#TMT binding guide

Explore tagged Tumblr posts

Text

Binding Wire in Construction: Types, Uses, and How It Complements Steel Products

Binding wires stands as one of the maximum vital yet left out substances in construction. Right from tying rebars to securing the framework, it guarantees that each structural detail stays in area at some point of the construct. Close behind it in importance are steel components like hot rolled coil and the dynamic shifts in hr coil prices, which directly influence material selection on site.

Understanding how binding wire suits into the wider construction puzzle starts with grasping its purpose: it binds metal rebars in RCC (strengthened cement concrete), offering grip and holding the structure’s shape before the concrete units. With rising demand for stable and price-powerful creation substances, warm rolled coil becomes any other cornerstone — its affordability and availability determined largely with the aid of fluctuating hr coil fees.

Types of Binding Wire Used in Construction

Construction binding wires vary based on coating, strength, and usage:

Galvanized Binding Wire: Offers resistance to rust and corrosion — perfect for regions vulnerable to moisture.

PVC Coated Binding Wire: Adds flexibility and extra safety, mainly where aesthetics and insulation depend.

Stainless Steel Wire: Used for high-stop or commercial programs needing advanced electricity and corrosion resistance.

Annealed Binding Wire: Soft, durable, and easy to curve, making it a popular preference for tying metal bars together.

Each of those types serves a selected motive, decided on based totally at the needs of the venture and the encircling environment.

Uses That Go Beyond Just Binding

While the primary function of binding wire is to tie rebar during reinforcement, its versatility allows use in:

Holding shuttering and centering materials temporarily

Supporting mesh in wall plastering

Assisting in fencing and garden structures

Securing scaffoldings or heavy-duty materials during transit

In essence, wherever steel meets steel, or where movement needs to be restricted, binding wire steps in silently.

Complementing Steel Products Like Hot Rolled Coil

Hot rolled coil is a staple in the steel industry — formed by rolling steel at high temperatures. Its affordability and malleability make it ideal for large-scale structural frameworks. But the role of binding wire becomes evident once hot rolled coil products are shaped into rods and beams. These components need stability during concrete pouring or welding, which is where the binding wire takes charge.

Choosing the Right Binding Wire for the Job

Selection isn't just about wire thickness or price. It’s about matching the right type to the structure's demands. For example:

For coastal projects, galvanized or PVC-coated wire prevents rust.

For interior infrastructure, annealed wire saves labor time due to its flexibility.

In heavy industrial builds where steel quantity is higher, durable and thicker wire ensures a firm tie.

The balance between the price of hot rolled coil and the reliability of binding wire can determine project success.

Key Considerations Before Purchasing

Tensile Strength: Should withstand enough stress without snapping.

Wire Gauge: Thinner wires suit light jobs; thicker ones for heavy reinforcement.

Corrosion Resistance: Especially vital for long-term or outdoor exposure.

Compatibility: Should match the steel type used — especially when using HR coil-based structures.

From Consideration to Purchase

Construction decisions often begin with material awareness. Once the value of binding wire is clear — not just as an accessory but as a core stabilizer — it becomes easier to justify investment in quality. A consumer evaluating hr coil prices should also assess whether the binding wire chosen can perform under those same structural pressures. When these small wires ensure large buildings stand tall, skimping on them can mean structural risks.

Steel products shine on the surface, but it’s the binding wire behind the scenes doing the heavy lifting.

#Binding wire use#Types of wire#Steel tie wire#Wire in RCC#TMT bar wire#Construction wire#Binding wire types#Steel fixing wire#Wire for columns#Binding material#Rebar tie wire#RCC wire guide#Strong wire ties#Wire for beams#Reinforce with wire#Wire in building#Best binding wire#SRJ steel wire#Steel frame wire#TMT binding guide

0 notes

Text

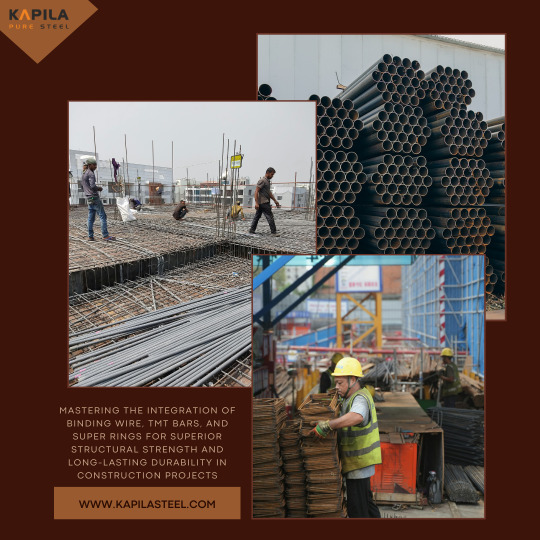

In construction, using the right materials can make a significant difference in the integrity and durability of structures. Binding wire, TMT bars, and Super Rings are essential components that ensure structural stability. This guide delves into how to maximize the effectiveness of these materials in your construction projects. By understanding the synergy between binding wire, TMT bars, and Super Rings, construction professionals can ensure stronger, longer-lasting outcomes. Whether it's for reinforcing structures or ensuring high tensile strength, the right combination of these materials can enhance performance and reduce long-term costs.

#binding wire#TMT bars#Super Rings#construction#reinforcement#steel bars#wire binding#TMT steel#structural wire#coil wire#construction wire#high strength#building material#wire mesh#steel reinforcement#concrete binding#construction rods#TMT wire#project materials#construction strength

1 note

·

View note

Text

Cement and Concrete: What Every House Owner’s Should Know Before Construction Begins

When planning a home, understanding the basics can save you time, money, and headaches—especially when it comes to building materials. One of the most common points of confusion for homeowners is the difference between cement vs concrete. While often used interchangeably, these two materials serve very different purposes in construction. Before your project breaks ground, it’s essential to know when to use cement, when concrete is a better choice, and how each impacts the strength and durability of your home. This guide will clear up the confusion so you can make informed decisions and communicate effectively with your contractor.

What Is Cement?

Composition and Function: Cement is a fine, powdery substance made primarily from limestone, clay, shells, and silica. It acts as a binder—a material that holds other substances together. When mixed with water, it forms a paste that hardens over time, making it an essential ingredient in construction.

Where Cement Is Commonly Used in a House

In residential construction, cement is not typically used on its own. Instead, it’s a vital component in mortar (for laying bricks), plaster (for walls), and grout (for tiles). Cement is also used for small repair jobs and surface coatings.

What Is Concrete?

Composition and Role in Structural Work

Concrete is a mixture of cement, sand, gravel (or crushed stone), and water. Cement is just one ingredient in concrete, but it's what gives the mix its binding properties. The result is a strong, durable material that can be molded into almost any shape and hardened to form a rock-like surface.

Concrete is used in the structural elements of a home:

Foundations

Columns

Slabs

Beams

Driveways and walkways

Read our other Blogs M Sand Supplier in Chennai – Your Trusted Partner

Cement and Concrete: Key Differences Every House Owner Should Know

Material Composition Comparison

The most important distinction is that cement is an ingredient, while concrete is the final product. Think of cement as the flour and concrete as the baked bread. Without cement, you can’t make concrete—but cement alone isn’t enough for structural work.

Strength and Durability

Concrete is far more durable and strong than cement on its own. Cement hardens but is prone to cracking if used alone in structural applications. Concrete, when properly mixed and cured, can withstand heavy loads and adverse weather conditions.

Cost and Long-Term Performance

Cement is generally more expensive per kilogram, but concrete is cost-effective when used for larger volumes. More importantly, using the wrong material for the job—like pouring pure cement for a foundation—can lead to structural failure and costly repairs.

Read our other Blogs Exploring Various Types of Steel for Residential Building

Choosing the Right Material for Each Part of Your Home

When to Use Concrete

Concrete should be used for any part of the house that requires load-bearing capacity or structural strength:

Footings and foundations

Columns and beams

Driveways and patios

Roof slabs and floors

When to Use Cement

Use cement for:

Mortar in bricklaying

Plastering and rendering walls

Minor repairs and patchwork

Tiling and grouting

Read our other Blogs Best Steel and TMT Rod Supplier Agencies in Chennai

Common Mistakes Homeowners Make with Cement and Concrete

Using Cement Instead of Concrete for Structural Work

A common and costly mistake is assuming cement alone is strong enough for major construction tasks. This misconception can lead to cracking, water damage, and structural instability.

Not Consulting with Professionals Early On

Another mistake is not involving your contractor or engineer when deciding materials. Choosing the wrong mix can compromise the longevity of your home.

Buy Cement and Ready Mix Concrete in Chennai at Chennai Civil Supply

Chennai Civil Supply is the Best Branded Cement and Ready Mix Concrete supplier in Chennai. With over 25 years of experience, this dependable supplier has provided builders, contractors, and house owners with high-quality supplies that are strong, durable, and affordable. We supply everything you need to keep your construction project running successfully.

Address: 112, Vallalar St, Moorthy Samy Colony, Padi, Chennai, Tamil Nadu 600050

Contact: 92063 12345

Website : https://www.civilsupply.in/

Conclusion: Make Informed Choices from the Ground Up

Understanding cement vs concrete is more than construction trivia—it’s essential for building a safe, durable, and cost-effective home. Cement is just one ingredient in concrete, and knowing when to use each can prevent expensive mistakes. Whether you're working closely with a contractor or overseeing the project yourself, this knowledge empowers you to ask the right questions and make better decisions from the very beginning.

Read our other Blogs OPC vs PPC Cement: Best Cement for House Construction in Chennai

FAQs About Cement and Concrete in House Construction

Can I use cement instead of concrete for a driveway? No. Cement alone lacks the strength and durability required for driveways.

Is ready-mix concrete better for home builds? Yes. Ready-mix ensures consistent quality and is often more cost-effective for large pours.

Can I mix my own concrete at home?

0 notes

Text

The Ultimate Guide to Finding the Best TMT Bar for Your West Bengal Project

In West Bengal, where the climate varies from heavy monsoons to high humidity, the quality of construction materials is crucial. The best TMT bar in West Bengal has the strength, flexibility, and resistance to environmental situations to assure construction. Be it residential, commercial, or infrastructure works, getting the right TMT bar gives a guarantee for life and safety. This blog explains the parameters you should check while deciding on procuring the best TMT bars in West Bengal for your construction works.

Benefits of TMT Bars:

TMT bars are preferred over traditional steel bars because of high-tech manufacturing techniques that augment the strength and flexibility of these bars.

Superior Tensile Strength: TMT bars are subjected to heat treatment, which strengthens these bars and allows them to carry heavy loads.

Corrosion Resistance: TMT bars with anti-corrosive properties add longevity, especially given the humid conditions of West Bengal.

Earthquake Resistance: Structures built using good-quality TMT bars are better suited to bind with seismic shakes, thus reducing damage to these structures.

Improved Bonding with Concrete: The ribs on the TMT bars help them to grip concrete better, thus providing stability to the very structure.

Cost-Effective and Economical: TMT bars help reduce the total quantity of steel to be consumed for construction, hence reducing costs as well as speeding up construction.

What to Look For When Choosing the best TMT Bars in West Bengal?

To ensure safety and durability, the factors that are to be kept in view while choosing the best TMT bar in West Bengal include:

Certification and Standards: The presence of a BIS (Bureau of Indian Standards) or ISI (Indian Standards Institute) mark shall verify the quality compliance.

Grade Selection: TMT bars come in several grades such as Fe 415, Fe 500, Fe 550. Residential construction projects require good performance from Fe 500 grade bars, while industrial projects and heavy load structurals benefit from the use of Fe 550.

Flexibility and Strength: Good quality TMT bars should be able to bend freely without fracturing but strong enough to take any stress.

Resistance to Rusting and Corrosion: Always look for TMTs treated by anti-rust technology for their longer life and in coastal or humid regions.

Bottom Line

Choosing the best TMT bar in West Bengal is fundamental in providing strength, durability, and safety to any construction work. Given that lasting structural integrity forms the very basis of a good decision for any builder or engineer, an investment in such premium quality TMT bars will be an assurance to reliability forever.

0 notes

Text

Learn about the importance and applications of steel binding wires in construction. This guide from Shree TMT covers their role in reinforcing structures and ensuring durability in building projects.

#Steel Binding Wires#Construction Materials#Structural Strength#Binding Wire Applications#Steel Reinforcement#Building Supplies#Shree TMT#construction industry#tmt bars#building strength#construction#building materials#building foundations#shreetmt

0 notes

Text

What types of reinforcing bars is manufactured by the best Reinforcing Bars Manufacturer in Nigeria?

Reinforcing steel bars play a vital role as a construction material. Steel reinforcing bars is mainly manufactured by the best Reinforcing Bars Manufacturer Nigeria. You can obtain Steel reinforcing bars from both internal and external sources.

The internal sources of reinforcing bars are indigenous major plants and the mini-mills located in different parts of the country. Imported steel reinforcing bars are coming from the country mainly Russia and Ukraine. Some reinforcing bars are procured for specific uses by multinational companies for some specific projects.

Most local Reinforcing Bars Manufacturer Nigeria make all bars reinforcing steel and guide to the users for the appropriate use of Reinforcing bars.

Reinforcement bars plays the role of the main input in the construction process when combined with cement and aggregates, which makes high capital outlay and quality implications. Reinforcing Bars Manufacturer Nigeria relied heavily on imports because of having the best quality reinforcement bars in their company. However, over the past two decades, the landscape has significantly changed and there is some credible reinforcing manufacturer within the shores of the country.

The reinforcement bar is known by many other names also like reinforcing steel rebar, reinforcing bar, and reinforcement steel. It is a versatile building material widely used in the construction industry for the manufacture of reinforced concrete.

Reinforcement concrete is a composite material made of concrete and some types of reinforcement - most commonly steel rods, bars, wires or steel rods and steel wire mesh. Steel reinforcement bars usually have shapes and sizes that they can be easily bent and placed in concrete to form a monolithic structure.

Steel reinforcement bars is divided into two parts

1. Primary reinforcement

2. Secondary reinforcement

.

· Primary reinforcement refers to steel, which is employed to guarantee the resistance required by the structure overall to support the design load.

• Secondary reinforcement is also called as distribution or thermal reinforcement and is employed in the construction industry for its durable nature and aesthetic reasons.

However, there are also other minor uses of reinforcing bars which are as follows:

· Steel reinforcing bars are also employed to provide resistance to concentrated loads by providing sufficient local resistance and stiffness for a load to propagate through a wide area.

· Steel reinforcing bars is also used to hold other types of steel bars in the correct position, to accommodate their loads.

The manufacturer of steel rods manufactures various steels products and iron products. So iron rods manufacturer Nigeria generally sell iron rods, common wire nails, wire mesh and binding wire.

Thermo-Mechanically-Treated (TMT) rebar are the best kind of ribbed bars known for superior bonding with concrete.

According to The Iron Rods Manufacturer Nigeria and Reinforcing Bars Manufacturer Nigeria, AFL BS 4449:2005 Grade B500B are high strength rebar’s yield strength over 500 MPa, substitute to imported rebar’s and are manufactured in a computerized controlled, highly automated, high-speed continuous mill. They are delivered in pilfer-proof 2-ton bundles. AFL rebar bundles are generally supplied with two tags per bundle.

The best Iron Rods Manufacturer Nigeria have multiple furnaces with State of the art and high tech manufacturing facilities including furnaces, Continuous Casting Machines (CCM) making billets, Rolling Mills for rolling of high strength rebar’s and allied products as well as Oxygen Plant. The best reinforcing bars manufacturer Nigeria produces top brands of reinforcing bars.

More Articles-

What type of the Iron Rods Manufacturer in Nigeria works?

Get premium quality iron rod from the best Iron Rods Manufacturer Nigeria

Get the High-quality Iron rods by any best Iron Rods Manufacturer Nigeria

#Iron Rods Manufacturer Nigeria#Reinforcing Bars Manufacturer Nigeria#Reinforcing Bars#Iron Rods#steel products#SabaSteel

1 note

·

View note

Text

What Are The Various Types And Sizes of TMT Bars?

India is currently the world's fourth-largest producer of crude steel, behind China, Japan, and the United States of America. By 2024, the production of steel is anticipated to increase to 200 million tonnes. In construction, TMT (Thermo-mechanically treated) bars are quickly replacing conventional HYSD (High Yield Stress Deformed) rods. Heat treatment is applied to these bars, changing their structural makeup, and improving their form so that they are better suited for use in building. Learn about the different sorts and sizes that these bars come in.

Types of TMT bars:

Top 10 TMT steel bars in India come in a variety of grades, where the grade refers to the level of stress utilized to cause the deformation of the material. Quality is an important consideration for every construction project, and it also affects the price of bars in the TMT bar price list in Himachal Pradesh. Better quality is available based on your demands. A broad variety of TMT steel bars are available for your selection, which includes:

1. Fe-415 grade TMT steel bars were replaced with Fe-500 grade bars because of the incredible dynamic loading resistance and bending capacity of these rods.

2. TMT of grade Fe-500 Steel bars: Fe here stands for iron. For RCC constructions in concrete structures like bridges and buildings, such types of bars are used.

3. TMT of grade Fe-550 Steel bars: Although there are differences in tensile strength and yield, these rods' qualities are comparable to those of Fe-500. These are employed for RCC structures exposed to subterranean, aquatic, or coastal environments. They are employed in the construction of concrete structural foundations, various manufacturing facilities, buildings, and more.

4. Even stronger TMT steel bars are available in Fe-600 grade, which also has extremely little elongation and flexibility. Fe-500 grade bars are better for TMT rods because they have a good balance of flexibility and strength to maintain strength and structural stability. They also have a reasonably high degree of strength along with high elongation or flexibility.

TMT Binding Wires are used to connect the rebars together at the joints, which can help hold the entire building together.

Sizes of TMT bars:

These types of steel bars can be found in varied diameters:

1. 8mm - 10mm: Bars between 8 and 10 mm are utilized in slabs and stairways, which support loads in slab dwellings.

2. These sorts of bars, which range in thickness from 12 to 25 mm, are used to create Columns and Beams, enabling them to support external loads.

3. These sizes—32mm to 36mm—are helpful for building exceedingly complex constructions like bridges and dams.

The outstanding qualities of TMT steel bars, which include strength, ductility, tensile properties, durability, and more, make them perfect for use in construction.

Currently, some well-known best TMT bars manufacturer in India are planning to produce bars with larger diameters specially Birla TMT Steel. Designs are used to guide the selection of various sizes. Occasionally, several sizes are utilized depending on the requirements of projects. The price list for TMT bars in India clearly shows that those with larger diameters cost more.

0 notes

Text

Importance of Steel Channels

MS channels are one of the most prevalent products for Stainless Structures. The use of stainless-steel channels is becoming very popular in numerous industries because of the obtainability of different sizes, grades, lengths, and finishes. The capabilities and product range of Stainless Structurals plays a very large part in this upsurge in the market. Stainless steel channels are the answer for any designs and structures needed for eroding or harsh environments.

Uses of MS channels include platforms, skids, tower supports, rails, stop-logs, guides and more. Some of the many industries that you can find our stainless-steel channels comprise building and construction, architecture, oil and gas, chemical plants, food processing.

We at Shree ji Steel Corporation deal in an extensive collection of MS Channels. We source them from some of the dependable vendors of the market. These MS channels are produced using first-class mild steel. Mild Steel channels are extensively utilised for structural support in construction works. We deliver these channels to our patron at most competitive prices in the market.

Steel Saria are one of the most widely used materials used in the construction industry. With an exclusive metallurgical procedure that binds work hardening along with heat-treatment to generate robust and high strength bars from low-carbon steel.

They can boast of high thermal stability and can resist temperatures ranging from 400 to 600 degrees Celsius. Thus, they are flawless for resisting fire and provide safety.

At Shree Ji Steel Corporation we are one of the renowned firms in the domain, involved in providing a broad spectrum of Steel Saria. TMT Rod/Saria find its wide usage in building construction. These high strength steel bars or concrete rebars, improve the safety and durability of the structures and prevent damages as they are precisely engineered under experts’ surveillance, using high-grade metal alloy at well-developed production unit.

0 notes

Text

TMT Bar Manufacturers India and Their Advantages

Everyone must be familiar with the term TMT bar which is abbreviated as Thermo-Mechanically Treated bars. These are used for constructing buildings and high rise skyscrapers. The house owners are more particular about choosing the best qualities of building materials. In case one does not have much knowledge on this, there are experts who can help one and guide in choosing the right material. The base of any edifice is the material, and hence one must not go for any compromise on the type as well as the quality of these materials. The TMT bars are known for their strength and quality that can help one create a home for long years. Hence they not only offer complete value for money but also the strength to a home on which one can rely under any weather condition.

The branded TMT bars can withstand many climatic conditions and can give you a great experience of your new home. The TMT bar comes with atmospheric cooling, and it can sustain hot temperatures. It can resist the corrosion, and thus the house owners are going for the branded building materials. Because of the high strength and better ductility, the workers don’t have to bind it manually which helps to save the crucial time of the workers as well the builders. Therefore from various viewpoints, they are known as the best bars for the building.

Benefits of the TMT bar suppliers West Bengal

Effective cost

The lightweight composition helps this TMT bars to be transported at a very reasonable cost. And most of the house owners look for the decent cost with good build in quality and these building materials are the best option for you to build a new home.

Great welding features

The wielding feature allows the workers to do the joints and welds properly. The high strength allows it to be used in vast numbers. The existence of carbon is very low, and hence the butt and other crucial joints are possible.

Good Bendability

The TMT bars are flexible, and it can be elongated easily, and hence it shows the best properties for the longevity of your home. You will experience good workability, and it can be easily installed in the concrete walls. The bendability property helps it to fit properly on the meshes.

As compared to any other building materials, the best quality of TMT bars helps the builders to make high rise building without any fear of falling off the structure in future. Without even thinking twice, they can easily rely upon these brands easily. This can be easily fixed in the cemented mixtures or the concrete without giving any headaches to the builders and workers. The superior strength of the materials helps the customers to go for buying these products in a heavy amount.

The TMT bars are completely fireproof and can resist earthquake incidents without even damaging your house. Whether you are living in the coastal areas or the earthquake-prone areas, these building materials will surely help your home to stand still for a long-term period. Visit https://www.srmbsteel.com/ for more information.

0 notes

Text

Why Binding Wire Quality Directly Impacts the Longevity of Dowel Bar Installations

In any well-carried-out infrastructure project, binding wire won't be the star; however, it is often the silent hero.

Tucked away from view, it quietly holds collectively vital additives like dowel bars and construction rings, appearing as a bridge between intent and execution. The pleasantness of this unsung fabric can be the difference between a structure that stands the test of time and one that fails when it is subjected to the most.

The Hidden Backbone of Reinforcement

At first glance, binding wire may also seem easy: just twisted steel tying two elements collectively. But in truth, it is a structural dedication. Especially while securing dowel bars, the wire must keep anxiety and form below steady strain, it from vehicular load, thermal expansion, or shifting subgrades. Inferior fine wires lose tension over time, which weakens the alignment of bars and reduces the efficiency of load switching among pavement slabs.

On large-scale production sites, especially on highways and airport runways, even a minor lapse in reinforcement balance can lead to catastrophic failures. Engineers understand this all too well, often, every time, every ring is subject. That’s why there’s no room for compromise on the subject of the material, keeping it all together.

The Real Cost of Using Low-Grade Wire

A dowel bar setup is only as reliable as the material that holds it in its vicinity. If binding twine corrodes early or becomes brittle, the alignment and anchorage of the dowel bars are compromised. This results in cracking inside the concrete, spalling, and eventually untimely failure of the slab. Once this happens, repair isn’t simply expensive—it’s disruptive and time-ingesting.

What’s more, terrible first-rate cord won't bond nicely with creation rings, especially in high-moisture or saline environments. The wire's gauge, tensile strength, and corrosion resistance directly affect how well it performs on-site Cheap twine may also keep some rupees in step with the package deal, but it often leads to primary structural problems that far outweigh any initial savings.

The Technical Perspective: Why Quality Matters

Highly exceptional twine is made from low-carbon metal and undergoes a particular annealing system. This makes it smooth enough to bend effortlessly but robust enough to keep its form beneath a load. Such traits are critical when used with dowel bars that want to stay aligned throughout the enlargement joints without lateral motion.

Properly annealed cord would not snap or flake at any point of twisting, which guarantees uniform tension throughout all creation rings and joints. It also resists rust better, preserving structural integrity even when exposed to water and competitive weather situations. For packages in coastal regions or industrial zones, this delivered resistance isn't always a bonus—it’s a need.

Trusted Materials Build Lasting Infrastructure

Every nice-aware engineer understands that infrastructure isn’t just about electricity; it’s approximately patience. From bridges and expressways to urban flyovers, the overall performance of dowel bars depends heavily on how they're tied and secured in place. And that protection starts off with the dependable binding cord.

In India’s rapid-paced creation atmosphere, in which timelines are tight and expectations are excessive, making an investment in the right substances could make or break a mission. Reputed suppliers ensure consistency in tensile power, diameter, and rust resistance. These are not minor technicalities—they may be fine checkpoints that immediately impact the structure’s lifecycle.

Final Thought

Precision in construction starts at the micro stage. The integrity of dowel bars, the alignment of production jewelry, and the very existence of a pavement slab rely on the quiet energy of binding cord. It won't shout for interest, but its effect speaks volumes through the durability of the very last shape.

#Binding Wire Uses#Dowel Bar Guide#Steel Wire Facts#Concrete Bonding#Wire for Dowel#Strong Wire Tips#TMT Binding Wire#Wire Impact Test#Durable Steel Wire#Bar Joint Safety#Wire Grade Check#Rust-Free Wire#Construction Wire#Rebar Tie Wire#High Tensile Wire#Steel Fixing Wire#Quality Wire Role#Long-Lasting Joints#Binding Wire Check#Secure Bar Ends

0 notes

Text

Budgeting for Road Projects: Dowel Bars, TMT, and More

In road construction, every rupee has a role. Overspend, and the project risks delays or downgrades. Underspend, and the result is premature wear, safety issues, and costly repairs. That's why budgeting must begin with a sharp focus on critical materials—especially dowel bars in road structures, the current TMT bar price, and the seemingly modest but vital binding wires.

These components aren’t just line items—they’re long-term performance indicators. Early alignment on their cost and quality can define the success or failure of a roadway. Understanding their role isn't just smart planning—it's good financial strategy.

Building Awareness: Why the Right Materials Drive the Right Budget

Roads aren’t just built—they’re engineered for decades of use. This longevity depends heavily on what’s beneath the surface. Dowel bars in road construction help distribute loads across joints, reducing cracking and wear. Skimping on these bars can lead to higher maintenance costs just a few years in. Budgeting for dowel bars isn’t an add-on—it’s foundational.

Equally crucial is tracking the current TMT bar price during estimation phases. TMT bars offer tensile strength and flexibility to handle dynamic traffic loads. Their prices can fluctuate with raw material availability, global steel demand, and transport conditions. Not accounting for these shifts early on can derail even the most accurate cost plan.

Then come binding wires—lightweight in appearance but indispensable for reinforcing cages and ensuring structural cohesion. Their usage touches every beam, slab, and support grid. Ignoring their cost or compromising on quality creates loose ends—literally and financially.

Consideration Phase: What Influences Cost, Durability, and Return on Investment

Planners often focus on big-ticket items, but seasoned contractors know that minor components can cause major budget variations. The current TMT bar price, for example, can shift weekly. Buying in bulk when rates are favorable or locking prices with suppliers can lead to significant savings across large-scale road projects.

When it comes to dowel bars in road designs, high-grade bars ensure smoother vehicle transitions and minimal joint failures. Their cost may seem steep at first glance, but the reduction in repair cycles makes them cost-effective over time. Using substandard or poorly aligned dowel bars might reduce initial spending, but the long-term implications—road closures, patchwork, and labor—are far more expensive.

Binding wires should never be an afterthought. Consistent gauge, flexibility, and corrosion resistance determine how well reinforcements hold through extreme temperatures and moisture exposure. Budgeting for higher-quality binding wires helps protect larger investments like TMT bars and dowel bars, acting as a safeguard against micro-failures that grow into macro problems.

Decision Time: Smart Sourcing for Sustainable Execution

Material choices speak louder than blueprints. Projects that prioritize the proper dowel bars in road builds show fewer disasters, smoother finishes, and lower lifecycle expenses. When choosing providers, the choice shouldn’t hinge totally on charge but also on consistency, traceability, and certification.

Price-aware doesn’t mean cutting corners—it means choosing wisely. Contractors and engineers who actively monitor the current TMT bar price can time their purchases to optimize budget efficiency without compromising quality. In today’s climate, where steel prices rise unexpectedly, that vigilance pays off.

Lastly, sourcing binding wires from reliable manufacturers ensures the integrity of the entire structure. Whether holding reinforcement cages together or locking mesh into place, these wires work quietly but critically in every joint, slab, and span.

Final Thoughts

A well-paved road doesn’t begin with asphalt—it begins with planning. By treating components like dowel bars in road structures, binding wires, and TMT bars as strategic financial entries—not just technical ones—contractors can protect both the project’s bottom line and its long-term performance.

Smart budgeting isn’t about spending less—it’s about spending right. And in road construction, the right spend starts beneath the surface.

#Road Budget Plan#TMT Bar Costs#Dowel Bar Use#Binding Wire Role#Smart Road Build#Budgeting Roads#Cost-Effective Roads#Highway Materials#Steel Cost Tips#Infra Cost Guide#Road Project Steel#TMT Price Trends#Dowel Bars Info#Road Build Hacks#Project Cost Plan#Steel in Roads#Site Cost Saver#TMT Planning#Roadwork Budget#Build Better Roads

0 notes

Text

How to Choose Reliable TMT Bar Manufacturers for Large Projects

Introduction

Large building projects might succeed or fail based on the choice of TMT bar manufacturers. The structural integrity and lifespan of buildings, bridges, and infrastructure improvements are directly impacted by the quality of these essential steel components, which serve as the foundation of contemporary construction.

Understanding TMT Bars and Their Role

TMT bars are a significant step forward in construction technology. In the manufacturing process, these steel bars undergo a complex process of rapid quenching and self-tempering, which creates a unique microstructure that combines a stronger outer layer with a ductile core. This unique composition makes them ideal for reinforced concrete structures, especially when paired with proper wire binding techniques.

The binding wire accompanying TMT bars supports in all ways while cementing. Quality binding wire materials prevent displacement and assure integration of a correct structure from the construction stage to its completion. Experienced contractors feel that even the best TMT bars need quality binding wire work to serve them well.

Key Consideration in Making the Right Choice

Manufacturing Capacity and Technology

First-class manufacturers of TMT bars invest in state-of-the-art production plants. Modern plants should have automatic quality control systems, precision cooling beds, and advanced testing laboratories. The manufacturing process should involve the latest metallurgical technologies to produce quality batches consistently.

Certification and Compliance

Look for manufacturers that have the necessary ISO certifications, and comply with national and international steel production standards. Their places of production must be audited regularly by third party auditors, and the products manufactured by them should have proper BIS (Bureau of Indian Standards) or equivalent certifications. These practices ensure that their binding wire and TMT bar products meet all the expected quality criteria.

Quality Control Measures

Good manufacturers ensure high-quality control systems at each production level. This involves:

Testing of raw material and checking for authenticity

In-process inspection in the manufacture process

Inspection of finished products for their mechanical properties

Regular calibration of test equipment

Record-keeping systems with traceability

Track Record and Market Reputation

Research into the manufacturer's reputation within the marketplace. Reputed manufacturers usually:

Holding significant experience in high-scale projects

A long-time partnership with most large construction firms

Good comment from engineering consultancy services

Excellent on-time delivery capabilities

Consistency of quality from one project to another

Technical Support and Service

Reputable TMT bar manufacturers can provide technical service as follows:

Product Specifications and Test Certificates

In-depth consultancy on engineering for particular applications

Guidelines on wire binding

After sales service and solutions

Periodic information about new product developments

Final Choice

Cost vs. Quality

Although cost is a vital factor, it shall not be the only determining one. The total cost of purchase shall be considered by taking into account:

Transport and handling cost

Wastage and other losses in construction

Risk mitigation value of good quality products

Maintenance cost in the long term

Impact on the project timeline and efficiency

Supply Chain Reliability

Evaluate the manufacturer's supply chain capabilities:

Production capacity versus project requirements

Geographic proximity to project site

Storage and inventory management systems

Transportation network and logistics expertise

Emergency response capabilities

Verification and Documentation

Before finalizing any agreement:

Request sample testing reports

Visit manufacturing facilities if possible

Check references from similar projects

Review quality control documentation

Verify compliance certificates

TMT bar manufacturers will be found with consistency in high-quality and reliability if these rules are followed and thorough diligence is conducted. Remember that the choice of manufacturer will have a setback impact not just during the construction phase but the entire life cycle of the structure. Selecting both the TMT bars and binding wire suppliers correctly ensures project success and structural durability for decades to come.

#TMT bar makers#steel rod guide#TMT quality tips#top TMT brands#binding wire#wire binding#steel bar buy#TMT bar choice#TMT price check#rod suppliers#best TMT bars#steel bar cost#TMT bar deals#TMT durability#rod manufacturers#bar selection#TMT for projects#binding tips#strong TMT bars#steel bar types.

0 notes

Text

Are You Paying Too Much? A Breakdown of 8mm Rod Pricing

Are you overpaying for something as basic as an 8mm rod? That’s a question many buyers never pause to ask. Yet, when the 8mm rod price per piece keeps fluctuating across suppliers, the difference could quietly chip away at your project budget. Most just accept the quote and move on — until the total cost starts to bite.

Why 8mm Rod Pricing Isn’t Always Straightforward

Pricing should be predictable, right? But in construction, it's anything but. Factors like raw material volatility, transportation charges, and even brand premiums can distort the actual value. The 8mm rod price per piece might look standard at first glance, but hidden variables often creep in. Some suppliers include wastage margins, others don’t. Then there’s the bundled cost of TMT saria and add-ons like Super Rings — and suddenly, the "great deal" doesn’t feel so great anymore.

What Are You Really Paying For?

Think about it. Two vendors offer what seems like the same 8mm rod. One is priced slightly higher, but includes corrosion resistance and better tensile strength. The other cuts corners, leaving you vulnerable in the long run. Now the cheaper rod doesn’t feel cheaper anymore — especially if it leads to structural weaknesses or replacements down the line.

That’s not just money lost — it’s time, safety, and peace of mind.

The Smarter Approach to Buying 8mm Rods

This is where the smarter buyers pause. Instead of rushing in for the lowest 8mm rod price per piece, they evaluate the entire product journey. How does the rod perform with the TMT saria being used? Is the binding quality of the Super Rings consistent across batches? Small decisions at this stage can echo through the entire project lifecycle — for better or worse.

The Cost of Reactive Purchases

Many end up making reactive purchases. A bulk order is placed under time pressure, and no one double-checks whether the material grade aligns with structural needs. Later, when cracks appear or alignment fails, the regret comes knocking. That’s the cost of ignoring the big picture.

A Surprising Parallel: Construction and Financial Planning

Now here’s an unexpected connection: this mindset shift isn’t limited to construction. It’s exactly how long-term financial planning works. Just like rushing to buy the cheapest rods, jumping into random investments without understanding their structure can be equally damaging.

That’s where tax-saving SIPs offer a smarter alternative. With a well-planned SIP, every monthly contribution works like a steady building block. It doesn’t just help save tax — it compounds into future gains, much like strong materials secure the integrity of a structure. There’s purpose, pacing, and long-term clarity. No guesswork. No last-minute panic.

The Role of a Certified Financial Planner

But how does one know which SIP is ideal? Or which combination leads to the best outcome?

Enter the certified financial planner. Much like a site engineer ensures rods, TMT saria, and Super Rings are aligned for maximum strength, a financial planner ensures investments, returns, and tax benefits are structured for optimal growth. They don’t just suggest where to invest — they guide when, why, and how much, making the difference between a scattered portfolio and a strategic wealth plan.

Conclusion: Proactive Choices Build Strong Futures

Both fields reward clarity. In construction, it saves you from rework and failure. In finance, it saves you from stress and shortfalls. It all comes down to being proactive instead of reactive.

So, the next time someone quotes an 8mm rod price per piece, pause before accepting it at face value. Ask what’s behind the number. Compare it not just with the price of TMT saria or Super Rings, but with the risks of compromise.

Because whether you’re building a home or a future, the real cost isn’t what you pay today — it’s what it becomes tomorrow.

#8mm rod price#rod rate today#TMT rod cost#steel rod price#8mm bar cost#TMT price list#rod pricing tips#cheap 8mm rods#buy 8mm rods#rod cost guide#steel bar rate#TMT rod rate#rod price check#rod cost India#8mm rod guide#latest rod rate#rod price today#TMT bar price#steel rod rate#bar price list

0 notes

Text

Why Binding Wire is Essential with TMT Bars in Concrete

When building bolstered concrete structures, TMT bars offer the critical tensile energy needed to withstand various structural stresses. However, these excessive-strength metal components don't work successfully in isolation—they require right fastening via binding wires to create the reinforcement cage that bureaucracy the spine of concrete systems. Let's explore why binding wires plays this type of critical function while running with TMT bars.

The Foundation of Reinforced Concrete

TMT bars (thermo-mechanically treated bars) have revolutionized contemporary construction with their superior electricity-to-weight ratio and extraordinary ductility. These steel reinforcement bars create the inner framework that lets in concrete to face up to anxiety forces. But clearly placing TMT bars into concrete isn't sufficient—they must be properly placed and secured.

This is in which binding twine turns into quintessential. This thin, annealed cord holds TMT bars collectively at their intersection factors, keeping the perfect spacing and alignment essential for structural integrity. Without the right binding twine utility, even the very best satisfactory TMT bars should shift in the course of concrete pouring, compromising the entire structure.

Critical Functions of Binding Wire

Binding twine serves several important functions while used with TMT bars:

First, it maintains the geometric configuration of reinforcement cages. By securing TMT bars at their junction factors, binding wire guarantees that the spacing between bars remains constant during the concrete pouring and curing system.

Second, binding twine prevents displacement of TMT bars in the course of concrete placement. The vibration and stress from pouring concrete can motivate unsecured bars to shift from their supposed positions, probably growing vulnerable points in the structure.

Additionally, binding cord enables the advent of complex reinforcement patterns. Modern production frequently calls for complicated arrangements of TMT bars, which might not be possible to preserve without proper binding.

Super Rings: Enhancing Binding Efficiency

For large construction projects using vast quantities of TMT bars, Super Rings have ended up becoming increasingly famous. These pre-shaped binding cord coils substantially accelerate the tying system while ensuring steady tension across connection points.

Super Rings are particularly designed for compatibility with TMT bars of numerous diameters. Construction professionals respect how Super Rings lessen exertion time while preserving first-rate binding. The uniform application provided with the aid of Super Rings additionally enables the elimination of human error that might arise with guide binding wire utility.

Quality Considerations for Structural Integrity

Not all binding cord performs similarly while securing TMT bars. Low-excellent binding cord may additionally corrode upfront, probably contaminating the encircling concrete or even causing enlargement that cracks the shape. Quality binding twine should possess sufficient tensile energy to maintain tight connections among TMT bars without breaking in the course of construction sports.

Similarly, well-synthesized Super Rings make certain regular binding tension throughout all connection points. This uniformity contributes extensively to the overall structural integrity while running with TMT bars in important load-bearing elements.

Making Smart Material Choices

Selecting appropriate binding twine primarily based on the precise requirements of TMT bar installations can pay dividends in structural longevity. For outside or corrosive environments, galvanized or PVC-covered binding cord offers advanced safety. Standard annealed wire may also suffice for indoor structural elements where corrosion concerns are minimal.

The modest cost of quality binding twine and Super Rings represents a trifling percent of average construction budgets, yet their effect on structural integrity is big. Cutting corners on these critical components while operating with premium TMT bars without a doubt would not make financial sense given the capability and long-term consequences.

Smart builders apprehend that the interplay among TMT bars and binding cord basically influences concrete structure overall performance. Making knowledgeable picks about these substances ensures homes stand the test of time.

#binding wire#TMT bars#concrete reinforcement#structural integrity#construction tips#TMT bar benefits#binding wire uses#reinforcement cage#TMT bars and wire#building strength#concrete structures#quality binding wire#Super Rings#TMT bar installation#construction materials#binding wire types#wire for TMT bars#concrete strength#durable binding wire#TMT bars in concrete#construction efficiency

0 notes

Text

TMT Bars vs. 8mm Rods: Which Is the Better Choice for Your Construction Project?

TMT bars shape the spine of cutting-edge creation initiatives, supplying the critical tensile energy wished for in bolstered concrete structures. When planning a construction assignment, deciding between special reinforcement alternatives can appreciably impact both structural integrity and finances. This manual examines the key differences between preferred TMT bars and 8mm rods to assist in making knowledgeable selections in your subsequent building undertaking.

Understanding Reinforcement Basics

Construction reinforcement serves because the skeleton inside concrete stops cracks and disasters while bearing hundreds of tons. Different diameter alternatives serve various purposes in the same shape, from foundation paintings to column guides.

The manufacturing manner for these metal reinforcements entails careful thermal treatment that creates a hard outer layer while maintaining a tender, ductile middle. This aggregate grants both electricity and flexibility—vital qualities for earthquake-resistant and durable structures.

Strength Considerations

The number one distinction between diverse reinforcement options lies in their load-bearing ability. Larger diameter bars certainly offer extra energy; however, this doesn't always mean bigger is better.

For residential projects like small homes or boundary walls, 8mm rods frequently offer sufficient reinforcement. The 8mm rod rate in step with the piece normally tiers between 30-45% less than larger options, making them economically attractive for appropriate programs. However, those financial savings ought to be weighed against structural requirements decided by using engineering specifications.

For multi-story homes, commercial structures, or regions with seismic activity, heavier reinforcement becomes important. Here, the preliminary savings from deciding on smaller-diameter reinforcement might create substantial long-term risks.

Application Versatility

Different reinforcement diameters serve precise functions in the equal challenge:

Foundation work generally calls for heavier reinforcement.

Columns and cargo-bearing partitions need carefully calculated reinforcement based totally on structural hundreds.

Slabs and non-load-bearing factors may use lighter options, which include 8mm rods.

Binding wires plays a crucial role in securing those reinforcements nicely throughout the setup. Quality binding wire guarantees the metallic framework keeps proper spacing and alignment before concrete pouring. Construction professionals advise using galvanized binding wire to prevent rust and corrosion, in particular in humid environments or uncovered regions.

Cost Analysis Beyond Purchase Price

While the 8mm rod price in keeping with the piece gives immediate financial savings, experienced builders keep in mind the entire task's economics:

Material amount necessities (smaller diameters can also require extra pieces.)

Labor expenses for setup (more pieces suggest more binding points)

Binding wire consumption (directly proportional to the variety of intersection points)

Long-term period upkeep considerations

The binding wire fee, though reputedly minor, adds up in large tasks. Proper estimation of binding wire wishes prevents mid-undertaking delays and price range overruns. Most professionals calculate binding wire necessities at approximately 8-10% of the entire reinforcement weight.

Making the Right Selection

Technical specs from structural engineers always have to include manual reinforcement alternatives. However, expertise in those primary differences allows for making plans and budgeting successfully.

For structural elements with higher load necessities, standard TMT bars in larger diameters remain the desired preference.

For lighter applications, the 8mm rod fee in keeping with the piece gives compelling value.

Always factor in binding wire and setup costs while comparing alternatives.

Regional availability additionally influences pricing. Metropolitan areas typically offer more competitive pricing because of decreased transportation costs and greater provider opposition.

Quality Assurance Matters

Regardless of diameter desire, exceptional verification stays essential. Legitimate suppliers offer a look at certificates confirming the steel meets strength and flexibility requirements. Substandard reinforcement, regardless of diameter or fee benefit, creates full-size protection risks.

Construction specialists suggest purchasing TMT bars and binding wire from setup providers with the right certification and fine management tactics. The small premium paid for excellent materials represents coverage towards structural screw-ups and highly priced remediation.

#TMT bars#8mm rods#construction materials#building materials#steel rods#TMT vs 8mm#TMT bars cost#8mm rod strength#building construction#construction steel#material comparison#steel reinforcement#8mm rods uses#TMT bars benefits#rod strength#best construction rod#TMT for buildings#steel for construction#durable rods#construction quality#cost-effective rods.

0 notes

Text

The Strength Behind Your Success – SRJ HR Coils

TMT bars constitute the important foundation of cutting-edge production, serving as the skeletal guide that transforms architectural visions into tangible, enduring systems. At the coronary heart in their structural integrity lies an often overlooked hero: exceptional binding wire—the critical element that determines the actual resilience and longevity of construction tasks.

Construction experts apprehend that TMT bars are a long way more than simple metallic rods. These specialised bars are engineered to provide fantastic electricity, superior corrosion resistance, and extraordinary structural guidance. Their unique thermomechanical treatment method creates a strong outer martensite layer with a softer, more ductile middle, making them the favoured choice for crucial infrastructure initiatives.

The Science Behind Structural Reinforcement

The performance of TMT bars extends beyond their inherent characteristics. Binding wire plays a crucial role in creating a unified, stable reinforcement framework that:

Ensures precise bar positioning

Distributes load evenly across structural elements

Prevents concrete cracking

Enhances the bond between concrete and reinforcement

Provides additional structural stability

Binding Wire: The Unsung Hero of Structural Integrity

The quality of binding wire can make or break a construction project. Low-quality wire introduces significant risks that can compromise entire structures:

Premature structural deterioration

Reduced load-bearing capacity

Increased vulnerability to environmental stressors

Potential safety hazards

Economic Considerations: 8mm Rod Price Dynamics

When evaluating the 8mm rod price per piece, contractors must look beyond immediate cost savings. The seemingly attractive 8mm rod price might tempt budget-conscious projects, but the long-term consequences of inferior binding wire can be catastrophic:

Exponential maintenance costs

Potential structural repairs

Reduced building lifespan

Compromised safety standards

Experienced professionals recognise that the 8mm rod price is an investment in structural longevity, not merely an expense to be minimised.

Technical Deep Dive: Binding Wire's Critical Performance Metrics

Professional-grade binding wire transforms TMT bars from individual components into a comprehensive reinforcement system. Key performance indicators include:

Tensile strength exceeding industry standards

Superior corrosion resistance

Optimal ductility

Consistent diameter and composition

Enhanced bonding capabilities

Real-World Impact of High-Quality Binding Wire

Construction experts have documented remarkable improvements with superior binding wire:

Up to a 20% increase in structural load-bearing capacity

Extended structure lifespan by multiple decades

Significant reduction in maintenance requirements

Improved resistance to environmental degradation

Selecting the Right Binding Wire: A Strategic Approach

Choosing binding wire is a complex decision that requires comprehensive evaluation:

Material Composition: High-carbon steel with precise metallurgical properties

Corrosion Resistance: Advanced protective coatings

Tensile Strength: Certified performance metrics

Dimensional Accuracy: Consistent diameter and flexibility

Workability: Easy manipulation during construction

Industry Standards and Quality Assurance

Professional-grade binding wire must meet rigorous quality standards:

ISO certification

Compliance with national construction regulations

Independent laboratory testing

Traceability of manufacturing processes

The Holistic Impact of Binding Wire Selection

Beyond technical specifications, binding wire selection reflects a commitment to:

Structural safety

Long-term performance

Economic responsibility

Professional excellence

Economic and Safety Implications

The consequences of binding wire selection extend far beyond initial costs:

Potential legal liabilities from structural failures

Reputation risks for contractors and developers

Long-term economic impact on infrastructure projects

Public safety considerations

Making an Informed Investment in Structural Excellence

Selecting high-quality binding wire for TMT bars transcends a simple purchasing decision. It represents a strategic investment in:

Structural integrity

Public safety

Long-term economic sustainability

Professional reputation

Professional construction demands nothing less than the highest standards of material selection. From skyscrapers to bridges, from residential complexes to critical infrastructure, the quality of binding wire determines the difference between a structure that merely stands and one that truly endures.

Professionals understand that every component matters. They choose binding wire that transforms good construction into exceptional engineering—a testament to human ingenuity and technical precision.

#Kapila Steel#Binding Wire#TMT Bars#Steel Wire#Wire for TMT#Strong Binding#Structural Wire#Construction Wire#Reinforcement Wire#TMT Support#High-Tensile Wire#Durable Wire#Steel Ties#Rebar Binding#TMT Reinforcement#Wire Strength#Secure TMT Bars#Binding Solutions#Industrial Wire#Quality Steel Wire

0 notes