#convert 3d to 2d pattern

Explore tagged Tumblr posts

Text

Effortless 3D to 2D Pattern Conversion with MPanel Software Solutions LLC

Transforming intricate 3D designs into precise 2D patterns is seamless with MPanel Software Solutions LLC. Our specialized software caters to architects, engineers, and manufacturers seeking efficient pattern development solutions. Whether you're crafting sailcloth panels, architectural membranes, or industrial components, our tools optimize material usage and minimize waste. MPanel Software ensures accuracy, streamlining the "convert 3D to 2D pattern" process to enhance design precision and production efficiency. Join industry leaders using MPanel Software to revolutionize 3D to 2D pattern conversion, enabling a smooth transition from concept to realization. Discover how MPanel Software Solutions LLC empowers your projects with innovative solutions for pattern development, ensuring meticulous results every time.

0 notes

Text

Update notes: another batch of pattern PDFs is up! Regular versions + Pattern Keeper ones.

I also fixed a math error in the DMC color-calculating function.

Actually, math moment incoming:

The bot gets its colors from the PyPalettes library, which is designed primarily for people who want to make good-looking scatterplots and bar graphs. It has a couple thousand color palettes in it, and the bot takes one at random and uses its colors when it makes a sampler.

To convert those colors into DMC ones, it takes each sampler color's RGB colors (like '0, 0, 0' for black, or '255, 255, 255' for white) and treats each as essentially a 3D coordinate-- like with 'x, y, z' coordinates. Then it checks to find which of the existing DMC threads has color coordinates that are closest to it in that 3D space using the distance formula:

√((x₂-x₁)² + (y₂-y₁)² + (z₂-z₁)²)

(if you've made it to high school math, you should recognize this! it's the same as the regular 2D distance formula, but with three variables).

(also the bot doesn't actually bother with the square root, since it doesn't care what the distance is, just which possible distance is smallest).

Anyway I messed it up the first time, and had it cube the binomials instead of square them, which led to some kinda wack negative stuff happening. The effect on the samplers wasn't noticeable, except that some of the samplers had less-harmonious color palettes than they might have.

So-- the samplers might be a little prettier from here on out! Or possibly similarly-pretty, but the math that makes them is nicer, at least. :)

I have some big ideas for things I'd like to add next, but life keeps me busy~

And as always, feel free to @ the bot if you see any cool posts!

43 notes

·

View notes

Text

Patterns of Cycling Saturn

(open image in new tab for proper resolution)

This post will use as an example an upcoming Saturn in Aries Transit that's going to generally take place from 2026 to 2029 together with the current Saturn in Pisces Transit that started in 2023, in order to show you various patterns of Saturn's movement together with its retrograde cycle.

In the image above, you can see a drawing of the Saturn in Pisces cycle from its beginning in 2023 until its final completion in 2026.

The ending of a Saturn cycle can be powerful, just like the beginning of a new one, because it offers us a sneak peek of the energies, that we will be dealing with in the future, in the next Saturn cycle. We don't always have that opportunity - for example, Saturn in Aquarius ended in March 2023 with no previous intermissions of Saturn Pisces energy, giving us no clue what to expect in the current cycle. This year, however, we will have an opportunity to peak into what the future Saturn in Aries transit means for us.

We do not definitively part with the Saturn in Pisces energies until February 2026, but between June and September 2025 we are going to experience an interlude, that will show us what we will be working on in the next cycle all the way till 2029. So pay attention to your life in those months this year, in 2025, watch the influence on your life, take notes, and prepare to be dealing with these same issues for good, all the way till 2029, once the next Saturn cycle becomes final.

At the same time, be ready to wrap up any final Saturn in Pisces business from September 2025 till February 2026, as it will be your last chance to do so for the next 30 years.

I thought it was really fun to see how when you draw out the Saturn cycle timeline, it looks like a piece of human DNA converted from 3D to 2D.

34 notes

·

View notes

Text

Kitchen Cabinet Door Making CNC Router Machine For Sale

Do You want to have a CNC computer cabinet machine that produces furniture? Here are IGOLDEN’s picks of the most popular furniture CNC machines of 2024 to create semi-custom and custom cabinets, including CNC wood cutting machines, carving machines, drilling machines, grinding machines, sanding machines, and laminating machines. We can customize a complete panel furniture production line, serving everyone from small cabinet shops to large industrial furniture manufacturers. What are you waiting for? let’s start choosing and buying.

Kitchen Cabinet Door CNC Router Machine

iGOLDENCNC’s newly launched CNC furniture manufacturing machine maybe can meet your need.This CNC plywood kitchen machine is manufactured using global state-of-the-art techniques, and It is equipped with a 9KW (12HP) high-frequency automatic tool-changing spindle with an 8-position tool post, a pneumatic telescopic vacuum cover and a multi-zone vacuum T-slot worktable. The main advantage of the automatic Kitchen Cabinet Door Making CNC is the tool rack moving together with the machine gantry, which can improve work efficiency. Now this machine can cut about 50 pcs of wood board per 8 hour, it can process wood, medium density fiberboard, Plywood and plastics, soft metals and many other different materials. Now, this CNC furniture manufacturing machine is widely used in the cabinet making industry.

The use of CNC technology in plywood furniture manufacturing offers several advantages. It enables efficient production, reduces material waste, ensures consistent quality, and allows for intricate and complex designs. CNC routers can create precise cuts, intricate patterns, and custom details that would be challenging to achieve manually. Whether it’s creating chairs, tables, cabinets, shelves, or other furniture pieces, CNC technology plays a significant role in the production process, providing furniture makers with the ability to produce high-quality plywood furniture efficiently and with precision.

This kitchen cabinet door making cnc router machine is a very cost-effective CNC router machine. Its cutting ability is very powerful. The cnc kitchen cabinets machine can do milling, drilling, engraving, and cutting work. Its biggest feature is the CNC router vacuum table, the The vacuum table can absorb the materials automatically by a vacuum pump, not need to fix the materials. Thereby improving work efficiency and quality. If you don’t like the auto CNC router vacuum table, then you can also fix the material with T-slots.

A cabinet CNC machine is an industrial automatic wood cutting machine with smart computer numerical controller, which is capable of nesting, routing, feeding, cutting, drilling and grooving all in one machine for custom furniture making. A CNC cabinet making machine works with CAD software to create 2D and 3D layout files, and CAM software then takes the CNC files as inputs, and converts them to G-code manufacturing instructions to control the machine to perform various actions. CNC furniture router machines come in single-process, double-process, three-process, and four-process based on the number of spindles, featuring with single-table, double-table, and moving-table based on the different table structures. In addition, it can be customized and designed to meet your personalized woodworking plans. Cabinet CNC router machines make everything easy to create kitchen cabinets, mirror cabinets, wardrobes, bathroom cabinets, makeup cabinets, dressing cabinets, storage cabinets, stock cabinets, pantry cabinets. Base cabinets, wall cabinets, tall cabinets, and any cabinet you want can be customized to match your home decor. Moreover, home doors, home decorations, and various home and office furniture are also available to be crafted.

Features of CNC Router for Cabinet Door Making

1. The four air-cooling spindles of the CNC router for cabinet making can automatic finish the vertical hole drilling, slot cutting, carving in one step.

2. The CNC router for cabinet making has advantages of saving time, labor and materials, replace traditional CAD draftsmen, splitting men, cutting men, only need 8 minutes to input size design and split. Automatic layout optimization, improve material utilization. High quantity automatic design, Automatic type setting, no human intervention.minimizing error rate to minimum, ensure the quality of the order.

3. High efficiency: Double table for cabinet making, when finish one work line, it can auto work on another table, greatly improve the work efficiency.

4. Drive Faster: Two motor driving on Y axis, Fast speed, high efficiency, Max Air move speed to 60m/min.

5. Operation Steadily: The best linear square guide, double row and four row ball slider, large loading capacity. Convenient operation, high precision, long life time.

6. Intelligent control: It adopts the original computer control system, has a break point, power outages, has the function of re-carving after break point and power failure.

7. Sturdy Durable: Heavy T type of lathe bed, strong rigidity, big strength, smooth rotation, speed for a long time not deformation, not shake.

8. Independently electric control box with perfect wiring and free moving pulleys.

How To Pick Your Best CNC Machine for Cabinet Making?

If you’re choosing a brand new or used CNC cabinet making machine, you may ask which one is the best? But it’s hard to find the right answer, depending on your specific needs.

If you’re a small cabinet shop owner, an affordable 4×8 ATC CNC router with tool changer is an ideal choice.

If you’re a professional cabinet maker, a smart CNC nesting machine is the best pick, featuring with nesting, routing, vertical drilling, cutting, side milling, and edge grinding all in one.

If you’re an industrial furniture manufacturer, the best option is a complete panel furniture production line, including automatic coding machine, feeder, holer, drilling machine, sliding table saw, sanding machine, slotter, cutter, miller, laminating machine, and edge banding machine. However, you can also pick some of these machines as the best solution to match your cabinet furniture making projects.

0 notes

Text

Essential Skills for Structural Drawing Production with AutoCAD & Revit

Structural drawings are the backbone of any construction project because they convert intricate engineering calculations into precise, buildable plans. For aspiring and current drafters, engineers, and architects, proficiency in industry-standard software like AutoCAD and Revit is non-negotiable. But it's not just about knowing the buttons; it's about mastering a specific set of skills that transforms good drawings into exceptional ones.

The Foundation: Core Drafting Principles

Before we even touch software, a strong grasp of fundamental drafting principles is paramount. These timeless skills ensure clarity, accuracy, and consistency in your work:

Understanding Engineering Concepts: This isn't about being a structural engineer, but understanding basic load paths, common structural elements (beams, columns, slabs, footings), and reinforcement principles will make your drawings more intelligent and error-resistant. You'll be able to anticipate potential clashes or design issues.

Orthographic Projections & Sectioning: Being able to visualize and accurately represent 3D structures in 2D views (plans, elevations, sections) is fundamental. This includes understanding cutting planes and how they reveal internal details.

Dimensioning & Annotation Standards: Precision is key. Knowing how to apply dimensions correctly, adhere to industry standards (like ISO or AISC), and effectively annotate drawings with notes, symbols, and callouts ensures clear communication.

Layer Management & Lineweight Control: Organized drawings are efficient drawings. Mastering layers for different elements (concrete, rebar, steel, dimensions, text) and applying appropriate lineweights for visual hierarchy makes your drawings readable and professional.

Attention to Detail & Accuracy: This might sound obvious, but overlooking small details can lead to significant errors on site. Meticulous checking of every line, dimension, and annotation is crucial.

AutoCAD: Precision and Control for 2D Structural Drawings

AutoCAD remains a powerful tool, especially for detailed 2D structural drawings where fine control over lines and text is required. Here are the key skills for structural drafters using AutoCAD:

Proficiency in Core Drawing Commands: Beyond the basics, you'll need to master commands like OFFSET, TRIM, EXTEND, FILLET, CHAMFER, ARRAY, BLOCK, and XREF to efficiently create and manage drawing elements.

Effective Use of Blocks and X-Refs: Creating and managing libraries of standard structural components (e.g., column details, beam sections, typical connections) as blocks, and utilizing external references (X-refs) for architectural or MEP backgrounds, streamlines the drafting process and ensures consistency across large projects.

Hatching and Pattern Application: Accurately representing different materials (concrete, masonry, earth) with appropriate hatch patterns is essential for clarity.

Layouts and Plotting: Setting up title blocks, viewports, scales, and preparing drawings for professional plotting is a critical final step. Understanding plot styles (CTB/STB) for lineweight control is also vital.

Customization (Optional but Valuable): For advanced users, creating custom lisp routines or macros can automate repetitive tasks and significantly boost productivity.

Revit: The Power of BIM for Integrated Structural Models

Revit has revolutionized structural drawing production by introducing Building Information Modeling (BIM). This means you're not just drawing lines; you're building a 3D model with intelligent information, from which all your 2D drawings are derived.

Understanding the BIM Workflow: The biggest shift from AutoCAD is understanding that changes made in the 3D model automatically update all associated 2D views (plans, sections, elevations, schedules). This minimizes errors and improves coordination.

Structural Element Modeling: Proficiently modeling structural columns, beams, walls, floors, foundations, and bracing using Revit's dedicated structural tools. This includes understanding family types, instances, and parameters.

Rebar Modeling and Detailing: Revit's capabilities for modeling reinforcement bars (rebar) are increasingly sophisticated. Skills here include placing individual bars, using rebar sets, creating rebar shapes, and generating rebar schedules and bending lists.

Analytical Model Generation: Understanding how Revit generates an analytical model from your physical model, and how this integrates with structural analysis software, is crucial for engineers and advanced drafters.

View Creation and Management: Creating and organizing various views (structural plans, framing plans, sections, callouts, details) and applying appropriate view templates, visibility/graphics overrides, and filters to control what's seen in each view.

Annotation and Tagging in Revit: While similar to AutoCAD in principle, Revit's intelligent tags and annotations automatically pull information from the model, ensuring consistency and reducing manual input.

Collaboration and Worksharing: In a multi-disciplinary BIM environment, understanding worksharing, central models, and coordination with architectural and MEP models is essential.

Family Creation (Optional but Valuable): For specialized structural elements not found in standard libraries, the ability to create custom parametric families is a powerful skill.

0 notes

Text

Types of 3D Scanners: A Complete Guide to Scanning Technologies and Their Uses

As the demand for precision, speed, and innovation continues to grow across industries, 3D scanners have become indispensable tools. These devices allow us to digitally capture the shape and dimensions of physical objects, enabling applications in manufacturing, healthcare, architecture, design, and more. However, not all 3D scanners are created equal. There are various types of 3D scanners, each utilizing different technologies, suitable for specific tasks and industries.

In this guide, we’ll explore the most common types of 3D scanners, their working principles, advantages, limitations, and ideal use cases.

What is a 3D Scanner?

A 3D scanner is a device that captures the physical geometry of an object and converts it into a digital 3D model. It works by collecting spatial data—such as shape, texture, and size—using techniques like laser beams, structured light, photogrammetry, or X-rays. These scanners have revolutionized workflows in product design, reverse engineering, prototyping, and even medical diagnostics.

Classification of 3D Scanners

3D scanners can be categorized based on two key criteria:

Technology Used

Form Factor and Use Case

Let’s dive into each category in detail.

I. Types of 3D Scanners Based on Technology

1. Laser Triangulation 3D Scanners

How It Works:

These scanners project a laser beam onto the object’s surface. A sensor then measures how the beam reflects back to calculate the object’s shape and contours.

Pros:

High accuracy

Suitable for small to medium objects

Good surface detail

Cons:

Sensitive to lighting and reflective surfaces

Slower than other types

Best For:

Jewelry design

Dental modeling

Industrial inspection

2. Structured Light 3D Scanners

How It Works:

These scanners project a series of light patterns onto the object. Cameras analyze the distortions in the patterns to reconstruct the object’s shape.

Pros:

Fast scanning

High resolution

Captures full color (in some models)

Cons:

Affected by ambient light

Not ideal for shiny or transparent surfaces

Best For:

Reverse engineering

Face and body scanning

Product design

3. Time-of-Flight (ToF) 3D Scanners

How It Works:

ToF scanners emit a laser or infrared beam and measure the time it takes to return. This time data is used to calculate distance and shape.

Pros:

Long-range scanning

Fast data capture

Cons:

Lower resolution

Less accurate for small details

Best For:

Architecture and construction

Surveying large areas

Robotics and automation

4. Photogrammetry

How It Works:

Photogrammetry creates 3D models using multiple 2D photographs taken from different angles. Software processes these images to generate a point cloud.

Pros:

Low-cost

No special hardware needed

Great for textured objects

Cons:

Time-consuming

Less precise

Dependent on camera quality

Best For:

Archaeology and cultural preservation

Hobbyists and artists

Outdoor environments

5. Contact-Based 3D Scanners

How It Works:

These scanners use a probe to physically touch the object at various points to record its dimensions.

Pros:

Very accurate

Unaffected by color or lighting

Ideal for complex internal geometries

Cons:

Slow and manual

Can damage delicate objects

Best For:

Industrial inspection

Internal cavity scanning

Precision engineering

6. CT (Computed Tomography) 3D Scanners

How It Works:

Uses X-rays to scan cross-sections of an object and reconstructs the internal and external geometry into a 3D model.

Pros:

Internal structure capture

High precision

Cons:

Expensive

Radiation exposure

Best For:

Medical imaging

Aerospace parts

Microelectronics

II. Types of 3D Scanners Based on Form Factor

1. Handheld 3D Scanners

Handheld scanners are portable, lightweight, and user-friendly. They allow users to move around the object freely, making them perfect for dynamic scanning needs.

Key Features:

Mobility

Real-time feedback

Versatile applications

Popular Models:

Artec Eva

Revopoint POP 3

2. Desktop 3D Scanners

Designed for scanning small objects with high accuracy, desktop scanners are ideal for controlled environments like studios or labs.

Key Features:

High resolution

Stationary scanning

Ideal for detailed parts

Popular Uses:

Dental models

Jewelry

Small mechanical parts

3. Industrial 3D Scanners

These scanners are built for high-performance and precision, often mounted or integrated into production lines.

Features:

Automation-ready

Ultra-precise

Suitable for quality control

Common Uses:

Automotive inspection

Aerospace part analysis

Tooling and molds

4. Aerial and Drone-Based 3D Scanners

Often used for large-scale scanning, these systems combine drones with laser or photogrammetry technology.

Features:

Wide area coverage

Ideal for inaccessible locations

Fast surveying

Common Uses:

Mining

Agriculture

Infrastructure inspection

Choosing the Right 3D Scanner

To select the best type of 3D scanner, consider the following factors:

Object Size: Large objects require long-range scanners like ToF or drone-based systems.

Accuracy Needs: Industrial and CT scanners are best for high-precision jobs.

Surface Texture: Some scanners struggle with shiny or transparent surfaces.

Budget: Photogrammetry and handheld scanners are more affordable.

Usage Environment: Indoor, outdoor, lab, or industrial floor?

Benefits of Using the Right 3D Scanner

Increased Productivity: Fast and accurate measurements reduce design and inspection time.

Cost-Effective Prototyping: Capture data once and use it repeatedly.

Improved Product Quality: Detect flaws and deviations with pinpoint precision.

Customization: Easily modify digital models to suit individual needs.

Digital Documentation: Preserve physical objects digitally for future use.

Final Thoughts

Understanding the types of 3D scanners and their applications helps you make an informed decision for your specific use case. From laser triangulation to structured light and photogrammetry, each scanning technology offers unique advantages. With increasing affordability and technological improvements, 3D scanning is no longer limited to industrial giants—startups, educators, and hobbyists can now leverage its power.

As industries move toward digital transformation, 3D scanning is set to play a key role in workflows, design thinking, and innovation.

0 notes

Text

How People Counting Software Helps Shopping Malls?

People counting software has become a vital tool for shopping malls looking to improve customer experiences, streamline operations, and boost profitability in today's cutthroat retail environment. Vemco Group provides cutting-edge solutions that convert unprocessed visitor data into useful insights since we recognize the particular difficulties that malls encounter.

Precise Foot Traffic Analysis for More Intelligent Choices

Sophisticated technologies including 2D/3D sensors, thermal imaging, and AI-powered video analytics are used in modern shopping mall people counts. These systems track entries, exits, and even individual store units to offer extremely accurate foot traffic counts, frequently reaching 90% to 98% accuracy. Mall management is able to monitor peak hours and high-traffic areas, as well as the precise number of people in the building at any one time, thanks to this real-time data.

Optimizing Operations and Resource Allocation

Shopping centers may more efficiently distribute workers and resources when they have accurate visitor flow data. For instance, in order to ensure safety and order, security officers can be assigned to busier locations, and cleaning and maintenance schedules can be modified in accordance with actual usage. Management can reorganize layouts or move kiosks for optimal efficiency by using heat maps produced by people counting software, which indicate areas that are often used and those that are not.

Improving the Client Experience

Creating a seamless shopping experience requires an understanding of client movement patterns. Malls may lessen traffic, enhance signage, and make sure that facilities and customer service desks are positioned effectively by examining foot traffic patterns. Additionally, by identifying bottlenecks and improving queue management, people counting software can shorten wait times during busy times.

Boosting Marketing and Tenant Relations

By linking increases in foot traffic to promotional activities, people counting software enables malls to assess the success of marketing campaigns and events. More focused marketing tactics and improved ROI analysis are made possible by this data-driven strategy. Accurate visitor counts also serve as verifiable proof of client exposure in various mall zones, which helps tenants defend rental costs.

Privacy and Smooth Integration

In order to provide a comprehensive picture of mall performance, Vemco Group's solutions are made to easily interact with current systems including POS, BI, and ERP platforms. By using technologies that anonymize data and adhere to GDPR and other requirements, we also place a high priority on privacy.

Conclusion

In conclusion, shopping mall operations are being revolutionized by people counting software. Both mall managers and tenants benefit from increased operational effectiveness, higher customer happiness, and more robust business outcomes thanks to the accurate visitor information it provides. Vemco Group is dedicated to providing creative, safe, and dependable people counting solutions to shopping centers so they can realize the full potential of their locations.

#people counting#footfall counting#people counting solutions#people counting software#footfall counter#visitor counting#customer counting#visitor counter#people counting for retail

0 notes

Text

Does Animation Require Coding? Here’s What You Really Need to Know

A decade ago, animators could pick up a pencil (or a Wacom pen) and set keyframes without ever glancing at a line of code. Today, the landscape feels different. If you scroll through job boards or watch conference keynotes, you’ll see studios looking for artists who can drop expressions into After Effects, write Python tools for Blender, or tweak shaders in Unity. As someone who started in traditional 2D before moving into 3D pipelines, I’m asked constantly: “Do I really need to learn coding to succeed in animation?” The honest answer is “sometimes”—and understanding when and why makes all the difference to your career and creative freedom.

How Code Powers Today’s Animation

Coding shows up in animation workflows in three big ways:

Automation & Efficiency

Python scripts batch-rename layers, bake simulations overnight, and generate thumbnails while you sleep.

Procedural Creativity

Node-based systems like Blender’s Geometry Nodes or Houdini’s VEX let artists describe motion with math—think flocks of birds that never repeat the same path.

Interactivity & Real-Time Engines

Game engines and virtual-production stages rely on C#, C++, or visual scripting to wire character logic, camera triggers, and VR controllers.

When you can write even a few lines of code, those tasks shift from “impossible” to “five-minute experiment.” It’s less about becoming a full-stack developer and more about adding one more brush to your kit.

No-Code Tools: Truth and Limitations

There’s never been a better time for artists who’d rather not code. Adobe’s May 2025 update to Character Animator introduced “Action Blueprints,” a drag-and-drop way to chain facial expressions to audio cues. Similarly, Unity’s revamped Visual Scripting 2025.1 lets you build gameplay loops entirely through nodes.

However, watch any studio pipeline and you’ll notice a ceiling:

Complex shots still need custom logic. A physics-driven crowd scene or stylized water ripple demands formulas beyond preset nodes.

Bespoke tools equal time saved. If your team can’t wait for the next software update, a quick Python plug-in often beats third-party solutions.

Portability matters. Procedural rigs that rely on code snippets move smoothly between Maya, Blender, and Houdini, whereas GUI-built rigs may break.

So while no-code platforms democratize entry, coding remains the secret handshake for higher-level control.

Latest Shifts in 2025

Keeping tabs on news helps foresee which skills will matter tomorrow:

Blender 4.1’s “Animation Nodes” Expansion (May 2025) Adds motion-graphics–style modifiers and a Python API that exposes every node parameter. Artists are already sharing GitHub repos of reusable node groups.

Pixar Open-Sources USD-Python Templates (March 2025) The studio released ready-to-adapt scripts that convert USD scenes into real-time previs, shrinking iteration cycles for indie teams.

Autodesk Buys Wonder Dynamics (April 2025) Their AI-assisted motion-capture platform now plugs directly into Maya, and early adopters report a 30% cut in cleanup time—if they tweak the provided MEL scripts.

Bengaluru’s State-Backed Animation Accelerator (June 2025) The Karnataka government launched grants for studios developing original IP that blends real-time rendering with AI tools, signaling fresh demand for tech-savvy artists in the city.

These updates reinforce a pattern: software companies embrace open scripting, and growth hubs—Bengaluru included—reward creators who ride that wave.

Choosing Your Learning Path

Not every animator needs to write algorithms from scratch, but everyone benefits from coding literacy—the ability to read, adapt, and debug small snippets. If you’re wondering where to start:

Python for Artists: Focus on file management and simple math. A weekend project—like generating random walk cycles—builds muscle memory.

Shader Basics: Even if you never touch GLSL, understanding how color and light equations work clarifies why a render looks flat.

Data-Driven Motion: Mess around with CSV files feeding keyframe values; it demystifies motion-capture cleanup.

Bengaluru’s studios are a case in point. The city’s boom in VFX outsourcing and original OTT content has created a hybrid role: the “technical animator,” expected to flip between storyboards and scripts. Programs like the Animation course in Bengaluru emphasize Python scripting inside Blender to prepare students for exactly this demand—evidence that education is evolving alongside industry needs.

Bridging Artistic Vision and Technical Skill

From my own shift into coding, three truths stand out:

Start small. Automate a repetitive task you already hate—renaming layers, exporting image sequences, anything.

Lean on communities. Discord servers for Blender, Unreal, and Houdini have “help” channels full of micro-scripts you can dissect.

Translate, don’t transform, your creativity. Think of code as a storyboard written for a computer. Your sense of timing, weight, and appeal still lead the show.

Students often worry that coding will dilute their artistry. Yet, when you write a function that flexes a character’s antennae perfectly in sync with a sound cue, you’re amplifying expression, not replacing it.

Final Thoughts

Coding isn’t a gatekeeper; it’s a doorway. The modern animator can absolutely create stunning work with intuitive tools, but knowing how to poke the hood gives you power over deadlines, budgets, and artistic nuance. Whether you kick-off your journey with a 2D animation course bengaluru or dive straight into scripting bespoke rigs, remember that code is simply another pencil—one that can redraw itself as fast as your imagination evolves. Embrace it, and you’ll future-proof your craft in an industry that never stops moving.

0 notes

Text

Top 5 Benefits of Using 3D Rendering in Architecture and Interior Design

The way we design and build spaces has been forever changed by technology, and at the forefront of this revolution is 3D rendering. Whether you're an architect, an interior designer, or a design student eager to explore new tools, 3D rendering is a powerhouse that can completely transform your creative process and interactions with clients.

What makes it so essential? By turning abstract concepts into visually stunning and photorealistic outputs, 3D rendering bridges the gap between imagination and reality. But this technology doesn’t just help you sell your ideas. It saves you time, money, and opens up limitless creative opportunities.

Curious to see what it can do? Let's break down the top 5 benefits of using 3D rendering in architecture and interior design.

What is 3D Rendering?

Before we jump into the benefits, let's clarify what 3D rendering is.

3D rendering is the process of converting 3D models into two-dimensional, lifelike images or animations. This digital technology allows architects and designers to represent spatial designs, lighting conditions, textures, and materials with incredible accuracy.

Wondering why so many professionals rely on it? Read on to find out how it’s reshaping the world of design.

Benefit 1: Enhanced Visualization

Have you struggled to help clients “see” your vision? Concepts that exist in your mind might not translate into sketches or technical drawings. This is where 3D rendering truly shines.

With 3D architectural visualization, you can create photorealistic images that showcase every design detail. From the play of natural light across the room to the placement of furniture and fixtures, 3D renders provide an immersive tour of the unbuilt space.

Here’s why this is a game-changer for architecture and interior design:

Highlight textures, such as marble countertops, wooden floors, or fabric upholstery.

Visualize the impact of varying lighting conditions during different times of the day.

Experiment with furniture arrangements to present cohesive layouts.

When clients can “walk through” their space before it’s built, they feel more excited and assured about the final execution.

Example

A top architecture company in Chennai presented clients with a 3D-rendered walkthrough of a residential project. The visuals showcased how natural light would filter into the living room at sunset, helping seal the deal in just days.

Takeaway

When clients see exactly what to expect, it eliminates guesswork and fosters stronger trust in your abilities.

Benefit 2: Better Client Communication

Every designer knows how important communication is. Even the best ideas can get lost in translation if clients don’t fully grasp your concepts.

With 3D rendering, visual storytelling takes the lead. Clients no longer need to interpret flat sketches or assume what 2D blueprints will look like in three dimensions. They can instantly “read” the design through vibrant, detailed visuals.

Key Advantages:

Reduce misunderstandings and design revisions.

Secure faster client approvals with clear imagery.

Instill confidence early, ensuring decisions are made quickly and collaboratively.

Example

An interior designer pitched a contemporary restaurant design using a 3D render of the dining area. Seeing the design laid out with color schemes, seating patterns, and lighting, the client made decisions on finishes and textures in one meeting.

Takeaway

When communication is seamless, projects move efficiently from planning to execution.

Benefit 3: Cost and Time Efficiency

Mistakes and last-minute adjustments don’t just stress you out. They eat into resources you could save with proper planning. 3D rendering is an upfront investment that pays for itself by identifying potential design flaws before construction begins.

How Does 3D Rendering Save You Time and Money?

Spot errors early in the design phase, saving costs on revisions.

Swiftly modify materials, layouts, and finishes without delaying timelines.

Ensure 100% alignment between client expectations and execution plans.

Example

A design student created a 3D model with an innovative ceiling design only to realize it clashed with the HVAC system upon closer inspection. By catching this during the modeling stage, they avoided costly construction interruptions later.

Takeaway

Time is money, and 3D rendering ensures you use both as efficiently as possible.

Benefit 4: Improved Marketing and Presentation

A good project can stand out in competitive markets with the help of high-quality visual assets. From brochures and websites to social media platforms, designers and architects are using 3D rendering to showcase their work in ways that wow audiences.

Why Does This Matter?

3D renders elevate your marketing pitch, impressing clients and stakeholders alike. They not only convey your technical skills but also highlight your artistry.

Applications Include:

Creating Pinterest-worthy imagery for interior design portfolios.

Showcasing architectural projects through immersive virtual tours.

Preparing professional visuals that attract investors or highlight innovation.

Example

A top firm in Chennai launched its urban mall concept with breathtaking 3D renders on their website and social media, leading to significant investor interest within two weeks.

Takeaway

Great presentation is an edge that inspires confidence, secures approvals, and attracts more opportunities.

Benefit 5: Design Flexibility and Experimentation

Finally, the creative possibilities offered by 3D rendering are nearly limitless when compared to traditional methods. Designers now have the freedom to test out bold ideas without committing to physical prototypes or manual labor.

Ways to Explore New Ideas Virtually:

Experiment with different layouts to maximize functional and aesthetic harmony.

Test various textures, materials, and hues within seconds.

Push creative boundaries, designing ambitious projects that captivate clients.

An interior designer exploring retro-futuristic vibes tested multiple color palettes and fixture styles via rendering software before deciding on the final theme. They delivered an innovative space without wasting physical resources.

Greater creative freedom fosters more innovative, personalized outcomes.

Why 3D Rendering is Essential for Architects and Designers

From reducing costs to elevating aesthetics, 3D rendering has become a must-have tool for architects, interior designers, and students. It aligns creativity with precision, ensuring smoother processes and stellar results.

A project that looks polished, performs well, and speaks directly to client needs defines modern success in this field. To stay competitive, leveraging this technology ensures you remain ahead of the curve.

Are you ready to revolutionize how you design and present projects? Learn more about incorporating 3D rendering into your professional workflows by exploring our resources or partnering with a top architecture company in Chennai.

#architecture firm#architecture company#architecture benifits#3d rendering#3d rendering architecture

0 notes

Text

From Sketch to Stitch: The Making of Our New Drop

Introduction to the 2025 Fashion Drop

Fashion is more than fabric—it’s a story woven in every thread. As we stand at the crossroads of innovation and nostalgia, our 2025 Fashion drop is a tribute to both the future and the roots we cherish. Think bold silhouettes, conscious craftsmanship, and a whole lot of heart.

The Inspiration Behind the Collection

Every design starts with a spark—a moment, a memory, a mood. This collection was born from street corners buzzing with life, the hush of untouched landscapes, and that rare feeling when something just clicks. The 2025 Fashion vibe is raw, refined, and real.

Why 2025 Fashion Is Different

2025 Fashion isn’t just a trend—it’s a movement. With people seeking authenticity and brands owning responsibility, fashion in 2025 is driven by intention. This drop reflects that shift: it's slower, deeper, and soulfully designed.

Ideation Phase – Where It All Begins

Mood Boards and Vision Crafting

Imagine a giant board layered with photographs, color swatches, vintage finds, and handwritten notes. That’s our playground. It’s here we dream, pin, scrap, and start to see the collection come alive before a single sketch hits paper.

Trend Forecasting in 2025 Fashion

Fashion in 2025 leans toward functional flair—think convertible garments, gender-fluid fits, and tech-integrated textures. But we don’t just follow trends—we interpret them, giving each one our signature twist.

Sustainable and Ethical Considerations

The buzzword isn’t just “fashion,” it’s responsible fashion. That means working with ethical suppliers, fair wages, zero-waste patterns, and recycled fabrics that don’t just look good but do good.

Designing the Dream

The Power of the Pencil: Sketching the Initial Looks

This is where magic happens. Our designers pour energy into every stroke, imagining not just clothes, but moments. Each look tells a story—some bold, some soft, all unforgettable.

Choosing the Right Palette: Colors of 2025

Colors speak louder than words sometimes. For 2025 Fashion, we went with earthy neutrals offset by electric accents—soft sand, moss green, dusty lilac, and jolts of cyber blue. It’s grounded with a punch.

Textures, Fabrics, and Feel

Comfort meets couture. From buttery organic cottons to fluid silks and structured hemp blends—our fabric choices were all about the feel. If it didn’t make you want to live in it, it didn’t make the cut.

The Prototype Process

From Paper to Muslin: Making the First Sample

Every sketch gets translated into a muslin prototype—our trial canvas. It’s like building a sculpture from scratch. There’s nothing quite like seeing 2D ideas breathe in 3D.

Draping, Cutting, and Assembling

Precision meets creativity as patterns are cut, stitched, and adjusted. Draping allows us to see how a fabric falls, hugs, or dances—and the difference it makes is everything.

Fitting Sessions and Reiterations

We tweak. We fit. We re-tweak. It’s a relentless pursuit of perfect proportions and flawless fits. Our models don’t just wear the clothes—they help shape them.

Behind the Stitch – Inside the Workshop

The Role of Master Tailors

These are the unsung heroes. The hands behind every perfect pleat and seamless stitch. Their skills go beyond technical—they interpret emotion and design language with their craft.

Embroidery, Detailing, and Hand Finishes

Our 2025 Fashion drop leans heavily into artisanal detail. Beadwork, threadwork, fabric manipulation—each piece carries hours of care and creative effort.

Slow Fashion vs Fast Fashion in 2025

In 2025, slow fashion is the new luxury. We’ve embraced it wholeheartedly, trading mass production for mindful creation. Every piece is limited, special, and meant to last.

Sustainability at the Heart

Eco-Friendly Materials in 2025 Fashion

We’ve partnered with textile innovators and small artisans to use biodegradable dyes, recycled polyester, banana fiber silks, and plant-based leathers. Sustainability isn’t a side note—it’s the core.

Small-Batch Production Philosophy

We don’t overproduce. Instead, we focus on crafting what’s needed, what’s loved, and what won’t end up in a landfill. Small batches. Big impact.

The Final Touches

Accessorizing the Looks

Bags, shoes, scarves, and even scent—our accessory range is subtle yet striking. Designed to complement, not compete, they’re the final brushstrokes to our canvas.

Quality Checks and Final Approvals

Each piece undergoes a strict checklist—stitch strength, color fastness, alignment, finish. Nothing leaves without the green light from both machine and eye.

The Campaign Rollout

Storytelling Through Fashion

We believe in stories. Each collection is shot like a short film—with a plot, a protagonist, and a mood. The 2025 Fashion story is one of rebirth, freedom, and clarity.

Photoshoots, Models, and Mood

Diverse faces. Raw landscapes. Candid captures. We wanted every image to scream "real people, real vibes." It’s not just aesthetics—it’s emotion.

Social Media Strategy for 2025 Fashion

We went bold—Reels, behind-the-scenes Lives, creator collabs, and community shoutouts. In 2025 Fashion, your story is part of our story.

Launching the Collection

Pop-Ups, Online Drops, and First Reveals

We dropped teasers, sent exclusive previews to our insiders, and opened pop-ups in cultural hubs. The goal? Make every customer feel like part of the journey.

Feedback, Community Love, and Next Steps

We listen. Through feedback loops, reviews, DMs, and polls—we’ve shaped future drops with you in mind. Your love fuels our next stitch.

Reflection and What’s Next

Lessons from the Process

No shortcut beats soul work. This drop taught us patience, perseverance, and the beauty of imperfection. Every flaw became a feature.

Teasers for Upcoming Projects

Without giving too much away—let’s just say textures will get bolder, silhouettes braver, and 2025 Fashion is only just heating up.

Conclusion

Fashion isn’t just worn. It’s felt. It’s lived. Our 2025 Fashion collection—from the first sketch to the final stitch—is a labor of love, creativity, and consciousness. Thank you for being part of the story.

FAQs

What makes this 2025 Fashion drop unique?

It’s consciously created, handcrafted, and rooted in both innovation and tradition—making it truly timeless.

Are the garments sustainable?

Yes! We use eco-friendly fabrics, ethical labor, and a small-batch approach to reduce waste and maximize love.

Where can I buy the collection?

Shop it online on our website or visit our pop-up locations in select cities. Follow us for real-time updates!

What inspired the designs?

Nature, tech, city culture, and human stories—all stitched into silhouettes that speak to the now and the next.

Will there be more drops this year?

Yes, this is just the beginning. We’re brewing some stunning surprises—stay tuned!

0 notes

Text

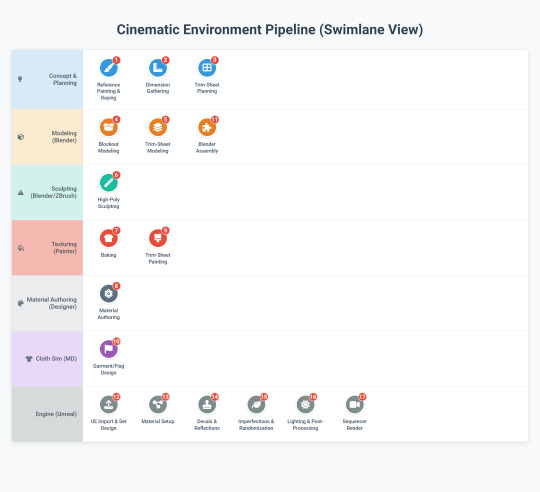

Blog 17| Pre Production| From Sketch to Sequencer—My End-to-End Environment Pipeline

Creating a believable, game-ready environment means balancing creativity with structure. Inspired by industry best practices, here’s a behind-the-scenes look at my full pipeline—from sketching over references all the way to a polished, cinematic render in Unreal Engine’s Sequencer.

Reference Painting & Keying Every project starts in the 2D realm. I import my reference photos into Photoshop (or Krita) and paint directly over them to isolate the elements I need—arches, moldings, trims, decorative friezes. By “keying out” each shape, I build a visual inventory that drives every later step.

Dimension Gathering With my shapes masked, I measure real-world proportions: how tall is that arch? What repeat distance does that decorative band use? I record these in a simple spreadsheet, ensuring that when I model, everything snaps to believable scale.

Trim-Sheet Planning Next, I arrange my keyed-out pieces into a trim-sheet atlas layout. I dedicate horizontal strips for large patterns (e.g. base moldings), mid-level bands for medium details (e.g. fluting), and narrow strips for fine edge work. This upfront planning ensures maximum reuse.

Blockout Modeling in Blender Switching to 3D, I block out the scene with basic cubes and planes—walls, columns, beam spans—always snapping to the real-world dimensions from my sheet. This greybox phase lets me verify composition and scale before any high-res work begins.

Trim-Sheet Modeling in Blender On a single flat plane, I model each trim element in place according to the atlas layout. Simple extrude/bevel operations give me a low-poly version that matches my keyed-out shapes exactly.

High-Poly Sculpting I bring these flat pieces into either Blender’s Sculpt mode or ZBrush to add bevels, chips, cracks, and worn edges. By using wrap-mode brushes, I ensure every detail tiles perfectly at the sheet’s borders.

Baking in Substance Painter Back in Painter, I bake my high-poly details (normal, ambient occlusion, curvature, and ID maps) onto the low-poly mesh. This gives me a data-rich trim sheet ready for texturing.

Material Authoring in Substance Designer I then craft my base materials—stone, wood, metal—in Designer, tweaking procedural noise, weathering effects, and edge-wear masks so they closely match my original references.

Trim-Sheet Painting Returning to Painter, I load in my Designer graphs and use ID masks to apply base colors. Smart masks generate dirt, rust, and moss automatically; hand-painting adds character—subtle color streaks, chipped paint, and patina.

Blender Assembly With my completed trim sheet, I reapply it to the blockout meshes in Blender. This step verifies correct UV alignment, consistent texel density, and seamless tiling across corners and joins.

Import & Set Design in Unreal Engine I export all modular pieces and texture maps, then import them into Unreal Engine. Using rigid grid snapping, I rebuild my environment—walls click together like digital LEGO.

Material Setup in UE Inside UE’s Material Editor, I convert my Substance Designer graphs into master materials and create instances to control tiling and trim-sheet channel selection per object.

Decals & Planar Reflections To break up uniform surfaces, I place decals—grime streaks, signage, narrative symbols—using Unreal’s decal actor with parallax occlusion. For puddles and window glass, I employ Planar Reflection actors to capture accurate, crisp reflections.

Imperfections & Randomization A key to realism is randomness: I scatter debris, fallen leaves, chipped paint decals, and slightly vary material roughness/color on repeated modules so nothing feels copy-pasted.

Lighting & Post-Processing I establish a primary directional light (sun or moon), complemented by a skylight and volumetric fog for depth. Post-process volumes refine exposure, color grading, bloom, lens flares, and filmic tonemapping.

Cinematic Render in Sequencer Finally, I use Unreal’s Sequencer to set up camera shots, animate subtle scene elements (flags swaying, water rippling), and record my cinematic passes. The result is a polished, story-driven environment ready for presentation.

By following this structured pipeline—grounded in reference, powered by trim-sheet modularity, and polished with decals and cinematic lighting—I’m able to go from concept sketches to a fully realised, game-ready world with confidence and consistency

0 notes

Text

Are Fingerprint Door Locks Secure? Myths Debunked & Real Facts

Fingerprint door locks have gained immense popularity as a secure and convenient solution for homeowners looking to upgrade their home security. By eliminating the need for traditional keys, these biometric locks offer enhanced protection and ease of access. However, myths and misconceptions often lead to skepticism about their reliability and safety.

In this blog, we’ll separate fact from fiction, explore how fingerprint door locks work, and discuss their advantages. We'll also touch upon the added benefits of integrating them with a smart video door lock for a complete security solution.

How Fingerprint Door Locks Work

Fingerprint door locks use biometric technology to authenticate users based on their unique fingerprint patterns. Here’s how the process works:

Fingerprint Capture: When you place your finger on the scanner, the lock captures your fingerprint’s unique ridge and valley pattern.

Data Conversion: The scanner converts the fingerprint into a digital template using advanced algorithms.

Storage and Matching: This encrypted template is stored securely within the lock. When you attempt to unlock the door, the scanner compares your fingerprint with the stored template to verify your identity.

Common types of fingerprint scanners include:

Optical Scanners: Capture a 2D image of your fingerprint using light. They are budget-friendly but can be less effective with dirty or wet fingers.

Capacitive Scanners: Measure the electrical charge variations from your fingerprint ridges. They offer higher accuracy and security.

Ultrasonic Scanners: Utilize sound waves to create a 3D image of your fingerprint, ensuring optimal accuracy even with minor dirt or moisture.

Debunking Myths About Fingerprint Door Locks

Myth 1: Fingerprints Can Be Easily Spoofed

A common misconception is that fingerprints can be lifted and replicated to bypass biometric locks. While Hollywood might make it seem easy, real-world attempts are extremely difficult. Advanced scanners, particularly capacitive and ultrasonic models, detect the unique depth, texture, and even pulse of a fingerprint, making spoofing nearly impossible.

Myth 2: Fingerprint Data Can Be Hacked

Many worry that storing biometric data on a fingerprint door lock makes it vulnerable to hacking. However, fingerprint templates are securely encrypted and stored locally within the lock, not on external servers or the cloud. This localized storage reduces the risk of cyberattacks.

Myth 3: Fingerprint Scanners Are Unreliable

While earlier versions of biometric locks occasionally struggled with recognition issues, modern fingerprint door locks use sophisticated algorithms to minimize false rejections and acceptances. Many models are designed to handle slightly dirty or wet fingerprints, enhancing reliability.

Real Security Advantages of Fingerprint Door Locks

Fingerprint door locks offer tangible security benefits that go beyond conventional locks:

Keyless Convenience: No more lost keys or duplicated copies. Biometric access eliminates this common security risk.

Enhanced Physical Security: Many fingerprint locks are built with durable materials like reinforced steel and anti-drill plates, providing robust resistance to physical attacks.

Activity Tracking: Some smart locks offer real-time access logs, allowing you to monitor who entered and when.

Integration with Smart Video Door Locks: For added security, combining a fingerprint door lock with a smart video door lock allows for two-factor authentication. Verify visitors visually via the video feed before granting access with a fingerprint scan.

Why Combine a Fingerprint Door Lock with a Smart Video Door Lock?

Integrating a fingerprint door lock with a smart video door lock enhances your home’s security and convenience. Here’s how:

Visual Verification: See who’s at your door in real-time before granting access.

Remote Control: Unlock doors remotely using your smartphone app.

Event Logs: Track all access attempts and receive notifications for suspicious activity.

Automation: Connect with your smart home ecosystem to trigger lights, cameras, or alarms based on door access events.

Conclusion

Fingerprint door locks are a secure and practical choice for modern homeowners. With advancements in biometric technology and encryption, concerns about spoofing, hacking, and reliability are largely unfounded. For ultimate peace of mind, integrating your fingerprint lock with a smart video door lock creates a robust, two-factor security system.

Ready to upgrade your home security? Explore secure and reliable fingerprint door locks at Onetouch and take the first step towards a safer home today!

0 notes

Text

Overcoming Mobile Mapping Challenges in Transportation: Expert Strategies & Solutions

Introduction

Mobile mapping plays a crucial role in transportation projects, enabling accurate data collection and analysis. However, challenges such as data accuracy, processing inefficiencies, and integration complexities can hinder project success. In this blog, we’ll explore expert strategies and solutions to overcome these challenges, with a focus on leveraging photogrammetry software to enhance mobile mapping workflows.

Leverage Advanced Photogrammetry Software for Accurate Data Capture

One of the most significant hurdles in mobile mapping is ensuring accurate, high-quality data collection. Advanced photogrammetry software provides a powerful solution by converting aerial imagery into precise 3D models and point clouds.

Photogrammetry software enables the processing of drone imagery to generate detailed geospatial data.

Features like automatic image matching, bundle adjustment, and dense point cloud generation enhance mapping accuracy.

Selecting the right software improves both efficiency and data precision, reducing errors in transportation project planning.

Beyond just software, successful mobile mapping also requires:

High-quality drones and cameras for superior image capture.

Proper training of field crews on data collection best practices.

Standardized data validation processes to ensure consistency and reliability.

By combining photogrammetry software with structured workflows, transportation projects can significantly enhance mapping accuracy and efficiency.

Implement Automated Georeferencing for Efficient Data Processing

After data collection, the next challenge is processing vast amounts of mobile mapping data. Automated georeferencing streamlines this phase by precisely aligning and positioning datasets within their geographic context.

Eliminates manual tie point selection, reducing processing time.

Enhances the efficiency of photogrammetry software by ensuring seamless spatial alignment.

Reduces human error, improving overall mapping accuracy.

By integrating automated georeferencing into photogrammetry software workflows, teams can accelerate data processing and focus on actionable insights for better decision-making in transportation projects.

Utilize 4D Capabilities for Comprehensive Project Monitoring

Transportation projects are dynamic, evolving over time. Traditional 2D and 3D mapping may not capture the full picture, but 4D capabilities—incorporating the time dimension—offer deeper insights.

Photogrammetry software with 4D capabilities enables visualization of project progress over time.

It helps detect trends, patterns, and potential bottlenecks before they become critical issues.

Enhances decision-making by providing real-time insights into project developments.

Implementing 4D mapping ensures continuous project monitoring, allowing transportation planners to optimize resources and minimize delays.

Integrate with Construction Management Software for Seamless Workflows

To maximize the benefits of mobile mapping, transportation projects must integrate their geospatial data with existing construction management systems. This integration:

Centralizes project data for easy access and analysis.

Enables real-time updates across teams and systems.

Enhances collaboration by ensuring all stakeholders work with the latest data.

Reduces errors and inefficiencies, streamlining project execution.

By embedding photogrammetry software data into construction management platforms, organizations create a seamless, end-to-end workflow that improves efficiency and project outcomes.

Collaborate with Expert Partners for Optimized Mobile Mapping

Mobile mapping success requires more than just technology—it demands expertise. Collaborating with industry leaders helps organizations leverage best practices and innovative solutions.

Photogrammetry software providers offer specialized tools and training for improved data processing.

Partnering with experts in aerial imaging and geospatial analytics ensures high-quality results.

Proven industry partnerships accelerate implementation and enhance project scalability.

Selecting experienced partners with deep knowledge of this software and mobile mapping technologies guarantees optimized workflows and successful transportation project execution.

Conclusion

Overcoming mobile mapping challenges in transportation requires a combination of advanced photogrammetry software, automated georeferencing, 4D monitoring, system integration, and expert collaboration. By implementing these strategies, organizations can improve data accuracy, streamline workflows, and enhance decision-making for transportation projects.

Ready to transform your mobile mapping processes? Discover how Magnasoft's advanced geospatial solutions can help optimize transportation projects. Contact us today to learn more.

0 notes

Text

THE FOREST: SUPPORTING THE BODY (FINAL)

Bifurca

cardboard

34x20

My structure reflects a stream that divulges into two: bifurca- the latin word for “two-forked”. The two cavities provide a resting place for the body as the legs go through each. Although it’s reminiscent of a stream, its form is interpreted by the viewer. It could be a tooth, a twig/branch, a clavicle, an antler, or even a blood vessel. This in itself demonstrates how patterns repeat themselves constantly in nature. The curves of the walls are meant to reflect the flow of water, yet if you look closely you’ll notice that they are cut roughly-a reference to how water can be rigid and harsh. I chose to cut loosely and allow the material to turn out how it wanted to. The walls offer a place for the arms to rest atop them; acting as an armrest.

Throughout the project, I found it difficult at times transferring my ideas into a 3D object as I’m more accustomed to working in 2D. However, the experience has taught me a lot in regards to converting thoughts into a physical form as well as introducing me to cardboard as a medium. Its ability to be flexible and surprisingly sturdy has drawn my interest. I will most likely experiment with creating cardboard structures further in the future.

1 note

·

View note

Text

I can’t find any tutorials converting complex 3d objects to 2d patterns by hand so I’ve been fuckass improvising.

It’s either gonna look pretty sick or so very stupid :D

Note that the draft shown did NOT work lmao

#prop making#does ANYONE have a better method than my fuckssery pls#cosplay#tiefling#horns#tiefling horns#current wip

1 note

·

View note

Text

How Do 3D Scanners Work? A Complete Guide

In the fast-evolving world of digital technology, 3D scanning has emerged as a game-changer. From manufacturing and design to healthcare and entertainment, 3D scanners are revolutionizing the way we capture real-world objects and convert them into digital 3D models. But how do 3D scanners work? In this comprehensive guide, we’ll break down the working principles of 3D scanning, the different types of scanners, and how they're used across industries.

What Is a 3D Scanner?

A 3D scanner is a device that analyzes a real-world object or environment to collect data on its shape and surface features. This data is then used to construct a three-dimensional digital model. Unlike traditional photography, which captures 2D images, 3D scanning captures depth, texture, and volume, allowing for high-precision modeling and analysis.

How Do 3D Scanners Work?

At the core of 3D scanning lies a process that involves capturing spatial data using lasers, light, or other sensing technologies. The basic workflow typically includes:

Data Acquisition – The scanner collects raw 3D data, often in the form of point clouds.

Data Processing – The raw data is converted into a 3D mesh.

Model Generation – The mesh is further refined into a usable 3D model, often exported in formats like STL, OBJ, or PLY.

Let’s dive into each of these components in more detail.

Types of 3D Scanning Technologies

There are various methods by which 3D scanners operate. Here are the most commonly used technologies:

1. Laser Triangulation

Laser triangulation uses a laser line or point projected onto the object. A sensor (usually a camera) captures the position of the laser as it appears on the object. Based on the angle between the laser source, object surface, and sensor, the system calculates the 3D coordinates.

Common Uses: Industrial inspection, small object scanning, reverse engineering.

2. Structured Light Scanning

This method projects a known pattern of light (usually stripes) onto the object. Cameras record how the pattern deforms, and software algorithms calculate the depth and shape of the surface.

Advantages:

High accuracy

Fast capture speed

Applications: Medical imaging, cultural heritage preservation, 3D modeling.

3. Time-of-Flight (ToF)

ToF scanners emit a laser pulse and measure the time it takes for the light to reflect back. The distance is calculated using the speed of light. This process is repeated across the object to create a 3D map.

Benefits:

Suitable for large-scale environments

Works well in varying lighting conditions

Used In: Architecture, robotics, drone mapping.

4. Photogrammetry

Photogrammetry is a technique that reconstructs 3D geometry from 2D photographs. Multiple overlapping images are taken from different angles, and software stitches them into a 3D model using triangulation.

Advantages:

Inexpensive (uses regular cameras)

High-detail texture mapping

Applications: Archaeology, game development, virtual reality.

Components of a 3D Scanner

A 3D scanner typically includes the following key components:

Light Source – A laser, LED, or projector to illuminate the object.

Sensor/Camera – Captures the reflected light or pattern.

Processor – Computes depth and spatial information.

Software – Processes raw data into usable 3D models.

Some high-end 3D scanners also come with motion tracking systems and rotary tables for automated scanning.

3D Scanning Workflow

Step 1: Object Preparation

Make sure the object’s surface is clean and visible. Reflective or transparent materials may need treatment (like powder coating) for accurate scanning.

Step 2: Scanning

The object is scanned from multiple angles. Handheld scanners offer mobility, while stationary scanners provide higher accuracy.

Step 3: Data Registration

Multiple scans are aligned and merged using reference points or software algorithms to create a complete 3D representation.

Step 4: Mesh Generation

The point cloud data is converted into a polygonal mesh. Holes or errors are filled during this step.

Step 5: Export & Application

The final model can be exported to CAD software, used for 3D printing, virtual simulation, or quality inspection.

Applications of 3D Scanning

1. Manufacturing & Engineering

3D scanners are widely used in reverse engineering, quality control, and rapid prototyping. Scanned data helps in redesigning parts or ensuring dimensional accuracy.

2. Healthcare

In the medical field, 3D scanning is used for creating custom prosthetics, dental implants, and orthopedic devices.

3. Architecture & Construction

Architects use 3D scanning to create as-built documentation, perform site analysis, and plan renovations more accurately.

4. Art & Heritage Preservation

3D scanners help preserve cultural artifacts by creating digital archives, especially of fragile or decaying objects.

5. Entertainment & Gaming

3D scanning plays a key role in creating realistic characters, props, and environments in movies and video games.

Advantages of 3D Scanners

Precision – Capture detailed and accurate measurements.

Speed – Rapid digitization of objects.

Versatility – Works across different materials and environments.

Non-contact – Ideal for delicate or hazardous surfaces.

Challenges and Limitations

While 3D scanners are powerful tools, they do have some limitations:

Cost – High-end scanners can be expensive.

Complexity – Requires trained personnel and post-processing.

Surface Dependency – Struggles with shiny, dark, or transparent materials.

Data Size – Large scans produce huge files that need powerful hardware.

Future of 3D Scanning

The future of 3D scanning is bright, with emerging trends such as:

AI-powered scanning for automatic object recognition.

Mobile 3D scanning apps using smartphone LiDAR.

Integration with AR/VR for immersive experiences.

Cloud-based processing for faster and collaborative workflows.

As the technology becomes more accessible, we can expect widespread adoption across even more sectors.

Conclusion

So, how do 3D scanners work? They operate by capturing spatial data using light or laser-based systems and converting that data into digital 3D models. With various scanning technologies like laser triangulation, structured light, and photogrammetry, 3D scanning serves as a bridge between the physical and digital world.

Whether you're a product designer, a medical professional, or a digital artist, understanding how 3D scanning works opens the door to limitless possibilities. As 3D scanners continue to evolve, they’re set to transform the way we interact with and replicate the world around us.

0 notes