#ipc-a-610 acceptability of electronic assemblies

Explore tagged Tumblr posts

Text

How Aimtron’s PCB Assembly Meets Industry Standards

In the fast-paced realm of electronics manufacturing, precision, reliability, and compliance are paramount. Aimtron, a trusted leader in the industry, sets itself apart by providing top-notch PCB Assembly Services that consistently meet and exceed industry standards. From meticulous craftsmanship to advanced technology, Aimtron demonstrates its commitment to excellence in PCB Assembly Solutions. Here’s a closer look at how Aimtron maintains its competitive edge while upholding the highest benchmarks in the industry.

Cutting-Edge Technology in PCB Assembly

Aimtron embraces state-of-the-art technology to ensure its PCB Assembly processes are efficient, precise, and scalable. With fully automated pick-and-place machines, in-line optical inspection systems, and advanced soldering techniques, Aimtron delivers unmatched quality in every project. The use of cutting-edge tools reduces errors and ensures that even the most complex assemblies meet stringent requirements.

Strict Adherence to Industry Standards

At Aimtron, compliance is more than a box to check—it's a core value. The company adheres to globally recognized standards, including ISO 9001 for quality management and IPC-A-610 for the acceptability of electronic assemblies. By aligning its Electronics Manufacturing processes with these benchmarks, Aimtron ensures that every product meets customer expectations for safety, reliability, and performance.

Tailored Solutions for Diverse Needs

No two projects are identical, and Aimtron understands the importance of customized PCB Assembly Solutions. Whether dealing with prototype development, low-volume production, or large-scale manufacturing, Aimtron adapts its approach to meet client-specific requirements. This flexibility allows the company to cater to industries such as automotive, healthcare, consumer electronics, and telecommunications.

End-to-End Services

Aimtron’s comprehensive PCB Assembly Services include design support, component sourcing, assembly, and rigorous quality control. This end-to-end approach ensures seamless project management and enables clients to focus on innovation while Aimtron handles the technical complexities of Electronics Manufacturing.

Sustainability and Innovation

In addition to meeting industry standards, Aimtron is committed to eco-friendly practices. The company minimizes waste, adheres to RoHS (Restriction of Hazardous Substances) directives, and optimizes energy consumption during PCB Assembly. This dedication to sustainability aligns with the growing demand for greener solutions in the electronics sector.

Conclusion

Aimtron’s unwavering commitment to quality, compliance, and innovation positions it as a leader in the PCB Assembly landscape. By delivering reliable PCB Assembly Services and customized PCB Assembly Solutions that meet industry standards, Aimtron continues to set the benchmark for excellence in Electronics Manufacturing. Whether you’re developing the next big tech innovation or streamlining an existing product, Aimtron is the partner you can trust for superior results.

0 notes

Text

Unlocking Excellence: The Journey to Become a Certified IPC Trainer (CIT)

From the world of fine craftsmanship and accuracy in electronics manufacturing! The IPC certification Trainee (CIT) credential is a must-have for anyone looking to advance their career and make a positive impact on the dynamic electronics industry. It is only offered by IPC-approved training facilities like Blackfox.

We'll explore the value of CIT soldering certification, the training requirements, and the advantages it offers to individuals and businesses in this blog.

Why Select Certification in CIT?

The electronics sector requires highly qualified workers to guarantee the dependability and quality of electronic assemblies. The purpose of the CIT certification is to empower employees in businesses, self-employed consultants, and instructors at colleges and universities. Let's examine the main justifications for CIT certification among prospective professionals:

Industry Recognition: In the electronics manufacturing sector, the CIT certification is well-known. It is evidence of a person's skill and dedication to upholding standards of excellence.

Program for "Training the Trainer": The IPC certification is basically a "train-the-trainer" initiative. After passing the exam, candidates will have the information and abilities needed to instruct other people in their company or at a school as Certified IPC Specialists (CIS).

Comprehensive Training Materials: CITs can conduct application-level (CIS) IPC training with the IPC materials that Blackfox, an IPC-authorized training center, provides. This includes current details on soldering methods, industry standards, and best practices for electronic assembly.

The Process of CIT Training

The path to becoming a Certified IPC Trainer is demanding but worthwhile. Let's go over the main stages of the CIT training procedure:

1. Prerequisite Knowledge: Before beginning the CIT certification process, candidates usually have a strong background in electronics and soldering procedures.

CIT candidates receive instruction in the IPC-A-610 standard, which outlines the requirements for acceptable electronic assemblies. This training ensures a thorough understanding of industry standards and requirements.

2. Assessment of Hands-On Skills: Practical application is a key component of the CIT certification. Candidates participate in a practical skills evaluation where they demonstrate their soldering abilities and application of IPC standards.

3. Certification Exam: An extensive test covering the IPC-A-610 standard is the last obstacle. Succeeding candidates exhibit their command of the subject and dedication to upholding standards in the production of electronics.3

Advantages of Certification in CIT

Getting certified as a CIT opens doors to a lot of advantages for people and their companies:

Enhancement of Skill: CITs' overall skill set is improved by their increased understanding of soldering methods, electronic assembly procedures, and IPC standards.

Credibility in the Industry: The CIT certification is a symbol of excellence that gives professionals in the electronics manufacturing sector respect and credibility.

Cost savings: Having in-house trainers helps organizations cut costs related to errors and rework, as well as the need for outside training services.

Constant Learning: To keep CITs abreast of the latest developments in technology and industry best practices, they are provided with regular updates on industry standards.

Joining Blackfox as a Certified IPC Trainer is more than just obtaining a credential—it's a pledge to excellence in the electronics manufacturing industry. Whether you work in the industry as a professional or as an instructor, earning your soldering certification and CIT certification guarantees that you contribute significantly to upholding the highest standards in electronic assembly and opens doors to new opportunities.

Visit Blackfox's IPC-authorized training facility in Delaware to start your journey toward CIT certification and discover your potential as a leader and educator in the exciting field of electronics.

0 notes

Text

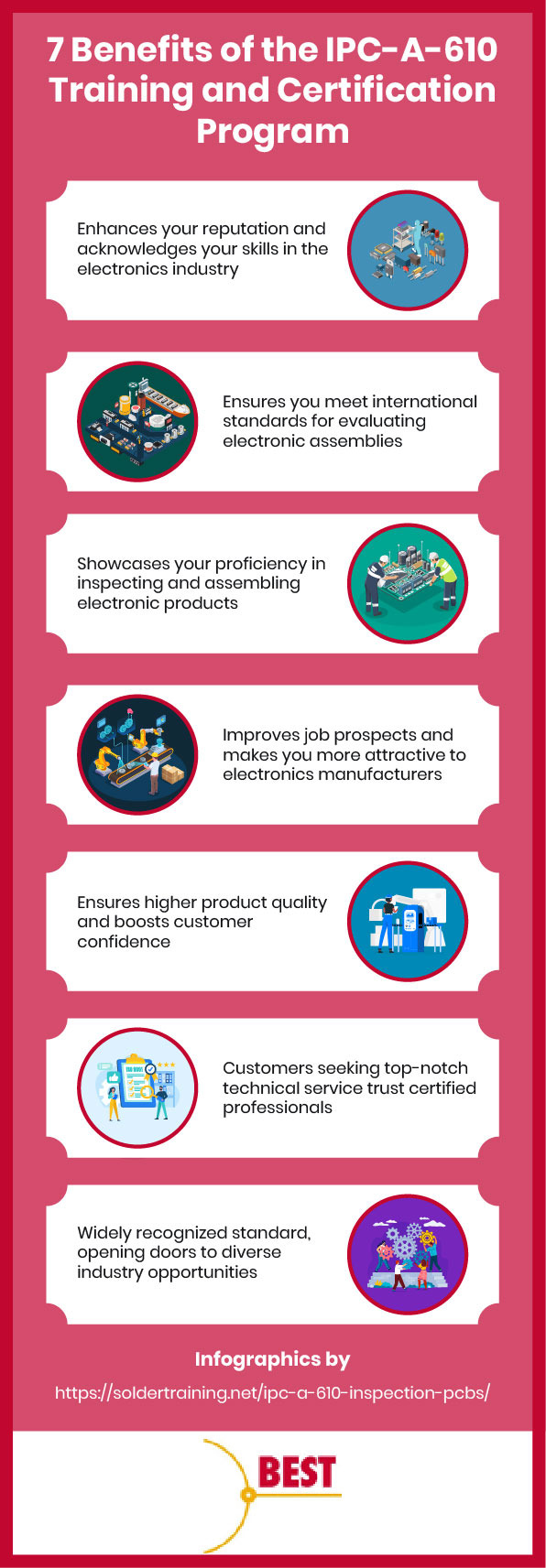

IPC-A-610 certification is an industry-standard document published by the Association of Connecting Electronics Industries (IPC). This widely recognized standard establishes the acceptability criteria for the assembly of electronic components, defining what is acceptable and what is not in terms of their artistry. To know more read this infographic: https://soldertraining.net/blog/benefits-of-ipca610-training-certification-program/.

0 notes

Text

Know what you will learn from IPC-A-610F: 10+ Important Topics to Go Through

Know what you will learn from IPC-A-610F: 10+ Important Topics to Go Through

Have you been deployed as a quality auditor at an electronic product-making company? Do you find it challenging to inspect the quality of each product before sending it to the distributor? Are you looking for ways to become great at your job? Well, the only solution to all your problems is the IPC-A-610 certification program. This program is specially designed for people like you who are…

View On WordPress

#ipc 610 certification near me#ipc 610 certification online#ipc 610 certification price#ipc 610 test questions#ipc-a-610 acceptability of electronic assemblies#ipc-a-610 challenge test#ipc-a-610 class 3#ipc-a-610 latest revision

0 notes

Photo

The IPC-A-610 CIS specialist Training course is designed to help electronic manufacturers achieve the highest quality, productivity, and cost-effective production by ensuring that personnel can correctly apply the acceptability criteria of the IPC-A-610 "Acceptability of Electronic Assemblies" whilst performing visual inspection of PCB's. Check here more…

#IPC-A-610 CIS Training#IPC-A-610 CIS specialist Training course#IPC-A-610 CIS certification#Acceptability of Electronic Assemblies#IPC-A-610 Training#IPC-A-610 certification

0 notes

Text

PCB Manufacture: China vs. US

Looking back on your daily life, have you noticed the growth of consumer electronics and automotive industries are affecting your life and work? Accordingly, it also drives the booming market of PCB Manufacture, which is expected to reach an estimated $89.7 billion by 2024 with a CAGR of 4.3% from 2019 to 2024. Much of this market is currently controlled by PCB manufacturer China companies in places like Shenzhen, which is located in Southeastern China. However, the history of PCB booming in the United States can be traced back to 1950, which is far earlier than China entering this market.

So why can PCB Manufacturer China dominates the market rather than the United States? To solve the confusion for PCB procurements about choosing PCB manufacturer China or US instead, we’ve listed the comparison between the United States and China.

Competitive factors of PCB manufacturer China

According to this report, price was the dominant primary competitive factor in Non-U.S PCB manufacturer, accounting for 76 percent of responses, and China was the leading location, accounting for 67 percent of responses.

And the comparative advantages in various costs which result in lower finished bare PCB prices are:

Labor Costs

Material Costs

Equipment Costs

Environmental Compliance Costs

Building Space Costs

R&D Costs

Supplier Chain

Let’s take Shenzhen MOKO Technology Co., Ltd as an example, which is one of the leading SEM PCB manufacturing and PCB assembly factory in Shenzhen, China.

Labor cost: As you know, Shenzhen is a fast-developing city that gathers many high-tech electronics and automotive industries, each company included MOKO requires clear division of labor, and due to the economic level of China compared to US and easier access to skilled workers, the labor cost of MOKO is far cheaper than in US.

Material cost: MOKO Technology was established since 2001, it’s proficient and experienced in manufacturing PCB and PCB assembly, and also established a stable relationship with accountable material supplier. For a PCB manufacturer that aims to win customers with high-quality and after-sale service, there are many audit processes to certified a material supplier, so the long-term relationship with material suppliers saves a lot of cost of MOKO Technology. Of course, it also doesn’t mean that there’s an opportunity for the material supplier to mix some poor material, from the material sourcing to the forming of substrate and the performance testing of the final products, each process is under strict requirements and testing.

Equipment cost: Chinese high-end equipment is constantly replacing the import, recognized and ordered by the famous PCB enterprises at home and abroad as its high-quality and cost-saving, such as laser drilling machine, laser cutting machine, CNC drilling machine, automatic laser imaging system (LDI), vertical continuous electroplating automatic line (VCP), automatic automatic on and off detection. The main PCB special equipment/instrument representative companies in China are Han’s Laser Technology Industry Group Co., Ltd, Zhengye Technology, UCE Group, Shenzhen Mason Electronics Co., Ltd., and Ta Liang Technology Co., Ltd.

R&D Costs: Due to the overall economic and outcome level in China, the educated and experienced Engineers' salaries and R&D equipment, relevant material and tooling are cheaper than in the US.

Supplier chain: As mass PCB production has shifted away from the U.S. towards Asia,especially Shenzhen, so China has the advantage of the industry supply chain.

Forty-five percent of BIS survey respondents stated that a reduction in U.S. companies that manufacture laminate and other circuit-board related materials has created supply problems for them.

Furthermore, Electronic Contract Manufacturing has been known historically to dramatically reduce supply chain costs, in some cases cutting them in half. ECM has made it possible for companies to shed all or most of their internal manufacturing facilities thereby freeing their valuable company resources for other productive business purposes. In some cases, Electronic Contract Manufacturing has enabled companies to operate without the need for internal manufacturing capabilities or internally-managed factories.

Many companies may choose to outsource their well-established longstanding products to an Electronic Contract Manufacturer, thereby allowing for a greater focus on internal operations for newer products of greater complexity which may have higher margins.

Competitive factors of PCB manufacturer US

According to respondents, U.S. bare PCB manufacturers possess the comparative advantage in:

Lead Time

Quality

Performance

Through the comparison of the advantage between PCB manufacturer China & the US, I believe you’ve got a clear idea for choosing the PCB manufacturer between China and the US, so the next thing you should figure out is what you most concerns when choosing a PCB manufacturer.

Cost

Quality

Lead time

MOQ

Design safety

Experience & Expertise

After-sale service

If you’re considering high-volume production and the price is the most essential factor for your market plan, then you should choose a PCB manufacturer in China as it can save you lots of money for other donate or patronage.

And of course the quality should not be ignored, there are many excellent PCB manufacturers in the US with advanced equipment for ensuring the quality and lead time, and if your company is based on the US, maybe it would be convenient for you to visit the company.

But we know, for business, who don’t want to cooperate with a company that can be conformed to both cost and quality? And of course, to establish your long-term relationship with the PCB manufacturer, most of you would choose to start with a prototype or sample, which is a good way to decrease the deficit and finding out the problem before mass production.

So in such a condition, I suggest you find a reputable and certified experienced PCB manufacturer in China.

Located in Shenzhen, China, MOKO Technology is an expert at PCB Manufacturing and PCB assembly since 2001. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there are 70 engineers for R&D team and 45 overseas sales for the business team.

Cost:

Firstly, based on geography advantage, MOKO Technology can save a lot of costs like material, component sourcing, labor cost and so on.

Secondly, it has a professional complete procedure from the inquiry to shipping. After receiving the inquiry, MOKO Technology has a team to evaluate customers’ requirements and make an optimized scheme for you, for the material, you will be suggested to choose the suitable material that can perform best for the property.

Thirdly, MOKO Technology has the advantage of supplier chain and it’s experienced in EMS with a one-stop service, which only saves you lots of time and money.

Quality:

For the R&D cost, MOKO Technology has hired experienced 70 engineers

Certified in accordance with ISO 9001: 2015, IPC, and UL (PCB factory: E501497 94V-0; PCB assembly factory: E499341) standards

Bare Board 100 % Visual Inspection & AQL on mechanical to IPC-600 Class II or III

Assembly 100% Visual Inspection to IPC-610 Class II or III

Polar TDR Impedance Testing

PCB Board Net List Electrical Testing 100%

Micro-section Evaluation and Reports

PCB Assembly – ICT testing

PCB Assembly – Functional Testing

PCB Assembly – Burn-In-Testing

X-ray for PC board registration

X-ray for BGA and Component Verification

Automated Optical Inspection (AOI)

Lead Time of PCB Assembly:

MOKO provide 2-50 layered PCBs for fabrication, including HDI, Rigid, Rigid-Flex, & flex boards. From low quantity to mass production, with high quality, and quick turn available at a low cost.

And for the monthly capacity, it can manufacturer 30,000 square meters PCB and 400,000 pcs.

There’s no minimum order requirement, and for the sample, MOKO Technology can accept 10 pcs as MOQ.

Design safety:

About this issue, you can never worry about it as MOKO Technology will sign DOD Contracts with ITAR Registered

After-sale service:

Online Tracking

ERP Systematic order process, you can check the production status of the entire purchase order, and the whole product cycle time.

Professional sales:

Whatever problems happening, you can be replied within 24 hours. There are 70 engineers to support you, including PCB design & PCB Layout, hardware design engineering, firmware & software development, and personalization.

One pair one timely customer order status feedback

MOKO Technology Ltd is a premiere turn-key PCB assembly manufacturer. We are dedicated to providing the best client service in the electronics manufacturing business. Your total satisfaction is extremely important to us. We will meet all your needs in PCB design and layout, PCB manufacturing, and circuit board assembly

Products application industries1> LED PCB

MOKO Technology can offer one-stop service for led light electronic parts focusing on ODM/OEM led PCBA, OEM LED control PCBA and OEM LED Driver PCBA.

It can design hardware, firmware, iOS/Android APP, plastic. If you have a Gerber file and BOM list, they also can offer OEM service for you.

What can MOKO Technology do for LED project:

PCB Design & Layout

Reverse Engineering Service

Fast PCB&PCBA Prototyping

Components sourcing

PCB Assembly

Cable, Wire Assemblies, and Housing Assemblies

Cover coating and glue

Loading firmware & function testing and Aging testing

ODM/OEM LED PCBA Service:

MOKO Technology produced lots of led PCBA, for example, UV LED PCBA for medical machine, UV LED PCBA for 3D printer, AC220V driverless led PCBA, AC110V driverless led PCBA, LED PCBA for street light, LED PCBA for tube light, LED PCBA for panel light, COB RGB LED PCBA for pool light, RGB LED PCBA for pixel light, LED PCBA for ceiling light, LED PCBA for traffic light, etc.

LED PCBA Design & Layout Cases:

MOKO Technology Ltd is a highly respected telecom PCB Assembly, telecom PCBA Manufacturer specializing in prototyping and small volume building in the highly complex area or telecom and industrial computing Printed Circuit Board Assembly(PCBA), PCB Assembly, PCB Assembly service for leading OEMs.

Telecom Printed Circuit Boards Applications:

Phone switching systems

Signal boost online systems

Cell transmission and tower electronics

Satellite technology High-speed routers and servers

Wireless industrial and commercial phone technology

Space communications technology

Military communications systems

Video collaboration Information security technology

PBX systems Voice over internet protocol

Latest Telecom PCBA Cases:

To ensure a positive response from “end”-consumers, many customers from MOKO build on the quality and reliability provided from MOKO.

Latest Consumer Electronics PCBA Cases:

MOKO offers world-class, custom-designed solutions for the automotive market including rapid prototyping, test and product development support with the highest level of quality and traceability to meet your unique requirements.

Latest Automotive PCBA Cases:

MOKO Technology Ltd specializes in the medical PCB assembly and medical PCB production for medical companies of all sizes.

The workmanship of MOKO Technology Ltd can be found in many medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

Latest Medical PCBA Cases:

For several years, MOKO has worked with a variety of customers in the industrial market segment from sensors, conditioning systems for alternative energy, power monitoring systems, industrial controls as well as others with demanding environmental requirements.

Latest Industrial PCBA Cases:

So after all this research above, I think choosing the most suitable PCB manufacturer according to your concern is a wise choice. Whatever it’s PCB manufacturer China or PCB manufacturer US, make sure you’ve been clear about your concerns and know your supplier well!

For more info about MOKO Technology Co., Ltd, you can visit https://www.mokotechnology.com/

1 note

·

View note

Text

PCB Manufacturer China and PCB Manufacturer US

Looking back on your daily life, have you noticed the growth of consumer electronics and automotive industries are affecting your life and work? Accordingly, it also drives the booming market of PCB Manufacture, which is expected to reach an estimated $89.7 billion by 2024 with a CAGR of 4.3% from 2019 to 2024. Much of this market is currently controlled by PCB manufacturer China companies in places like Shenzhen, which is located in Southeastern China. However, the history of PCB booming in the United States can be traced back to 1950, which is far earlier than China entering this market.

So why can PCB Manufacturer China dominates the market rather than the United States? To solve the confusion for PCB procurements about choosing PCB manufacturer China or US instead, we’ve listed the comparison between the United States and China.

Competitive factors of PCB manufacturer China

According to this report, the price was the dominant primary competitive factor in Non-U.S PCB manufacturer, accounting for 76 percent of responses, and China was the leading location, accounting for 67 percent of responses.

And the comparative advantages in various costs which result in lower finished bare PCB prices are:

Labor Costs

Material Costs

Equipment Costs

Environmental Compliance Costs

Building Space Costs

R&D Costs

Supplier Chain

Let’s take Shenzhen MOKO Technology Co., Ltd as an example, which is one of the leading SEM PCB manufacturing and PCB assembly factory in Shenzhen, China.

Labor cost: As you know, Shenzhen is a fast-developing city that gathers many high-tech electronics and automotive industries, each company included MOKO requires clear division of labor, and due to the economic level of China compared to US and easier access to skilled workers, the labor cost of MOKO is far cheaper than in US.

Material cost: MOKO Technology was established since 2001, it’s proficient and experienced in manufacturing PCB and PCB assembly, and also established a stable relationship with accountable material supplier. For a PCB manufacturer that aims to win customers with high-quality and after-sale service, there are many audit processes to certified a material supplier, so the long-term relationship with material suppliers saves a lot of cost of MOKO Technology. Of course, it also doesn’t mean that there’s an opportunity for the material supplier to mix some poor material, from the material sourcing to the forming of a substrate and the performance testing of the final products, each process is under strict requirements and testing.

Equipment cost: Chinese high-end equipment is constantly replacing the import, recognized and ordered by the famous PCB enterprises at home and abroad as its high-quality and cost-saving, such as laser drilling machine, laser cutting machine, CNC drilling machine, automatic laser imaging system (LDI), vertical continuous electroplating automatic line (VCP), automatic automatic on and off detection. The main PCB special equipment/instrument representative companies in China are Han’s Laser Technology Industry Group Co., Ltd, Zhengye Technology, UCE Group, Shenzhen Mason Electronics Co., Ltd., and Ta Liang Technology Co., Ltd.

R&D Costs: Due to the overall economic and outcome level in China, the educated and experienced Engineers' salaries and R&D equipment, relevant material and tooling are cheaper than in the US.

Supplier chain: As mass PCB production has shifted away from the U.S. towards Asia,especially Shenzhen, so China has the advantage of the industry supply chain.

Forty-five percent of BIS survey respondents stated that a reduction in U.S. companies that manufacture laminate and other circuit-board related materials has created supply problems for them.

Furthermore, Electronic Contract Manufacturing has been known historically to dramatically reduce supply chain costs, in some cases cutting them in half. ECM has made it possible for companies to shed all or most of their internal manufacturing facilities thereby freeing their valuable company resources for other productive business purposes. In some cases, Electronic Contract Manufacturing has enabled companies to operate without the need for internal manufacturing capabilities or internally-managed factories.

Many companies may choose to outsource their well-established longstanding products to an Electronic Contract Manufacturer, thereby allowing for a greater focus on internal operations for newer products of greater complexity which may have higher margins.

Competitive factors of PCB manufacturer US

According to respondents, U.S. bare PCB manufacturers possess the comparative advantage in:

Lead Time

Quality

Performance

Through the comparison of the advantage between PCB manufacturer China & the US, I believe you’ve got a clear idea for choosing the PCB manufacturer between China and the US, so the next thing you should figure out is what you most concern when choosing a PCB manufacturer.

Cost

Quality

Lead time

MOQ

Design safety

Experience & Expertise

After-sale service

If you’re considering high-volume production and the price is the most essential factor for your market plan, then you should choose a PCB manufacturer in China as it can save you lots of money for other donate or patronage.

And of course the quality should not be ignored, there are many excellent PCB manufacturers in the US with advanced equipment for ensuring the quality and lead time, and if your company is based on the US, maybe it would be convenient for you to visit the company.

But we know, for business, who don’t want to cooperate with a company that can be conformed to both cost and quality? And of course, to establish your long-term relationship with the PCB manufacturer, most of you would choose to start with a prototype or sample, which is a good way to decrease the deficit and finding out the problem before mass production.

So in such a condition, I suggest you find a reputable and certified experienced PCB manufacturer in China.

Located in Shenzhen, China, MOKO Technology is an expert at PCB Manufacturing and PCB assembly since 2001. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there are 70 engineers for R&D team and 45 overseas sales for the business team.

Cost:

Firstly, based on geography advantage, MOKO Technology can save a lot of costs like material, component sourcing, labor cost and so on.

Secondly, it has a professional complete procedure from the inquiry to shipping. After receiving the inquiry, MOKO Technology has a team to evaluate customers’ requirements and make an optimized scheme for you, for the material, you will be suggested to choose the suitable material that can perform best for the property.

Thirdly, MOKO Technology has the advantage of supplier chain and it’s experienced in EMS with a one-stop service, which only saves you lots of time and money.

Quality:

For the R&D cost, MOKO Technology has hired experienced 70 engineers

Certified in accordance with ISO 9001: 2015, IPC, and UL (PCB factory: E501497 94V-0; PCB assembly factory: E499341) standards

Bare Board 100 % Visual Inspection & AQL on mechanical to IPC-600 Class II or III

Assembly 100% Visual Inspection to IPC-610 Class II or III

Polar TDR Impedance Testing

PCB Board Net List Electrical Testing 100%

Micro-section Evaluation and Reports

PCB Assembly – ICT testing

PCB Assembly – Functional Testing

PCB Assembly – Burn-In-Testing

X-ray for PC board registration

X-ray for BGA and Component Verification

Automated Optical Inspection (AOI)

Lead Time of PCB Assembly:

MOKO provides 2-50 layered PCBs for fabrication, including HDI, Rigid, Rigid-Flex, & flex boards. From low quantity to mass production, with high quality, and quick turn available at a low cost.

And for the monthly capacity, it can manufacturer 30,000 square meters PCB and 400,000 pcs.

There’s no minimum order requirement, and for the sample, MOKO Technology can accept 10 pcs as MOQ.

Design safety:

About this issue, you can never worry about it as MOKO Technology will sign DOD Contracts with ITAR Registered

After-sale service:

Online Tracking

ERP Systematic order process, you can check the production status of the entire purchase order, and the whole product cycle time.

Professional sales:

Whatever problems happening, you can be replied within 24 hours. There are 70 engineers to support you, including PCB design & PCB Layout, hardware design engineering, firmware & software development, and personalization.

One pair one timely customer order status feedback

MOKO Technology Ltd is a premiere turn-key PCB assembly manufacturer. We are dedicated to providing the best client service in the electronics manufacturing business. Your total satisfaction is extremely important to us. We will meet all your needs in PCB design and layout, PCB manufacturing, and circuit board assembly

Products application industries1> LED PCB

MOKO Technology can offer one-stop service for led light electronic parts focusing on ODM/OEM led PCBA, OEM LED control PCBA and OEM LED Driver PCBA.

It can design hardware, firmware, iOS/Android APP, plastic. If you have a Gerber file and BOM list, they also can offer OEM service for you.

What can MOKO Technology do for LED project:

PCB Design & Layout

Reverse Engineering Service

Fast PCB&PCBA Prototyping

Components sourcing

PCB Assembly

Cable, Wire Assemblies, and Housing Assemblies

Cover coating and glue

Loading firmware & function testing and Aging testing

ODM/OEM LED PCBA Service:

MOKO Technology produced lots of led PCBA, for example, UV LED PCBA for medical machine, UV LED PCBA for 3D printer, AC220V driverless led PCBA, AC110V driverless led PCBA, LED PCBA for street light, LED PCBA for tube light, LED PCBA for panel light, COB RGB LED PCBA for pool light, RGB LED PCBA for pixel light, LED PCBA for ceiling light, LED PCBA for traffic light, etc.

LED PCBA Design & Layout Cases:

MOKO Technology Ltd is a highly respected telecom PCB Assembly, telecom PCBA Manufacturer specializing in prototyping and small volume building in the highly complex area or telecom and industrial computing Printed Circuit Board Assembly(PCBA), PCB Assembly, PCB Assembly service for leading OEMs.

Telecom Printed Circuit Boards Applications:

Phone switching systems

Signal boost online systems

Cell transmission and tower electronics

Satellite technology High-speed routers and servers

Wireless industrial and commercial phone technology

Space communications technology

Military communications systems

Video collaboration Information security technology

PBX systems Voice over internet protocol

Latest Telecom PCBA Cases:

To ensure a positive response from “end”-consumers, many customers from MOKO build on the quality and reliability provided from MOKO.

Latest Consumer Electronics PCBA Cases:

MOKO offers world-class, custom-designed solutions for the automotive market including rapid prototyping, test and product development support with the highest level of quality and traceability to meet your unique requirements.

Latest Automotive PCBA Cases:

MOKO Technology Ltd specializes in the medical PCB assembly and medical PCB production for medical companies of all sizes.

The workmanship of MOKO Technology Ltd can be found in many medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

Latest PCBA Cases:

For several years, MOKO has worked with a variety of customers in the industrial market segment from sensors, conditioning systems for alternative energy, power monitoring systems, industrial controls as well as others with demanding environmental requirements.

Latest Industrial PCBA Cases:

So after all this research above, I think choosing the most suitable PCB manufacturer according to your concern is a wise choice. Whatever it’s PCB manufacturer China or PCB manufacturer US, make sure you’ve been clear about your concerns and know your supplier well!

For more info about MOKO Technology Co., Ltd, you can visit https://www.mokotechnology.com/ and https://www.mokotechnology.com/pcb-manufacturer-china-vs-us/

1 note

·

View note

Text

IPC-A-610G, Acceptability of Electronic Assemblies Boards

New Post has been published on https://piek.international/ipc-610g-acceptability-electronic-assemblies-boards/

IPC-A-610G, Acceptability of Electronic Assemblies Boards

IPC-A-610 Acceptability of Electronic Assemblies, in its latest G Revision, was published in October 2017. Of all the acceptance criteria documents in the IPC portfolio it is the one that is used most frequently and is best known throughout the electronics industry. It has been the base document in inspection departments at EMS companies and OEMs for decades. Apart from this, it has been referred to in numerous contract documents for the procurement of PCBAs (Printed Circuit Board Assemblies) worldwide.

One major improvement in this G Revision has been the alignment with other commonly used IPC standards, like for instance IPC-A-620C and IPC-J-STD-001G. Conflicting criteria in the various documents have been addressed by a group of specialists, and modifications have been made, for instance to paragraph 4.2, Jackpost mounting, which is now in line with the other documents. Pictures have been exchanged and added for clarification of the texts.

Obviously, the criteria from Amendment 1 to the F-Revision were considered as well when the G-Revision was under development, which means for instance that table 7-4 is now completely up to date.

Even though this G Revision is the latest version of the document, IPC states that the use of the newer revision is not automatically required. Which revision is applicable will have to be decided by a customer.

The IPC-A-610 starts with a general introduction section where we find topics like product classification, definition of requirements, terms and definitions, personnel proficiency, inspection methodology, lighting, magnification aids, and materials and processes. Criteria have been revised and if necessary updated. New criteria have been added. Definitions have been added or the wording changed for clarification.

As usual the third chapter concentrates on handling, but only limited changes were made here. However, IPC now forbids not only the use of tobacco products but also includes smoking and even e-cigarettes.

Other topics dealt with are general soldering criteria, including lead-free connections, soldering anomalies, such as tombstoning, non-wetting and de-wetting, voiding and more, high voltage criteria, soldered connection requirements for connecting to terminals, soldered connection requirements for plated-through holes, surface mounting criteria for chip components, leadless and leaded chip carriers, component mounting criteria for DIPS, socket pins and card-edge connectors, jumper wire assembly requirements, solder fillet dimensional criteria for all major SMT component groups, criteria for component damage, laminate conditions, cleaning and solder mask and conformal coating, hardware installation and solderless wire wrap.

Like all IPC standards the IPC-A-610 is developed and reviewed by a committee with members from a variety of companies and organisations in the electronics industry. Here we find people working at training centres, OEMs and EMS companies. It is their knowledge and experience that nourishes this document, thus being a true industry standard.

The vast amount of pictures helps the user of the IPC-A-610 to better understand the criteria by providing pictorial information on the topics addressed in this standard. However, it is these pictures that may also lead to misinterpretation if used incorrectly. Even though IPC documents can be bought and used by anybody that has an interest in them, proper training in many cases proves beneficial to the proper understanding and interpretation of the criteria contained within.

The trainers at PIEK are experienced and offer optimum guidance in the proper use and interpretation of this standard. Benefit from the extensive experience the PIEK trainers have in the use of this document in daily practice and avoid the pitfalls in daily life caused by misinterpretation.

If you consider using either of the above-mentioned documents, it may be a good idea to learn all the ins and outs by attending an IPC-A-610 certification course based on them. These certification courses are provided by PIEK both in your company or in regionally organised training sessions, and they will increase your knowledge level. Furthermore, training will help you to use the criteria correctly and avoid misinterpretation, which may save time and money. Benefit from the extensive experience the PIEK trainers have in the use of these documents in daily practice and avoid the pitfalls in daily life caused by misinterpretation.

1 note

·

View note

Video

tumblr

IPC-A-610 Certification

Are you looking for IPC-A-610 Certification:?

VIsit:https://www.soldertools.net/ipc-a-610h-acceptability-of-electronic-assemblies-revision-h-hard-copy/

IPC-A-610H is the most widely accepted standard for electronic modules in the electronics industry. The IPC-A-610H standard includes general updates to the document, introduces several new types of surface mount components, and eliminates target conditions. Participants from 29 countries provided their input and expertise to make this document accessible to the electronics industry.For more details, watch this video.

0 notes

Text

What are IPC standards

Factors such as long-term reliability, the appearance of the assembly, etc, also play a role in determining the quality of a printed circuit board assembly. Designing a PCBA is more complex than you may think.

The printed circuit board in the assembly is itself very complicated with all the finishes and materials, different components, and a solder which does the job of holding all these things together.

For almost all businesses dealing with electronic equipment and their manufacturing, IPC 610 and 620 standards are an agreed-upon standard that their products have to adhere to. These standards define what is good, what is bad, what is acceptable, and what is not in the PCBA production world.

These days there are ways in which you can link your PCBA manufacturing to AI-based tools and programs. This would make the entire process much more efficient, free of human error, and it would also save you a lot of time as well. You can take the help of a good AI consulting company for this purpose.

If you are new in the industry or if you are working in the industry for quite some time and wish to carry out an IPC 620 standard or IPC 610 standard revision, you can always contact Solder Tools company who can help you ease the process to a great extent.

0 notes

Photo

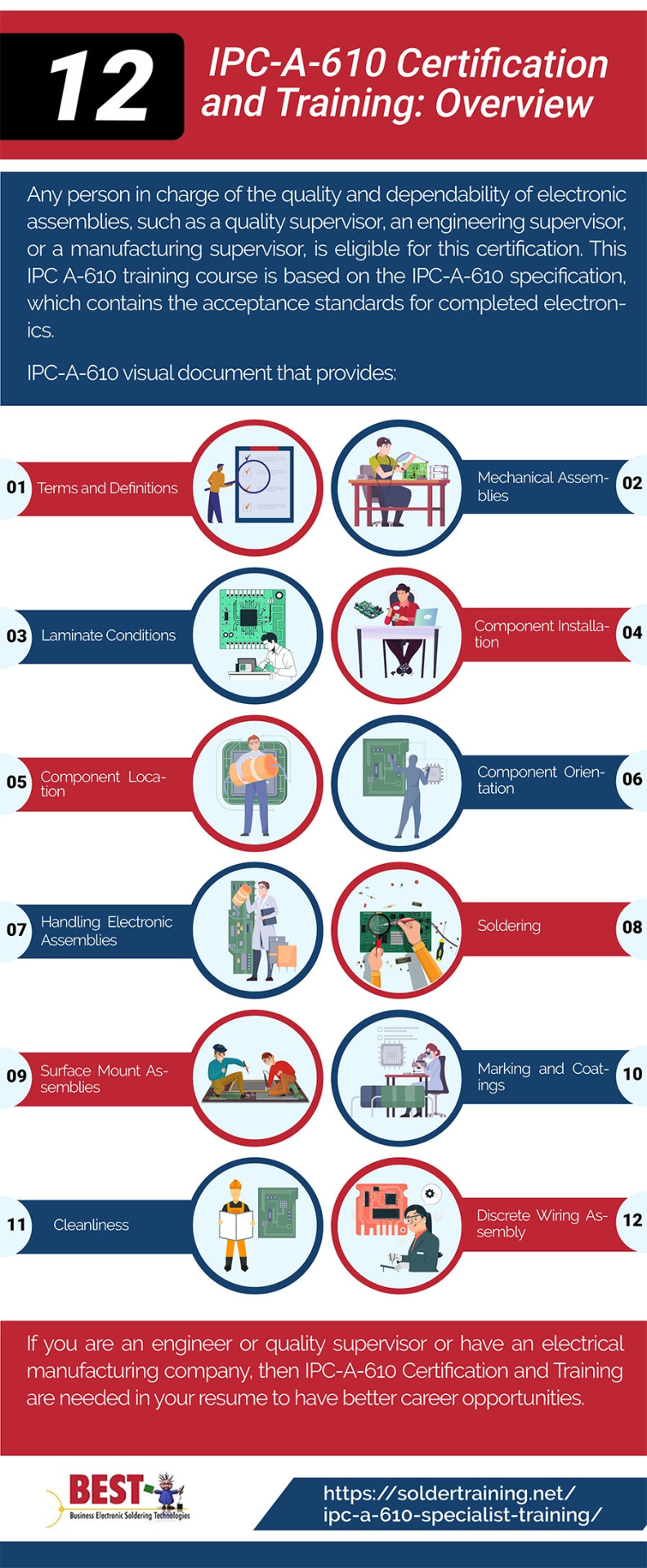

Any person in charge of the quality and dependability of electronic assemblies, such as a quality supervisor, an engineering supervisor, or a manufacturing supervisor, is eligible for this certification. This IPC A-610 training course is based on the IPC-A-610 specification, which contains the acceptance standards for completed electronics. To know more read this infographic: https://soldertraining.net/blog/ipc-a610-certification-training-overview/

0 notes

Text

Top 3 Training Materials for Technicians that You Need to Know

Are you trying to map out the training for your operators, technicians, and engineers? Haven't you found a candidate-centric solder training institute yet? We can provide you some valuable suggestions for that but knowing only that might not work for you. You need to have adequate information about the training materials before your technicians start learning the core matter. The IPC 620 training material and IPC A 610G training material remains in high demand for making the trainers, instructors, and operators informed about the acceptability of electronic assemblies and cable and wire harness assemblies in the electronics industry. If you want to certify your employees in these areas, you must know what information these training materials hold.

So, in this write-up, we're going to make you familiar with different standard books for PCBs, cable, and wire that are part of the course training materials:

What is IPC-A-610G?

It is a simple standard book for the acceptability of electronic assemblies. The IPC A 610G training material consists of the latest criteria of assembling electronic products along with many new and revised graphics. To create this small handbook, experts from 17 countries have participated and given their valuable inputs. It is a must-have training material for professionals interested in knowing the acceptance criteria for electronic assemblies to deliver high-quality and reliable electronic products. In this instruction book, you will find hundreds of new and revised photographs and illustrations on different topics, including soldering, coatings, SMT assemblies, marking of assemblies, and many more.

What is IPC-A-620C?

It is another simple standard book for requirements and acceptance for cable and wire harness assemblies. The IPC 620 training material has new sections for safety cable, safety wiring, raceways, grommets, and updated information about the rest of the areas. In its 700+ photographs and illustrations, you will find the standards that explain methods, tests, materials, and acceptance criteria for making robust soldered interconnections. What's more, this instructional book also contains pictures of most of the assembly activities related to cable and wire harness assemblies.

What is IPC-A-600J?

In layman's terms, IPC-A-600J is an informative standard book that describes the acceptability of printed boards. This informative material encourages operators to produce high-quality PCBs based on the specified standards for rigid printed boards. You will find many full-colour photographs and illustrations that show various types of printed board surfaces and their conditions between their pages. Having such an essential book in the electronics industry is pretty important because it allows users and manufacturers to speak the same language regarding printed circuit board specifications.

Ending remarks

I hope you know how different standard books can help you plan out the training of in-house operators and engineers. If you want to see what kind of illustrations these standard-cum-illustration books contain, you must order one copy from the leading electronics e-commerce site. Following this suggestion, you can get access to highly experienced instructors who can respond to specific queries about IPC 610, 620, and 600 standards that you may have.

0 notes

Text

What IPC 610 Certification Classes Can Teach? Soldering Geeks BEST

IPC A-610 is the most widely used standard published by the IPC. This is a mandatory course and provides a professional foundation for future learning. It has an international reputation as the source for end product acceptance criteria for consumer and high reliability printed wiring assemblies. This class can provide certification for either CIT and CIS which are highly valuable to the electronics industry.

1 note

·

View note

Text

Best PCB prototype assembly service - Ideas PCB

Dinner is always a popular activity, especially after a long and hard day. Stopping, taking a breath or two breaths, spending time with family and/or friends, and the opportunity to recharge your biological system can help you relax and rejuvenate. But on some days, even those attractions don’t seem to be enough. These days, for these rare special occasions, the best is needed. Indeed, a five-star dining experience is enough.

Cm always offers you the same good service as the manufacturer. There are still many times to consider the best PCB prototype assembly service; for example, service type, delivery speed, quality, and cost (such as NRE and price per unit). However, for some projects, the good may not be good enough. For these special developments, the best PCB electronic components are needed. In this paper, we will first define the above basis, then discuss the uniqueness of the best PCB prototype assembly service, and then discuss the key points of selecting this best PCB prototype assembly service.

Basic cm function of assembling electronic circuit board Before assembling the board, the developer must determine the type of CM to use. When determining the type of CM service with the most complex design, most developers choose complete PCBA manufacturing. Advantages such as dealing with only one vendor (not two or three or more), releasing internal resources for other projects, and accelerating development is inherent in turnkey and can be utilized in all PCB builds. “Turnkey” is the most commonly used service type for circuit board developers.

In addition, whether your cm outsources assembly or manufacturing is an important decision that must be made. And the minimum assembly requirements listed below must be observed. Basic requirements for electronic circuit board assembly L compliance with regulations and standards As a minimum, these contents shall include j-std-001 and IPC-a-610, respectively, on the requirements and acceptability of electronic components for welding. L provide well-defined and easily accessible DFA rules and guidelines Without assembly design (DFA) to define the operating limits of assembled equipment, multiple redesign, extended development time and additional costs may limit development efficiency. L use good quality control to maximize the reliability of the circuit board Ultimately, your customers and/or end-users will worry about the reliability of circuit boards and electronics throughout their life cycle. PCBA quality is affected by all aspects of the development process. However, assembly is the production process of the final product and bears the

responsibility of reliability verification. If your board assembly contains the items listed above, the process will produce quality products that meet your basic design requirements. However, in order to obtain the best PCB electronic assembly experience, these requirements need to be improved, as described below. Choose the best electronic PCB assembly service Understanding and implementing the basics is essential for all successful operations, and building boards and electronics is no different. Indeed, in the highly competitive PCBA and electronics markets, minimization is not enough to succeed. Even in the future, there is no reason to expect that greater market share will face greater challenges. Sustained growth is expected to be achieved in many of the business units whose products are most dependent on circuit boards and electronic systems. Therefore, new manufacturing innovations are needed to maintain the competitiveness of advanced board assembly technology considering the threats to security and supply chain.

For more details on our products and services, please feel free to visit us at: Low Cost PCB Assembly, PCB Fabrication and assembly, China pcb assembly, Quick Turn PCB Assembly, Surface Mount PCB Assembly.

0 notes

Text

Evolution of the IPC Standards

For most PCB Board manufacturers, not knowing about the IPC Standards is equivalent to committing a cardinal sin. The entire industry of PCB printing specialists, OEMs, design engineers, and other incumbents relies on the IPC Standards as the common ground for differentiating between acceptable and unacceptable PCB boards.

What is IPC?

IPC is an industry consortium and self-regulating body that sets the standards of quality at a global scale for printed circuit boards. It was started in 1957 as the Institute of Printed Circuits with the primary agenda of standardizing the methods and processes that go into building reliable and consistently performing printed circuit boards.

With offices in the United States, Greater China, Southeast Asia, India, and Europe, it is now a global body responsible for standard-setting, human capital augmentation via training, certification, and networking.

What are the IPC Standards?

IPC Standards is a comprehensive set of benchmarks, rules, and guides that govern the process or output quality of PCB Board design, fabrication, assembly, quality control, testing, and documentation.

While the core document with all the IPC Standards is accessible only to the member organizations, it is worthwhile to follow the trajectory of evolution for the standards. It can give insights into how the standards have changed with the advent of innovative methods in the industry:

1958: IPC publishes 'How to Design and Specify Printed Circuits.

1964: IPC-A-600 published as the standard for Acceptability of Printed Boards.

1994: IPC provides certification for IPC-A-610B 'Acceptability of Electronic Assemblies.'

2002: IPC publishes IPC-A-620 ‘Requirements and Acceptance for Cable and Wire Harness Assemblies.

2008: IPC co-develops IPC-J-STD-075 ‘Classification of Non-IC Electronic Components for Assembly Processes.

2020: IPC publishes ‘H’ Revision for Electronic Assembly Standards IPC-J-STD-001 and IPC-A-610.

You can explore a snapshot of the summarized standards by clicking here (made available under the Creative Commons License)or get in touch with our team of experts to understand how the standards dictate the quality of output by clicking here.

0 notes

Link

IPC 610 Class based on standard of the acceptability of electronic assemblies is divided into three categories classe 1, class 2, class 3.In which Class 2 has more rigorous manufacturing requirements and includes most industrial products and consumer appliances. It is intended for electronic assemblies in which extended reliability is the goal.

0 notes