#Pipeline Inspection

Explore tagged Tumblr posts

Text

Magnetic Particle Test: Techniques and Principles Explained

Magnetic Particle Test (MPT) is a widely used non-destructive testing (NDT) method. It detects surface and near-surface discontinuities in ferromagnetic materials, such as iron, nickel, cobalt, and their alloys. This technique is renowned for its speed, cost-effectiveness, and relative ease of application, making it a preferred choice across various industries, including aerospace, automotive,…

#Defect Detection#Engineering Testing#Flaw Detection#Industrial Testing#Infrastructure Testing#Magnetic Field Testing#Magnetic Inspection#Magnetic Particle Inspection#Magnetic Particle Test#Magnetic Particles#Magnetic Testing#Manufacturing Quality#Material Testing#Metal Testing#MPT#MPT Procedure#NDT#NDT Methods#NDT Technology#Non-Destructive Testing#Pipeline Inspection#Quality Inspection#Safety Inspection#Structural Integrity#Subsurface Defects#Surface Defects#Testing Equipment#Weld Inspection#Welding Defects

0 notes

Text

Frequent Problems Detected During Tank and Piping Inspections

Engaging in regular "internal tank and pipeline inspection services" is crucial for the ongoing safety and functionality of industrial systems. A qualified tank inspection company can help identify common issues that, if left unaddressed, could lead to significant damage and costly repairs.

Corrosion is one of the most common issues found during inspections. Tanks and pipelines are often subjected to harsh environmental conditions and corrosive substances, which can eat away at metal surfaces. Corrosion can lead to thinning of the metal, reducing the structural integrity of the system and increasing the risk of leaks or ruptures.

Another prevalent issue is the buildup of sediment or sludge within tanks and pipelines. This accumulation can obstruct the flow of materials, reduce the efficiency of operations, and exacerbate corrosion by trapping moisture and chemicals. Regular inspections and cleanings are necessary to keep systems running smoothly and to prevent damage.

Cracks and leaks are frequently detected during inspections. These can occur due to a variety of reasons, including corrosion, mechanical stress, or manufacturing defects. Identifying and repairing cracks and leaks early is critical to avoid environmental contamination, product loss, and expensive repairs.

1 note

·

View note

Text

Innovating Pipeline Rehabilitation: Pipe CIPP Lining Engineering Design Services as per ASTM F1216

In the dynamic world of plumbing and pipe rehabilitation, Cured-In-Place Pipe (CIPP) lining stands as a testament to the industry's progress and innovation. Pioneering a non-invasive, cost-effective, and efficient approach to pipeline repair, CIPP lining engineering design services have carved a significant niche in the industry. Adherence to the ASTM F1216 standard, set by the American Society for Testing and Materials, has further cemented the integrity and reliability of these services.

CIPP Lining: A Brief Overview

CIPP lining is a trenchless rehabilitation method that effectively repairs existing pipelines without the need for excavation. This process involves inserting and running a felt lining into a pre-existing pipe that is impregnated with a specially formulated resin. This resin is then cured, essentially creating a "pipe within a pipe."

The CIPP method addresses a wide array of issues, such as leaks, corrosion, root intrusion, and age-related wear and tear, without disrupting the landscape or the daily activities of businesses or households.

CIPP Lining Engineering Design Services

CIPP lining engineering design services employ advanced technology and innovative engineering principles to create effective, long-lasting solutions for pipeline problems. These services are critical to accurately assessing the damage, designing the CIPP liner, implementing the solution, and ensuring successful pipeline rehabilitation.

These engineering design services consist of various steps, such as:

Inspection: Before any design work can begin, the pipe's condition needs to be assessed using closed-circuit television (CCTV) inspection and other technologies. This inspection enables engineers to evaluate the damage extent and pinpoint its location.

Design: Based on the inspection, engineers design the CIPP liner considering factors such as pipe diameter, length, material, operating conditions, and the type and extent of damage.

Installation: This step involves inserting the designed liner into the damaged pipe and curing it using hot water, steam, or UV light.

Post-installation Inspection: The final step involves inspecting the rehabilitated pipe to ensure the CIPP liner is correctly installed and functioning as expected.

The Role of ASTM F1216

The ASTM F1216 - "Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube," is a globally recognized standard that guides the CIPP lining process. It prescribes the material requirements, resin preparation, inversion process, curing method, and testing techniques for CIPP lining.

Adherence to this standard ensures that the CIPP lining engineering design services meet the necessary quality and safety standards. It also guarantees the end product's durability, structural integrity, and optimal functionality.

Benefits of CIPP Lining Engineering Design Services

CIPP lining engineering design services offer numerous benefits, such as:

Durability: CIPP linings have a lifespan of up to 50 years, making them a long-lasting solution.

Non-disruptive: Being a trenchless method, CIPP lining causes minimal disruption to daily activities and avoids damaging landscapes or structures.

Versatility: CIPP lining is suitable for various pipe materials and diameters, making it a versatile solution.

Cost-effective: CIPP lining eliminates the need for excavation and extensive manual labor, significantly reducing costs.

Efficiency: The entire CIPP lining process can often be completed in a day, making it an efficient solution for pipeline rehabilitation.

Among the many engineering firms providing CIPP lining design services, Little P.Eng. Engineering has distinguished itself as a leader. Leveraging a combination of industry expertise, innovation, and adherence to the ASTM F1216 standard, the firm has been able to provide high-quality, efficient, and reliable pipeline rehabilitation services.

Firstly, the firm's deep-rooted understanding of pipeline systems is undeniable. They have a team of dedicated professional engineers (P.Eng.) who bring a wealth of knowledge and experience to the table. Their engineers understand the intricacies of different pipeline materials, their response to various environmental conditions, and potential failure modes.

Their specialization in CIPP lining, a modern, trenchless pipeline rehabilitation method, has allowed them to handle a broad range of pipeline issues effectively. Whether it's handling minor leaks, major corrosion issues, or extensive root intrusion, their team is adept at designing and implementing the appropriate CIPP lining solution.

Adherence to the ASTM F1216 standard has been a cornerstone of Little P.Eng. Engineering's approach to CIPP lining engineering services. This commitment ensures that the resin preparation, inversion process, curing methods, and testing techniques used meet the highest quality and safety standards. It also guarantees that the resulting CIPP lining possesses the durability, structural integrity, and functionality necessary for long-term pipeline performance.

Moreover, Little P.Eng. Engineering is known for its innovative approach. They harness the latest technologies and engineering principles to improve the effectiveness and efficiency of their CIPP lining design services. This includes using state-of-the-art CCTV technology for initial pipeline inspection and advanced curing methods to ensure optimal resin curing.

Lastly, the firm's dedication to customer satisfaction sets them apart. They understand that every client has unique needs and circumstances, and they strive to provide tailored solutions that are both effective and cost-efficient. They also prioritize transparent communication, ensuring their clients understand every aspect of the rehabilitation process.

In conclusion, Little P.Eng. Engineering's deep expertise, innovative approach, and commitment to customer satisfaction make them a preferred choice for CIPP lining engineering design services. Their rigorous adherence to ASTM F1216 further assures clients that they are receiving high-quality, safe, and durable pipeline rehabilitation solutions. The combination of these factors positions Little P.Eng. Engineering as a reliable partner in the industry, capable of effectively addressing a wide array of pipeline challenges.

Conclusion

In the realm of plumbing and pipeline rehabilitation, CIPP lining engineering design services as per ASTM F1216 have proven to be a game-changer. By providing a non-invasive, cost-effective, and efficient solution to pipe repair, they have redefined traditional methods. As the industry continues to innovate, the importance of these services and the ASTM F1216 standard's adherence will only grow, paving the way for a future where pipeline problems are no longer a headache but a manageable, efficient process.

Read More:

Innovating Pipeline Rehabilitation: Pipe CIPP Lining Engineering Design Services as per ASTM F1216

Pipeline Rehabilitation Engineering Design Services as per ASTM F1216 Using CIPP and PVC

Little P.Eng. Engineering For CIPP Liner Design As Per ASTM F1216 Using Finite Element Method

Revolutionizing Pipe Rehabilitation: Little P.Eng. Engineering's Mastery of CIPP Liner Design via Finite Element Method in Accordance with ASTM F1216

Tags:

Meena Rezkallah

Little P.Eng. Engineering

ASTM F1216

Professional Engineers

Pipe Rehabilitation

CIPP Lining

Engineering Design Services

Trenchless Technology

Pipeline Repair

Cured-In-Place Pipe

Resin-Impregnated Tube

Plumbing Industry Innovation

Pipe Lining Solutions

Pipeline Inspection

Durability and Structural Integrity

Cost-Effective Pipeline Solutions

Engineering Services

Pipe Rehabilitation

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng. Engineering#ASTM F1216#Professional Engineers#Pipe Rehabilitation#CIPP Lining#Engineering Design Services#Trenchless Technology#Pipeline Repair#Cured-In-Place Pipe#Resin-Impregnated Tube#Plumbing Industry Innovation#Pipe Lining Solutions#Pipeline Inspection#Durability and Structural Integrity#Cost-Effective Pipeline Solutions

0 notes

Text

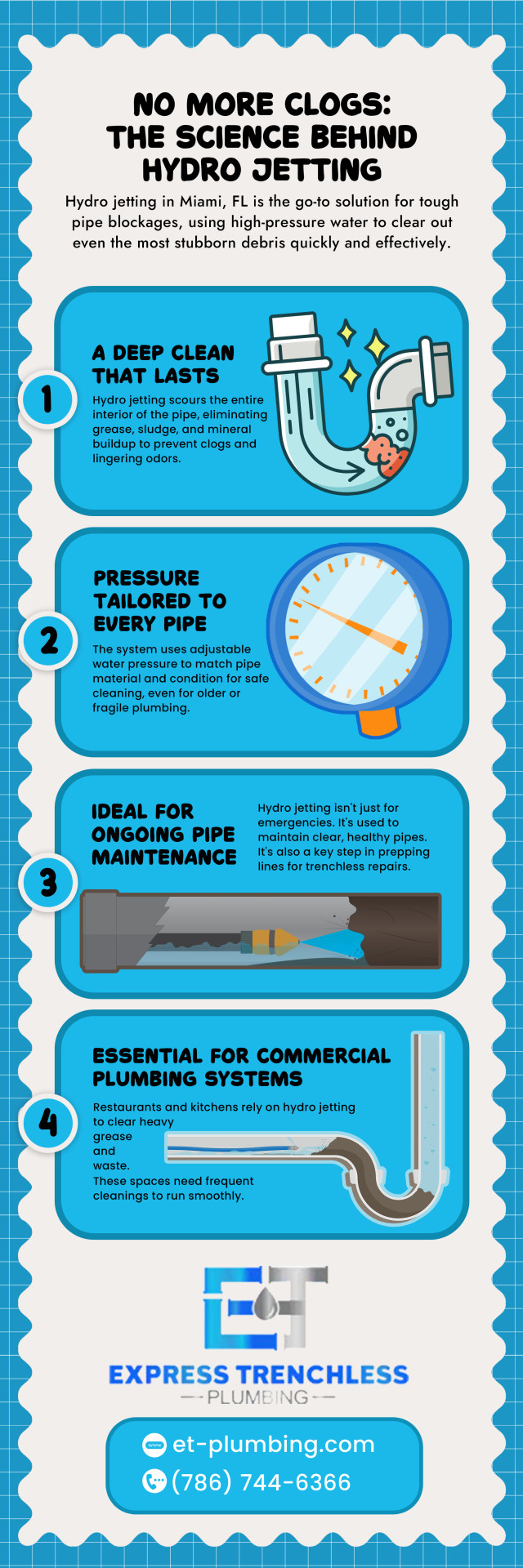

No More Clogs: The Science Behind Hydro Jetting

Hydro jetting in Miami, FL is the go-to solution for tough pipe blockages, using high-pressure water to clear out even the most stubborn debris quickly and effectively.

Learn more.

0 notes

Text

Can Your Systems Handle the Pressure? 2025’s Guide to Pipeline & Tank Inspections

In 2025, industrial systems face increasing scrutiny from both regulators and the public. It’s more important than ever to ensure pipelines and storage tanks can stand up to pressure—both literally and figuratively. That’s where high-quality pipeline inspection services come into play.

These services are designed to detect early signs of wear, corrosion, and operational stress in pipeline systems. With the integration of remote sensors and non-invasive testing techniques, inspections are more accurate and less disruptive than ever before.

Equally important is the role of a trusted tank inspection company. Storage tanks, often containing hazardous or pressurized substances, require regular evaluations to maintain structural soundness. In 2025, this means using technologies like ultrasonic thickness testing and 3D imaging to stay ahead of issues.

Inspections aren’t just about passing tests—they’re about creating a culture of prevention. Companies that take proactive steps to monitor their infrastructure reduce downtime, avoid environmental hazards, and gain a competitive edge in a tightly regulated industry.

These services also support long-term planning. By tracking inspection data over time, businesses can anticipate maintenance needs and extend asset lifespan. In an environment where safety, sustainability, and compliance are paramount, inspection services are no longer optional—they’re essential.

Ensure your infrastructure can handle the pressure of 2025. Invest in inspection partners who deliver reliability, insight, and peace of mind.

1 note

·

View note

Text

Aligning Pipeline Inspection Practices with ESG Compliance Goals

Companies operating in sectors like oil, gas, and chemicals are under mounting pressure to demonstrate strong ESG performance. One effective way to support ESG goals is through comprehensive pipeline inspection services. These services are instrumental in identifying vulnerabilities that could lead to environmental damage or regulatory violations.

Pipeline inspection companies now utilize a combination of visual checks, ultrasonic testing, and data analytics to ensure systems are functioning optimally. This proactive approach helps mitigate risks before they escalate into serious issues, aligning with the environmental aspects of ESG compliance.

Similarly, tank inspection services contribute by safeguarding storage systems from leaks and corrosion. When properly maintained, tanks reduce the risk of contamination, which not only protects the environment but also ensures compliance with government safety regulations.

Beyond environmental protection, thorough inspections promote better governance and operational integrity. Detailed reports from certified inspectors provide documentation that supports corporate accountability and transparency. These records are invaluable during ESG audits or investor evaluations.

Integrating regular inspections into company policy is more than a best practice—it’s a strategic move. It signals to stakeholders that the company is serious about sustainability, safety, and ethical operations. As ESG standards become more rigorous, partnering with experienced pipeline inspection companies can give businesses a competitive edge.

Ultimately, the road to ESG compliance is paved with diligence, and it starts with effective inspection services that protect both people and the planet.

1 note

·

View note

Text

Unlocking the Power of Drone Thermal Imaging with Thermo Elite

In today’s fast-paced world, the demand for faster, safer, and more precise inspection and analysis methods is skyrocketing across industries. Whether it's infrastructure, agriculture, construction, or energy—organizations are seeking smarter technologies to gain insights and optimize operations. This is where drone thermal imaging comes into play, and Thermo Elite is proud to be at the forefront of this cutting-edge service in Canada.

What is Drone Thermal Imaging?

Drone thermal imaging involves the use of unmanned aerial vehicles (UAVs), or drones, equipped with advanced thermal cameras that detect heat emitted by objects. These thermal sensors capture temperature variations invisible to the naked eye and convert them into detailed infrared images. The result? A powerful, non-invasive tool for identifying problems, inspecting assets, and improving decision-making.

At Thermo Elite, we integrate the latest in drone technology with high-resolution thermal cameras to deliver accurate, real-time data that helps our clients reduce risks, cut costs, and enhance efficiency.

Why Choose Drone Thermal Imaging?

Traditional inspection methods often involve scaffolding, rope access, or shutting down equipment—costly and time-consuming processes that also carry safety risks. In contrast, drone thermal imaging allows for:

Non-contact inspections

Faster turnaround times

Access to hard-to-reach or dangerous areas

Accurate temperature mapping

Minimal downtime and disruption

Thermo Elite’s drone thermal imaging services are designed to serve a broad range of applications while ensuring safety, compliance, and exceptional accuracy.

Industries We Serve

1. Building and Roof Inspections

Leaks, insulation problems, or moisture accumulation can lead to costly damages if left undetected. Drone thermal imaging identifies temperature anomalies on rooftops and building envelopes—pinpointing issues such as water intrusion, heat loss, or faulty insulation before they escalate.

2. Solar Panel Inspections

Maintaining solar panel efficiency is crucial for both residential and commercial installations. Our drone-mounted thermal cameras detect underperforming cells, hot spots, and defects without needing to physically touch or disassemble panels—saving time and improving maintenance strategies.

3. Electrical and Mechanical Inspections

Overheated components, loose connections, and failing motors are visible in thermal. Using drones, Thermo Elite can inspect high-voltage transmission lines, transformers, and electrical systems in real time—safely and efficiently.

4. Agriculture and Crop Monitoring

Thermal imaging is revolutionizing precision agriculture. Our drone services help farmers identify irrigation issues, detect pest infestations, and monitor plant health by capturing variations in canopy temperature, ensuring smarter farming and healthier crops.

5. Oil and Gas Industry

Drone thermal imaging helps in detecting leaks in pipelines, monitoring storage tanks, and ensuring facility safety. Inspections can be performed without shutting down equipment or risking personnel, making operations more secure and efficient.

Why Thermo Elite?

At Thermo Elite, we combine decades of experience in thermographic inspection with the latest drone technology to deliver unparalleled service. Here's what sets us apart:

Certified Thermographers: Our team includes Level 1, 2, and 3 thermographers certified to industry standards.

Advanced Equipment: We use high-resolution FLIR thermal sensors for accurate diagnostics.

Customized Reports: Every project comes with a comprehensive, easy-to-understand report complete with images and recommendations.

Safety First: All our drone pilots are certified and trained to operate in compliance with Canadian aviation laws.

Nationwide Coverage: Whether you’re in Montreal, Toronto, Calgary, or Vancouver—we bring our services to your site.

Drone Thermal Imaging: A Smart Investment

From identifying early-stage faults to monitoring system performance, drone thermal imaging is a game-changer. It transforms how businesses handle inspections—making them smarter, faster, and safer.

For facility managers, property developers, solar farm owners, or agricultural experts—this service offers unmatched value. And with Thermo Elite as your partner, you can trust that you’re getting reliable data backed by real expertise.

Ready to See the Unseen?

Thermal imaging with drones opens a world of invisible data—and Thermo Elite is here to help you access it. Whether you need routine maintenance or urgent diagnostics, we tailor our services to your exact needs.

Want to know how drone thermal imaging can benefit your next project? Contact Thermo Elite today and schedule a free consultation with our certified team. Let's help you see what your eyes can’t—and make informed, data-driven decisions every step of the way.

#drone thermal imaging#thermal drone inspection#infrared drone services#drone roof inspection Canada#Thermo Elite inspections#aerial thermography#building heat loss detection#drone thermographic survey#solar panel thermal inspection#pipeline leak detection drone#agricultural drone imaging#drone inspection Montreal#UAV thermal inspection Canada#commercial thermal imaging services#thermal inspection company Canada

0 notes

Text

Real-time collaboration between on-site crews and remote experts becomes smoother with mobile apps. As data is logged, remote teams can offer immediate recommendations, reducing guesswork and improving accuracy. Ultimately, mobile apps reduce non-productive time (NPT), optimize resource use, and ensure better compliance with environmental and safety standards.

#mobile apps for oil and gas industry#oil and gas field service mobile apps#real-time data apps for oil industry#mobile inspection apps for gas pipelines

0 notes

Text

Drone Pipeline Inspection: A Smarter, Safer, and More Efficient Approach

Pipeline networks play a crucial role in transporting oil, gas, and other resources over vast distances. Ensuring their integrity is essential for preventing leaks, environmental damage, and costly repairs. Drone pipeline inspection is revolutionizing the industry by providing faster, safer, and more cost-effective monitoring solutions compared to traditional ground or manned aerial inspections.

Why Use Drones for Pipeline Inspections?

Drones equipped with high-resolution cameras, thermal sensors, LiDAR, and AI-powered analytics allow operators to detect potential issues such as leaks, corrosion, and structural weaknesses with unmatched precision. Unlike ground-based inspections, which can be slow and labor-intensive, drones provide real-time data over extensive areas with minimal human intervention.

Key Benefits of Drone Pipeline Inspection

1. Increased Safety

Traditional inspections often require personnel to operate in hazardous environments, extreme weather conditions, or difficult terrains. Drones eliminate the need for human exposure, significantly reducing the risk of accidents.

2. Faster Data Collection

Drones can cover hundreds of miles in a single flight, capturing high-resolution imagery and thermal data within minutes. This efficiency reduces downtime and allows for more frequent inspections.

3. Cost-Effectiveness

Compared to helicopters and ground-based methods, drones reduce inspection costs by eliminating expensive equipment, fuel costs, and labor-intensive procedures.

4. Enhanced Accuracy with AI and Machine Learning

Advanced drones use AI-powered image recognition to identify anomalies such as leaks, cracks, or vegetation encroachment. These insights enable predictive maintenance, reducing the likelihood of failures.

Applications of Drone Pipeline Inspection

1. Oil & Gas Pipeline Monitoring

Detects leaks, corrosion, and structural damages.

Monitors pipeline integrity in remote and hard-to-reach areas.

2. Environmental Protection

Prevents oil spills and gas leaks, reducing environmental risks.

Monitors compliance with regulatory safety standards.

3. Thermal & Gas Leak Detection

Uses infrared and methane detection sensors to identify gas leaks.

Provides real-time analysis to prevent hazardous incidents.

4. Right-of-Way (ROW) Maintenance

Monitors vegetation encroachment to prevent damage.

Ensures regulatory compliance for land-use and safety protocols.

Best Drones for Pipeline Inspection

1. DJI Matrice 300 RTK

55-minute flight time with 15 km transmission range.

Supports Zenmuse H20T (thermal, zoom, and laser rangefinder camera).

Ideal for long-range and high-precision inspections.

2. DJI Mavic 3 Thermal

Compact and lightweight with 45-minute flight time.

Features 640×512 thermal imaging for leak detection.

Best suited for small to mid-sized inspections.

Conclusion

Drone pipeline inspection is transforming the industry by offering faster, safer, and more precise data collection. With advanced thermal imaging, AI-powered analytics, and automated flight paths, drones help operators detect issues before they become critical, ensuring cost savings, environmental protection, and enhanced safety. As drone technology continues to evolve, its role in pipeline inspection will only become more essential.

0 notes

Text

CCTV Pipe Inspection Services for Accurate Pipeline Assessment

Detect blockages, cracks, and leaks with advanced CCTV pipe inspection services. Our high-resolution cameras provide a clear view inside pipelines, helping you identify issues before costly repairs. Get reliable pipe inspections today. For more information visit site: https://cnilocates.com/

0 notes

Link

Advanced In-Line Inspection Detecting Pipeline Integrity with Smart Pigging

#pipeline#oil and gas#waterfall#wastewater#inspection#inlineinspection#rotextechnologies#conditionmonitoring#magneticfluxleakage#ultrasonicsensor#eddycurrent

1 note

·

View note

Text

Why regular plumbing servicing is helpful, and how you can do it yourself.

Your living space reflects your state of mind, pristine works if pristine it seems. Messy works too if that your vibe is. Imagine shut windows, boarded up, what do you think that reflects? Decay; not just mess, Now, mess is when there exist leaks or no electricity. Well, leaks and electricity issues are common place. Let’s quit the meditation on decay and messy states and check into reality. Why is a regular plumbing maintenance important on a regular basis?

Simplifying this,

What are some plumbing grievances that could disrupt your daily routine, and how you could do it yourself, although getting professional plumbing services would be better and it is easy on your pockets too.

Leaks, drainage clogs, water heater hazards, flushing issues and the likes. A regular plumbing maintenance routine would look something this,

Simple routine things if done on a regular could save you from potential water hazards.

Checking water pressure, making sure it is in the normal range.

Checking for leaks, inspecting pipes, shower heads, faucets, valves and taps to check in case there are leaks.

Drainage cleaning, plungers come in handy or perhaps natural solutions like using baking sodas or vinegar to rid of the sheen.

Toilet maintenance, water heater, flush them both to eradicate the sediment accumulated.

Finally, checking the water quality, and taking care of the garbage disposal, since that is the key.

Now you know how to prevent blockages and clogs, issues with the sewer line and drain clogs, this would be real helpful to avoid damages and any other potential plumbing hazards.

But despite this, you encounter any plumbing hazards or issues. Reach out to us to get instant fixes.

Contact: +91 9980806696

Visit: www.instafix.in

#pipe installation services#pipe fitting services#gas pipeline installation services#commercial drain cleaning equipment#drain cleaning berlin#drain cleaning website#drain cleaning and unclogging services definition#water heater repair services near me#water heater installation & repair systems#water heater repair routine maintenance checklist#maintenance routine#routine inspection maintenance#leak detection and repair services#leak detection and repair companies#leak detection and repair system

0 notes

Text

Plumbing in Miami, FL

Looking for a dependable plumber in Miami, FL? Express Trenchless is here to serve you!

0 notes

Text

What is the Best Drone for Pipeline Inspection?

Drone technology has transformed how industries handle pipeline inspections. With drones offering efficient, cost-effective, and safer alternatives to traditional methods, companies can now inspect pipelines in remote or hazardous areas with precision and ease. But with a wide range of drones available, finding the best one for

Drone Pipeline Inspection depends on specific needs like flight time, camera quality, and data integration capabilities.

In this blog, we’ll explore the key features to look for in drones for pipeline inspection and highlight some of the top drones suited for this purpose.

Why Use Drones for Pipeline Inspection?

Before diving into the best drones, it’s essential to understand why drones are ideal for inspecting pipelines:

Efficiency: Drones can cover vast stretches of pipelines in less time than ground-based inspection teams.

Cost Savings: Using drones reduces the need for manpower, helicopters, or vehicles, lowering overall inspection costs.

Enhanced Safety: Drones can navigate hazardous environments, such as high elevations or areas with dangerous chemicals, keeping human inspectors out of harm’s way.

High-Resolution Data: Equipped with advanced cameras and sensors, drones provide detailed images, thermal data, and even gas detection capabilities.

Real-Time Monitoring: Drones allow for live-feed monitoring, enabling immediate identification of leaks, corrosion, or structural damage.

Key Features to Look for in a Drone for Pipeline Inspection

To determine the best drone for Drone Pipeline Inspection, you should consider the following factors:

Camera Quality: High-resolution cameras are essential for capturing clear visuals of pipelines. Look for drones with 4K cameras and zoom capabilities to identify fine details like cracks or corrosion.

Thermal Imaging Sensors: Thermal imaging is crucial for detecting leaks or temperature anomalies in pipelines. Drones with built-in thermal cameras are ideal for such tasks.

Flight Time: Longer battery life ensures drones can cover extensive pipeline networks without frequent recharging. Opt for drones with at least 30 minutes of flight time per battery cycle.

Range and Connectivity: Pipelines often span remote or inaccessible areas. Drones with long-range connectivity and reliable GPS tracking are vital for ensuring smooth operations.

Durability: Drones used for pipeline inspections must withstand harsh weather conditions, including strong winds and rain. Rugged designs and weatherproofing are key.

Payload Capacity: The ability to carry additional sensors, such as gas detectors or LiDAR, enhances the drone’s versatility for more advanced inspections.

Software Integration: Drones should support software for data analysis, mapping, and reporting, making it easier to integrate inspection results into the overall pipeline management system.

Top Drones for Pipeline Inspection

Here are some of the best drones suited for Drone Pipeline Inspection based on their features:

1. DJI Matrice 300 RTK

Why It’s Great: The Matrice 300 RTK is known for its reliability and advanced features. It offers up to 55 minutes of flight time, advanced thermal imaging with the Zenmuse H20T payload, and precise GPS capabilities.

Best For: Long-range and complex inspections with high-resolution and thermal imaging requirements.

2. DJI Mavic 3 Enterprise

Why It’s Great: Compact and versatile, the Mavic 3 Enterprise provides excellent imaging capabilities and thermal sensors in a smaller package. It’s ideal for quick and efficient inspections.

Best For: Smaller-scale pipeline networks or spot inspections.

3. Parrot Anafi Thermal

Why It’s Great: This lightweight drone is equipped with a 4K camera and a FLIR thermal sensor, making it perfect for detecting leaks or temperature anomalies. It’s also portable and easy to deploy.

Best For: Budget-friendly thermal inspections.

4. Skydio X2

Why It’s Great: Known for its autonomous flight capabilities, the Skydio X2 can navigate around pipelines with minimal manual intervention. It features 4K cameras and infrared sensors.

Best For: Inspections in challenging environments with obstacles.

5. Freefly Systems Alta X

Why It’s Great: The Alta X is a heavy-lift drone that can carry additional sensors like LiDAR or gas detectors. Its rugged design makes it suitable for extreme conditions.

Best For: Advanced inspections requiring custom payloads.

Benefits of Using the Best Drones for Pipeline Inspections

Investing in the right drone for pipeline inspection offers numerous advantages:

Accurate Leak Detection: Advanced thermal and gas sensors help pinpoint leaks before they become major issues.

Cost Reduction: High-quality drones reduce the need for expensive equipment like helicopters or scaffolding.

Faster Inspections: Drones cover miles of pipelines quickly, reducing downtime and ensuring pipelines remain operational.

Comprehensive Reporting: With integrated software, drones provide detailed insights and actionable reports.

Future of Drone Pipeline Inspection

The future of Drone Pipeline Inspection lies in integrating AI and automation. AI-powered drones can analyze data in real time, identify potential issues, and even suggest maintenance actions. Autonomous drones capable of flying pre-programmed routes will further streamline inspections.

Conclusion

The best drone for Drone Pipeline Inspection depends on specific project requirements, including the size of the pipeline network, environmental conditions, and the type of data needed. Drones like the DJI Matrice 300 RTK and Parrot Anafi Thermal stand out for their advanced features and versatility.

By leveraging drone technology, companies can ensure pipeline safety, improve efficiency, and reduce operational costs, making it an invaluable tool in modern infrastructure management.

#Drone Pipeline Inspection#Drone pipe inspection#uav pipeline inspection#pipeline inspections#oil pipeline inspection#gas pipeline inspection

1 note

·

View note

Text

Understanding the Importance of Water Utility Surveys

Water is a fundamental resource that sustains life, and the infrastructure supporting its supply and distribution is a critical component of urban and rural development. A water utility survey plays a pivotal role in ensuring the efficient and sustainable management of water resources.

Learn more at https://www.cyberswift.com/blog/water-utility-solution-detailed-overview/

#3D mapping for water utilities#Digital mapping for water utilities#GIS-based water utility mapping#Hydrographic utility surveys#Remote sensing for water pipelines#Surveying for water utility systems#Underground water pipeline surveys#Utility mapping for water projects#Water distribution network survey#Water distribution system assessment#Water infrastructure surveys#Water leakage detection surveys#Water pipeline mapping#Water pipeline monitoring solutions#Water supply network survey#Water utility asset management#Water utility inspection surveys#Water utility network monitoring#Water utility survey services

1 note

·

View note