#Remote sensing for water pipelines

Explore tagged Tumblr posts

Text

Understanding the Importance of Water Utility Surveys

Water is a fundamental resource that sustains life, and the infrastructure supporting its supply and distribution is a critical component of urban and rural development. A water utility survey plays a pivotal role in ensuring the efficient and sustainable management of water resources.

Learn more at https://www.cyberswift.com/blog/water-utility-solution-detailed-overview/

#3D mapping for water utilities#Digital mapping for water utilities#GIS-based water utility mapping#Hydrographic utility surveys#Remote sensing for water pipelines#Surveying for water utility systems#Underground water pipeline surveys#Utility mapping for water projects#Water distribution network survey#Water distribution system assessment#Water infrastructure surveys#Water leakage detection surveys#Water pipeline mapping#Water pipeline monitoring solutions#Water supply network survey#Water utility asset management#Water utility inspection surveys#Water utility network monitoring#Water utility survey services

1 note

·

View note

Text

Egyptologists Clash Over ‘Underground City’ Beneath Pyramids

Claims that an “underground city” exists beneath ancient Egyptian pyramids have caused a row among experts.

Researchers from Italy say they have uncovered giant vertical shafts wrapped in “spiral staircases” under the Khafre pyramid.

They said on Sunday that they found a limestone platform with two chambers and channels that resemble pipelines for a water system more than 2,100 feet below the pyramid, with underground pathways leading even deeper into the earth.

But the claims – which have not been published or independently peer-reviewed – were labelled “false” and “exaggerated” by fellow Egyptologists.

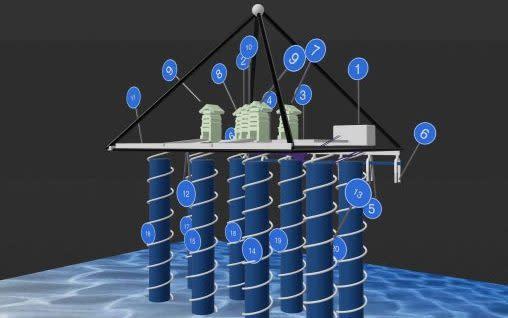

Researchers claim they have discovered eight cylinder-shaped structures below the Khafre - Khafre Project.

Prof Corrado Malanga and his team from the University of Pisa used radar pulses to create high-resolution images deep into the ground, similar to how sonar radar maps the ocean.

In a statement, he said: “When we magnify the images [in the future], we will reveal that beneath it lies what can only be described as a true underground city.”

The scientists have also said there is “an entire hidden world of many structures’’ and that “the Pyramid of Khafre might conceal undiscovered secrets, notably the fabled Hall of Records”.

The Hall of Records, a concept popularised in ancient Egyptian lore, is believed to be an ancient library beneath the Great Pyramid or the Sphinx, with vast amounts of information about the ancient civilisation.

Prof Lawrence Conyers, a radar expert at the University of Denver who focuses on archaeology, told the Daily Mail it was not possible for the technology to penetrate that deeply into the ground.

He said the idea that it proves an underground city existed is “a huge exaggeration”.

But he said it was conceivable small structures, such as shafts and chambers, may be present from before the pyramids were built.

He highlighted how “the Mayans and other peoples in ancient Mesoamerica often built pyramids on top of the entrances to caves or caverns that had ceremonial significance to them”.

The work by Prof Malanga and fellow researchers Filippo Biondi and Armando Mei was previously discussed during a briefing in Italy last week.

The project’s spokesman, Nicole Ciccolo, shared a video on Saturday of the trio discussing the findings that are yet to be published in a scientific journal.

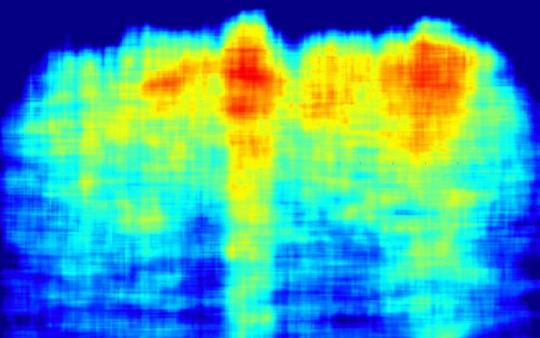

Tomographic images could indicate internal artificial structures under the pyramid - Khafre Project.

The team focused on the Khafre pyramid, which, along with Khufu and Menkaure pyramids, make up the three in the Giza complex.

The pyramids are thought to have been built some 4,500 years ago and sit on the west bank of the Nile river in northern Egypt.

The vertical shafts identified below the ground were about 33 to 39 feet in diameter, located at a depth of at least 2,130 feet, the researchers said, adding that they may support the pyramid, which needs “a strong foundation, otherwise it may sink”.

The team showed an image created by using the pulses which they claim includes “a complex, luminous structure with distinct vibrations” they believe is “an actual underground city”.

“The existence of vast chambers beneath the earth’s surface, comparable in size to the pyramids themselves, have a remarkably strong correlation between the legendary Halls of Amenti,” Ms Ciccolo said.

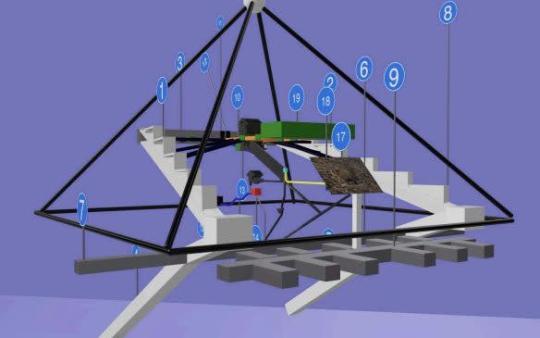

A 3D model displays the structures inside the central part of the Pyramid of Khafre - Khafre Project.

Prof Malanga and Mr Biondi published a separate peer-reviewed paper in October 2022 in the scientific journal Remote Sensing, which found hidden rooms and ramps inside Khafre, along with evidence of a thermal anomaly near the pyramid’s base.

The new study used similar technology but with extra help from satellites orbiting Earth.

Radar signals from two satellites about 420 miles above Earth were directed into the Khafre pyramid.

The experts then monitor how they bounce back and convert the signals into sound waves, which allows them to “see” through the solid stone and map out underground structures in 3D.

Prof Malanga claimed the results had been “completely consistent” and using two satellites ruled out the chance of “misinterpretation”.

By Michael Searles.

View of the ancient crypt inside the Great step pyramid of Djoser, Saqqara. Cairo.

#Egyptologists Clash Over ‘Underground City’ Beneath Pyramids#Scientists using new radar technology find 'vast city' beneath pyramids#Khafre pyramid#Khafre Project#The Hall of Records#ancient artifacts#archeology#history#history news#ancient history#ancient culture#ancient civilizations#ancient Egypt#egyptian history

167 notes

·

View notes

Text

Geotechnical Instrumentation and Monitoring Market Size Safeguarding Infrastructure with Smart Sensing

In today’s infrastructure-driven economy, the Geotechnical Instrumentation and Monitoring Market Size plays a critical role in ensuring structural safety and environmental sustainability. With increasing investments in megaprojects such as dams, tunnels, bridges, and high-rise buildings, the demand for geotechnical monitoring solutions has intensified globally.

Overview

According to Market Size Research Future, the Geotechnical Instrumentation and Monitoring Market Size was valued at USD 3.8 Billion in 2023 and is projected to reach USD 7.6 Billion by 2030, registering a compound annual growth rate (CAGR) of 10.3% from 2024 to 2030.

These systems are used to detect ground movement, subsurface shifts, and stress on structural elements. Their integration into civil engineering, mining operations, and environmental monitoring projects enhances risk management, minimizes failures, and improves project planning and execution.

Market Size Segmentation

The market is segmented based on Offering, Technology, Application, and End Use.

By Offering:

Hardware (Sensors, Data Acquisition Systems, Inclinometers)

Software (Data Visualization & Analytics)

Services (Installation, Monitoring, Maintenance)

By Technology:

Wired

Wireless

By Application:

Tunnels and Bridges

Buildings and Utilities

Dams

Mining

Oil & Gas

Landfills

By End Use:

Infrastructure

Energy and Power

Oil & Gas

Mining

Environment

By Region:

North America

Europe

Asia-Pacific

Middle East & Africa

Latin America

Market Size Trends

1. Smart Infrastructure Demands Real-Time Monitoring

With growing investment in smart cities and resilient infrastructure, geotechnical instrumentation is being upgraded with wireless technology and IoT-based real-time data acquisition systems. This allows engineers to receive alerts about structural anomalies and act swiftly to prevent failures.

2. Integration with Building Information Modeling (BIM)

Geotechnical monitoring systems are now being integrated with BIM platforms, allowing civil engineers to overlay geotechnical data into construction models. This improves project accuracy, coordination, and decision-making.

3. Sustainability and Environmental Safety

As environmental compliance becomes a key concern, geotechnical instrumentation helps monitor landfills, embankments, and mining operations to detect hazards like soil erosion, ground settling, and leakage that could harm the ecosystem.

4. Wireless Monitoring Gaining Traction

Wireless systems are replacing traditional wired setups in remote or harsh environments. They offer easier installation, lower costs over time, and access to cloud-based analytics for enhanced decision-making.

Segment Insights

Infrastructure Projects

Tunnels, bridges, and skyscrapers require precise monitoring during both construction and operation phases. Instrumentation ensures load-bearing elements are performing within design limits, safeguarding public and property.

Mining and Energy

In mining operations, monitoring slope stability and ground movement is crucial for worker safety and machinery integrity. In oil and gas sectors, these systems monitor ground deformation near drilling and pipeline sites.

Environmental Monitoring

For projects near wetlands, forests, or unstable terrain, geotechnical systems help prevent soil and water contamination by providing early warning of subsurface changes, landslides, or sinkholes.

Dams and Reservoirs

Instrumentation is vital for detecting seepage, pressure changes, and structural stress in large dams, helping to prevent catastrophic failures and maintain water resource management.

End-User Insights

Government and Public Sector

Public infrastructure projects rely heavily on geotechnical monitoring to meet regulatory compliance and safety standards. Governments are increasing their budgets for smart infrastructure equipped with real-time monitoring systems.

Private Sector Construction

Large contractors and civil engineering firms are integrating geotechnical systems into their projects to reduce liability, ensure construction quality, and prevent delays from unexpected ground behavior.

Utilities and Power Plants

Hydroelectric dams, nuclear facilities, and underground pipelines need continuous subsurface monitoring to avoid structural damages and support long-term operational reliability.

Key Players

Leading companies in this market are investing in innovation, automation, and IoT integration. Major players include:

Geokon, Inc.

Fugro N.V.

RST Instruments Ltd.

Keller Group plc

Roctest Ltd.

Nova Metrix LLC

Geomotion Singapore

Sisgeo S.r.l.

James Fisher and Sons plc

Campbell Scientific, Inc.

These firms offer turnkey geotechnical solutions including installation, data acquisition, cloud storage, and analytics tailored for high-stakes engineering projects.

Conclusion

The Geotechnical Instrumentation and Monitoring Market Size is vital in today’s world of complex infrastructure and rising environmental concerns. With real-time insights into subsurface conditions, these systems protect assets, minimize risk, and ensure long-term structural stability.

As construction scales upward and outward—reaching into urban centers and environmentally sensitive zones—the role of geotechnical instrumentation will only become more prominent. From smart cities to underground tunnels and high-speed railways, data-driven monitoring is essential to building safe and sustainable infrastructure.

Trending Report Highlights

Explore related technologies shaping the future of infrastructure, automation, and sensing:

Collimating Lens Market Size

Electronic Access Control Systems Market Size

Equipment Monitoring Market Size

Track Geometry Measurement System Market Size

Microprinting Market Size

Vision Sensor Market Size

Microprocessor and GPU Market Size

InGaAs Camera Market Size

Far-Field Speech and Voice Recognition Market Size

Functional Printing Market Size

Predictive Emission Monitoring System (PEMS) Market Size

Soft Robotics Market Size

0 notes

Text

Why 2D Animation Is Thriving in the Modern Media World

Ask any classroom of creative students what excites them, and animated stories still light up the room. Yet parents and career counselors often wonder whether 2D animation is a sustainable path in 2025. After all, isn’t everything moving to 3D or photoreal VFX? The short answer: 2D animation is not only alive—it’s expanding into fresh niches, riding a content boom, and rewarding artists who marry classic motion principles with new-age production tech.

A Market That Refuses to Slow Down

Worldwide demand for animated content has surged with the rise of streaming platforms and digital media. India mirrors that trend: the animation sector is rapidly evolving, and new platforms are driving consistent demand for original, stylized, and affordable animated content.

Several forces drive this curve:

Streaming wars – Platforms from Netflix to JioCinema are green-lighting 2D series that can be produced faster than photoreal shows.

Ed-tech and advertising – Short-form explainers, e-learning clips, and branded motion graphics all lean on 2D clarity.

Mobile and casual gaming – Lightweight 2D assets keep file sizes small and devices cool, making the style ideal for emerging markets.

Because 2D animation scales well—single assets can be reused, re-timed, and localized—studios see solid returns even on modest budgets.

Skills That Turn Passion into Paychecks

What do hiring managers actually look for? Three overlapping buckets:

Motion Mastery – Timing, spacing, squash and stretch, and staging are key fundamentals that never go out of style.

Digital Fluency – Familiarity with software like Toon Boom Harmony, After Effects, or Blender’s Grease Pencil gives you a competitive edge.

Story Sense – The ability to pitch visual gags, compose shots, and evoke emotion remains one of the most sought-after skills.

Pair these with soft skills—communication, adaptability, and the ability to collaborate in pipelines—and you’re already ahead of many applicants.

Why Location Still Matters (and How It’s Changing)

While remote work has grown, creative ecosystems still thrive in physical hubs where studios, training centers, and events converge. One such example is the booming animation industry in South India. The region is seeing a rise in studios focused on web series, original IPs, mobile content, and e-learning animation. The infrastructure for training and production continues to improve, and local governments have introduced initiatives that support AVGC (Animation, Visual Effects, Gaming, Comics) sectors.

Studios aren’t just looking for cheap labor; they’re investing in skill development and hiring artists who can blend artistry with tech-savviness. A growing number of students are joining an Animation course in Bengaluru to learn not just animation basics but also software automation, rigging, and hybrid workflows.

Fresh Trends That Shape the Industry

It’s important to stay updated with how technology continues to shape the field. In recent months, several new developments have reinforced the value of 2D animation:

New updates to professional software have streamlined pose generation, rig management, and scene exports.

Multiple international platforms have expanded their slates to include 2D adult animation, animated documentaries, and stylized comedies.

Industry events have seen record participation, with workshops on rig-based animation, procedural FX, and asset reusability drawing the largest crowds.

All these signs point to a future where 2D animation doesn’t fade out—it adapts.

Career Paths Beyond “Animator”

2D animation opens more doors than just animating characters. You can specialize and branch out into various focused roles:

Character Rigger – Builds deformation systems that allow animators to move characters without redrawing.

FX Artist – Designs dynamic effects like smoke, water, or sparks using procedural animation.

Layout Artist – Plans camera movements, staging, and composition.

Technical Director – Automates production pipelines and supports the animation team with tools.

Production Coordinator – Ensures tasks are organized, deadlines are met, and quality remains consistent.

These roles highlight the depth of the industry and give individuals with different strengths—be it technical, managerial, or creative—a way to contribute meaningfully.

Earning Potential and Job Security

Salaries in 2D animation vary depending on role, skill, and location. However, two trends are encouraging:

Steady Growth – Entry-level salaries are becoming more competitive due to streaming, gaming, and ed-tech expansion.

Freelance Flexibility – More artists are balancing full-time jobs with freelance gigs, international projects, and indie collaborations.

The wide range of opportunities ensures that animators can build diverse portfolios, work with multiple clients, and develop long-term careers.

The Role of Technology in Sustaining 2D

While 3D animation, virtual production, and AI-assisted workflows are advancing rapidly, they haven’t replaced the unique charm and utility of 2D animation. In fact, technology has made 2D animation more efficient and relevant.

AI-driven tools can now assist with inbetweening and lip-sync, allowing animators to focus more on timing and performance. Real-time game engines like Unity and Unreal also support 2D sprites and layered visuals, opening up cross-platform storytelling. These tools don't replace human creativity—they amplify it.

Moreover, stylized 2D remains a favorite for indie games, music videos, digital ads, and even hybrid feature films. The ability to stand out visually gives 2D artists a lasting edge.

The Road Ahead

The creative economy is shifting toward flexible, stylized, and niche content. Animation is no longer confined to big-screen blockbusters or Saturday morning cartoons. It’s in mobile apps, branding campaigns, Instagram reels, explainer videos, and VR experiences.

With consistent training, a strong reel, and the right mindset, 2D animators can work across industries—education, health, gaming, retail, and entertainment. Whether you’re a storyteller, designer, coder, or manager, this field welcomes you.

The demand for high-quality, fast-turnaround, culturally nuanced 2D content is only growing. The career possibilities are broadening, not narrowing.

Conclusion

So, is 2D animation a good career? Yes—and more than ever. As content formats diversify and audiences crave authentic, visually distinct stories, 2D animation has secured a powerful, flexible role in modern media. The industry offers space for every kind of talent, from classic animators to tech-driven artists, from freelance specialists to studio leaders.

For anyone looking to blend creative flair with practical skills, especially in regions seeing industry-wide growth, enrolling in a vfx course bengaluru could be a strategic next step. It’s about future-proofing your skill set in an industry that thrives on reinvention.

0 notes

Text

Innovative Foundations: How Geotechnical and Environmental Systems Shape Infrastructure

Modern construction demands more than just architectural brilliance—it relies heavily on a stable foundation guided by deep scientific understanding. Whether building skyscrapers or laying pipelines, ensuring site suitability and environmental compliance is a critical first step. This is where the expertise of geotechnical and environmental engineers becomes indispensable. The importance of proper ground assessment and environmental analysis can’t be overstated. GeoKinetics Geotechnical and Environmental Engineers play a pivotal role in evaluating soil properties, stability risks, and ecological impacts to secure successful project execution and long-term sustainability.

THE RISING IMPORTANCE OF GEOTECHNICAL EXPERTISE IN MODERN CONSTRUCTION

Infrastructure development today is more intricate than ever before. Urban expansion, climate change, and stricter environmental regulations make it essential to consider subsurface conditions from the very beginning. GeoKinetics Geotechnical and Environmental Engineers specialize in subsurface explorations, site investigations, and lab testing that guide crucial engineering decisions. Their data-driven insights support the structural integrity of buildings and protect public safety by anticipating potential soil-related issues like settlement or liquefaction. Working in tandem with architects and civil engineers, these experts lay the groundwork for resilient and compliant infrastructure systems.

ENVIRONMENTAL CONSIDERATIONS IN ENGINEERING PROJECTS

Environmental impact is another essential facet in infrastructure planning. Construction can disrupt natural habitats, affect groundwater levels, and introduce pollutants into ecosystems. This is why GeoKinetics Geotechnical and Environmental Engineers integrate environmental assessments with engineering analyses. Their environmental evaluations cover aspects such as air quality, water runoff, waste management, and biodiversity protection. These evaluations ensure that projects align with national and regional environmental regulations, reducing liability and delays. Their ability to balance development needs with environmental stewardship makes them valuable contributors to sustainable development.

COMPREHENSIVE NATIONWIDE ENGINEERING SOLUTIONS

As construction needs diversify across different regions, nationwide solutions have become vital. GeoKinetics Nationwide Environmental Engineering and Geotechnical Systems offer tailored services that consider the unique geological and environmental conditions of each project location. From coastal cities to arid inland zones, they adapt methodologies and equipment to suit various terrain and weather challenges. Their widespread reach and adaptable systems ensure uniform quality and efficiency across multiple sites. This nationwide capability is particularly beneficial for multi-state infrastructure projects requiring consistency in engineering protocols and environmental compliance.

ADVANCED TECHNOLOGY AND SYSTEMS FOR COMPLEX PROJECTS

Technology plays a major role in the evolution of modern engineering services. GeoKinetics Nationwide Environmental Engineering and Geotechnical Systems utilize advanced testing equipment, remote sensing tools, and simulation software to generate precise and reliable data. These technologies support predictive modeling, allowing engineers to forecast future soil behavior or environmental shifts. By integrating digital systems with fieldwork, GeoKinetics Nationwide Environmental Engineering and Geotechnical Systems help reduce project risks, optimize design parameters, and improve cost efficiency. This modern approach ensures accuracy and enhances coordination across all project phases.

THE CRITICAL VALUE OF EXPERT GEOTECHNICAL SERVICES

Foundational stability, environmental responsibility, and regulatory compliance are all non-negotiable in today’s construction world. Accurate geotechnical and environmental evaluations save time, prevent costly redesigns, and contribute to the long-term viability of infrastructure. The role of geotechnical engineers goes far beyond soil analysis—they provide the knowledge necessary to transform raw land into functioning, safe, and enduring structures. Their work ensures that infrastructure is not only structurally sound but also harmonized with the surrounding environment, creating a balance between innovation and preservation.

CONCLUSION: LAYING THE GROUNDWORK FOR A RESILIENT FUTURE

Reliable engineering starts from the ground up, with careful planning and deep technical insight. Companies that offer comprehensive geotechnical and environmental services are critical in achieving this standard. One standout in the field is Geotechnical Engineering Services, a trusted name synonymous with excellence and dependability. For more information, visit. Whether addressing the challenges of urban development or ensuring environmental sustainability, GeoKinetics Geotechnical and Environmental Engineers and GeoKinetics Nationwide Environmental Engineering and Geotechnical Systems continue to lead the charge with expertise, innovation, and a commitment to foundational integrity.

0 notes

Text

Exploring the Deep: Bathymetry as the Epitome of Ocean Mapping

The ocean covers over 70% of the Earth's surface, yet much of its vast expanse remains unexplored. Unlocking the mysteries beneath the waves requires advanced techniques, and one of the most crucial among them is bathymetry — the science of measuring the depth of water bodies and charting the underwater features of the ocean floor. Often hailed as the epitome of ocean mapping, bathymetry provides the foundation for everything from scientific discovery to national security, maritime navigation, and climate research.

What is Bathymetry?

Bathymetry is the underwater equivalent of topography. While topographic maps depict land elevation above sea level, bathymetric maps illustrate the shape and features of the ocean floor. These maps show mountains, valleys, trenches, ridges, and plains beneath the sea. The data collected through bathymetric surveys enables scientists and engineers to understand the physical features and geological processes of the seafloor.

Tools and Techniques for Bathymetry

Modern bathymetric mapping is carried out using technologies such as sonar (sound navigation and ranging), LIDAR (light detection and ranging), and satellite altimetry.

Single-beam and multibeam sonar systems are mounted on ships or autonomous underwater vehicles (AUVs) and send sound pulses toward the ocean floor. The time it takes for the sound waves to bounce back is used to calculate depth.

Multibeam sonar is particularly powerful, as it can scan wide swaths of the seafloor in high resolution.

Satellite altimetry measures the sea surface height and uses variations caused by seafloor features to infer underwater topography.

Importance of Bathymetry

Bathymetry plays a critical role in various fields:

Maritime Navigation: Safe navigation of ships depends on accurate seafloor charts, especially in shallow or coastal waters.

Environmental Management: It helps in monitoring and managing marine ecosystems, coral reefs, and fishing grounds.

Geological Research: Bathymetric data supports the study of tectonic plate movement, underwater earthquakes, and volcanic activity.

Tsunami and Flood Prediction: Bathymetric maps help model ocean currents and wave behavior, crucial for predicting the impact of natural disasters.

National Defense and Offshore Engineering: Governments and industries use bathymetry for submarine operations, laying pipelines, and building offshore wind farms.

The Epitome of Exploration

What makes bathymetry the epitome of ocean mapping is its ability to reveal the unseen. It transforms a flat, blue surface into a richly detailed underwater landscape, enabling a deeper understanding of our planet’s geology and hydrology. Thanks to advances in remote sensing and digital mapping, today’s bathymetric maps are more precise than ever, offering insights into ecosystems and resources previously unknown.

Future of Bathymetric Mapping

Projects like Seabed 2030, a global initiative to map the entire ocean floor by 2030, underline the growing importance of bathymetry. With the use of AI, robotics, and crowd-sourced data, the science is evolving rapidly, bridging the gap between surface exploration and deep-sea knowledge.

In conclusion, bathymetry stands as the cornerstone of marine science and exploration. As we continue to explore the final frontier on Earth — our oceans — bathymetry remains our most reliable guide, truly the epitome of ocean mapping.

0 notes

Text

Pipeline Integrity in Focus: Why Intelligent Pigging is Critical in 2024 and Beyond

The global intelligent pigging service market was valued at US$ 907.2 million in 2023 and is projected to grow at a CAGR of 6.7% from 2024 to 2034, reaching an estimated US$ 1.8 billion by the end of 2034. This growth is driven by a rising need for pipeline integrity, surging investments in oil & gas infrastructure, and advancements in inspection technologies.

Request a Sample Report Copy

Market Overview: The Need for Smart Pipeline Inspection

Pipeline networks remain the backbone of the global energy supply chain. However, they face persistent challenges such as metal loss, internal corrosion, and cracking—all of which pose safety, environmental, and financial risks. Intelligent pigging services offer an efficient solution to monitor pipeline health through non-destructive in-line inspections (ILI).

These services rely on technologies such as Magnetic Flux Leakage (MFL), ultrasonic pigging, and caliper inspection to detect pipeline anomalies. The increasing need for real-time, high-resolution data is prompting pipeline operators to adopt next-generation pigging tools to prevent failures before they occur.

Drivers of Market Growth

1. Rising Focus on Pipeline Corrosion Control

Corrosion is a critical issue for the oil & gas industry. Substances such as water, CO₂, H₂S, and microorganisms in transported fluids accelerate pipeline degradation. Undetected corrosion can result in catastrophic leaks, environmental damage, and production losses.

Intelligent pigs are equipped with high-precision sensors that detect corrosion, metal loss, and wall thinning. These tools allow operators to take preventive action, enhancing safety and extending asset life. As the industry emphasizes operational resilience, corrosion monitoring has become a top priority—significantly fueling market demand.

2. Surge in Oil & Gas Infrastructure Investment

Global investment in oil & gas exploration, production, and transport infrastructure is gaining momentum. This trend is being driven by:

Rising global energy consumption, which grew from 122,000 TWh in 2000 to 173,000 TWh in 2019.

Regional initiatives to boost energy security and domestic production capacity.

For example, Vedanta announced a US$ 4 billion investment in 2024 to double its oil output in India. Similarly, Indian PSUs such as ONGC and IOCL are committing US$ 143.6 billion in 2024–2025 toward oil & gas expansion projects. Such developments necessitate robust inspection systems—paving the way for intelligent pigging services.

Technology Landscape: Advancing Pipeline Integrity

Magnetic Flux Leakage (MFL)

The most commonly used technique, MFL detects corrosion and wall loss by magnetizing the pipeline and sensing variations in magnetic flux. It offers high-speed and accurate measurements, making it ideal for long-distance pipelines.

Ultrasonic Pigging

Ultrasonic inspection uses pulse-echo and angle beam techniques to detect both internal and external flaws. It is particularly effective for assessing pipe wall thickness and identifying metal loss.

Caliper Inspection

Caliper pigs use mechanical arms to measure the geometry and internal diameter of pipelines. It is a cost-effective method for identifying dents, deformations, and ovalities.

Trends and Innovations

Next-generation ILI tools are combining features of cleaning pigs and intelligent sensors to create multifunctional inspection devices.

The integration of System-on-Module (SoM) technologies is enabling autonomous, remote monitoring with real-time data analytics.

Intelligent pigs are now capable of visual inspection using high-resolution cameras and AI-assisted image processing for improved defect recognition.

These innovations are transforming the traditional approach to pipeline maintenance, shifting from reactive to predictive strategies.

Regional Insights: Asia Pacific Leads the Market

In 2023, Asia Pacific emerged as the largest regional market and is expected to maintain this dominance through 2034. Key growth contributors include:

Strong investment in pipeline expansion and refinery projects.

Rapid urbanization and industrialization increasing energy demand.

Government initiatives in countries like India, China, and Japan to modernize oil & gas infrastructure.

With companies such as ONGC and IOCL planning substantial investments in pipeline development, the demand for intelligent pigging services is set to grow exponentially in this region.

Competitive Landscape

Prominent players in the intelligent pigging service market include:

LIN SCAN

T.D. Williamson, Inc.

Baker Hughes Company

GE Vernova

NDT Global

Enduro Pipeline Services, Inc.

Shell Plc

ConocoPhillips Company

Petrobras

OMV Aktiengesellschaft

These companies are focusing on technological innovation, global expansion, and strategic partnerships. For example:

In May 2024, ConocoPhillips acquired Marathon Oil to enhance its upstream capabilities.

In 2022, T.D. Williamson partnered with Artera Services to deliver combined solutions for natural gas and electric infrastructure inspection.

Conclusion

As oil & gas operators strive to improve pipeline safety, reduce downtime, and comply with regulatory norms, the intelligent pigging service market is poised for robust expansion. With a strong technological foundation and rising global demand for energy infrastructure integrity, intelligent pigging services will remain a cornerstone of modern pipeline management through 2034 and beyond.

0 notes

Text

The Advantages of Smart Pipes and Home Heating Technology

The Advantages of Smart Plumbing and Home Heating Technology

Are you tired of sky-high energy expenses and constant stress over prospective water damages? Smart pipes and home heating technology might be the service you've been looking for. With sophisticated functions like boosted power effectiveness and remote, these systems don't just save you money - they also provide unequaled benefit and comfort. Imagine a home that adjusts to your needs, automatically enhancing efficiency and capturing issues prior to they become significant problems. Fascinated? There's more to discover concerning how this advanced innovation can change your living experience.

Key Takeaways Smart plumbing and heating unit can lower power intake by approximately 30%, resulting in substantial savings on month-to-month energy bills. Real-time tracking and leak discovery capacities prevent water damage and maximize water use, contributing to environmental sustainability. Automated controls and user-friendly interfaces boost comfort and ease, permitting personalized temperature level setups and upkeep scheduling. Advanced analytics forecast part failings, enabling proactive maintenance and enhancing general system efficiency. IoT integration and artificial intelligence algorithms allow constant system optimization and integration with renewable energy resources. Improved Energy Efficiency

Smart plumbing and heating technology can substantially enhance your home's power effectiveness. Advanced systems now feature intelligent controls that instantly readjust temperatures and water usage based upon your routines and choices, lowering waste and reducing your utility costs. Smart thermostats, for instance, learn your family members's routine and temperature level preferences, then instantly make modifications to maintain your home comfy while reducing energy intake.

youtube

youtube

Energy audits can also assist identify locations where your home is shedding warm or making use of water inefficiently. These expert assessments provide in-depth recommendations for upgrades, such as shielding pipelines, setting up high-efficiency home appliances, or changing obsolete a/c systems. By making these improvements, you'll see immediate cost savings on your regular monthly costs and take pleasure in a more environment-friendly, comfy living room.

Smart plumbing and home heating innovation places you in control of your home's energy usage. With smart systems and calculated upgrades, you can make best use of efficiency and reduce environmental effect - all while taking pleasure in greater convenience and cost financial savings.

Boosted Leak Discovery

You'll rejoice to know that clever pipes technology offers real-time leakage tracking.

If a leakage is identified, the system can instantly shut down the water to decrease damage.

With these improved leak detection features, you can delight in peace of mind and safeguard your home from costly water damage.

youtube

Real-time Leak Monitoring

Real-time plumbing installation leak surveillance can assist you avoid pricey water damages by quickly identifying even the tiniest leaks in your plumbing system. Advanced sensing units throughout your home continually monitor water stress and circulation, sending out data to an analytics system that identifies possible leaks. If the system discovers an abrupt drop in pressure or unanticipated water usage, i

0 notes

Text

Marine Construction in Extreme Environments: A Technical Overview

Marine construction in extreme environments involves building and maintaining structures in some of the most challenging conditions on Earth. Whether it’s building offshore oil rigs in deep waters, installing wind farms in storm-prone seas, or constructing tunnels beneath the ocean, marine construction projects require specialized knowledge, advanced technology, and the use of robust materials. This article provides an overview of the critical aspects of marine construction, the engineering challenges faced, and the solutions that have emerged to overcome them.

Addressing the Challenges of Engineering on the Water

One of the most significant challenges in marine construction is dealing with the unpredictable and often harsh conditions of the marine environment. Unlike land-based construction, marine construction requires engineers to consider not only the weather but also the physical forces of the water.

Weather plays a crucial role in the planning and execution of marine construction projects. For instance, offshore projects must contend with high winds, heavy rains, and extreme temperatures. In regions like the North Sea or the Arctic, ice and freezing temperatures complicate the construction process, reducing the window of opportunity for building to just a few months each year.

In addition to the weather, marine construction projects must also account for the constantly shifting terrain of the ocean floor. Seafloor topography can vary greatly, from rocky substrates to soft, shifting sands. This variability makes it essential to adapt construction techniques and ensure that structures are anchored securely to withstand the pressures of tides, currents, and waves. Engineers use a variety of tools, such as dynamic positioning systems and remote sensing equipment, to monitor and analyze these conditions, ensuring that projects are completed safely and efficiently.

The Role of Advanced Materials in Marine Construction

Marine construction projects require materials that can withstand the severe conditions of the marine environment. Saltwater, extreme temperatures, and constant exposure to the elements can quickly degrade traditional materials, making it necessary to use specialized construction materials for these projects.

One of the most common materials used in marine construction is high-strength steel. This material is often treated with coatings to prevent corrosion caused by saltwater exposure. Offshore oil rigs, underwater pipelines, and marine platforms all rely on corrosion-resistant materials to ensure longevity and durability.

For more extreme conditions, engineers turn to advanced composites, such as carbon fiber and fiberglass. These materials offer an excellent balance of strength and weight, making them ideal for floating structures that need to withstand constant movement. Carbon fiber, in particular, is increasingly used in marine construction for its durability and resistance to fatigue.

In addition to these materials, engineers are exploring the use of self-healing materials. These materials are designed to repair themselves when damaged, which is especially valuable for underwater infrastructure that is difficult to access for repairs. For example, self-healing coatings can automatically seal small cracks, reducing maintenance costs and extending the lifespan of marine structures.

Adapting to Coastal and Environmental Challenges

Coastal areas present their own unique challenges for marine construction. The movement of tides, shifting sands, and the potential for coastal erosion require engineers to design structures that are not only resilient but also adaptable over time.

Floating structures, such as those used for offshore wind farms or oil platforms, are one solution to these challenges. These structures are anchored to the seafloor but are designed to float and adjust to the movement of the waves. By using dynamic positioning systems, engineers can ensure that these structures remain stable and secure, even in rough seas.

Coastal erosion is another issue that engineers must address in marine construction. Over time, the natural movement of water can wear away shorelines, threatening the stability of coastal structures. Engineers use a combination of barriers, such as sea walls and artificial reefs, to protect structures from erosion. These measures help to absorb the impact of waves and reduce the effects of rising sea levels.

Additionally, some marine construction projects involve building structures underwater or below the seafloor, such as submerged tunnels or pipelines. These projects require advanced tunneling techniques, specialized equipment, and continuous monitoring to ensure the safety and stability of the structure. The Channel Tunnel, for example, required innovative engineering to handle the pressure of deep water and shifting soil conditions.

The Future of Marine Construction: Innovations and Sustainability

The future of marine construction is heavily focused on sustainability and innovation. With increasing global concerns over climate change and the growing demand for renewable energy, the industry is evolving to incorporate more sustainable practices and technologies.

One of the most significant trends in marine construction is the integration of renewable energy into offshore structures. Offshore wind farms, for example, are becoming more common, providing a clean source of energy while also serving as a model for sustainable marine construction. These structures use wind turbines to generate electricity, and many are designed to be self-sustaining, reducing the need for external energy sources.

Other innovations in marine construction include the use of automation and artificial intelligence (AI). Drones and robots are increasingly being used to inspect marine structures, survey construction sites, and carry out maintenance tasks. These technologies reduce the need for human labor in hazardous environments and improve the efficiency of marine construction projects.

Additionally, there is a growing emphasis on using eco-friendly materials and construction methods. Engineers are exploring ways to reduce the environmental impact of construction materials and processes, such as using recycled materials or designing structures that minimize waste. These efforts are part of a broader movement toward green building practices, which aim to reduce the carbon footprint of construction projects while still meeting the demands of modern infrastructure.

0 notes

Text

Pilot Operated & Wafer Type NRV Valves – Udhhyog

💧 Industrial Flow Control with Pilot Operated and Wafer Type NRV Valves – Powered by Udhhyog

In the world of industrial piping and fluid systems, the demand for reliable, efficient, and compact valve solutions continues to rise. Whether it’s for controlling flow direction, managing pressure, or preventing backflow, non return valves (NRVs) are essential. Among these, two of the most in-demand designs are the pilot operated non return valve and the wafer type NRV valve.

At Udhhyog, we specialize in delivering advanced flow control solutions to industries across India. With a strong presence in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and other key industrial states, our goal is to provide high-performance valves backed by engineering excellence and customer support.

In this article, we’ll explore both the pilot operated non return valve and the wafer type NRV valve, understand their working principles, advantages, applications, and how Udhhyog delivers the best in class products across sectors.

🔍 What is a Non Return Valve (NRV)?

A non return valve, also known as a check valve, allows fluid to flow in only one direction. Its primary role is to prevent reverse flow, which could otherwise damage pumps, contaminate clean lines, or disrupt system operation.

Unlike gate or globe valves, NRVs are automatic. They require no manual actuation or power supply, making them ideal for energy-efficient flow control.

🧠 Understanding the Pilot Operated Non Return Valve

The pilot operated non return valve is a smart evolution in NRV technology. Unlike conventional NRVs that depend purely on flow pressure to open or close, this type of valve includes a pilot mechanism—a control device that senses upstream or downstream conditions to trigger the valve operation.

✅ Key Features of Pilot Operated NRVs:

Precise Control: Opens only when system conditions meet specific pressure criteria.

No Slamming: Prevents sudden shut-off, reducing water hammer and shock.

Failsafe Mechanism: Designed to lock or unlock under set pilot pressures.

Remote Actuation: Some models allow manual or pneumatic overrides.

🔧 Applications:

High-pressure pumping stations

Water distribution networks

Oil and gas flow lines

Fire suppression systems

Marine and offshore platforms

These valves are especially valuable where flow reversal could damage critical equipment, or where automated safety control is required.

🧩 Wafer Type NRV Valve – Compact, Reliable, and Efficient

The wafer type NRV valve is one of the most space-efficient non return valves. It is designed to be sandwiched between two flanges in a piping system.

Instead of using a large body and bonnet like conventional valves, wafer NRVs consist of a flat disc or dual plates that open and close based on flow pressure.

✅ Benefits of Wafer Type NRV Valves:

Space Saving: Ideal for compact setups or where installation space is limited.

Lightweight Design: Reduces pipeline load and shipping cost.

Quick Installation: No need for special fittings—fits between existing flanges.

Low Pressure Drop: Disc design allows smooth, streamlined flow.

🔧 Typical Use Cases:

HVAC systems

Chemical dosing lines

Irrigation and agriculture

Cooling towers

Food and pharma processing units

At Udhhyog, our wafer type NRV valves are available in cast iron, stainless steel, bronze, and PTFE-lined variants to suit a wide range of fluids.

⚙️ Comparing Pilot Operated vs Wafer Type NRVs

FeaturePilot Operated NRVWafer Type NRVOperationControlled via pilot pressureAutomatic, spring/disk operatedInstallation SpaceRequires more spaceCompact and flange-mountedResponse TimeSlower but preciseFast closureApplicationsHigh-pressure, critical systemsStandard fluid flow systemsCostHigher due to control systemAffordable and widely used

🏭 Why Industries Prefer Udhhyog Valves

At Udhhyog, we are dedicated to delivering premium valve solutions to industries across India. Here’s why we’re the preferred partner for NRV systems:

✅ Wide Product Range:

Swing NRV

Lift NRV

Pilot operated non return valve

Wafer type NRV valve

Dual plate check valves

Foot valves and strainers

✅ Material Options:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304, SS 316)

Bronze and Gunmetal

✅ Regional Expertise:

We are trusted suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and NCR regions—ensuring rapid dispatch and strong service support.

✅ Services Offered:

Bulk order support

OEM manufacturing

Technical consultation

On-site valve sizing and selection

Credit facility for loyal buyers

Explore our complete catalog: 👉 https://udhhyog.com/valves

🧰 Installation Tips for Long Valve Life

Whether you’re using a wafer type NRV valve or a pilot operated valve, correct installation is key to performance and safety.

Always verify the flow direction arrow during installation.

Use correct gaskets and flange standards.

Make sure the pipeline is free from debris before installation.

Do not overtighten bolts—use torque values recommended by the manufacturer.

For pilot operated valves, test the pilot control line for leaks or blockages.

At Udhhyog, we offer free technical support to clients for pre-installation and commissioning.

🌍 Where Are These Valves Used?

Here’s where our NRV valves deliver unmatched performance:

🚰 Water treatment plants

🏭 Chemical & petrochemical industries

🚢 Marine systems and shipyards

🛢️ Refineries and oil storage terminals

🧪 Pharma and clean water systems

🌾 Agricultural irrigation networks

🔥 Fire hydrant and suppression systems

Wherever there is flow, there is the need to control and protect—and that’s where Udhhyog comes in.

💡 How to Select the Right NRV Valve?

Choosing between pilot operated non return valve and wafer type NRV valve depends on:

✔ System pressure and flow conditions

✔ Space constraints

✔ Fluid type (corrosive, clean, viscous)

✔ Requirement of automation or pilot control

✔ Budget and maintenance access

Our engineering team at Udhhyog helps clients identify the best fit by analyzing data sheets, pressure ratings, and real-time flow demands.

📦 Udhhyog Valve Solutions – Fast, Reliable, Affordable

From custom valve sourcing to bulk supply for EPC projects, we are equipped to support industrial demands at scale.

🔹 Available Sizes: 15mm to 600mm 🔹 Pressure Classes: PN10, PN16, PN25, ANSI 150# 🔹 Certifications: ISI, ISO, IBR-compliant products 🔹 MOQ: As per customer need 🔹 Delivery Time: 2–5 working days (based on location)

🔚 Conclusion

If you're setting up a critical pumping system or optimizing a process line, the pilot operated non return valve offers unmatched control and protection. On the other hand, the wafer type NRV valve gives you compact, cost-effective backflow prevention.

At Udhhyog, we bring you both—crafted to perfection, tested for performance, and delivered with service you can trust.

📞 Get in touch today to order, get specifications, or schedule a consultation. Let’s power your industrial pipelines with the best in flow control engineering.

#PilotOperatedNRV#WaferTypeNRVValve#NonReturnValve#CheckValvesIndia#FlowControlValves#UdhhyogValves#DelhiValveSupplier#IndustrialValvesIndia#BackflowPrevention#EngineeringSolutions

1 note

·

View note

Text

Pilot Operated & Wafer Type NRV Valves – Udhhyog

💧 Industrial Flow Control with Pilot Operated and Wafer Type NRV Valves – Powered by Udhhyog

In the world of industrial piping and fluid systems, the demand for reliable, efficient, and compact valve solutions continues to rise. Whether it’s for controlling flow direction, managing pressure, or preventing backflow, non return valves (NRVs) are essential. Among these, two of the most in-demand designs are the pilot operated non return valve and the wafer type NRV valve.

At Udhhyog, we specialize in delivering advanced flow control solutions to industries across India. With a strong presence in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and other key industrial states, our goal is to provide high-performance valves backed by engineering excellence and customer support.

In this article, we’ll explore both the pilot operated non return valve and the wafer type NRV valve, understand their working principles, advantages, applications, and how Udhhyog delivers the best in class products across sectors.

🔍 What is a Non Return Valve (NRV)?

A non return valve, also known as a check valve, allows fluid to flow in only one direction. Its primary role is to prevent reverse flow, which could otherwise damage pumps, contaminate clean lines, or disrupt system operation.

Unlike gate or globe valves, NRVs are automatic. They require no manual actuation or power supply, making them ideal for energy-efficient flow control.

🧠 Understanding the Pilot Operated Non Return Valve

The pilot operated non return valve is a smart evolution in NRV technology. Unlike conventional NRVs that depend purely on flow pressure to open or close, this type of valve includes a pilot mechanism—a control device that senses upstream or downstream conditions to trigger the valve operation.

✅ Key Features of Pilot Operated NRVs:

Precise Control: Opens only when system conditions meet specific pressure criteria.

No Slamming: Prevents sudden shut-off, reducing water hammer and shock.

Failsafe Mechanism: Designed to lock or unlock under set pilot pressures.

Remote Actuation: Some models allow manual or pneumatic overrides.

🔧 Applications:

High-pressure pumping stations

Water distribution networks

Oil and gas flow lines

Fire suppression systems

Marine and offshore platforms

These valves are especially valuable where flow reversal could damage critical equipment, or where automated safety control is required.

🧩 Wafer Type NRV Valve – Compact, Reliable, and Efficient

The wafer type NRV valve is one of the most space-efficient non return valves. It is designed to be sandwiched between two flanges in a piping system.

Instead of using a large body and bonnet like conventional valves, wafer NRVs consist of a flat disc or dual plates that open and close based on flow pressure.

✅ Benefits of Wafer Type NRV Valves:

Space Saving: Ideal for compact setups or where installation space is limited.

Lightweight Design: Reduces pipeline load and shipping cost.

Quick Installation: No need for special fittings—fits between existing flanges.

Low Pressure Drop: Disc design allows smooth, streamlined flow.

🔧 Typical Use Cases:

HVAC systems

Chemical dosing lines

Irrigation and agriculture

Cooling towers

Food and pharma processing units

At Udhhyog, our wafer type NRV valves are available in cast iron, stainless steel, bronze, and PTFE-lined variants to suit a wide range of fluids.

⚙️ Comparing Pilot Operated vs Wafer Type NRVs

FeaturePilot Operated NRVWafer Type NRVOperationControlled via pilot pressureAutomatic, spring/disk operatedInstallation SpaceRequires more spaceCompact and flange-mountedResponse TimeSlower but preciseFast closureApplicationsHigh-pressure, critical systemsStandard fluid flow systemsCostHigher due to control systemAffordable and widely used

🏭 Why Industries Prefer Udhhyog Valves

At Udhhyog, we are dedicated to delivering premium valve solutions to industries across India. Here’s why we’re the preferred partner for NRV systems:

✅ Wide Product Range:

Swing NRV

Lift NRV

Pilot operated non return valve

Wafer type NRV valve

Dual plate check valves

Foot valves and strainers

✅ Material Options:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304, SS 316)

Bronze and Gunmetal

✅ Regional Expertise:

We are trusted suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and NCR regions—ensuring rapid dispatch and strong service support.

✅ Services Offered:

Bulk order support

OEM manufacturing

Technical consultation

On-site valve sizing and selection

Credit facility for loyal buyers

Explore our complete catalog: 👉 https://udhhyog.com/valves

🧰 Installation Tips for Long Valve Life

Whether you’re using a wafer type NRV valve or a pilot operated valve, correct installation is key to performance and safety.

Always verify the flow direction arrow during installation.

Use correct gaskets and flange standards.

Make sure the pipeline is free from debris before installation.

Do not overtighten bolts—use torque values recommended by the manufacturer.

For pilot operated valves, test the pilot control line for leaks or blockages.

At Udhhyog, we offer free technical support to clients for pre-installation and commissioning.

🌍 Where Are These Valves Used?

Here’s where our NRV valves deliver unmatched performance:

🚰 Water treatment plants

🏭 Chemical & petrochemical industries

🚢 Marine systems and shipyards

🛢️ Refineries and oil storage terminals

🧪 Pharma and clean water systems

🌾 Agricultural irrigation networks

🔥 Fire hydrant and suppression systems

Wherever there is flow, there is the need to control and protect—and that’s where Udhhyog comes in.

💡 How to Select the Right NRV Valve?

Choosing between pilot operated non return valve and wafer type NRV valve depends on:

✔ System pressure and flow conditions

✔ Space constraints

✔ Fluid type (corrosive, clean, viscous)

✔ Requirement of automation or pilot control

✔ Budget and maintenance access

Our engineering team at Udhhyog helps clients identify the best fit by analyzing data sheets, pressure ratings, and real-time flow demands.

📦 Udhhyog Valve Solutions – Fast, Reliable, Affordable

From custom valve sourcing to bulk supply for EPC projects, we are equipped to support industrial demands at scale.

🔹 Available Sizes: 15mm to 600mm 🔹 Pressure Classes: PN10, PN16, PN25, ANSI 150# 🔹 Certifications: ISI, ISO, IBR-compliant products 🔹 MOQ: As per customer need 🔹 Delivery Time: 2–5 working days (based on location)

🔚 Conclusion

If you're setting up a critical pumping system or optimizing a process line, the pilot operated non return valve offers unmatched control and protection. On the other hand, the wafer type NRV valve gives you compact, cost-effective backflow prevention.

At Udhhyog, we bring you both—crafted to perfection, tested for performance, and delivered with service you can trust.

📞 Get in touch today to order, get specifications, or schedule a consultation. Let’s power your industrial pipelines with the best in flow control engineering.

#PilotOperatedNRV#WaferTypeNRVValve#NonReturnValve#CheckValvesIndia#FlowControlValves#UdhhyogValves#DelhiValveSupplier#IndustrialValvesIndia#BackflowPrevention#EngineeringSolutions

1 note

·

View note

Text

Pilot Operated & Wafer Type NRV Valves – Udhhyog

💧 Industrial Flow Control with Pilot Operated and Wafer Type NRV Valves – Powered by Udhhyog

In the world of industrial piping and fluid systems, the demand for reliable, efficient, and compact valve solutions continues to rise. Whether it’s for controlling flow direction, managing pressure, or preventing backflow, non return valves (NRVs) are essential. Among these, two of the most in-demand designs are the pilot operated non return valve and the wafer type NRV valve.

At Udhhyog, we specialize in delivering advanced flow control solutions to industries across India. With a strong presence in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and other key industrial states, our goal is to provide high-performance valves backed by engineering excellence and customer support.

In this article, we’ll explore both the pilot operated non return valve and the wafer type NRV valve, understand their working principles, advantages, applications, and how Udhhyog delivers the best in class products across sectors.

🔍 What is a Non Return Valve (NRV)?

A non return valve, also known as a check valve, allows fluid to flow in only one direction. Its primary role is to prevent reverse flow, which could otherwise damage pumps, contaminate clean lines, or disrupt system operation.

Unlike gate or globe valves, NRVs are automatic. They require no manual actuation or power supply, making them ideal for energy-efficient flow control.

🧠 Understanding the Pilot Operated Non Return Valve

The pilot operated non return valve is a smart evolution in NRV technology. Unlike conventional NRVs that depend purely on flow pressure to open or close, this type of valve includes a pilot mechanism—a control device that senses upstream or downstream conditions to trigger the valve operation.

✅ Key Features of Pilot Operated NRVs:

Precise Control: Opens only when system conditions meet specific pressure criteria.

No Slamming: Prevents sudden shut-off, reducing water hammer and shock.

Failsafe Mechanism: Designed to lock or unlock under set pilot pressures.

Remote Actuation: Some models allow manual or pneumatic overrides.

🔧 Applications:

High-pressure pumping stations

Water distribution networks

Oil and gas flow lines

Fire suppression systems

Marine and offshore platforms

These valves are especially valuable where flow reversal could damage critical equipment, or where automated safety control is required.

🧩 Wafer Type NRV Valve – Compact, Reliable, and Efficient

The wafer type NRV valve is one of the most space-efficient non return valves. It is designed to be sandwiched between two flanges in a piping system.

Instead of using a large body and bonnet like conventional valves, wafer NRVs consist of a flat disc or dual plates that open and close based on flow pressure.

✅ Benefits of Wafer Type NRV Valves:

Space Saving: Ideal for compact setups or where installation space is limited.

Lightweight Design: Reduces pipeline load and shipping cost.

Quick Installation: No need for special fittings—fits between existing flanges.

Low Pressure Drop: Disc design allows smooth, streamlined flow.

🔧 Typical Use Cases:

HVAC systems

Chemical dosing lines

Irrigation and agriculture

Cooling towers

Food and pharma processing units

At Udhhyog, our wafer type NRV valves are available in cast iron, stainless steel, bronze, and PTFE-lined variants to suit a wide range of fluids.

⚙️ Comparing Pilot Operated vs Wafer Type NRVs

FeaturePilot Operated NRVWafer Type NRVOperationControlled via pilot pressureAutomatic, spring/disk operatedInstallation SpaceRequires more spaceCompact and flange-mountedResponse TimeSlower but preciseFast closureApplicationsHigh-pressure, critical systemsStandard fluid flow systemsCostHigher due to control systemAffordable and widely used

🏭 Why Industries Prefer Udhhyog Valves

At Udhhyog, we are dedicated to delivering premium valve solutions to industries across India. Here’s why we’re the preferred partner for NRV systems:

✅ Wide Product Range:

Swing NRV

Lift NRV

Pilot operated non return valve

Wafer type NRV valve

Dual plate check valves

Foot valves and strainers

✅ Material Options:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304, SS 316)

Bronze and Gunmetal

✅ Regional Expertise:

We are trusted suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and NCR regions—ensuring rapid dispatch and strong service support.

✅ Services Offered:

Bulk order support

OEM manufacturing

Technical consultation

On-site valve sizing and selection

Credit facility for loyal buyers

Explore our complete catalog: 👉 https://udhhyog.com/valves

🧰 Installation Tips for Long Valve Life

Whether you’re using a wafer type NRV valve or a pilot operated valve, correct installation is key to performance and safety.

Always verify the flow direction arrow during installation.

Use correct gaskets and flange standards.

Make sure the pipeline is free from debris before installation.

Do not overtighten bolts—use torque values recommended by the manufacturer.

For pilot operated valves, test the pilot control line for leaks or blockages.

At Udhhyog, we offer free technical support to clients for pre-installation and commissioning.

🌍 Where Are These Valves Used?

Here’s where our NRV valves deliver unmatched performance:

🚰 Water treatment plants

🏭 Chemical & petrochemical industries

🚢 Marine systems and shipyards

🛢️ Refineries and oil storage terminals

🧪 Pharma and clean water systems

🌾 Agricultural irrigation networks

🔥 Fire hydrant and suppression systems

Wherever there is flow, there is the need to control and protect—and that’s where Udhhyog comes in.

💡 How to Select the Right NRV Valve?

Choosing between pilot operated non return valve and wafer type NRV valve depends on:

✔ System pressure and flow conditions

✔ Space constraints

✔ Fluid type (corrosive, clean, viscous)

✔ Requirement of automation or pilot control

✔ Budget and maintenance access

Our engineering team at Udhhyog helps clients identify the best fit by analyzing data sheets, pressure ratings, and real-time flow demands.

📦 Udhhyog Valve Solutions – Fast, Reliable, Affordable

From custom valve sourcing to bulk supply for EPC projects, we are equipped to support industrial demands at scale.

🔹 Available Sizes: 15mm to 600mm 🔹 Pressure Classes: PN10, PN16, PN25, ANSI 150# 🔹 Certifications: ISI, ISO, IBR-compliant products 🔹 MOQ: As per customer need 🔹 Delivery Time: 2–5 working days (based on location)

🔚 Conclusion

If you're setting up a critical pumping system or optimizing a process line, the pilot operated non return valve offers unmatched control and protection. On the other hand, the wafer type NRV valve gives you compact, cost-effective backflow prevention.

At Udhhyog, we bring you both—crafted to perfection, tested for performance, and delivered with service you can trust.

📞 Get in touch today to order, get specifications, or schedule a consultation. Let’s power your industrial pipelines with the best in flow control engineering.

#PilotOperatedNRV#WaferTypeNRVValve#NonReturnValve#CheckValvesIndia#FlowControlValves#UdhhyogValves#DelhiValveSupplier#IndustrialValvesIndia#BackflowPrevention#EngineeringSolutions

0 notes

Text

The Top Industries That Rely on Construction Equipment Rental

Owning construction equipment can be cost-effective over time, but the initial investment is often overwhelming. You’ll need to cover significant upfront expenses, including storage, maintenance, and repairs. Fortunately, there’s a hassle-free alternative: renting construction equipment in Ontario. This option provides access to high-quality equipment without the burden of long-term commitments. Notably, the construction equipment rental market was valued at USD 39.22 billion in 2022 and is projected to grow at a CAGR of 4.73% by 2029.

Source: https://www.arizton.com/market-reports/us-construction-equipment-rental-market

Intrigued to know who else relies on rented construction equipment? Well, here are the top five industries where renting machines can make all the difference.

#1 Construction and Infrastructure Development

If we start with the most obvious industry, it will be the construction ecosystem. Have you ever watched a busy construction site with machines that are rented from the industry’s best? We mean, think about it: why would a contractor invest in a fleet of excavators, dump trucks, or bulldozers when they only need the equipment for a few months?

This is when they resort to a construction equipment rental company that uses the latest equipment for specific tasks without worrying about storage or upkeep. Whether we are talking about a small-scale residential project or massive highway construction, renting offers construction firms the flexibility and cost savings they have been looking for for so long.

#2 Oil and Gas Industry

The oil and gas industry tends to operate in remote, rugged environments, which is why specialized equipment is the need of the hour here. From digging trenches for pipelines to maintaining access roads, the oil and gas projects require heavy-duty machinery like loaders, backhoes, and even horizontal drilling machines.

Instead of hauling their equipment across long distances, oil and gas companies rent what they need locally to save time and ensure they are using the right machines for the job.

#3 Landscaping and Agriculture

Yes, even the green-thumb industries rely on heavy machinery! Landscapers and farmers often need equipment like skid steers, compact tractors, or mini excavators for short-term projects.

For example, let’s say a landscaping company lands a contract to reshape a large outdoor space with retaining walls and water features. Owning all the necessary equipment wouldn’t make sense for such occasional, high-stakes jobs. Renting ensures they get exactly what’s needed without draining their budget.

If you are in this line of work, renting is like borrowing a friend’s truck for a weekend, except the “friend” is a rental company with a massive selection.

#4 Mining and Quarrying

Mining is all about efficiency, and the right equipment can make or break a project. Dump trucks, excavators, and drilling rigs are just a few of the machines needed to extract minerals and resources.

But here’s the catch: mining companies don’t always need the same equipment for every site. Renting gives them the freedom to pick and choose what’s necessary for each project. It’s a flexible, budget-friendly approach that helps them stay competitive.

If you have ever thought mining was all about owning big machines, think again; rental is a huge part of their game plan.

Are you scouring the web for a construction equipment rental company for your next big construction project? Our team at Elvaan Equipment Solutions will be more than happy to help!

This content was originally published on: Elvaan Equipment Solutions

This has been republished with permission.

Original Source: https://elvaan.com/the-top-industries-that-rely-on-construction-equipment-rental/

0 notes

Text

Picking the Right Propane Gas Relationship in Ionia and Allegan Areas, MI!

Propane gas is fundamental for warming, eating homes and affiliations, and completing things in the Ionia Area and Allegan District, Michigan. Picking a solid propane gas association is critical whether you need propane warming, cooking, driving home gear, or running machines. This article investigates what to search for in a propane provider and the advantages and sides of neighborhood propane connections in these regions. Whether in the Ionia Region, Allegan Locale, or elsewhere in Michigan, a good propane gas association is your key to affirmed energy quietness.

Making Sense of Propane's Work in Michigan

Propane is an adaptable energy source regularly utilized across Michigan. It provides tremendous warmth during the state's cold winters and is typically used in provincial areas where ignitable gas pipelines may not reach. Propane gas company Ionia County is similarly fundamental for green endeavors, such as grain dryers, water system siphons, and other family gear. Moreover, propane is a cleaner-consuming energy source, making it harmless to the climate for private and business needs.

With its extensive extent of purposes, solid areas for a provider guarantee vital help, serious worth, and a specialist bearing uncommonly fit to your energy needs. Search for a relationship with a firm delegate of a dependable vehicle, particularly during winter. Changed improvement affiliations or remote tank-checking choices can add quietness and affirmation you never run out of propane. Propane costs can change because of financial conditions.

Why to Search for Propane Gas Company in Allegan County

Propane gas company Allegan County offers direct looking over structures, adaptable installment plans, and cost insurance to assist clients with overseeing costs. Propane gas requires careful preparation and consideration to ensure its life span. Choose a relationship with confirmed specialists who follow cautious health and safety procedures during tank establishment, sponsorship, and repair. This reliable propane provider pivots around purchaser consistency. Whether through crisis support, exact correspondence, or instructive materials about propane use, breathtaking client care shows a dependable association.

Ranchers depend upon propane to control grain dryers, animal radiators, and water structure frameworks. Affiliations serving country clients routinely give mass vehicle affiliations custom-fitted to make it work. Associations in the Ionia and Allegan Regions use propane to control current stuff, support generators, and work in business kitchens. Extreme improvement times and high-limit tanks are fundamental responsibilities regarding business clients.

Advantages of picking the right Propane Gas Company Ionia County MI

Close by propane affiliations consistently handle their affiliations' extraordinary necessities. Their nearness permits them to answer rapidly to clients and keep up with solid areas. Propane Gas Company Ionia County MI offer a degree of affiliations expected to meet the other requirements of their clients. From warming homes to driving water radiators, stacks, and kitchen devices, ordered vehicles guarantee property holders respect and solace.

As frequently as could be expected, propane affiliations provide solid groundwork for over-the-ground or underground tanks and guarantee standard upkeep to ensure ideal execution. One of the best propane providers like Dependable LP Gas Company offers uncommon chamber top-off affiliations nearby for more confined-size needs, such as barbecuing or versatile warmers. Nearby affiliations sometimes revolve around building long-term relationships with their clients, which can impact exceptionally made affiliations and better exhaustive experiences.

Conclusion

Propane is a focal energy asset for the occupants and the association between the Ionia District and Allegan Region, Michigan. You pick a propane gas association due to reliability, straightforwardness, flourishing, and superb client support. By selecting a nearby propane provider, you can participate in the additional advantages of a revamped connection, fast response times, and a more fundamental impression of your splendid energy needs. Investing in a sensible propane connection guarantees a fundamental energy source, keeping your home warm, your machines running, and your business or solid ranch running.

0 notes

Text

Pipeline Monitoring: A Comprehensive Guide

Pipeline monitoring is a critical process in ensuring the safety, efficiency, and longevity of infrastructure. Whether transporting water, gas, or oil, pipelines are the backbone of many industries. However, managing pipelines effectively requires constant attention and the use of advanced technologies. In this blog post, we’ll delve into the essential aspects of pipeline monitoring, explore the challenges involved, and provide a detailed step-by-step guide on how to implement an effective monitoring system. We'll also present a case study to demonstrate how pipeline monitoring can improve operations.

Why Pipeline Monitoring is Essential

Pipeline monitoring plays a pivotal role in detecting leaks, corrosion, pressure changes, and other potential failures before they become catastrophic. Proper monitoring ensures regulatory compliance, reduces maintenance costs, and minimizes environmental damage. Without adequate pipeline monitoring, a small issue could lead to significant financial and operational losses.

Common Pipeline Monitoring Systems Everyone Should Know

1. Acoustic Monitoring Systems

Acoustic monitoring systems are designed to detect anomalies in pipelines by capturing sounds emitted during the flow of materials. They detect pressure changes, leaks, or ruptures in the pipeline by analyzing acoustic waves. These systems are sensitive enough to pick up the smallest abnormalities, allowing for early detection of potential failures.

2. Fiber Optic Sensors

Fiber optic technology is an innovative solution in pipeline monitoring. It detects temperature, pressure, and strain in real-time. By embedding fiber optic cables along the pipeline, operators can receive instant feedback on any changes or issues that might arise. This method is cost-effective and can monitor extensive pipeline networks over long distances.

3. Ultrasonic Testing

Ultrasonic monitoring uses sound waves to detect changes in the thickness of pipeline walls. It’s particularly effective for identifying corrosion or cracks within the pipe, making it one of the most reliable methods for ensuring the integrity of pipelines over time.

4. Satellite-Based Monitoring

With advancements in technology, satellite monitoring has become an increasingly popular option for overseeing large pipeline systems. By using satellite imagery and remote sensing, companies can monitor pipeline routes, detect unauthorized activities, and assess environmental impacts in hard-to-reach areas.

Challenges in Pipeline Monitoring