#Profinet Cables

Explore tagged Tumblr posts

Text

Ethernet cable vs network cable - what are the differences?

When setting up a network, whether it's for your home or office, one of the key components you'll need is cables to connect your devices. Two common types of cables used in networking are Ethernet cables and network cables. While these terms are often used interchangeably, there are differences between them. Here, we will explore the distinctions between Ethernet cables and network cables, and provide insights into choosing the best option for your networking needs.

1. Ethernet Cables:

Ethernet cables are a specific type of network cable that is commonly used to connect devices within a local area network (LAN). These cables typically have an RJ45 connector at each end, which is designed to plug into Ethernet ports on computers, routers, switches, and other network devices. Ethernet cables are used to transmit data using the Ethernet protocol, which defines standards for communication and data transfer within a network.

2. Network Cables:

Network cables, on the other hand, refer to a broader category of cables used for networking purposes. While Ethernet cables are a type of network cable, not all network cables are Ethernet cables. Network cables encompass a variety of cable types and standards, including Ethernet, coaxial, and fiber optic cables. These cables may be used for different networking technologies and applications, such as connecting devices to the internet, linking network switches, or connecting devices to a server.

3. Differences Between Ethernet Cables and Network Cables:

The main differences between Ethernet cables and network cables lie in their specific applications and standards:

- Ethernet cables adhere to the Ethernet standard, which specifies protocols and hardware requirements for Ethernet networking. These cables are typically used for local area networks (LANs) and follow standards such as Cat5e, Cat6, and Cat6a for data transmission.

- Network cables encompass a broader range of cable types and standards, including Ethernet, coaxial, and fiber optic cables. While Ethernet cables are a subset of network cables, other types of network cables may be used for different networking technologies and applications.

4. Choosing the Best Option:

When selecting cables for your networking setup, consider the following factors:

- Speed and Bandwidth: Ethernet cables support different speeds and bandwidths, with newer standards offering higher performance. Choose a cable that meets your network's speed requirements, such as Cat6 or Cat6a for gigabit or 10-gigabit Ethernet.

- Distance: Consider the distance between network devices when choosing cables, as different cable types have limitations on maximum transmission distances.

- Application: Determine the specific application and requirements of your network, such as data transfer speed, reliability, and environmental factors, to select the most appropriate cable type.

- Compatibility: Ensure that the cables you choose are compatible with your network devices, including computers, routers, switches, and other equipment.

Ethernet cables and network cables are essential components of networking infrastructure, enabling data transmission and connectivity within local and wide area networks. While Ethernet cables are a specific type of network cable used for Ethernet networking, network cables encompass a broader range of cable types and standards. Understanding the differences between Ethernet cables and network cables can help you make informed decisions when setting up your network and choosing the best cables for your needs. Whether you're buying Ethernet cables online or selecting network cables for your networking project, consider factors such as speed, distance, application, and compatibility to ensure optimal performance and reliability in your network setup.

#Etherline Cat 6A#Ethernet Cable Accessories#Ethernet Cable Cat#Ethernet Cable Connector#Ethernet Cable Price#Ethernet Cable Wire#Ethernet Cables#Ethernet Cat 7#Ethernet LAN Cable#Ethernet Power Cable#Profinet Cables#Profinet Cat 5#Profinet Wire#Rj45 Ethernet Cable#Cable LAN Cat 6#LAN Cat 5E#LAN Cat 6A#Industrial Ethernet Cable#Rj45 Cable

0 notes

Text

A Human-Machine Interface: What Is It and How Does It Operate?

Human-Machine Interfaces from best Weidmuller power supplies create a usable interface that helps a person establish a communication system with a device. We can explain this more straightforwardly by saying it is simply an input/output device. The information is input here. The person operating the machine inputs it into the machine. The machine outputs the commands based on the data fed into it. On the other hand, the machine may also input the information from its sensors or hardware, which is then outputted on the HMI for the machine operator to decipher and ultimately make out.

Next, combined with programmable logic controllers or PLC, machine sensors record and put forward the information as inputted and received. HMIs are often utilised in industrial settings because of the particular input/output relationship they carry with them. In this sector, an HMI is very frequently used to decipher, see, and control the following information:

Production Time

Production Trends

Visual Data

Temperature Control

Human-Machine Interface and Its Benefits

Human Machine Interfaces, or HMI, from us as one of the best cable assemblies in India, has become part and parcel of machine designs in the industrial sector primarily because of the number of benefits it offers its users. First, the increased visibility of these interfaces makes data centralisation easy to read and ensures that vital notifications or production changes are never missed. This interface's enhanced efficiency results in accurate, real-time data generation that is particularly useful in such a high-paced environment. Here are some other benefits of Human Machine Interface and they are:

Reduction in Cost

Improved Usability

Improved Management of Time

Areas of Application of HMI

We find the maximum utilisation of Human Machine Interface from Hengstler counters supplies in the industrial settings as this sector needs to communicate with and control the machines accurately. This sector requires this kind of control so that industrial processing can be maintained at the optimal level, proper control over the final finished product can be maintained, and the overall safety of the process can be taken care of. To be specific, the industries that use HMIs include:

Manufacturing

Recycling and Waste Management

Oil and Gas

Energy and Power

Food and Beverage

We Give a New Meaning to the Word “Efficiency”

We, SR Indus Electro System, one of the best Weidmuller Distributors in India, are the single source provider equipped with the latest Human-machine Interface technology. It is capable of meeting complex processes of machines and systems. Weidmuller HMI provides efficient integration to your automation systems. They are optimised to meet specific human-machine interfaces. Through our UV66-BAS-4-RES-W easy multi-touch panels, it becomes easier to monitor and control the machines and systems. Moreover, the u-view multi-touch panels from Weidmuller offer perfect image quality and are fit for use in the industrial environment devoid of any restrictions. Additionally, we provide profinet encoders.

Our HMI is very efficient performance-wise, as its image quality is unparalleled. Besides the image quality, its powerful processors make working with u-view multi-touch panels smooth and enjoyable. The compatibility rate of u-view multi-touch panels allows them to be used in various applications. This becomes possible because we use world-class web technology based on HTML5. Hengstler encoders presents robust motor feedback encoders tailored for demanding applications, compatible with both brushless servo and stepper motors. Leveraging Acuro drive technology, dynamic servo drives transition into a fully digital realm for the first time. Even under harsh operating conditions, such as those encountered within motor housings, reliability remains uncompromised. Proudly brought to you by Sr Indus Electro Systems.

#hengstler encoders#weidmuller power supplies#cable assemblies#harting han connectors#electronic components supplier#profinet encoders

0 notes

Text

Fluke Distributor in Bangalore

The Fluke Networks Industrial Ethernet DSX CableAnalyzer™ Kit (Model: DSX2-5-IE-K1) is a comprehensive copper cable certifier designed for industrial Ethernet networks. It ensures compliance with TIA and ISO standards, supports various industrial protocols, and offers advanced troubleshooting capabilities.

🔧 Key Features

Comprehensive Certification: Validates twisted-pair copper cabling from Category 5 through 6A, ensuring adherence to TIA Level IIIe accuracy.

Rapid Testing: Provides Pass/Fail results within 10 seconds, accompanied by detailed measurement information.

Industrial Protocol Support: Compatible with cables running EtherNet/IP™, PROFINET™, Modbus TCP™, EtherCAT, and other industrial protocols.

Connector Compatibility: Supports RJ45, M12D, and M12X connectors, facilitating versatile testing options.Main Website

Advanced Troubleshooting: Identifies and locates cable issues swiftly, reducing downtime and preventing unnecessary bypass installations.

Touchscreen Interface: Features a user-friendly touchscreen with integrated project management tools for efficient operations.

Extended Battery Life: Offers up to 8 hours of continuous use on a single charge, ensuring reliability during extended testing sessions.

Comprehensive Documentation: Utilizes LinkWare™ software to document test results, supporting compliance with TIA 1005-A and ISO 11801:3 standards.

https://sapphire-tech.com/product/fluke-networks-industrial-ethernet-dsx-cableanalyzer-copper-cable-certifier-kit/

0 notes

Link

0 notes

Text

https://www.verifiedmarketreports.com/pt/product/profinet-cables-market/

0 notes

Text

Why ET 200SP CPU is the Ideal Choice for Distributed Automation Systems

The ET 200SP CPU is designed as a powerful yet compact controller from Siemens that meets the latest demands of a growing number of distributed automation systems. The features of the CPU, coupled with its capabilities for easy integration, are liberating the industries in the approach to automation.

Key Features of ET 200SP CPU

Compact Design: This ET 200SP CPU has been designed compactly to fit inside very close control cabinets and still outperform others by strong performance.

Scalability and Flexibility: Thanks to its modular structure, the ET 200SP CPU can be easily expanded so that users may adapt the whole system to their own industrial needs.

High Processing Power: It has necessarily a very fast CPU which does a performance very fast and fairly accurate efficiency even for the most complex operations.

Integrated Profinet Connectivity: The integrated PROFINET interface makes it an easy and simple way to connect devices and reduce cabling in automated environments.

Energy Efficiency: Siemens ET 200SP CPU does energy-efficient operations which realize the use of sustainability goals without compromising performance.

Applications of ET 200SP CPU

Manufacturing Automation: Reduces the effort and increases efficiency through the assembly line.

Process Industries: Administration of complicated processes in industries such as food production, pharmaceutical products, and chemicals.

Building Automation: Improve HVAC systems, lighting controls, and energy management.

Transportation Systems: Incorporate intelligent control at railways, airports, and hubs for logistics.

Why Choose ET 200SP CPU for Your Business?

Easy Integration: With the ability to play in the whole Siemens automation ecosystem, the ET 200SP CPU means a seamless transfer to advanced systems.

Future-Ready: Its versatility and capability in modern communication protocols render it perfect for Industry 4.0 frameworks.

Reliability: The quality standards of Siemens ensure that products last long and work in a consistent manner, even in the most challenging situations.

Conclusion

ET 200SP CPU does not work just as a controller but also acts as a gateway to build better automation systems by Naksh Technology Solutions LLP. The CPU assures reliability, flexibility, and performance at a pace demanded by the industries, whether for upgrading existing setups or beginning new projects.

0 notes

Text

6XV1840-2AH10 CÁP PROFINET Siemens

6XV1840-2AH10 CÁP PROFINET Siemens Mã sản phẩm:

6XV1840-2AH10 Thông số kỹ thuật:

Industrial Ethernet FC TP Standard cable, GP 2×2 (PROFINET Type A), TP installation cable for connection to IE FC RJ45 2×2, for universal use, 4-core, shielded CAT 5E, sold by the meter, delivery unit max.

4000 m minimum order quantity 20 m.

Tình trạng:

Hàng có sẵn, mới 100% Chứng từ COCQ, tờ khai hải quan, có xuất hóa đơn VAT Hãng sản xuất:

Siemens Giảm thêm 5% khi mua sản phẩm cùng danh mục có giá cao hơn 👉 Xem thêm:

0 notes

Text

6XV1840-2AH10 CÁP PROFINET Siemens

6XV1840-2AH10 CÁP PROFINET Siemens Mã sản phẩm:

6XV1840-2AH10 Thông số kỹ thuật:

Industrial Ethernet FC TP Standard cable, GP 2×2 (PROFINET Type A), TP installation cable for connection to IE FC RJ45 2×2, for universal use, 4-core, shielded CAT 5E, sold by the meter, delivery unit max.

4000 m minimum order quantity 20 m.

Tình trạng:

Hàng có sẵn, mới 100% Chứng từ COCQ, tờ khai hải quan, có xuất hóa đơn VAT Hãng sản xuất:

Siemens Giảm thêm 5% khi mua sản phẩm cùng danh mục có giá cao hơn 👉 Xem thêm:

0 notes

Text

Future Trends: The Advancement of Encoders in Industrial Automation

Industrial automation has come a long way since its commencement, with technology playing a critical role in enhancing efficiency, productivity, and precision in manufacturing and other industrial processes. One key component dynamic these improvements is the encoder. Encoders, which convert motion into an electrical signal that can be read by a control device, are fundamental in ensuring precise movement and positioning of machinery. As we look to the future, the advancement of encoders in industrial automation is set to bring about significant changes and improvements. This blog explores the future trends in encoder technology and their impact on industrial automation.

What Are Encoders?

Before diving into future trends, it’s essential to understand what encoders are and how they function. Encoders are sensors that provide feedback on position, speed, and direction of a rotating shaft or linear movement. They are crucial in applications where precise control of motion is required. There are two main types of encoders:

Rotary Encoders: These encoders measure the rotational position and speed of a shaft. They can be either incremental or absolute.

Linear Encoders: These measure the linear position and speed of an object, providing feedback for precise control in linear motion applications.

Future Trends in Encoder Technology

As technology continues to progress, several trends are influential the future of encoders in industrial automation. These trends promise to enhance the capabilities of encoders, making them more accurate, reliable, and versatile.

1. Higher Resolution and Accuracy

One of the most significant trends is the push for higher resolution and accuracy in encoders. As industries demand greater precision, manufacturers are developing encoders with finer resolution capabilities. Higher resolution encoders provide more detailed feedback, allowing for better control and accuracy in applications such as semiconductor manufacturing and precision machining.

2. Integration of Advanced Communication Protocols

Modern industrial automation systems rely heavily on communication networks to exchange data between various components. The integration of advanced communication protocols such as Ethernet/IP, PROFINET, and EtherCAT into encoders is becoming increasingly common. These protocols enable faster and more reliable data transmission, improving the overall efficiency and performance of automation systems.

3. Miniaturization and Compact Designs

With the trend towards smaller and more compact machinery, there is a growing demand for miniaturized encoders. Advances in micro-electromechanical systems (MEMS) technology have made it possible to develop compact encoders without compromising performance. These smaller encoders are ideal for applications with limited space, such as medical devices and compact robotic systems.

4. Enhanced Durability and Environmental Resistance

Industrial environments can be harsh, with factors such as dust, moisture, and extreme temperatures posing challenges to encoder performance. Future encoders are being designed with enhanced durability and environmental resistance. Encoders with IP67 or higher ratings, for example, can withstand exposure to water and dust, ensuring reliable performance in demanding conditions.

5. Development of Wireless Encoders

Wireless technology is making its way into industrial automation, and encoders are no exception. Wireless encoders eliminate the need for cables, reducing installation complexity and maintenance requirements. They are particularly useful in applications where wired connections are impractical or hazardous. Advances in wireless communication protocols are ensuring that wireless encoders provide reliable and secure data transmission.

6. Increased Customization and Flexibility

Industries are increasingly seeking customized solutions to meet specific application requirements. Encoder manufacturers are responding by offering more customizable and flexible products. This trend includes the ability to configure encoders with different output signals, mounting options, and communication interfaces. Customizable encoders allow for tailored solutions that optimize performance in specific applications.

7. Integration with Advanced Sensors

Encoders are being integrated with other advanced sensors to provide more comprehensive feedback and control. For example, combining encoders with gyroscopes and accelerometers can enhance the precision and stability of motion control systems. This integration is particularly valuable in applications such as autonomous vehicles and advanced robotics.

8. Energy Efficiency and Power Management

As industries strive to reduce their carbon footprint and energy consumption, the energy efficiency of automation components is becoming increasingly important. Future encoders are being designed with energy-efficient components and power management features. Low-power encoders are particularly beneficial in battery-powered applications, such as portable devices and remote monitoring systems.

9. Enhanced Safety Features

Safety is a top priority in industrial automation, and encoders are playing a crucial role in enhancing safety measures. Encoders with built-in safety features, such as redundant sensing elements and self-diagnostics, provide additional layers of protection. These safety features help prevent accidents and ensure the reliable operation of machinery in critical applications.

Impact of Future Encoder Trends on Industrial Automation

The advancements in encoder technology are set to have a profound impact on industrial automation. Here are some key ways these trends will shape the future of industrial processes:

Improved Precision and Quality

Higher resolution and accuracy in encoders will lead to improved precision and quality in manufacturing processes. This is particularly important in industries such as aerospace, automotive, and electronics, where even minor deviations can have significant consequences. Enhanced precision will result in higher-quality products and reduced waste.

Increased Efficiency and Productivity

The integration of advanced communication protocols, IoT capabilities, and wireless technology will streamline data exchange and improve the efficiency of automation systems. Real-time data collection and analysis will enable predictive maintenance, reducing downtime and increasing productivity. Automation systems will be able to operate more smoothly and efficiently, leading to cost savings and higher output.

Greater Flexibility and Customization

The trend towards customization and flexibility in encoder design will allow industries to implement customized solutions that meet specific requirements. This flexibility will enable manufacturers to optimize their processes and achieve better performance. Customizable encoders will also make it easier to adapt to changing production needs and technological advancements.

Enhanced Safety and Reliability

The incorporation of advanced safety features and durable designs will enhance the reliability and safety of industrial automation systems. This is crucial in applications where safety is paramount, such as in the chemical, pharmaceutical, and food industries. Reliable encoders with robust safety features will help prevent accidents and ensure consistent performance.

Adoption of Smart Manufacturing Practices

The integration of IoT and Industry 4.0 capabilities into encoders will drive the adoption of smart manufacturing practices. Smart factories, equipped with connected and intelligent components, will be able to optimize operations, reduce energy consumption, and improve overall efficiency. The data generated by smart encoders will provide valuable insights for continuous improvement and innovation.

Expansion of Automation into New Areas

Advancements in encoder technology will enable the expansion of automation into new areas and applications. For example, miniaturized and wireless encoders will make it possible to automate processes in confined spaces and remote locations. This expansion will open up new opportunities for automation in industries such as agriculture, healthcare, and logistics.

Conclusion

The future of encoders in industrial automation is bright, with numerous advancements set to enhance their capabilities and impact. Higher resolution, advanced communication protocols, miniaturization, durability, IoT integration, wireless technology, customization, advanced sensors, energy efficiency, and enhanced safety features are some of the key trends shaping the future of encoder technology. These advancements will lead to improved precision, efficiency, flexibility, safety, and the adoption of smart manufacturing practices.

#industrial automation#auto2mation#industrial equipment#industrial spare parts#industrial and marine automation equipment#industrial and marine automation#industrial automation equipment#automation#industrial encoder

0 notes

Text

Siemens 6GK5991-2VA00-8AA2 SCALANCE X accessory

Siemens 6GK5991-2VA00-8AA2 BA 2xRJ45VD HA, bus adapter VVD (Variable Distance), for Ethernet- communication via 2-, 4- or 8-wire-copper cables, 2xRJ45 sockets for industrial Ethernet and PROFINET, extended temperature range -40 ??C…+70 ??C, conformal coating, installation altitude up to 4000m, distances up to 2 wire up to 1000 m at 10 Mbit/s 2 wire up to 100 m at 100 Mbit/s 4 wire up to 300 m at…

View On WordPress

0 notes

Text

0 notes

Text

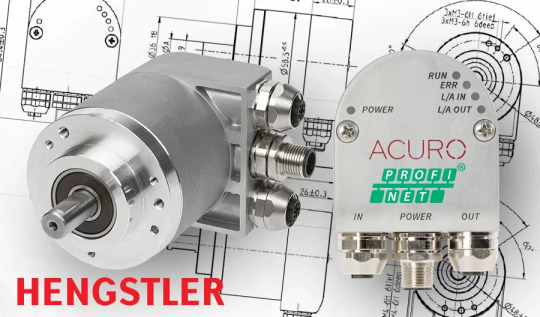

Choosing the Right Profinet Encoder: Characteristics and Best Practices

Profinet Encoder

Multitier encoders with fieldbus, outright encoders collection MEM-Bus, best quality hengstler profinet encoders profile Specifications V4.1 version 3.162 related to Profidrives, demands of the Application Courses 3 and 4, RT Actual Time and IRT Isochronous Real Time Transmission Mode, common telegrams 81, 82, 83, 84, the customer telegram 860, encoders actual time diagnostic function makes sure the gadget state consistent monitoring, MEM-Bus encoders, multitier version with 29-bit resolution, Different mechanical versions are offered. The electric link is provided by 3 M12 adapters, the stout aluminium instance guarantees a high defence level. The building technology allows for high acceleration and rate worth’s and gives the transducer a long life.

Profinet Encoder Characteristics:

Fieldbus user interface: Profinet

Encoder Account V4.1 Variation 3.162

Application courses 3–4

Transmission settings (RT and IRT)

Conventional telegrams 81, 82, 83, and 84

Customer telegram 860

Aluminium situation

Defence level: IP67; shaft side: IP65

Resolution: 29 little bit

PROFINET-ready outright encoders function separately and are non-reactive.

Network frameworks are commonly subject to regular modifications, e.g., in the case of new robotics with constant changes of tools or expansions during procedures. PROFINET-ready outright encoders, Design A58HE (blind hollow birthed) and Version A58SE (shaft), are developed for harsh factory and plant atmospheres.

Conveniently designed right into a wide array of applications, these encoders plug straight right into a connect with marginal requirements and work in different setups, consisting of bus, ring, and star setups that can proceed interaction in the event of a line break.

As absolute encoders, they keep absolute position information even after a power loss, assisting in quick system healing at start-up without the requirement for system re-homing. Prepared for Market 4.0 and the Industrial Internet of Things, data exchange between the Model A58HE, Setting A58SE, and other applications has no influence on the control loophole.

These encoders are non-reactive and can function independently from the PLC or master, moving information through network entrances to various other automation networks and sites, as well as the cloud for analysis.

Encoders with Profane Communications

Encoder Products Company showcased its brand-new Design A58HE and Version A58SE, which are multi-turn, Ethernet-ready outright encoders made for rough manufacturing facilities and plant environments. Along with Ether pet cat Deterministic Interaction, the versions A58HE and A58SE now supply PROFINET communication procedures as well.

These encoders are especially suited to applications where fieldbus connectivity is needed and the encoder has to maintain absolute placement information after power-off occasions. The Model A58HE is a 58 mm encoder in a blind hollow-birthed construction, and the Model A58SE is a 58 mm shaft encoder readily available with either a securing flange or synch flange, in both compact and sturdy arrangements. The portable version is the most compact Ether feline or PROFINET-capable encoder readily available.

“Both the A58HE and A58SE encoders are easily made into a wide variety of applications," claims Sarah Walter, electric designer and EPC Technical Applications Manager. "And with the new heavy-duty design and the new small model—which is one of the most compact devices available on the market—they are unbelievably flexible mechanically. What actually sets our encoders apart, however, is their high accuracy. These absolutes will provide you with accurate activity comments whenever.

Conclusion

Sr. Indus Electro Systems Pvt. Ltd.: The non-reactive and independent operation of these encoders, coupled with their capability to deal with network portals, facilitates efficient information exchange within the network and also extends to cloud-based evaluation. As shown by Encoder Products Company's A58HE and A58SE designs, these encoders satisfy the demands of different applications, offering portable and sturdy configurations to accommodate diverse mechanical demands.

On the whole, the Profinet Encoder series stands out for its adaptability, reliability, and high performance, making it a beneficial component in the developing landscape of industrial automation.

#profinet encoders#Profinet Encoders Distributors#cable assemblies#maxon distributors india#harting han connectors#hengstler encoders

0 notes

Text

How Siemens Siprotec 5 6MD86 Bay Controller Protection Relay Can Help Increase Your Grids Productivity

In the dynamic landscape of power distribution, ensuring the smooth and efficient operation of electrical grids is of utmost importance. To achieve this, grid operators are constantly seeking innovative solutions that can boost productivity while maintaining a high level of protection for critical assets. This article explores how the Siemens Siprotec 5 6MD86 Bay Controller Protection Relay can play a pivotal role in enhancing grid productivity. By seamlessly integrating advanced protection and control functionalities, this cutting-edge relay offers unparalleled reliability and performance, empowering grid operators to optimize their network's efficiency and ultimately contribute to a more sustainable and reliable power supply.

A Brief Overview Of Siemens Siprotec 5 6MD86 Bay Controller Protection Relay

The Siemens Siprotec 5 6MD86 Bay Controller is a protection relay device designed to provide comprehensive protection and control functionalities for electrical systems at various voltage levels, ranging from distribution to transmission. The Siemens Siprotec 6MD86 Bay Controller serves as a control and automation device with optional protection features, suitable for various voltage levels from distribution to transmission. As part of the SIPROTEC 5 family, it offers a wide range of protection functions from the SIPROTEC library, sharing identical parameters with protection devices. Its adaptable hardware design allows precise alignment with different process data requirements.

The 6MD86 Bay Controller is equipped with flexible hardware, allowing it to adapt precisely to different process data requirements, making it a versatile and effective solution for ensuring the stability and security of critical power systems. Its advanced automation capabilities enable seamless integration into control systems, enhancing the overall efficiency and reliability of electrical networks.

Functions of Siemens 6MD86 Bay Controller Protection Relay

Integrated bay controller with versatile protection function from medium to extra-high voltage

Control of switching devices

Synchrocheck, switchgear interlocking protection and switch related protection functions, such as circuit-breaker failure protection and automatic reclosing

Integrated electrical Ethernet RJ45 for DIGSI 5 and IEC 61850 (reporting and GOOSE)

Up to 4 pluggable communication modules usable for different and redundant protocols (IEC 61850, IEC 60870-5-103, IEC 60870-5-104, DNP3 serial and TCP, Modbus TCP, PROFINET IO)

Secure serial protection data communication, also over great distances and all available physical media (fibre-optic cable, 2-wire connections and Communication Networks)

Capturing operational measured variables and protection function measured values to evaluate the plant state, support commissioning, and analyze faults

Phasor Measurement Unit (PMU) synchrophasor measured values and IEEE C37.118 protocol integrated

Powerful fault recording (buffer for a max. record time of 80 s at 8 kHz or 320 s at 2 kHz)

Auxiliary functions for simple tests and commissioning

Flexibly adjustable I/O quantity structure within the scope of the SIPROTEC 5 modular system

How The Relay Works To Monitor And Protect Grid Assets

Siemens Siprotec 5 6MD86 Bay Controller Protection Relay is a sophisticated device designed to monitor and protect various assets within an electrical grid. Its primary function is to detect abnormal conditions or faults that may occur in the grid and take prompt actions to mitigate potential risks, ensuring the safety and stability of the entire power distribution system. Here's how the relay works to monitor and protect grid assets:

Fault Detection: The relay continuously monitors the grid for any abnormal conditions, such as overcurrent, undercurrent, overvoltage, Undervoltage, frequency deviations, etc. When it detects a fault or an irregularity beyond the predefined threshold, it triggers an alarm to notify operators of the issue.

Data Acquisition: The relay collects real-time data from various sensors and instruments installed throughout the grid. This data includes voltage levels, current flow, power factor, and other essential parameters. The relay processes this data to analyze the grid's operating condition.

Event Logging: The relay maintains a detailed log of events and disturbances that occur within the grid. This log provides valuable information for post-event analysis and helps engineers to understand the root cause of disruptions and take preventive measures.

Fast Tripping Mechanism: In the event of a fault, the relay's primary objective is to isolate the affected section of the grid quickly. It sends a tripping signal to the circuit breaker associated with the faulty segment, allowing it to open within milliseconds. This rapid tripping prevents the fault from spreading and causing cascading failures in the system.

Communication Capabilities: The Siprotec 5 6MD86 is equipped with communication interfaces that enable seamless integration into Supervisory Control and Data Acquisition (SCADA) systems and other grid management platforms. This allows for remote monitoring, control, and diagnostics, enhancing the overall grid management efficiency.

Real-time Condition Monitoring: The relay continuously monitors the health and performance of critical grid assets, such as transformers and circuit breakers. It provides real-time diagnostics and alerts operators of any abnormalities or degradation in equipment performance, enabling predictive maintenance and extending asset lifespan.

In summary, the Siemens Siprotec 5 6MD86 Bay Controller Protection Relay works as an intelligent guardian of the electrical grid, vigilantly monitoring its health, detecting faults, and responding rapidly to protect valuable assets. Its ability to identify and isolate faults swiftly, coupled with advanced communication and diagnostic features, helps power utilities maintain grid stability, enhance productivity, and ensure a reliable power supply to consumers.

Conclusion

In conclusion, the Siemens Siprotec 5 6MD86 Bay Controller Protection Relay stands as a game-changer for power utilities, playing a vital role in enhancing grid productivity and ensuring a reliable and secure power distribution system. By adopting these cutting-edge protection relay technologies, power utilities can pave the way for a smarter, more efficient, and sustainable energy future.

Discover the ultimate offer on the Siemens Siprotec 5 6MD86 Bay Controller Protection Relay from Reliserv Solution, your authorized Supplier and Channel Partner for SIEMENS Numerical Relays, Automation Products, Power Quality Meters & Instruments, MV Switchgear Spares, and PSS SINCAL Software. As the leading Siemens Siprotec 5 Relays supplier and exporter in Mumbai, Maharashtra, we pride ourselves on providing top-notch products and services to various industries and panel builders.

Feel free to get in touch with us at +917506112097 or email your requirements to [email protected]. At Reliserv Solution, we deal with a wide range of products, including the Siemens 6MD86 Bay Controller Protection Relay, ensuring that you have access to cutting-edge technology and reliable solutions. Don't miss out on this fantastic opportunity and contact us today for the best deals! Please click here.

#siemens#Siprotec5#protection#numerical#relays#electricalsafety#powerprotection#industrialautomation#panelbuilders#powerquality#electricalsolutions#energyefficiency#smartgrid#powerdistribution#electricalengineering

0 notes

Link

0 notes

Photo

(vía Comunicación Logo S7-1200 en proyecto TIA Portal y LOGO SoftV8)

Realizar una comunicación Logo S7-1200 mediante una conexión con cable ethernet en una red Profinet. Controlar entradas y salidas del Logo, programado todo en el S7-1200, simplemente utilizando el Logo como una ampliación de entradas y salidas, sin necesidad de realizar un programa en el Logo.

1 note

·

View note