#Smart Factory Automation

Explore tagged Tumblr posts

Text

Top 21 AI Trends in Manufacturing You Must Know in 2025

Understand the newest AI developments in manufacturing, such as Salesforce Einstein GPT integration and predictive maintenance solutions. Discover how Salesforce Manufacturing Cloud implementation services, AI-powered CRM consulting for manufacturers, and Agentforce for Manufacturing integration are transforming smart factory operations.

#AI in Manufacturing#Smart Factory Automation#Salesforce Manufacturing Cloud#Salesforce AI Integration#Agentforce for Manufacturing#Salesforce Einstein GPT#CRM for Manufacturers#PredictiveMaintenanceAI#Salesforce Service Cloud#Salesforce CRM Consulting#Getoncrm

0 notes

Text

5G-Powered Drones: Ericsson, Qualcomm And Dronus Collaboration In Developing Autonomous Drone Solutions

5G mmWave technology for industrial use. Ericsson, Qualcomm, and Dronus Collaboration in developing autonomous drone solutions. The world of industrial automation is on the cusp of a revolution, and at the forefront is a powerful combination, of 5G technology and autonomous drones. A recent collaboration between Ericsson, Qualcomm Technologies, Inc., and Dronus provides a glimpse into this exciting future.

#5G drones#Industrial automation#Indoor drone applications#Warehouse inventory management#mmWave 5G technology#Autonomous drones#Industry 4.0#5G smart factory#(PoC)#Qualcomm QRB5165 processor#Telit Cinterion#mmWave#Industrial M.2 data card#5G Modem-RF System#Native mmWave connectivity#High-performance 5G connection#Bandwidth-intensive industrial operations#drone

2 notes

·

View notes

Text

Smart Factories Need Smart Data: Leveraging Real-Time Analytics for Operational Excellence

Unlock the value of live data for faster decisions, smoother workflows, and a more responsive shop floor. Drowning in Data, Still Lacking Clarity? All of the machines, sensors, and control systems across your shop floor are generating data. That is not the problem. The actual problem? To take that constant, flowing stream and make it something your team can actually act upon—now. That’s…

#Factory Automation#Industrial IoT#Manufacturing Data#Operational Excellence#Secondary Keywords (Short-Tail): Smart Factory

0 notes

Text

How to Convince Workers to Embrace Factory Automation

Learn practical strategies to overcome resistance to automation on your factory floor. This presentation breaks down how to address worker concerns, build trust, and turn skepticism into support—without pushing fear or job loss narratives. Ideal for plant managers and CI leaders navigating the people side of digital transformation.

0 notes

Text

Explore how manufacturing, electronics, and robotics have transformed mankind—from early automata and industrial machinery in the 1950s to today's smart factories, AI-powered robots, and space exploration. Learn how innovations like CNC machines, pick-and-place electronics robots, surgical bots, and Mars rovers increased productivity, safety, and scientific discovery, playing a pivotal role in human progress and future advancements.

#Manufacturing programs#Manufacturing Electronics History#The role of robots in human evolution#Industrial automation impact#CNC and robotics evolution#pick-and-place electronics robots#Smart factories IoT#Surgical robots' benefits#Mars rover robotics#Electronics and human progress

0 notes

Text

Vidgastech is a leading innovator in Industrial Automation, delivering smart, scalable, and cutting-edge automation solutions to enhance manufacturing efficiency and precision. Our team of experts specializes in PLC programming, SCADA systems, IoT integration, robotics, and turnkey automation projects tailored to your industrial needs.

We help industries reduce downtime, boost productivity, and transition into Industry 4.0 with seamless automation technologies. With a strong commitment to quality, innovation, and customer satisfaction, Vidgastech is your trusted partner for transforming industrial operations.

Services:

PLC & SCADA Development

Industrial IoT (IIoT) Integration

Robotics & Machine Automation

Process Control & Monitoring Systems

Custom Industrial Software Development

Maintenance & Support Services

#Industry Automation#Industrial Automation Company#PLC SCADA Automation#Factory Automation#Smart Manufacturing#IIoT Solutions#Industrial Robotics#Vidgastech Automation#Industry 4.0 Solutions

0 notes

Text

CNC Machine Manufacturer in India

Looking for a reliable CNC machine manufacturer in India? Discover high-quality, precision-engineered CNC machines that power industries across automotive, aerospace, electronics, and more. Indian CNC machine manufacturers have quickly emerged as global leaders, offering advanced, affordable, and durable solutions for both small businesses and large-scale industries.

One of the standout names in the Indian CNC sector is Sahil Machines. Known for their innovation and commitment to quality, Sahil Machines provides a wide range of CNC solutions, including CNC turning centers, vertical machining centers (VMC), and custom-built systems. Their machines are designed for accuracy, speed, and longevity—making them ideal for high-demand applications.

With strong after-sales service, installation support, and training, Indian CNC machine manufacturers ensure that your production lines stay efficient and productive. Whether you're a startup or an established industry player, choosing a trusted Indian manufacturer helps reduce costs without compromising on performance.

Many manufacturers now also offer smart features like IoT integration, real-time monitoring, and automated production capabilities—ensuring you stay ahead in a competitive market.

Bookmark this page if you’re planning to invest in reliable CNC machinery made in India. Experience engineering excellence, world-class support, and unbeatable value with top CNC brands from India.

0 notes

Text

Industry 4.0: Powering the Next Industrial Revolution with Intelligence, Connectivity, and Automation

The world is undergoing a radical transformation. As we move deeper into the 21st century, the fusion of digital, physical, and biological systems is reshaping how we manufacture, operate, and innovate. This revolution has a name: Industry 4.0—the fourth industrial revolution. It represents a new era where smart technology, real-time data, automation, and interconnected networks converge to…

#5G Connectivity#Additive Manufacturing#advanced robotics#Artificial intelligence#Automation#Big Data Analytics#Blockchain#Cloud Computing#connected industry#Cyber-physical systems#data-driven operations#Digital Transformation#Digital twin#Edge computing#fourth industrial revolution#IIoT#Industrial Networking#Industry 4.0#intelligent systems#manufacturing innovation#next-gen industry#Predictive maintenance#Real-time analytics#Robotics#smart factory#Smart Grid#Smart logistics#Smart manufacturing#SolveForce#Supply Chain Visibility

0 notes

Video

youtube

Telescopic Sliding Gates | Automatic & Industrial Gate Systems by Secure...

#youtube#telescopic sliding gate#AutomaticGatesIndia#industrial sliding gates#SecureIndiaGates#AutomaticTelescopicGate#HeavyDutyGates#IndustrialGateAutomation#sliding gate system#automatic swing gate#SecurityGatesManufacturer#Automatic Gate Installation#Industrial Entrance Gates#Smart Gate Solutions#Automatic Gate for Factory#Motorized Gate Systems#Commercial Sliding Gate#Automatic Gate Supplier India#Gate Automation Ahmedabad#Entrance Control Solutions#Secure India Security Products#Automated Entry Gates#Perimeter Security Solutions

0 notes

Text

Smart Factory Market to Hit $30.1 Billion by 2029: The Future of Manufacturing is Here

The smart factory market is undergoing a rapid transformation, driven by a blend of advanced technologies, robust government support, and the rising demand for efficient, automated production processes. According to a recent report by MarketsandMarkets™, the smart factory market is expected to surge from $18.8 billion in 2024 to $30.1 billion by 2029, growing at an impressive CAGR of 9.8%.

This growth reflects a major shift in how industries operate, moving from traditional manufacturing to connected, intelligent, and automated ecosystems. The smart factory revolution is well underway, and industries are leading the charge.

What’s Fueling the Smart Factory Boom?

Several factors are contributing to this explosive market growth

1. Advanced Technology Adoption

The rapid implementation of Industry 4.0 technologies, including IoT, AI, machine learning, and 3D printing, is transforming the industrial landscape. Manufacturers are using real-time data, automation, and smart systems to improve efficiency, reduce costs, and enhance product quality.

2. Strong Government Support

The government has created a favorable environment for innovation, funding R&D initiatives, and pushing for the adoption of digital manufacturing technologies across sectors. Programs such as Manufacturing USA are key enablers, accelerating the transition to smarter, more agile manufacturing processes.

3. Focus on Operational Efficiency

Increased pressure to optimize resource usage, reduce downtime, and ensure product traceability is driving companies to adopt smart factory solutions. By digitizing workflows, factories can enhance responsiveness and quality while maintaining cost-effectiveness.

Key Segments Leading the Market Growth

The report highlights several crucial components and solutions that are powering the smart factory boom in the

1. Industrial Sensors

In 2023, industrial sensors captured a significant share of the market. These sensors are critical for monitoring machinery, detecting anomalies, and collecting real-time data. As factories become smarter, sensors enable predictive maintenance, process optimization, and real-time decision-making.

Driven by the Internet of Things (IoT), the adoption of smarter sensors helps manufacturers reduce waste, enhance safety, and remain competitive in an increasingly digital ecosystem.

2. Industrial 3D Printing

Industrial 3D printing is projected to register the highest CAGR during the forecast period. This technology plays a vital role in enabling rapid prototyping, on-demand production, and customization. With strong demand from aerospace, automotive, and medical device industries, 3D printing is becoming a core component of smart manufacturing.

The benefits from a rich base of technological infrastructure and a skilled workforce make it a global leader in 3D printing adoption.

3. Manufacturing Execution Systems (MES)

MES solutions are expected to hold a significant share of the smart factory market. MES bridges the gap between factory floor operations and enterprise systems, ensuring that data flows seamlessly and efficiently.

With real-time visibility into production activities, MES helps manufacturers manage resources, monitor performance, and make informed decisions. It’s especially valuable in industries like pharmaceuticals, automotive, and electronics, where precision and compliance are essential.

Market Opportunities and Challenges

Opportunities

Increased investments in AI, robotics, and IoT

Government support for digital infrastructure

Rising need for mass customization

Adoption of cloud platforms and edge computing

These trends are unlocking new possibilities, allowing manufacturers to innovate faster, reduce operational costs, and maintain global competitiveness.

Challenges

While the outlook is positive, the smart factory market faces notable hurdles

High upfront costs for advanced technologies and infrastructure

Integration challenges with legacy systems

Cybersecurity concerns due to increased connectivity

Shortage of skilled labor for operating and maintaining smart systems

Companies must address these challenges with thoughtful planning, training programs, and robust cybersecurity strategies.

Leading Market Players

The smart factory ecosystem is supported by prominent industry leaders, including

Emerson Electric Co.

General Electric

Honeywell International Inc.

Rockwell Automation, Inc.

Dwyer Instruments, LLC.

Stratasys

3D Systems Corporation

These companies are pushing the envelope by developing innovative hardware and software solutions that form the backbone of modern smart factories.

Conclusion: The Future is Automated and Intelligent

The growth of the smart factory market signals a broader transformation in the way goods are designed, produced, and delivered. From smart sensors and 3D printers to MES platforms and predictive analytics, smart factories are at the heart of the next industrial revolution.

To stay ahead, businesses must embrace these changes and invest in digital transformation. With the right strategy and technology, the future of manufacturing looks smarter, faster, and more resilient than ever.

#digital transformation#smart factory#manufacturing industry#automated production processes#monitoring machinery#thirdeye ai#ai

1 note

·

View note

Text

#Industrial Automation Training kits in Pune#Hydraulics and Pneumatics Manufacturer in Pune#Hydraulic Training Kit Supplier in Pune#Pneumatic Training Kit Exporter in Pune#PLC Training Kit Manufacturer#Robotics Equipment Exporter#Smart Factory Systems Trader#Mechatronics Training Kit Supplier#Industrial Automation Equipment Manufacturer#CNC Simulators Exporter#Technical Training Solutions Manufacturer#Didactic Equipment Supplier in Pune#Robotics Training kits in Pune#PLC Training kits in Pune#HMI Training kits in Pune#SCADA Training kits in Pune

0 notes

Text

Top Companies for Automation Services in Naperville, IL

Naperville, Illinois, stands out as a technology-driven city with a thriving industrial and commercial sector. As the demand for smarter, more efficient systems continues to grow, companies automation services in Naperville are becoming essential for businesses aiming to stay competitive in today's digital age.

Automation is no longer just an advantage—it’s a necessity for businesses looking to scale operations, reduce labor-intensive tasks, and increase efficiency across various departments. Whether in manufacturing, logistics, commercial buildings, or process industries, automation technologies are transforming how companies in Naperville operate, manage resources, and deliver value.

Why Automation is Crucial for Businesses in Naperville

Automation is revolutionizing the way Naperville-based companies handle their day-to-day operations. Here are several reasons why local businesses are investing in automation:

Increased productivity: Automation reduces the need for manual labor, leading to faster production cycles and reduced downtime.

Cost savings: Automated systems can significantly lower operational expenses over time.

Accuracy and consistency: Automated machines and software ensure precise execution of tasks with minimal errors.

Real-time data and analytics: Intelligent systems provide insights that help improve decision-making.

Workforce optimization: Employees can focus on high-value tasks rather than repetitive or dangerous duties.

Compliance and safety: Automation helps meet strict regulatory standards and safety requirements.

For Naperville’s growing tech and industrial scene, these benefits position automation as a long-term strategic asset.

Key Industries Leveraging Automation in Naperville

Naperville businesses across multiple industries are adopting automation technologies to streamline their operations:

Manufacturing: Robotics, CNC machinery, and industrial automation are optimizing production lines.

Warehousing and logistics: Automated conveyors, barcode scanners, and inventory systems ensure smooth supply chain operations.

Healthcare: Automation helps in diagnostics, lab testing, and administrative workflows.

Retail and service sectors: POS automation, customer service chatbots, and order tracking systems are improving customer experiences.

Building management: Building automation systems (BAS) regulate lighting, HVAC, and security systems for commercial properties.

As Naperville continues to attract diverse business investments, the demand for reliable automation companies is on the rise.

Types of Automation Services Offered by Naperville Companies

Automation companies in Naperville, Illinois offer a broad range of services tailored to specific business needs. These include:

PLC Programming and Integration: Custom logic programming for industrial control systems.

SCADA and HMI Design: Supervisory control systems with user-friendly interfaces.

Robotics Integration: Installation and configuration of robotic arms for precise and repetitive tasks.

IoT and Smart Systems: Device interconnectivity for real-time monitoring and control.

Building Automation Solutions: Energy-efficient systems for HVAC, lighting, and building access.

Custom Software Development: Development of automation software for scheduling, reporting, and analytics.

Each service is designed to help companies improve their workflows and align with modern operational standards.

Choosing the Right Automation Partner in Naperville

Not all automation companies offer the same level of expertise. When selecting a provider in Naperville, consider the following factors:

Experience and specialization: Choose companies with a proven track record in your specific industry.

Technical capabilities: Ensure they can handle the level of system complexity required.

Scalability: Look for solutions that can grow with your business.

Customer support: Strong post-installation service is key to long-term success.

Customization: Your business needs a partner that can tailor solutions to your workflow.

Certifications and compliance: Check for relevant industry certifications like UL, ISO, or OSHA compliance.

A trusted partner can help you navigate technology decisions, integrate systems, and train staff effectively.

Automation Trends Transforming Naperville Businesses

The landscape of automation is constantly evolving. Here are some top trends influencing Naperville’s commercial and industrial environments:

AI-Powered Automation: Machine learning algorithms enhance predictive maintenance and production optimization.

Edge Computing: Local data processing reduces latency and improves response time in real-time systems.

Cloud-Based Control Systems: Enables remote access, monitoring, and updates.

Green Automation: Energy-efficient solutions aligned with sustainability goals.

Cybersecurity for Automation Networks: Enhanced protection of control systems from cyber threats.

Staying ahead of these trends is key for companies looking to maintain a competitive edge in the Naperville market.

Benefits of Automation for Small and Medium Enterprises (SMEs)

Automation is not exclusive to large corporations. In Naperville, small and medium businesses are increasingly investing in automation technologies for:

Inventory management and procurement

Workflow automation in administrative tasks

Customer relationship management (CRM) systems

Automated billing and invoicing

Smart energy control in small office buildings

The accessibility and affordability of modern automation tools make them an excellent investment for SMEs aiming to scale without hiring extensively.

Automation and Economic Development in Naperville

Automation is playing a key role in Naperville’s economic growth. As companies become more efficient and competitive, they attract more business and create high-skill job opportunities. Local schools and training institutions are also responding by offering specialized programs in automation, robotics, and engineering—helping to create a talent pipeline that supports long-term innovation.

With Naperville’s continued investment in infrastructure and technology parks, the city is well-positioned to be a hub for automation excellence in Illinois.

Empowering Naperville Through Smart Automation

From small businesses to large enterprises, the ability to implement smart automation systems is critical for long-term success. The right automation partner can help you optimize operations, increase profits, and stay agile in an ever-changing market. As demand for precision, speed, and efficiency increases, Naperville businesses are finding automation to be one of their most strategic investments.

Partner with a Trusted Automation Company in Naperville

If you're seeking high-quality automation solutions tailored for your Naperville business, Xtreme Automation LLC delivers the expertise and support needed to elevate your operations. Whether you require industrial controls, building automation, or full-system integration, their team is committed to delivering scalable, efficient, and customized automation solutions. Learn more at xtremeautomationllc.com.

#automation companies Naperville IL#industrial automation Naperville#automation engineering Naperville Illinois#smart factory solutions Naperville#Naperville automation systems

0 notes

Text

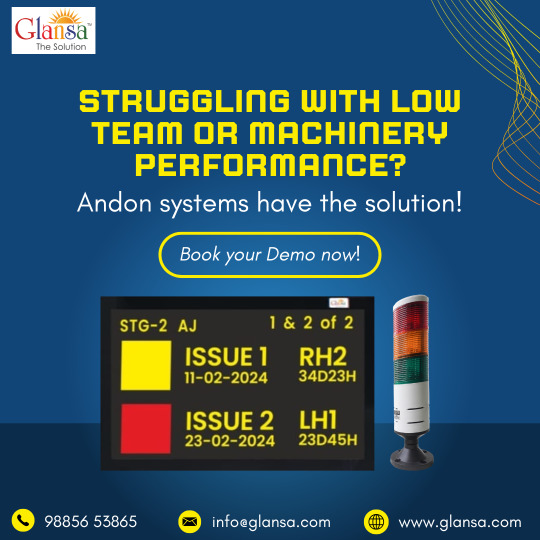

https://glansa.com/andon/

Discover how Industry Automation in India is revolutionizing manufacturing with smart solutions like Andon systems. Glansa Solutions offers a real-time alert and monitoring system to reduce downtime, improve efficiency, and support Industry 4.0 implementation. Explore how Indian industries are leveraging automation to stay globally competitive.

#Industry Automation in India#Andon System#Manufacturing Automation#Industrial Solutions India#Smart Factory#Glansa Andon#Industry 4.0 India#Real-time Production Monitoring

0 notes

Text

#Productronica China 2025#smart factories#digitaltransformation#SmartManufacturing#Automation#AI#Industry40#Electronics#electronicsnews#technologynews

0 notes

Text

AI in Automotive Manufacturing 2025: Driving the Future of Smart Production

Introduction

The automotive industry is undergoing a paradigm shift, with artificial intelligence (AI) playing a crucial role in transforming manufacturing processes. AI in automotive manufacturing 2025 is set to revolutionize production efficiency, quality control, and supply chain optimization. From predictive maintenance to autonomous quality inspection, AI is enhancing every aspect of car production, making factories smarter and more efficient. In this article, we explore how AI is reshaping the automotive manufacturing landscape, its benefits, and the future it holds.

The Role of AI in Automotive Manufacturing

AI is bringing unprecedented efficiency and precision to car manufacturing by enabling automation, predictive analytics, and intelligent decision-making. Key areas where AI is making a significant impact include:

1. Smart Robotics & Automation

AI-driven robotic arms are streamlining manufacturing processes by executing tasks such as welding, painting, and assembly with extreme accuracy. Unlike traditional robots, AI-powered machines adapt to new tasks through machine learning algorithms, reducing downtime and improving productivity.

2. Predictive Maintenance

Predictive maintenance powered by AI helps automotive manufacturers prevent unexpected equipment failures. By analyzing data from IoT sensors, AI can predict machinery breakdowns and recommend timely maintenance, reducing downtime and costs.

3. AI-Powered Quality Control

Traditional quality control methods are being replaced by AI-driven vision inspection systems that detect even the smallest defects in car components. AI ensures consistency and precision, minimizing recalls and warranty claims.

4. Supply Chain Optimization

AI is optimizing the automotive supply chain by predicting demand, managing inventory, and identifying disruptions before they occur. This helps manufacturers maintain a steady production flow while reducing costs and improving efficiency.

5. Autonomous Vehicles in Manufacturing Plants

Automakers are integrating AI-powered autonomous vehicles within factories to transport materials, enhancing efficiency and reducing human intervention in logistics.

Benefits of AI in Automotive Manufacturing

The integration of AI in car manufacturing offers numerous advantages, including:

• Enhanced Efficiency: AI automates repetitive tasks, reducing manual labor and increasing production speed.

• Cost Savings: Predictive analytics minimize operational costs by preventing breakdowns and optimizing resource allocation.

• Improved Product Quality: AI-driven quality control ensures defect-free components, leading to higher customer satisfaction.

• Sustainability: AI helps reduce waste and energy consumption, making manufacturing more environmentally friendly.

• Workforce Safety: AI-powered robots take over hazardous tasks, improving workplace safety for employees.

Challenges in Implementing AI in Automotive Manufacturing

Despite its benefits, AI adoption in automotive manufacturing faces several challenges:

• High Initial Investment: Implementing AI-driven systems requires significant investment in technology and infrastructure.

• Skilled Workforce: Companies need trained professionals who can manage AI systems effectively.

• Data Privacy & Security: Protecting sensitive manufacturing data from cyber threats remains a critical concern.

• Integration Complexity: AI systems must be seamlessly integrated into existing manufacturing processes, requiring careful planning.

The Future of AI in Automotive Manufacturing

By 2025, AI is expected to become an integral part of every automotive production process. Key future trends include:

• Fully Automated Factories: AI will lead to the development of smart factories with minimal human intervention.

• AI-Driven Customization: Personalized car manufacturing will be possible, allowing customers to customize vehicle features in real time.

• Sustainable Manufacturing: AI will enhance sustainability by optimizing resource usage and reducing emissions.

• Collaboration Between AI & Humans: AI will complement human workers, enabling them to focus on high-value tasks while AI handles repetitive processes.

Conclusion

The AI in automotive manufacturing 2025 revolution is transforming the industry by improving efficiency, quality, and sustainability. As automakers embrace AI-driven technologies, they will unlock new opportunities for growth and innovation. While challenges exist, the benefits of AI far outweigh the hurdles, making it a game-changer for the future of car manufacturing.

#tagbin#writers on tumblr#artificial intelligence#technology#ai trends 2025#AI in automotive manufacturing 2025#AI in car production#artificial intelligence in auto industry#AI-driven vehicle manufacturing#smart factories in automotive#AI-powered car assembly#robotics in automobile production#future of AI in automotive#AI automation in car factories#machine learning in automotive industry

0 notes