small error in liquid quantity can affect quality or safety.

2. Maintains Product Consistency

Consistent dosing means every batch is the same in quality and performance.

Whether it's a food recipe or a chemical reaction, the Liquid Dosing System keeps all doses uniform.

This builds trust in product quality and brand reliability.

3. Reduces Human Error

Manual pouring or measuring often leads to mistakes.

A Liquid Dosing System is automated, removing the chances of incorrect quantities.

It also reduces operator fatigue and lowers the chances of spillage or mixing errors.

4. Minimizes Liquid Wastage

Liquid materials, especially chemicals or flavoring agents, can be expensive.

This system avoids over-dosing or unnecessary wastage.

Over time, companies save a significant amount on raw materials.

5. Increases Production Speed

Manual dosing is slow and needs constant attention.

A Liquid Dosing System is quick and automatic, which means more production in less time.

Faster operations help in meeting market demands and delivery schedules.

6. Supports Multiple Liquid Inputs

These systems can be designed to handle more than one liquid at a time.

Whether it’s blending, mixing, or dosing different fluids in a sequence, the Liquid Dosing System can manage all tasks efficiently.

This helps in complex manufacturing processes.

7. Easy Integration into Existing Plants

You don’t need to rebuild your factory setup to install a dosing system.

A Liquid Dosing System can be easily added to mixers, tanks, or processing lines.

It works with PLC-based automation, which keeps the system simple to operate.

8. Improves Worker Safety

Some liquids may be reactive, hot, or dangerous to handle.

A sealed Liquid Dosing System keeps workers safe by reducing direct contact.

This lowers the risk of accidents, burns, or exposure to toxic substances.

9. Helps with Data Monitoring and Control

Modern systems come with digital displays and data logging.

You can track how much liquid was used in each batch.

This data helps in audits, quality control, and process improvement.

10. Reduces Maintenance and Downtime

Timesautomation’s Liquid Dosing Systems are built using high-quality components.

They require less frequent cleaning and are resistant to clogging or leakage.

This reduces downtime and increases plant availability.

Why Choose Timesautomation for Liquid Dosing Systems?

Times automation is one of the top automation solution providers in India.

We offer customized Liquid Dosing Systems based on flow rate, type of liquid, industry standards, and safety needs.

Our systems are made using corrosion-resistant materials and meet hygiene standards.

We provide complete support from system design, installation, to maintenance.

Whether you run a small plant or a large factory, we have dosing solutions that work reliably.

Conclusion

The right Liquid Dosing System is more than just a machine—it’s a key part of modern industrial processing. It brings accuracy, reduces waste, ensures product consistency, and protects workers. Industries that rely on liquid ingredients can greatly benefit from this technology.

If your process needs exact and safe liquid handling, Timesautomation’s trusted Liquid Dosing System can make a big difference. With a focus on innovation and quality, we help industries move towards cleaner, faster, and more efficient production.

#Liquid Dosing system#Liquid Dosing system manufacture#LIquid Dosing system manufacturer in india#machinery

0 notes

Text

Rotary Torque Sensors by Star EMBSYS: Precision in Motion Measurement

A rotary torque sensor is a critical device used to measure the torque—or rotational force—applied to a rotating system such as an engine shaft, gearbox, or motor. In high-precision applications ranging from automotive testing to industrial automation, accurate torque measurement is essential. Star EMBSYS, a trusted name in embedded systems and sensor technology, provides advanced rotary torque sensors designed for high accuracy, durability, and seamless integration with digital control systems.

What is a Rotary Torque Sensor?

A rotary torque sensor, sometimes called a rotary torque transducer, measures the torque transmitted through a rotating shaft. It typically consists of a strain gauge attached to the shaft, which senses deformation under torque. The sensor then converts this mechanical strain into an electrical signal that can be processed and analyzed.

Rotary torque sensors can operate with slip rings, wireless telemetry, or rotating transformers to transmit data from the spinning shaft to a stationary data acquisition system. These sensors are widely used in real-time torque monitoring and dynamic testing environments.

Star EMBSYS Rotary Torque Sensor Technology

Star EMBSYS offers a line of rotary torque sensors engineered for demanding industrial, automotive, and research applications. Their sensors are built to deliver:

High Measurement Accuracy: Designed with advanced strain gauge and signal conditioning technology for precise torque readings.

Wide Measurement Range: Suitable for both low and high torque applications, with customizable ranges.

Robust Mechanical Design: Withstands high-speed rotations, vibrations, and temperature fluctuations.

Digital Output Options: Interfaces easily with embedded systems, PLCs, and data loggers via analog, digital, or CAN output formats.

Real-Time Monitoring: Perfect for dynamic torque measurement in rotating machinery, especially for motor testing and drive performance analysis.

Applications of Rotary Torque Sensors

Star EMBSYS rotary torque sensors are used in a wide range of applications, including:

Automotive Testing – To measure engine and drivetrain torque in real-time for efficiency and durability analysis.

Electric Motor Monitoring – For performance assessment of industrial motors and drives.

Robotics – For force feedback in robotic arms and actuators.

Aerospace and Defense – For torque analysis in aircraft components and missile control systems.

Industrial Machinery – To monitor torque loads in rotating equipment like pumps, compressors, and gearboxes.

These sensors are often critical in closed-loop systems where feedback control is necessary for optimizing performance and preventing mechanical failure.

Why Choose Star EMBSYS?

Star EMBSYS combines deep expertise in embedded systems with advanced sensor design to provide integrated, ready-to-deploy torque sensing solutions. Their rotary torque sensors are customizable, highly reliable, and backed by strong technical support. Whether for a prototype or large-scale deployment, Star EMBSYS delivers scalable, sensor-based solutions tailored to customer needs.

Conclusion

As industries shift toward smart automation and data-driven maintenance, rotary torque sensors from Star EMBSYS offer the precision and reliability required to keep machines running optimally. With state-of-the-art engineering and a focus on embedded integration, Star EMBSYS stands out as a trusted partner in advanced torque measurement solutions.

Visit:- https://www.starembsys.com/rotary-torque-sensor.html

0 notes