#Structural rebarring

Explore tagged Tumblr posts

Text

Rebarring Fixing Services in Maharashtra | Construction Fixing 9923437177

Get Expert Rebarring Fixing Contractors Services in Maharashtra with SB Demolition. We Ensure Strong, Safe Structural Reinforcement For All Types Of Construction Projects.

#Rebarring fixing in Pune#Rebarring fixing in Maharashtra#structural reinforcement in pune#rebarring services in pune#SB Demolition#rebarring contractors in Maharashtra#rebarring experts in pune#construction fixing in pune#Structural rebarring#Concrete rebarring contractors#Reinforcement bar fixing Pune#Rebar installation Pune#Steel rebarring services#Professional rebarring experts#Construction rebarring services#Rebar fixing specialists#Quality rebarring services Maharashtra#Safe rebarring solutions#Rebarring for construction projects#Affordable rebarring services Pune

0 notes

Text

i get off 9 hours breaking my back with a structural belt building some bullshit racks and i log onto tumblr and go through the shadowzel tag while smoking a cigarette on the porch then i go to bed at 8pm

#THE STRUCTURAL BELT IS KICKING MY ASS SO BAD ill get a pic of it. ough and when my bags have bolts in them...#i havent worn a belt other than a fucking FENCE BELT. FENCE BELT. IN OVER A YEAR#im so out of shape w carrying weight on me full time and structural specifically is so heavy#even my rebar belt fully loaded up with 5 extra wire spools is nothing compared to a structural. esp cause its a full fall arrest

10 notes

·

View notes

Text

Beach sand dynamics are stupidly complicated. In some places, yes, native vegetation holds the sand together and stabilizes the dunes. In other places, invasive vegetation introduced to stabilize the dunes fucks up the cycles of where sand is eroded from and deposited, leading to dunes forming in places people don't want them even as beaches erode nearby. (Also, massive changes to the structure of coastal wetlands.)

Whether waves deposit sand on a beach, or erode it away, has to do with the beach slope, the sand particle size, the angle at which waves approach, the wavelength and amplitude of the waves..... A guest lecturer for my coastal engineering class told us that, when running computer models of erosion and deposition responses to proposed beach projects like this, you're lucky if you end up in the right order of magnitude.

Beaches are very dynamic. It's not uncommon for hundreds of tons of sand to shift on and off a beach over the course of a year, usually scoured off by winter storms and deposited back over the summer. Anything that tries to modify that process - such as to prevent the sand from scouring away past a certain point - runs the risk of massively changing the dynamics in unpredictable ways.

And then, with "beach nourishment" projects like this, there's the question of where the sand comes from - where it was mined, and what the environmental impacts of sand mining there are - as well as the question of where the sand ends up if it all erodes away like this. (Did you know there's a sand mafia? That's more to do with the mining of sand for concrete, though.)

Anyway the bottom line is: don't put your fucking house there.

You think you're "next to" the beach, but you're very much *on* the beach as far as the scope of its natural processes go. And either you're fucking those dynamics up, or they're going to fuck you up. Or both!

absolutely losing my mind that a bunch of nimby assholes spent $500k to build a sandcastle that was promptly wiped away

#My understanding is that on the east coast of north America many of the problems stem from loss of native beachgrass and plant communities#While on the west coast many of the problems stem from the introduction of invasive plant species to hold the dunes#Including those same east coast grasses! As well as iceplant and other things#Also seawalls. Those have been built all over and they're a stupid idea everywhere#I said these dynamics are complicated to model but for seawalls specifically its actually very easy#A seawall redirects wave force in such a way as to undermine its own footing. There's physically nothing else it can do.#Frankly one of the most concisely self-destructive ideas ever implemented#And we built a lot of them!#There's many other types of shoreline armoring or soft shoreline protection#From those giant concrete jacks to rock rubble to anchoring driftwood down with rebar#All of which have their own mess of possible effects#Some of which are much better ideas than others#But as a baseline - colonist land use has been incredibly obtuse about building permanent structures in dynamic environments#Like coasts. And river banks. And other places but *especially* coasts and rivers#Trying to pin down a landspace which exists in a dynamically stable state is going to backfire in so many huge messy ways#Dumping half a million dollars of sand into the ocean is frankly the least of it

63K notes

·

View notes

Text

Beyond Pavements: Unconventional Uses of Dowel Bars in Modern Construction

Dowel Bars Aren’t Just for Roads Anymore

Dowel bars are typically associated with concrete pavements, bridging the joints between slabs to ensure load transfer and alignment. But the construction world is evolving—and with it, the scope of dowel bar applications. Tucked behind their seemingly humble appearance lies a surprising versatility. From heavy industrial floors to precast modular structures, dowel bars are stepping into the spotlight. And as bar dowel production becomes more advanced, thanks in part to TMT bar manufacturers pushing material innovation, these sturdy connectors are finding new homes in places one wouldn't expect.

Structural Synergy in Industrial Flooring

Industrial floors bear the brunt of dynamic loads from forklifts, machinery, and equipment. This isn’t a space for weak links. In these high-stress environments, dowel bars are embedded at construction joints to evenly distribute weight, minimize curling, and reduce long-term cracking. Unlike traditional reinforcement that spans the entire slab, dowel bars offer targeted support right where it's needed—at the joints—delivering both strength and efficiency without excessive material use.

Elevated Platforms and Parking Decks

Parking structures and elevated platforms demand more than just surface strength—they need reliable joint transfer systems. Dowel bars slide into this role effortlessly. By acting as shear connectors, they help absorb repetitive vehicular stress, resisting joint faulting and maintaining slab integrity. The beauty here is in the balance: flexibility at the joints without compromising structural stability.

Precast Construction Gets a Boost

As modular construction takes off, the need for seamless connections between precast elements is more critical than ever. Here, bar dowels act as silent heroes—creating mechanical continuity between walls, columns, and slabs. Whether it’s a hotel assembled like building blocks or rapid-deployment housing, dowel bars make the entire system feel monolithic, not modular.

Warehouses and Logistics Hubs

Warehouses experience constant wear and tear from loaded pallet trucks and rapid movements. Uneven floors lead to equipment damage and operational slowdowns. Embedding dowel bars in slab joints helps eliminate vertical displacement and unevenness, ensuring smoother logistics and lower maintenance costs. It’s a small component with big implications for efficiency.

Cold Storage Facilities

Cold storage brings unique challenges—extreme temperatures, constant condensation, and the threat of cracking due to thermal contraction. Here, dowel bars offer a dual advantage: flexibility and stability. Their use in slab-on-grade floors ensures that despite temperature fluctuations, the concrete remains strong and unbroken at the joints.

Tunnel Segments and Underground Construction

Tunnels—especially metro lines or sewage channels—rely heavily on segmental construction. Connecting these segments securely is critical. Dowel bars are embedded to ensure shear resistance and joint alignment, allowing the tunnel to act as a single, cohesive unit under ground pressure and vibrations.

Data Centers and Clean Rooms

High-tech facilities require perfectly even floors—not just for machinery, but also for airflow and cabling. Dowel bars maintain slab alignment with surgical precision, reducing micro-movements that could compromise delicate infrastructure. Their inclusion ensures both strength and symmetry in environments where error margins are razor thin.

The Material Edge: What TMT Bar Manufacturers Bring to the Table

None of these innovations would be possible without the evolution of bar dowel materials. TMT bar manufacturers, by enhancing strength, corrosion resistance, and dimensional precision, are enabling dowel bars to expand their portfolio. It’s not just about rods anymore—it’s about precision-engineered components built to last.

Conclusion: Look Beyond the Obvious

In construction, it’s often the unseen components that carry the most weight—literally and metaphorically. Dowel bars, long typecast in the role of pavement support, are now redefining their place across the built environment. From modular marvels to massive infrastructure, their versatility is unmatched. It’s time to start seeing dowel bars not just as accessories, but as essential instruments of innovation.

#dowel bar uses#bar dowel guide#tmt bar uses#bridge dowel bars#slab joints bars#dowel for concrete#tmt for structure#load transfer bar#dowel in floors#dowel bars types#tmt bar support#dowel in columns#dowel bar detail#dowel vs rebar#dowel bars India#dowel bar strength#concrete dowel bar#bar dowel strength#tmt dowel steel#dowel bar install

0 notes

Text

How Construction Rings Strengthened Krupasindhu Commercial Complex – A Case Study

When the Krupasindhu team envisioned their twelve-floor commercial complex in the heart of Maharashtra, one problem loomed large—structural reliability under constant commercial load. Weak foundational systems often haunt developers like bad design haunts good architecture. In this case, the solution came down to a trio of engineering reinforcements: construction rings, hot rolled coil, and bar dowel systems—all critical in keeping the structure rock-solid.

The Risks of Underestimating Structural Load

Commercial buildings face unpredictable stress from high footfall, machinery, and shifting loads. Without the right reinforcement strategy, even the best architectural design falters. Poor quality materials or old-school rebar alignment can't hold up against dynamic movement or expansion-contraction cycles.

This is why choosing high-durability components like construction rings isn’t optional—it’s foundational.

The Krupasindhu Challenge: Going Taller, Safer

Located in a high-traffic zone, the Krupasindhu Commercial Complex needed reinforcement that wouldn’t just meet code—it had to exceed it. The building’s central spine, meant to hold elevators, HVAC systems, and multiple floor loads, demanded a solution that could distribute stress evenly across vertical columns and beam junctions.

This is where SRJ Steel’s construction rings entered the blueprint.

Construction Rings: The Silent Strengtheners

Think of construction rings as the ligaments in a building’s skeleton. They bridge joints and columns, ensuring the entire frame moves as one, not in isolated shivers. In the Krupasindhu project, these rings provided:

Enhanced shear resistance in beam-column junctions

Balanced tensile strength for vertical load bearing

Reduced risk of crack propagation under thermal expansion

More importantly, their precision fit meant faster installation with minimal on-site modification.

Hot Rolled Coil: The Backbone of Flexibility

Let’s talk material quality. The hot rolled coil used in these construction rings wasn’t just any generic steel. SRJ Steel sourced coils known for:

High ductility, allowing structural elements to flex without snapping

Uniform surface finish, which makes welding seamless

Consistent grain structure, ensuring load distribution under varying temperatures

These properties gave the Krupasindhu team the confidence to go taller without compromising lateral stability.

Bar Dowel Placement: Anchoring the Load

A structure is only as strong as its weakest transition. For Krupasindhu, this meant focusing on the slab-to-column transitions and expansion joints.

That’s where bar dowels came into play.

These dowels were strategically placed to:

Absorb and distribute floor load stresses

Prevent slab lifting or separation

Allow controlled movement between concrete sections

They essentially allowed the structure to “breathe” without breaking.

Why the Trio Worked: Harmony in Reinforcement

One part doesn't solve the puzzle. It’s the combination of precision-engineered construction rings, hot rolled coil, and bar dowel systems that made Krupasindhu’s build seamless. Each component played its part in:

Increasing seismic resistance

Speeding up construction timelines

Reducing long-term maintenance costs

That synergy helped SRJ Steel deliver more than just material—it delivered peace of mind.

Lessons from Krupasindhu: Building Beyond the Blueprint

Krupasindhu Commercial Complex stands today not just as another real estate addition—but as a case study in how smart material choices lead to safer, more resilient builds.

And this isn’t just about skyscrapers. Whether it's mid-rise housing, hospitals, or industrial parks, incorporating construction rings, hot rolled coils, and bar dowel connections can mean the difference between mediocre and masterpiece.

Looking Ahead: Smarter Steel, Smarter Structures

Projects like Krupasindhu didn’t cut corners—and it shows. As more developers focus on longevity and structural integrity, the demand for tested reinforcements is rising.

Reinforcement that holds firm when pressure rises? That’s what SRJ Steel’s materials delivered.

Projects like Krupasindhu trust advanced reinforcement solutions—shouldn’t yours?

#Construction Rings#Structural Rings#RCC Ring Uses#Rebar Ring Design#Beam Ring Setup#Ring Beam Role#Ring for Columns#Concrete Ring Bar#Building Reinforce#Site Ring Layout#TMT Ring Bar#Tie Ring Use#Strong Ring Frame#Ring in RCC Work#Joint Support Ring#Load Bearing Ring#Ringed RCC Beam#Reinforced Ring Bar#Steel Ring Design#Column Ring Fixing

0 notes

Text

Duraneo GFRP Bent Rebars – Durable, Flexible Reinforcement for Complex Concrete Structures

Duraneo’s GFRP bent rebars are engineered to provide reliable reinforcement in intricate concrete shapes such as corners, hooks, and stirrups. Made from corrosion-resistant glass fiber reinforced polymer, these bars ensure long-lasting performance in harsh environments while being lightweight and easy to handle. Perfect for infrastructure projects demanding strength, flexibility, and durability without the drawbacks of traditional steel.

#GFRP bent rebar#composite reinforcement#corrosion-resistant rebar#glass fiber reinforced polymer#bent rebars#lightweight reinforcement#durable rebar#structural reinforcement#concrete reinforcement#non-metallic rebar#corrosion-free rebars#reinforced concrete solutions#precision-formed rebar#infrastructure reinforcement#marine-grade rebar

0 notes

Text

Types of Rebar Couplers for Concrete Structure

Rebar couplers play a crucial role in connecting reinforcing bars and are essential components for strengthening concrete structures. By utilizing rebar couplers, the compressive performance, load-bearing capacity, overall stability, flexibility, and seismic resistance of structures can be significantly enhanced.

Types of Rebar Couplers:

1. Fixed Rebar Couplers:

Fixed rebar couplers are a common type of coupler made of metal material, typically cylindrical in shape with an inner diameter that matches the diameter of the rebar. These couplers are easy to install, closely compatible with the rebars, effectively transfer forces, and ensure a stronger and more secure structure.

2. Threaded Rebar Couplers:

Threaded rebar couplers are a prevalent high-strength connection method compared to traditional fixed couplers. Usually made of carbon steel, these couplers undergo galvanization treatment to enhance corrosion resistance, providing higher load-bearing capacity and durability.

3. Plastic Rebar Couplers:

A relatively new option is plastic rebar couplers, constructed from high-strength plastic with characteristics such as lightweight and excellent insulation properties. Plastic rebar couplers are suitable for structures with less stringent weight requirements, helping reduce construction burdens, and offering outstanding environmental benefits.

In conclusion, selecting the appropriate type of rebar couplers is crucial for ensuring the structural integrity and performance of concrete structures. Whether opting for fixed, threaded, or plastic couplers, each type offers unique advantages in terms of installation ease, compatibility, strength, and environmental considerations.

0 notes

Text

GRP (Glass Reinforced Plastic) pipes are the ultimate solution for corrosive environments, offering superior durability, chemical resistance, and long-term performance.

0 notes

Text

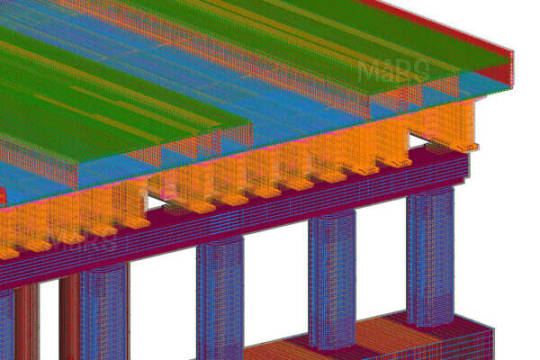

Get the detailed information regarding the various building stages for your #structuralproject through the utilisation of digitised 3D #BIM Models by outsourcing your requirement for #RebarDetailing Services to #OffshoreOutsourcingIndia, where we provide services at the most competitive rates across the entire #AEC Sector. Our team of #RebarDetailers is equipped with the highest standards in 3D #RebarModeling Solutions, designed to augment your #BIMproject by offering in-depth insights into rebar placements, structural concrete detailing, structural design, among other aspects, through our sophisticated 3D Rebar Models. We invite you to explore our premier #CADOutsourcing Services today.

Our Services

Rebar Shop Drawings Services

Rebar with BBS Services

Rebar Detailing Services

Rebar 3D Modelling Services

Rebar Bending Schedule Services

Rebar Concrete Shop Drawings Services

We are distinguished leaders within the industry, renowned for our proficiency in advanced 3D Rebar Modelling, leveraging state-of-the-art software such as AutoCAD, Tekla Structures, RebarCAD, SDS/2, SolidWorks, and Bentley Detail to offer premier #StructuralServices across the globe. Our competencies extend to Europe, encompassing nations like Germany, Greece, and the UK; North America with Chile and Brazil; Africa with South Africa and Ghana; Asia with Taiwan and Singapore; the Middle East with Saudi Arabia; and Australia and New Zealand. Our approach is dedicated to achieving precision, efficiency, and cost-effectiveness, by delivering customised rebar detailing solutions. These solutions not only augment structural integrity but also optimise material usage, thereby enhancing the efficiency of projects, and we meticulously cater to the specific needs of each project with meticulous attention to detail.

For more details click on the link below

#Structural Rebar Detailing#Rebar Shop Drawings#Rebar Drawings#Rebar Detailing#AEC#CAD Drawings#USA#Texas#Florida#Nevada#New York#California#New Jersey#Ohio

0 notes

Text

Rebarring Fixing Services in Maharashtra | Construction Fixing 9923437177

Get Expert Rebarring Fixing Contractors Services in Maharashtra with SB Demolition. We Ensure Strong, Safe Structural Reinforcement For All Types Of Construction Projects.

#Rebarring fixing in Pune#Rebarring fixing in Maharashtra#structural reinforcement in pune#rebarring services in pune#SB Demolition#rebarring contractors in Maharashtra#rebarring experts in pune#construction fixing in pune#Structural rebarring#Concrete rebarring contractors#Reinforcement bar fixing Pune#Rebar installation Pune#Steel rebarring services#Professional rebarring experts#Construction rebarring services#Rebar fixing specialists#Quality rebarring services Maharashtra#Safe rebarring solutions#Rebarring for construction projects#Affordable rebarring services Pune

0 notes

Text

steel structure rebar design in india

Rebar, also known as reinforcement steel and reinforcing steel , is a steel bar or mesh of steel wires used in reinforced concrete and masonry structures to strengthen and hold the concrete in tension , RCC, and steel structure design for houses, apartments, and bridges. As a rebar service company, we specialized in detailing, drawing, 3D modeling, and estimation. 3D-LABS has been offering the service in following industry standards which include ASTM, ACI, CRSI, AASHTO, RSIO, and BS 8666 to our clients all over the globe. The detailing and estimation services that we provide are ideal for structural engineers, rebar fabricators, steel erectors, detailers, general contractors, concrete contractors, and designers.

0 notes

Text

"Expert BIM Rebar Contractors | Enhance Efficiency & Quality"

"Discover top BIM rebar contractors for streamlined construction projects. Our specialists utilize Building Information Modeling (BIM) to ensure precision, efficiency, and superior quality. Contact us today to transform your construction process!" BIM Rebar contractors Services

0 notes

Text

Structural rebar detailing is the key to enhancing construction projects. Accurate drawings ensure better planning, cost savings, faster completion, and improved safety. By partnering with reliable rebar detailing services provider, construction companies can optimize their projects and deliver high-quality results.

0 notes

Text

How Premium TMT Bar Manufacturers Ensure Earthquake Resistance

The Silent Strength Behind Every Structure

Every structure tells a story — some stand tall for centuries, while others crumble at the first tremor. The difference often lies buried in the very bones of the building. In regions where earthquakes pose a real threat, the choice of construction material is not just about strength — it’s about survival. This is where the expertise of premium TMT bar manufacturers becomes a silent but critical force in disaster-ready design.

Why TMT Bars Matter in Earthquake Zones

A structure's ability to withstand disasters begins inside, with the steel rods that make up its core frame. Builders often pick TMT steel to build structures that can stand up to earthquakes because it's tough and bends without breaking. But not all TMT bars are created equal. The quality, consistency, and performance of TMT steel depend heavily on the manufacturing process. That’s why choosing a reputed TMT saria manufacturer makes all the difference between a vulnerable structure and one that can withstand seismic shocks.

How Premium Manufacturers Build Earthquake-Resistant Steel

Built-In Flexibility for Seismic Absorption

Premium TMT bar manufacturers integrate earthquake-resistance principles from the ground up. The bars these companies make are designed to flex without snapping — a key feature in areas prone to earthquakes where structures need to soak up and spread out energy. These producers put money into state-of-the-art cooling and heating methods that give the bars both high pulling strength and stretchiness. It's a mix that not many materials can pull off but one that's crucial for buildings to last through quakes.

Quality Control: The Backbone of Reliable Steel

At the heart of this reliability is a stringent quality control system. Trusted TMT bar manufacturers conduct multiple levels of testing — from checking chemical composition to stress-strain behavior — ensuring each batch meets national and international earthquake-resistance standards. The microstructure of TMT steel is carefully monitored to avoid brittleness, a common failure point during high-magnitude tremors.

Innovation That Anchors Buildings

A trusted TMT sari manufacturer doesn't stop at meeting the minimum requirements. Innovation plays a key role. Advanced manufacturing units now employ Thermex or Tempcore processes, designed to produce bars with uniform rib patterns and consistent strength throughout their length. These rib patterns are not just cosmetic — they enhance bonding with concrete, providing critical anchorage when the earth shifts beneath.

Real-World Impact: Steel That Holds Up Under Pressure

Consider a mid-rise apartment building designed in a seismic zone. Without earthquake-ready reinforcement, even the best architecture could falter. But with TMT steel sourced from premium TMT bar manufacturers, the structure gains a hidden ally — one that flexes under stress, holds firm against shocks, and supports the building’s integrity through disaster.

More Than Just Steel — It’s Peace of Mind

What often goes unnoticed is the emotional and financial toll a poorly built structure can take. Collapse doesn't just bring rubble — it brings uncertainty, trauma, and rebuilding costs. Choosing a reliable TMT saria manufacturer is not a technical decision alone; it's a commitment to peace of mind. These manufacturers not only deliver a product but also an assurance — that the steel holding your walls together will not let go when it matters the most.

Conclusion: A Quiet Promise of Resilience

Homeowners, builders, and planners who put money into high-quality TMT steel are taking action ahead of time. They're recognizing that nature can be unpredictable and getting ready for it with assurance.

Beyond strength and price, what truly defines good TMT bars is their silent promise of safety.

Structures may never speak, but through earthquake-resistant TMT bars, they whisper resilience. That’s the quiet power premium TMT bar manufacturers bring to every pillar and beam — a strength forged not just in furnaces, but in foresight.

#TMT bars#earthquake safe#premium TMT#TMT steel#earthquake bars#strong TMT#TMT manufacturers#seismic bars#anti-quake bars#steel reinforcement#TMT strength#durable rebar#construction bars#safety TMT#TMT rods#quake resistance#building safety#reinforced steel#high-grade TMT#structural bars

0 notes

Text

Smart Structures Start with Super Rings: Engineering Precision by SRJ Steel

The strength of a structure begins at its very foundation — and Super Rings are increasingly proving themselves as indispensable components in high-performance construction.

These seemingly simple circular reinforcements offer far more than just support; they engineer precision into every build, especially when paired with essential materials like binding wires and dowel bars in rigid pavement.

Why Structural Precision Matters

In heavy-obligation construction and infrastructure, precision isn't non-compulsory — it's fundamental. Any variance in alignment or structural bonding can bring about long-term weaknesses. This is where Super Rings play a crucial role. Their design ensures uniform spacing and circular reinforcement, allowing concrete structures to maintain form and function under various stress conditions.

What Are Super Rings?

Super Rings are specialized circular ties used to reinforce concrete columns and piers. Unlike conventional rings, they’re manufactured with higher dimensional accuracy and consistent strength. This translates to:

Enhanced load distribution

Reduced risk of deformation

Improved seismic resistance

Their integration with binding wires creates a tightly wound reinforcement cage that can handle dynamic loads without displacement.

Binding Wires: The Silent Strength

Often underestimated, binding wires are the unsung heroes of steel reinforcement. These wires tie the rebars, Super Rings, and other steel components securely in place before concrete pouring. They:

Prevent movement during concrete setting

Maintain geometric alignment

Distribute internal stress evenly

In practice, binding wires work synergistically with Super Rings to ensure stability. Without proper tying, even the most advanced Super Rings can’t fulfill their potential.

Dowel Bars in Rigid Pavement: Supporting the Horizontal Load

Horizontal alignment in pavements demands a different kind of reinforcement — dowel bars in rigid pavement. These cylindrical bars are embedded at slab joints to:

Transfer load between concrete panels

Prevent differential settlement

Enhance longevity of roads and airport runways

In infrastructure projects involving both vertical and horizontal elements, dowel bars and Super Rings complement each other. While dowel bars handle the shear force and slab movement, Super Rings ensure columnar integrity, especially at intersections.

How Super Rings Enhance Performance

Super Rings are engineered for precision, which offers several tangible benefits:

Consistent Spacing: Ensures even stress distribution across the rebar cage.

Improved Safety Margins: Reduces failure risks in earthquake-prone zones.

Faster Installation: Minimizes alignment errors, saving time on-site.

These benefits become especially valuable in projects where binding wires and dowel bars in rigid pavement are already being used, creating a cohesive and durable system.

Material Compatibility and Engineering Efficiency

Super Rings, binding wires, and dowel bars in rigid pavement are not standalone solutions. Their efficiency comes from how well they integrate:

Binding wires secure Super Rings and longitudinal bars, reinforcing vertical integrity.

Dowel bars maintain horizontal integrity across pavement slabs.

Super Rings ensure concrete holds shape and structural load across the column height.

Using materials from a single, quality-controlled source like SRJ Steel ensures uniformity, avoiding mismatches in tensile strength or diameter that could compromise performance.

Smart Structures Demand Smart Components

As infrastructure moves towards smarter, more sustainable practices, engineering elements like Super Rings aren’t just add-ons — they’re integral. Today’s flyovers, metro stations, and industrial buildings demand a level of mechanical discipline that only precision-engineered components can deliver. Super Rings provide the stability and alignment that traditional rings often fail to achieve, especially under long-term stress.

Conclusion: Built to Last with Engineering Foresight

Structures of the future are not only taller and stronger — they’re also smarter. Behind the scenes, precision components like Super Rings are making that possible. Alongside binding wires and dowel bars in rigid pavement, these elements ensure every beam, column, and slab is reinforced with integrity. SRJ Steel’s commitment to manufacturing excellence stands as a testament to what's achievable when engineering precision becomes non-negotiable.

#Super Rings#SRJ Steel#Smart Structures#Steel Rings#Rebar Rings#Construction Rings#Precision Steel#Steel Support#Concrete Frames#Reinforced Steel#Building Rings#Smart Steel#Steel Innovation#Super Ring Tech#Structural Steel#Steel Solutions#Modern Rebar#Ring Reinforcement#Steel Strength#Advanced Rings

0 notes

Text

Precision Redefined: Unraveling the Wonders of 3D Reinforcement Modeling

3D Reinforcement Detailing brings precision to structural engineering by creating detailed and accurate 3D models of reinforcement elements. This advanced service ensures a comprehensive understanding of the reinforcement layout, aiding in construction planning, coordination, and minimizing errors. The three-dimensional representation enhances visualization and collaboration, contributing to the seamless execution of construction projects. Opt for 3D Reinforcement Detailing for superior accuracy and efficiency in reinforcing structures.

#3D Reinforcement Detailing#Rebar Shop Drawing Services#Rebar Detailing Services#Rebar Drawings#Structural rebar Modeling Services#Rebar Modeling Services

0 notes