#clay forms in wet environments

Explore tagged Tumblr posts

Text

Spoken like a true geologist!

(yes, we really do lick rocks to help ID them sometimes! Usually salt, but we can lick sediments to help identify grain size: sand and silt will feel gritty, finer grains won't. We also lick things to see if they're porous because they'll stick to your tongue. Some minerals are porous, and so is bone. I licked a number of charred animal bone fragments at an archaeology dig ¯\_(ツ)_/¯ )

[Image ID: 3 screenshots from Cloudward, Ho! with captions. The first shows Daisuke saying, "Do you want to lick this?" The second shows Monty saying, "Yeah," and the third shows him saying, "It's the same." end ID]

#dimension 20#though i will absolutely get needlessly nit-picky and say that ceramic is just clay#and one of the places you would not expect to find clay is in a desert sand dune field#clay forms in wet environments#and while you can have clay in a desert#it gets eroded away very easily so wind-blown desert sand will have lost all its clay already#not that it matters at all I just study and love clay#and my sister studies and loves sand#so i had to talk about it :)#but i simply do not care if sci-fi/fantasy is scientifically accurate and certainly not this lol#d20#cloudward ho#d20 spoilers#sam speaks#geology

95 notes

·

View notes

Text

HiPOD: Dragon Scales of Mars

This intriguing surface texture is the result of rock interacting with water. The rock was then eroded and later exposed to the surface. The pinkish, almost dragon-like scaled texture represents Martian bedrock that has specifically altered into a clay-bearing rock.

The nature of the water responsible for the alteration, and how it interacted with the rock to form the clay remains poorly understood. Not surprisingly, the study of such altered rocks on Mars is an area of active investigation by the Mars science community. Understanding such interactions, and how they happened, help scientists to understand the past climate on Mars, and if the Red Planet ever harbored life.

Recent studies indicate that the early Martian climate may not have been as warm, wet, and Earth-like, as previously suggested. This is not a problem for finding life on Mars as one might think. Ongoing studies of dry and cold environments on Earth shows that life finds ways to adapt to such extremes. Such work provides hope for finding evidence for life on other planets, like Mars, someday. (Enhanced color cutout is less than 1 km across.)

ID: ESP_050275_1500 date: 17 April 2017 altitude: 253 km

NASA/JPL-Caltech/UArizona

44 notes

·

View notes

Text

Minecraft Slime Headcanon (real) (also a suggestion to replace slime chunks with a different alternative spawning place)

Ah, the Slime. one of the most peculiar creatures in the world of minecraft. Most consistently found in swamps and mangrove swamps, yet even then... said consistency relies on moon phases. Perhaps you've wondered why this is, what type of magic is involved. Well, I have potential answers here for you, in this headcanon-lore written in a semi-nature-documentary style!!! Ahem

The creation of slime is a natural process of the overworld, and it is facilitated via numerous factors, but the basis of all slime is that of mud. You may notice slimes only seem to appear in damp, muddy areas of the overworld, and this is for good reason

The process of a living slime forming, which shall be referred to as "Oozing" for sake of convenience, starts with a wet soil, aka mud! When a slime oozes out of said soil, however, their creation partially dries up said mud. This oozing could take a toll on the environment. If it happened in any less damp of an environment than a swamp, it could not continue to last as Mud, likely reverting to Clay (as seen with dripstone drying water out of mud, into clay blocks). Slimes are smart enough to know that their "oozing grounds" would hence be cut short, and thus do prefer to stick to swamps when it comes to the surface.

However, you may notice that slimes only seem to Ooze themselves into existence during the night. Why is this? Well, you see, the second key ingredient, and main facilitator of oozing, is light. But not just any light: Natural light. This is because light helps slime (the substance) stay tangible, rather than melting yet more into a puddle, reverting to the mud where it came from. The reason you don't see this process occur during the day is that too much light and heat is also bad for the formation of slimes. They need a cool environment, or else they struggle to keep their substance. Pitifully, swamps happen to be some of the most humid places during the day, so for these reasons, Slimes will only come out during a good, cold night. Interestingly, it has also been noted that as the phase of the moon changes, so too does the speed of the Oozing process. This has been discovered to be caused by the brightness of the moonlight. More light speeds up the process, and thanks to the sun not being out to dry them up with overwhelming amounts of light, slimes are born.

As you can tell, Slimes are very picky about their environment. It needs to be damp enough for them to begin to "ooze" out of a block, like water dripping out of mud... and must be cold enough, yet light enough, and even more specifically, not too bright... for them to form a tangible body.

(Now this gets into a proposal for slimes spawning in lush caves because slime chunks are weird and unintuitive) There is only one other environment than swamps that fits the bill for slimes, and that is lush caves. A seasoned adventurer may ask to themselves how the large amounts of clay remain dry in such a damp environment, one damp enough to facilitate moss growth... The reason? Just as the clay begins to form into mud, the oozing process begins, and due to the lack of immense dampness such as in swamps, the mud cannot stay as mud.

But why does the oozing process occur in lush caves? What entices slimes to attempt it here, of all places? The answer hangs from the ceiling -- that's right, glow berries! Earlier we talked about slimes needing light, but being put off by too substantial amounts of light. While moonlight fulfills this need quite well, so too do glow berries. and as glow berries shine all hours of the day, as opposed to moonlight... slimes have taken notice of these environments, despite these caves' lack of the swamps' immense dampness needed to sustain mud.

Finally, lush caves are cold, as they are underground... which checks that off the list for the oozing process.

Put simply: When a slime is oozed, (which happens due to the environmental conditions of dampness, coldness, and constant light) it counters the dampening of clay into mud. These environments walk a very fine line. Any drier and the oozing process would not begin... but any wetter, and instead of clay, lush caves would have mud as their predominent soil.

Overall, minecrafts slimes are very interesting creatures, and thats not even delving into their interdimensional cousin, the magma cube...

Thank you for reading, and if you have any notes or critiques about this Lore i literally just came up with, feel free to lmk!!

30 notes

·

View notes

Text

"The planet Mars is home to thick layers of clay that can span hundreds of feet. Since they need water to form, these outcrops have long been of interest to scientists looking for signs of past life on the red planet.

In a new study published in Nature Astronomy, scientists from The University of Texas at Austin and collaborators took a closer look at these clay terrains and found that most formed near standing bodies of surface water, which were common on Mars billions of years ago. This environment would help foster the chemical weathering needed to create thick, mineral-rich layers of clay and could have provided the right mix of water, minerals and a calm environment for life to develop.

"These areas have a lot of water but not a lot of topographic uplift, so they're very stable," said the study's lead author Rhianna Moore, who conducted the research as a postdoctoral fellow at the UT Jackson School of Geosciences. "If you have stable terrain, you're not messing up your potentially habitable environments. Favorable conditions might be able to be sustained for longer periods of time.""

"The researchers noted that the thick clays could also be a sign of an imbalanced water and carbon cycle on ancient Mars, which could explain why Mars appears to be missing carbonate rocks in environments where they would be expected on Earth.

Billions of years ago, Mars was a wet world. It had lakes and rivers, which created geological formations that are carved on the surface of the planet today. The thick clay layers formed during this wet period. However, before this study, little was known about the environments in which they formed and how the surrounding terrain influenced their evolution."

continue reading article

#mars#life on mars#ancient mars#water on mars#natural history#solar system#evolution#clay#planet#astrobiology#astronomy#space#universe#life#mars environment#mars atmosphere#mars history#cosmos

5 notes

·

View notes

Text

Thick clay layers on Mars may have been stable place for ancient life

The planet Mars is home to thick layers of clay that can span hundreds of feet. Since they need water to form, these outcrops have long been of interest to scientists looking for signs of past life on the Red Planet.

In a new study in Nature Astronomy, scientists from The University of Texas at Austin and collaborators took a closer at these clay terrains and found that most formed near standing bodies of surface water, which were common on Mars billions of years ago. This environment would help foster the chemical weathering needed to create thick, mineral-rich layers of clay and could have provided the right mix of water, minerals and a calm environment for life to develop.

“These areas have a lot of water but not a lot of topographic uplift, so they’re very stable,” said the study’s lead author Rhianna Moore, who conducted the research as a postdoctoral fellow at the UT Jackson School of Geosciences. “If you have stable terrain, you’re not messing up your potentially habitable environments. Favorable conditions might be able to be sustained for longer periods of time.”

The study was conducted as part of UT’s Center for Planetary Systems Habitability, which investigates the origins and requirements for life on Earth and other planetary bodies. Moore is now with NASA as part of a team supporting the Artemis mission to Earth’s Moon.

The researchers noted that the thick clays could also be a sign of an imbalanced water and carbon cycle on ancient Mars, which could explain why Mars appears to be missing carbonate rocks in environments where they would be expected on Earth.

Billions of years ago, Mars was a wet world. It had lakes and rivers, which created geological formations that are carved on the surface of the planet today. The thick clay layers formed during this wet period. However, before this study, little was known about the environments in which they formed, and how the surrounding terrain influenced their evolution.

Moore analyzed images and data from 150 clay deposits that had been previously identified in a global survey conducted by NASA’s Mars Reconnaissance Orbiter. She investigated trends in their topographical characteristics and how close they were to other geological features, such as former bodies of water.

She found that the clays were mostly found at low elevations near lake deposits but away from valley networks, where water is thought to have flowed more vigorously across the terrain. This balance between chemical and physical weathering led to their preservation through time. Co-author Tim Goudge, an assistant professor at the Jackson School’s Department of Earth and Planetary Sciences, said that the Mars clay environment is similar to the tropical places where thick clay layers are found on Earth.

“On Earth, the places where we tend to see the thickest clay mineral sequences are in humid environments, and those with minimal physical erosion that can strip away newly created weathering products,” he said. “These results suggest that the latter element is true also on Mars, while there are hints at the former as well.”

However, the clays also reflect an ancient Martian world that was very different from the Earth of today.

On Earth, shifting tectonic plates are constantly exposing fresh rock that can readily react with water and CO2 in the atmosphere, which helps regulate the climate. However, Mars lacks tectonic activity. When Martian volcanoes released CO2 into the atmosphere, the lack of a source for new reactive rock would have led the greenhouse gas to linger — causing the planet to become warmer and wetter. The researchers suggest that these conditions may have contributed to the formation of the clays.

What’s more, the lack of new rock on the surface may have impeded the chemical reactions needed to form carbonate rock — which would normally form from volcanic rock that underlies most Martian geology given CO2, water and time. Ongoing clay formation may have contributed to the dearth of carbonates by sucking up water and sequestering chemical byproducts in the clay, rather than having them leach out into the wider environment, where they could react with the surrounding geology.

“It’s probably one of many factors that’s contributing to this weird lack of predicted carbonates on Mars,” said Moore.

The research was funded by NASA and the Canadian Institute for Advanced Research.

TOP IMAGE: A clay-rich mesa in the Hellas basin of Mars. The blue color near the rim is aluminum bearing clays. The red-orange color below that is iron and magnesium bearing clays. The image captures an area that’s 1 kilometer across. Credit NASA/JPL-Caltech/UArizona

LOWER iMAGE; A map from the study showing the location the clay deposits on Mars, along with other geological features that the researchers examined. Credit Moore et al.

5 notes

·

View notes

Note

hi Mara, you've mentioned etiquette for the left handed before, and I'm curious about it, aside from writing left to right what else counts as proper etiquette?

hey christmas anonymous;

sincere uncertainty: i don:t know if i publicly mentioned etiquette for left-handed people before, or were just talking about etiquette from bacterial will for myself to adhere to -- the uncertainty is mostly because i usually reserve the 'etiquette' word to refer to those prior rules (these would be things like: not using diagnostic terminology; never expressing doubt in the faith to properly perform deknitting-of-thought against outsider influence; not being allowed to use doctors or treat self; so-and-so rules to create wilderness against 'logic') <- i try to be consistent with terminology but i fail sometimes / confuse the message;

prescriptions for left-handed persons to un-confuse are mostly laid out in the gracecon story and can be extrapolated out from that: the lefties write right->left, the righties go left->right; the left are not permitted to sing or hear music (and by extension song can:t be permitted in public spaces where confusion is at risk of contamination; births should be silent; before handedness can be accurately assessed, song and iconography should be kept bare from the environment, & names shouldn:t be given yet); the right are not permitted to observe idolatrous forms (representational drawing, art, pictures, sculpture -- exceptions are made for abstractive form exclusively through "geometric form" (tile, architecture) and calligraphy); the left should observe an eight-day calendar, the right the seven-day calendar; baptisms for the left should be a dry baptism done through sterilized sands or clays or ash; wet baptism for the right, submersion; prayer services for the left should be silent, and/or done through physical creation in lieu of abstract choruses to heaven (reserved to the right); left-handed names should be representational and idolatrous: ie valid names would be new-demonic representational nouns (paper, plastic, chemical, book, cathedral, green, sun) or old-demonic abstractive names as grandfathered 'legal' names (your baals and belphegors and etceteras); right names are non-existent abstractive nouns (jacobs and richards and so-and-so); sacred text for the left has to be reproduced "as accurately as possible" to the original (this mostly relates to the original physical material of the text) and denoted as a child of the original idol, and treated as an idol itself; ideally everything is observed at as young an age as possible and adhered to as strictly as possible to create clean non-confusion of chirality; annihilation of the soul for the left; eternal subsumation for the right;

that:s mostly it -- if you:re bored check out kageki shoujo(!!), i started watched it lately and really like it;

take care, christmas anonymous

14 notes

·

View notes

Text

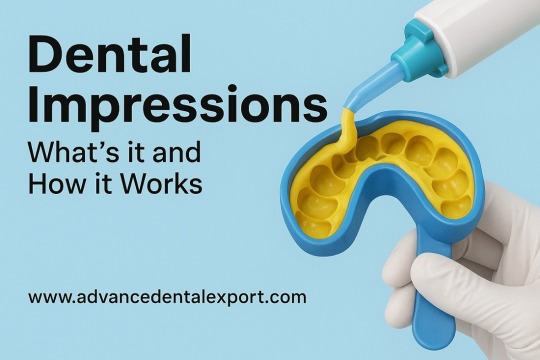

Ultimate Guide to Dental Impressions: What It Is and How It Works

What is a Dental Impression?

Dental impressions are the process of taking a "negative" image of your teeth, gums, and the surrounding area of your mouth. Just as when you press something into wet clay and it leaves an impression, a dentist uses a special material to make an exact copy of the structure inside your mouth. This copy is called an "impression."

A plaster model of your teeth (also called a "cast" or "study model") is made in a lab using these impressions. This model is a "positive" image of your teeth and gums, which dentists use for various treatments such as:

Creating crowns and bridges.

Creating dentures.

Creating orthodontic appliances (braces to straighten teeth).

Planning for implants.

Making protective mouthguards.

And other restorative tasks.

Simply put, a dental impression is a 3D blueprint of your mouth, based on which precisely fitting appliances are made for your dental treatment.

Techniques for Taking Dental Impressions

There are mainly two types of techniques used to take dental impressions:

1. Conventional Impression Technique

This is the most common and oldest method. It uses an impression tray and impression material.

Impression Tray: This is a U-shaped instrument that is shaped like your dental arch. It is made of plastic or metal and is available in various sizes so that it can fit the patient's mouth exactly.

Impression Material: This material is usually in the form of a paste and is filled into a tray. When it is placed in the mouth and pressed against the teeth, it sets and becomes rubbery in a short time, and takes an accurate impression of your teeth and gums.

Common materials used:

Alginate: This is the most commonly used material because it is cheap, fast, and easy to use. It is made from a mixture of water and powder and sets quickly. However, its accuracy can be less than some other materials, and a plaster model has to be made immediately after it sets.

Polyvinyl Siloxane (PVS): This is a high-precision rubber-based material. It gives very detailed impressions and remains stable even after setting. It is widely used for specific treatments such as crowns, bridges, and implants. It takes a little longer to set in the mouth.

Polyether: Another high-precision material similar to PVS. It also gives very detailed impressions and performs well in humid environments. Its setting time is shorter than PVS, and it is slightly stiffer.

2. Digital Impression Technique

The digital dental impression is a modern and technology-based method that has reduced the need for traditional impressions.

How it works: In this method, a direct 3D digital image of your teeth and gums is taken using a small, handheld scanner (called an intraoral scanner). This scanner is rotated inside the mouth and takes thousands of images that are instantly collected on a computer screen to create an accurate 3D model of your mouth.

Advantages:

More comfortable: The patient does not experience the taste or choking sensation of traditional impression material.

Faster: The scanning process is very fast, and results are seen immediately.

More accurate: Digital scans often provide greater accuracy than traditional impressions, leading to greater precision in treatment.

Environmentally friendly: No material is wasted.

Data storage and sharing: Digital files can be easily stored and shared with labs or other specialists.

Disadvantages:

Expensive: Digital scanners and related software can be costly.

Learning curve: Dentists and staff have to learn to use digital systems.

Procedure for Taking Dental Impressions

Whether the method is traditional or digital, there are some basic steps in the impression-taking process:

Traditional Impression Procedure

Preparation: The dentist will examine your mouth and select an appropriately sized impression tray. Sometimes, an adhesive is applied to the tray to help the material adhere well.

Material Mixing: The impression material (such as alginate or PVS) is mixed with water or other chemicals until it becomes a paste. This must be done very quickly because the material begins to set quickly.

Tray Filling: The mixed material is filled into the impression tray.

Placement: The dentist will carefully place the tray in your mouth and press it against your teeth. During this time, you will feel some pressure.

Allowing to Set: You will need to wait a few minutes (depending on the type of material) to allow the material to set completely. During this time, you should not move your mouth.

Tray Removal: When the material has completely set and hardened, the dentist will carefully remove the tray from your mouth.

Impression Inspection: The dentist will check the quality of the impression taken. If it is not perfect, the procedure may need to be repeated.

Model Making: The impression is sent to a dental lab, or a precise model of the tooth is made in the clinic by filling it with plaster or stone material.

Digital Impression Process

Preparation: The dentist will prepare the teeth in the mouth for scanning, sometimes applying a light coat of powder (if the scanner requires it).

Scanning: The dentist will move a small, handheld intraoral scanner into your mouth. The scanner takes thousands of digital images of the surface of the teeth and gums.

Real-time model: These images are instantly stitched together on a computer screen to create a 3D model of your mouth. You can also see a model of your teeth on the screen.

Verification: The dentist will check the accuracy of the model on the computer and make sure that all the necessary details have been captured correctly. If there are any errors, they can be corrected immediately.

Data transmission: The completed digital model file is sent electronically to the dental lab, where further processes (such as creating a crown via CAD/CAM) begin.

Comprehensive Comparison Between Traditional and Digital Impressions

Both traditional and digital methods of taking dental impressions have their distinct advantages and limitations, which influence clinical choices.

In traditional impressions, dentists take physical impressions of a patient's mouth by filling a tray with a paste-like impression material (such as alginate or PVS). This method has been a mainstay of dental practice for decades because it is relatively inexpensive and can be easily implemented in any clinical setting.

However, patients can often experience discomfort with this method; the strange taste of the material, gag reflex, or pressure from placing the tray in the mouth are common complaints. Additionally, the material takes a certain amount of time to set, and there is a possibility of some physical distortion of the impression during or after this process, which can affect the accuracy of the final restoration. It also takes time to send the physical impression to the lab and create a plaster model of it, and this also includes the cost of couriering.

In contrast, digital impressions use a small, handheld intraoral scanner to capture a 3D image of the tooth directly onto a computer. This process is much more comfortable for patients because there is no material to taste or choke on. The scanning process is extremely fast, and the 3D model of the mouth appears immediately on the computer screen, where its accuracy can be checked and immediately corrected if necessary. This high accuracy, absence of material-related distortions, and instant feedback lead to a more accurate fitting of the dental restoration.

Furthermore, the digital files can be sent to the dental laboratory electronically, saving both time and cost and making the workflow more efficient. However, the initial equipment setup cost, such as a digital scanner and related software, is much higher than the traditional method, which can be a barrier for smaller clinics. Thus, the choice between the two methods is determined by the clinic's budget capacity, priority for patient convenience, and accuracy and efficiency requirements.

0 notes

Text

Enhancing Fencing with Gravel Boards

The Foundation of Durable Fencing

Fencing serves as a vital component of any property, providing privacy, security, and aesthetic appeal. At the base of many fences lies an often-overlooked element that significantly enhances their longevity and stability. Gravel boards act as a protective barrier between the ground and the fence panels, shielding them from moisture, soil, and debris. By elevating the fence above the ground, these boards prevent rot, corrosion, and other forms of deterioration, ensuring the structure remains robust for years.

Available in materials like wood or concrete, these boards are designed to withstand the elements while complementing the fence’s overall design. Their installation is a practical choice for homeowners and property managers seeking to extend the lifespan of their fencing, particularly in areas prone to damp or uneven terrain. This foundational element transforms a standard fence into a durable and visually appealing boundary.

The Strength of Concrete Solutions

For those seeking maximum durability, one material stands out in the construction of these foundational components. Concrete gravel boards offer unparalleled strength and resistance to environmental wear, making them ideal for challenging conditions. Unlike wooden alternatives, concrete boards are impervious to rot, insect damage, and weathering, ensuring long-term stability even in wet or coastal environments.

These boards are typically cast in precise molds, resulting in a uniform and sturdy product that fits seamlessly beneath fence panels. Their weight and solidity provide added stability to the fence, reducing the risk of leaning or collapse during strong winds or heavy rain. While heavier and often more expensive than wood, their low maintenance and extended lifespan make them a cost-effective choice for those prioritizing durability.

Balancing Aesthetics and Functionality

Gravel boards do more than protect; they contribute to the overall aesthetic of a fence. Available in various finishes and textures, they can be tailored to match the style of the property, from rustic wooden designs to sleek, modern concrete options. Wooden boards offer a natural look that blends seamlessly with garden landscapes, while concrete versions provide a clean, contemporary appearance suitable for urban settings.

Functionally, these boards act as a barrier against soil erosion and weed growth, keeping the area beneath the fence tidy and reducing maintenance efforts. They also prevent direct contact between the fence panels and the ground, minimizing damage from moisture or pests. By combining style with practicality, gravel boards enhance both the visual appeal and longevity of fencing systems.

Installation for Long-Lasting Results

Proper installation is critical to maximizing the benefits of gravel boards. The process begins with assessing the terrain to ensure a level foundation, as uneven ground can compromise the fence’s stability. For wooden boards, secure attachment to posts is essential to prevent shifting, while concrete boards require robust posts to support their weight. In both cases, ensuring proper alignment and secure fittings is key to a seamless installation.

Professional expertise can streamline the process, particularly for larger or more complex fencing projects. Technicians account for factors like soil type, drainage, and fence height to ensure the boards perform effectively. For properties with heavy rainfall or clay-heavy soil, additional drainage measures may be incorporated to further protect the fence. A well-installed gravel board sets the stage for a fence that stands strong against time and the elements.

Sustainability and Maintenance Benefits

Gravel boards contribute to sustainable fencing solutions by extending the lifespan of the entire structure, reducing the need for frequent replacements. Wooden boards, when sourced from responsibly managed forests, offer an eco-friendly option that aligns with environmental consciousness. Concrete boards, while more resource-intensive to produce, provide unmatched durability, minimizing the environmental impact of repeated fence repairs or replacements.

Maintenance requirements vary by material. Wooden boards may need periodic treatments to protect against moisture and UV damage, ensuring they remain resilient. Concrete boards, on the other hand, require minimal upkeep, with occasional cleaning sufficient to maintain their appearance. By choosing the right material and maintaining it properly, property owners can enjoy a low-maintenance fencing solution that supports sustainability goals.

Enhancing Property Value

The addition of gravel boards elevates a property’s functionality and aesthetic appeal, making it a valuable investment. A well-maintained fence with a sturdy base signals quality and care, appealing to potential buyers or tenants. In residential settings, these boards create a polished look that enhances curb appeal, while in rural or commercial properties, they provide practical benefits like livestock containment or boundary definition.

Customization options allow owners to align the boards with their property’s style, whether through natural wood tones or textured concrete finishes. This versatility ensures the fence complements the landscape while serving its protective purpose. By investing in gravel boards, property owners can boost both the practicality and marketability of their spaces.

A Solid Foundation for Fencing

Gravel boards represent a small but transformative element in fencing design, offering durability, style, and sustainability. Whether crafted from wood or concrete, they protect fences from environmental wear, extending their lifespan and reducing maintenance costs. Their ability to blend functionality with aesthetic appeal makes them a versatile choice for properties of all types, from cozy gardens to expansive estates.

By prioritizing quality installation and regular care, property owners can ensure their fences remain strong and attractive for years. As environmental awareness and property value continue to shape homeowner decisions, gravel boards stand as a practical and elegant solution. From safeguarding panels to enhancing landscapes, these boards lay the groundwork for fencing that is both enduring and beautiful.

0 notes

Text

How to Match Landscape Supplies with Auckland’s Climate and Soil for Lasting Results

Creating a thriving garden or landscape in Auckland isn’t just about aesthetics. It’s about understanding the local environment and choosing landscape supplies that complement it. Auckland's unique subtropical climate and varied soil types require careful planning and material selection to ensure your outdoor space remains healthy and beautiful year-round.

In this guide, we’ll walk through the essential considerations when matching landscape supplies Auckland with local climate and soil conditions—from decorative elements to structural materials. You’ll learn what works, why it works, and how to use each element strategically.

Understanding Auckland’s Climate and Soil

Climate Overview

Auckland enjoys a warm, humid subtropical climate. Summers are mild to warm (averaging 20-25°C), while winters are cooler but rarely extreme (averaging 10-15°C). High rainfall (approximately 1,200 mm per year) means water management is crucial in any landscape design.

Common Soil Types

Auckland’s soil is primarily derived from volcanic and sedimentary origins. The most common types include:

Volcanic soil (fertile and well-draining)

Clay soil (dense, poor drainage)

Loamy soil (ideal for gardening)

Understanding your property’s specific soil type will influence your choice of plants, drainage systems, and hardscaping materials.

Soil Preparation: The Foundation of Landscape Success

Before laying down decorative features or structures, it’s critical to ensure your soil is suitable for planting and drainage.

Using Screened Topsoil for Healthy Growth

High-quality topsoil auckland is essential for root development and water retention. For Auckland gardens, screened Waikato soil is a reliable option. It’s locally sourced, nutrient-rich, and screened for consistency.

Tip: Blend screened topsoil with compost for even better fertility and structure.

Managing Drainage with GAP Products

Poor drainage can lead to root rot and structural issues. Products like GAP 20 and GAP 40 are ideal for base layers beneath driveways, pathways, or retaining walls.

GAP 20 is a fine gravel, great for compacting.

GAP 40 is coarser and ideal for deeper foundations.

Use Case: For a garden path with good drainage, lay GAP 40 as the base, followed by a thinner layer of GAP 20, and top with decorative pebbles or pavers.

Decorative Supplies: Enhancing Form and Function

Functional doesn’t have to mean boring. The right decorative materials can enhance your garden’s health and style.

Decorative Bark: Natural Weed Control and Moisture Retention

Decorative bark is more than a pretty finish. It suppresses weed growth, maintains soil moisture, and protects roots from extreme temperatures.

Great for flower beds, borders, and around trees.

Helps reduce erosion on slopes.

Expert Tip: Apply bark in a 5-8cm layer for optimal weed suppression and insulation.

Flagstone Pavers: Durable Elegance for Auckland Gardens

For a timeless and durable surface, flagstone pavers are a top choice. Their porous texture allows for some water permeability, which is ideal in Auckland’s rainy climate.

Use for patios, walkways, and courtyard spaces.

Pair with ground covers like creeping thyme to soften the look.

Climate Considerations in Material Selection

Coping with Heavy Rainfall

High rainfall can wash away poorly placed materials and drown roots. Ensure proper grading and use permeable materials.

Add GAP 40 and drainage pipes under paved areas.

Choose mulches and barks that hold shape in wet conditions.

Sun and Heat Exposure

In summer, some Auckland areas can experience hot, dry spells. Use materials that reflect rather than absorb heat.

Light-coloured pavers can prevent heat build-up.

Bark mulch prevents soil moisture loss during dry periods.

Smart Planting: Aligning with Soil and Supplies

It’s not just the hardscape that needs to match the local environment—your plant choices should too.

For Volcanic Soil

This soil drains well and supports most garden plants. Use topsoil to smooth out inconsistencies.

Great for native plants like flax (harakeke) and koromiko.

Add bark mulch to retain moisture and enrich nutrients.

For Clay Soil

Heavy and slow-draining, this soil needs amendment and raised beds.

Use GAP 20 for underlay and screened topsoil on top.

Raised beds or planters improve root health.

Local Trends and Case Study: Sustainable Landscaping in Auckland

One rising trend is the move toward sustainable, low-maintenance gardens that reduce water usage and chemical dependency.

Case Study: North Shore Native Garden An Auckland homeowner revamped their backyard with:

GAP 40 foundation for pathways.

Flagstone pavers and native groundcovers.

Decorative bark to eliminate lawn mowing.

The result: 30% lower water usage and minimal maintenance over 12 months.

Final Tips for Auckland Gardeners

Always test your soil’s drainage by digging a hole, filling it with water, and observing how fast it drains.

Choose materials that support both aesthetic appeal and function.

Think long-term: select supplies that hold up to Auckland’s unique weather.

Conclusion: Building Landscapes That Last in Auckland

Creating a sustainable and visually striking landscape in Auckland starts with matching your materials to your environment. From the foundational GAP 40 layers to the finishing touch of decorative bark, every element has a role to play. Understanding Auckland’s unique climate and soil isn’t just helpful—it’s essential for long-term success.

By investing in the right landscape supplies Auckland has to offer, you’re not just building a garden. You’re building resilience, beauty, and functionality into every inch of your outdoor space.

Ready to transform your garden? Explore premium products tailored to Auckland’s needs at Citi Landscape Supplies.

Source : https://citilandscape.blogspot.com/2025/05/how-to-match-landscape-supplies-with.html

0 notes

Text

The Science Behind Aohong's Bentonite Waterstop: How This "Smart Clay" Outsmarts Water Leakage

As a materials scientist who's tested hundreds of waterproofing solutions, I've seen too many construction projects fail due to one simple oversight: they treated concrete joints as static when they're actually dynamic, breathing systems. That's why Aohong's bentonite waterstop fascinates me—it's one of the few materials that actually respects concrete's natural behavior.

The Molecular Magic Behind the Waterstop

What makes our bentonite different from the clay in your kid's pottery class? Three key properties:

1.Montmorillonite Structure

Each gram contains approximately 7×10²⁰ negatively charged silicate layers. When water molecules (H₂O) enter, they:

Get absorbed between layers → causes 300% volumetric expansion

Form hydrogen bonds → creates a gel with 10⁻⁹ m/s permeability (that's 100,000× slower than water through concrete)

2.Self-Healing Mechanism

Unlike synthetic materials, bentonite:

Re-hydrates after drying (tested through 50+ wet-dry cycles)

Migrates to refill cracks up to 8mm wide (observed under SEM microscopy)

3.Cation Exchange Capacity

Our specially treated bentonite retains Ca²⁺ and Mg²⁺ ions that:

React with cementitious materials → forms secondary sealing compounds

Maintains swelling pressure >3.5 psi even in hard water (verified per ASTM D5890)

Real-World Validation: Beyond Lab Tests

During the Guangzhou Metro Line 14 project, we instrumented joints with:

-Strain gauges (measuring 0.2-1.3mm daily movement)

-Moisture sensors (tracking 0.02% water ingress reduction after Aohong installation)

The data showed something remarkable: the bentonite not only sealed initial gaps but actually improved its performance over 18 months as it formed mineral bonds with the concrete.

Why Most "Bentonite" Products Fail (And How to Spot Quality)

Not all bentonite is created equal. Through XRD analysis, we've found:

⚠️ 68% of "bentonite waterstops" on Amazon/Alibaba contain <40% pure montmorillonite

⚠️ 23% use inferior calcium bentonite (swells only 150-200%)

⚠️ 9% adulterate with sand or gypsum to cut costs

Aohong's quality markers:

✔ Wyoming-sourced sodium bentonite (85-92% montmorillonite)

✔ 24-hour swelling test results showing ≥280% expansion

✔ Documented cation exchange capacity >80 meq/100g

The Future: Where This Technology is Heading

We're currently prototyping:

-Bentonite-polymer hybrids for extreme environments (-40°C to 120°C)

-Conductive bentonite with carbon nanotubes to enable leak detection

-Photocatalytic versions that break down pollutants while sealing joints

For now, though, Aohong's existing hydrophilic waterstop remains what I specify for all my consulting projects—because in materials science, sometimes the best solutions come from nature's own nanotechnology.

0 notes

Text

Concrete Crack Repair: Preventing Structural Damage and Prolonging Lifespan

Cracks in concrete may seem like a minor issue at first, but they’re often the early signs of deeper structural concerns. Whether you’re managing a residential driveway, commercial slab, or a high-traffic warehouse floor, addressing these cracks early is essential. Timely concrete crack repair doesn’t just preserve aesthetic appeal—it protects the integrity and longevity of the structure itself.

From thermal movement to settling foundations and water ingress, cracks can form due to various reasons. Understanding the causes, treatment options, and choosing the right professional can make a significant difference in performance and cost-efficiency. This article explores the key aspects of concrete crack repair, highlighting when to act and who to trust for reliable results.

Why Concrete Cracks and Why You Shouldn’t Ignore It

Concrete is strong, but it’s not immune to stress. Over time, pressure, weather cycles, and poor installation can lead to cracks. These may start small but can widen, deepen, or multiply quickly depending on the environment.

Common causes of cracks include:

Shrinkage during the curing process

Subgrade settlement

Corrosion of reinforcing steel

Thermal expansion and contraction

Overloading

Poor joint design or placement

If left untreated, cracks can allow moisture to seep in, compromising reinforcement, accelerating corrosion, and even causing safety hazards. That’s why working with concrete crack repair specialists is essential to assess damage and recommend the right repair method.

Types of Concrete Cracks You Might Encounter

Not all cracks are created equal. Before repairs can begin, it’s important to identify the type of crack and its likely cause.

1. Hairline Cracks

Often surface-level and caused by shrinkage, these cracks may not affect structural integrity but can be entry points for moisture.

2. Structural Cracks

These extend deeper and may affect the strength of the structure. They’re often found in load-bearing elements such as beams, walls, and slabs.

3. Settlement Cracks

As the soil beneath a concrete slab shifts or compresses, the structure above settles, creating diagonal or stair-step cracking patterns.

4. Expansion Cracks

These occur when concrete expands in the heat and lacks room to move, leading to pressure buildup and splitting.

5. Heaving Cracks

Typically caused by the upward movement of soil during wet seasons, especially in areas with clay-heavy subgrades.

Accurate diagnosis is crucial. Experienced professionals offering trusted crack repair services may use detailed assessments and advanced tools such as crack width gauges and moisture meters to determine the best course of action.

Repair Methods for Concrete Cracks

Depending on the severity, location, and function of the structure, there are several ways to address concrete cracking.

Epoxy Injection

For structural cracks, epoxy injection is often the go-to method. The resin fills the crack and bonds the concrete back together, restoring its original strength. This method is best suited for dry, dormant cracks.

Polyurethane Foam Injection

For actively leaking cracks, especially in basement walls or retaining structures, flexible polyurethane foam may be used. It expands upon contact with moisture, sealing the crack from the inside.

Routing and Sealing

This method involves enlarging the crack slightly before applying a flexible sealant. It is commonly used for surface-level cracks that don’t affect structural performance.

Stitching

In cases where reinforcement is required, metal staples or rods are inserted across the crack and bonded with epoxy. This physically restrains crack movement.

Overlay or Resurfacing

For widespread surface cracks, particularly on floors or pavements, a new layer of concrete or specialised repair mortar may be applied on top.

All of these techniques should be implemented by qualified concrete crack repair specialists to ensure durability and code compliance.

When to Call a Professional

While DIY repair kits might seem appealing for cosmetic fixes, not all cracks are harmless. It’s best to consult with professionals if:

The crack is wider than 2 mm

You notice movement or shifting around the crack

Water is seeping through

The area is load-bearing or critical to the structure

There is visible rust on exposed steel

Professional inspection may help avoid misdiagnosis and ensure the correct materials and repair method are used. This is particularly important for commercial sites, high-rise buildings, and heavily trafficked surfaces.

The Benefits of Proactive Concrete Repair

Preventing small problems from becoming costly repairs is the key reason to address concrete cracks early. But there are several other benefits to regular inspections and prompt repairs:

Improved safety: Prevent trips, falls, or structural failures

Enhanced property value: A well-maintained surface reflects on overall asset quality

Extended lifespan: Repairs protect the core structure from water, salt, and chemical intrusion

Lower long-term costs: Early intervention often saves thousands in future remediation

Compliance with building codes: Especially important in commercial and public spaces

A helpful breakdown of these advantages can be seen in related blog content over at Tumblr, where property maintenance strategies are often discussed by industry enthusiasts.

Choosing the Right Concrete Crack Repair Specialist

A good repair job does more than hide the problem—it solves it. Here’s what to look for when hiring a crack repair expert:

Experience: Look for a provider with a proven track record in both small and large-scale projects

Assessment tools: Modern diagnostic methods offer more precise, tailored solutions

Material quality: Using premium-grade epoxies, sealants, or mortars makes a lasting difference

Service range: From inspection to post-repair monitoring

Safety and compliance: Providers should adhere to all applicable Australian Standards and OH&S guidelines

Providers such as Sonaa deliver trusted crack repair services across varied property types, offering practical and code-compliant outcomes that property owners can count on.

Applications Across Property Types

Concrete cracking can affect various kinds of structures, including:

Driveways and footpaths

Commercial warehouse slabs

Structural columns and beams

Car parks and loading docks

Tilt-up panels in industrial units

Basement walls and retaining systems

Repair approaches may vary depending on the site, which is why tailored solutions from concrete crack repair specialists are essential. Overviews of industry examples, including before-and-after photos, are often shared by professionals on Tumblr, offering real-life insights into what effective crack remediation looks like.

Final Thoughts

Concrete may be tough, but it’s not immune to time, pressure, and environmental exposure. Recognising and addressing cracks early can save property owners significant cost and stress in the long run.

Whether it’s a single joint showing signs of stress or widespread cracking across a large slab, trusting experienced professionals with the right equipment and approach makes all the difference.

Explore lasting solutions with concrete crack repair specialists who combine technical know-how with an understanding of site-specific challenges. A well-maintained concrete structure not only looks better—it lasts longer, performs better, and safeguards everyone who depends on it.

0 notes

Text

How Used Heavy Equipment Ages Differently Based on Terrain

The Science of Wear and Tear

Heavy equipment needs to handle tough conditions yet its survival depends mainly on operating environment factors. Irregular surfaces of rocks and mud make difficult operating conditions that cause faster damage to machines. Buyers and contractors need to understand terrain effects on equipment parts to pick used heavy equipment wisely. Mechanical stress and environmental elements along with how operators use equipment determine the speed at which machines age which affects their usefulness and maintenance requirements.

The Impact of Rocky and Hard Terrain

Rocks and mountains push the undercarriage system beyond its limits in both quarry and mountain areas. Metal parts in the system fail sooner by developing cracks when heavy rocks keep hitting the same spots. Operating over uneven ground worsens damage to joint parts, bearings, and hydraulic links which raises the risk of mechanical breakdown and fluid leakage. Dirt and debris from off-road areas enter into vehicle cooling systems and filters plus engine areas which makes them work poorly and creates a danger of engine overheating. Equipment from used sources that worked in demanding conditions tends to show stress on its frame and needs a complete inspection before being acquired.

How Soft and Muddy Terrain Affects Equipment Lifespan

When machinery operates on soft muddy surfaces such as construction sites with loose soil and wet clay it endures high pressure. Operating machines becomes challenging when they lose traction which makes operators push their engines harder and causes both fuel waste and damage to mechanical parts. Water enters metal parts which leads them to develop rust and become gradually weaker. Continuous exposure to wet muddy undercarriage surfaces speeds up wear damage to hydraulic parts and other critical elements. Inspection of used heavy equipment from muddy areas must identify corrosion damage plus signs of excessive hydraulics wear and engine problems caused by pushover work.

Sand and Desert Conditions

The desert terrain poses special damage effects on heavy equipment. Sand causes faster damage to mechanical parts such as gears and hydraulic cylinders than any other surface type. Dust particles build up in air filters leading to engine problems and overheating unless air filter maintenance is done regularly. Heat extremes hurt equipment life by changing hydraulic fluid thickness and raising the chance of overheating. The heat speeds up rubber part failure in tire seals so it must be checked often. Buyers considering used heavy equipment from desert areas need to focus on inspecting wear on visible moving parts and the cooling system performance.

Cold and Icy Terrain

Heavy machinery operators in cold construction zones must deal with specific operational issues. When temperatures drop metal parts shrink creating a risk of cracks that form when the parts face load. Cold temperatures make hydraulic fluids and engine oils harden which puts more stress on pumps and cylinders as they work less efficiently. Snow and ice make it harder to stop and slide more often which puts extra strain on braking parts and undercarriage parts. Running engines for long periods without use becomes necessary for system warmth which wastes fuel and damages the engine over time. Cold environment equipment needs inspections for metal damages plus testing of fluid systems and traction parts wear.

Swamps and Wetlands

When operating equipment in wet swampy areas it faces serious damage from rust because of excessive moisture exposure. Water contact damages steel components including frames buckets and undercarriages because it makes them weaker. Organic residue that builds up in cooling systems and hydraulic lines stops proper flow which reduces performance and makes the engine too hot. Water that enters electrical systems creates short circuits and damages sensor performance. Examine hydraulic hoses and electrical components after buying used heavy equipment that worked in water since these elements could need replacement when found damaged.

Urban and Paved Surfaces: Wear Patterns in City Projects

Despite being less demanding than off-road terrains urban construction sites require special tire treatment. Repeated work on paved roads creates extra tire and track friction which wears them down faster. The frequent stopping and starting work at city construction jobs puts heavy pressure on engines and transmission systems which causes them to wear out sooner. The metal parts in machinery suffer faster corrosion when they take in pollutants along with road salts and industrial chemicals. When buying used heavy equipment from urban areas customers should check the transmission fluid quality as well as brake parts and tire or track health to assess the machine's potential lifespan.

Preventative Maintenance Strategies for Different Terrain Types

Heavy equipment needs proper maintenance based on where it operates to reach its full lifespan. Equipment that works on rocky surfaces needs regular examination of its base parts and shock absorption system tests. Muddy terrain needs frequent equipment cleaning to stop moving parts from gathering debris and desert operations need air filter changes plus checking the cooling system. To avoid hydraulic system issues in cool weather use winter-grade fluids while adding engine oil protection and swamp components can last longer with rust-prevention coating. Using predictive maintenance tools helps fleet managers detect equipment wear trends so they can solve problems before they become serious issues.

0 notes

Text

Prefabricated Prefinished Volumetric Construction (PPVC): A Structural Engineer's Viewpoint in Singapore

In the face of rapid urbanisation and increasing demand for high-quality, cost-effective buildings, Singapore has witnessed a monumental shift in its construction methodologies. Prefabricated Prefinished Volumetric Construction (PPVC) is among the innovations revolutionising the construction industry. This cutting-edge approach offers significant speed, sustainability, and efficiency advantages—imperatives in the land-scarce city-state. To enhance productivity, the Building and Construction Authority (BCA) has been a driving force behind the widespread adoption of PPVC, advocating its use for various building types, from residential towers to commercial and public projects.

PPVC is more than just an innovative form of modular construction; it completely rethinks traditional construction practices. This article delves into the structural engineering perspective of PPVC in Singapore, discussing its unique features, challenges, and future potential while addressing the regulatory landscape and technological advancements shaping its future.

Understanding PPVC: A Game-Changer in Modern Construction

PPVC is often regarded as a transformative solution for urban construction, especially in cities with space constraints like Singapore. Unlike conventional prefabrication, where only parts of the building are constructed off-site, PPVC modules are fully pre-assembled, including walls, floors, ceilings, and interiors, before being transported and stacked on-site.

Key Features of PPVC

Off-Site Manufacturing: Modules are produced in high-precision factory settings, ensuring high-quality finishes and reducing the impact of on-site weather conditions.

Pre-Completed Interiors: Electrical systems, plumbing, and interior finishes are installed before the module is shipped, drastically cutting down the on-site labour needed.

Efficient Assembly Process: Modules are delivered and stacked in a pre-planned configuration, reducing construction time.

Minimal Wet Trades: Traditional construction methods involve extensive on-site work, including pouring concrete, plastering, and painting. PPVC dramatically cuts these processes down to a minimum.

PPVC is particularly suited for high-rise residential buildings, hotels, dormitories, and healthcare facilities—environments with premium space and repetitive layouts are common.

Structural Engineering Considerations for PPVC

While PPVC offers numerous benefits, it presents a unique engineering challenge. Structural engineers must consider several critical aspects to ensure the safety, stability, and longevity of PPVC buildings.

1. Load Transfer and Structural Integrity

PPVC modules are typically stacked to form multi-story structures. To ensure that these buildings remain safe and stable, engineers must design the modules to handle a variety of structural loads:

Gravity Loads include the weight of the building itself and any additional loads from occupants, furniture, and equipment. Engineers must ensure that each module can effectively transfer vertical loads down to the foundation and maintain this load distribution as the structure grows taller.

Lateral Loads: These forces, caused by wind, seismic activity, or other external factors, can place significant stress on a building. While Singapore is not as prone to large-scale seismic events, engineers must still account for lateral forces, especially for taller buildings. PPVC structures often incorporate reinforced concrete cores or steel-framed structures to resist these forces.

Differential Movement and Settlement: Singapore's soil conditions often involve soft clay and can result in differential settlement. Engineers must design foundations that accommodate settlement without compromising structural integrity, using techniques like post-tensioning or deep pile foundations to counteract the uneven settling of modules.

2. Material Selection for PPVC

The selection of appropriate materials is paramount in PPVC construction. Each material must contribute to the building's overall structural strength and durability while aligning with BCA regulations regarding fire safety, acoustic performance, and environmental sustainability.

Reinforced Concrete (RC): Used for its superior compressive strength and durability, reinforced concrete is often the material of choice for the core structure of PPVC modules.

Structural Steel: Steel offers a balance of strength and flexibility and is commonly used for module frameworks. It facilitates rapid assembly and enables lighter, more flexible structures.

Light Gauge Steel (LGS): LGS is a suitable option for buildings with less demanding load requirements, providing flexibility and ease of fabrication.

These materials must be engineered to meet stringent fire resistance standards, particularly for high-rise buildings, and ensure that acoustic performance meets expectations in terms of privacy and comfort.

3. Connection Systems and Modular Integration

One of the biggest challenges in PPVC is ensuring that the modular units integrate seamlessly once they are delivered to the site. The connection systems between these modules must be designed for both structural integrity and ease of assembly:

Bolted vs. Welded Joints: Engineers must decide whether bolted or welded joints are most suitable for the project. Bolted joints allow quicker assembly and disassembly, while welded joints offer enhanced stability.

Inter-Module Connections: These connections are vital for ensuring that all modules are securely integrated. Steel plates, grout pockets, and post-tensioning techniques are commonly used.

Waterproofing and Sealing: Preventing water ingress at module joints is critical for maintaining the building's durability and comfort. Advanced waterproofing membranes and sealing techniques ensure that moisture does not affect the internal spaces.

Regulatory Compliance and Standards for PPVC in Singapore

The Building and Construction Authority (BCA) plays a central role in regulating the use of PPVC in Singapore. The government's focus on construction productivity and sustainability means that PPVC projects must meet strict standards to ensure their success.

1. BCA's Guidelines for PPVC Implementation

To maintain safety and quality, the BCA enforces rigorous standards for PPVC:

Structural Robustness: PPVC projects must comply with the Eurocode 2 and 3 standards, which provide guidelines for the design of concrete and steel structures.

Fire Safety: Modules must meet fire safety codes, ensuring fire-resistant materials use and maintaining fire compartmentalisation throughout the building.

Acoustic Performance: Acoustic testing and compliance with BCA's acoustic performance standards are essential to maintaining privacy and comfort.

CONQUAS Compliance: The Construction Quality Assessment System (CONQUAS) evaluates construction quality, and PPVC projects are required to meet high-quality standards in both construction and finishes.

2. Government Incentives for Productivity

The BCA actively supports the use of PPVC through financial incentives and prioritisation of projects that incorporate Design for Manufacturing and Assembly (DfMA) principles. The government encourages builders and contractors to adopt more efficient construction methods by offering grants and tax incentives. Structural engineers play a critical role in ensuring compliance with these regulations while optimising the overall efficiency of PPVC projects.

Successful Case Studies of PPVC in Singapore

Several key projects in Singapore have already showcased the success of PPVC in transforming construction timelines, costs, and quality.

1. The Clement Canopy – Singapore's First High-Rise PPVC Residential Tower

Project Type: Residential (40-storey twin towers)

PPVC Strategy: Over 1,800 volumetric modules were prefabricated off-site and assembled on-site.

Results: The project saw a 25% reduction in construction time and improved quality control.

2. Jewel Changi Airport's YOTELAIR Hotel

Project Type: Hospitality (130 modular hotel rooms)

PPVC Strategy: Pre-assembled modular units were delivered and installed in record time.

Benefits: The project minimised disruption to airport operations and provided a high level of finish accuracy.

3. Tengah HDB Housing Development

Project Type: Public housing (Future Smart & Sustainable Town)

PPVC Strategy: Modular concrete units were extensively used to reduce construction time.

Impact: The project has provided faster delivery and sustainability benefits, serving as a model for future public housing in Singapore.

Looking Ahead: The Future of PPVC in Singapore

1. Digital Innovation in Design and Construction

Integrating Building Information Modeling (BIM) and Artificial Intelligence (AI) transforms PPVC design. Engineers can now simulate the structural performance of modules before fabrication, allowing for more precise error prediction and optimisation. These tools also enable the streamlining of supply chains and better coordination between architects, engineers, and contractors.

2. Sustainability and Circular Economy Practices

PPVC supports Singapore's Green Plan 2030, which aims to create more sustainable urban environments. Innovations in PPVC include solar-integrated facades and recyclable modular units, which contribute to a circular economy in which materials can be reused or repurposed.

3. The Future of Skyscrapers and Complex Structures

As PPVC technologies advance, constructing high-rise skyscrapers and complex structures through modular construction is becoming more feasible. The next frontier for PPVC may include 50-storey and taller buildings by utilising hybrid systems combining steel and concrete for enhanced load-bearing capacity.

Conclusion

PPVC is revolutionising the way buildings are constructed in Singapore. Providing faster, safer, and more sustainable construction solutions offers significant advantages over traditional methods. For structural engineers, adopting PPVC requires careful consideration of load distribution, material selection, and modular integration. With regulatory backing from the BCA and the integration of advanced technologies, PPVC has the potential to shape the future of urban construction in Singapore, leading to smarter, greener cities.

As Singapore continues its journey toward sustainable urbanisation, PPVC stands poised to play a central role in shaping the skyline of tomorrow.

1 note

·

View note

Text

Interlock fixing and installation Provider in Dubai

Interlock Fixing and Installation Services in Dubai: Enhancing Aesthetics and Durability

Dubai, a city known for its remarkable infrastructure and stunning landscapes, is home to some of the most beautiful paving and flooring solutions. One of the most preferred options for outdoor surfaces is interlocking paving, a durable and visually appealing solution for driveways, walkways, patios, and other exterior spaces. If you're looking for top-quality interlock fixing and installation services in Dubai, you've come to the right place.

Why Choose Interlocking Pavers?

Interlocking pavers deliver extensive advantages which establish them as the best material selection for residential areas together with commercial facilities. Here are some key benefits:

Durability and Strength

The manufacturing materials of interlocking pavers consist of concrete along with clay together with natural stone so they deliver outstanding durability and long service life. The material withstands heavy weight and harsh temperatures together with intense pedestrian patterns which makes it an ideal outdoor solution for the hot environment of Dubai.

Aesthetic Appeal

The selection of various color options together with different textures and design patterns allows interlocking pavers to bring added beauty to all exterior areas. Such pavers enhance architectural designs by bringing sophisticated style while remaining highly demanded in contemporary buildings.

Easy Maintenance

Interlocking pavers provide better maintenance than the standard concrete and asphalt surfaces because users can easily replace non-functioning pavers without harming other parts of the surface. Pavers damaged in the surface can be replaced individually which maintains the rest of the area and lowers operational costs.

Slip-Resistant Surface

Interlock pavers provide better traction which decreases the possibility of people slipping especially during wet weather. The product functions as a safer solution for both pathways as well as poolside locations and exterior areas.

Environmentally Friendly

Pavers with interlocking designs enable the passage of water through the surface thus decreasing runoff water as the water replenishes groundwater reserves. Being environmentally friendly these sustainable construction items form an excellent choice.

Our Interlock Fixing and Installation Services in Dubai

We operate as Dubai's top interlock installation and fixing company which specializes in residential along with commercial and industrial property services. Our team comprises professionals who deliver exact and superior work with high-speed performance for each task.

Our Services Include:

Driveway Interlock Installation

Paved driveways both boost property wow appeal at first sight besides improving the aesthetic beauty of the entrance. The company delivers tailored designs together with premium materials to guarantee a solid driveway which looks attractive.

Walkway and Pathway Paving

Every human pathway and garden path at our company receives interlocking pavers which become part of the natural environment while creating pleasant walking surfaces.

Patio and Outdoor Space Paving

Our patio interlocking solutions will help you convert your outdoor regions into functional and well-designed outdoor areas. Our company provides a range of designs and surface finishes which enables you to choose styles that match your preferences.

Poolside Interlocking Paving

Bring elegance and safety features together through the installation of interlock paving systems suitable for poolside areas. The installations we create function under water conditions and preserve an upscale aesthetic appearance.

Commercial and Industrial Paving Solutions

Our company manages massive projects regarding parking lots together with commercial walkways and industrial flooring requirements. The interlock solutions from our company deliver strong durability combined with heavy traffic resistant performance.

Interlock Repair and Replacement

Our repair and replacement services will fix both functional and aesthetic problems in your existing integrally-collected pavement which has sustained damage and cracked surfaces.

Why Choose Us?

Expertise and Experience

Our organization has achieved success through diverse interlock fixing and installation projects in Dubai after dedicating many years to the industry. Our team of accomplished workers delivers workmanship of the finest quality.

High-Quality Materials

Our company selects superior materials provided by reliable suppliers who guarantee lasting appeal and durability in the results. The construction materials endure extreme conditions of Dubai's climate while being resistant to frequent heavy traffic.

Customized Solutions

All of our clients have individual needs we recognize. Our staff assists customers through a working partnership to create and position interlocking pavers according to requirements.

Affordable Pricing

Our company provides affordable rates that maintain premium standards during all operations. You will get maximum value from your investment because our pricing system shows every expense clearly.

Timely Project Completion

Our organization focuses both on operational effectiveness and rapid project fulfillment. Our efficient project management system enables your interlock installation to finish in the agreed period without encountering excess time delays.

Poolside Interlocking Paving

Your poolside space can achieve better appearances through the use of slip-resistant stylish interlock paving. The designed installations provide both waterproof durability along with elegant visual appeal.

Commercial and Industrial Paving Solutions

Our company handles big construction projects which include parking lots, commercial walkways together with industrial flooring installations. The interlock solutions demonstrate superior durability characteristics alongside resistance to vehicle traffic loads.

Interlock Repair and Replacement

We offer technical expertise for both repair and full replacement of interlocking pavements when you need to restore their original look and functionality.

How We Work

We use a straightforward process with no complications that leads to a smooth service for every client.

We start every project through an extensive consultation to identify client requirements followed by an inspection of the site location. Expert personnel inspect sites to evaluate the area before making recommendations.

Our team utilizes your specification to develop an exclusive design blueprint which selects suitable materials with color schemes and pattern options.

The team commences by setting up a firm base foundation which allows them to position interlock pavers with high accuracy.

After completion of installation our team performs an extensive quality assessment to confirm both endurance and excellence of the project.

The team supports you through all maintenance aspects and delivers repair services after installation for the care of your pavement.

Contact Us Today!

Our company provides dependable interlock fixing and installation services for clients throughout Dubai. Our organization delivers outstanding results for residential driveways alongside commercial walks as well as industrial flooring installations.

Contact us now for a free project quote we can provide for your project discussion. Your outdoor areas will benefit from lasting interlocking systems found at our location.

0 notes

Text

Porcelain Tiles from Morbi: The Perfect Balance of Style and Durability.

Morbi village in Gujarat is world famous because of the ceramic and tile-making industry flourishing there, due to the innovative designs created by its people, always focusing on high-quality, artistic tiles. Among the major brands in this competitive market is SNK Surfaces, one of the biggest Morbi tiles companies at Matel Road, 8-A, National Highway, Dhuva, Morbi, Gujarat – 363621. SNK Surfaces has focused on fine craftsmanship and high-end designs to grow into one of the largest porcelain tile manufacturers in Morbi, offering style and durability solutions that match international standards.

Rise of the Tile Industry in Morbi

Indeed, Morbi tile industry has also gradually improved, forming to become among the strongest manufacturers from Indian tile exports. Known for being one of the most technologically advanced production processes around, the Morbi-based tile manufacturers produce a significant variety of tiles that varies from standard ceramic to super-grade porcelain tiles. Due to this fame, Morbi has emerged as the ideal destination for buyers who want to purchase top-grade quality tiles, whether a domestic or international buyer.

Why Porcelain Tiles?

Porcelain tiles have emerged as an immensely sought product by people for durability, versatility, and beauty. With refinement in clay, porcelain is fired at high temperatures; hence, they are much denser and more watertight than ceramic tiles. As a renowned Morbi tiles designer, SNK Surfaces manufactures each tile with perfection, providing not only superior performance but also breathtaking beauty. Here is why porcelain tiles make the ideal choice:

Highly durable. They can be utilized at busy zones since they resist wear and tear well. Comes in extensive varieties of designs. Can be found in various finishes, textures, and even designs which imitate the natural designs like wood, stone, etc. Low maintenance, thus ideal for busy house owners and commercial locations. It is easy to clean, thus no mess or marks anywhere in such cases. Moist Resistance Suitable for wet spaces such as bathrooms and kitchens as well as outdoor spaces due to their low porosity.

Creative designs by SNK Surfaces

Being a forward-thinking Morbi company, SNK Surfaces offers an ample collection of modern and vintage designs. It doesn't matter if you are keen on having a sleek modern finish or timeless traditional pattern- the porcelain tile collection would definitely satisfy your diversified needs. Be it elegant high-gloss finishes or texture surfaces for depth, the combination of functionality and style makes their tiles the perfect fit for all residential and commercial projects. SNK Surfaces has shown lately that the Morbi tiles industry is increasingly committed to sustainability manufacturing. Adding to eco-friendly technologies in production, waste product minimization, and keeping their whole production processes both efficient and environmentally responsible have helped ensure the high quality of products from SNK Surfaces. The sustainability commitment allows their company to make them a choice for customers seeking greener ways. Versatile Applications of Porcelain Tiles Porcelain tiles by SNK Surfaces are highly versatile and can be used in a variety of settings: Flooring: Both for indoor and outdoor application as it is strong and weather resistant. Wall Cladding: It provides a stylish touch to the interior and exterior walls. Countertops: Offers a durable and stylish surface option for kitchens and bathrooms. Commercial Spaces: Ideal for offices, retail stores, and hospitality environments as they are incredibly robust, with aesthetic beauty.

Why choose SNK Surfaces?

Partner with SNK Surfaces which is company committed to product quality, aesthetics, and complete customer satisfaction. As among the largest manufacturers of Morbi porcelain tiles, they provide: Extensive Design Options: There are designs in an extensive range to fit your personal style, ranging from modern to traditional. High Quality Products Each tile undergoes rigorous quality checks to meet international standards.

Customer-Focused Service: Their team provides seamless support in product selection and delivery for smooth satisfaction. SNK Surfaces is a name one can bank upon for premium porcelain tiles that symbolize class, durability, and sustainability. Innovation and quality are its dedication, making the clients choose them across India and all over the world. For a visit, kindly proceed to Matel Road, 8-A, National Highway, Dhuva, Morbi, Gujarat – 363621, for its spectacular Morbi tiles design collection and elevate your next project with the best of tiles in the industry.

0 notes

Text

How to Identify Waterproofing Needs in Birmingham