#PrecisionMachines

Explore tagged Tumblr posts

Text

Dynemech Anti-Vibration Technology Membrane Air Springs – Stability and Precision for Sensitive Machinery

On the topic of Machinery that Requires Precise Accuracy, any form of Vibration Counts. Dynemech Anti-Vibration Technology Membrane Air Springs are designed to provide your Machines with the Smooth and Stable Support they Require. Crafted to support delicate Equipment such as Coordinate Measuring Machines (CMMs), gear profile testers, microscopes, hardness testers, and surface roughness measuring devices, Air Springs Dampen Vibrations and maintain your machines exactly level at all times.

Our Membrane Air Springs employ Pneumatic Isolation with automatic 3-point levelling. That is, the system self-adjusts to maintain machines in a stable state despite uneven weight distribution. That is quite useful when you need repeatable Precise results each time.

These Air Springs have a natural frequency of between 1.5 and 2.0 Hz and serve to damp even low-frequency Vibrations that could compromise measurement accuracy. All the details are well considered so your Machines can operate in peace without jolts.

They are also fitted with an Elastomeric Diaphragm and a safety valve so that your machines remain safeguarded at all times. The compact aluminum housing makes them simple to mount and manage, and you can adjust the Damping as needed. Even microscopic adjustments count when your machine must function with microns. And you'll enjoy levelling precision of as little as 0.015 mm to 0.15 mm, so you can rely on your machines to remain perfectly horizontal and balanced.

That is why industries across the globe select Dynemech Anti-Vibration Technology Membrane Air Springs for their most delicate machinery. If you own a high-precision test machine or sensitive laboratory equipment, our air springs provide you with the assurance that your machines will function at their utmost best.

Are you on the lookout for tried-and-tested solutions that minimize Vibrations, Enhance Accuracy, and make your machines last longer? Dynemech Anti-Vibration Technology Membrane Air Springs are the solution you're looking for. Proudly Make in India, we stand behind each unit we manufacture.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #Antivibration, #VibrationControl, #MembraneAirSprings, #VibrationIsolation, #MakeInIndia, #PrecisionMachines, #MachineStability, #IndustrialSolutions, #VibrationTechnology, #Manufacturing, #Engineering

📞 +91-98107-60131 📧 [email protected] 🌐 www.vibrationmountsindia.com

#Dynemech#Antivibration#VibrationControl#MembraneAirSprings#VibrationIsolation#MakeInIndia#PrecisionMachines#MachineStability#IndustrialSolutions#VibrationTechnology#Manufacturing#Engineering

0 notes

Text

Enhancing Precision and Efficiency with Automatic Cashew Nut Shelling Machines

Boost your cashew processing with advanced Automatic Cashew Nut Shelling Machines, designed to improve precision and efficiency. These machines ensure consistent results, streamline operations, and enhance productivity. Perfect for businesses aiming to optimize their cashew nut shelling process. With advanced technology, the automatic cashew nut shelling machine reduces manual labor and increases output. Integrating the rcn shelling system enhances the overall shelling process, ensuring higher accuracy and reduced wastage. Experience higher accuracy in nut shelling and reduce product wastage. Ideal for businesses looking to scale up and meet demand efficiently with Giagro’s reliable solutions.

#cashewprocessing#shellingmachine#rcnshellingsystem#cashewindustry#automationinprocessing#giagro#efficiencyinshelling#precisionmachines#cashewnutshelling#foodprocessingtechnology

0 notes

Text

Understanding Heat Staking Machines

The Ultimate Guide to Heat Staking Machines: Basics, Applications, and Benefits

In the world of manufacturing, precision and reliability are paramount. One technology that embodies these qualities is the heat staking machine. This guide delves into the fundamentals of heat staking machines, explores their applications across various industries, and highlights the benefits they offer. By the end, you’ll understand why a heat staking machine from Vimalssonic could be a game-changer for your production processes.

Basics of Heat Staking Machines

What is a Heat Staking Machine?

How Does a Heat Staking Machine Work?

The heat staking process can be broken down into several key steps:

Heating: The machine heats a staking tip to a specific temperature, which is determined by the type of plastic and the desired bond strength.

Pressing: The heated tip is then pressed against the plastic part, causing it to soften and flow.

Forming: The softened plastic deforms and fills the cavity or groove of the mating part, creating a mechanical bond.

Cooling: The assembly is allowed to cool, solidifying the bond.

Heat staking machines come in various configurations, including manual, semi-automatic, and fully automatic systems. Each type is designed to meet different production needs, from low-volume, high-mix production to high-volume, low-mix environments.

Applications of Heat Staking Machines

Heat staking machines are incredibly versatile and find applications across a wide range of industries. Here are some common uses:

Automotive Industry

In the automotive sector, heat-staking machines are used to assemble components like dashboards, door panels, and electronic modules. The precision and reliability of heat staking ensure that these critical components are securely joined, enhancing the overall quality and safety of vehicles.

Consumer Electronics

Heat staking is widely used in the assembly of consumer electronics, including smartphones, tablets, and laptops. The process helps in joining delicate plastic parts without the risk of damaging sensitive electronic components.

Medical Devices

The medical device industry relies on heat staking for assembling products such as disposable medical instruments, diagnostic devices, and housing for electronic medical equipment. The strong, reliable bonds created by heat staking are essential for ensuring the safety and functionality of medical devices.

Aerospace

In aerospace applications, where durability and precision are critical, heat staking machines are used to join components in aircraft interiors, control panels, and other equipment. The process provides robust bonds that can withstand extreme conditions.

Household Appliances

Manufacturers of household appliances like vacuum cleaners, coffee makers, and washing machines use heat staking machines to assemble various plastic components. The process ensures a neat finish and long-lasting bonds, contributing to the overall durability of the products.

Benefits of Heat Staking Machines Vimalssonic

Using a heat staking machine offers several advantages that make it a preferred choice in many manufacturing settings:

1. Strong and Reliable Bonds

Heat staking creates robust mechanical bonds that are resistant to vibrations, impacts, and environmental factors. This makes it ideal for applications where durability and reliability are crucial.

2. Versatility

Heat staking machines can handle a wide range of materials and part geometries, making them suitable for various industries. Whether you need to join small, intricate parts or larger components, a heat staking machine can accommodate your needs.

3. Cost-Effective

Compared to other joining techniques like ultrasonic welding or adhesives, heat staking is often more cost-effective. It requires less energy and fewer consumables, reducing overall production costs.

4. Clean and Aesthetic Joints

The heat staking process produces clean, neat joints without the need for additional finishing steps. This is particularly important in applications where the appearance of the final product is a critical factor.

5. Flexibility in Design

Heat staking allows for more flexibility in the design of components. Engineers can design parts with specific features, such as bosses or studs, that can be easily heat staked, providing more design freedom.

6. Minimal Thermal Stress

The localized heating in heat staking minimizes the risk of thermal stress on surrounding areas, preserving the integrity of sensitive components. This is especially important in the assembly of electronic devices and medical instruments.

7. Environmentally Friendly

Heat staking is an environmentally friendly process as it does not involve the use of adhesives or solvents that can release harmful chemicals. This aligns with the growing demand for sustainable manufacturing practices.

Why Choose Vimalssonic Heat Staking Machines?

youtube

When it comes to selecting a heat staking machine, reliability and performance are key. Vimalssonic, a leading manufacturer and exporter of heat staking machines, offers a range of high-quality solutions tailored to meet your specific needs. Here’s why you should consider Vimalssonic:

1. Superior Quality and Precision

Vimalssonic heat staking machines are built with precision and durability in mind, ensuring consistent and reliable performance across various applications.

2. Customizable Solutions

Whether you require a manual, semi-automatic, or fully automatic machine, Vimalssonic provides customizable solutions to match your production requirements.

3. Global Reach

As an exporter, Vimalssonic serves clients worldwide, delivering cutting-edge heat staking technology to manufacturers across different industries.

4. Comprehensive Support

Vimalssonic offers extensive support and training to ensure that your team can operate the machines efficiently and effectively, maximizing your investment.

Heat staking machines are a vital tool in modern manufacturing, offering a reliable, versatile, and cost-effective method for joining plastic and plastic-to-metal components. Their applications span across various industries, including automotive, consumer electronics, medical devices, aerospace, and household appliances. By understanding the basics, applications, and benefits of heat staking machines, manufacturers can make informed decisions to enhance their production processes and product quality.

Investing in a heat staking machine from Vimalssonic can lead to stronger, more reliable bonds, greater design flexibility, and improved overall efficiency. Whether you are looking to optimize your current manufacturing process or develop new products, a heat staking machine from Vimalssonic could be the solution you need.

Ready to take your manufacturing to the next level? Contact Vimalssonic today to learn more about our high-quality heat staking machines and find the perfect solution for your production needs. Visit our website or reach out to our sales team for more information.

#Vimalssonic#PrecisionMachines#AssemblyProcess#PrecisionInstruments#SkilledTeam#QualityProducts#Manufacturing#MachineTools#Accuracy#Technology#Youtube

0 notes

Link

Tumblr Post

✨ Transform Alloy Wheels with Cutting-Edge Machines! ✨

Tired of uneven finishes or lengthy repairs? It’s time to upgrade your workshop with the best cutting wheel machines for refurbishing wheel faces!

🌟 Featured Machine: HAISHU CKL26Q CNC Wheel Lathe ✔️ ±0.02mm precision for professional results ✔️ Refurbishes wheels in 10-15 minutes ✔️ Advanced features like laser scanning and automatic tool changers

Whether you’re tackling surface scratches, dents, or corrosion, this machine delivers factory-grade finishes every time.

📌 Read the full guide: [https://haishucnclathe.com/what-is-the-best-cutting-wheel-machine-for-refurbishing-wheel-faces/]

#AlloyWheelRepair #CNCWheelLathe #HAISHUMachinery #PrecisionMachining

2 notes

·

View notes

Text

🔧 HAISHU CK50 CNC Lathe Machine offers precision machining, durability, and efficiency for industries like aerospace and medical.

💡 Key Features: ✔️ ±0.01 mm precision ✔️ Spindle speeds up to 4,000 RPM ✔️ Advanced CNC automation

👉 Learn more: Super CNC Machine Guide

#CNCInnovation #PrecisionMachining

2 notes

·

View notes

Text

Precision CNC Solutions for the Refrigeration Industry – CCI CNC

Refrigeration systems demand high-precision components to ensure reliability, energy efficiency, and long-term performance. At CCI CNC, we specialize in manufacturing custom CNC-machined parts for the refrigeration industry using advanced equipment and decades of engineering experience.

From compressor components to heat exchanger parts and valve housings, our CNC capabilities ensure tight tolerances, durability, and consistent quality. Whether you're developing new cooling technology or upgrading existing systems, we provide the precision manufacturing support you need.

As a trusted CNC machining partner, CCI CNC serves top-tier refrigeration manufacturers across the U.S., offering quick turnarounds, competitive pricing, and strict quality control. We work with aluminum, stainless steel, copper alloys, and high-performance plastics to meet demanding environmental and performance standards.

Visit: www.cci-cnc.com

#Refrigeration#CNCManufacturing#CCICNC#CoolingSolutions#HVAC#PrecisionMachining#RefrigerationTechnology

0 notes

Text

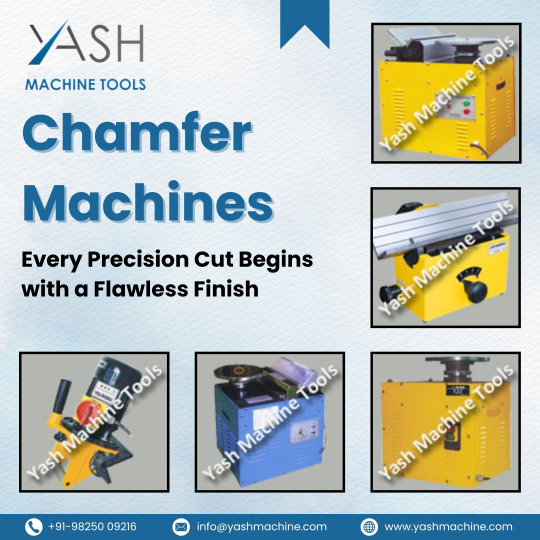

In machining, speed and precision make all the difference. Yash Machine Tools’ Chamfer Machines offer five powerful options for flawless angle preparation and edge refinement. Get perfect angles, smoother finishes, and reduced manual effort to enhance productivity and quality output in your production line. Explore more: https://www.yashmachine.com/product/drill-point-grinder/chamfer-machine

#yashmachinetools#chamfermachines#precisionmachining#ManufacturingExcellence#Metalworking#ProductionEfficiency#MachiningSolutions#QualityOutput

0 notes

Text

Level up your workshop with the unmatched reliability of Bhavya’s All-Geared Lathe Machine. Crafted from high tensile casting, featuring hardened gears and precision engineering, it delivers consistent results across metals and materials. Designed for industry pros who value long-term performance. https://www.bhavyamachinetools.com/category/all-geared-lathe-machine

#bhavyamachinetools#AllGearedLathe#PrecisionMachining#LatheMachineExperts#CNCReadyWorkshop#MetalworkingSolutions

0 notes

Text

How to Operate a Lathe

Operating a lathe might seem intimidating at first, but once you understand the core principles and develop proper habits, it becomes one of the most rewarding skills in machining. A lathe is a powerful and precise machine tool used to shape materials like metal or wood by rotating a workpiece against a stationary cutting tool. Whether you're creating a custom part or repairing something mechanical, learning how to operate a lathe opens the door to countless creative and practical possibilities.

In this guide, we’ll break down everything you need to know as a beginner, from safety tips to setting up your lathe and performing basic and advanced operations. This isn’t just theory; it’s a real-world introduction to getting hands-on with your lathe confidently.

Start With Safety

Before touching the power switch, your first priority must be safety. Lathes operate at high speeds and use sharp tools. Follow these essential safety tips:

Always wear eye protection like goggles or a face shield

Use hearing protection if your lathe is noisy

Remove or secure loose clothing, jewelry, and long hair

Know the location of the emergency stop button

Never leave the lathe running unattended

Essential Tools and Setup

A successful lathe operation starts with the right tools and setup. Make sure you have the following:

Cutting Tools:

Wood lathes: gouges, parting tools, skew chisels

Metal lathes: carbide-tipped or high-speed steel tools

Measuring Instruments:

Calipers (digital or dial)

Micrometers

Dial indicators

Safety Equipment:

Safety glasses or face shields

Earplugs or earmuffs

Close-fitting clothing and proper footwear

Tool Holders and Inserts: Secure cutting tools for stability and precision

Workholding Devices:

Chucks (three-jaw or four-jaw)

Faceplates

Centers (live and dead)

Getting the Lathe Ready

Proper setup makes your work more accurate and safer. Here’s how to prepare:

Level your lathe using a precision level

Fasten the lathe securely to a stable surface

Clean and lubricate all moving parts

Mount and align the cutting tool properly

Position the workpiece accurately in the chuck or on centers

Perform a test run and listen for unusual noise or vibration

Understanding Basic Operations

Let’s break down the first steps of real machining:

Mounting the Workpiece:

Use a chuck for symmetrical workpieces

Use a faceplate for irregular shapes

Use centers for long or thin workpieces

Selecting the Right Cutting Tool:

Choose based on the material (HSS for versatility, Carbide for durability)

Ensure the tool geometry matches the operation (turning, facing, threading)

Set correct speed and feed rate for optimal results

Lathe Cutting Process:

Set the lathe speed according to material and tool

Move the tool into the workpiece slowly and evenly

Use the compound rest to control the depth of cut

Monitor cutting for heat, noise, or tool wear

Moving Into Advanced Work

Once you’ve mastered the basics, try more advanced operations:

Taper Turning:

Use tailstock offset for light tapers

Use a taper attachment for precision and longer tapers

Threading:

Select a threading tool that matches your thread type

Engage the lead screw for synchronized tool movement

Cut threads in multiple shallow passes for control and accuracy

Drilling with a Lathe:

Mount a drill bit in the tailstock

Feed into the rotating workpiece slowly

Use coolant if drilling deep holes to prevent overheating

Final Thoughts

Operating a lathe blends craftsmanship and mechanical precision. Start with careful preparation, follow safety guidelines, and grow your skills one project at a time. Whether you're shaping wood or metal, success comes from patience, practice, and attention to detail.

For more guides, tools, and expert advice, visit Lathe Operation

Frequently Asked Questions

What safety equipment should I wear when operating a lathe? Wear safety goggles or a face shield, hearing protection, and avoid loose clothing or jewelry. Use gloves only during setup, not while operating the lathe.

Can I use a wood lathe for metal projects? No. Wood lathes lack the torque, rigidity, and tooling needed for metal. Using them for metal is unsafe and can damage the lathe.

How do I choose the right cutting tool? Base your choice on the material you're working with. Use HSS for most applications and carbide for harder materials or high-speed work.

How do I determine lathe speed settings? Use lathe speed charts based on your material type and diameter. Most lathe manuals provide guidelines for speed and feed rates.

Is threading suitable for beginners? Yes, with practice. Start with practice stock, use the correct thread pitch settings, and take light passes to avoid tool breakage.

#metalworking#tooltalk#woodworking#latheprojects#machinistlife#lathetools#woodturning#craftwithlathe#precisionmachining#workshopgear

0 notes

Text

Laser welding tube machine If interested please contact now 【Email】[email protected] 【Whatsapp】+86 13315702602 【Web】www.steelmama.com www.tilemakingmachinery.com

#LaserWelding#Welding#Metalworking#Engineering#Manufacturing#FactoryLife#MachineShop#IndustrialTech#LaserTubeWelding#TubeMachine#PipeWelding#PrecisionMachining#SteelFabrication#LaserCutting#Automation#OddlySatisfying#SatisfyingMachines#FactoryPOV#TechTok#LearnOnTikTok

0 notes

Text

Engineered to be Stable. Designed to Perform. Dynemech Anti-Vibration Technology

In each industrial installation, Precision and Reliability begin from the ground level. At Dynemech Anti-Vibration Technology, we appreciate that even the most sophisticated machinery can't deliver at its optimum without a solid foundation. That's why we provide an extensive line of Anti Vibration Technology to remove vibrations, enhance machine performance, and prolong equipment life.

Our product range is designed for actual usage. Be it with CNC machines, Compressors, Injection moulding machines, textile machines, printing presses, or heavy press units, Dynemech Anti-Vibration Technology has the ideal Vibration Isolation Solution for you.

Our products range from:

Wedge Mounts for precise machine levelling and shock damping

Spring Isolators for dynamic equipment

Air Springs for sensitive devices

Shock Mounts for heavy impact absorption

Rubber Pads and Bushings for shock absorption

Precision tool Anti Vibration Platforms

And much more.

All the products are Engineered to deliver superior Vibration Isolation Performance with simplicity in installation and servicing. The designs ensure even load distribution, reduce Vibration, and help maintain machinery alignment for years. Your machines work better, are less repair-prone, and consistently deliver quality output this way.

Our products are not just useful; they're investment-worthy for your operational success. All Dynemech Anti-Vibration Technology products are crafted and manufactured with high-quality materials and go through high-level quality check procedures to make them long-lasting, efficient, and safe. We take pride in being TUV SUD ISO 9001 certified and make in India partner, reflecting our emphasis on quality and innovation.

At Dynemech Anti-Vibration Technology, we’re not just about products. We’re a technology partner focused on solving real challenges on the factory floor. Since our founding, we’ve worked closely with industries across India and the globe to provide custom Vibration Control Solutions backed by expert support.

Our vision is straightforward: To offer a solid foundation to each machine, in each industry. We're confident that if machines are solid, productivity follows, and businesses prosper.

Feel the Dynemech Anti-Vibration Technology difference—where engineering and reliability come together, and your machines receive the stability they need.

To learn more about our products: https://www.Vibrationmountsindia.com/products/

#Dynemech, #AntiVibration, #MachineStability, #Dynemech, #VibrationControl, #IndustrialSolutions, #MadeInIndia, #EngineeringInnovation, #PrecisionMachining, #VibrationIsolators, #MachineMounts, #SpringIsolators, #RubberPads, #VibrationReduction, #HeavyMachinerySupport, #StableMachines, #FactorySolutions, #IndustrialMounts, #TUVCertified, #ManufacturingSupport, #CNCStability

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#Dynemech#AntiVibration#MachineStability#VibrationControl#IndustrialSolutions#MadeInIndia#EngineeringInnovation#PrecisionMachining#VibrationIsolators#MachineMounts#SpringIsolators#RubberPads#VibrationReduction#HeavyMachinerySupport#StableMachines#FactorySolutions#IndustrialMounts#TUVCertified#ManufacturingSupport#CNCStability

0 notes

Text

🔩 Threading in Process | Performance in Every Piece 📍 Ananka Fasteners Pvt. Ltd. In focus: Double-ended studs (Size: 1/2" x 61mm) 📏 Material Grade: B8 Class 2 🛠️ Ready for Roll Threading — a process that enhances strength, accuracy, and surface finish. This is not just a stud — it’s a symbol of our precision-engineered excellence. At Ananka Fasteners, we combine advanced manufacturing with global quality benchmarks. ✅ ISO Certified | Progressing towards Aerospace and API Certifications 🌐 We're not just in India anymore — now proudly operating in the USA and UK. (Details on our profile.) 🎯 Headquartered in India. https://anankafasteners.com/contact-us/

💼 Industries We Serve: * Marine * Oil & Gas * Offshore * Chemical Processing * Subsea * Nuclear * Medical Devices 🔧 Our Capabilities: * Design & Prototyping * Rapid Manufacturing * Custom Coating & Plating 🔩 Our Product Range Includes: * High-performance fasteners * Custom fastener solutions * Precision-engineered components * Specialty alloy products * Corrosion-resistant and non-standard parts * Metric and Imperial sizes We engineer with intent. We manufacture with excellence.

#AnankaFasteners#StudBolts#ThreadRolling#B8Class2#PrecisionMachining hashtag#ISOcertified hashtag#AerospaceFasteners hashtag#OilAndGas hashtag#RollThreading hashtag#CustomFasteners hashtag#ManufacturingIndia hashtag#USA hashtag#UK hashtag#GlobalEngineering#MetricImperial#EngineeringExcellence

1 note

·

View note

Text

Shop Premium Metric Stainless Steel Rods Online – Alexandria Precision

Looking for high-quality metric stainless steel rods for your business or industrial application? At Alexandria Precision, we provide top-grade stainless and alloy rods in precise metric dimensions—engineered to meet the demands of today’s manufacturing, machining, and engineering industries across the USA.

Whether you're sourcing components for a custom build or restocking your fabrication shop, our precision ground metric rods offer durability, accuracy, and consistency—every time.

Why Choose Stainless Steel Metric Rods?

Stainless steel metric rods are widely used in industries like aerospace, medical, automotive, and manufacturing due to their excellent corrosion resistance, mechanical strength, and dimensional stability. Compared to imperial rods, metric rods offer better alignment with international engineering standards, especially for global manufacturing or export-focused operations.

Our Range of Metric Rods at Alexandria Precision

At Alexandria Precision, we specialize in precision-ground stainless steel rods manufactured with strict tolerance control and polished finishes. We offer:

Metric stainless steel rods in sizes from 1mm to 50mm diameter

Available grades include 303, 304, 316, and 416 stainless steel

Custom cut lengths and bulk orders available

Tight diameter tolerances up to ±0.001mm

Fast turnaround and U.S.-based fulfillment

Our rods are ideal for use in:

CNC machining and turning

Custom shafts, pins, and axles

Fixture building and jigs

Instrumentation components

Alloy Steel and Specialty Metric Rods Also Available

Need more than just stainless? We also offer alloy steel metric rods for projects that demand even higher strength or heat resistance. From 416-H precision-ground rods to hardened steel options, you can count on consistent material properties and surface finishes designed for critical applications.

Benefits of Buying Metric Rods from Alexandria Precision

When you shop with us, you’re not just buying raw material—you’re partnering with a team that understands what matters in industrial supply:

✅ Tight Tolerances: Perfect for high-precision applications ✅ Wide Inventory: Large selection of diameters and grades ✅ Fast U.S. Shipping: Reduce downtime with local fulfillment ✅ Customization: Cut-to-length options and bulk pricing ✅ Expert Support: Decades of experience in precision metals

We supply the highest quality metric stainless steel rods that professionals trust for mission-critical applications.

Choosing the Right Rod for Your Application

Not sure which grade or size is right for your needs? Here’s a quick overview:GradePropertiesBest For303Easy to machine, non-magneticGeneral machining304High corrosion resistanceFood processing, marine use316Marine-grade, chloride resistantChemical, medical416Hardenable, great machinabilityGears, fasteners, shafts

For more detailed guidance, we recommend referencing this Thomasnet guide on stainless steel rods, which breaks down the strengths of each alloy.

About Alexandria Precision

With years of experience in precision metal products, Alexandria Precision is committed to delivering engineered rod solutions that exceed industry standards. Our focus on quality, service, and consistency has made us a trusted supplier for thousands of industrial buyers nationwide.

FAQs About Metric Stainless Steel Rods

What are metric stainless steel rods used for?

Metric stainless rods are used in machining, prototyping, fixture design, and various industrial and engineering applications due to their corrosion resistance and dimensional accuracy.

How are metric rods different from imperial rods?

Metric rods are measured in millimeters and offer better compatibility with international specs. Imperial rods are in inches and more common in U.S.-specific applications.

Which stainless steel grade should I choose?

It depends on your needs. 303 is easy to machine, 304 is great for general corrosion resistance, and 316 is ideal for marine or chemical environments.

Can I order rods in custom lengths?

Yes! Alexandria Precision offers cut-to-length services for bulk and custom orders.

Do you offer fast shipping in the U.S.?

Absolutely. Most orders ship within 1–2 business days from our U.S. facility.

Quick Summary

Alexandria Precision offers a wide range of premium metric stainless steel rods with precision-ground finishes, fast shipping, and custom sizing. Ideal for engineers, machinists, and industrial buyers looking for reliable quality and accurate dimensions.

#MetricRods#StainlessSteelRods#SteelSuppliersUSA#MetalFabrication#PrecisionMachining#IndustrialSupplies#AlloySteel#CustomMetalParts#AlexandriaPrecision#USAManufacturing#EngineeringSolutions#CNCMachining#MachineShopLife#IndustrialBuyers#MaterialEngineering

0 notes

Video

youtube

🎥 Welcome to our channel! If you’re tired of complicated setups and imprecise results in wheel hub machining, we’ve got you covered. In this video, discover how advanced tool tip detection technology makes your lathe operations more economical, precise, and effortless. Let’s revolutionize your workflow!

Part 1: Why Tool Tip Detection is a Game-Changer

🛠️ Why is tool tip detection essential? Without accurate tool tip detection, you could face: Poor machining quality. Increased material waste.

Higher operational costs due to errors and rework. With cutting-edge detection systems, you’ll achieve:

✅ Consistent precision,

✅ Cost savings,

✅ And faster production cycles!

Part 2: Features of Advanced Tool Tip Detection

✨ What makes this technology a must-have? Economical: Reduces waste and downtime. Cuts costs without sacrificing quality. Precise: Aligns tool tips with sub-millimeter accuracy. Guarantees flawless wheel hub finishes. Effortless Operation: User-friendly interface for all skill levels. Automated calibration saves time and effort. Versatile: Compatible with various lathe machines, including CNC and manual setups.

🔧 Whether it’s for professional manufacturing or small-scale workshops, this tool tip detection system is your key to better results.

Part 3: Step-by-Step Instruction for Tool Tip Detection

📝 How to use the tool tip detection system: Install the Sensor: Attach the detection sensor to your wheel hub lathe. Calibrate the System: Activate the detection feature through the lathe’s interface. The system will automatically align the cutting tool with the workpiece. Verify Alignment: Review the detection results displayed on the screen. Adjust manually if needed. Start Machining: Confidently begin machining, knowing your tool tip is perfectly aligned. This process ensures precision, saves time, and improves efficiency.

Part 4: Real-Life Results: A Workshop Transformation

📊 Case Study: A mid-sized automotive workshop adopted this tool tip detection system and: Reduced machining time by 30%. Lowered material waste by 20%, saving thousands annually. Improved machining precision even for complex wheel hub designs.

Part 5: Conclusion and Call to Action

🚀 Ready to elevate your machining operations? With advanced tool tip detection for wheel hub lathes, you’ll enjoy: Lower costs, Better precision, And effortless operation.

👉 Don’t forget to subscribe for more machining tips and tech updates!

👉 Click the link in the description to learn more about this tool tip detection system and how to get started.

🔗 Learn more here: [Your Website Link or Product Page] #PrecisionMachining #WheelHubLathe #ToolTipDetection #CNCInnovation #MetalProcessing

2 notes

·

View notes

Text

Swiss Type Screw Machines – Precision Machining by ANJALI T PRECISION

Swiss Type Screw Machines by ANJALI T PRECISION – Engineered for complex geometries, tight tolerances, and flawless finishes. Our multi-axis technology delivers high-volume, high-accuracy results where every micron counts. Trust the experts in precision machining.

📞Call On: +91 77579 70589

✉️ Email Id: [email protected]

🌐 Book An Appointment: www.anjalitprecision.com

#SwissTypeScrewMachine#AnjaliTPrecision#PrecisionMachining#HighAccuracy#TightTolerances#CNCMachining#MultiAxisMachining#ComplexGeometries#MicronLevelPrecision#ManufacturingExcellence#EngineeringSolutions#HighVolumeProduction#MachineryExperts#AdvancedManufacturing

0 notes

Text

Top CNC Manufacturing Company for Precision Machining – CCI CNC.

Looking for a reliable CNC manufacturing company that delivers unmatched precision and quality? Discover CCI CNC, a leader in custom CNC machining services based in the USA. With decades of experience, state-of-the-art equipment, and a commitment to excellence, CCI CNC provides tailored solutions for industries including aerospace, medical, automotive, and defense.

From prototyping to high-volume production, our skilled team ensures tight tolerances and superior finishes using advanced CNC milling, turning, and multi-axis machining. We specialize in both metal and plastic components, offering fast turnaround times without compromising on quality.

At CCI CNC, we prioritize customer satisfaction through transparent communication, engineering support, and strict quality control. Whether you need complex parts or simple precision components, we have the expertise and technology to bring your project to life. Visit: www.cci-cnc.com

1 note

·

View note