#SmartWarehouse

Explore tagged Tumblr posts

Text

Smart Warehousing: The Future of B2B Logistics

0 notes

Text

AgTrustt Platform Integrated ERP, B2B Marketplace & Smart Warehouse Solutions for Agri-Processors

Explore AgTrustt’s tech-enabled solutions: customizable ERP for food processors, a real-time B2B agri marketplace, and AI-driven warehouse intelligence. Empowering traceable procurement, seamless inventory, and direct farmer-to-industry trade.

0 notes

Text

From Chaos to Coordination - Smarter Warehouses Begin with Better Data

Every shelf, every box, every barcode - your warehouse runs on data. But without precisely labeled datasets, your AI models are guessing in the dark. We illuminate the warehouse floor.

Whether it's object detection for inventory, 2D/3D labeling for robotics, or anomaly tagging for quality control - we deliver industry-trained annotation teams to build vision models that don’t just see… they understand.

Forklifts that avoid collisions.

Systems that track pallets in real time.

Robots that don’t need second guesses.

We annotate the foundation that powers all of it - with speed, scale, and precision.

Let's transform your warehouse into a vision-powered command center. Connect with Wisepl today for a custom annotation strategy.

#WarehouseAutomation#DataAnnotation#ComputerVision#LogisticsAI#Wisepl#SmartWarehouse#MachineLearning#3DLabeling#SupplyChainInnovation#AIinLogistics#InventoryManagement#WarehouseRobots#AnnotationExperts#DeepLearningData#AITrainingData#ImageAnnotation#DataLabeling

0 notes

Text

Enhance operational efficiency with a smart Warehouse Management System (WMS). From real-time inventory tracking to seamless team coordination, streamline your entire supply chain using intelligent automation tools. Explore solutions at www.auckam.com for advanced industrial and IoT-driven innovations.

#WarehouseManagement#SupplyChainSolutions#IndustrialAutomation#SmartWarehouse#InventoryControl#LogisticsTech#IoTInLogistics#ManufacturingTech#OperationsManagement#DigitalTransformation#WarehouseEfficiency#TeamCollaboration#RealTimeData#Industry40#SmartLogistics

0 notes

Text

AI + WMS = Game-Changing Logistics Performance

Digital transformation in manufacturing is heavily centered on warehouse management—the new frontier of revolution in logistics. While warehouse management systems (WMS) have long been in place, most operations still rely on outdated systems that can no longer keep up with the pace, complexity, and technological demands of today's market. That's where AI Consulting Services come into play, offering tailored strategies to modernize operations and implement intelligent, scalable solutions that meet the demands of today's digital supply chain.

Over 90% of warehouses are already adopting or plan to adopt advanced WMS solutions. This signals a significant shift in how logistics leaders view technology. Many now recognize that legacy systems are not just inefficient—they're holding businesses back. If your warehouse still runs on legacy WMS, you're not just missing out on efficiency and savings; you're at risk of falling behind.

The Case Against Legacy WMS

Legacy WMS platforms were once the backbone of logistics operations. But in today's fast-paced, data-driven world, they present more challenges than benefits:

Poor integration with modern tech: Inability to sync with AI, IoT, and machine learning tools leads to fragmented operations.

Scalability issues: Growth becomes costly and cumbersome with rigid, outdated systems.

Operational inefficiencies: Slower processes drain productivity and increase delays.

Error-prone workflows: Manual data entry and outdated logic contribute to frequent mistakes.

Limited real-time insights: Decision-making suffers without live data and dynamic reporting.

Increased costs: Manual labor, delayed fulfillment, and poor optimization raise expenses.

Customer dissatisfaction: Legacy systems struggle to meet modern customer expectations for speed and accuracy.

Security vulnerabilities: Outdated architecture increases the risk of data breaches and compliance failures.

How AQe Digital Modernizes WMS with AI

AQe Digital empowers organizations to transform their legacy WMS into agile, AI-powered platforms—without the need for a full system overhaul. Here's how:

1. Real-Time Inventory Tracking

AI-driven sensors, RFID, and IoT devices feed live inventory data directly into your system. This automation eliminates manual errors and allows accurate, up-to-the-minute stock visibility.

Benefits:

Increased accuracy

Fewer stock discrepancies

Faster, data-driven decisions

2. Predictive Analytics for Smarter Forecasting

AI learns from your sales history and market trends to forecast demand accurately. This enables timely procurement, optimal stock levels, and proactive replenishment.

Benefits:

Reduced stockouts and overstocking

Smarter, data-driven purchasing

Improved cost efficiency and planning

3. Automation of Repetitive Tasks

Collaborative robots, intelligent conveyors, and AI-driven task automation boost productivity while reducing error rates.

Benefits:

Higher throughput

Reduced manual errors

Lower labor costs

4. Enhanced Order Fulfillment

AI prioritizes orders dynamically, optimizes picking routes, and enables real-time tracking for both staff and customers.

Benefits:

Faster processing and shipping

Real-time order visibility

Improved customer satisfaction

5. Scalable, Flexible Architecture

AQe Digital’s modular AI tools grow with your business—adding capabilities without requiring system replacement.

Benefits:

Easy scalability

Cost-effective expansion

Cloud-ready for multi-location deployment

6. Insight-Driven Reporting

Custom dashboards and real-time analytics provide visibility into KPIs like stock levels, order accuracy, and warehouse performance.

Benefits:

Smarter decision-making

Real-time operational transparency

Continuous improvement with AI-suggested optimizations

7. Seamless Integration with Existing Systems

AI connects via APIs to your WMS, ERP, and TMS platforms, enabling synchronized workflows and centralized control.

Benefits:

Minimal disruption during rollout

Unified data flow

Faster time-to-value

Why Now Is the Time

In today's competitive market, logistics operations cannot afford inefficiency. AI-driven platforms are no longer optional—they're essential. By upgrading legacy WMS with AI, companies gain real-time insight, predictive power, and automated execution, enabling them to meet rising customer demands while optimizing costs and operations.

At AQe Digital, we specialize in enhancing existing infrastructure through strategic AI integration. Let us help your warehouse evolve into a smarter, faster, and more scalable operation—ready for the future of logistics.

#AIConsultingServices#WarehouseManagement#AIinLogistics#SmartLogistics#SupplyChainInnovation#LegacySystemModernization#DigitalTransformation#WMSUpgrade#AIDrivenSolutions#LogisticsTechnology#PredictiveAnalytics#AIinSupplyChain#SmartWarehouse#AutomationInLogistics#FutureOfLogistics#InventoryOptimization#LogisticsEfficiency

0 notes

Text

Join our training program now and take your skills to a whole new level in the world of warehouses and supply chains.

🔥 Did you know that technology and digitalization have become the foundation of success in warehouse management and supply chains?

📈 Join our training program now and elevate your skills to a whole new level of efficiency using advanced Warehouse Management Systems (WMS), artificial intelligence, and data analysis!

Discover the latest technological innovations that are revolutionizing warehouse and supply chain management, and be part of the digital revolution reshaping the future of businesses.

🌟 What will you learn? ✅ Implement advanced WMS to enhance operational efficiency. ✅ Understand how digitalization impacts supply chain management and data analysis. ✅ Explore strategies for using robotics and artificial intelligence in smart warehouses. ✅ Achieve speed and accuracy in logistics operations.

🚀 Don’t miss your chance to be part of the smart future of warehouse and supply chain management! 📞 Register or learn more now:

Phone: 010 67580194

WhatsApp: https://wa.me/201067580194 📩 Email: [email protected] 🌐 Website: www.europeanqualitytc.com

0 notes

Text

Charting the Growth Path of the Warehouse Robotics Market: Robotic Logistics Revolution

The global warehouse robotics market size is anticipated to reach USD 17.29 billion by 2030, exhibiting a CAGR of 19.6% over the forecast period, according to a new report published by Grand View Research, Inc. The expansion of the e-commerce industry, rising labor costs, and the need for greater efficiency and accuracy in warehouse operations fuel the growth of the market.

The e-commerce sector is witnessing remarkable growth due to technological advancements. Technologies like Virtual Reality (VR), Augmented Reality (AR), blockchain technology, Machine Learning (ML), and Artificial Intelligence (AI) are enhancing the shopping experience. Thus, companies seek new methods to enhance operations and logistics while reducing delivery time and costs.

Warehouse Robotics Market Report Highlights

The cartesian robots are expected to witness a CAGR of approximately 20% in the product segment from 2023 to 2030. The factors such as accuracy, precision, and ability to handle heavy loads is expected to fuel the growth

In terms of function, the transportation segment is anticipated to grow at the fastest CAGR of 20.4% over the forecast period. The growth is attributed to increased demand for sorting, loading, and unloading goods from robots

The 11 kg to 80 kg warehouse robots is likely to witness a CAGR of approximately 20% from 2023 to 2030. The ability to efficiently handle medium and heavy-weight items in manufacturing, healthcare, food, beverages, and other industries is expected to support the growth

The software segment is estimated to experience a CAGR of approximately 21% over the forecast period. The segment is divided into a warehouse management system, a warehouse control system, and a warehouse execution system

The healthcare industry is anticipated to witness the fastest CAGR of approximately 21% in the application segment from 2023 to 2030. The growth is attributed to the continuous developments and increased implementation of robots in the healthcare sector to perform a variety of tasks in healthcare warehouses

For More Details or Sample Copy please visit link @: Warehouse Robotics Market Report

Robots offer a smart, cost-efficient alternative to human labor by automating warehouses catering to the increasing need of the e-commerce sector. The robots help companies to maintain employee safety standards and enhance production quality by performing various tasks such as handling the incoming consignment, picking, packing, slotting, shipping, and asset tracking by saving considerable time and effort.

The COVID-19 pandemic impacted the warehouse robotics industry substantially in terms of the demand for robotics and the supply chain of the robotics industry. However, the need for efficient and contactless order fulfillment and labor shortage due to lockdowns fueled the demand for robots and other automation tools in business operations. The market has shown rising demand and continuously growing as companies invest heavily in research and development activities to improve existing technologies and launch advanced robots.

The initial investment of the robotic set-up into the warehouse is high, creating significant challenges for small and mid-sized companies. Furthermore, implementing robots in warehouse operations is affecting labor jobs. The rising adoption of robots is expected to affect employment and wages, affecting the further growth of the warehouse robotics industry over the forecast period.

#WarehouseRobotics#LogisticsAutomation#RoboticWarehousing#SupplyChainTech#AutomationSolutions#SmartWarehouses#RoboticsInLogistics#Industry40#TechInnovation#EfficientSupplyChain#LogisticsTechnology#RoboticsIntegration#AutomatedStorage#DigitalTransformation#InnovativeLogistics#WarehouseEfficiency#AutonomousWarehousing#RoboticsIndustry#TechInvestment#FutureofLogistics

0 notes

Text

Navigating Choices: What to Look For When Selecting a Warehouse Manufacturer

When it comes to choosing a warehouse manufacturer, the decision holds significant implications for your business operations, efficiency, and overall success. As the market offers a myriad of options, it becomes paramount to discern the key factors that set a top manufacturer apart. In this exploration, we'll unravel the crucial elements to consider and shed light on why EPACK Prefab stands out as a top-tier warehouse manufacturer and supplier.

1. Quality of Construction Materials: Selecting a warehouse manufacturer begins with scrutinizing the quality of construction materials. Your warehouse's durability and longevity hinge on the materials used. EPACK Prefab excels in this aspect, utilizing premium materials that withstand the test of time and environmental factors.

2. Customization Options: Every business has unique requirements, and a reputable warehouse manufacturer should offer customization options. EPACK Prefab understands the importance of tailoring warehouse solutions to meet specific needs. Their customizable designs ensure that your warehouse is not just a structure but a solution crafted for your business.

3. Experience and Expertise: The longevity and success of a warehouse manufacturer are often indicative of its experience and expertise. EPACK Prefab, as a seasoned player in the industry, brings a wealth of knowledge to the table. Their team of experts understands the intricacies of warehouse design and construction, ensuring a seamless and efficient process.

4. Innovative Technology Integration: Warehousing has evolved with technology, and a forward-thinking manufacturer should integrate innovative solutions. EPACK Prefab stays ahead of the curve by incorporating state-of-the-art technology into their warehouse designs, enhancing functionality and efficiency.

5. Compliance with Industry Standards: Meeting and exceeding industry standards is non-negotiable in warehouse construction. EPACK Prefab's commitment to quality is evident in its adherence to the highest industry standards, ensuring that your warehouse not only meets but surpasses regulatory requirements.

6. Cost-Effective Solutions: Budget considerations are integral to any business decision. EPACK Prefab understands the importance of cost-effectiveness without compromising on quality. Their solutions offer a balance between affordability and long-term value.

7. Client Testimonials and Case Studies: The experiences of previous clients serve as a valuable testament to a manufacturer's capabilities. EPACK Prefab proudly showcases client testimonials and case studies, providing insight into successful warehouse projects and satisfied customers.

In the realm of warehouse manufacturing and supply, EPACK Prefab emerges as a top choice, embodying excellence in construction, customization, technology integration, and adherence to industry standards. When selecting a warehouse manufacturer, look beyond the structures—they're not just buildings; they're the foundation of your business's success. Choose EPACK Prefab for a warehouse solution that goes beyond expectations, setting the stage for efficient operations and enduring success.

Also Read: EPACK Prefab Redefines Cold Storage Warehouse Construction

#WarehouseConstruction#PrefabWarehouses#IndustrialBuildings#EPACKPrefab#SmartWarehouses#CustomWarehouseDesign#LogisticsConstruction#InnovativeWarehousing#GreenWarehouseSolutions#EfficientStorageSpaces

0 notes

Text

Locus Robotics Expands Reach in Italy and Poland

Transformative Robotics Solutions Arrive in Italy and Poland

In a groundbreaking move, Locus Robotics of Wilmington, Mass., the pioneering leader in autonomous mobile robots (AMR) for fulfillment warehouses, has announced the availability of its award-winning AMR warehouse automation solution to customers in Italy and Poland. This expansion marks a significant stride in Locus Robotics' quest to extend its European footprint. The company's intelligent robots employ cutting-edge technology and artificial intelligence to revolutionize productivity, cost efficiency, and workplace conditions for employees. "We are thrilled to bring Locus's transformative warehouse automation solutions to Italy and Poland as we continue expanding our European footprint," said Rick Faulk, CEO of Locus Robotics. "Our AI-powered robotics solutions allow customers in these countries to optimize productivity, efficiency, and accuracy in their facilities, boosting output 2-3X while lowering labor costs by 50% or more. As the pressure grows on supply chains, our intelligent robots enable companies to cost-effectively scale and stay competitive. We enable the future of smart warehouses." Collaborative Robotics Enhance Efficiency and Flexibility Locus Robotics' innovative AMRs are designed to work collaboratively with human associates, offering scalability to meet fluctuating order volumes during peak and standard seasons. The flexible robotics-as-a-service subscription model provides customers with a fully managed solution that encompasses bots, upgrades, maintenance, and support. By working hand-in-hand with human workers, Locus enhances productivity and fulfillment efficiency. The award-winning technology, algorithms, and real-time analytics optimize warehouse layouts, reduce travel time, and boost accuracy, resulting in faster processing and reduced costs. A Proven Track Record and Global Impact Currently deployed at over 65 sites in Europe, Locus serves a diverse clientele. This clientele includes retail, e-commerce, healthcare, manufacturing, and logistics companies. Moreover, in August, the company celebrated a monumental milestone by surpassing its 2 billionth pick globally. This achievement occurred just 11 months after reaching the industry-first landmark of 1 billion picks in 2022. "LocusBots have already helped our European customers in retail, e-commerce, healthcare, and logistics to significantly improve productivity and efficiency," said Denis Niezgoda, Vice President, EMEA at Locus Robotics. "Our powerful and flexible AMR technology enables a wide range of businesses to easily meet today's existing demand, seamlessly scale for future growth, and remain competitive within their industries." LocusOne Revolutionizes Warehouse Automation Execution Locus Robotics' AI and data science-driven LocusOne warehouse automation execution platform stands as the linchpin for orchestrating multiple robotic form factors at an enterprise scale within a single coordinated platform. It offers real-time optimization of tasks within warehousing environments, from task allocation and route planning to resource use, while delivering invaluable real-time business insights into warehouse operations. Award-Winning Innovation The company's solution have claimed more than 27 industry awards, including the prestigious IFOY award. Businesses across global industries such as retail, e-commerce, logistics, and 3PL have harnessed Locus's technology to pick over 2 billion units worldwide with an astounding 99.99% accuracy. Locus AMRs seamlessly integrate into existing warehouses and new greenfield sites without requiring infrastructure changes or disrupting workflows. Moreover, the Locus solution delivers a measurable return on investment (ROI) within months, as opposed to years. A Bright Future for Fulfillment At a time when supply chains face unprecedented challenges, Locus Robotics empowers labor-challenged 3PL, retail, healthcare, and manufacturing operators to effortlessly introduce robots into their operations, thereby increasing capacity, reducing costs, and ensuring competitiveness in the ever-evolving fulfillment and e-commerce landscape.

Exploring the Future with Locus Robotics

For warehouse operators eager to learn more about the transformative Locus solution, please contact Francesco Ferrari in Italy ([email protected]) or Marcin Gwozdz in Poland ([email protected]).

About Locus Robotics

Locus Robotics stands as the global leader in enterprise-level warehouse automation, featuring intelligent, AI-driven autonomous mobile robots (AMRs) that work in tandem with human workers to elevate productivity 2-3X. With a presence at more than 270 sites worldwide and supporting over 120 of the world's top brands, Locus Robotics empowers retailers, 3PLs, and specialty warehouses to meet and exceed the increasingly complex demands of today's fulfillment environments. Recognized on the Inc. 5000 list for three consecutive years and a recipient of over 27 industry and technology awards, the company delivers substantial increases in order fulfillment productivity, reductions in operational costs, and improved workplace quality, safety, and ergonomics for workers. Sources: THX News & Locus Robotics. Read the full article

#AI-poweredrobotics#autonomousmobilerobots#collaborativerobotics#fulfillmentefficiency#laborcostreduction#LocusRobotics#productivityoptimization#smartwarehouses#warehouseautomation#warehouseautomationsolutions

0 notes

Text

The MHI annual industry report projects that by 2026 the adoption of AI-powered warehouse solutions by businesses will reach 60+% as compared to 2020.

The use of AI in #warehouse operations is ushering in a new era of

#smartwarehouses, offering unparalleled #efficiency, #accuracy, and #optimisation. But what does the future for AI in warehouse management look like? Check in this blog: https://nextgeninvent.com/blogs/warehouse-management-systems-ultimate-guide/

@Amazon, for example, has 200,000 robots working in their warehouses. In 26 of Amazon’s 175 fulfillment centers, robots help humans in picking, sorting, transporting, and stowing packages.

@nextgeninventInvent Can Provide AI Assistance to Improve Your Logistics Management: https://nextgeninvent.com/supply-chain-services/

#Nextgeninvent#tracking#analysis#demandforecasting#inventory#labourtracking#amazon#warehouse#qualitycontrol#transportation

1 note

·

View note

Video

tumblr

the applications and benefits of IoT in smart warehouse management are numerous, from increased efficiency and productivity to enhanced visibility and control over inventory and assets. By adopting IoT-based applications, companies can stay ahead in the competitive market and thrive in the rapidly-evolving digital age through real-time data and insights.

Click here to know more: https://www.rejigdigital.com/blog/iot-in-smart-warehouse-moving-towards-effective-operations/

0 notes

Photo

Only two days left to meet Falcon Autotech team at Parcel & Post Expo, Frankfurt at Booth 4106. Meet our experts and don’t miss the chance to catch up on the latest trends on how our solutions are making intra-logistics automation smarter, improving efficiency, and driving ROI.

Drop by our booth #4106 for a quick chat with our intralogistics automation experts. If you can’t attend the event, feel free to reach out to us for a personalized showcase of the latest trends and solutions. https://bit.ly/3SiouCB

#sortingsolutions#ecommercesolutions#shipmentssorting#logistics#LastMileExperts#smartwarehouse#parcelpostexpo#parcelpostexpo2022

0 notes

Photo

Warehouses are an integral part of any supply chain management process. A temperature-controlled environment is required to store raw materials, products, spares, etc. In some cases, temperature and humidity variations can degrade the quality of a product to an excessive extent. Maintaining a specific temperature and humidity for food products until they are transported is necessary. Most of the warehouses have a temperature-monitoring system, which is a wired system. Either such warehouses have solutions where past-recorded data in data loggers are used to analyze the trend, or a wired system is laid to obtain real-time data involving cost, effort, and time. Such solutions include issues as given below. UniConverge Technologies offers Temperature/Humidity sensor node device, which provides real-time ambient temperature and humidity at remote locations. Multiple node devices can easily connect with Wireless Ethernet Gateway, which can transfer data to a cloud server through MQTT or to a local server through Modbus TCP/IP for monitoring the real-time data.

0 notes

Photo

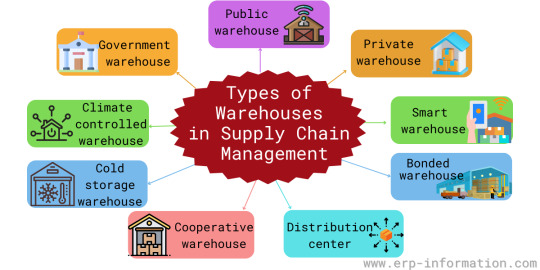

Warehouses are a vital part of the supply chain because they store inventory and help with order fulfillment. They can assist you to understand how products move from supplier to consumer. Go through this post to learn about the nine different types of #warehouses available for businesses.

#typesofwarehouse#supply chain#governmentwarehouse#smartwarehouse#www.erp-information.com/types-of-warehouses

0 notes

Link

Mendix Use Case showing benefits of Low Code platform to develop a highly adaptable smart warehousing application.

#ThinkPROLIM#DigitalTransformation#TodayMeetsTomorrow#PLMSolutions#SiemensPLM#mendix#lowcode#locodedevelopment#lowcodeapplication#smartwarehouse#smartfactory

1 note

·

View note

Link

Mendix Use Case showing benefits of Low Code platform to develop a highly adaptable smart warehousing application.

#ThinkPROLIM#DigitalTransformation#TodayMeetsTomorrow#PLMSolutions#SiemensPLM#mendix#lowcode#locodedevelopment#lowcodeapplication#smartwarehouse#smartfactory

0 notes