#jst connector

Explore tagged Tumblr posts

Text

DIY Air Quality Monitors for Home Assistant

#air quality#capacitor#DIY#electronics#ENS160#ESP8266#ESPHome#Home Assistant#humidity#JST connector#make#making#particulate matter#SEN50#Si7120#soldering#temperature#VOC#Wemos D1

0 notes

Text

Type of PCB edge connector, jst connector, harting connectors, PCB edge connector

Z-PACK Series 154 Position 2 mm Pitch Press Fit Through Hole Backpanel Connector

0 notes

Text

https://www.futureelectronics.com/p/interconnect--pin-and-socket-connectors--header-plug-board-mount/bm04b-srss-tbt-d-lf-sn-p-jst-3033965

Socket Crimp Terminal, Receptacle Housings, Crimp Split Pin, ic socket types

BM04B Series 1 mm Pitch 4 Position SMT Single Row Top Entry Shrouded Header

#Pin and Socket Connectors#Headers Connectors#BM04B-SRSS-TB(LF)(SN)#JST#data#Plug Housings#8 pin ic socket#plug header#Pin Contacts#ic socket adapter#usb#header plug#Socket Crimp Terminal#Receptacle#Crimp Split Pin#ic socket types

1 note

·

View note

Text

https://www.futureelectronics.com/p/interconnect--pin-and-socket-connectors--header-plug-board-mount/bm04b-srss-tb-lf-sn-jst-4527065

Angled pin headers, Pin Connector, Board Mount PCB Header, PCB header plug

BM04B Series 1 mm Pitch 4 Position SMT Single Row Top Entry Shrouded Header

#JST#BM04B-SRSS-TB(LF)(SN)#Pin and Socket Connectors#Headers Connectors#PCB header plug#socket header#Board mount connector#Pin Connector#Board Mount PCB Header#Rectangular Connectors#receptacle socket#Header plug#Ribbon cable connector

1 note

·

View note

Text

mini Sparkle Motion prototype - a tiny, fully-featured WLED board ✨🔌📏💡🌈

We're doing a lot of serious testing with our WLED mega-board, code-name Sparkle Motion .

While doing some holiday lighting projects, we also wanted something slim enough to slip into any design. It still uses an ESP32 for the best support, with USB-serial programming, 5A fuse, 5V level shifting + 100 ohm series resistors for pixel drivers, user/reset buttons, a user LED and onboard neopixel, JST SH analog/digital connector, QT I2C connector, 4 GPIO plus power/ground breakouts, and USB type C power/data input.

However, this version is made simpler and less expensive by dropping the DC jack and USB PD support: it's only for 5V strips if you want to power them directly (you could still drive 12V or 24V pixels, but you'll need separate power for them). Instead of a full set of terminal blocks for 3 signals, we only have two outputs, and they have to share the power and ground pins. It could also be used for a single two-pin dotstar LED setup. We kept the built-in I2S mic but dropped the on-board IR sensor - if you want an IR sensor, you'll be able to plug it into the JST SH port with a simple cable or solder it into the breakout pads.

The trade-off is that it's much smaller and slimmer, especially when no terminal blocks are soldered in by default: only 1.2" long x 0.785" wide (~1 sq in) x 0.3" thick vs. the original's 2" x 1.3" (2.6 sq in) x 0.55". To get it that small, we went 4-layer to give us a nice big ground and 5V plane in the middle and double-sided assembly. Coming soon.

#sparklemotion#wled#esp32#neopixel#holidaylighting#ledprojects#makers#electronics#prototyping#hardwaredesign#usbtypec#qtconnector#gpio#micromaker#slimdesign#techinnovation#ledcontroller#openhardware#adafruit#diylighting#iotprojects#esp32projects#compactdesign#ledenthusiast#holidaydecor#iotmaker#makercommunity#hardwarehacks#tinytech#ledlights

30 notes

·

View notes

Note

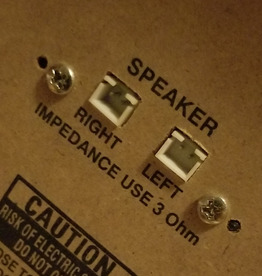

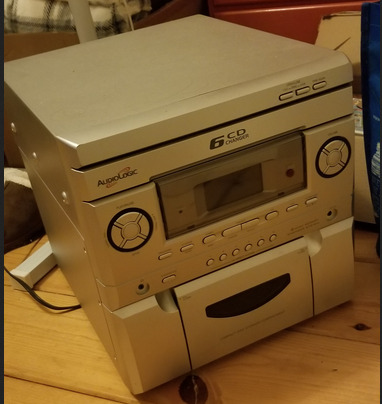

I can't believe I haven't asked this earlier; but have you ever seen a port like this before? A while back I researched everywhere to try and find a replacement for the speakers on this CD player and I'm at a loss when it comes to even finding a name for this type of thing. It's from this brand called AudioLogic which I can find next to nothing about, so I can only assume they're defunct and have been for a long time. One of the speakers is broken, and the other is missing, so unfortunately I can't really demonstrate them actually plugging into this.

I'm not really all that knowledgeable in audio, but those look like JST 2-pin connectors. Given that they say "IMPEDANCE USE 3 OHM", it sounds like they're just being hooked directly up to some speakers. Like, stereo systems like this usually have speaker terminals, but I think they just used JST connectors to make it a little easier to connect.

So you should just be able to get a set of passive speakers, approximately match the impedance, and get some JST connectors to use as speaker wires.

56 notes

·

View notes

Text

Moisture sensor development - 2022/23

Multiple sensors have been running over winter 22 to summer 23 and some problems have arisen:

One temperature sensor stopped functioning but in a way that eluded the error detection. The symptom was that the two sensors showed exactly the same measurement. This turned out to be a configuration issue, where both sensor were mapped to the same temperature.

Battery life was too short on a couple of sensors. This may be because of poor quality batteries, poor connections in the battery holder or due to excess drain somewhere. After experimentation with better quality batteries (Samsung 25R rated at 2500 mAh) it seems the main problem is poor quality batteries.

Moisture sensors losing discrimination. On a new sensor the range from wet to dry is typically 900 but this reduced to 270. I found that cleaning off the old silicon sealant, cleaning the board and resealing brought the readings back to normal.

Moisture sensor connection. The waterproofing with silicon and the JST connector are a poor design. Securing this connector with a zip tie helps to secure this connector.

Rusty main board. One device failed due to rust getting into the pins and socket on the main board connector. This is evidence of moisture in the device container. The sensor cable entrance is sealed with a large amount of silicon sealant which often fails. However when a second device also failed, having drained new , quality batteries very quickly, it seems that the idea of using socket strips on an outdoor device, however well sealed, is a mistake. In any case the board and the chip are really the only significant components so they may as well be soldered together.

One sensor on a public Tiny Forest was stolen. This despite being well - hidden and having a notice inside the box explaining the scientific purpose of the device.

I had considered changing the design of the PCB to avoid the use of a ground plane since I found this made soldering to ground terminals difficult and poor connections created problems. On reflection, my problem is probably insufficient thermal inertia in my small iron and the use of a better, temperature-controlled iron would solve this issue whilst retaining the benefits of a ground plane.

Labels printed on a label printer fade very quickly in sunlight.

An error in the code for the test phase meant that sleep time could be negative with odd results.

It has been suggested that over-the-wire updating of the code should be implemented but I am concerned about the current demand,

Improvements

Have a working set of all three sensors which can be plugged into a device to check the cause of a failed sensor.

Replace the cheap 18650 batteries with Samsung 25R flat top batteries.

Solder the chip directly to the PCB instead of using a socket strip

Develop a better sealing system for the cable entry.

Use a chinagraph pen for labeling

Reconsider strategy for protecting devices in public places

3 notes

·

View notes

Text

Asia Pacific Cable Connector Market Size, Share, Growth Trends,and Forecast (2025-2032

More than 12% of the global cable connector consumption is attributed to Japan. Some of the major cable connector manufacturers in Japan are JST, JAE, Fujitsu, etc. All of these cable connector supplier companies have engineering, manufacturing, and marketing facilities available in the Japanese mainland.

0 notes

Text

The Role of JST Connectors in Modern Electronics and Manufacturing

JST connectors are a vital component in electrical and electronic applications, offering reliable and efficient connections for various industries. Developed by Japan Solderless Terminals (JST), these connectors have become widely used due to their compact design, durability, and versatility. Whether in automotive, industrial, or consumer electronics, JST connectors provide seamless connectivity solutions for diverse applications.Get more news about jst connector production,you can vist our website!

Types of JST Connectors JST connectors come in multiple types, each serving distinct purposes. Some of the most commonly used JST connector types include:

JST PH Series – A compact, low-profile connector suitable for small-scale electronic applications.

JST XH Series – Designed for medium-power applications with robust connectivity features.

JST VH Series – High-current connectors commonly used in industrial machinery and automotive systems.

JST SM Series – Ideal for LED lighting applications and power distribution.

Each series is distinguished by pin configurations, housing materials, and connection mechanisms, ensuring compatibility with different electrical designs.

Applications in Various Industries JST connectors are widely used in multiple sectors, including:

Automotive – JST connectors play a crucial role in vehicle wiring systems, ensuring secure and efficient transmission of electrical signals.

Consumer Electronics – From laptops to gaming consoles, JST connectors provide compact solutions for seamless power and signal connections.

Industrial Machinery – These connectors enable reliable connectivity in manufacturing systems, automation equipment, and control panels.

Renewable Energy – JST connectors are instrumental in solar power systems, ensuring efficient energy transmission and durability.

Their adaptability makes them essential in environments where high performance and reliability are required.

Advantages of JST Connectors JST connectors offer several benefits that make them a preferred choice for engineers and manufacturers:

Compact Design – Their small size allows for efficient space utilization in electronic assemblies.

High Durability – Engineered with quality materials, these connectors withstand mechanical stress and environmental factors.

Easy Installation – Many JST connectors feature plug-and-play functionality, reducing installation time and complexity.

Versatile Applications – Available in various configurations, JST connectors support different voltage and current levels, catering to diverse needs.

Conclusion JST connectors continue to shape the landscape of electronic connectivity, offering reliability, versatility, and efficiency across industries. Whether in high-performance automotive systems or compact consumer electronics, these connectors provide dependable solutions for seamless electrical connections. As technology advances, JST connectors will remain a key component in ensuring connectivity, efficiency, and innovation in modern applications.

0 notes

Text

Design 2 & Extension board design

After ordering and examining my design, I decided to swap around the extension connector and the IMU slot, as it increases the clearance for the battery JST connector.

This design ends up simplifying the traces too, so it's better overall. I also made a simple Extension board, inspired by the official SlimeVR extension board for BNO-Style slimes. It's a very simple design, designed with holes to fit in a case that I'd make if I had the time.

Here is what it looks like along with the schematic. One of the pins connects to nothing to make it compatible with the official SlimeVR extension cables, although cheap ones from aliexpress can also be bought. I made a massive mistake when I first made this PCB though, as I hooked up all of the traces backwards and ordered them like that, so I now have 5 almost-useless PCBs. This design flaw has been rectified but if i want to use those PCBs I will have to custom make some cables that go from connector 1 to 5, and so on.

0 notes

Text

Amphenol LD09S33E4GV00LF D-Sub Connector | Trusted Distributor of Electronics & Quality Connectors Supply

High-Performance Connection Choice: In-Depth Look at Amphenol LD09S33E4GV00LF Connector

In today’s complex and highly integrated systems, reliable and high-quality connectors are critical to overall performance. As a global leader in interconnect solutions, Amphenol delivers outstanding quality through its wide product line. One such product is the LD09S33E4GV00LF, a D-sub connector that stands out for its durability, precision, and broad applicability.

Product Overview

Brand: Amphenol

Model: LD09S33E4GV00LF

Type: 9-pin D-sub female connector

Termination: Through-hole solder

Shell: Metal shell with EMI shielding

Contacts: Gold-plated copper alloy

Environment: RoHS compliant, lead-free

Key Features

Rugged and reliable design, suitable for harsh industrial and outdoor environments

Gold-plated contacts for excellent signal transmission

Strong EMI protection via metal shielding

Easy integration into standard D-sub interfaces

Long life cycle, suitable for high-usage applications

Application Fields

The LD09S33E4GV00LF connector is used across multiple industries due to its stable electrical performance and mechanical strength:

Industrial Automation Deployed in industrial control systems, PLCs, robotics, servo motors, and manufacturing equipment where continuous, reliable signal connections are vital.

Communication and Networking Applied in routers, modems, base stations, and satellite systems for data transfer and signal integrity.

Medical Equipment Integrated into diagnostic instruments, monitoring systems, and imaging machines that require stable and interference-free connections.

Security and Surveillance Used in access control, surveillance cameras, and alarm systems for transmitting video and control signals over long durations.

Aerospace, Defense, and Transportation Suitable for rugged environments in aviation, military-grade electronics, rail communication, and vehicular diagnostics.

Source from a Trusted Partner

If you're looking for a trusted distributor of electronics, Asourcing Electronics Limited is your ideal partner. As a professional quality electronic components and parts distributor, we offer original and factory-sealed stock of the LD09S33E4GV00LF and other Amphenol products.

Asourcing also specializes in Connectors supply, covering leading global brands such as TE Connectivity, Molex, JST, Hirose, Phoenix Contact, and more. Our streamlined logistics and in-house quality inspection process ensure every shipment meets high reliability standards.

For customers seeking an electronic components website that combines technical support with competitive pricing, Asourcing Electronics Limited is the answer. We cater to global procurement needs and help solve urgent shortages for OEMs, EMS providers, and engineers.

Visit our electronic components website today and let us help you source the right parts, faster and more efficiently.

Contact us now! Email: [email protected] Website: https://www.asourcingelectronics.com/

#ElectronicComponents#Amphenol#Connectors#DSubConnectors#IndustrialAutomation#MedicalElectronics#ElectronicsDistributor#ConnectorSupply#QualityComponents#TechSolutions#Engineering#SupplyChain#GlobalSourcing

1 note

·

View note

Text

Automotive Socket Connectors Market set to hit $3.2 billion by 2035

Industry revenue for Automotive Socket Connectors is estimated to rise to $3.2 billion by 2035 from $1.2 billion of 2024. The revenue growth of market players is expected to average at 9.2% annually for the period 2024 to 2035.

Automotive Socket Connectors is critical across several key applications including vehicle lighting, infotainment systems, electric vehicle power systems and engine control modules. The report unwinds growth & revenue expansion opportunities at Automotive Socket Connectors’s Product Type, Application, Connection Type and Material including industry revenue forecast.

Industry Leadership and Competitive Landscape

The Automotive Socket Connectors market is characterized by intense competition, with a number of leading players such as TE Connectivity Ltd, Amphenol Corporation, Molex Incorporated, Delphi Automotive LLP, Yazaki Corporation, Sumitomo Electric Industries Ltd, Japan Aviation Electronics Industry Ltd, Hirose Electric Co. Ltd, JST Mfg. Co. Ltd, Rosenberger Hochfrequenztechnik GmbH & Co, Foxconn Technology Group and AVX Corporation.

The Automotive Socket Connectors market is projected to expand substantially, driven by rise in electric vehicle production and integration of advanced technologies. This growth is expected to be further supported by Industry trends like Implementation of Strict Automobile Standards.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/automotive-socket-connectors-market-research-report

Moreover, the key opportunities, such as electric vehicle integration, enhanced safety features and emerging markets, are anticipated to create revenue pockets in major demand hubs including U.S., Germany, Japan, China and South Korea.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two most active and leading regions in the market. With challenges like technological innovation and adoption challenges and economic factors and market saturation, Automotive Socket Connectors market’s supply chain from raw material procurement / component manufacturing / assembly & testing to end user industry is expected to evolve & expand further; and industry players will make strategic advancement in emerging markets including Vietnam, Turkey and South Africa for revenue diversification and TAM expansion.

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. We offer bespoke market research projects designed to meet the specific strategic objectives of the business. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. DataString Consulting’s data aggregators and Industry experts monitor high growth segments within more than 15 industries on an ongoing basis.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

0 notes

Text

In-Depth Analysis of Toggle Switch Terminal Connection Methods: Technical Selection and Scenario Adaptation for Soldered, Plug-In, and PCB-Mounted Designs

Introduction

In B2B applications such as industrial control, automotive electronics, and medical equipment, the terminal connection method of a toggle switch is a critical factor determining product reliability, installation efficiency, and long-term maintenance costs. Soldered, plug-in, and PCB-mounted designs each have unique advantages and limitations, requiring a comprehensive evaluation of electrical performance, environmental resistance, and production automation. This article analyzes structural design, application scenarios, and compatibility challenges, supported by industry cases (e.g., automotive ECU controls, industrial PLC modules) and emerging trends (e.g., high-density PCB integration), to provide engineers and procurement decision-makers with a systematic selection guide.

1. Soldered Terminal Connections: The "Permanent Bond" for High Reliability

Structure & Process

Physical Connection: Permanently fixes switch terminals to PCBs or wires via soldering (solder or reflow).

Terminal Type: Through-hole pins (0.6–1.2mm diameter), typically made of tin-plated or gold-plated phosphor bronze.

Key Standard: Compliant with IPC-A-610 to avoid cold joints or voids.

Applications & Cases

High-Vibration Environments: Siemens’ train control panels use soldered toggle switches validated for 10-year maintenance-free operation under EN 61373.

High-Current Loads: ABB frequency converters employ soldered emergency stop switches to withstand 50A short-circuit currents.

Pros & Cons

Advantages: Stable contact resistance (<5mΩ), superior vibration resistance (passes MIL-STD-202G), low cost (no connectors required).

Limitations: Difficult repairs (thermal desoldering needed), limited flexibility in automated production.

Innovations

Hybrid solder-crimp terminals (e.g., TE Connectivity’s DUOBILIT) balance reliability and removability.

High-temperature solder (Sn96.5Ag3Cu0.5) extends lifespan in automotive engine compartments.

2. Plug-In Terminals: Modular Flexibility for Easy Maintenance

Structure & Standards

Connection Types: Tab terminals, receptacles, or spring cages with 5–20N insertion force (UL 310).

Common Sizes: 2.8mm (automotive) or 4.8mm (industrial) tab widths.

Applications & Cases

Medical Equipment: GE MRI control switches use gold-plated tabs for <3mΩ contact resistance and 10,000-cycle durability.

Smart Home Gateways: C&K’s T-series plug-in terminals enable cross-device compatibility.

Pros & Cons

Advantages: Tool-free installation, hot-swappable (e.g., data center PDUs), space-efficient (2.54mm pitch).

Limitations: Higher contact resistance (+10–30% vs. soldered), vibration-induced loosening (requires locking mechanisms).

Innovations

Foolproof designs (e.g., AMP’s Mate-N-Lok asymmetric tabs).

Self-cleaning multi-point contacts (e.g., JST PA series).

3. PCB-Mounted Terminals: Miniaturization for High-Density Integration

Structure & Process

Mounting Types: Through-hole (THT) or surface-mount (SMT) with L/J-shaped leads.

Typical Dimensions: THT pins (3–5mm length), SMT packages (60% smaller than THT).

Applications & Cases

Consumer Electronics: ALPS SSSS series SMT toggle switches (2.3mm thickness) in TWS earphone cases.

Robotics: SMT switches integrated with FPGAs on 0.5mm-pitch PCBs.

Pros & Cons

Advantages: Ultra-compact, automated production-friendly (>20,000 CPH), low EMI.

Limitations: Vulnerable to PCB flexing, limited heat dissipation.

Innovations

Hybrid SMT-THT designs (e.g., E-Switch TL series).

Flexible PCB-compatible curved pins (Würth Elektronik WM series).

4. Compatibility Challenges & Solutions

Cross-Platform Adaptation: Phoenix Contact’s COMBICON modular terminals switch between THT and plug-in modes.

Moisture Resistance: 3M Parylene coating + O-rings prevent dendrite growth.

High-Frequency Noise: C&K KSC series with shielded pins and Rogers RO4003 substrates.

5. Industry Trends & Selection Guide

Smart Integration: LEM GoSwitch series with current sensors and I²C interfaces.

Green Manufacturing: DSM EcoPaXX halogen-free materials for RoHS 3.0 compliance.

en.dghongju.com

0 notes

Text

Common JST Connector Types – Matt's Tech Pages

https://www.mattmillman.com/info/crimpconnectors/common-jst-connector-types/#gh

0 notes

Text

QT adapter for Sensirion SEN6x 🔌🌡️

Sensirion just came out with the new SEN6x series of 'everything including the kitchen sink' environmental sensors - and you can pick them up at DigiKey right now

https://www.digikey.com/short/c4tndnd4

We noted that the cable for the 6 series is the same as the SEN5x, BUT power supply requirements differ, so our existing SEN5x adapter won't work

Here's a simple level-shifting breakout that converts to the JST GH cable connector

#sensirion#sen6x#environmentalsensors#qtadapter#electronics#sensorintegration#adafruit#digikey#makers#engineering#iot#smarthome#arduino#raspberrypi#hardware#electronicsprojects#sensortech#embedded#robotics#opensource#innovation#techgadgets#powerconversion#jstgh#programming#linux#python#java#software engineering#coding

9 notes

·

View notes

Text

Solid Backshell Market: Emerging Trends, Competitive Landscape, and Regional Growth Opportunities

The Solid Backshell Market is growing steadily, driven by the increasing demand for durable and high-performance connector protection solutions across industries such as aerospace, defense, automotive, telecommunications, and industrial automation. Backshells are critical components that provide strain relief, electromagnetic interference (EMI) shielding, and environmental protection for cable and connector assemblies, ensuring reliable performance in harsh environments.

The Solid Backshell Market CAGR (growth rate) is expected to be around 4.99% during the forecast period (2025 - 2032).

The shift toward advanced military communication systems, high-speed data transmission, and miniaturized electronics is further boosting demand for ruggedized and EMI-protected backshells. With stringent MIL-SPEC and aerospace industry standards, manufacturers are continuously innovating to develop lightweight, corrosion-resistant, and high-strength solid backshells.

Key Market Trends

Rising Demand in Aerospace & Defense – Military and aviation sectors require high-reliability backshells for secure communication, avionics, and navigation systems.

Growth of Electric Vehicles (EVs) & Automotive Electronics – Increasing use of high-voltage and sensor-based wiring systems is driving backshell adoption in the automotive industry.

Increased Adoption of EMI/RFI Shielding Backshells – With growing data transmission needs, EMI-protected backshells are in high demand for telecommunications and industrial automation applications.

Advancements in Lightweight Materials – Development of aluminum, composite, and stainless steel backshells with superior corrosion resistance and mechanical strength.

For In depth Information Get Free Sample Copy of this Report@

Solid Backshell Market Companies Are:

Platinum Tools, Molex, Radiall, Amphenol, Soldering Technologies, Heller, Samtec, Emerson Electric, TE Connectivity, Bel Fuse, JST, Hirose Electric, Littelfuse, Navigator, Harting Technology

Market Dynamics (DROC)

Drivers

Rising Aerospace & Defense Investments – Increasing military spending and commercial aircraft production are driving demand for high-performance, MIL-SPEC backshells.

Growing Demand for High-speed & Secure Data Transmission – Industries such as 5G, IoT, and industrial automation require backshells for EMI shielding and secure connectivity.

Expansion of Electric & Hybrid Vehicles (EVs/HVs) – The shift toward high-voltage electrical architectures in EVs is boosting backshell adoption in automotive connector assemblies.

Harsh Environment Applications – Backshells are critical in oil & gas, marine, space exploration, and military applications where extreme temperatures, vibration, and moisture resistance are required.

Restraints

High Manufacturing Costs – Advanced materials and compliance with MIL-SPEC and aerospace standards lead to higher production costs, affecting pricing.

Supply Chain Disruptions & Material Shortages – The global semiconductor and raw material supply crisis impacts the availability of metal and composite backshell components.

Complex Installation & Maintenance – Some high-performance backshells require specialized installation procedures, increasing labor costs and complexity.

Opportunities

Development of Smart & Miniaturized Backshells – Innovations in compact, lightweight, and high-density connectors are driving demand for next-gen backshells.

Expansion in Emerging Markets – Growing industrialization in Asia-Pacific, Latin America, and the Middle East is creating new opportunities in telecommunications, automotive, and defense sectors.

Integration of Advanced Coatings & Materials – Adoption of nano-coatings, composite materials, and corrosion-resistant alloys to enhance durability and lifespan.

Rise in Space & Satellite Programs – Increasing investments in satellite communications, space exploration, and commercial spacecraft are boosting demand for high-reliability backshells.

Challenges

Intense Competition & Pricing Pressure – The presence of multiple manufacturers and OEM suppliers creates pricing challenges, especially for customized and high-performance backshells.

Stringent Compliance & Certification Requirements – Industries such as military, aerospace, and medical electronics have rigorous testing and certification protocols, extending product development timelines.

Shifting Toward Wireless Technologies – Growth in wireless communication solutions could reduce demand for certain wired connector applications, impacting market growth in specific sectors.

0 notes