#automation centre

Explore tagged Tumblr posts

Text

OMRON opens new Automation Centre in Stuttgart to drive innovation and customer collaboration

Stuttgart, Germany – OMRON has celebrated the grand opening of a new Automation Cent in Stuttgart, reaffirming its commitment to innovation, excellence, and customer-centric solutions in industrial automation. Strategically located near key customers and partners, the new facility serves as a hub for expertise in advanced automation solutions. It enables true co-creation, proof-of-concept development, and hands-on collaboration.

The OMRON Automation Center Stuttgart joins a global network of 48 Automation Centers and Proof-of-Concept labs to support customers and partners across Germany and Europe. Spanning 2,372 m², and located just minutes from the Stuttgart international airport, the facility is home to a team of experts in industry-specific solutions, including sensing, control, vision, safety, robotics, and AI-driven technologies. By actively co-developing solutions with customers, OMRON helps manufacturers, machine builders, and system integrators tackle key societal challenges, such as labor shortages.

Fernando Colás, CEO at OMRON Industrial Automation Europe comments: “This new Automation Center in Stuttgart represents our significant investment in Germany and in the EMEA region. I am incredibly proud of the dedication and teamwork that made this vision a reality. Seeing this project come to life and now standing in a space where we can innovate together with our customers is an inspiring moment. We are excited to shape the future of manufacturing together with our customers and partners.”

Peter Ehl, General Manager at Automation Center Stuttgart concludes: “At OMRON, we believe that the best innovations emerge through collaboration. What makes this Automation Center so special is that it was purpose-built from the ground up specifically for OMRON. Every part of this facility has been designed with our customers in mind—to provide an environment where we can collaborate, test, and refine real-world automation solutions.”

The new facility aligns with OMRON’s long-term vision to drive innovation and continue to contribute to the development of society. OMRON is dedicated to supporting its customers with innovative, scalable, and flexible solutions that drive operational excellence in manufacturing.

For more information about OMRON and the new Automation Centre Stuttgart, please visit https://industrial.omron.eu/en/our-value/automation-center. For scheduling a visit, please contact your local OMRON office.

#automation centre#industrial automation#pharma packaging news#packaging b2b#cosmetic packaging news#customer collaboration

3 notes

·

View notes

Text

damn i cant believe i saw one single image of theatre production and went "oh they didnt label the production.... but that looks like somethin Hale Centre Theatre would do" AND I WAS RIGHT. i love being a nerd about theater lmao

#it was hale centre theatre 2023 newsies btw#they brought their bowery beauties in from the ceiling btw#it looked gorgeous#“the most rich thats rich thats ever riched” yea fr#ily most technically advanced automation system in an american regional theater#newsies#hale centre theatre

3 notes

·

View notes

Text

Place Igor Stravinsky

#europe#france#paris#place igor stravinsky#saint-merri#art urbain#jef aerosol#europa#centre pompidou#fontaine stravinsky#fontaine des automates#chuuutt!!!#shepard fairey#knowledge + action

5 notes

·

View notes

Text

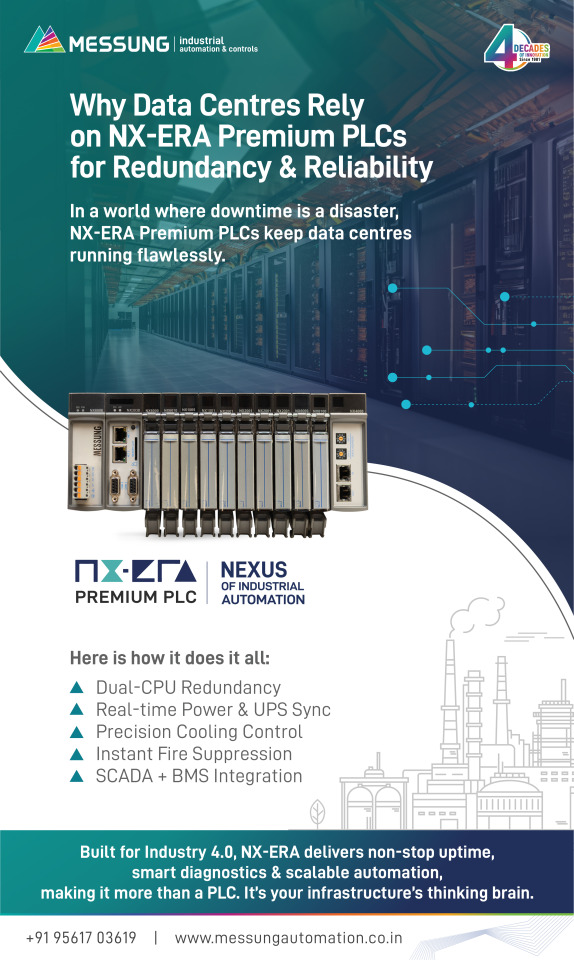

Why Data Centres Rely On NX-ERA Premium PLCs For Redundancy & Reliability

Data centres are the online headquarters of businesses today. Every click, transaction, login, or query is responded to via a data centre. In this hyper-connected world, downtime is more than a slowdown; it's a disaster.

Whether it is hosting cloud applications, running finance systems, or managing mission-critical enterprise data, data centres simply can't afford failure of control. That's why businesses often spend money on layers of redundancy, not merely power or cooling, but even on the thinking brain of their infrastructure: the Programmable Logic Controller (PLC).This is where Messung Industrial Automation's NX-ERA Premium PLCs come in as a strategic benefit, designed to provide unparalleled modular scalability, PLC redundancy, and seamless SCADA integration for control that's future-proof. For more information about NX-ERA Premium Plc visit us https://www.messungautomation.co.in/why-data-centres-rely-on-nx-era-premium-plcs-for-redundancy-reliability/

#data centres#Programmable Logic Controller (PLC)#PLC redundancy#SCADA integration#mini PLCs#Premium PLC#PLC controller#data centre automation#redundant PLC#high-speed PLC#modular PLC design#MODBUS TCP/IP#NX-ERA Premium PLCs#PLC architecture#PLC systems#Industry 4.0 PLC#AI-based decision systems

0 notes

Text

ASIC told me to "seek professional help" (regarding the issues with the shareholder being a deregistered company) great even ASIC think I'm a narcissistic manipulative asshole forcing things on people and controlling them and enjoying the drama and satisfaction of--- (I don't know what I'm enjoying, nothing really, I enjoyed spending $$$$$ at big W yesterday)

#awesome#thank you ASIC#while i was on hold for ASIC an automated voice said 'our call centres are now closed please call back Monday to Friday in business hours'#ohhhhh today is Saturday#My bad#happy Saturday!!!!! why am i at work#i work on Saturdays now#I've become Sophia#yesterday i had my weekly shower and had the bandages wrapped by all the nurses and the cleaner came and the cook and the neighbours dog and#now it's Saturday time to work and call employees and bother them while they enjoy their weekend activities and#i am Sophia#although Sophia doesn't need professional help#Sophia is perfect#i wish i could be more like Sophia#maybe if i was Sophia I'd still be friends with#ah well

1 note

·

View note

Text

Enhance contact center performance with the DORA framework

Running a contact center can be a real juggling act. Between managing customer queries, keeping your team on track, and making sure everything runs smoothly, things can get pretty hectic. The last thing you need is a system failure or unexpected disruption that throws everything off course.

That’s where the DORA framework comes in. It’s designed to help businesses, including contact centers, stay resilient and keep operations flowing without a hitch. By focusing on risk management, it helps ensure that your critical systems are secure and running smoothly, so you can focus on what matters most—your customers.

Adopting the DORA framework isn’t just about avoiding disasters; it’s about making sure your contact center is always performing at its best. Let’s dive into how DORA can boost your efficiency and make your team’s job a whole lot easier.

Why choose Blackchair for DORA compliance in contact centers?

At Blackchair, we specialize in helping contact centers achieve DORA compliance for operational resilience. Our team works closely with you to ensure your systems are secure, efficient, and always available. We proactively identify risks and inefficiencies, offering actionable insights to enhance performance and minimize disruptions. Let us manage the compliance details while you focus on delivering exceptional customer service and driving business growth.

The DORA (Digital Operational Resilience Act) is a regulatory framework introduced by the European Union aimed at ensuring that financial entities, including contact centers, maintain operational resilience in the face of digital disruptions. DORA focuses on reducing risks to operational activities caused by technology, cyber threats, and system failures. It sets clear standards for risk management, incident reporting, and continuity planning to protect critical systems and services.

Discover how building a robust digital resilience strategy can enhance your CX optimization center operations. Learn more about how we can help improve system stability, minimize disruptions, and ensure smooth, uninterrupted service for your customers.

#CX optimization#CCaaS migration#CCaaS Configuration#Information Technology & Services#CX DevOps Automation#Contact centre consultancy

0 notes

Text

Strengthen contact centers with digital operational resilience strategies

Building resilience in a CX center isn’t easy. Complex systems and tools make it difficult to pinpoint vulnerabilities while evolving regulations add extra layers of pressure. Many CX centers also struggle with limited visibility into operational risks, which leaves them reacting to issues rather than preventing them. And let’s not forget the customer impact—any downtime, no matter how brief, can lead to frustrated customers, lost revenue, and reputational damage.

Why prioritize DORA for your CX center?

Building DORA compliance ensures your CX center stays secure, efficient, and prepared for disruptions. By proactively identifying risks and strengthening system stability, you can minimize downtime and maintain seamless operations. A strong resilience strategy not only protects your CX optimization center from cyber threats and compliance challenges but also enhances customer trust and long-term growth. Stay ahead with a proactive approach to resilience.

A digital operational resilience strategy is a proactive approach to ensuring a contact center can withstand, adapt to, and recover from digital disruptions like cyberattacks, system failures, or regulatory changes. It involves risk management, continuous monitoring, secure infrastructure, and compliance measures to minimize downtime and maintain seamless operations.

Discover how to build digital operational resilience and keep your business running smoothly through any disruptions Learn key strategies to stay ahead.

#CX DevOps Automation#Contact centre consultancy#telecommunications solutions#Business consultant#Information Technology#CX solutions#CX optimization#CCaaS migration#CCaaS Configuration

0 notes

Text

AI Voice Services by Think AI: Revolutionising Business Communication

AI Voice Services by Think AI is revolutionising the way businesses interact with their customers by offering advanced AI-powered voice solutions tailored for seamless automation, customer engagement, and operational efficiency. Designed to integrate effortlessly into existing systems, Think AI’s voice services provide businesses with a scalable and intelligent approach to automated communication.

From AI voice agents handling customer queries to automated appointment scheduling, AI-powered call routing, and personalised voice interactions, Think AI’s services are built to enhance customer experiences while reducing costs. By leveraging natural language processing (NLP) and deep learning, these AI-driven voice solutions enable human-like interactions, ensuring smooth and natural conversations.

Think AI's voice automation solutions are ideal for businesses in customer service, healthcare, finance, retail, and beyond, providing 24/7 availability and real-time responses to improve efficiency and customer satisfaction. Whether you need AI-powered call handling, automated voice assistants, or custom voice integrations for CRM and business operations, Think AI delivers state-of-the-art solutions designed for scalability, accuracy, and seamless deployment.

With AI-powered voice agents capable of multilingual support, sentiment analysis, and intelligent decision-making, Think AI ensures that businesses stay ahead in the era of digital transformation. The company also provides custom AI voice models to match brand identity and enhance customer engagement through conversational AI. Visit: https://www.thinkai.co.uk

#AI Voice Services#Think AI#AI-powered voice agents#voice automation#AI call handling#AI chatbots#automated voice assistants#customer service AI#conversational AI#AI phone agents#natural language processing#AI voice technology#call centre automation#business automation AI#AI appointment scheduling#AI-powered CRM integration#AI call routing#digital transformation

1 note

·

View note

Text

OMRON opens new Automation Centre in Stuttgart, strengthening pharma packaging news, packaging b2b, and cosmetic packaging news innovation links.

#automation centre#industrial automation#pharma packaging news#packaging b2b#cosmetic packaging news#customer collaboration

3 notes

·

View notes

Text

Most popular Sales reporting software for businesses.

Looking for the Automated Daily Sales Reporting Software for shopping malls? Then WovVTech is ADSR Software helps you to streamline your business operations with their comprehensive daily sales reporting tool. Gain actionable insights, track performance metrics,

Track Sales Metrics and optimize decision-making with real-time data.

For Further details visit their website and book the demo now. https://www.wovvtech.com/products/wovvra-revenue-assurance/

0 notes

Text

Why Data Centres Rely on NX-ERA Premium PLCs for Redundancy & Reliability

Data centres are the online headquarters of businesses today. Every click, transaction, login, or query is responded to via a data centre. In this hyper-connected world, downtime is more than a slowdown; it's a disaster.

Whether it is hosting cloud applications, running finance systems, or managing mission-critical enterprise data, data centres simply can't afford failure of control. That's why businesses often spend money on layers of redundancy, not merely power or cooling, but even on the thinking brain of their infrastructure: the Programmable Logic Controller (PLC).This is where Messung Industrial Automation's NX-ERA Premium PLCs come in as a strategic benefit, designed to provide unparalleled modular scalability, PLC redundancy, and seamless SCADA integration for control that's future-proof.

The Challenge: When Control Systems Become the Weak Link

Power? Backed up. Cooling? Redundant. However, what about the control systems controlling these vital components?

Standard or mini PLCs lack the sophistication needed to handle the mission-critical data centres' demand. One logic mistake or hardware malfunction can take down numerous systems, usually with SLA fines, reputation damage, and monetary loss.

What is required is a Premium PLC solution that guarantees:

High-speed, deterministic control

Hardware and logic level redundancy

Modern SCADA and BMS integration

Scalability as the data centre grows

The Solution: NX-ERA Premium PLCs, Control that Never Sleeps

Built to provide dependable, high-availability automation, our NX-ERA provides much more than your average PLC controller. Let's break down what makes NX-ERA the top choice for data centre automation:

Built with Redundancy: Always On, Always Watching

Designed with a redundant PLC, NX-ERA runs on two CPUs - one primary and one hot-standby. They are mirroring each other in real time. If the main unit fails because of power problems, software glitches, or hardware malfunction, the standby takes over immediately, with no downtime. This degree of PLC redundancy is mission-critical to sustain:

Continuous HVAC and precision cooling

Real-time UPS and power distribution management

Live fire detection and suppression procedures

Integrated High-Speed PLC Performance

NX-ERA is a high-speed PLC with processing power for complex, distributed systems. With event sequencing, real-time I/O update, and determinism support, it ensures that each action is done with precision and accuracy. It's like having a control system that can anticipate trouble before it occurs.

Modular PLC architecture for changing infrastructure

In contrast to fixed systems, our NX-ERA boasts a modular PLC design wherein you can introduce new elements, such as I/O racks, processors, or server room sensors, without having to reconfigure or replace the original configuration. This is necessary in contemporary data centres where growth is ongoing.

Centralised Command SCADA Integration

NX-ERA enables smooth SCADA integration via MODBUS TCP/IP and lets you:

Monitor system health through central dashboards

BMS and environmental management system integration

Allow predictive maintenance and compliance monitoring

Custom logic event-based fire alarms

This turns your PLC controller into the eyes and ears of your operation, reporting, responding, and recording in real time.

NX-ERA in Action: Where It Delivers Inside a Data Centre

Contemporary data centres are precision ecosystems. Every subsystem, power, cooling, and fire protection, has to work in a very sophisticated unison. And NX-ERA Premium PLCs are the invisible heroes, directing all the elements to work together in precision, in complete synchrony and faultlessly.

Let's observe how NX-ERA extends operational excellence to the most critical automation domains:

Precision Environmental & Cooling Management

Maintaining the right temperature and humidity is not just about extending equipment life; it's about performance reliability and data integrity. Any slight discrepancy can cause server throttling, random shutdown, or damage due to condensation. NX-ERA exercises close control over:

CRAC units and air handlers: Thermal hotspots are averted by continuous feedback loops and high-speed actuation.

Chilled water distribution and airflow systems: Adaptive logic keeps cooling in phase with current server loads.

Humidity control: Essential in helping prevent electrostatic discharge and hardware long-term health.

What is special about NX-ERA in this regard is that it can perform environmental control logic with microsecond accuracy, supplemented with real-time data monitoring and logging for auditing, regulatory compliance, and AI-driven optimisation.

UPS Control & Power Synchronisation

Uninterruptible Power Supply (UPS) systems are only as good as the logic behind them. Our NX-ERA functions as a moderator, synchronising among multiple PDUs, UPS systems, and switchgear units. It ensures:

Seamless power source transitions during outages or load fluctuations

Real-time load balancing to avoid overloads and maintain energy efficiency

Phase synchronisation for harmonised energy supply between server halls

Where basic PLCs can lag or lose a beat during transitions, NX-ERA's high-speed PLC architecture anticipates power shifts and actively synchronises systems to absorb the impact, critical in Tier III and Tier IV data centres where downtime is not an option.

Fire Detection & Suppression Integration

When safety is not negotiable, response time is paramount. NX-ERA has real-time fire detection integration with intelligent logic chains that coordinate:

Smoke, temperature, and gas detector sensor integration

Alarm signalling through audio-visual signals

Release logic for chemical or inert gas extinguishing agents

But here's the surprise: NX-ERA performs these life-safety functions without affecting other automation tasks. Fire suppression systems may initiate in one area, yet cooling, power, and access control systems continue uninterrupted in other zones.

Shutdown-Free Maintenance: Redundancy in Action

All PLC systems will eventually need maintenance, but taking down operations to make it happen? That's a luxury no contemporary data centre can afford. NX-ERA avoids this inconvenience with live-switching redundancy:

You can upgrade firmware, replace I/O modules, or perform diagnostics on the main PLC.

In the meantime, the secondary PLC continues the automation uninterrupted.

After maintenance is finished, the jobs reverse, without any effect on operations.

This is redundancy in practice, not on paper, but in everyday ops. It's the way Redundant PLC logic makes scheduled downtime a non-event.

Business Benefits Over Engineering Specs

NX-ERA is more than just an upgrade to technology; it is an enabler for business. Here is how it immediately impacts operational and financial KPIs:

Uptime Confidence: Meets even the strictest SLAs with real-world dependability, minimising risk of penalties and guaranteeing service continuity.

Cost Efficiency: Avoids the enormous cost of downtime—lost business, manual intervention, and recovery of the system—and optimises energy usage with intelligent logic.

Compliance-Ready: With NX-ERA's thorough logging, audit trails, and snapshots of environmental data, ISO, ASHRAE, and Tier certifications are simple to comply with.

Future-Proofing: Built with Industry 4.0 PLC capabilities, such as remote access PLC capabilities, analytics, and diagnostics that become increasingly smarter with your infrastructure.

This is intelligent automation systems delivering tangible return on investment, not in years, but in months

The Road Ahead: Industry 4.0 Compliant, Future-Ready

NX-ERA is designed for the future by predicting the needs of tomorrow's data centre architecture today.

Designed for Edge computing applications where distributed processing is paramount

Smart analytics tools that are AI-enabled, performance optimisation compliant

Remote diagnostics and control, allowing for predictive maintenance anywhere

Integrates perfectly with AI-based decision systems, positioning your business for the next decade

As the business shifts towards smart control systems, NX-ERA is leading the way—not just prepared but already ahead.

Conclusion: Trust NX-ERA for Control that Never Compromises

Trust drives data centres. Trust that each byte is secure. Trust that there's uninterrupted uptime. Trust that operations persist, no matter what. NX-ERA Premium PLCs are designed for this trust.

Where time matters, every control logic matters. And that's where NX-ERA sets the pace: redundant PLCs, real-time SCADA integration, and modular PLC architecture for the intricacies of the future. We don't merely create control systems at Messung Industrial Automation. We create trust.

FAQs

In what way is NX-ERA different from standard PLC controllers?

NX-ERA is a High-availability Premium PLC that is suitable for high-availability environments. It accommodates redundant configurations, modular scalability, and advanced SCADA integration, as opposed to basic or micro-PLCs.

What is the method of NX-ERA's PLC redundancy?

NX-ERA has dual CPUs (main and standby). If the main fails, the standby takes over at once, with zero downtime or loss of data.

Is NX-ERA compatible with the current data centre infrastructure?

Yes. With MODBUS TCP/IP and SCADA-ready capabilities, NX-ERA is easily compatible with all control systems and BMS.

Is NX-ERA able to support small and large-scale data centres?

In fact. Its modular PLC design allows for effortless scaling, from small server rooms to multi-hall Tier IV data centres.

Does NX-ERA support Industry 4.0 PLC features?

Yes, it also has remote access, diagnosis, data logging, and intelligent analytics capabilities, and therefore is fully Industry 4.0-compatible.

#data centres#Programmable Logic Controller (PLC)#PLC redundancy#SCADA integration#mini PLCs#Premium PLC#PLC controller#data centre automation#redundant PLC#high-speed PLC#modular PLC design#MODBUS TCP/IP#NX-ERA Premium PLCs#PLC architecture#PLC systems#Industry 4.0 PLC#AI-based decision systems

0 notes

Text

Jharkhand Braces for Intense Monsoon Activity: Widespread Rainfall and Thunderstorms Expected

Heavy rainfall and thunderstorm alerts issued for multiple districts as monsoon trough passes through Daltonganj Meteorological Centre Ranchi forecasts increased precipitation across Jharkhand, with warnings for flash floods in southern regions RANCHI – The Meteorological Centre, Ranchi has issued a series of weather alerts for Jharkhand, indicating an intensification of monsoon activity across…

#automated weather station data jharkhand#राज्य#flash flood preparedness jharkhand#heavy rainfall alert east singhbhum#jharkhand district-wise rainfall data#meteorological centre ranchi updates#monsoon intensification jharkhand#monsoon trough daltonganj#state#temperature trends jharkhand cities#thunderstorm warning jharkhand#weather forecast Jamshedpur

1 note

·

View note

Text

ADYPU's School of Engineering is the gateway to mastering automation at our state-of-the-art Engineering Innovation Centre. Dedicated to fostering a dynamic ecosystem, we empower creative minds to conceive, design, and implement multidisciplinary automation solutions. Be inspired, educated, and lead the next generation of innovators through cutting-edge research, collaborative excellence, and a commitment to societal impact.

Join us as Dr. Ravi Gandhi from the School of Engineering offers an exclusive glimpse into the transformative experiences at the Engineering Innovation Centre.

#adypu#ajeenkyadypatiluniversity#school of engineering#robotic innovation#innovation#automation#Innovation Centre

0 notes

Text

I took a look in the nether to find warped stems for my build and it was really close to the portal!

#i spent a long time replacing blocked with warped stem+quartz and all that#havin a late dinnar again#the civic centre looks really cool! i got oxidized copper warped stem quartz pillar and amethyst!#i was gunna make a lower level for storage and an automated farm room!#personable

0 notes

Text

1 note

·

View note

Text

"Canadian scientists have developed a blood test and portable device that can determine the onset of sepsis faster and more accurately than existing methods.

Published today [May 27, 2025] in Nature Communications, the test is more than 90 per cent accurate at identifying those at high risk of developing sepsis and represents a major milestone in the way doctors will evaluate and treat sepsis.

“Sepsis accounts for roughly 20 per cent of all global deaths,” said lead author Dr. Claudia dos Santos, a critical care physician and scientist at St. Michael’s Hospital. “Our test could be a powerful game changer, allowing physicians to quickly identify and treat patients before they begin to rapidly deteriorate.”

Sepsis is the body’s extreme reaction to an infection, causing the immune system to start attacking one’s own organs and tissues. It can lead to organ failure and death if not treated quickly. Predicting sepsis is difficult: early symptoms are non-specific, and current tests can take up to 18 hours and require specialized labs. This delay before treatment increases the chance of death by nearly eight per cent per hour.

[Note: The up to 18 hour testing window for sepsis is a huge cause of sepsis-related mortality, because septic shock can kill in as little as 12 hours, long before the tests are even done.]

[Analytical] AI helps predict sepsis

Examining blood samples from more than 3,000 hospital patients with suspected sepsis, researchers from UBC and Sepset, a UBC spin-off biotechnology company, used machine learning to identify a six-gene expression signature “Sepset” that predicted sepsis nine times out of 10, and well before a formal diagnosis. With 248 additional blood samples using RT-PCR, (Reverse Transcription Polymerase Chain Reaction), a common hospital laboratory technique, the test was 94 per cent accurate in detecting early-stage sepsis in patients whose condition was about to worsen.

“This demonstrates the immense value of AI in analyzing extremely complex data to identify the important genes for predicting sepsis and writing an algorithm that predicts sepsis risk with high accuracy,” said co-author Dr. Bob Hancock, UBC professor of microbiology and immunology and CEO of Sepset.

Bringing the test to point of care

To bring the test closer to the bedside, the National Research Council of Canada (NRC) developed a portable device they called PowerBlade that uses a drop of blood and an automated sequence of steps to efficiently detect sepsis. Tested with 30 patients, the device was 92 per cent accurate in identifying patients at high risk of sepsis and 89 per cent accurate in ruling out those not at risk.

“PowerBlade delivered results in under three hours. Such a device can make treatment possible wherever a patient may be, including in the emergency room or remote health care units,” said Dr. Hancock.

“By combining cutting-edge microfluidic research with interdisciplinary collaboration across engineering, biology, and medicine, the Centre for Research and Applications in Fluidic Technologies (CRAFT) enables rapid, portable, and accessible testing solutions,” said co-author Dr. Teodor Veres, of the NRC’s Medical Devices Research Centre and CRAFT co-director. CRAFT, a joint venture between the University of Toronto, Unity Health Toronto and the NRC, accelerates the development of innovative devices that can bring high-quality diagnostics to the point of care.

Dr. Hancock’s team, including UBC research associate and co-author Dr. Evan Haney, has also started commercial development of the Sepset signature. “These tests detect the early warnings of sepsis, allowing physicians to act quickly to treat the patient, rather than waiting until the damage is done,” said Dr. Haney."

-via University of British Columbia, May 27, 2025

#public health#medical news#sepsis#cw death#healthcare#medicine#medical care#ai#canada#north america#artificial intelligence#genetics#good news#hope

945 notes

·

View notes