#basic types of diode

Explore tagged Tumblr posts

Text

Diode Testing...

#jaipur #phone #iphoneonly #iphone #iphonex #iphone7 #repairing #institute #jaipurblogger #phonerepair #phonecamera #diode #mobicationhub #mobilerepairinstitutepatna #mobicationhub📞9509959090 #motherboardrepair

#diode#diode testing#zener diode#diode working#how to test diode#diodes explained#how to test diode with multimeter#diodes#how to test a diode#diode types#diode test#how to test diode in circuit#schottky diode#testing of diode#how to check diode using multimeter#uses of diode#how to check diode with multimeter#types of diode#types of diode in hindi#types diodes#how to check diode#pn junction diode#types of diodes#basic types of diode

0 notes

Text

cant stop thinking about thisstupid show concept me and a few others came up with so im gonna freakinh RANT about it!!!!!

welcome to my fucked up evil The Badly Done Object Show post!!!!!

me and @frostealeef and @apology-of-paradise and @elyne0-0 all made these little freaks together with the power of friendship <3

this is gonna be a long post with a lot of drawings so uh. whatever go my read more

team 1 - the shrimp wimps

left to right - waypoint, airhorn, batty, raspberry cheesecake, mask, animal scale, microscope slide, boombox, pomegranate, scythe

DIODE IS ALSO ON THIS TEAM BUT I FORGOT!!!! :(

i think their personalities show pretty well thru this drawing im proud of it :3

animal scale was originally a little personality chart thing that @apology-of-paradise made!! somehow made into an object oc... the silly

team 2 - the lobster monsters

left to right - spine, tragedy & comedy, painty, camcorder, star wand, name tag, beetle jelly, scribble, water wiggler, coffee cup, ink vial

this team has the most contestants made by me with technically 4!! but comedy and tragedy only count as a single contestant in the game..

their host is plastic mic, a young god who has been given a group of souls to toy around with and figured "hey why dont i put these bitches on a game show!!"

though plastic mic doesnt recognize them, star wand is an angel who had to be silenced as to not tell the regular objects about. yknow. Heaven

this show doesnt have much of a plot yet just characters... BUT there r some cool ideas and little fun facts done so far

the first ever challenge is a fishing challenge!!! whichever team does the best is deemed the Lobster Monsters, and the worst team is the Shrimp Wimps

the recovery center is a jack in the box that characters pop out of!! there is a chance that they can come back flawed... usually flawed contestants end up almost as an opposite to their usual personalities, but sometimes they can come out. uh. we dont talk about that

scribble can go onto any type of paper ish object, possessing it and controllijg it!! which includes name tag, scythes bandages(which i confused for a scarf in my og drawing. sorry...), and coffee cup :3

animal scale can mimic voices...

ink vial and painty r sisters!!!!

ALSO ALSO we have made a lot of little info posts in discord that i dont wanna retype so screenshot time (click for full images :()

holf is frosty gay ligigi is me and keysmash name is kira... elyne is elyne

ALSO WE GOT YAOI IN THIS SHOW. SO IMPORTANT.

anyways uhhfnfmgmcn yeah.... rant post with basically all the info we've came up with for this show... may be updated as we figure out more.... go my fanart

+ plastic mic design i couldnt fit it when i mentioned them

12 notes

·

View notes

Text

Light Bars vs. LED Light Bars: What’s Best for DJs and Stage Setups?

Lighting plays a defining role in shaping the experience of a live event. Whether managing energy on a dance floor or setting mood transitions in a performance venue, lighting bars have become essential tools in both stage and DJ setups. But there’s often confusion between traditional light bars and LED light bars—two fixtures that might look similar, yet perform very differently.

This article outlines the differences, use cases, and practical considerations to help identify which type of fixture works best in real-world applications.

Contrasting lighting in action: Traditional light bars offer warm ambiance, while LED bars deliver color-driven dynamics.

Understanding the Two: What Makes Them Different?

The term “light bar” has evolved from its original meaning. Traditionally, it referred to long linear fixtures using halogen or fluorescent lamps—tools commonly used in theatres, early live productions, or static wash lighting.

By contrast, LED light bars represent a modern take on the same format, built with energy-efficient diodes and designed for color mixing, pixel control, and dynamic effects. Their rise in popularity has coincided with the growth of compact stage setups, digital control systems, and mobile DJ rigs.

Today, both versions still have a place in the lighting world, but LED variants have become the go-to for setups requiring more than just basic illumination. They’re now widely available through professional Audio Video supply stores that serve live production, education, and entertainment sectors.

Output Capabilities: Warm Wash vs. Programmable Effects

Choosing between the two often starts with the kind of visual atmosphere you need to create.

Traditional light bars emit a warm, consistent glow. They’re suitable for soft fills or mood lighting but lack adaptability unless fitted with gels or combined with dimmers.

LED light bars offer integrated RGB or RGBW color mixing. That means quick transitions, color cycling, and visual movement with minimal effort. Many models also include sound-activated and chase modes, offering automated visuals that respond to music or timing cues.

LED bars are frequently used in DJ booths, club ceilings, and truss setups, especially when motion and color variety are part of the visual experience.

Control and Integration

Older light bars rely on analog control—on/off switching or standalone dimmers. While functional, they offer limited interactivity.

Modern LED bars, however, support DMX protocols, giving users complete control over color, brightness, speed, and timing through lighting desks or software platforms. They can be incorporated into multi-fixture scenes, respond to preset programs, or be used in sync with sound sources in real time.

When designing a setup that requires coordination between audio, video, and lighting elements, fixtures compatible with stage lighting control systems streamline programming and ensure more consistent results.

Installation and Power Efficiency

Another key advantage of LED fixtures lies in their portability and power draw.

Traditional bars consume more electricity and generate heat, which can be a concern in tightly packed venues or portable rigs. They also tend to be bulkier and heavier, requiring more hardware for safe mounting.

By contrast, LED bars are lightweight, efficient, and often daisy-chainable, allowing for both power and signal to run across multiple units from one source. This is particularly helpful in compact venues, where circuits may be shared with sound and video gear.

Fixtures designed for quick deployment and efficient cabling are now a staple across many audio-visual equipment sellers , especially those serving mobile DJs and touring techs.

Durability and Maintenance

Reliability is always a concern in live environments. Traditional light bars use bulbs or tubes that are prone to breakage or burnout over time. Regular maintenance is required, especially during transport or frequent setup.

LED bars are built with solid-state components and are far more resistant to shock and movement. With lifespans measured in tens of thousands of hours, they’re often chosen for applications where maintenance access is limited or downtime must be avoided.

When evaluating durability for recurring events, look for fixtures listed under professional stage lighting gear, where features like rugged casings and tour-friendly designs are common.

Practical Applications

DJs and Performers

LED bars are ideal for DJ booths and mobile rigs. They can be mounted above, behind, or alongside the performer to enhance visual energy. Sound-active modes also allow these bars to sync with beats and transitions without needing a dedicated operator.

Venues and Clubs

Smaller clubs or multi-use halls benefit from LED bars due to their low power demands and mounting flexibility. Even a few fixtures placed strategically can transform a flat room into a performance-ready space with dynamic light coverage.

Theatrical Use

Traditional bars still find use in theatres where consistent warm wash is required. However, LED fixtures can now replicate those tones digitally, offering the same ambiance with added control and energy savings.

For mixed-use stages, combining older light bars for soft fill and LED versions for movement effects can strike a balance between mood and adaptability.

Pixel Control and Design Freedom

More advanced LED bars offer pixel mapping, allowing each segment of the fixture to be controlled independently. This opens up creative design possibilities like chasing sequences, animated waves, or pulsing accents—all from a single unit.

While not essential for every event, pixel control can elevate lighting design from simple color changes to layered visual storytelling. These features are increasingly found in fixtures within the DMX-controlled lighting categories commonly supplied by full-service Audio Video shops.

Ease of Use in Quick Turnaround Setups

In fast-paced environments like weddings, one-nighters, or short changeovers, speed matters. Many LED bars come with auto modes, built-in programs, or wireless remotes. These simplify setup while still offering engaging effects.

Combined with power efficiency and long LED lifespan, these traits make LED bars a go-to for situations where setup time is limited but performance quality must remain high.

LED light bars are being configured for an event setup, offering control, reliability, and efficient power management in dynamic venues.

Final Thoughts

Both light bars and LED light bars have roles in today’s live production landscape. Traditional fixtures continue to serve specific functions in stage design, but LED bars are now the preferred choice for flexible lighting design, energy savings, and control integration.

For those designing systems around DMX, compact rigging, or mobile use, LED light bars offer unmatched versatility. They’re compatible with the broader ecosystem of control surfaces, rigging hardware, and accessories typically found at specialty pro audio and lighting stores serving the live event and production industries.

#audio video installation#audio video stores#DJ#Dj lightings#DJ set up#Events#Pro audio equipment's#Pro audio shop#Pro audio gears#Professional Audio#Dj equipment's#dynamic led#static lighting

2 notes

·

View notes

Text

AM-Detection -the not easy way

Sometimes quite simple things can be a real nightmare if you take a closer look. One of those is AM detection. Your worst enemies are distortion and fading (the latter results in the first). The AM-Detector is only one little part in a receiver, exactly that kind of part usually no one thinks about. "It works, so what should be wrong with?" -a lot and sometimes there's more wrong than right.

A good part of that distinctive AM-Sound we all know is because of the Detector, even under the best conditions. If you're listen to shortwave or the broadcast band during the night then you also have to cope with Fading. Shouldn't be that problem, the automatic gain control takes care of that, right? Ehmmm... Yes. Sometimes. Why the sound gets so distorted when the signal goes down? Just because it's very often 'Selective Fading' and not just Fading -and your Detector doesn't like it.

Really good AM-Reception has a lot in common with High-End-Audio: if it shall work well EVERYTHING has to be well. So let's just talk a bit about Detectors...

Basically the Detector just splits the Audio Signal from the received and amplified Signal. Sounds easy and in fact it is -up to some degree. If you want more than this things getting complicated -really complicated. In at least 999 out of 1000 AM-Receivers for the Detector a small circuitry called 'Envelope Detector' is used, it's just a small Diode (Tube or Semiconductor), a few Resistors and small Capacitors. So, from the view of the Development Engineer: just put half a dozen cheap Components together and Bob's your Uncle. To tell the Truth: compared to the expense that thingy works surprisingly well. Because of this it's the 'Gold Standart' for this task since at least the mid 30s. But as good as it is, it absolutely has it's Limitations. Up to about 15...30% Distortion at a 100% Modulation Level is one, the inability to detect a signal with different sidebands (>selective Fading!) properly another.

To overcome these Limitations a thing named 'Synchronous Detector' was developed many Decades ago. This kind of Circuit has many advantages over the Envelope Detector, but to make one the complexity and the component count of those is just hilarious compared to the Envelope Detector. If only the result counts and nothing else: that's the way to go. We'll talking later how this exactly works, but before this you have to know that in a receiver with a Synchronous Detector also an Envelope Detector is needed: just for tuning in. So first we'll have a closer look how we can get the most ideal Envelope Detector.

Basically it's quite simple: want to have low overall Distortion? Feed it with at least 'a few' volts RF at it's input for having a high ratio between the input voltage and the 'forward voltage' of the Diode. Want low Distortion at low modulation levels? Use a Diode with low Impedance and a load Resistor with a value as low as possible. Want low Distortion at high modulation levels? Just make the input Impedance of the following Stage as high as possible for having the highest possible Ratio between the Resistance of the Load Resistor and the input Impedance of the following Stage.

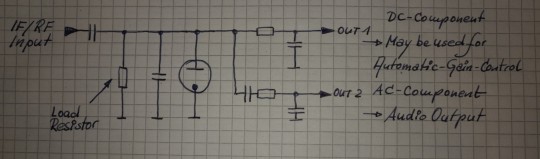

The Receiver i wanted to use (R+S EK07) has an IF output, meant for exactly such things, the IF Level there's about 250mVpp @ 300kHz. So having everything above in mind -and just adding a 700mVpp IF output for the Synchronous Detector and an additional AGC-Circuitry, then we're coming to this:

The EK07 is a fully tube equipped receiver, so i also want to use tubes as far as possible and -like in the EK07- in a way which guarantees 10k's of Service hours. If at one point a Semiconductor may perform muuuch better -ok, so then. First of all i want high performance. So what tubes may perform optimal here?

For the first IF-Amp (IF1) not much is needed, the Gain is only about 3, the output voltage low and besides that it has to be an remote-controlled type. Selectivity isn't needed or desired, so no IF-Can, only a Broad-Band setup. Nearly every IF-Tube with a Transconductance of at least about 3000mhos (3mA/V) would do that job. To have better performance i took the EF805s, which is a Special Quality Version of the EF85 -or 6BY7.

Transconductance is about twice what's needed, so we'll have Gain to spare, anyway, it's getting controlled with the AGC so it will work with less current which adds greatly to the service life. So no problems here.

For the second IF-Amp (IF2), things aren't exactly that easy. First: the output for the Synchronous Detector is placed between both Amps and has to deliver a constant voltage, so for the 2nd IF we need an Amplifier with an fixed Gain. A STABLE fixed Gain over long time periods. Further we want to have a relatively high and undistorted output voltage which calls for quite a bit of gain. Wait: there was also that thing with the low-value Load Resistor in the detector itself -so we also need a quite reasonable amount of output power from this stage. In Addition we want to have a stable gain for a time as long as possible. A IF-Tube like the EF805s could also handle this, but then we have to 'beat the crap' out of this thing. Not a good start for a long and stable service life, also not with Special Quality Tubes.

Because of all that my choice was a kinda 'special'-Special-Quality type: the E81L.

The datasheet calls this a 'Long range, Special Quality Tube for the use in Telephone Equipment'. Telephone Equipment? Like an answering machine?? Nope, by far not. Back in these days telephone companies needed to have Amplifiers for pushing the calls through loooong cables for long range service. But: this was all multiplex service, so they pushed dozens and dozens of calls simultaneously through one pair of wires or a Coax. The same way like for cable TV. THIS was these bulbs were meant for. For this task every company employed tens of thousands of such tubes 24/7/365. If a single one failed -most likely somewhere in nowhere of course- they had a problem. So they absolutely had to last.

These little bulbs are designed for about 4.5W plate dissipation at 20mA, the Transconductance is 11000mhos (11mA/V)-so it's about twice an usual IF Tube in every respect. So that's exactly what's needed here: a tube especially designed to last, quite powerful, so we can drive it with comfortable low settings, enhancing service life and stability much further.

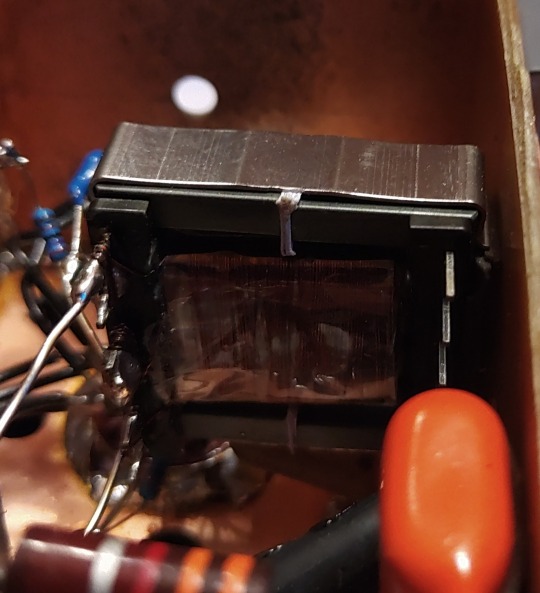

Because we need some amount of power the usual Broad-Band Amplifier arrangement (still: selectivity is not wanted or desired) with just a plate Resistor isn't good here, a suitable inductor works way better here. This has the further advantage that we can build it with a Tab like an Autotransformer -we don't need that much voltage it could deliver with that inductor by far, so this adds further to a good SNR and lower output Impedance. 300kHz trough a transformer? Yep, no problem. Just use the right core. Here it's not a laminated iron core but a ferrite one instead. Cause it's a single-A Amplifier of course we must add an air-gap, preventing saturation.

In a penthode stage the gain depends nearly exclusively on the Transconductance of the tube used, have to much just cut it down. The E81L has a quite high transconductance, about 3 times more than needed -and in the same order than big output tubes like the 6550, EL34 or 6CA7. For cutting that down to the desired level just put a Resistor or Pot in series to the bypass cap of the cathode Resistor. This acts as an series feedback so it also enhances linearity and long time stability greatly. Yap, i thought quite a while about which tube i should use here.

So after all Amplification is done now, we need a Diode for the Envelope Detector. Back in the Octal-Days this was the 6H6 / EB34, later in the Miniature-Days the 6AL5 / EAA91, both with two separate diodes in one bottle (or Can for the 6H6). These were not A DIODE, these were THE DIODE, so there's not much to choose from. Both are kinda close to each other, but are these ideal for what we want? They both can handle a reverse voltage of several hundreds of volts, so waaaay more than we need here. Both having a Plate Resistance of 600-something Ohms per System which is quite low -could be lower, even with both Systems in parallel. Of course these would be work well, no doubt about. But still.... Hey, this should be High-end so we're whining here at a very high level!

Basically we can use EVERY TUBE as a diode: just take the control grid as Anode, the Cathode as what it is and everything else as Shielding. We don't need hundreds of Volts reverse Voltage, nor high current, so also no big Cathode. We only want to have an internal Resistance as low as possible, so a close spacing between the Grid and the Cathode. This calls for a small Tube with a high Gm (or Transconductance) -like the 6AK5 / EF95. Can it handle the reverse voltage we need? Datasheet says 50V, so at least twice of what's needed. So just take one, put some current trough and take the voltage drop. Result: 210 ohms -way less than that what one of the double-diodes would provide, even with both Systems in parallel. Fits very well!

This is the soviet-military version of the 6AK5W / E95F. Special Quality. See these 'trenches' in the bulb? And the microscopic rivets holding the Plate together? The Soviets literally ruggedized the heck out of this tube! Why? Just because they used it widely in their Fighter Planes, ICBM's, Tanks and so on. Doubts about the soviet built quality? Hey, they wanted to win WWIII with them -so: nope. If you ever saw a ruggedized tube: this it is.

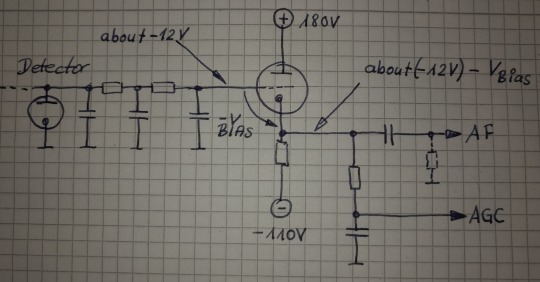

After the Detector itself is done, we come to last part of our little contraption: the buffer Amplifier. At the output of the Detector we have the AF as well with the overlayed AGC-Voltage and we want to have an input Impedance as high as possible for the Buffer Amp. Voltage Gain isn't needed -we have plenty of both from the Detector- so we just can use a Cathode Follower for the buffer. Ideally the Buffer should handle both voltages simultaneously, but then the output will be negative with respect to Ground. How to....? Simple: just put that thing between a positive and a negative supply rail. Then the output can swing freely between every positive or negative Potential as desired. Further: we don't need a Grid Resistor! The Grid just follows any voltage swing of the Detector, this also adds to a high input Impedance.

This Circuit will provide us a very high input Impedance, but this is High-End! So: what tube will be the best for? Because of the lack of any Grid Resistor the input Impedance depends now largely on the contact potential of the grid. So we want a tube with low contact potential which calls for a tube with a low Transconductance. Further we want a tube which needs only a low bias voltage for it's Grid, 'cause we'll loose any bias-volt in our AGC-Output voltage. This calls for a tube with an high Gain. Low contact potential and low Transconductance? High Gain?? That's the 12AX7 / ECC83! Ok, it's of course a double Triode, but we still can use the second system for something else -like for the Line-Output Amp. In that Stage there's not much needed so it also will perform well enough there -we're still talking about AM!

So let's put everything neatly together, adding adequate shielding and so on -and we get this:

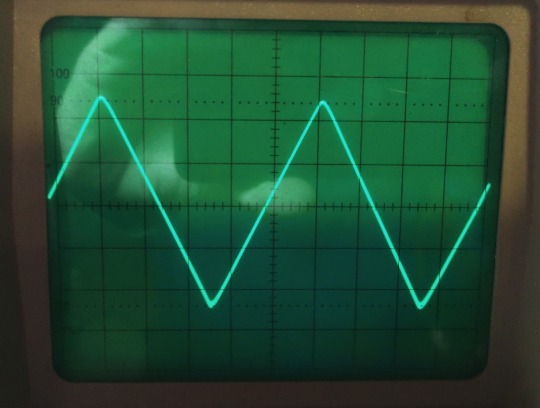

So now it's time to have a closer look we did everything right. Just put a 300kHz-Carrier in, 100% modulated with a triangle-signal. We should get a perfect Triangle at the AF-Output -if physics are with us. Due to the Triangle Signal any Distortion can easily be spotted on the Scope.

Looks promising! But somehow... Is the beam defocused? Let's take a very close look:

No, it's not. Those are just the very small remnants of the Carrier, so we actually have a look how the Detector works on a nearly 'microscopic' Level. I could take a measurement how much distortion we have left, but the Flanks of the Triangle are perfectly straight, so the Distortion will be really small -like 1% or so worst case. At least for the moment it's not worth the Effort. Compared to the usual 15...30% Distortion at a 100%-Modulation level this works really well, there's no doubt about.

So finally: we wanted to have a Envelope-Detector as good as possible and here we are. Ok, tbh it's better than needed, cause finally the REAL Detector will be a synchronous one. So why i took this that far? Easy: because of mental peace. Now i never have to think about if that part of the whole final thing could work better. As i said before: it's High-End.

Will update you if the next module is ready. But i fear this here was just the more easy part of the whole thing. From now on things may get a bit more tricky...

3 notes

·

View notes

Text

Notes on Class 12 Physics Semiconductor Electronics: Materials, Devices and Simple Circuits

Introduction to Semiconductor Electronics: Materials, Devices, and Simple Circuits

Semiconductor electronics forms the backbone of modern technology, revolutionizing communication, computing, and countless other fields. This branch of physics deals with the study of semiconductor materials, devices, and their applications in electronic circuits. Semiconductors, such as silicon and germanium, play a pivotal role due to their unique properties, which lie between those of conductors and insulators.

In this study, we explore the intricate workings of semiconductor devices like diodes, transistors, and integrated circuits. These devices enable the manipulation, amplification, and regulation of electronic signals, essential for powering electronic gadgets, processing information, and controlling machinery.

Through understanding semiconductor physics, device operation principles, and circuit design techniques, we embark on a journey to comprehend the intricate world of semiconductor electronics. This knowledge not only forms the foundation for advanced studies in electronics but also empowers us to innovate and contribute to the ever-evolving landscape of modern technology.

Here are some notes on Class 12 Physics Semiconductor Electronics: Materials, Devices, and Simple Circuits:

Introduction to Semiconductor Physics:

Semiconductors are materials with electrical conductivity between that of conductors and insulators. Examples include silicon (Si) and germanium (Ge).

Intrinsic semiconductors are pure semiconductors with equal numbers of electrons and holes.

2. Extrinsic Semiconductors:

Doping introduces impurities into semiconductor crystals to modify their conductivity.

N-type semiconductors are doped with materials that increase the number of free electrons.

P-type semiconductors are doped with materials that create electron-deficient holes.

3. PN Junction Diode:

A PN junction diode is formed by joining a P-type semiconductor with an N-type semiconductor.

It allows current to flow in one direction (forward-biased) and blocks it in the other direction (reverse-biased).

Characteristics include forward and reverse biasing, breakdown voltage, and diode equation.

4. Diode Applications:

Rectification: Converting AC to DC using diodes in half-wave or full-wave rectifier circuits.

Clipping and Clamping: Limiting voltage levels in electronic circuits using diodes.

Voltage Regulation: Stabilizing voltage levels using Zener diodes.

5. Transistors:

Bipolar Junction Transistor (BJT) and Field Effect Transistor (FET) are common types.

Transistors amplify or switch electronic signals and can be used as amplifiers, switches, or oscillators.

6. Transistor Configurations:

Common emitter, common base, and common collector configurations for BJTs.

Common source, common gate, and common drain configurations for FETs.

7. Transistor Amplifiers:

Amplifier circuits use transistors to increase the amplitude of electrical signals.

Common emitter and common collector configurations are commonly used for amplification.

8. Logic Gates:

Basic building blocks of digital circuits that perform logical operations (AND, OR, NOT, etc.).

Implemented using transistors to process binary inputs and produce binary outputs.

9. Integrated Circuits (ICs):

ICs are miniaturized electronic circuits fabricated on a single semiconductor chip.

Types include analog ICs (op-amps, voltage regulators) and digital ICs (microprocessors, memory chips).

10. Simple Circuits:

Basic electronic circuits incorporating semiconductor devices like diodes, transistors, and ICs.

Examples include amplifiers, oscillators, timers, and voltage regulators.

Understanding semiconductor electronics is essential for various applications in modern technology, including computers, telecommunications, and consumer electronics. These notes provide a foundational understanding of semiconductor materials, devices, and circuits, laying the groundwork for further exploration in the field of electronics.

1 note

·

View note

Text

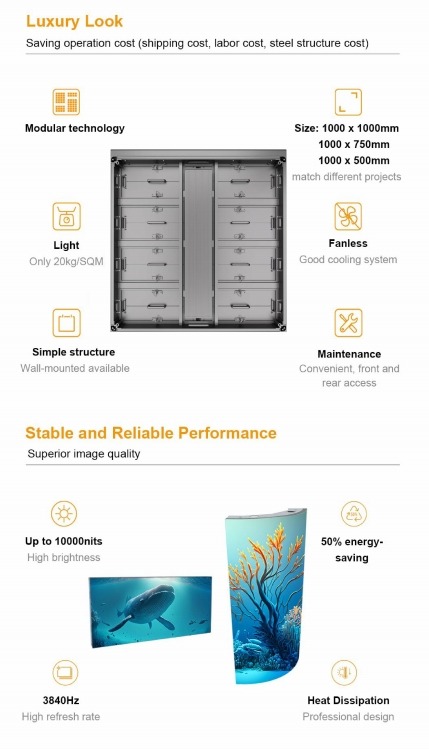

LED vs LCD Video Walls: Which One Should You Rent for Your Event?

When planning an event—whether it's a corporate conference, trade show, concert, or product launch—visual impact matters. That’s why more event organizers are turning to video wall rental for event setups to deliver high-quality visuals, real-time content, and immersive branding.

But one big decision still needs to be made: Should you rent an LED or LCD video wall? Both technologies have their strengths, and the right choice depends on your event type, venue, and budget. Here's a breakdown to help you decide.

Understanding the Basics

LCD Video Walls use multiple high-definition panels (similar to TVs) placed side by side. They offer sharp resolution but have visible bezels between screens.

LED Video Walls use light-emitting diodes to create a seamless, bezel-free display. They are modular and scalable, ideal for larger or irregular formats.

1. Visual Impact and Seamlessness

If you're aiming for a smooth, uninterrupted visual experience, LED video walls are the clear winner. Their bezel-free design creates a seamless screen, perfect for large-format visuals, dynamic presentations, and immersive environments. LCD video walls, while crisp, do have visible gaps (bezels) that may break the visual flow—especially noticeable in graphics and videos.

Best for impactful, uninterrupted visuals: LED

2. Brightness and Viewing Conditions

LED video walls offer exceptional brightness, making them ideal for outdoor events or brightly lit indoor venues. They maintain clarity in sunlight or high ambient light conditions. LCD walls, while bright, are better suited for indoor use in controlled lighting. If your event is outdoors or in a glass-walled venue, an LED screen will perform better.

Best for outdoor or high-light environments: LED

3. Resolution and Image Quality

LCD panels typically offer higher pixel density, making them great for close-up viewing at smaller events like meetings or exhibit booths. LED walls have improved significantly and now offer high-resolution options (even 4K and beyond), but to match LCD sharpness at close distances, they need a tighter pixel pitch, which can be more expensive.

Best for close-range, high-detail content: LCD

4. Flexibility and Setup

LED video walls are highly modular. You can build them to any size or shape, wrap them around corners, or suspend them from trusses. LCD video walls are more rigid, limited to rectangular configurations. If your event calls for creativity in layout or custom dimensions, LED is far more flexible.

Best for creative layouts or large-scale setups: LED

5. Budget Considerations

When it comes to pricing, LCD video walls are generally more budget-friendly for small to mid-sized setups. LED walls can cost more upfront, especially for high-resolution indoor use, but they offer more value for larger events or high-visibility situations.

Best for tight budgets and smaller venues: LCD

So, Which Should You Choose for Your Event?

Choose LCD if you’re hosting a small indoor event with close-range viewing and need a cost-effective solution.

Choose LED if your event is large-scale, outdoors, or demands creative layouts, bright visuals, or a seamless display.

Ultimately, the right video wall rental for event depends on your goals, audience, and venue. Speak with a professional AV rental provider in advance—they can guide you on the best option based on your setup and content needs.

0 notes

Text

Achieve Radiant Skin at a Trusted Beauty Clinic in Bangalore

The pursuit of flawless skin and youthful radiance is no longer a distant dream, thanks to the advanced services offered by a beauty clinic in Bangalore. These clinics combine science and aesthetics to deliver treatments that rejuvenate and restore skin health. From anti-aging therapies to acne management, Bangalore’s beauty clinics offer personalized skincare solutions tailored to your skin type and concerns. Backed by experienced professionals and cutting-edge technology, these clinics provide a safe, clean, and result-oriented environment, making them an ideal choice for individuals looking to enhance their natural beauty through professional care.

Consult the Best Skin Doctor in Bangalore for Expert Guidance When it comes to skincare, expert advice makes all the difference. The Best skin doctor in Bangalore brings a wealth of experience, knowledge, and skill in diagnosing and treating various skin conditions, from pigmentation to eczema. With a compassionate and consultative approach, these dermatologists ensure that every patient receives a personalized plan that addresses their specific needs. Whether it’s for medical dermatology or cosmetic enhancements, their treatment regimens are holistic, safe, and effective. A trusted skin doctor also educates clients about proper skin care, ensuring long-term health and results beyond just temporary improvements.

Comprehensive Services Offered by a Leading Skin Treatment Clinic A good Skin treatment clinic offers far more than basic facials or topical applications. It provides an extensive range of treatments including chemical peels, microdermabrasion, PRP therapy, laser toning, and hydrafacials. These treatments are designed to target concerns such as dullness, scars, pigmentation, and uneven skin tone. Clinics also often offer non-invasive anti-aging solutions such as dermal fillers and Botox. What sets the best clinics apart is their focus on customizing every procedure based on individual skin analysis. By combining clinical dermatology with cosmetic care, these centers ensure sustainable beauty that goes skin deep.

Advanced Solutions from a Laser Hair Clinic Near Me Dealing with unwanted hair is a common concern, and the solution lies in finding a trusted laser hair clinic near me. Bangalore houses numerous reputable clinics equipped with advanced laser technology like diode and IPL systems that are effective on Indian skin tones. These treatments are quick, relatively painless, and provide long-term reduction in hair growth. Moreover, laser hair removal is cost-effective in the long run and significantly reduces the need for shaving or waxing. Proper consultations and patch tests are usually conducted to ensure safety and suitability for each client, making the process reliable and efficient.

Conclusion: Elevate Your Skincare Journey with Blowout Skin Clinic In today’s world, skincare is an essential aspect of wellness and self-care. Whether you’re looking for aesthetic enhancements or treatment for chronic skin issues, choosing the right clinic plays a crucial role in your journey. From consulting with experienced dermatologists to undergoing modern treatments in a hygienic setting, Bangalore offers some of the best services in the country. For those seeking a one-stop destination for all their skincare needs, Blowout Skin Clinic stands out with its commitment to excellence, personalized care, and state-of-the-art technology. Discover healthier, glowing skin under the guidance of experts who care.

0 notes

Text

Signal Line SPD Market : Size, Share Growth, SWOT Analysis, Key Players, Industry Trends and Regional Outlook

Signal Line SPD Market, Trends, Business Strategies 2025-2032

The global Signal Line SPD Market size was valued at US$ 456.80 million in 2024 and is projected to reach US$ 847.20 million by 2032, at a CAGR of 9.21% during the forecast period 2025–2032. The U.S. accounts for 25% of the global market, while China is expected to grow at a faster pace with an estimated 8.2% CAGR.

Signal Line SPD (Surge Protection Device) is a critical component designed to protect sensitive electronic equipment and communication lines from transient voltage surges caused by lightning strikes or electromagnetic interference. These devices typically incorporate zinc oxide varistors, gas discharge tubes, or silicon avalanche diodes to divert excess voltage. The technology offers rapid response times (nanosecond-level protection) and can handle surge currents up to 20kA, making it essential for modern infrastructure.

Market growth is driven by increasing digitalization across industries, stricter electrical safety regulations, and rising demand for reliable communication networks. The industrial sector currently holds the largest market share (38%), followed by commercial applications. Recent innovations include smart SPDs with remote monitoring capabilities, with major players like Eaton and Siemens launching IoT-enabled solutions in 2023. However, price sensitivity in developing markets and the need for standardized testing protocols remain key challenges for wider adoption.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://semiconductorinsight.com/download-sample-report/?product_id=103178

Segment Analysis:

By Type

Voltage Switch Type Segment Dominates Owing to High Surge Protection Efficiency

The global Signal Line SPD market is segmented based on type into:

Voltage Switch Type

Pressure Limiting Type

Combination Type

By Application

Industrial Segment Leads Due to Critical Need for Equipment Protection

The market is segmented based on application into:

Residential

Commercial

Industrial

Others

By Protection Level

High Protection Segment Gains Traction for Critical Infrastructure Applications

The market is segmented based on protection level into:

Basic Protection

Medium Protection

High Protection

By Installation Type

Plug-in Solutions Remain Popular for Their Ease of Installation

The market is segmented based on installation type into:

Plug-in

Hardwired

Modular

Regional Analysis: Signal Line SPD Market

North America The North American Signal Line SPD market is characterized by strict regulatory standards and increasing digital infrastructure investments. With the U.S. holding the largest share in the region, stringent safety regulations like NEC (National Electrical Code) requirements and IEEE standards drive demand for high-performance surge protection devices. The growing adoption of IoT and 5G technologies further fuels market growth, as these infrastructures require robust protection against voltage spikes. Industrial and commercial applications dominate demand, though residential adoption is steadily rising due to increased awareness of electrical protection needs. Major players like Eaton, Siemens, and General Electric maintain strong footholds, supporting innovation in protective solutions.

Europe Europe exhibits steady demand for Signal Line SPDs, driven by the region’s focus on industrial automation and smart grid development. Regulatory frameworks such as the IEC 61643 standards enforce the deployment of surge protection in critical infrastructure. Countries like Germany and France lead in demand, supported by expansive manufacturing and telecommunication sectors. The shift toward renewable energy projects, particularly in Nordic and Benelux countries, presents additional opportunities for surge protection solutions. Despite economic fluctuations, the emphasis on resilient infrastructure ensures sustained growth, with companies like DEHN SE and Phoenix Contact playing pivotal roles.

Asia-Pacific As the fastest-growing market, Asia-Pacific is propelled by rapid industrialization, urbanization, and telecom expansions—particularly in China and India. Government-led initiatives such as India’s Smart Cities Mission and China’s 5G network rollout significantly increase SPD adoption. However, regional cost sensitivity favors mid-tier and locally manufactured products, limiting penetration of premium solutions. Japan and South Korea, with their technologically advanced industrial base, focus on high-precision SPDs for automotive and semiconductor applications. The absence of uniform regulations across emerging economies remains a challenge, though market awareness is gradually improving.

South America South America presents a developing market for Signal Line SPDs, where Brazil and Argentina exhibit moderate growth due to expanding industrial and commercial sectors. The lack of standardized regulations and economic instability deter investments in advanced protection devices, but telecom infrastructure upgrades provide niche opportunities. The mining and energy industries, especially in Chile and Peru, drive demand for rugged surge protection. Local manufacturers compete with global brands by offering cost-effective solutions, though quality concerns persist. Long-term prospects hinge on infrastructure modernization and regulatory strengthening.

Middle East & Africa The Middle East’s Signal Line SPD market benefits from megaprojects in UAE and Saudi Arabia, where smart city developments and oil & gas infrastructure necessitate surge protection. Africa’s growth is slower but emerging, with South Africa and Nigeria deploying SPDs in telecom and power distribution networks. Limited awareness and budget constraints restrict widespread adoption, yet increasing foreign investments in renewable energy and IoT applications signal gradual market expansion. Gulf Cooperation Council (GCC) countries prioritize high-grade SPDs, while Sub-Saharan regions rely on imported, budget-friendly alternatives.

List of Key Signal Line SPD Manufacturers

Phoenix Contact USA (Germany)

Eaton (Ireland)

Siemens (Germany)

Obo Bettermann (Germany)

DEHN SE (Germany)

CITEL (France)

nVent (UK)

General Electric (U.S.)

Mersen Electrical (France)

Littelfuse (U.S.)

The global signal line SPD market is experiencing substantial growth due to rising demand for reliable protection of sensitive electronic equipment across industries. With the proliferation of IoT devices and smart technologies, businesses increasingly require robust surge protection solutions to safeguard critical infrastructure. Industrial automation, telecommunications, and data centers represent key growth sectors where signal line SPD adoption is accelerating. The market is further driven by stricter safety regulations mandating surge protection in commercial and industrial facilities, compelling organizations to invest in high-quality SPD solutions.

Government initiatives worldwide to modernize power grids are creating significant opportunities for signal line SPD manufacturers. Smart grid projects require extensive protection for communication networks and control systems that monitor and manage electricity distribution. Recent infrastructure bills in major economies have allocated billions toward grid modernization, with substantial portions dedicated to protective technologies. This trend is expected to continue as nations prioritize energy security and transition to renewable energy sources, both of which depend on well-protected monitoring and control systems.

The rapid expansion of industrial automation across manufacturing sectors globally is driving increased deployment of signal line SPDs. Modern automated factories rely on delicate sensors, controllers, and communication networks that require protection from electrical surges. The growing implementation of Industry 4.0 technologies has made surge protection a critical component of automation infrastructure. With predictive maintenance becoming standard practice, facilities managers are prioritizing investments in protective solutions that minimize downtime and equipment failures.

The global rollout of 5G infrastructure creates substantial opportunities for signal line SPD manufacturers. 5G base stations and small cells require robust protection for their sensitive electronics deployed in outdoor environments. As telecommunications providers continue expanding 5G coverage, the demand for specialized surge protection solutions is expected to grow substantially. This trend is particularly strong in urban areas where network density requirements are highest.

The transition to renewable energy sources is opening new markets for signal line SPD solutions. Solar and wind power installations require comprehensive protection for their monitoring and control systems, particularly in remote locations. As renewable energy capacity continues growing globally, specialized SPD products tailored for these applications are gaining traction. This represents a high-growth segment within the broader market.

Leading manufacturers are pursuing strategic collaborations to enhance product offerings and expand into new geographic markets. Recent partnerships between SPD producers and system integrators have improved solution accessibility for end-users. These alliances also foster innovation by combining complementary technologies, leading to the development of next-generation protection solutions with enhanced capabilities.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103178

Key Questions Answered by the Signal Line SPD Market Report:

What is the current market size of Global Signal Line SPD Market?

Which key companies operate in Global Signal Line SPD Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Browse More Reports:

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

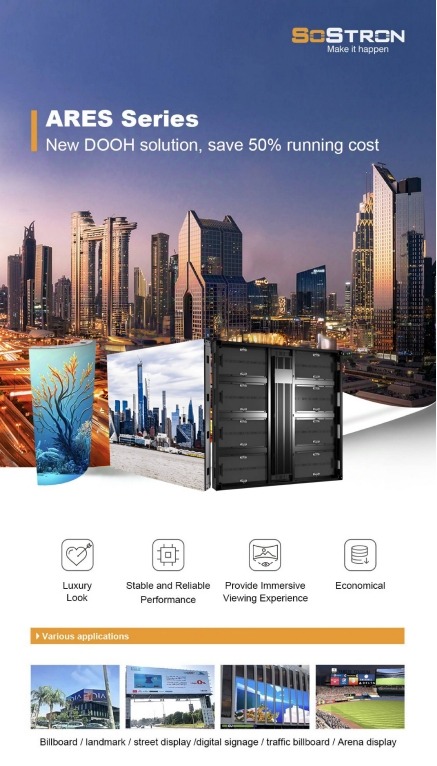

Which is better, LED backlight or CCFL backlight?

You may often hear the words "LED backlight" and "CCFL backlight" when buying TV, monitor, or notebook. It sounds quite high-tech, but to put it bluntly, they are the lights you use to "light" behind your screen. Today we will talk about: How does LED backlit display shine? Compared with traditional CCFL backlight, who is more reliable?

How does the LED backlit display emit light?

Although we call it "LED display", to be precise, it is still an LCD screen (LCD), but the backlight is replaced with an LED light.

The process of glowing is not complicated. First a row or group of white LED lights light up to illuminate the entire screen. This light is evenly distributed through a device called a "light guide" to ensure that the brightness of every corner of the screen is consistent. Then, the liquid crystal layer controls the passage of light according to different voltages, and combines with color filters to finally present various images you see.

To put it simply: LED lights are turned on, and LCDs are dimmed and colored. Without LED lights, the LCD can't display anything. Let you understand how LED light beads work.

Which is better, LED backlight or CCFL backlight?

Speaking of the two backlighting methods of "LED" and "CCFL", they are actually the difference between the new and old technologies. LEDs are latecomers, using light emitting diodes, while CCFL uses cold cathode fluorescent tubes similar to fluorescent lamps.

What are the advantages of LED backlighting? First of all, it has higher brightness and looks clearer and more transparent. Secondly, it is more power-saving - this is a real energy-saving for people who are staring at the computer for 8 hours a day. Next, the LED backlight is thinner and lighter, making the device more compact. It has a longer lifespan, generally more than 50,000 hours, while CCFL is about 20,000 hours.

Another very important point is that LED backlight does not contain mercury and is more environmentally friendly. On the other hand, there is mercury in CCFL. If it is broken, it will not only pollute the environment, but also harm the human body.

So in a summary: LED backlight almost crushes CCFL backlight in all directions. Now, the new displays on the market have basically eliminated CCFL. Here is an analysis of LED backlight display technology.

Is "LED display" the same thing as "LCD display"?

Many people regard "LED display" and "LCD display" as two different things, which is actually a misunderstanding. LED display is actually an LCD display with LED backlight. In other words, its essence is still an LCD screen, but the backlight has been upgraded to LED. What are the main advantages of using LED displays compared to traditional LCDs?

The true "full LED display" is like a stage large screen, advertising large screen, or even OLED used in high-end mobile phones. That is another technology: it does not use LCD, and the lamp beads can shine by themselves, which belongs to a higher-level display method. The monitors and TVs used by ordinary people in daily life are basically a combination of LCD + backlight. Here is a comparison of LCD, LED and OLED displays.

How to choose a reliable LED backlit monitor?

If you are an office worker and mainly work and browse the web, it is recommended to choose an IPS panel with LED backlight, which has soft colors and wide viewing angles.

If you are engaged in design, editing, and editing videos, in addition to LED backlighting, it is best to look at the color gamut and color accuracy indicators, such as the coverage of sRGB and AdobeRGB.

If you are a gamer, it is recommended to choose an LED backlit screen with a high refresh rate (such as above 144Hz) and a low latency, which will make the picture smoother.

In a word, LED is only part of the backlight. What really determines the display effect is also panel type, color gamut, brightness, refresh rate, etc. Don’t be fooled by the three words “LED”.

FAQ

Q: Will LED backlight be broken?

Answer: Of course. After using it for a few years, the screen may become dark, uneven brightness, flickering, etc., indicating that the LED lamp beads have aging or circuit problems.

Q: Can the LED be repaired if it breaks?

Answer: Technically OK, but labor and accessories are costly. If it is a mid-to-low-end device, it is usually recommended to replace it with a new one directly and be more cost-effective.

Q: Is the brighter the LED, the better?

Answer: No. Too bright will hurt your eyes, especially when used at night. It is recommended to turn on automatic brightness adjustment or use eye protection mode, protecting your vision is the most important thing.

LED backlight is the mainstream

Ten years ago, CCFL was mainstream, but today, LED backlight has won all the way. Not only is it good picture quality, power saving and environmentally friendly, it can also be made lighter and thinner. Unless you have a habit of collecting old monitors, there is really no need to consider CCFL again.

Next time you are looking at the display specifications, you might as well pay more attention to the backlight type, panel parameters, and color gamut coverage. Don’t just look at the advertising slogans and the technical details to buy a good screen that truly suits you.

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. We provide all kinds of displays, display leasing and display solutions around the world. If you want to know: Budget analysis of LED background wall in conference room. Please click read.

Follow me! Take you to know more about led display knowledge.

Contact us on WhatsApp:https://api.whatsapp.com/send?phone=+8613510652873&text=Hello

0 notes

Text

🖥️ Understanding Computer Monitors: A Complete Guide

In today’s digital world, a computer monitor is more than just a screen — it's the window through which we interact with our devices. Whether you’re working, gaming, designing, or simply browsing the web, the quality and type of monitor you use can significantly impact your experience. This article explores the different types of monitors, key features to consider, and how to choose the right one for your needs.

📌 Types of Monitors

LCD (Liquid Crystal Display): The most common type today, LCD monitors offer good image quality and are energy-efficient. They’re great for everyday use, from office work to media consumption.

LED (Light Emitting Diode): Technically a type of LCD, LED monitors use backlighting to provide better contrast and color accuracy. They are thinner and more energy-efficient than traditional LCDs.

IPS (In-Plane Switching): Known for superior color and wider viewing angles, IPS monitors are ideal for graphic design, video editing, and professional use.

TN (Twisted Nematic): TN panels offer fast response times, making them a favorite for gamers, though they may compromise on color and viewing angles.

OLED (Organic LED): With deep blacks and vibrant colors, OLED monitors deliver excellent picture quality, but they come at a higher cost and are less common in desktop setups.

📌 Key Features to Consider

Screen Size: Larger screens (24" and above) offer better multitasking and immersion, especially for creative work and gaming.

Resolution: Higher resolutions like Full HD (1080p), QHD (1440p), and 4K (2160p) provide sharper images and more screen real estate.

Refresh Rate: Measured in Hz, higher refresh rates (like 144Hz or 240Hz) are essential for smooth gameplay and video.

Response Time: Lower response times (measured in milliseconds) reduce motion blur, important for gaming.

Connectivity: Make sure your monitor has the right ports — HDMI, DisplayPort, USB-C — to match your devices.

Ergonomics: Adjustable stands, VESA mount compatibility, and eye-care features (like blue light filters) enhance long-term usability.

📌 Choosing the Right Monitor

Your monitor should match your primary needs:

For general office work, a 24" Full HD monitor with an IPS panel offers great value.

For creatives, look for color accuracy, at least 2K resolution, and factory calibration.

For gamers, prioritize high refresh rates (120Hz+) and low response times.

For entertainment, a curved or ultrawide monitor can boost your viewing experience.

✅ Conclusion

A good monitor can transform how you work, play, and create. With so many options on the market, it's important to consider your specific needs and budget when making a choice. Whether you're searching for a basic display or a high-performance monitor, understanding the types and features available ensures you make an informed decision.

At Grace IT Solutions, we help you find the right monitor for your setup and provide expert support for all your tech needs. Stop by or contact us today to explore our range of monitors and accessories!

0 notes

Text

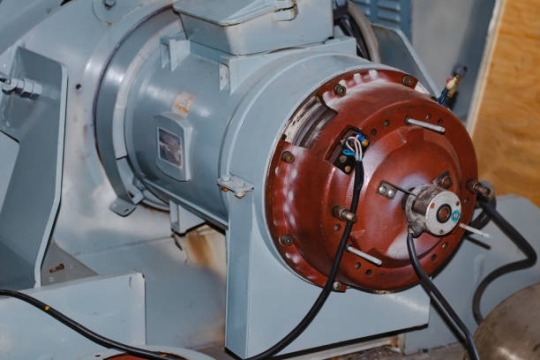

Understanding Generator Excitation: A Complete Technical Guide

1. Introduction to Generator Excitation Generator excitation is a fundamental aspect of power generation systems, playing a critical role in regulating voltage and ensuring system stability. Whether in hydroelectric, thermal, or renewable energy plants, excitation systems are essential for the efficient and reliable operation of synchronous generators. This technical guide offers a comprehensive overview of generator excitation, focusing on its principles, components, types, and applications.

2. The Purpose of Generator Excitation Generator excitation refers to the process of supplying a controlled DC current to the rotor winding of a synchronous generator. This excitation current produces the magnetic field necessary for generating electricity. The strength of this magnetic field directly influences the terminal voltage of the generator. By adjusting the excitation current, operators can regulate the output voltage and reactive power flow, which is vital for grid stability and load balancing.

3. Basic Components of Excitation Systems A typical excitation system comprises several core components including the exciter, voltage regulator, and power source. The exciter provides the DC supply to the rotor winding, while the automatic voltage regulator (AVR) continuously monitors and adjusts the excitation current to maintain the desired generator voltage. The power source for the exciter may come from an external DC supply or be derived from the generator itself, depending on the excitation system design.

4. Types of Generator Excitation Systems Generator excitation systems are broadly classified into three main types: static excitation, brushless excitation, and DC excitation.

In static excitation systems, power for the field winding is taken from the generator terminals through a transformer and rectifier setup. This type offers fast response and precise control, making it ideal for modern power plants.

Brushless excitation systems use a small AC generator mounted on the same shaft as the main generator. This exciter produces AC power which is then rectified by rotating diodes and supplied to the rotor winding. The brushless design eliminates the need for slip rings and brushes, thereby reducing maintenance and increasing reliability.

DC excitation systems, although less common in modern setups, use a separate DC generator to supply excitation current. These systems are typically found in older power stations or in applications where simplicity and independence from the main generator are prioritized.

5. Automatic Voltage Regulation and Control The automatic voltage regulator (AVR) is a crucial element of the generator excitation system. It maintains the output voltage within specified limits by adjusting the excitation current in real time. The AVR receives feedback from the generator output and modulates the excitation accordingly to respond to load changes, ensuring consistent voltage supply.

In advanced excitation systems, the AVR is integrated with other control mechanisms such as power system stabilizers (PSS) and protective relays, enhancing the overall stability and performance of the generator under dynamic grid conditions.

6. Importance of Proper Excitation in Power Systems Proper generator excitation is vital for maintaining voltage stability, controlling reactive power, and preventing system disturbances. An inadequately excited generator can lead to voltage fluctuations, increased losses, and even generator damage. In contrast, over-excitation can cause excessive reactive power generation, leading to overvoltage and potential grid instability. Hence, well-designed and precisely controlled excitation systems are indispensable in power plant operations.

7. Applications and Industry Relevance Generator excitation systems are used across various industries, including electric utilities, industrial manufacturing, and renewable energy sectors. Their application spans from small-scale backup generators to large-scale utility power generation units. As grid demands grow and power systems become more dynamic, the role of efficient generator excitation continues to expand, making it a crucial area of focus for engineers and operators.

8. Conclusion In summary, generator excitation is a key technical process that underpins the operation of synchronous generators. From regulating voltage to ensuring system stability, the importance of an effective excitation system cannot be overstated. As power generation technology continues to evolve, the demand for reliable and efficient excitation systems will remain central to the success of modern energy infrastructure. Understanding generator excitation, its types, and its operational significance is essential for anyone involved in the field of power systems and electrical engineering.

Contact Info

2500 State Highway 160, Warrior, AL 35180

Phone: 205-590-3505

Email

Map

https://maps.app.goo.gl/c7y7BLamTPvecBqWA

0 notes

Text

Explosion-Proof Electrical Safety Barrier Market: Technological Innovations and Future Roadmap 2025–2032

Explosion-Proof Electrical Safety Barrier Market, Trends, Business Strategies 2025-2032

Explosion-Proof Electrical Safety Barrier Market size was valued at US$ 187.6 million in 2024 and is projected to reach US$ 267.8 million by 2032, at a CAGR of 4.6% during the forecast period 2025-2032

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=103398

MARKET INSIGHTS

The global Explosion-Proof Electrical Safety Barrier Market size was valued at US$ 187.6 million in 2024 and is projected to reach US$ 267.8 million by 2032, at a CAGR of 4.6% during the forecast period 2025-2032.

Explosion-proof electrical safety barriers are critical components designed to prevent ignition of flammable gases, vapors, or dust in hazardous industrial environments. These devices limit electrical energy to safe levels through intrinsic safety principles, using either Zener diode barriers or galvanic isolation techniques. They find primary application in Zone 0, 1, and 2 hazardous areas as classified by IEC 60079 standards.

The market growth is driven by stringent industrial safety regulations such as ATEX in Europe and NEC in North America, coupled with increasing automation in oil & gas facilities. However, the emergence of alternative protection methods like explosion-proof enclosures presents competitive challenges. Recent technological advancements include smart barriers with IoT-enabled condition monitoring, with companies like Pepperl+Fuchs and Eaton Corporation leading innovation in this space.

List of Key Explosion-Proof Safety Barrier Companies

Pepperl+Fuchs (Germany)

Eaton Corporation (Ireland)

R. STAHL (Germany)

Phoenix Contact (Germany)

PR ELECTRONICS (Denmark)

DATEXEL SRL (Italy)

TURCK (Germany)

Panasonic Eco Solutions (Japan)

FineTek (Taiwan)

Adalet Inc. (U.S.)

Recent competitive dynamics reveal three strategic patterns: established players are divesting non-core safety businesses to focus on explosion-proof technologies, mid-market competitors are forming consortiums to pool R&D resources, and regional specialists are expanding certification portfolios to meet multinational client demands. The market’s technical complexity creates high barriers to entry, but also rewards companies that continuously advance their safety and connectivity features.

Segment Analysis:

By Type

Multi-Channel Segment Leads Due to High Demand in Complex Industrial Setups

The market is segmented based on type into:

Single Channel

Subtypes: Basic, Smart-connected, and others

Multi-Channel

Subtypes: Dual-channel, Four-channel, and others

By Application

Oil and Gas Industry Dominates Due to Stringent Safety Requirements in Hazardous Environments

The market is segmented based on application into:

Oil and Gas

Chemical Processing

Mining

Pharmaceutical

Others

By Technology

Smart Barriers Gain Traction With IoT Integration for Remote Monitoring Capabilities

The market is segmented based on technology into:

Conventional Barriers

Smart Barriers

Subtypes: Wireless-enabled, IoT-connected, and others

By Certification

ATEX-Certified Barriers Lead Due to European Market Dominance

The market is segmented based on certification standards into:

ATEX

IECEx

NEC

Others

Regional Analysis: Explosion-Proof Electrical Safety Barrier Market

North America North America dominates the explosion-proof electrical safety barrier market due to stringent safety regulations, particularly in high-risk industries like oil & gas, chemical processing, and mining. The region’s well-established regulatory framework, including standards set by OSHA (Occupational Safety and Health Administration) and NEC (National Electrical Code), drives the adoption of advanced safety solutions. The United States remains the largest market, accounting for approximately 65% of the regional revenue, with Canada following due to its expanding industrial sector. Investments in digital transformation and industrial automation further stimulate demand for IoT-enabled safety barriers that offer real-time monitoring capabilities. Leading manufacturers like Eaton Corporation and Cooper Crouse-Hinds continue to innovate, focusing on energy efficiency and compliance with ATEX directives.

Europe Europe’s market is characterized by strict compliance requirements under ATEX and IECEx regulations, ensuring high safety standards across hazardous environments. Countries like Germany, France, and the UK lead in adoption due to advanced manufacturing and energy sectors. The EU’s emphasis on Industry 4.0 has accelerated the integration of smart safety barriers capable of predictive maintenance and remote diagnostics. While Western Europe remains the largest consumer, Eastern Europe shows gradual growth, driven by industrial modernization in nations like Poland. Pepperl+Fuchs and R. STAHL are key players, leveraging their expertise to cater to specialized applications such as offshore wind farms and pharmaceutical manufacturing. However, high costs associated with certification and installation pose challenges for SMEs.

Asia-Pacific Asia-Pacific is the fastest-growing market, propelled by rapid industrialization in China, India, and Southeast Asia. China alone contributes over 40% of regional demand, supported by its booming oil & gas and chemical industries. Governments across the region are enforcing stricter workplace safety regulations, spurring the need for explosion-proof solutions. However, price sensitivity leads to a preference for cost-effective, single-channel barriers, particularly in developing markets. Japan and South Korea focus on high-end, multi-channel barriers for precision manufacturing and semiconductor industries. Leading suppliers include Panasonic Eco Solutions and FineTek, who are expanding their distribution networks. The rise of automotive electrification and smart factories further fuels long-term growth prospects.

South America South America presents moderate but steady demand, primarily driven by Brazil’s oil & gas and mining sectors. The region struggles with economic volatility, which limits investments in high-cost safety infrastructure. Local manufacturers often prioritize basic explosion-proof solutions due to budget constraints, while multinational corporations opt for certified ATEX barriers in critical facilities. Argentina and Colombia show nascent growth, supported by small-scale industrial expansions. The lack of uniform safety regulations across countries remains a hurdle, though initiatives like MERCOSUR safety standards aim to harmonize requirements. Partnerships with global players such as TURCK and Phoenix Contact are helping bridge the technology gap.

Middle East & Africa The Middle East’s market is fueled by oil-rich GCC nations (Saudi Arabia, UAE), where stringent safety norms in refineries and petrochemical plants drive adoption. Israel and Turkey are emerging markets due to growing electronics and automotive sectors. Africa faces slower adoption due to limited industrial development, though mining operations in South Africa and Nigeria create localized demand. Infrastructure gaps and lack of skilled labor for installation remain barriers, but foreign investments in energy projects could unlock potential. Companies like Adalet Inc. and DATEXEL SRL are targeting niche applications in desalination plants and LNG facilities, leveraging the region’s energy diversification efforts.

MARKET DYNAMICS

The lack of harmonization between regional certification requirements poses significant hurdles for manufacturers and end-users alike. While ATEX dominates in Europe and NEC in North America, emerging markets often develop their own evolving standards. A single product might require separate certifications for Brazil (INMETRO), Russia (EAC), and China (CCC), each with different testing protocols. This regulatory fragmentation forces manufacturers to maintain multiple product versions, increasing inventory costs by an estimated 15-20%. The challenge intensifies with recent geopolitical shifts, as trade restrictions alter certification reciprocity agreements between regions. Multinational corporations must navigate this complex landscape while ensuring all facilities maintain equivalent safety standards.

Retrofitting Legacy Systems Many industrial facilities operate aging infrastructure where integrating modern safety barriers proves technically challenging and cost-prohibitive. Retrofitting often requires complete electrical system overhauls rather than simple component replacements.

Material Compatibility Issues Certain industrial environments contain corrosive chemicals that degrade standard enclosure materials. Finding safety barriers that withstand both explosion risks and chemical exposure remains an ongoing engineering challenge.

The development of modular, scalable safety solutions creates opportunities in previously underserved markets. Compact barriers designed for confined spaces are gaining traction in pharmaceutical clean rooms and semiconductor fabrication plants. Plug-and-play systems now allow facilities to incrementally upgrade protection as operations expand. This flexibility makes explosion-proof technology accessible to smaller specialty chemical producers and research laboratories handling volatile compounds. The modular approach reduces total cost of ownership by enabling selective rather than complete system replacements during facility upgrades.

Advanced diagnostics embedded in modern safety barriers create new revenue streams for manufacturers through value-added services. Cloud-connected systems can predict component failures before they occur, transforming the traditional break-fix model into proactive maintenance programs. Early adopters report these services improve system uptime by over 95% while reducing emergency service calls. The data collected also helps manufacturers optimize future designs, creating a feedback loop that continually enhances product reliability. This shift toward service-based offerings represents a strategic opportunity to deepen customer relationships beyond equipment sales.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103398

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Explosion-Proof Electrical Safety Barrier Market?

Which key companies operate in this market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Related Reports:

https://semiconductorblogs21.blogspot.com/2025/07/gas-scrubbers-for-semiconductor-market_14.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/sequential-linker-market-economic.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/lever-actuator-market-swot-analysis-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/probe-station-micropositioners-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/gesture-recognition-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/multi-channel-piezo-driver-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/video-sync-separator-market-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/tv-tuner-ic-market-investment-analysis.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/single-channel-video-encoder-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/sic-ion-implanters-market-revenue.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/quad-flat-no-lead-packaging-qfn-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/ntc-thermistor-chip-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/low-dropout-ldo-linear-voltage.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/logic-test-probe-card-market-strategic.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/led-display-module-market-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/industrial-led-lighting-market-trends.html

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes

Text

Designing Reliable Green Hydrogen Projects: The Role of Thyristor Rectifiers

As the global energy transition accelerates, green hydrogen projects have moved from vision to reality. Around the world — and especially in countries like India — renewable power is now being transformed into clean hydrogen to decarbonize industries, transport, and power systems.

But designing a reliable green hydrogen plant isn’t just about choosing electrolysers and installing solar panels. It requires deep engineering — particularly in power electronics that convert variable renewable energy into stable, usable power. Among these, the thyristor rectifier plays a critical but often overlooked role. Without it, the promise of large-scale, cost-effective green hydrogen production would be hard to achieve.

In this blog, we explore why thyristor rectifiers matter, how they work, and why every successful green hydrogen project should take them seriously.

What Is a Thyristor Rectifier?

A thyristor rectifier is a type of controlled AC-DC rectifier that uses thyristors — semiconductor devices that can be switched on and off electronically. In green hydrogen plants, thyristor rectifiers convert alternating current (AC) — typically from the grid or renewable energy sources — into the direct current (DC) required by hydrogen electrolysers.

Beyond conversion, thyristor rectifiers offer active control over voltage and current, help smooth out fluctuations, and protect electrolysers from power quality issues. Their robustness and scalability make them ideal for industrial-scale green hydrogen projects, especially in regions with variable renewable energy supply.

The Challenge: Variability of Renewable Energy in Green Hydrogen Projects

Renewable energy in India and globally is plentiful, but naturally inconsistent. Solar farms produce only during daylight and are affected by weather. Wind generation can vary by season or even minute to minute.

Hydrogen electrolysers, whether PEM or alkaline, require stable DC power to split water efficiently. Unstable power leads to lower efficiency, higher wear, and reduced hydrogen purity — all of which impact plant economics.

Thyristor rectifiers help overcome this challenge by actively shaping and stabilizing DC output, even when the input AC supply varies.

How Thyristor Rectifiers Support Reliable Green Hydrogen Projects

Converting Renewable AC Power into Stable DC

Every green hydrogen project starts with renewable energy, typically produced in AC. Electrolysers can’t run on AC; they need DC power that’s steady and controlled.

A thyristor rectifier performs this conversion, turning variable AC power into DC suitable for electrolysis. Unlike basic diode rectifiers, thyristor rectifiers actively regulate the output, ensuring the electrolysers receive power within precise voltage and current limits.

This precision is essential for large-scale projects where power swings can damage equipment or disrupt production.

Managing Power Fluctuations for Consistency

Renewable energy — especially wind and solar — often fluctuates due to weather and demand. Thyristor rectifiers respond by dynamically adjusting their firing angle, effectively controlling the DC output to match the electrolyser’s needs.

This capability keeps production steady, improving hydrogen output quality and protecting equipment. For green hydrogen production intended for industrial or export markets, where reliability is non-negotiable, this makes a big difference.

Protecting High-Value Hydrogen Electrolysers

Electrolysers are the heart of any green hydrogen project and among its most expensive components. Voltage spikes, harmonics, and other power quality issues can damage electrolyser stacks or reduce their lifespan.

Thyristor rectifiers filter out these issues, deliver smoother DC power, and act as a buffer against sudden grid events. This protection extends equipment life and lowers maintenance costs — improving overall project economics.

Enabling Scalability and Flexibility

India’s green hydrogen industry is evolving quickly, with projects ranging from demonstration plants to planned gigawatt-scale facilities.

Thyristor rectifiers are well suited for this growth because they can handle high power levels (from a few megawatts to hundreds) and be configured modularly. As a result, they support plant designs that can start small and expand as demand increases or as more renewable capacity becomes available.

This scalability is vital for a green hydrogen company in India competing in dynamic markets.

Improving Efficiency and Lowering Costs

Every percent of efficiency gained during power conversion translates to lower hydrogen production costs. Thyristor rectifiers are highly efficient under high load conditions and can be designed to match the specific characteristics of the renewable energy supply.

By reducing energy losses during conversion and ensuring optimal electrolyser operation, they directly contribute to making green hydrogen production more cost-competitive.

Why This Matters: Beyond Equipment

Power electronics like thyristor rectifiers might seem like small details compared to big headlines about electrolysers or solar farms. But in reality, they bridge the gap between renewable energy variability and the strict, stable power needs of hydrogen electrolysers.

When green hydrogen projects overlook these details, they risk higher operational costs, equipment failures, and inconsistent hydrogen output — all of which can derail project economics and investor confidence.

By investing in high-quality, properly engineered rectifier systems, developers ensure plants are not only technically feasible but commercially sustainable.

Final Thought

The global race to scale green hydrogen production isn’t just about building bigger plants. It’s about building smarter ones — where every component, from electrolysers to power electronics, is selected and integrated to maximize reliability, efficiency, and long-term value.