#defective detection

Explore tagged Tumblr posts

Text

The slightest surface defects are detected

1 note

·

View note

Text

Local private detective office thinks weird college student should get some self preservation instincts!!

Just some doodles of some ocs before I start writing today. I found an old story from middle school and I redesigned all of them for fun,,,, but now I think I'm kind of obsessed with them. oopsies! it will happen again

#sawyer is so offputting and i love that about her#art#digital art#doodles#oc#oc art#orginal character#do i put tags for their names?#eh fuck it#sawyer sloan#diana b carter#kenny graham#andy holiday#erinwantstowrite#defective detective

208 notes

·

View notes

Text

How's about a change in scenery?

Makoto looked around. This was, indeed, the Dark Hour, but this was definitely not Iwatodai or Tartarus. The team looked around, wondering what the hell is going on.

Suddenly, a box goes flying out of nowhere, and the source of it happens to be the nuisance that is the Box Ghost.

"PERSONA!" Makoto was the first to call the currently-equipped persona, Arahabaki.

Heat Wave was what was used, striking at the Box Ghost with quite a bit of force. This caused the Box Ghost to go after Makoto. Whilst boxes flew, Makoto sliced at the boxes, some splitting whilst others were knocked away.

Junpei summoned Trismagestus and blasted the ghost with some agidyne. it wasn't long before the others engaged in combat with the box ghost. Someone flew up behind the ghost and sucked it into what seemed to be a thermos.

"Get souped, idiot," the person said.

the person then flew down to the group and seemed to form legs.

"While that was risky, thanks for that," the ghost guy said, "even though I can handle him most of the time."

"You're welcome," Junpei grinned.

"who're you?" Makoto asked.

"I'm Danny," Danny introduced.

"Makoto."

"I'm Junpei Iori, Ace Detective,"

"More like-" Yukari started her retort.

"more like stupei, ace defective," Junpei rolled his eyes, "Like I haven't heard this one before."

"Anyways, even is that?" Makoto pointed to the thermos-like object.

"Oh- that's the Fenton Thermos, sucks in ghosts so I can release them back through the portal."

"okay."

"Anyways, I don't know what's going on, but this is definitely not the Ghost Zone."

"This is the Dark Hour," Mitsuru explained, "It's the 25th hour, and it's when Shadows are roaming around."

"Right.. Like those weird dark blob things over there?"

Danny had pointed to a cowardly maya, which was just roaming along the road.

"Yep, that's a Shadow."

"Thought it was a weird ghost that wouldn't be sucked into the thermos. When I blasted them, they just- poof, melted into whatever."

"that's pretty much what happens when they are attacked," Makoto shrugged."

Friendly reminder that I still don't know the characters other than the characterization the fans give.

#persona 3#writing#creative writing#makoto yuki#minato arisato#mitsuru kirijo#yukari takeba#junpei iori#junpei iori ace detective#stupei ace defective#p3 x danny phantom crossover#danny phantom#danny fenton#fenton thermos#dark hour#box ghost

13 notes

·

View notes

Text

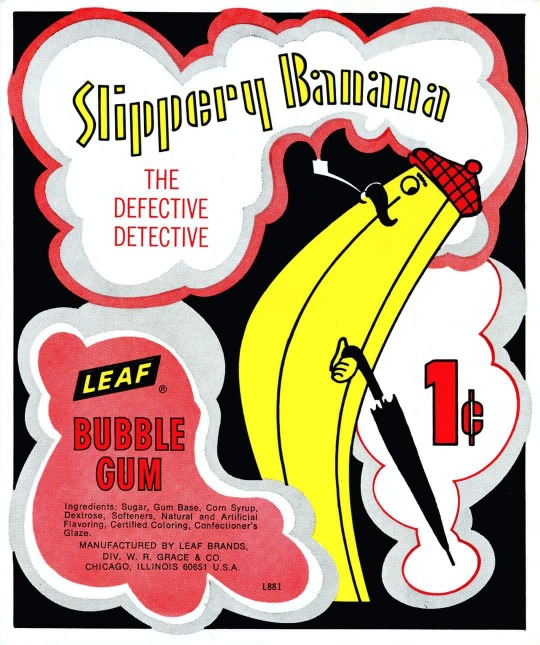

Peel Away The Mystery

14 notes

·

View notes

Text

The girl is Amber and the gacha guy is her bf Alastair (He's a vampire cowboy and she's a detecive)

#art#oc#dc#dc oc#vampire#vampire cowboy#vampire cowboy oc#gacha#defective#detective oc#dc comics#dc comics oc#animation#oc animation

11 notes

·

View notes

Text

Fun fact: I never failed a dance of deduction so I don't know what happens if you do, and that's one of my reasons for wanting to replay tgaa. I really want to see what happens if you fail a dance of deduction

#ace attorney#the great ace attorney#i think itd be funny if you got an achievement for it. “defective detective” or somethin

12 notes

·

View notes

Text

Only started playing P3P yesterday but Junpei is already my favorite character

#junpei iori#persona 3 portable#this looks like a job for junpei iori ace detective#ace detective?#more like stu-#ace defective#yeah I know yukari doesn’t actually say that but it’s the funni#stupei iori#also I like akihiko too#his voice is just so sinister I love it

6 notes

·

View notes

Text

tag dump

he boris on my shuster until i case files

#[ooc] out of office.#[ic] destiny has sent me on a journey#v; done-for gumshoe#v; icon-hunter.#[prompt] a calling card.#[ask] the investigation continues.#[aesthetic] rain on asphalt#[crack] defective detective#[art] facial composites#[new follower] the collective

2 notes

·

View notes

Text

How AI is Revolutionizing the Manufacturing Industry: A Complete Guide

AI in manufacturing, AI defect detection, and machine vision systems are revolutionizing the way industries operate. These cutting-edge technologies are improving quality inspection processes, enhancing production efficiency, and reducing human errors. Visual inspection systems powered by computer vision have become indispensable tools in various sectors, from electronics manufacturing to automotive production. The integration of AI into these systems is enabling faster, more accurate detection of defects, resulting in better product quality and reduced production costs. In this blog, we’ll dive into how Computer Vision AI is transforming industries, with a focus on its role in manufacturing and quality control.

Understanding the Role of Computer Vision AI in Manufacturing

Computer vision AI is a technology that allows machines to "see" and interpret visual data, much like the way humans process images. This technology plays a crucial role in manufacturing, particularly when it comes to inspecting products for defects. AI in manufacturing uses computer vision to automate tasks such as identifying faulty parts, ensuring product quality, and reducing human errors.

In traditional manufacturing settings, human inspectors would manually examine each product for defects, which could be time-consuming and prone to mistakes. With the integration of machine vision systems and AI, these tasks can now be automated, making them faster and more accurate. Whether it's identifying cracks on metal parts or checking the alignment of components, AI-powered visual inspection systems can handle these tasks with precision.

Machine vision systems equipped with computer vision AI allow manufacturers to detect even the smallest defects, which may go unnoticed by the human eye. This technology improves overall product quality and reduces waste, ensuring that only top-quality products are shipped out to customers.

With AI defect detection, machine vision systems have become faster, more accurate, and more efficient than traditional inspection methods. They can now identify even the smallest of defects that might be invisible to the human eye. In industries where precision is crucial—such as in electronics manufacturing—this level of detail is indispensable.

The Role of AI in Quality Inspection

AI is transforming quality inspection across multiple industries by automating visual inspection systems. These systems, which are powered by AI, provide real-time analysis, helping identify defects as soon as they appear in the production line. In traditional quality inspection, workers had to manually check each product, which could be time-consuming and prone to human error.

Machine vision systems that incorporate AI have dramatically reduced these issues by ensuring that every product is inspected consistently and accurately. Whether it’s detecting cracks on metal parts, flaws in printed circuit boards (PCBs), or defects in plastic components, AI-driven visual inspection systems can handle it all. The ability to automate quality control not only improves efficiency but also ensures that each product meets the required standards.

In electronics manufacturing, for example, computer vision AI plays a significant role. The production of components like microchips, circuit boards, and semiconductors requires precise and detailed inspection. AI systems are capable of detecting microscopic faults in these tiny components, which would otherwise go unnoticed by human inspectors. This level of accuracy is essential for maintaining the performance and reliability of electronic devices.

Benefits of Machine Vision Systems in Defect Detection

The introduction of machine vision systems for AI defect detection has had a huge impact on manufacturing. Traditional methods of defect detection relied heavily on manual inspection, which was not only slow but also subject to inconsistency. Human inspectors might miss defects, leading to subpar products and costly recalls.

However, machine vision systems equipped with computer vision AI can detect defects much faster and with greater precision. These systems continuously monitor the production process, analyzing images from cameras in real-time and identifying potential issues immediately. Once a defect is detected, the system can send an alert, allowing for swift corrective actions, such as halting production or making adjustments.

Machine vision systems are especially beneficial for industries with high-volume production. In these cases, even a small defect rate can result in significant losses. By detecting defects early in the process, manufacturers can minimize waste, reduce the need for rework, and improve overall product quality.

Computer Vision in Electronics Manufacturing

In industries like electronics manufacturing, where product complexity and precision are paramount, computer vision AI plays a critical role. Manufacturing processes in electronics, such as assembling PCBs or inspecting semiconductors, require high levels of accuracy. Visual inspection systems powered by computer vision AI help to maintain these high standards by ensuring that no defective products are shipped out.

AI in electronics manufacturing is used for various tasks, from component verification to end-of-line testing. Computer vision can detect missing components, misalignments, and incorrect soldering, ensuring that only products that meet strict quality standards move forward. This reduces the risk of product failures and helps manufacturers maintain a competitive edge in a market where quality is king.

As the complexity of electronic devices continues to increase, the role of machine vision systems in electronics manufacturing will only grow. With AI’s ability to continually learn and adapt, these systems will become even more efficient at detecting and addressing defects, resulting in smarter, more reliable production lines.

Contact Us Today for Cutting-Edge AI Solutions

Incorporating AI in your manufacturing processes can drastically improve your production efficiency and quality control. At Lincode.ai, we provide state-of-the-art machine vision systems and AI-powered defect detection solutions that help businesses stay ahead of the competition. Whether you’re looking to implement visual inspection systems in your electronics manufacturing or improve AI in manufacturing processes, our team is ready to assist. Contact us today to learn more about how we can help transform your operations with AI technology.

Conclusion

Computer vision AI, machine vision systems, and AI defect detection are changing the way industries approach manufacturing and quality control. By automating visual inspections and defect detection, these technologies ensure faster, more accurate, and more efficient production processes. Whether it’s in electronics manufacturing or other sectors, the benefits of AI-driven systems are clear—improved product quality, reduced waste, and greater efficiency. As AI continues to evolve, it will play an even more significant role in shaping the future of manufacturing.

If you’re looking to harness the power of AI for your business, Lincode.ai offers the tools and expertise to help you implement these transformative technologies.

#computer vision ai#ai in manufacturing#ai defect detection#machine vision systems#quality inspection#visual inspection systems#Computer Vision in Electronics Manufacturing#machine vision system

0 notes

Text

Is this the worst ever roof in Sydney?

When you think you've seen it all, you see it again. In the world of leak detection, we encounter a vast spectrum of building issues, from the minor drip to the catastrophic flood. Yet, every so often, a property comes along that truly redefines what's possible in terms of poor construction. Recently, our team at 1300 FINDLEAK carried out an inspection for a young couple in Beaconsfield, Sydney, on what was supposed to be their dream: a stunning, architect-designed, newly built home valued at over $3 million. What we discovered on the roof of this high-value property left us, seasoned professionals, in utter disbelief. It wasn't just a few minor flaws; it was a systemic failure of building standards that raises serious questions about quality control in new construction.

The couple had called us in desperation. Their newly built main house was experiencing severe water ingress every time heavy rain hit. This wasn't a minor damp patch; it was significant water penetration compromising their brand new living spaces. The irony was palpable: a substantial investment in a modern, architect-designed property, yet already plagued by fundamental issues. As we arrived, the builder was still on-site, seemingly attempting remedial work on the very problems we were there to diagnose. Little did we know, the true extent of the catastrophe lay hidden, waiting for us to ascend to the roof.

Ascending to a Nightmare: The Shocking Reality

Stepping onto the roof of the main house, the initial shock was immediate and profound. The term "non-compliant" isn't strong enough to describe what met our eyes; it was a masterclass in how not to build a roof. Every critical detail, every standard practice, seemed to have been overlooked or deliberately ignored.

The first glaring issue was the flashing secured with plaster screws. Yes, you read that correctly – plaster screws, designed for internal drywall, were being used to secure external flashing, a vital waterproofing component. This alone is a monumental failure, guaranteeing water penetration. Beyond this, we found missing returns and laps on crucial flashing elements. Flashing is meant to be meticulously overlapped and turned up or down at edges to create a continuous, watertight barrier. Here, these fundamental details were absent, leaving open pathways for water. Many sections of flashing were also below minimum cover, meaning they simply weren't extending far enough to effectively shed water away from the building envelope.

The list of egregious defects continued to grow. We observed missing apron downturns, which are essential for directing water away from wall junctions. In several areas, exposed bricks were visible where they should have been properly covered and protected by flashing or cladding, creating direct entry points for moisture. The flue (likely for a hot water system or ventilation) was unsecured, not only a leak risk but a potential safety hazard. Crucially, there were no Dek-Tites for penetrations – specialized, flexible flashings designed to seal around pipes, vents, and other roof penetrations. Instead, we saw makeshift attempts at sealing that were clearly failing. Even the A/C unit was not properly braced and secured, risking damage to the roof and creating further vulnerabilities for water ingress. And as a final, desperate attempt to cover up these widespread failures, butyl tape was plastered everywhere – haphazardly applied to seal pan laps and skylights. Butyl tape is a temporary fix at best, and its widespread, unsystematic use indicated a profound lack of understanding of proper waterproofing principles. This entire scenario directly explained the severe water ingress the living spaces below were experiencing.

The Root Cause: Why Are Standards Falling Short?

This Beaconsfield case study, while extreme, is unfortunately not an isolated incident. It highlights a worrying trend in the construction industry where fundamental building standards are consistently falling short. Why does this happen, especially on high-value, new builds?

Rushed Construction Schedules: Pressure to complete projects quickly often leads to shortcuts, particularly in hidden areas like flashing and waterproofing, where defects may not be immediately visible.

Lack of Skilled Tradespeople: A shortage of experienced and properly trained roof plumbers and waterproofers means critical tasks are sometimes undertaken by unqualified individuals or those who cut corners.

Cost-Cutting Measures: In a competitive market, some builders may opt for cheaper materials or less time-consuming (and often less effective) installation methods to save on costs, compromising long-term integrity.

Insufficient Oversight and Inspections: Regulatory inspections may not always catch every hidden defect, and internal quality control by builders can be inadequate, allowing non-compliant work to go unnoticed until leaks manifest.

Complexity of Modern Designs: Architect-designed homes often feature complex rooflines, multiple junctions, and varied materials, which require an even higher level of expertise and meticulous attention to detail during construction. When this expertise is lacking, these complex designs become highly vulnerable to water ingress.

The consequences for homeowners are devastating. Beyond the immediate water damage and the stress of dealing with a faulty new build, there are significant financial burdens. Repairs for systemic waterproofing failures can be incredibly expensive, often running into tens or even hundreds of thousands of dollars. There are also potential health risks from mould growth, diminished property value, and often, protracted disputes with builders and insurance companies.

Don't Let Your Dream Home Become a Nightmare

The Beaconsfield case is a stark reminder that a new, expensive, or architect-designed home is not automatically immune to severe building defects. Water leaks, particularly those caused by underlying construction flaws, are complex and require expert diagnosis. Relying on superficial fixes or unqualified trades can lead to recurring problems and escalating damage, turning a dream home into a persistent nightmare.

At 1300 FINDLEAK, we pride ourselves on our non-invasive, evidence-based approach to leak detection. Using advanced thermal imaging, moisture surveys, and targeted water testing, we pinpoint the exact source of water ingress, even when it's hidden behind walls or under floors, or when the defects are as egregious as those found in Beaconsfield. We provide comprehensive reports, identifying defects, compliance issues, and clear repair recommendations that address the root cause, not just the symptoms.

If you're experiencing persistent leaks, water damage, mould, or dampness in your Sydney property, especially a new build, don't wait for the problem to worsen. Early and accurate detection is key to preventing costly repairs and safeguarding your investment. Trust Australia's leading leak detection specialists. Contact 1300 FINDLEAK today – we find leaks plumbers can't!

#Sydney's worst ever roof#AFA#building defects#roof compliance#a current affair#leak detection sydney

0 notes

Text

Manga Review: Case Closed Volumes 91-94

Manga Review: Case Closed Volumes 91-94 by Gosho Aoyama Very quick recap: Shin’ichi Kudou (Jimmy Kudo in the dub) is a teen genius detective. He crossed paths with the mysterious Black Organization, criminals that gave him an experimental poison. Instead of killing him as intended, it shrunk him to child size, so he must solve crimes while pretending to be a “normal” kid, Conan Edogawa. See the…

#abduction#age regression#allergies#antidotes#arson#attempted murder#basketball#beaches#birthday#blindness#boys#butlers#cafes#camping#canon immigrant#challenges#charms#chefs#children#class trip#clumsiness#codes#defective detective#detectives#disguises#dying clue#estrangement#families#flashbacks#Friday the 13th

0 notes

Text

i swear to fuck if we start liking junpei thanks to whatever potential chidori alter is up here i’m gonna LOSE IT

0 notes

Text

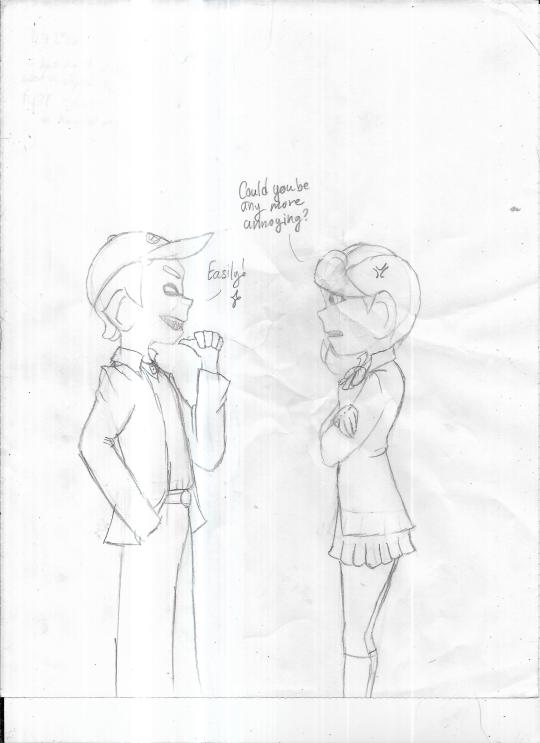

Silly thing feat. Yuka-tan and our favorite Ace defective

Yukari, being pissed at him only makes the dumbass funnier

#persona 3#yukari takeba#junpei iori#junpei iori ace detective#more like#stupei ace defective#p3 x splatoon crossover#splatoonified#splatoonify#splatoonifying#splatsillies

6 notes

·

View notes

Text

Revolutionizing Infrastructure Monitoring: Drones That Detect Defects in Pipelines and Powerlines

Skyintelli, Inc specializes in deploying advanced drone systems tailored for industrial inspection, including solutions for pipelines and powerlines. With expertise in aerial data collection, defect analysis, and regulatory compliance, Skyintelli, Inc helps organizations elevate their inspection programs, reduce risks, and protect their critical infrastructure investments. Trust Skyintelli, Inc to guide you into the future of safer, smarter infrastructure monitoring.

0 notes

Text

Revolutionizing Packaging with the LIS-2S Automatic Label Inspection System

In the world of high-speed packaging, precision isn’t optional—it’s critical. Just one poorly applied or misaligned label can cost manufacturers customer trust, regulatory compliance, or even an entire product batch. Enter the LIS-2S automatic label inspection system—a cutting-edge solution designed for the pharma, FMCG, and cosmetics industries that demand nothing less than perfection. Operating seamlessly on high-speed bottling lines, this system brings unmatched accuracy and inspection reliability, ensuring every bottle leaving your facility is 100% label-verified.

Why an Automatic Label Inspection System is a Must-Have Today

Manual label inspection is quickly becoming obsolete. Human eyes can't consistently catch defects at production speeds of 14,000 bottles per hour. Plus, the margin for error grows with fatigue and environmental distractions. That’s why more companies are investing in automated, vision-based solutions. The LIS-2S automatic label inspection system detects: • Label misplacement or skew • Wrinkles or air bubbles • Incorrect label orientation • Missing labels • Overlapping or double-labeled bottles By integrating a robust vision camera setup with intelligent software, LIS-2S offers real-time decision-making—rejecting faulty products before they reach the packaging zone.

High-Speed Performance with Precision Engineering Speed without precision is a recipe for disaster. Fortunately, LIS-2S is engineered to handle both. • Throughput: Up to 14,000 bottles/hour • Inspection Modes: Front label, back label, wrap-around label • Orientation Correction: Capable of verifying label orientation in relation to bottle shape or cap • User Interface: Simple, touchscreen-based GUI for setup and monitoring • Footprint: Compact, easily integrates into existing lines without the need for reconfiguration Whether you’re packaging antibiotics in glass bottles or shampoos in PET containers, the LIS-2S adapts effortlessly, thanks to its custom configurability.

How the Automatic Label Inspection System Ensures Compliance Global compliance standards are tightening. For industries like pharma or cosmetics, even a 0.01% labeling error can result in batch rejection, penalties, or blacklisting by retailers. The automatic label inspection system gives manufacturers a proactive way to stay ahead of audits. Key compliance advantages: • 21 CFR Part 11 ready (for pharma) • Customizable reports & batch logs • Traceability of rejected units • Audit trail with user access control Plus, it helps ensure packaging meets branding standards—logos are correctly placed, labels are level, and branding integrity is never compromised.

Designed for Indian Manufacturing. Built for Global Standards. Optomech’s LIS-2S isn’t just fast and smart—it’s designed with real production environments in mind. Unlike imported systems that are complex to maintain, the LIS-2S offers: • Local tech support & quick servicing • Easy-to-source spares • Customization for Indian bottle formats (HDPE, PET, Glass, etc.) • Affordable total cost of ownership compared to foreign systems This makes LIS-2S a future-ready solution not just for large-scale manufacturers but also for mid-sized companies scaling up their packaging operations.

Key Benefits of Using an Automatic Label Inspection System When you switch to an automated system like LIS-2S, you unlock real, measurable improvements: • Reject rate reduced by up to 95% • Downtime minimized through predictive maintenance • Brand image protected by flawless labeling • Line efficiency improved via real-time rejection alerts • Zero human intervention means zero fatigue-based errors The ROI? Many users recover their investment within 6 to 12 months purely through reduction in wastage and customer complaints.

Where LIS-2S Fits Best This automatic label inspection system is ideal for: • Pharmaceutical packaging lines • FMCG bottling plants • Cosmetic and personal care product lines • Nutraceutical liquid packaging • Agrochemical bottle labeling Whether you're handling 100 ml syrup bottles or 1-liter shampoo containers, LIS-2S adapts to your workflow.

Smart Label Inspection, Smarter Business Investing in the LIS-2S automatic label inspection system is more than just buying a machine—it’s a strategic move. It signals to your customers, partners, and regulatory agencies that your company is committed to zero-defect manufacturing and continuous improvement. It’s not just about catching errors. It’s about preventing brand damage before it happens.

Final Thoughts: Make Every Label Count With the stakes so high in modern packaging, the question isn’t if you need label inspection automation—it’s when. And if you're serious about quality, the LIS-2S automatic label inspection system should be your answer. From regulatory peace of mind to zero-defect shipments, this is one investment your packaging line—and your brand—can’t afford to skip.

#High-speed label inspection machine#Label inspection system#Label defect detection#Automatic label inspection#Inline bottle inspection

0 notes

Text

Radiography Test: Key Techniques and Benefits Explained

Radiography test is a non-destructive testing (NDT) method. It uses X-rays or gamma rays to examine the internal structure of materials. This technique is essential for detecting hidden flaws without causing damage, ensuring the integrity and safety of components. Radiography test is widely applied in industries such as manufacturing, construction, and aerospace to inspect welding, castings, and…

#Computed Radiography#Defect Detection#Digital radiography#Gamma-ray Testing#Industrial radiography#NDT Techniques#Non-Destructive Testing (NDT)#Radiographic Evaluation#Radiographic Examination#Radiographic Film Analysis#Radiographic Imaging#Radiographic Interpretation#Weld Defect Identification#Weld Inspection#Weld Integrity Testing#Weld Quality Assessment#Welding Inspection#X-ray Inspection

0 notes