#lab automation solutions

Explore tagged Tumblr posts

Text

Revolutionise Your Lab Workflow with Advanced Lab Automation | Tekmatic

Explore the future of laboratory operations with Tekmatic's cutting-edge lab automation solutions. Streamline your research processes, enhance accuracy, and boost productivity using state-of-the-art technologies offered by Tekmatic. Visit our website to discover how our innovative solutions can transform your lab into a hub of efficiency and precision.

0 notes

Text

The Elec Lab Step Down Transformer 3.5KVA 230Vac to 115Vac from Auto2mation is a reliable power solution for industrial and laboratory use. It efficiently converts 230V input to 115V output, ensuring safe and stable voltage for sensitive equipment. With a capacity of 3.5KVA, it supports various high-performance devices, enhancing operational efficiency. Designed for durability and consistent performance, this transformer is ideal for voltage regulation in automation systems. Its compact and robust build ensures easy installation and long-term reliability. Choose Auto2mation for quality-tested transformers that deliver dependable performance.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Elec Lab#Step Down Transformer#Transformer

0 notes

Text

Transform Subscription Models with SAP Subscription Billing by Acuiti Labs

Acuiti Labs helps businesses unlock growth with SAP Subscription Billing—designed for modern subscription management. From flexible pricing to full lifecycle automation, we offer tailored SAP billing solutions and a risk-free POC to accelerate your subscription transformation.

#SAP Subscription Billing#SAP Subscription Management#SAP Billing Solution#Acuiti Labs#Subscription Lifecycle#Recurring Billing#Cloud Billing#Quote-to-Cash#Subscription Automation

0 notes

Text

https://www.acuitilabs.com/q2c-customerportal/

#Q2C Customer Portal#Subscription Management Software#SAP BRIM Integration#S4HANA Cloud Billing#Self-Service Subscription Platform#Acuiti Labs Billing Solutions#Subscription Billing Automation#Customer Self-Management Tools#B2B Subscription Management#Mobile Subscription Management App#Scalable Subscription Software#Subscription Lifecycle Management#Invoicing and Payment Automation

1 note

·

View note

Text

"Canadian scientists have developed a blood test and portable device that can determine the onset of sepsis faster and more accurately than existing methods.

Published today [May 27, 2025] in Nature Communications, the test is more than 90 per cent accurate at identifying those at high risk of developing sepsis and represents a major milestone in the way doctors will evaluate and treat sepsis.

“Sepsis accounts for roughly 20 per cent of all global deaths,” said lead author Dr. Claudia dos Santos, a critical care physician and scientist at St. Michael’s Hospital. “Our test could be a powerful game changer, allowing physicians to quickly identify and treat patients before they begin to rapidly deteriorate.”

Sepsis is the body’s extreme reaction to an infection, causing the immune system to start attacking one’s own organs and tissues. It can lead to organ failure and death if not treated quickly. Predicting sepsis is difficult: early symptoms are non-specific, and current tests can take up to 18 hours and require specialized labs. This delay before treatment increases the chance of death by nearly eight per cent per hour.

[Note: The up to 18 hour testing window for sepsis is a huge cause of sepsis-related mortality, because septic shock can kill in as little as 12 hours, long before the tests are even done.]

[Analytical] AI helps predict sepsis

Examining blood samples from more than 3,000 hospital patients with suspected sepsis, researchers from UBC and Sepset, a UBC spin-off biotechnology company, used machine learning to identify a six-gene expression signature “Sepset” that predicted sepsis nine times out of 10, and well before a formal diagnosis. With 248 additional blood samples using RT-PCR, (Reverse Transcription Polymerase Chain Reaction), a common hospital laboratory technique, the test was 94 per cent accurate in detecting early-stage sepsis in patients whose condition was about to worsen.

“This demonstrates the immense value of AI in analyzing extremely complex data to identify the important genes for predicting sepsis and writing an algorithm that predicts sepsis risk with high accuracy,” said co-author Dr. Bob Hancock, UBC professor of microbiology and immunology and CEO of Sepset.

Bringing the test to point of care

To bring the test closer to the bedside, the National Research Council of Canada (NRC) developed a portable device they called PowerBlade that uses a drop of blood and an automated sequence of steps to efficiently detect sepsis. Tested with 30 patients, the device was 92 per cent accurate in identifying patients at high risk of sepsis and 89 per cent accurate in ruling out those not at risk.

“PowerBlade delivered results in under three hours. Such a device can make treatment possible wherever a patient may be, including in the emergency room or remote health care units,” said Dr. Hancock.

“By combining cutting-edge microfluidic research with interdisciplinary collaboration across engineering, biology, and medicine, the Centre for Research and Applications in Fluidic Technologies (CRAFT) enables rapid, portable, and accessible testing solutions,” said co-author Dr. Teodor Veres, of the NRC’s Medical Devices Research Centre and CRAFT co-director. CRAFT, a joint venture between the University of Toronto, Unity Health Toronto and the NRC, accelerates the development of innovative devices that can bring high-quality diagnostics to the point of care.

Dr. Hancock’s team, including UBC research associate and co-author Dr. Evan Haney, has also started commercial development of the Sepset signature. “These tests detect the early warnings of sepsis, allowing physicians to act quickly to treat the patient, rather than waiting until the damage is done,” said Dr. Haney."

-via University of British Columbia, May 27, 2025

#public health#medical news#sepsis#cw death#healthcare#medicine#medical care#ai#canada#north america#artificial intelligence#genetics#good news#hope

953 notes

·

View notes

Note

Hey my dear mutual! Another super stupid and weird request coming, so, please, feel totally free to ignore completely if you want, really. So, let's say instead of a criminal organization, the Akatsuki are actually a lab team. Which would be their roles, their work focus or their research topics? How would they behave at work with each other or, I don't know, whatever you can think of. Inspired by your agar plates post, by the way, hahahaha

Hello Sasuke, my dear. Don't call your asks weird, I love how creative they are! If anyone wants to write a fic about this please TAG me!

Big thanks to @the-real-sasuke-uchiha for requesting!

The Akatsuki in a modern research lab AU

Akatsuki Labs, Inc. No one knows what they're actually researching, and how they get their funding, however everyone hires them, they're incredibly popular with institutions and businesses alike...

Deidara is a lab rookie who is still at the beginning of his study. He went to a scientific high school and an absolute ace at chemistry. Besides studying chemistry, his other major is pyrotechnical engineering. He blows shit up on the regular and even adds copper sulphate to fires when he is the one supposed to put them out. He frequently steals minerals from the lab to use them for his pottery projects. And yes, he knows how to make meth.

Hidan is on his way to become a neurologist. He is fascinated by the way the nervous system works (especially while processing pain) and has the ego of a neurosurgeon twice his age. However he is regularly asked for a second opinion because he knows his shit. He's pretty popular with the ladies due to his confidence, however many of them are freaked out when they find out what a huge masochist he is.

I've never seen Itachi as a huge stem guy, but I've actually had a discussion about this with my dear moots @pet-plasma-bubble and @suki91 and came to the conclusion that he's either a plant biologist or studies medicine because he's one of these kids with a chronic and/or underdiagnosed illness going into medicine to make a change. Plant biologist!Itachi regularly talks to his plants when no one is looking and he gives them names as well. He doesn't really care much for the actual lab work and prefers to take care of the plants in the different lab greenhouses. Med student!Itachi is one of these anatomy girlies who draw their stuff in fancy colors and actually enjoy studying human anatomy.

Kakuzu is a senior scientist/professor who initially studied pharmacology/pharmacy to save many lives and prolong the lives of millions, but eventually got disillusioned and sold his soul to the pharma industry. He should technically be retired now, but he joined the Akatsuki labs inc to make some money on the side.

Kisame started out as a marine biologist specializing in shark research, however, seeing these beautiful, innocent creatures get bastardized by Hollywood and pollution made him apply to Akatsuki labs inc to help find solutions to the current crises caused by humanity. During his free time, he volunteers in a dolphin rehabilitation center.

Konan is the cofounder of Akatsuki labs inc, everyone respects her and even looks up to her. Once a brilliant scientist in the field of engineering, she got tired of how male dominated it was and how her male colleagues kept getting the credit for her ideas. She frequently holds lab courses for young girls interested going into the scientific field.

Nagato is the Akatsuki labs founder, and rarely seen in the lab. He has made himself a name in the field of robotics by inventing the Shurado robotics system which helps millions of automated machines run to this day. Rarely seen in the lab, he communicated with his employees via his Pain Alias Email. though to be fair, Konan writes most of these emails for him; she's the only one regularly talking to him face-to-face.

Orochimaru is a geneticist and biochemist, his focus being finding ways to avoid cellular decay, as well as the human genome and anti aging research. His parents are academics as well and he lived up to their expectations to the fullest. He has his own skincare formula which keeps him looking snatched at all times. Given the rumors about several scientific ethical code violations, everyone is kinda scared of him except for his personal lab tech, Kabuto.

Sasori is a renowed mortician who's also very interested in histology. His preparation techniques are unmatched and he even invented new preparation- and histological staining methods, which are called "Red Sand" and "Red Technique", respectively. He often gets into fights with Kakuzu about his microtome collection being unnecessarily expensive.

Tobi is the Akatsuki labs CEO cosplaying as a clueless intern that always steals from the candy bowl in the waiting room. In reality, he has a PHD in physics, his thesis being about rifts in space time and interdimensional interactions, however all of his papers are published under an alias. He has a soft spot for Deidara and refuses to fire him despite the latter's frequent "accidents".

Zetsu is a biological anthropologist fascinated by human evolution and human behavior. Some think even his colleagues are subjects of his studies. Some people say he's two-faced, but he is very chatty and inquisitive most of the time. He volunteered to have Itachi's venus fly traps in his office and can sometimes be seen feeding them dead flies or mosquitoes.

#naruto#naruto shippuden#naruto headcanons#naruto scenarios#naruto au#akatsuki#akatsuki headcanons#naruto modern au#deidara headcanons#hidan headcanons#itachi headcanons#kakuzu headcanons#kisame headcanons#konan headcanons#nagato headcanons#orochimaru headcanons#sasori headcanons#obito headcanons#tobi headcanons#zetsu headcanons#naruto fanfiction#naruto imagines

95 notes

·

View notes

Text

Meet the Townies: ᴇᴛʜᴀɴ ᴀɴᴅ ɪꜱᴀᴀᴄ

Ethan Harper grew up an only child and spent his formative years immersed in the world of engineering. His fascination with machines and technology was inspired by his father who was a skilled mechanic. While attending high school, Ethan secretly began working on a personal project where he attempted to design and build a robot. He poured countless hours into this endeavor, often sacrificing teenage milestones to tend to this robot he later named ISAAC (Intelligent System and Advanced Assistant Companion). Upon graduating High School, Ethan enrolled at Foxbury Institute where he pursued a degree in Mechanical Engineering. During his time there, Ethan excelled in his studies, consistently earning top marks and impressing his professors with his innovative ideas and dedication to the craft. In his free time, he continued to work on ISAAC since the university's state-of-the-art facilities and access to cutting-edge resourced allowed him to make significant improvements. He refined ISAAC's design, enhanced its capabilities and incorporated the latest advancements in artificial intelligence and robotics. After graduating with honors from Foxbury, Ethan quickly began carving out a professional life for himself. His reputation as a brilliant young engineer opened many doors and he received numerous job offers from leading tech companies. Ethan's expertise eventually caught the attention of the military who offered him a position to develop a project for them. Though he initially hesitated, the opportunity was too enticing to pass up. Despite his professional success and the accolades he received for his work, Ethan felt an intense void in his life that he couldn't seem to fill. His relentless pursuit of perfection in his projects, particularly with ISAAC, often left him feeling isolated. The extensive time he spent in the lab, both during his time at Foxbury and throughout his career, meant that his personal life took a backseat. Ethan's social interactions were limited and he found it difficult to connect with others on a deeper level. His closest colleagues, at one point, noticed and gently encouraged him to step out of his comfort zone and try dating. Ethan reluctantly agreed and while the dates he went on did not lead to a lasting relationship, it helped Ethan open up and see the value in balancing his personal and professional life. As he continued to make strides in his professional career, Ethan was approached by his alma mater, Foxbury institute, with an invitation to teach part-time. The university recognized his achievements and believed that his expertise could inspire and educate the next generation of engineers. Teaching at Foxbury became a profoundly rewarding experience for him. Standing before eager students, he shared his knowledge and passion. He found joy in helping them navigate their own paths and would often encourage them to think creatively and push the boundaries of what was possible. Meanwhile, ISAAC continued to improve every day, becoming an indispensable part of Ethan's life. By this point, ISAAC's capabilities extended far beyond what Ethan originally intended. ISAAC excelled in research assistance, laboratory management, and technical maintenance. The robot could analyze complex data, run simulations and suggest innovative solutions to engineering problems which significantly sped up Ethan's workflow. ISAAC also managed clerical tasks such as organizing files, scheduling meetings, and maintaining equipment, allowing Ethan to focus on more critical aspects of his projects. ISAAC'S home automation features made Ethan's personal life a breeze, as well. The robot could control various smart devices, perform household chores, such as cleaning and grocery shopping, and even cook meals based on Ethan's dietary preferences. Recently, Ethan and ISAAC relocated to the town of Oasis Springs due to a job offer at a cutting-edge research lab.

62 notes

·

View notes

Text

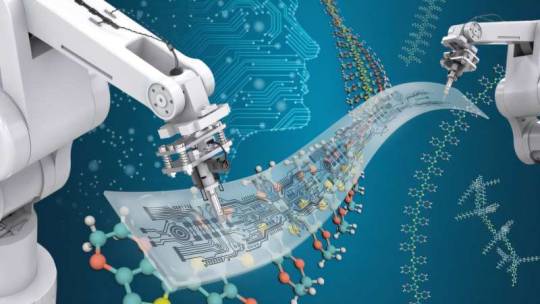

Self-driving lab transforms electronic polymers discovery

Plastic that conducts electricity might sound impossible. But there is a special class of materials known as "electronic polymers" that combines the flexibility of plastic with the functionality of metal. This type of material opens the door for breakthroughs in wearable devices, printable electronics and advanced energy storage systems. Yet, making thin films from electronic polymers has always been a difficult task. It takes a lot of fine-tuning to achieve the right balance of physical and electronic properties. Researchers at the U.S. Department of Energy's (DOE) Argonne National Laboratory have created an innovative solution to this challenge with artificial intelligence (AI). They used an AI-driven, automated materials laboratory, a tool called Polybot, to explore processing methods and produce high-quality films. Polybot is located at the Center for Nanoscale Materials, a DOE Office of Science user facility at Argonne.

Read more.

#Materials Science#Science#Electronics#Polymers#Plastics#Electrical conductivity#Thin films#Materials processing#Artificial intelligence#Computational materials science

15 notes

·

View notes

Text

Streamline Your Lab Operations with Tekmatic Cutting-Edge Lab Automation Solutions

Explore Tekmatic comprehensive range oflab automation solutionsdesigned to revolutionise your laboratory workflows. From automated sample handling to data analysis, our state-of-the-art technologies enhance efficiency, accuracy, and productivity. Visit our website to discover how Tekmatic is shaping the future of laboratory automation.

0 notes

Text

OMRON opens new Automation Centre in Stuttgart to drive innovation and customer collaboration

Stuttgart, Germany – OMRON has celebrated the grand opening of a new Automation Cent in Stuttgart, reaffirming its commitment to innovation, excellence, and customer-centric solutions in industrial automation. Strategically located near key customers and partners, the new facility serves as a hub for expertise in advanced automation solutions. It enables true co-creation, proof-of-concept development, and hands-on collaboration.

The OMRON Automation Center Stuttgart joins a global network of 48 Automation Centers and Proof-of-Concept labs to support customers and partners across Germany and Europe. Spanning 2,372 m², and located just minutes from the Stuttgart international airport, the facility is home to a team of experts in industry-specific solutions, including sensing, control, vision, safety, robotics, and AI-driven technologies. By actively co-developing solutions with customers, OMRON helps manufacturers, machine builders, and system integrators tackle key societal challenges, such as labor shortages.

Fernando Colás, CEO at OMRON Industrial Automation Europe comments: “This new Automation Center in Stuttgart represents our significant investment in Germany and in the EMEA region. I am incredibly proud of the dedication and teamwork that made this vision a reality. Seeing this project come to life and now standing in a space where we can innovate together with our customers is an inspiring moment. We are excited to shape the future of manufacturing together with our customers and partners.”

Peter Ehl, General Manager at Automation Center Stuttgart concludes: “At OMRON, we believe that the best innovations emerge through collaboration. What makes this Automation Center so special is that it was purpose-built from the ground up specifically for OMRON. Every part of this facility has been designed with our customers in mind—to provide an environment where we can collaborate, test, and refine real-world automation solutions.”

The new facility aligns with OMRON’s long-term vision to drive innovation and continue to contribute to the development of society. OMRON is dedicated to supporting its customers with innovative, scalable, and flexible solutions that drive operational excellence in manufacturing.

For more information about OMRON and the new Automation Centre Stuttgart, please visit https://industrial.omron.eu/en/our-value/automation-center. For scheduling a visit, please contact your local OMRON office.

#automation centre#industrial automation#pharma packaging news#packaging b2b#cosmetic packaging news#customer collaboration

3 notes

·

View notes

Text

• What are the core modules of a School ERP ?

Answer : The core modules of a School ERP (Enterprise Resource Planning) system are designed to streamline and automate various administrative and academic tasks in schools. Here’s a simplified list of the main modules from PRAYAGEDU :

1. Student Information System 📌 PrayagEdu centralizes all student records—admission, academics, attendance—making it easy for staff to access and manage data in one place.

2. Academic Management 📌 With PrayagEdu, teachers can create timetables, assign subjects, and plan lessons efficiently. This reduces manual errors and saves time.

3. Attendance Management 📌 PrayagEdu automates daily attendance tracking and generates reports, helping schools monitor student and staff presence accurately.

4. Examination & Report Card 📌 Conduct exams, record marks, and auto-generate report cards with PrayagEdu, making academic evaluation faster and error-free.

5. Fee Management 📌 Schools can collect fees online, issue receipts, and track dues using PrayagEdu. This avoids long queues and manual record-keeping.

6. Admission Management 📌 PrayagEdu simplifies student admissions with online forms and automated workflows—reducing paperwork and delays.

7. Parent Portal 📌 PrayagEdu keeps parents in the loop with updates on their child’s attendance, marks, homework, and school announcements.

8. Staff Management 📌 Manage teacher details, leaves, payroll, and roles in one dashboard with PrayagEdu, improving HR efficiency.

9. Communication Tools 📌 PrayagEdu sends instant alerts via SMS or email for announcements, emergencies, and homework—keeping everyone informed.

10. Library & Inventory 📌 PrayagEdu manages books, uniforms, lab equipment, and other resources to prevent loss and ensure availability.

🎯 Result:

With all core modules working together, PrayagEdu offers a complete digital solution for schools—saving time, reducing errors, improving communication, and enhancing the learning experience for students, parents, and staff.

For free demo contact us : 9863377711

Email - [email protected]

2 notes

·

View notes

Text

https://www.acuitilabs.com/port/

#AcuitiPort#Port Billing Solution#BRIM Accelerator for Seaports#Maritime Sector Technology#Acuiti Labs#Invoicing Solution for Ports#Revenue Management at Ports#ERP Integration for Ports#Digital Transformation for Seaports#Automate Port Billing#Terminal Operating System Integration

0 notes

Text

eLABSS Laboratory Stock Management Software: Real-Time Inventory Control

eLABSS Laboratory Stock Management Software helps labs monitor and manage inventory in real time. Track usage, set reorder points, receive low-stock alerts, and prevent wastage with a centralized, automated system. Our software improves stock accuracy, reduces costs, and ensures critical materials are always available when needed. Ideal for pharma, research, and diagnostic labs, eLABSS also supports barcode scanning, expiry tracking, and vendor integration. Maintain full inventory control, ensure compliance, and eliminate the inefficiencies of manual tracking. Keep your lab stocked and ready with eLABSS’s smart inventory management solution.

2 notes

·

View notes

Text

Why Sabaragamuwa University is a Great Choice.

Sabaragamuwa University of Sri Lanka (SUSL) is increasingly recognized for its technological advancement and innovation-driven environment, making it one of the leading universities in Sri Lanka in terms of technology. Here are the key reasons why SUSL stands out technologically.

Here’s why SUSL stands out as a technological powerhouse among Sri Lankan universities:

🔧1. Faculty of Technology

SUSL established a dedicated Faculty of Technology to meet the demand for tech-skilled graduates. It offers degree programs such as:

BTech in Information and Communication Technology

BTech in Engineering Technology

These programs combine practical experience in labs, workshops and real-world projects with a strong theoretical foundation.

🖥️2. Advanced IT Infrastructure

SUSL has modern computer labs, smart classrooms, and high-speed internet access across campus.

A robust Learning Management System (LMS) supports online learning and hybrid education models.

Students and lecturers use tools like Moodle, Zoom, and Google Classroom effectively.

🤖 3. Innovation & AI Research Support

SUSL promotes AI, Machine Learning, IoT, and Data Science in student research and final-year projects.

Competitions like Hackathons and Innovative Research Symposia encourage tech-driven solutions.

Students develop apps, smart systems, and automation tools (e.g., Ceylon Power Tracker project).

🌐 4. Industry Collaboration and Internships

SUSL connects students with the tech industry through:

Internships at leading tech firms

Workshops led by industry experts

Collaborative R&D projects with government and private sector entities

These connections help students gain hands-on experience in areas such as software engineering, networking, and data analytics that make them highly employable after graduation.

💡 5. Smart Campus Initiatives

SUSL is evolving into a Smart University, introducing systems that streamline academic life:

Digital student portals

Online registration and results systems

E-library and remote resource access

Campus Wi-Fi for academic use

These initiatives improve the student experience and create an efficient, technology-enabled environment.

🎓 6. Research in Emerging Technologies

The university is involved in pioneering research across emerging technological fields, including:

Agricultural tech (AgriTech)

Environmental monitoring using sensors

Renewable energy systems

Students and faculty publish research in international journals and participate in global tech events.

🏆 7. Recognition in National Competitions

SUSL students often reach fina rounds or win national competitions in coding, robotics, AI, and IoT innovation.

Faculty members are invited as tech advisors and conference speakers, reinforcing the university's expertise.

Sabaragamuwa University is actively shaping the future not only with technology, but by integrating technology into education, research and operations. This makes it a technological leader among Sri Lankan Universities. Visit the official university site here: Home | SUSL

2 notes

·

View notes

Text

Innovative low tension insulators for modern rail and transit infrastructure

As global urbanization accelerates, the demand for efficient and safe rail and transit systems is at an all-time high. One of the critical yet often overlooked components that contribute to the stability and reliability of electric rail systems is the low tension insulator. These insulators are especially crucial in systems like trolley buses and small conductor rails, where compact, high-performance solutions are a necessity.

Radiant Enterprises, a trusted name in electrical insulation technology, is leading the charge in developing innovative low tension insulators for trolley buses and small conductor rails. As an experienced epoxy insulator manufacturer and a globally recognized low tension insulators exporter and supplier in USA, Russia and beyond, Radiant is redefining standards for modern transit infrastructure.

youtube

The Critical Role of Low Tension Insulators in Rail Systems

Low tension insulators serve a fundamental purpose: they electrically isolate conductive components while bearing mechanical loads and withstanding environmental challenges. In modern rail systems—particularly those with trolley buses and compact conductor rail networks—these insulators must offer high dielectric strength, dimensional stability, and resistance to heat, moisture, and pollution.

The growing trend toward electrified public transportation requires components that can perform flawlessly under continuous load, vibration, and varied weather conditions. This is where advanced low tension insulator solutions make all the difference.

Applications: Trolley Buses and Small Conductor Rails

Trolley buses and light rail systems are experiencing a renaissance in many cities due to their energy efficiency and lower emissions. These systems rely on overhead wires or compact conductor rails to supply electrical energy. Low tension insulators for trolley buses and small conductor rails ensure that power is transmitted safely and efficiently while preventing current leakage and minimizing the risk of electrical faults.

Radiant Enterprises specializes in tailor-made insulator designs that meet the unique constraints of these applications. Their insulators are compact yet robust, offering high mechanical strength and excellent electrical performance.

youtube

Why Epoxy Insulators Are the Future

Traditionally, materials like porcelain and glass have been used for insulation, but they are heavy and prone to breakage. Epoxy resin insulators are fast replacing these older materials, thanks to their superior mechanical, thermal, and electrical properties.

As a dedicated epoxy insulator manufacturer, Radiant Enterprises has perfected the use of cast resin technology to produce insulators with excellent tracking resistance, UV stability, and moisture repellence. Epoxy insulators are also significantly lighter, reducing the overall weight of support structures and improving energy efficiency in mobile applications such as trolley buses.

youtube

Key advantages of epoxy insulators include:

Excellent resistance to thermal and mechanical stress

Enhanced dimensional accuracy and consistency

High dielectric strength and arc resistance

Reduced maintenance costs due to better longevity

Radiant Enterprises: Manufacturers for Low Tension Insulators

With decades of expertise, Radiant Enterprises stands out among manufacturers for low tension insulators. The company offers end-to-end solutions—from custom product design and prototyping to mass production and international shipping.

Radiant’s in-house R&D and quality control labs ensure each insulator meets the highest standards for reliability and safety. Their manufacturing processes adhere to global standards like IEC, ANSI, and ASTM, ensuring suitability for both domestic and international markets.

Moreover, Radiant Enterprises is constantly innovating by integrating automation and smart monitoring capabilities into their insulator systems—a step that aligns with the future of smart rail infrastructure.

youtube

Global Reach: Low Tension Insulators Exporter and Supplier in USA and Russia and Globally

Radiant Enterprises has successfully expanded its footprint beyond India and is now a well-regarded low tension insulators exporter and supplier in USA, Russia and several other countries across Europe, Asia, and the Middle East. Their deep understanding of international compliance standards and logistics ensures seamless delivery and reliable service across borders.

Their epoxy-based low tension insulators are currently used in:

Metro rail systems in Russia and USA

Trolley bus networks across Central Asia

Electrified light rail transit (LRT) systems in Eastern Europe

This global reach is a testament to Radiant’s commitment to quality, performance, and customer satisfaction.

Tailored Low Tension Insulator Solutions

Modern infrastructure demands customization, not one-size-fits-all solutions. Radiant Enterprises offers bespoke low tension insulator solutions tailored to the specific technical and environmental requirements of each client.

Whether it is modifying the insulator shape to fit tight spaces in a conductor rail or optimizing the resin formulation to withstand coastal humidity, Radiant’s engineering team works closely with clients to deliver optimal results.

youtube

Custom solutions include:

Compact epoxy insulators for space-constrained installations

UV-resistant insulators for outdoor overhead systems

High-strength mounts for mechanical stability under dynamic loads

Fire-retardant coatings for safety compliance

Quality Assurance and Testing

Every low tension insulator produced at Radiant Enterprises undergoes rigorous quality testing, including:

Dielectric withstand testing

Tensile and compressive strength testing

Thermal aging analysis

Salt spray and pollution performance evaluations

By combining these tests with continuous in-process inspections, Radiant guarantees that every product shipped meets or exceeds customer expectations.

Supporting the Evolution of Electrified Transit

Electrified public transport systems like trams, metros, and trolley buses are expanding rapidly in urban centers globally. Low tension insulators play a foundational role in these systems, enabling safer, more efficient electricity transmission.

Radiant Enterprises is proud to support this evolution by delivering next-gen epoxy insulators that blend durability, performance, and innovation. From being a reliable epoxy insulator manufacturer to an agile low tension insulators exporter and supplier in USA, Russia, and globally, Radiant ensures that its clients are equipped with the best solutions for their transit needs.

Conclusion: Shaping the Future of Transit Infrastructure

Modern rail and transit systems demand high-performance, reliable, and efficient components—and low tension insulators are no exception. With increasing adoption of electrified transport across urban landscapes, the need for advanced insulation technology is more critical than ever.

Radiant Enterprises leads the way with its state-of-the-art epoxy-based low tension insulators for trolley buses and small conductor rails. As trusted manufacturers for low tension insulators, they offer a full suite of products and services designed to meet the demands of 21st-century transportation.

Whether you are a transit authority upgrading your infrastructure, an OEM seeking reliable insulation components, or a project developer exploring low tension insulator solutions for your next big rail project, Radiant Enterprises is your trusted partner on the journey toward smarter, safer, and more sustainable mobility.

Contact Radiant Enterprises today to learn more about our epoxy insulators and innovative low tension insulator solutions tailored for your application.

#Low tension insulators for trolley busses and small conductor rails#Manufacturers for low tension insulator#Low tension insulators exporter and supplier in the USA#united arab emirates#Epoxy insulators#Low tension insulator solution#Epoxy insulators manufacturer#India#Youtube

6 notes

·

View notes

Text

Self Hosting

I haven't posted here in quite a while, but the last year+ for me has been a journey of learning a lot of new things. This is a kind of 'state-of-things' post about what I've been up to for the last year.

I put together a small home lab with 3 HP EliteDesk SFF PCs, an old gaming desktop running an i7-6700k, and my new gaming desktop running an i7-11700k and an RTX-3080 Ti.

"Using your gaming desktop as a server?" Yep, sure am! It's running Unraid with ~7TB of storage, and I'm passing the GPU through to a Windows VM for gaming. I use Sunshine/Moonlight to stream from the VM to my laptop in order to play games, though I've definitely been playing games a lot less...

On to the good stuff: I have 3 Proxmox nodes in a cluster, running the majority of my services. Jellyfin, Audiobookshelf, Calibre Web Automated, etc. are all running on Unraid to have direct access to the media library on the array. All told there's 23 docker containers running on Unraid, most of which are media management and streaming services. Across my lab, I have a whopping 57 containers running. Some of them are for things like monitoring which I wouldn't really count, but hey I'm not going to bother taking an effort to count properly.

The Proxmox nodes each have a VM for docker which I'm managing with Portainer, though that may change at some point as Komodo has caught my eye as a potential replacement.

All the VMs and LXC containers on Proxmox get backed up daily and stored on the array, and physical hosts are backed up with Kopia and also stored on the array. I haven't quite figured out backups for the main storage array yet (redundancy != backups), because cloud solutions are kind of expensive.

You might be wondering what I'm doing with all this, and the answer is not a whole lot. I make some things available for my private discord server to take advantage of, the main thing being game servers for Minecraft, Valheim, and a few others. For all that stuff I have to try and do things mostly the right way, so I have users managed in Authentik and all my other stuff connects to that. I've also written some small things here and there to automate tasks around the lab, like SSL certs which I might make a separate post on, and custom dashboard to view and start the various game servers I host. Otherwise it's really just a few things here and there to make my life a bit nicer, like RSSHub to collect all my favorite art accounts in one place (fuck you Instagram, piece of shit).

It's hard to go into detail on a whim like this so I may break it down better in the future, but assuming I keep posting here everything will probably be related to my lab. As it's grown it's definitely forced me to be more organized, and I promise I'm thinking about considering maybe working on documentation for everything. Bookstack is nice for that, I'm just lazy. One day I might even make a network map...

6 notes

·

View notes