#compression mold

Explore tagged Tumblr posts

Text

Carbon Fiber and Composite Materials: A New Era for Heavy-Load Railway Freight Cars

The Role of Carbon Fiber Composite Materials in Modern Rail Transportation

Jointly developed by the China Energy Group’s Railway Equipment Company, the Beijing Low-Carbon Clean Energy Research Institute, and CRRC Qiqihar Rolling Stock Co., Ltd., these railway freight cars not only represent a leap forward in the application of new materials but also contribute to green, low-carbon rail transportation solutions.

Lightweight and Intelligent Design for Energy Efficiency

Under the guidance of national strategies like "Strengthening Transportation" and "Dual Carbon," there is a growing demand for the green transformation of the transportation sector. The China Energy Group, managing over 57,000 railway freight cars, plays a key role in transitioning toward energy-efficient, lightweight solutions for large-scale freight operations, particularly in coal transport.

The new carbon fiber composite railway freight cars are a significant advancement in lightweight, high-strength, and low-energy solutions. These cars are a direct result of integrating compression molding technology and advanced composite materials, setting new benchmarks for efficiency and sustainability.

Advantages of Carbon Fiber Composite Materials

1. Higher Strength-to-Weight Ratio

Compared to traditional materials, carbon fiber composites offer a strength-to-weight ratio 3-5 times higher than aluminum alloys, making them ideal for heavy-load railway freight cars. This higher ratio allows for reduced vehicle weight without compromising structural integrity.

2. Reduced Weight for Increased Efficiency

The carbon fiber composite body reduces the weight of the railway freight cars by more than 20% compared to similar aluminum vehicles. This significant weight reduction, with a self-weight coefficient as low as 0.22, allows for greater load capacity and improves overall transportation efficiency.

3. Enhanced Durability and Environmental Resistance

Technological Innovations in Heavy-Load Freight Cars

1. Optimized Bogies and Air Brake Systems

The new cars are equipped with optimized K6-type bogies, which enhance load distribution and stability. Integrated air brake systems ensure efficient braking, further improving the cars' safety and control.

2. Smart Monitoring Systems for Real-Time Data Collection

These freight cars incorporate smart monitoring systems powered by IoT, big data, and cloud computing, enabling real-time data collection on the performance of the cars. This system improves predictive maintenance and helps optimize energy consumption, contributing to greener transportation solutions.

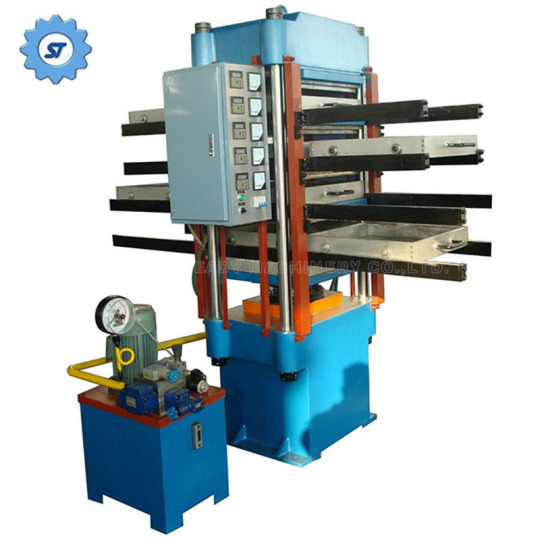

Compression Molding: A Key Manufacturing Technique

The use of compression molding for carbon fiber composite materials has been instrumental in the development of these new railway freight cars. Compression molding allows for the efficient production of large, complex parts with precision, making it ideal for large-scale components such as the car bodies.

Advantages of Compression Molding for Carbon Fiber Components

High precision and consistency in part production.

Efficient manufacturing of large parts in a single operation.

Minimized material waste, especially important with high-cost materials like carbon fiber.

Conclusion: Pioneering the Future of Green Rail Transport

The successful development of carbon fiber composite heavy-load railway freight cars signals a major step forward in the future of rail transportation. With the combined benefits of lightweight design, improved durability, and cutting-edge technologies like smart monitoring systems, these cars offer revolutionary advantages for green, low-carbon transport.

As global transportation continues to evolve, the integration of composite materials and compression molding technology will remain pivotal in shaping the next generation of heavy-load railway freight equipment.

#compression tooling#compression mold#smc mold#bmc mold#smc tooling#bmc tooling#composite mold#compression molding

2 notes

·

View notes

Text

Asia Pacific PCB Compression Molding Press Market (Type: Up Stroking Machine, and Down Stroking Machine; and Compression Layer: 4 Layers, 6 Layers, and above 6 Layers) – Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2023-2031

0 notes

Text

Industry Benefits from Reliable and Flexible Cap Compression Technology

The Cap Compression Molding Machine serves as a cornerstone in many packaging processes, offering manufacturers an efficient and reliable method for producing high-quality caps. This advanced machinery from Taizhou Chuangzhen Machinery enables companies to meet diverse industry requirements, adapting to various materials and design specifications with remarkable consistency.

This compression molding equipment applies precise heat and pressure to form plastic caps that ensure durability and secure sealing. Its versatility allows it to handle a wide range of cap styles, from simple screw tops to sophisticated safety closures. This adaptability is crucial in industries such as food and beverage, pharmaceuticals, and personal care, where product protection and consumer safety are top priorities.

Operational flexibility is another key feature of these systems. They support both large-scale production and smaller custom orders, responding quickly to market demands without compromising on quality. With intuitive controls and robust design, downtime is minimized, helping manufacturers maintain steady production schedules.

Energy efficiency and material conservation are also important aspects of this molding technology. By optimizing process parameters and reducing waste, these machines contribute to more sustainable manufacturing practices. Taizhou Chuangzhen Machinery emphasizes these benefits, integrating green technologies that meet modern environmental standards.

The ability to consistently produce precision caps with high speed makes these compression systems a valuable investment for companies looking to enhance their packaging lines. As market trends evolve, such adaptable and efficient equipment becomes increasingly essential for maintaining a competitive edge.

For more information on the wide-ranging applications and benefits of these molding technologies, please visit the official Taizhou Chuangzhen Machinery page at: capping-machine.net/news/industry-news/cap-compression-molding-machines-price-types-process-and-future-trends.html

#Cap Compression Molding Machine#Capping-machine#packaging solutions#industry applications#energy efficiency

0 notes

Text

How Can a Rubber Compression Molding Machine Improve Manufacturing Efficiency?

Rubber components are vital to countless industries, from automotive and aerospace to medical and consumer goods. For manufacturers seeking a cost-effective way to produce high-strength, precision rubber parts, the rubber compression molding machine is a reliable solution. Known for its simple operation and high adaptability, this equipment remains a preferred choice for producing rubber products with complex shapes and superior durability.

0 notes

Text

Mastering the Silicone Overmolding Process: Techniques, Applications & Expert Support

Silicone overmolding is becoming a key process in many industries. From medical devices to consumer tech, this technique brings better durability, comfort, and style to products. As demand grows, mastering the process is crucial to ensure quality and efficiency. Understanding how to do it right can set your products apart and keep you ahead of the competition.

Understanding Silicone Overmolding: An Overview

What Is Silicone Overmolding?

Silicone overmolding is a manufacturing method where a layer of silicone is molded over an existing part. Unlike traditional molding, which shapes solid parts, overmolding adds a flexible silicone layer onto a substrate, like plastic or metal. This creates a stronger, more comfortable, and more functional product.

Overmolding has been around for decades, but technology has improved fast. Today, it allows brands to design products that feel better and last longer. It’s a way to integrate multiple functions and boost user experience.

Benefits of Silicone Overmolding

Choosing silicone overmolding offers many advantages:

Flexibility: Silicone stretches and bends without breaking, making it perfect for grips and seals.

High-temperature resistance: Silicone withstands extreme heat and cold.

Biocompatibility: Safe for medical and wearable products touching skin.

Enhanced product longevity: Adds extra protection and durability.

Ergonomic design: Improves handling and comfort.

Cost-effective in mass production: Once set up, it’s faster and cheaper to produce large quantities.

Common Industries Using Silicone Overmolding

Many industries rely on silicone overmolding because of its benefits:

Healthcare: Medical devices like catheters, prosthetics, and trainers.

Consumer Electronics: Smartphone cases, headphones, and fitness trackers.

Automotive: Dashboard parts, seals, and protective covers.

Techniques for Effective Silicone Overmolding

Material Selection and Compatibility

Picking the right silicone is key to success. Types like High-Temperature Vulcanizing (HTV) and Liquid Silicone Rubber (LSR) work best depending on the application. LSR is fast and suitable for high-volume runs, while HTV offers more durability.

Compatibility is just as important. Make sure your silicone bonds well with the substrate—whether plastic, metal, or other materials. Testing adhesion and durability beforehand saves headaches later.

Surface Preparation and Design

A clean surface is a must. Dirt, oil, or residue can cause poor bonding. Use suitable cleaning and priming methods to prepare the substrate.

Design tips include:

Draft angles: Simple changes that make removal easier.

Part shape: Keep geometries simple to avoid voids or weak spots.

Use inserts or molds to create complex shapes or add features like buttons or textures easily.

Overmolding Processes and Equipment

The main methods are:

Compression Molding: Good for low to medium volumes; simple but slower.

Transfer Molding: Better for small to medium batches; allows more complex parts.

Injection Molding: Ideal for high volume; precise and fast.

Modern machines come with automation and smart controls that improve quality. Adjust parameters like temperature, pressure, and cycle time to match your materials and design needs for best results.

Troubleshooting Common Challenges

Common problems include:

Delamination (layer separation): Usually caused by poor surface prep or incompatible materials.

Incomplete filling: Can happen if pressure or temperature are set improperly.

Mold wear: Use quality molds and maintain them regularly.

Expert tips include testing and adjusting process parameters often. For example, increasing mold temperature may improve flow and reduce air traps.

Applications of Silicone Overmolding: Case Studies & Industry Insights

Medical Devices: Ensuring Safety and Compliance

Silicone overmolding helps make medical devices safer and more comfortable. Catheters with soft silicone covers reduce irritation. These products must follow strict rules like FDA regulations and ISO standards, ensuring safety and reliability.

Consumer Electronics: Enhancing User Interaction and Durability

Overmolded grips make phones, headphones, and controllers more comfortable. They also protect sensitive electronics from shocks and drops. Many leading brands swear by silicone for quality feel and longevity.

Automotive and Industrial Uses

In cars, silicone overmolding is used for dashboard dials, seals, and protective covers. These parts must endure heat, moisture, and vibrations. Silicone’s durability makes it a smart choice to meet safety standards and environmental challenges.

New Trends and Future Opportunities

Innovations include using biocompatible and eco-friendly silicones. Smart silicones with embedded sensors or conductive features are emerging. These materials can connect products to the internet, opening new opportunities for innovation.

Expert Support and Collaborations in Silicone Overmolding

Choosing the Right Partner

Partner with molders who have experience in your industry. Look for certifications like ISO 13485 for medical or IATF16949 for automotive. Their proven quality ensures consistent results and compliance.

Collaborate for Custom Solutions

Work with experts to optimize designs and prototypes. Simulation tools can help test how materials will behave before manufacturing begins. This reduces waste and speeds up development.

Stay Updated on Industry Innovations

Attend trade shows, webinars, and training sessions. Engage with professional forums and industry groups to learn about new materials and processes. Staying current gives you a competitive edge.

Cost Optimization and Scale-Up Strategies

Transitioning from prototypes to mass production requires planning. Analyze your ROI, and don’t forget to use ongoing technical support to adjust processes and reduce costs over time.

Partnering with a Trusted Manufacturer

YEJIA, a leading custom silicone product manufacturer, provides expert silicone overmolding solutions tailored to client requirements. With years of experience and advanced molding capabilities, the company ensures precise, durable, and high-performance parts for various industries. From material selection and mold design to production and quality control, YEJIA offers full technical support to help customers achieve optimal product performance.

Common Substrate Materials

Silicone can be overmolded onto various materials including:

Plastics such as PC, ABS, PA, PPS, PEEK

Metals like stainless steel, aluminum, brass, and titanium

Other elastomers, depending on compatibility

Silicone Overmolding Techniques

Insert Molding: The substrate is inserted into the mold and silicone is injected around it. This is commonly used when the base part is pre-fabricated.

Two-Shot Molding: Both materials are molded in sequence in the same machine, providing stronger bonding and better process control.

Compression Overmolding: Less common but suitable for lower-volume production or specific geometries.

Conclusion

Mastering silicone overmolding takes understanding, experience, and good collaboration. Techniques like proper material selection, surface prep, and process control build a solid foundation for success. Working with industry experts ensures quality and saves time and money.

Keep learning, experimenting, and staying connected with innovations. Investing in proper training and choosing the right partners will help you produce top-quality, durable, and creative products. The future of silicone overmolding holds exciting possibilities—are you ready to lead the way?

#Compression Overmolding#Silicone Overmolding#silicone duckbill valve#liquid injection molding#silicone rubber valves

0 notes

Text

0 notes

Text

How to Make Injection Molded Plastic Parts

Injection molding is a fast, repeatable process for producing plastic parts at scale. Here's a quick breakdown of how it works:

Design the Part Create a 3D CAD model with proper draft angles, consistent wall thickness, and structural support. Keep the design mold-friendly to reduce production issues.

Choose the Right Material Select a plastic that suits your part’s needs—like PP for flexibility, ABS for rigidity, or PC for clarity and impact resistance.

Build the Mold A custom steel or aluminum mold is machined based on your design. It includes cavities, cooling lines, and ejection systems. Mold making is a one-time cost for mass production.

Start Injection Molding Plastic pellets are melted and injected into the mold at high pressure. Once cooled, the part is ejected. Each cycle typically takes seconds.

Finish & Inspect Excess material is trimmed, and parts are checked for defects. Additional finishes (painting, printing) are applied if needed.

Package & Deliver Parts are packaged according to your specs and shipped out.

Need custom plastic parts? We offer full injection molding services—from design to delivery. Get in touch for a quote.

1 note

·

View note

Text

Can a Rubber Compression Molding Machine Enhance Your Production Process?

For manufacturers working with rubber materials, efficiency and precision are top priorities. In this context, a rubber compression molding machine plays a crucial role in achieving consistent, high-quality parts across various industries. Positioned at the heart of many production lines, this equipment is designed to streamline operations and support both small and large-scale manufacturing.

0 notes

Text

#plastic manufacturing services#plastic manufacturers company#plastic manufacturing companies#plastics manufacturers#Injection Molding Die#Extrusion Die#Blow Molding Die#Compression Molding Die#Finding MFG#plastic die manufacturers#plastic die manufacturers India#plastic die manufacturers Company#plastic die manufacturers Companies

0 notes

Text

The Science Research Notebooks of S. Sunkavally, p 585.

#hatching of eggs#diclofenac#magnetic field of Earth#Bremsstrahlung#uranium#ionization of gases#aluminum#beta radiation#radiowaves#magnetization of iron#high frequency discharge#thermal conductivity of wood#compressed air#angiosperms#Rumford#synovial fluid#cyclotron#hydrogen#grey mold#chickpea crop#fusarium oxysporum#rust#Uromyces ciceris

0 notes

Text

How Much Does a Compression Mold Cost?

Compression molding is a widely used manufacturing process, particularly for thermosetting plastics, which involves the shaping of material through heat and pressure. As businesses explore this method for producing high-quality parts, understanding the costs associated with compression molds becomes essential. This article will delve into the factors influencing compression mold pricing, the average costs, and tips for managing these expenses effectively.

Factors Influencing Compression Mold Costs

1. Material Selection

The type of material used for the mold significantly impacts its cost. Common materials for compression molds include aluminum and steel, with steel being more durable and typically more expensive. The specific requirements of the part being produced, including its size and complexity, will also dictate material choices.

2. Mold Complexity

3. Size of the Mold

The size of the mold correlates directly with its cost. Larger molds require more material and machining time, which can lead to higher overall expenses. For instance, a small, single-cavity mold might cost around $5,000, whereas a large, multi-cavity mold could cost $50,000 or more.

4. Production Volume

The anticipated production volume plays a significant role in mold cost justification. For high-volume production runs, investing in a more expensive mold may be cost-effective in the long run due to lower per-part costs. Conversely, for small production runs, businesses may opt for less expensive molds, even if they sacrifice durability or efficiency.

5. Lead Time

The lead time required for mold creation can also affect costs. Rushed projects typically incur premium charges due to expedited services. Standard lead times can range from a few weeks to several months, depending on the complexity and current workload of the manufacturing facility.

Average Costs of Compression Molds

On average, the cost of compression molds can range significantly based on the factors discussed:

Simple Single-Cavity Molds: $3,000 - $10,000

Moderately Complex Molds (Multi-Cavity): $10,000 - $50,000

Highly Complex or Large Molds: $50,000 - $150,000+

Tips for Managing Compression Mold Costs

1. Design Optimization

Investing time in optimizing the mold design can lead to significant cost savings. Simplifying the design while ensuring functionality can reduce material and machining costs.

2. Consider Long-Term Needs

Evaluate the long-term production needs. While a higher initial investment may seem daunting, the overall cost per unit can decrease with larger production volumes, making it a more economical choice.

3. Supplier Selection

Choose a reputable mold manufacturer with a track record of quality and reliability. Established suppliers may offer better pricing due to their experience and efficiency in production processes.

4. Regular Maintenance

Conclusion

Understanding the costs associated with compression molds is crucial for businesses looking to leverage this manufacturing process. By considering the various factors that influence mold pricing—such as material selection, complexity, size, and production volume—companies can make informed decisions that align with their budget and production goals. Implementing strategies for cost management can further enhance the financial viability of using compression molds in manufacturing. For businesses aiming to produce high-quality, durable parts, investing in the right compression mold is not just a cost—it's a valuable asset for future growth.

#compression tooling#compression mold#smc mold#bmc mold#bmc tooling#smc tooling#composite mold#compression molding#money

0 notes

Text

#compression-molding-Toronto-On#rubber-moulding-company#Custom-rubber-mold-making#Compression-moulding-process#compression-rubber-moulding-Toronto-On

0 notes

Text

Optimizing Investment in Cap Compression Moulding Machines

In today’s fast-paced packaging sector, equipment pricing can significantly influence production planning and profitability. For plastic cap manufacturers, understanding the Cap Compression Moulding Machine Price is essential when upgrading systems or starting new production lines. The Cap Compression Moulding Machine Price reflects a complex combination of technology level, output capacity, energy efficiency, and after-sales support. Taizhou Chuangzhen Machinery, a trusted name in compression molding, provides cost-effective solutions that meet both quality standards and budget expectations.

One of the most prominent cost drivers is machine capacity. Systems with more cavities—such as 32 or 48—naturally command a higher investment than entry-level models. However, these high-capacity machines offer lower cost-per-cap production, making them ideal for beverage or pharmaceutical companies requiring millions of closures monthly. Chuangzhen’s rotary compression units are designed to handle high-volume manufacturing with precision and consistency, justifying their investment through long-term operational savings.

Automation is another pricing factor. Fully automated machines with PLC control, touchscreen interfaces, and advanced safety features tend to cost more but dramatically reduce labor dependency. By investing in smart control systems, manufacturers improve repeatability, reduce scrap, and gain better control over production. Chuangzhen’s systems offer integrated monitoring and diagnostics, reducing the risk of breakdowns and supporting predictive maintenance strategies.

The quality of materials used in construction also plays a role in pricing. Machines built with high-grade steel, anti-corrosion coatings, and precision-milled components may come with a higher price tag but deliver significantly better durability. Lower-quality machines might need frequent maintenance or parts replacement, leading to downtime. Chuangzhen’s robust machine design includes long-life components, centralized lubrication systems, and user-friendly access panels to ensure reliable performance under continuous use.

Flexibility is another factor that influences cost. Manufacturers often need to switch between different cap sizes or formats. Compression molding machines that allow quick mold changes and offer compatibility with various cap types usually come at a premium. Chuangzhen’s modular machine platforms support rapid mold replacement and adjustment, enabling producers to respond to shifting market demands with minimal disruption.

Operational costs, including energy consumption and maintenance, should also be considered. Compression molding is inherently more energy-efficient than injection molding, offering savings over time. Chuangzhen integrates servo-driven systems and optimized heating elements to reduce power usage and support eco-friendly operations. This not only helps lower utility bills but also supports sustainability goals.

Finally, support services add value to the overall price. Comprehensive training, technical support, and spare parts availability can reduce long-term risk and improve machine uptime. Chuangzhen provides dedicated post-sales assistance to ensure buyers maximize their equipment’s potential. The availability of remote assistance and fast service response further enhances the machine's value proposition.To explore full specifications, request a custom quote, or compare machine models, visit Taizhou Chuangzhen Machinery’s official website: https://www.capping-machine.net/ .

#Cap Compression Moulding Machine Price#Cap Compression Machine#Capping-machine#packaging machinery#molding technology

0 notes

Text

What Makes a Rubber Compression Molding Machine a Smart Choice for Manufacturers?

Manufacturing high-quality rubber components requires precision, efficiency, and the right equipment. Among the various methods available, the rubber compression molding machine stands out as a reliable solution for shaping durable rubber parts. With its ability to handle complex designs and high-performance materials, it’s become a preferred tool in many industries.

0 notes

Text

The plastics market in the United States is experiencing robust growth, driven by several key factors. Firstly, the increasing demand for lightweight and durable materials in various industries, such as automotive and packaging, has propelled the plastics market forward. Moreover, the versatility of plastics in design and functionality enhances their appeal, contributing to heightened adoption across diverse applications. Additionally, the escalating need for sustainable and eco-friendly solutions has spurred innovation in bio-based and recycled plastics, creating new avenues for market expansion.

#United States Plastics Market Report by Type (Polyethylene#Polypropylene#Polyvinyl Chloride#and Others)#Application (Injection Molding#Blow Molding#Roto Molding#Compression Molding#Casting#Thermoforming#Extrusion#Calendering#End User (Packaging#Automotive#Infrastructure and Construction#Consumer Goods#and Region 2024-2032

0 notes

Text

Revolutionizing Manufacturing: Top Trends in Rubber Compression Molding Machines in the USA

Discover the latest trends in rubber compression molding machines revolutionizing manufacturing in the USA! Explore how advanced technologies, sustainability, and customization are driving innovation across industries. Dive into our in-depth blog to stay ahead in the dynamic world of industrial production.

0 notes