#component lifecycle

Explore tagged Tumblr posts

Text

Purecode | Use Conditional Redirects Wisely

Implement conditional redirects, such as those based on user authentication status, with care. Ensure you check conditions as early as possible in the component lifecycle, preventing rendering unnecessary components.

#Use Conditional Redirects Wisely#user authentication status#component lifecycle#preventing rendering unnecessary components.#purecode#purecode ai company reviews#purecode company#purecode software reviews#purecode reviews#purecode ai reviews

0 notes

Text

#tutorial#shorts#react#react developer#state vs props#props#State#Stateless components#Stateful Components#class components#functional component#hooks#life cycle methods#Components#JSX (JavaScript XML)#Props#Component Lifecycle#Functional Components and Hooks#React Router#State Management#Conditional Rendering#Lists and Keys#Forms and Controlled Components#Component Composition#Styling#Error Handling#Testing#Performance Optimization#React DevTools

0 notes

Text

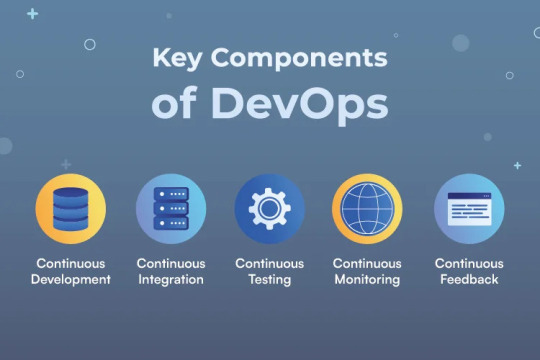

#DevOps lifecycle#components of devops lifecycle#different phases in devops lifecycle#best devops consulting in toronto#best devops consulting in canada#DevOps#kubernetes#docker#agile

2 notes

·

View notes

Text

High-Temp Metals: Breaking Down Barriers in Manufacturing

In the fast-paced world of manufacturing, efficiency and durability are paramount. High-temp metals have emerged as game-changers, revolutionizing how industries tackle extreme conditions.

Case Study: Streamlining a Manufacturing Process

A leading aerospace parts manufacturer faced frequent downtime due to component failures in high-temperature environments. By switching to Accromet’s high-temp metals, they reduced component wear by 30%, improved product lifespan, and significantly decreased production interruptions.

Expert Insight: Reducing Downtime with High-Temp Metals

We spoke with John Smith, a materials engineer with 20+ years of experience: "High-temp metals are vital for modern manufacturing. Their exceptional thermal resistance prevents failures in extreme environments, ensuring smooth operations and reduced maintenance costs."

The Numbers Speak for Themselves

25%: Average increase in manufacturing efficiency reported by companies adopting high-temp metals.

40%: Reduction in downtime due to enhanced durability and thermal resistance.

50%: Longer lifespan of components made with high-temp alloys compared to standard materials.

Storytelling: Transitioning to High-Temp Metals

Imagine a small-scale automotive manufacturer struggling with heat damage in their exhaust systems. After integrating high-temp metals into their design, they not only resolved the issue but also improved vehicle performance. Their success story showcases the transformative power of these materials.

Actionable Advice: Steps to Integrate High-Temp Metals

Identify Problem Areas: Pinpoint where thermal resistance is critical in your processes.

Consult Experts: Work with specialists to select the best alloy for your needs.

Test and Iterate: Start with prototypes to ensure compatibility with your manufacturing line.

Train Your Team: Educate staff on handling and maintaining high-temp components.

Visuals: Lifecycle of a High-Temp Metal Component

Let’s Hear From You!

What’s the biggest challenge you face in manufacturing with high-temp materials? Share your thoughts in the comments below and join the conversation!

By incorporating high-temp metals, you can overcome manufacturing barriers and unlock new levels of efficiency and reliability. Let Accromet be your partner in this transformative journey.

#High-temp metals#Manufacturing#Thermal resistance#Heat-resistant materials#High-temperature alloys#Manufacturing efficiency#Durable materials#Metal component lifecycle#Industrial applications#Heat-resistant components

0 notes

Text

Sell Electronic Components with Confidence!

Are you dealing with an overstock of electronic components? Our network of reliable buyers at Resion will help you sell electronic components with confidence and convenience. Our primary services are consignment and identification of leftover OEM stocks to create demand for your goods. Partner with us today, and let us show you how you can fully utilize your inventory.

#Electronics Parts Suppliers#Largest Electronic Component Distributor#Sell Electronic components#Electronic Parts Distributor#Proactive Supplier Lifecycle Management

0 notes

Text

Devops lifecycle is a methodology used by software development developers to bring products to market faster and more efficiently.

0 notes

Text

youtube

The Unique Lifecycle of the Longleaf Pine

Longleaf Pine, Pinus palustris, is the longest-lived of our southern pine species, with some individuals reaching 450 years old. It has evolved an unusual life cycle to adapt to the frequent fires that are a critical component of its ecosystem.

via: Florida Native Plant Society

135 notes

·

View notes

Text

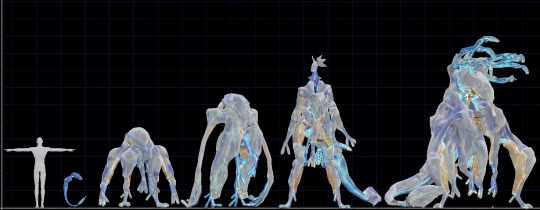

All currently active NeoBuilders.

Minecraft default skins in Ancient Ruins, reference picture at the end for comparison.

Don’t look too close at the faces, had to speedrun this so I could actually motivate myself to finish the entire lineup. Definitely not my best work. Clothing was a pain to figure out and I’ll definitely change some things in the future as I’m still not entirely happy with the general aesthetics of some sets. Zuri and Efe were the worst to figure out, their clothing styles were very modern in comparison to what I’m going for with Ancient Ruins so it took me a while.

But first of all, what is a NeoBuilder?

Lore entry Ahead, body horror warning, nothing too extreme I wouldn’t say, but the concept definitely isn’t the prettiest.

“NeoBuilder” describes a category of individuals that appear to be within the homo-genus (Artisan Family.).

The dissection of a deactivated individual showed (us) they are made of about 85% mechanical components, most of which consist of copper and iron. Organs however remain fully functional and can be traced back to Ancient Artisans in origin through DNA sampling. Blood vessels aswell as a large portion of their flesh has been replaced by machinery, activated regulated and moved through restricted soul energy coursing through their veins as blood would on a fully biological human.

The change of energy source makes them effectively immune to the green plague, which is transmitted through blood. In place of a heart they have a still unnamed chamber (Ch1), acting akin to a cockpit housing a freshly created soul, which is replaced by converting experience farmed in the previous lifecycle to the next, taking the raw energy and morphing it into a new soul. As souls are neither human nor animal but simply an energy cluster made of (if found post mortum) memories and life experience this can easily (and understandably) be transferred, even if the origin of the experience in question happens to be non-sentient. The experience is collected and stored within yet another unnamed organ replacing their left kidney (Ch2).

But do not be fooled, this process by no means makes them immortal. If the body is in critical shape it will resort to exporting the active soul and using the remaining soul energy still running through the machinery to activate the emergency program. In this state the body will do nothing but return to whatever point the machine has clocked as “safe” (this kind of reset happens when the person is resting for an extended period of time, as it marks said area as safe enough to stay vulnerable within.) and fix its injuries back to base point, excluding the bio-matter, as there no longer is any such material around. Through the expelling of the last soul, and slow process of developing a new one, the machine will power down there until the next energy burst. This means that even though the body itself remains alive, every life cycle houses a different person. If you see the same NeoBuilder twice it is therefore not guaranteed it will come with the same intention, as it might be a completely different soul speaking through the same form.

If the damage is too bad however, the NeoBuilder will shut down and cannot be reactivated unless one with actual knowledge of how to do so were to interfere. The how has been lost to history however, we blame the creature of despair and decay that shall not be named. It is different from deactivation, as it renders the body permanently dead. Many NeoBuilders have deactivated, we assume only 9 of the previous 30 remain.

We have no idea as to why these manmade humanoids were created, as the why has also been buried and lost to years of untouched unaddressed missing history.

Infact, their names are quite new, till about half a century ago, due to my own research if I may pat myself on the back, we had assumed them to be a strange strain of plague infested ancients, as they’d always remained distant to us and a dead specimen was a more than rare find. It is not a fully worked out name whatsoever, the “Builder” merely connecting them to the Artisan family, and the word “Neo”- as in “New” replacing the word “Ancient” we’ve been using to describe the other half of the family thus far, it is a placeholder by all means, but so is the latter.

Their nature would definitively make them more akin to bio-mechanical golems, however we chose to group them into the artisan family for the previously mentioned bio material, which matched identical to that of the mummified remains cave divers had found a few years back lodged between long forgotten pathways shut to time. Wasn’t a pretty sight when they showed me. One would think after a good few millennia they’d be nothing but a pile of ash and bones, but low oxygen levels within the closed off cave system made for some awfully good preservation, not pretty I dare say, I’m just glad nothing snapped at me during inspection as, perhaps in this case thankfully, the undead plague only infects the living; anything that doesn’t breathe and lacks running blood cannot fall victim to such a thing. But personal tangent aside, some interesting notes here:

- Despite the soul of the Neobuilder swapping with each lifecycle they generally keep the same base morals of the previous host.

- it seems Mother Earth isn’t very fond of them for whatever reason. The undead are very manageable if one isn’t around, but as soon as one chooses to stay in close vicinity it very quickly gets nearly impossible to maneuver, they’re like a magnet. It seems this is the reason they rarely last longer than 20 years within a single lifecycle.

- they’re actually quite cooperative, and many have learned our language. Though sorrowfully it appears they only store a single slot for their language, and forget all other information of a previously spoken one upon interaction (perhaps they were meant as a situational translation device?). I’ve attempted my best to reteach them, but I’m no linguist; I limit my research to history, with a limited understanding of biology. To figure out the mechanics alone I had to get a whole other villager to help my case.

- despite a large portion of their flesh being replaced by mechanical components an extra layer of the fat cells within the subcutis create an artificial layer of flesh like material dampening any slashes at the golem like form below.

More research to be added once I acquire more material to work with. This is a work in progress.

Understudied field, more research either classified information or unable to be attained due to both lack of examples and individuals willing enough to risk their lives acquiring such needless information. Ivan D. P. Retired shortly after writing his book discussing categorized biological information regarding the entities within our realm, which has since been removed from the market. The authors doctor title has been revoked due to a less than fortunate suspected alliance with the Illager cult on his end, so choose the information you’re willing to believe wisely, the villages dislike him for a reason.

We sincerely apologize but certain behaviors are to be taken seriously regarding the issues the cult on the outskirts has caused us in the past. Rumors have to be believed regarding individuals actively choosing to house away from the masses for whatever reason, to keep the general public safe.

Moving just out of sight to dedicate your life to dissecting humanoids on your dinner table is not normal behavior and was it not for his living position would hastily be investigated,

mumbling about how you hate our community doesn’t lessen our concerns, if you read this Ivan, it was not funny and it will never be, you know of the missing people concerns: if it happens again we’re sorry to inform you but you’ll no longer be welcome within this village.

#minecraft#minecraft lore#mineblr#minecraft au#minecraft theory#minecraft art#artists on tumblr#fanart#artwork#minecraft steve#steve minecraft#minecraft alex#minecraft efe#minecraft zuri#minecraft kai#minecraft makena#minecraft sunny#minecraft ari#minecraft noor#minecraft artist#minecraft villagers#the villagers don’t fw historians#I mean fair enough it’s kind of a pipeline in their case#try to talk about Minecraft without bringing up the ancient freaks challange level impossible#Minecraft Ancient Ruins#au#I’d love to talk about the seperate individuals and where they live and whatever but I kinda just wanted to yap about NeoBuilders (Players)#just ask if you have anything specific#lore dump#minecraft default skins

131 notes

·

View notes

Text

Wajahat Ali and Yusuf Zakir at The Left Hook:

If you listen to Donald Trump, Maga Republicans and lazy comedians, DEI is the modern-day villain. It’s a wicked and terrifying Trojan horse of wokeness that is seeking to “replace” Americans and indoctrinate our children with a subversive agenda. It’s allegedly orchestrated by transgender people, immigrants of color, Muslims, Black people, Jewish people and feminists – anyone that isn’t straight, white and Christian. According to the president-elect, the rest of us are “poisoning the blood of our country” and destroying it.

DEI is an easy, direct and convenient way to package all of these fears. If you fall for this narrative, it can be terrifying and feel unfair. Events such as the collapse of the Silicon Valley Bank, the problems with Boeing aircraft and the destruction of the Francis Scott Key bridge in Maryland were blamed on DEI. This was a con.

Instead of pointing to a corrupt system and deregulation that benefits the wealthy at the expense of many, DEI was seen as the culprit. The bad-faith talking point is that had DEI not existed, these tragedies would not have occurred and real Americans – who are not “woke” – would be safe and economically prosperous. Unfortunately, the deception works as companies such as McDonald’s announced this week that they are renouncing their previous commitment to DEI. It was just revealed that anti-DEI shareholder proposals have tripled since 2020. In reality, DEI refers to three simple but important words: diversity, equity and inclusion.

Diversity is an outcome. Equity is the path to get there. Inclusion ensures we travel that path together. Diversity represents varied identities and differences, including race, ethnicity, gender, sexual orientation, socioeconomic status, disability and veteran status. That means white people, Black people, straight people, gay people, rich people, poor people and more. Equity is the allocation of resources and opportunities and the elimination of barriers to create a path towards equality. The concept of equity acknowledges that there is not a level playing field. Inclusion is creating an environment where everyone is welcome, respected, supported and valued. It is about bringing people together and creating safety and belonging. It is, by definition, the opposite of exclusion.

[...]

Several years later, we see that organizational commitment to DEI has waned. For example, in addition to McDonald’s, Harley-Davidson and Ford recently announced that they will curb some of their DEI efforts. With the continued rightwing political onslaught against DEI and Donald Trump’s election, this could be the moment when many organizations decide to pull the plug entirely. This would be a major mistake.

For organizations considering this decision, we would like to remind you that DEI impacts your talent lifecycle, your culture and your economic success in significant ways. We need to remind US workers about the benefits of DEI as we risk losing them entirely. First, companies have to find and recruit the best talent and as such they will naturally have to cast a very broad net. DEI encourages and helps this outreach. Talent is everywhere, not just among children of politicians, the privileged class or those lucky to attend Ivy League schools and live in wealthy zip codes. DEI encourages us to look beyond traditional (and often archaic) measurements of success, such as SAT scores, and consider the hidden jewels of talent that exist everywhere.

Second, because hiring is so expensive and time-consuming, DEI helps organizations try and retain their valued employees. Equity is a key component that recognizes everyone has different skill sets, talents, strengths and weaknesses. By recognizing this, addressing it and supporting it, DEI helps employees maximize their potential. Studies have repeatedly shown employees are more likely to stay when they feel like they can grow, advance and continue to break through glass ceilings. [...] Costco is an example worth following. Their board unanimously recommended that its shareholders reject a proposal that would require Costco to report on the risks of its diversity and inclusion goals. In making this recommendation, Costco noted that DEI efforts help the company attract and retain employees and improve its products and services. Those who make DEI into a bogeyman paint society as a zero-sum game: a slice for you means no slice for me. But, that is a narrow vision fueled by fear, greed and ignorance. Unlike Trump, DEI views America as generous and limitless. It’s in the best interest of corporations, organizations and US workers to adopt such a vision if we truly want to become great again as a nation.

Love this column in The Left Hook on why DEI makes businesses better, despite what right-wing polemics say otherwise (*cough* Robby Starbuck, Christopher Rufo, Elon Musk *cough*).

#DEI#Diversity#Diversity Equity and Inclusion#New Orleans Truck Attack#California Wildfires#Equity#Business#Francis Scott Key Bridge Collapse#Costco#McDonald's

22 notes

·

View notes

Text

One of Europe’s key players in automotive recycling is expanding its industrial capacity with a new dismantling center set to open later this year at the Flins Refactory site in France. The new facility will process 7,000 end-of-life vehicles (ELVs) annually, recovering more than 25 reusable components per vehicle and processing 14+ different materials for recycling.

This latest move strengthens the operator’s ability to serve the entire automotive circular economy value chain — from raw recycled material supply through to responsible dismantling and parts reuse. It responds directly to growing demand from insurance and repair sectors for sustainable alternatives to new parts and materials, while helping to address regulatory and environmental pressures on the industry.

The new dismantling line at Flins introduces industrial-scale vehicle processing with a focus on efficiency, compliance, and traceability. The facility incorporates a seven-station line running 24/7, supported by integrated vehicle storage and an advanced administrative management system. It is equipped to handle all vehicle types, including electric vehicles (EVs), using diagnostic tools from the site’s Battery Repair Expert Center.

In addition to dismantling, the center manages the full lifecycle of recovered parts — from sorting and protective packaging to online cataloging. Components are photographed and listed on the Opisto platform, which holds 50,000 references, enabling traceable, fast-moving reuse of parts across Europe’s automotive aftermarket.

The new center complements an integrated set of circular economy operations at the Flins site, forming what is being positioned as Europe’s most complete closed-loop ecosystem for damaged vehicles. The site already houses capabilities in used vehicle reconditioning, repair services, component remanufacturing, and battery recycling.

Recovered parts will flow directly into repair and reconditioning activities, while reclaimed materials feed back into European manufacturing supply chains. The growing volume of EVs processed also supports the site's evolving expertise in battery lifecycle management and recycling. Strengthening industrial processing capacity helps shorten supply chains for recycled components and aligns with sustainability goals set by OEMs and insurers alike.

#europe#automobiles#recycling#reuse#good news#environmentalism#science#environment#auto recycling#auto recycler#france#cars

9 notes

·

View notes

Text

𝔼𝕟𝕕𝕝𝕖𝕤𝕤 𝕞𝕦𝕥𝕖 𝟘𝟙

Slugs are friends.

01.Rigelian Bodyplans

Mmf'tir. A race hailing from the 2nd moon of Rigel. A fairly warm, oceanic world. According to their ships archives, they are a living fossil on their homeworld, one of the last of the Mucorposi kingdom, their survival is thanks to a number of reasons, but most important one of them is their insane adaptability, spawned out of their equally unhinged lifecycle.

_ (fig.1 Rigelian Hydra (Mmf'tir<a>umf'm)) The Rigelians' life starts inside the hydra as a bud. These buds grow into the larval rigelian, and develop internal organs before fully separating from their host.

The Hydra itself is the backbone of rigelian social structure, serving as both a nursery, 3d printer and information server. It's the longest living form of a rigelian, able to survive up to 230 years, however, due to the fact it has no "main" head, it is unable to heptate, and therefore is doomed to expire. This however, does not bother the hydra, as it does not posses any manner of autonomy, it's previously exhibited personality erased entirely.

_ ((fig.2 Rigelian larvae(Mmf'aAr))

The larvae remain in the shallow waters for the better part of 6 years as they grow in both sentience and shape. During this time, they go from animals in need of tending to, to menial workers, able to preform manual labor in specially designed exobodies.

_ (fig.3 Rigelian larvae piloting an Aethlynn exobody)

The Aethlynn was developed long before the first official contact with humans to aid in ambassadorial duties. As you can see, it's nervous system is not integrated into the larvas, allowing for easy separation when need arises.

_ (fig.4 The Aethlynns major structural components) This body is a middle ground between rigelian and human anatomy, created based on the data received by the rigelian ships brain over 192 years prier to it's arrival in the solar system. At that time, the ship had not utilized electronic sequencing interpretation. So from what little it could understand, it sourced that humans had long, dexterous upper appendages and strong, upright standing lower ones. This minuscule amount of info it applied to the basic rigelian body plan, resulting in the aethlynn.

_ (fig.5 Rigelian larvae piloting a golem exobody)

The golem is a unique exobody, a result of collaboration between rigelian colonists and humans. If we remove the opaque exogracii, we can see that the main body is an incredibly dense pod of structural exogracii, making the golem a kind of hardsuit for manual labor.

_ (fig.6 golem exobody with opaque exogracci removed)

These exobodies have become so popular, than there are multiple scientific efforts to create a method to allow for other races to pilot them, sadly, there has yet to be any meaningful development on it.

_ (fig.6 Adult Rigelian(Mmf'tyr))

Also known as "the heirophant" this exobody is unique as it's nervous system fully integrates the larva into itself, allowing not only for more precise control, but also heptation and further evolution. The Rigelian will spent around 30 years in this state, until it heptates, turns into a hydra, or expires of old age.

_ (fig.7 Side by Side size comparison)

Rigelians evolved to be rather large due their amphibious lifestyle, of course, it should be noted, that any exobody can be modified by the hydra to suit the rigelians personality and preferences. The most popular bodypart to grow among the colonists are the sensory lobes on their head, which allow for a better depth channel pickup range.

119 notes

·

View notes

Text

#tutorial#shorts#react#react developer#state vs props#props#State#Stateless components#Stateful Components#class components#functional component#hooks#life cycle methods#Components#JSX (JavaScript XML)#Props#Component Lifecycle#Functional Components and Hooks#React Router#State Management#Conditional Rendering#Lists and Keys#Forms and Controlled Components#Component Composition#Styling#Error Handling#Testing#Performance Optimization#React DevTools

0 notes

Text

Bambrew’s range of eco-friendly packaging alternatives

Bambrew, an Indian startup specializing in sustainable packaging, is making strides in the fight against single-use plastics by offering a range of 'eco-friendly' alternatives, says Vaibhav Anant, founder & CEO. The company provides packaging solutions made from renewable, biodegradable materials such as bamboo, seaweed, banana fiber, and agro-waste. According to Anant, these materials are fully compostable and serve as viable alternatives for businesses seeking to reduce their environmental footprint.

“Our solutions are governed by four core principles of sustainability—eco-friendliness, functionality, cost-efficiency, and scalability. These guiding principles enable us to deliver packaging options that are not only environmentally responsible but also commercially viable for businesses of all sizes,” Anant says.

Bambrew offers a range of packaging alternatives, including mailer bags, flexible pouches, rigid boxes, and custom solutions, all designed to meet the functional needs of various sectors while remaining scalable. It has developed solutions for industries such as FMCG, CPG, fresh fruits and vegetables (F&V), food and beverages (F&B), and e-commerce and retail packaging.

Notable clients include Amazon, Nykaa, Hindustan Unilever, Mahindra Logistics, and Tata 1mg.

Material-Agnostic Company

Anant explains that Bambrew is a material-agnostic company, meaning it develops solutions using various materials, all adhering to the four core principles of sustainability as mentioned earlier.

Bambrew prioritizes sustainability not only in its products but throughout the entire product development lifecycle, from sourcing and compounding to conversion processes, says Anant. The company works closely with raw material providers and maintains complete control over production with the latest technology machines for in-house manufacturing. It also operates tech-assisted warehousing and logistics to ensure timely delivery to customers.

“By reducing our reliance on fossil fuels through the use of biofuels and solar energy, we are significantly lowering our carbon footprint. Equally important is the well-being of our workers, and we are committed to maintaining a healthy work-life balance. We adhere to an 8-hour shift structure and offer a range of benefits to ensure a supportive and positive work environment, with a strong emphasis on mental health,” Anant states.

The company has its manufacturing facility in Bangalore and collaborates with several contract manufacturing units across India to expand its reach and capabilities.

Rapid Growth

According to Anant, the company has made big progress over the last 12 months, with growth exceeding 8x.

“This momentum has been incredibly encouraging, and we’re excited to continue building on it in the years to come. As the demand for sustainable solutions grows, we’re committed to scaling responsibly and staying focused on our mission,” he says.

New Offerings

Bambrew is actively working towards the continuous development of advanced meta-materials. It has been extensively researching materials such as Biophil, a home-compostable bioplastic alternative, while also exploring other renewable resources. These materials are designed to offer high performance while being environmentally friendly.

In August of this year, the company introduced a new category of rigid boxes that utilize Kappa boards produced from post-consumer recycled fibers. The product features components like non-animal-based glue, recycled paper cladding, plastic-free Biophil lamination, and plant-based inks. Each element of this product is designed to meet Bambrew's environmental goals and contribute to a fully sustainable manufacturing cycle.

“Additionally, we are actively developing alternative solutions for pharmaceutical packaging, as well as advanced barrier films for food packaging within the FMCG sector. While these are only a few examples, all our efforts are directed towards the broader aim of pushing the envelope of what’s possible within the realm of sustainability and delivering solutions that meet the highest standards of quality while supporting a greener, more sustainable transition into the future,” Anant concludes.

11 notes

·

View notes

Text

#Precision-#molded #aluminum #diecast #keg valves #play a #critical #role in preserving #pressure & #flavor from #tank to #tap #Component are engineered for #leak-#proof #reliability & long #lifecycle under repeated #couplings ⚙️ Tight tolerances for perfect sealing 🧊 Rustproof in cold storage conditions 🔁 Cycle-tested for commercial-grade reuse Every #pour begins with #quality you can count on

📞 Goyal Inc 🌐 www.Incgoyal.com | 📧 [email protected] | ☎ +91 9811088250

http://incgoyal.com https://x.com/goyal_inc https://www.youtube.com/@GoyalInc https://www.instagram.com/goyalinc https://in.pinterest.com/goyalinc https://www.facebook.com/incgoyal https://www.threads.net/@goyalinc #BreweryInnovation #AluminumDiecasting #KegValves #BreweryFittings #DrinkTech #CraftBrewSolutions #LeakProofDesign #FoodSafeEngineering #GoyalInc

2 notes

·

View notes

Text

Integrated Lifecycle Management for Electronics – Future-Proof Your Supply Chain!

Resion delivers integrated lifecycle management for electronics, providing expert strategies and inventory solutions to support your operations from start to finish. Our services ensure your components remain compliant and functional throughout their lifecycle. Get lifecycle management that works efficiently. Call us now at 516-742-6300 to boost your supply chain!

#Proactive Product Supplier Lifecycle Management#Proactive Supplier Lifecycle Management#Electronic Product Lifecycle Management#Integrated Lifecycle Management For Electronics#Electronics Components Life Cycle Management

0 notes

Text

KIOXIA Unveils 122.88TB LC9 Series NVMe SSD to Power Next-Gen AI Workloads

KIOXIA America, Inc. has announced the upcoming debut of its LC9 Series SSD, a new high-capacity enterprise solid-state drive (SSD) with 122.88 terabytes (TB) of storage, purpose-built for advanced AI applications. Featuring the company’s latest BiCS FLASH™ generation 8 3D QLC (quad-level cell) memory and a fast PCIe® 5.0 interface, this cutting-edge drive is designed to meet the exploding data demands of artificial intelligence and machine learning systems.

As enterprises scale up AI workloads—including training large language models (LLMs), handling massive datasets, and supporting vector database queries—the need for efficient, high-density storage becomes paramount. The LC9 SSD addresses these needs with a compact 2.5-inch form factor and dual-port capability, providing both high capacity and fault tolerance in mission-critical environments.

Form factor refers to the physical size and shape of the drive—in this case, 2.5 inches, which is standard for enterprise server deployments. PCIe (Peripheral Component Interconnect Express) is the fast data connection standard used to link components to a system’s motherboard. NVMe (Non-Volatile Memory Express) is the protocol used by modern SSDs to communicate quickly and efficiently over PCIe interfaces.

Accelerating AI with Storage Innovation

The LC9 Series SSD is designed with AI-specific use cases in mind—particularly generative AI, retrieval augmented generation (RAG), and vector database applications. Its high capacity enables data-intensive training and inference processes to operate without the bottlenecks of traditional storage.

It also complements KIOXIA’s AiSAQ™ technology, which improves RAG performance by storing vector elements on SSDs instead of relying solely on costly and limited DRAM. This shift enables greater scalability and lowers power consumption per TB at both the system and rack levels.

“AI workloads are pushing the boundaries of data storage,” said Neville Ichhaporia, Senior Vice President at KIOXIA America. “The new LC9 NVMe SSD can accelerate model training, inference, and RAG at scale.”

Industry Insight and Lifecycle Considerations

Gregory Wong, principal analyst at Forward Insights, commented:

“Advanced storage solutions such as KIOXIA’s LC9 Series SSD will be critical in supporting the growing computational needs of AI models, enabling greater efficiency and innovation.”

As organizations look to adopt next-generation SSDs like the LC9, many are also taking steps to responsibly manage legacy infrastructure. This includes efforts to sell SSD units from previous deployments—a common practice in enterprise IT to recover value, reduce e-waste, and meet sustainability goals. Secondary markets for enterprise SSDs remain active, especially with the ongoing demand for storage in distributed and hybrid cloud systems.

LC9 Series Key Features

122.88 TB capacity in a compact 2.5-inch form factor

PCIe 5.0 and NVMe 2.0 support for high-speed data access

Dual-port support for redundancy and multi-host connectivity

Built with 2 Tb QLC BiCS FLASH™ memory and CBA (CMOS Bonded to Array) technology

Endurance rating of 0.3 DWPD (Drive Writes Per Day) for enterprise workloads

The KIOXIA LC9 Series SSD will be showcased at an upcoming technology conference, where the company is expected to demonstrate its potential role in powering the next generation of AI-driven innovation.

2 notes

·

View notes