#lvds controller board

Explore tagged Tumblr posts

Text

Kyocera Industrial Touch Panel LCD Screens

In the fast-evolving industrial landscape, the demand for rugged, high-performance display solutions is greater than ever. Among the key players delivering reliable visual technology for industrial environments, Kyocera stands out as a trusted and innovative manufacturer of industrial LCD screens. With decades of expertise in electronics and ceramic components, Kyocera’s LCD product line exemplifies cutting-edge technology built to withstand harsh operating conditions.

Built for Industrial Demands

Kyocera industrial LCD screens are engineered for durability, clarity, and long-term use. Unlike consumer displays, these modules are designed specifically for challenging industrial settings such as factories, medical labs, outdoor kiosks, transportation systems, and automation equipment.

TFT LCD Modules and Custom Solutions

Kyocera offers a broad lineup of TFT LCD display modules, ranging in size from 1.8 inches to 12.1 inches, including both standard and wide-format screens. Many models support touch panel integration, enabling intuitive Human-Machine Interface (HMI) operation. Capacitive and resistive touch options are available, depending on the user environment and control requirements.

Moreover, Kyocera supports custom LCD module solutions, providing design flexibility for manufacturers needing specific display specifications, mounting options, or performance characteristics. Their vertical integration ensures tight quality control and reliable supply chains — a critical factor for industrial customers.

Industrial Applications

Kyocera’s LCD displays are widely adopted in numerous industrial sectors:

1. Factory Automation: Control panels and embedded systems rely on clear, real-time display of process data. Kyocera’s TFT panels deliver consistent performance under fluctuating temperatures and electromagnetic conditions.

2. Medical Equipment: High-resolution LCD monitors are essential for diagnostic instruments, patient monitoring systems, and portable medical devices, where visual accuracy and device reliability can be life-critical.

3. Transportation Systems: From vehicle dashboards to train control panels and marine navigation systems, Kyocera screens withstand vibration, UV exposure, and extreme weather.

4. Test and Measurement Devices: LCD modules offer excellent precision and readability in instruments for laboratories and field diagnostics.

Commitment to Sustainability and Innovation

Kyocera combines its LCD display technology with a deep commitment to sustainability. The company continuously invests in materials and production methods that reduce environmental impact. Their LCDs also reflect this ethos — offering long life, energy efficiency, and reliable operation, reducing maintenance needs and electronic waste.

For more LCD display information,click here.

#board controller#square display#square lcd display#custom lcd screen#20 pin lcd display#monochrome display#10.1 inch touch screen#tft module#wholesale lcd screen#monochrome lcd#lcd 7 inch#panel screen#dust particle counter#4.3 inch tft lcd#small lcd#crystal display#touch screen module#laptop screen replacement#lvds controller board#lvds lcd display#lcd touch#display lcd screen#lvds#lcd screen module#3.5 inch tft lcd#panel touch

0 notes

Text

61016718 Timer Relay for SANY machinery

61016718 Timer Relay SANY spare parts Mail:[email protected] 10209048 Shaft 10038369M 销铸坯30*130/G1-9- 22066697 Cylinder rod welding assembly SPHSK-0070 10420524 SANY PARTS 160101080007A006 Water Pump 10208433 Cylinder end 24911259 Vertical Plate 24919292 SANY PARTS 10241491 Bottom forging stock of cylinder (BZM500 160102040014B050 Spring Cap 10102445 Right lasting 180102080234A Chamfering Cutter 10100447 Protective Plate 10187498L SANY PARTS 10119539 钻模JZ-163 10185504L SANY PARTS 21033636 SANY PARTS 10022376L 弯板料坯QY100.1.1.3-2(L) 160101070020A020 Cover Plate 10213845 SANY PARTS 10277257 SANY PARTS 52001688 SANY PARTS 520255 CH230B-AB-35120-01-1 * 22060728 LED power cable SPEEA-0898 24919965 SANY PARTS 10027117 connecting plate [email protected] 24916065 SANY PARTS 61018850 防尘圈260×275×13 LVD 180102990277A Bell Milling 22063768 4th boom body SP447T30-A 10412673 SANY PARTS 10108725 Short bending handrail 10217777 SANY PARTS 501734 Plug 61031480 扭矩扳手开口头19 配NB-100 准达 10063727 Square Tube 61001734 Door Lock 10483301 SANY PARTS 160101080035A031 harness bracket welding part 180605000625A Check Valve 180110020005A collet 919111300011A Reduction motor 10267507 SANY PARTS 22062802 SPS16500HT CRANE SP303-ST-J 10077641 SANY PARTS 160102090063A338 Shock Absorber 22038949 Ladder welding assembly SP1212C01-A30 180604000760A Amair 61012508 内齿套54×84×47/Z45 180102080023B Chamfer Milling Cutter 160102080025B099 Screw, Twelve Point Cap 10041772 Copper Tube 160102150009A025 Spacer Plate 10185470 Grease nipple 51001491 SANY PARTS 180106990283A Ball Type Rough Boring Head 22024989 Crane ZJ00246 24901436 SANY PARTS 59005722 SANY PARTS 160201000018A Water Pump 180699001056A safety warning 24900269 Washer 6735633380 Sleeve SPELG-0012 /ELG 009 161001000005A161 O-ring 10448541 Steel Pipe Assy 10504101B SANY PARTS 160102070056A003 Multi-wedge Belt 10174979 Right adjusting plate 160102050021B116 Secondary Balance Mechanism 160102120008A061 Rear Pto Gear Shaft 180106060181A Boring Blade 61030448 电控系统SRTG522312 180102060078A Thread Milling 10015547 Inner right-angle bent plate (left 21034814 Rope stop rod 21034791 Rigid board 10661371 Left upper baffle 180109990271A Other Tool Holders 10027861 Lower circular table SR330.5.3.5.3.1-1 160801010363A029 Fc Bracket 22024351 Reinforced plate SPBS002A0113 10530422 SANY PARTS 10208473 Clapboard 5 61012862 Trumpf digit control punch upper die 160801010466A003 Intercooler 61003375 Stainless Steel Tee 61026302 Timing Indicator 61027960 Circuit breaker 180299000273A O Washer 51000916 SANY PARTS 10115202 Back Plate 24003682 Rubber Hose 10431962 外部接线腔接线图J2HⅠ.10X.2-5 10492023 SY5418THB 56ⅡTruck-mounted concrete 10112135 Main boom sensor harness installation 24901069 Valve Block 51003674 iron lock 10628569 reinforced plate 160101060001A024 Air Compressor 10041277 Supporting Plate 22004062 Bottom board SP301S0132 10674181 Water tank body 521953 HYD MOTOR * 10685827 Gear Shaft 22057208 Chassis assembly of 12m SP1212C01KD 160101020001A156 Screw 160101050021A095 Fuel Injector Harness Assembly 10175686 Reinforced plate 10505172 SANY PARTS 22067544 Flange SP202F0101 10120629 SANY PARTS 10004624 Upper wall panel 10568176 SANY PARTS 180109020062A 模块化刀��系统BT50-CN63-75L 67340296650 Presing plate SPEFA-0980 919081400026A UPVC 168899000652A Air Intake Pipe Welding Part 21018593 Split pin 22036382 extension cylinder SPUP-0336 /BB UP1172 180109010483A Full Type Tool Holder System 21011872 Pipe 10138741M m 10015740 Body part 10115873 Plate 24003021 Circular Copper Rod 10452922 钢管HZS180LFQ.4.2-1 918080900082 PP法兰DN80/PN10 22058496 Plate SPKMG00699A1001 61000046 磨头丝母MW1450B 10010780 Power case 160102060060A086 Sealing Gasket 10059178 SANY PARTS 10679865 SANY PARTS 10063231 A/C Cover Assy. 24907264 SANY PARTS 24911844 Tension wheel group 24919002 SANY PARTS 9190226000037 滤网(粗滤)175-49-11221 160801020151A006 Radiator 61028764 bolt 530403 SOLENOID KIT 10173739 SANY PARTS 160102180007A123 Oil Pan 10537197 SANY PARTS 21022832 Main riser 22044152 Gear box assembly SPKHY00397 [email protected] 10032540 Earring 21012156 PFEIFER bag rope end-0322A026 23-26 Read the full article

0 notes

Text

Abstract Vibration testing is a crucial element in validating the reliability, structural integrity, and durability of components and finished products throughout their operational lifespan. This paper discusses how vibration testing equipment, specifically the LISUN LVD-100KG Electrodynamic Vibration Generator System, plays a pivotal role in determining product resistance to real-world mechanical stresses. By simulating various vibration profiles across multiple axes, this system helps manufacturers meet international standards and improve product designs. Comprehensive performance data, testing configurations, and industry applications are explored alongside comparative analysis, highlighting the significance of modern vibration testing equipment in contemporary quality assurance processes. 1. Introduction In an increasingly demanding consumer and industrial market, ensuring the longevity and robustness of electronic and mechanical products is more critical than ever. Vibration testing equipment serves as a simulation platform that helps evaluate how products behave under operational vibrations. Whether the product is destined for automotive, aerospace, electronics, or household use, it is expected to perform reliably despite constant exposure to mechanical stress. The LISUN LVD-100KG Electrodynamic Vibration Generator System is designed for high-performance vibration simulation, enabling precise testing of product response to mechanical stresses. This paper investigates the utility of such systems, discusses standard testing procedures, and provides analytical results from typical testing scenarios. 2. Importance of Vibration Testing Equipment in Product Development Vibration testing is a foundational step in product development and certification, helping in: • Detecting structural weaknesses • Identifying premature failure risks • Improving packaging designs • Optimizing component layout and materials Without proper vibration simulation, products may suffer from early failures due to resonance, fatigue cracks, or misalignments. Vibration testing equipment facilitates both developmental diagnostics and final validation. Electrodynamic Vibration Generator System LVD-100KG 3. Overview of LISUN LVD-100KG Electrodynamic Vibration Generator System The LISUN LVD-100KG system provides programmable vibration profiles that comply with international standards like IEC, MIL-STD, ISO, and ASTM. The system supports vertical and horizontal test modes, making it suitable for a wide range of product testing applications. Key Features: Parameter Specification Max Load Capacity 100 kg Frequency Range 2–5000 Hz Max Acceleration 100 g Max Displacement 25 mm (peak to peak) Vibration Mode Sine, Random, Shock Axis Support X, Y, Z Cooling System Air-cooled Controller Interface PC-based with programmable sweep profiles The system’s ability to simulate shock and continuous vibration makes it ideal for evaluating resonance, looseness, and material fatigue in components like circuit boards, battery packs, vehicle modules, and consumer electronics. 4. Test Methodologies Supported by Vibration Testing Equipment The LVD-100KG supports several standardized testing methods: 4.1. Sinusoidal Sweep Test Used to find the natural frequency and potential resonances. 4.2. Random Vibration Test Mimics real-world vibration environments such as transportation or operational engine noise. 4.3. Shock Test Applies abrupt pulses to assess resistance to sudden impacts or drops. 4.4. Dwell Test Applies vibration at a fixed frequency for extended durations to study fatigue. 4.5. Transportation Simulation Reproduces shipping and handling conditions to validate packaging and product robustness. 5. Application Scenarios Vibration testing equipment is used across various sectors: Industry Test Objective Example Components Automotive Validate mechanical stability ECU, Sensors, Dashboard Aerospace Ensure performance in flight Avionics, Wiring, Brackets Electronics PCB durability & connector stability Mobile Devices, Laptops Household Appliances Noise and vibration reduction Washing Machines, Compressors Lighting Assess joint and housing endurance LED Drivers, Bulbs 6. Case Study: LED Driver Vibration Test Objective: To assess mechanical robustness and solder joint integrity of LED drivers under operational vibration conditions. Equipment Used: • LISUN LVD-100KG Vibration Testing Equipment • Acceleration sensors • Data acquisition system Test Parameters: Test Mode Sine Sweep Frequency Range 10–1000 Hz Acceleration 10 g Duration 2 hours per axis Axes Tested X, Y, Z Results Summary: Axis Observations X Minor casing vibration, no structural failures Y Slight connector loosening noted Z No anomalies detected The test highlighted potential design improvements in connector attachment methods to enhance product longevity. 7. Software Capabilities and Control Flexibility The LVD-100KG system includes intuitive, PC-based software that offers: • Automatic frequency sweep • Custom test profiles • Real-time data logging • Alarm and shutdown features for test safety • Report generation in CSV and PDF formats Such automation ensures repeatability and minimizes human error, increasing overall test reliability. 8. Compliance and Standards The LVD-100KG meets various global testing standards: Standard Application IEC 60068-2-6 Environmental testing MIL-STD-810G Military-grade vibration tests ISO 16750 Automotive electrical and mechanical requirements GB/T 2423.10 Chinese national vibration test standard By adhering to these benchmarks, the system ensures product acceptance in both domestic and international markets. 9. Comparative Analysis with Competing Systems Feature LISUN LVD-100KG Competitor A Competitor B Max Load 100 kg 80 kg 60 kg Frequency Range 2–5000 Hz 5–3000 Hz 10–4000 Hz Acceleration Up to 100 g 60 g 75 g Cost-effectiveness High Medium Medium Software Control Advanced Basic Intermediate LISUN’s LVD-100KG stands out for its high acceleration capacity, wider frequency range, and superior control software, making it a cost-effective solution for comprehensive vibration testing. 10. Conclusion Vibration testing equipment is essential in ensuring the long-term stability and reliability of electronic and mechanical components. The LISUN LVD-100KG Electrodynamic Vibration Generator System offers advanced testing features, comprehensive standard compliance, and exceptional control flexibility, making it a premier choice for developers and quality control engineers across industries. By simulating real-world mechanical stress environments, the LVD-100KG helps manufacturers uncover potential weaknesses, improve product designs, and meet global reliability standards. This ultimately leads to safer, longer-lasting products that perform reliably throughout their lifecycle. References LISUN Group. LVD-100KG Electrodynamic Vibration Generator System. . Available: https://www.lisungroup.com/products/led-test-instruments/dc-electronic-load.html IEC 60068-2-6: Environmental testing – Vibration (sinusoidal) MIL-STD-810G: Environmental Engineering Considerations and Laboratory Tests ISO 16750: Road vehicles – Environmental conditions and testing for electrical and electronic equipment GB/T 2423.10-2008: Basic environmental testing procedures Read the full article

0 notes

Text

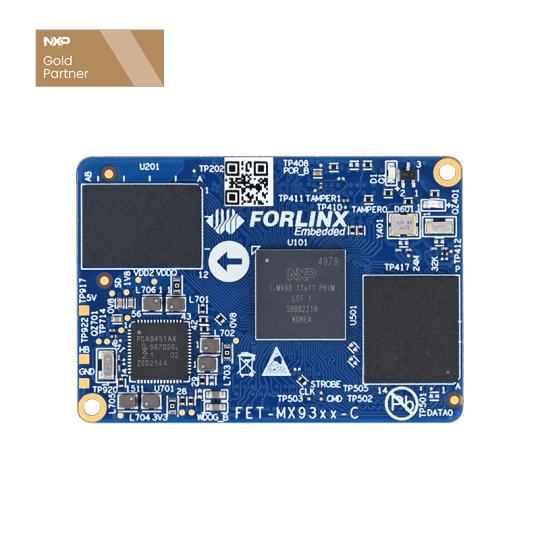

Compact. Robust. Intelligent. Discover the Forlinx i.MX9352 SoM

The Forlinx FET-MX9352-C SoM powered by NXP's i.MX 9352 processor delivers industry-leading multi-core performance, ultra-efficient AI inference, and deterministic networking in a compact, SMT-friendly form factor, making it ideal for industrial automation, robotics, edge AI, and smart IoT applications.

Key Performance Highlights

High-Performance Processing

Dual Cortex-A55 @ 1.7 GHz handles complex Linux workloads and multi-threaded applications with ease.

Cortex-M33 @ 250 MHz real-time core delivers deterministic control and low-latency tasks without offloading to external MCUs.

Edge AI Acceleration

Arm Ethos-U65 microNPU achieves up to 0.5 TOPS of AI acceleration for vision and machine-learning inference at the edge.

On-board NPU enables secure, offline inferencing for applications like predictive maintenance and intelligent video analytics.

Deterministic Networking

Dual Gigabit Ethernet ports—one with TSN (Time-Sensitive Networking) support—ensure sub-millisecond synchronization and zero-packet loss for real-time industrial networks.

Built-in IEEE 1588 & 802.1Qbv/bu standards support precise time synchronization across distributed systems.

Rich Connectivity

Comprehensive interfaces include 2× USB 2.0, 2× CAN-FD, 3× SD/SDIO 3.0, up to 8× UART, 8× SPI, 8× I²C, 2× I³C, and audio interfaces (SPDIF, PDM).

High-speed multimedia features with 1× 4-lane MIPI-DSI, 1× LVDS, RGB888 output, and up to 2-lane MIPI-CSI for camera input.

Industrial Reliability & Longevity

Wide-temperature operation from –40 °C to +85 °C with all industrial-grade components for harsh environments.

15-year longevity program aligns with NXP's supply guarantee for the i.MX 93 family, ensuring stable supply through at least 2038.

Compact SMT-Ready Design

QFN SMT module measures just ~33 × 48 mm and can be directly reflow-soldered onto customer carrier boards, reducing BOM cost and assembly complexity.

Optimized signal integrity & power management deliver robust performance in a miniaturized footprint.

Elevate your next project with the FET-MX9352-C SoM's unmatched compute, AI, and network determinism.

🔗 Explore product details & request samples

#iMX93SoM#SystemOnModule#EmbeddedSystems#IndustrialIoT#EdgeAI#CortexA55#EthosU65#TimeSensitiveNetworking

0 notes

Text

A Complete Guide to TV Repair Parts in Toronto

Televisions are an essential part of modern homes, but like any electronic device, they can experience technical issues over time. Instead of replacing your TV entirely, you can often fix the problem by purchasing TV repair parts. Whether you need replacement components for an LED, OLED, or plasma TV, finding the right TV repair parts in Toronto can save you money and extend the lifespan of your device.

In this guide, we’ll explore common TV issues, essential TV repair parts, and where to find reliable replacement components in Toronto.

Common TV Issues That Require Repair Parts

If your TV has stopped working, it’s important to diagnose the issue before buying any TV repair parts. Here are some common problems and their possible solutions:

🔴 No Power or Won’t Turn On

Likely Causes: Faulty power supply board, damaged capacitors, or a broken power cord.

Required TV repair parts: Power supply board, fuses, capacitors, or power cables.

🔵 No Picture or Black Screen

Likely Causes: Malfunctioning T-Con board, faulty backlight, or main board failure.

Required TV repair parts: T-Con board, LED backlight strips, or main board replacements.

🟡 No Sound or Audio Distortion

Likely Causes: Speaker damage, defective audio IC chip, or motherboard issues.

Required TV repair parts: Internal speakers, audio circuit boards, or mainboards.

🟢 Lines or Flickering on the Screen

Likely Causes: Faulty ribbon cables, loose connections, or damaged display panel.

Required TV repair parts: LVDS cables, T-Con boards, or new screen panels.

🟠 Remote Control Not Responding

Likely Causes: Defective IR sensor, broken remote, or software malfunction.

Required TV repair parts: IR sensor replacements, universal remotes, or software updates.

Essential TV Repair Parts in Toronto

When repairing your television, knowing the right TV repair parts to buy is crucial. Here are some of the most commonly replaced components:

Power Supply Board: A faulty power supply board is one of the most frequent causes of a dead TV. If your TV won’t turn on, replacing this part can restore its functionality.

T-Con Board: The timing control (T-Con) board is responsible for displaying images on the screen. If your TV has flickering, lines, or no picture, replacing the T-Con board may fix the issue.

LED Backlight Strips: Dim screens or flickering lights often indicate failing backlight strips. These are commonly replaced in LED TVs.

Mainboard & Logic Board: The TV’s mainboard controls its overall functions, including picture processing, audio output, and connectivity. Replacing a defective mainboard can resolve many operational issues.

TV Speakers & Audio Boards: If your TV has sound distortion or no audio, replacing the internal speakers or audio IC chip might be necessary.

Ribbon Cables & Connectors: Loose or damaged cables can cause screen issues. Replacing LVDS cables and internal connectors can fix display problems.

Remote Control & IR Sensors: If your TV isn’t responding to the remote, replacing the remote control or IR sensor can help restore functionality.

Where to Buy TV Repair Parts in Toronto

Finding quality TV repair parts in Toronto is essential for a successful repair. Here are some recommended sources:

1. Local Electronics Repair Shops

Many electronics repair stores in Toronto specialize in TV repairs and sell replacement parts. Visiting a local shop allows you to get expert advice and find compatible components.

2. Online Marketplaces

Websites like TV Parts Canada, Amazon, eBay, and Newegg offer a variety of TV repair parts with fast shipping to Toronto. Make sure to check product specifications and reviews before purchasing.

3. TV Manufacturer Service Centers

If you own a branded TV (Samsung, LG, Sony, etc.), you can purchase genuine parts directly from the manufacturer’s service centers in Toronto. This ensures high-quality replacements.

4. Electronics Recycling Centers

Some electronics recycling centers offer salvaged TV repair parts at discounted prices. This can be a great option for finding rare or older components.

Tips for Choosing the Right TV Repair Parts

Check Your TV Model Number – Always match the part number with your TV model to ensure compatibility.

Buy Genuine Parts When Possible – Manufacturer-approved parts tend to be more reliable and durable.

Read Customer Reviews – If buying online, check customer feedback to avoid defective or low-quality components.

Consult a Professional – If unsure, visit a TV repair shop in Toronto for guidance on the best replacement parts.

Final Thoughts

Repairing your TV instead of replacing it can save you money while reducing electronic waste. By purchasing the right TV repair parts in Toronto, you can restore your television’s performance and extend its lifespan. Whether you need a power supply board, LED backlight strips, or a new remote, Toronto offers plenty of options for finding quality replacement parts.

If your TV is malfunctioning, consider diagnosing the issue and sourcing the right TV repair parts to get it back in working order. With the right knowledge and resources, you can make cost-effective repairs and enjoy your entertainment system for years to come.

#TV repair parts#TV repair parts in Toronto#TV parts#TV parts Canada#TV repair parts Canada#TV replacement parts#tv parts near me

0 notes

Text

MSI Launches MS-CF16 Pico-ITX SBC For Industry Applications

MSI Introduces the MS-CF16 Pico-ITX SBC, a Wide Temperature Range SBC for Severe Uses.

Intel Alder Lake-N/Amston Lake family CPUs, which provide up to 16GB of LPDDR5X memory for effective, high-performance computing, power the MS-CF16 Pico-ITX SBC. It has two M.2 slots for flexible connection, USB 10Gbps/5Gbps, 2.5 GbE/1GbE, and many I/O choices, including support for two separate displays via HDMI and LVDS/eDP interfaces. The board’s very small 2.5″ Pico-ITX form size makes it simple to integrate into situations with limited space.

MS-CF16 Pico-ITX Features

Packed with cutting-edge features appropriate for severe environment and industrial applications, the MS-CF16 Pico-ITX includes:

Compact Pico-ITX Form format

The MS-CF16 provides powerful computing in a compact, space-efficient design with to its 2.5″ Pico-ITX form format (101mm x 73mm). It combines excellent performance with a wide range of connection choices, making it perfect for portable devices or embedded systems. Industrial robots and kiosks may use this compact form size without sacrificing functionality or expandability.

Broad Operating Temperature

The MS-CF16 can tolerate tough situations from -40°C to 85°C. For exterior installations and industrial devices, this wide range offers durability and reliable performance in extreme conditions from freezing to high heat.

Rich Connectivity Options

The MS-CF16 facilitates flexible device integration and extension with a variety of I/O interfaces, including USB 10Gbps/5Gbps, HDMI, and COM connections. It makes connectivity with industrial machines, dual independent displays, and quick data transfers possible. It may be expanded for wireless modules or storage with to the M.2 slots, which makes it suitable for a range of sectors.

Fanless Design for Low Power Operation

The MS-CF16’s fanless, low-power design improves durability and energy economy. It lessens wear and tear by doing away with mechanical cooling, which makes it appropriate for dusty or debris-filled situations. Additionally, the fanless design allows for quiet operation, which makes it ideal for applications that are sensitive to noise and medical equipment.

Twin Independent Display Support

The MS-CF16 has twin independent displays that enable users to operate two screens at once with to its HDMI and LVDS/eDP connectors. This improves user experience and efficiency without the need for extra hardware in applications like digital signs, control rooms, or monitoring systems where crisp, real-time data presentation is crucial.

MS-CF16 Pico-ITX Applications

The MS-CF16 Pico-ITX board is intended for a range of embedded and industrial uses, such as:

Industrial Automation

The MS-CF16 is perfect for industrial automation due to its sturdy design and broad working temperature. It can withstand the demands of robotics, machine control systems, and industrial settings. It provides dependable operation under harsh circumstances, guaranteeing steady performance for applications needing round-the-clock uptime in demanding production settings.

Edge Computing for the Internet of Things

The MS-CF16 is a good fit for edge computing devices and Internet of Things gateways because of its strong processing capabilities and flexible connections. In smart city and industrial IoT configurations, it facilitates local data processing, lowering latency, increasing productivity, and enabling real-time decision-making in dispersed and distant areas.

Medical Equipment

The MS-CF16 is perfect for medical applications because of its small size, low power consumption, and fanless design. It integrates easily into embedded or portable medical diagnostic instruments, providing dependable performance in crucial healthcare settings where silent operation, energy efficiency, and space are crucial.

Digital Signage Outside

The MS-CF16’s robust construction and broad working temperature range make it ideal for outdoor digital signs, kiosks, and other systems that interact with the public. It is a reliable option for interactive kiosks or public information displays since it guarantees seamless functioning in inclement weather, from very cold to extremely hot temperatures.

The MSI MS-CF16 is a crucial tool for companies wishing to deploy dependable, high-performance computing solutions in demanding settings because of its characteristics and application areas.

Read more on Govindhtech.com

#MSCF16PicoITX#SBC#MSI#singleboardcomputers#PicoITX#pico#govindhtech#news#TechNews#Technology#technologynews#technologytrends

0 notes

Text

IBM SCSI & RAID Devices Driver

Ibm Scsi Hard Drive

Ibm Scsi & Raid Devices Drivers

We offer new SCSI SSDs for replacement of obsolete SCSI drives, SSDs, Magneto Optical and tape drives with SE, LVD, and Differential interface. Red Rock Technologies specializes in supporting customer's legacy SCSI systems with custom solutions to allow our product to be drop-in replacement without modification of the legacy system. We have proprietary FPGA-based technology that we developed for use on our VME boards and have honed over 20 years to provide maximum capability with a wide range of SCSI systems. We can analyze, troubleshoot, and provide custom firmware solutions for difficult SCSI systems. We have successfully integrated our products with industrial, military, and telecommunications companies around the world.

File link File size File description; ibmfwhbaaic79xx4.30.02anyosnoarch1.chg. 1,004: CHANGE HISTORY for the IBM Ultra320 SCSI controller BIOS.

How to create virtual SCSI adapters on PowerVM Virtual I/O Server (VIOS) and AIX client using the HMC Classic GUI. This includes: 1. Creating the virtual SCSI Server adapter, which translates to a vhost# on the VIOS and 2.

The IBM Ultra320 SCSI Controller PCIe (43W4324) provides a solid performing storage solution for managing internal and external storage.

We replace a range of obsolete drives. Please contact us or check out our list of drives we replace if you're looking for a replacement drive and we will build a custom solution for you.

The Red Rock Technologies Difference:

In-house designing, manufacturing, and testing of our products

Industrial-grade solutions

Better performance than Compact Flash-based solutions

Direct customer support

20 years of experience

Features include:

New, drop-in replacement for obsolete SCSI drives

Available in Narrow, Wide Differential, and LVD (low voltage differential

Capacities currently up to 4TB

Custom capacities available for systems that require exact capacity value

Custom sector sizes available

Extended temperature options available

Rugged options for high shock and vibration environments

Options for discrete controlled military secure erase

SCSI termination can be enabled within unit on some models

Ibm Scsi Hard Drive

3.5' SCSI 68-Pin Wide, Wide Differential, Wide LVD

Ibm Scsi & Raid Devices Drivers

SCSI Magneto Optical Drives

SCSI Floppy Drives

SCSI Tape Drives

SCSI PC Cards

1 note

·

View note

Text

Completely independently developed display controller

Brief introduction of PCM-3499 motherboard PCM-3499 is an embedded control module with extremely high cost performance, size and compactness. Almost all the functions required by industrial computers are realized on the PC104 specification board. PCM-3499 onboard embedded high-performance 16-bit processor, which is internally 32-bit RISC architecture and compatible with 80C186 processor, has extremely high performance, main frequency up to 100MHz, built-in 100M Ethernet, and supports 1MB of SDRAM. The instructions are compatible with other X86 microprocessors.

Onboard functions include 10 / 100M high-speed Ethernet interface, PC104 interface, TFT interface and LVDS interface, VGA interface, support standard IDE interface (DOM, ordinary hard disk), parallel port, four serial ports (RS-232 and RS-485, four Each serial port can be configured as TTL level interface), USB interface, DOC interface, PS / 2 keyboard port, RTC real-time clock, ferroelectric, battery-backed SRAM non-volatile memory, watchdog, buzzer interface, general purpose GPIO, 8/16 bit compatible ISA bus, etc. Integrates the system BIOS, 1.44M flash disk

(Flash Flopy Disk-FFD, which can be expanded to 8M flash memory according to user needs) and a 16-point matrix Chinese character library on a single flash memory chip to achieve the smallest size with a minimum number of chips The most functions of the module. Completely independently developed display controller, can achieve up to 1024 768 true color high-performance display effect. If you need more other functions, you can expand the relevant function modules through the PC / 104 bus. Second, PCM-3499 textile controller solution system architecture

In the case of the loom reed suppliers controller successfully developed by Lanyu Technology customers, we briefly introduce one of the customers' textile controller system solutions based on Lanyu Technology PCM-3499. The system architecture is shown in Figure: According to the control realization principle of the entire system scheme shown in the above figure, we divide the main control unit of this scheme into upper and lower computer structures, and PCM-3499 completes the coordination with the upper computer and the control of the terminal equipment . The host computer is mainly responsible for human-computer interaction,

1 note

·

View note

Text

The structure and working principles of the car charger

With the development of society, the two problems of energy shortage and environmental pollution are becoming more and more serious. The low-carbon travel concept of green energy saving and emission reduction is taking root in the hearts of the people. One of the hot spots for development and use.

Among them, as a representative pure electric vehicle (Electric Vehicle, EV), compared with traditional fuel vehicles, it has the characteristics of no pollution, low noise, energy saving, and emission reduction, convenient maintenance, energy recovery, etc. support. In addition to pure electric vehicles, fuel cell vehicles (FCVs), hybrid electric vehicles (HEVs), and plug-in hybrid electric vehicles (PHEVs) are gradually gaining attention.

The charging technology of the onboard battery of electric vehicles is one of the bottlenecks restricting the development of electric vehicles. The charging technology not only affects the performance and life of the battery but also affects the driving distance, charging speed, and convenience of the car. Therefore, the onboard charging technology of electric vehicles is studied. has very important practical significance. Due to the space and cost constraints of electric vehicles, the fast charging technology of electric vehicle batteries generally relies on charging piles or charging stations to achieve. The electric vehicle charger has the advantages of small size, lightweight, easy installation, high safety factor, and convenient use. Home electric vehicles can be charged at night to meet the needs of the car's travel the next day. When charging electric vehicles, only the power cord and power supply are required. The socket can be connected, which is conducive to promoting the popularization and development of electric vehicles.

Structure and working principle

The system framework of the car charger is divided into two parts: the main circuit and the control circuit. Among them, the main circuit topology structure of the car charger is composed of an EMI filter, AC/DC converter, DC/DC converter, and rectifier filter circuit; while the MCU control center, drive circuit, signal detection and acquisition circuit, auxiliary power supply, and protection circuit, etc. constitute the topological structure of the control loop of the charger. In order to prevent electromagnetic interference to the power grid when the on-board charger is charging and disturbs the working stability of other electrical equipment, an EMI filter is added between the power supply line and the charger, and the AC mains is connected to the AC/DC converter through the EMI filter. The AC/DC converter is rectified and filtered by the AC/DC converter and the APFC correction is sent to the DC/DC converter, which is adjusted and transformed by the power switch tube of the DC/DC converter to generate high-frequency pulsating DC power, which is stepped down by the high-frequency transformer, and then After rectification and filtering, it is converted into a stable DC power, and finally the battery is charged.

Wuxi Fugenes Technology Co., Ltd. is a company invested by MY SOLAR, a photovoltaic module factory established in Wuxi, Jiangsu in 2005. The company established FGNEX in 2019 to expand its product line of inverters, racks, energy storage systems, and EV chargers. In 2020, FGNEX and Hiconics formed a new company to develop and manufacture DC EV chargers. FGNEX 22kW AC Charger-Wall Mounted is one of our products, more details are as follow:

Vehicle Interface

PWM

Supervision Capability

Wireless: 4G, WIFI

Access & Identification

RFID reader/ Plug & Charge/ App (with backend)

Standard compliance

EMI CISPR22/EN 55022 Class B

EMC EN 61000 4 5 ±2 KV/KV/±4KV perf. Criteria B

EN 61851 1 & EN 61851 22

LVD Directive 2014/35/EU

Input connection

1P+N 230V/3P+N 400V

If you are interested in our products, please contact us.

Related news of electric vehicle chargers

Several different EV charging devices

The significance of developing new energy electric vehicle chargers

Classification and functions of electric vehicle chargers

0 notes

Text

Intelligent development of industrial control LCD screens

With the advancement of Industry 4.0 and intelligent manufacturing, industrial control LCD screens are developing in the direction of intelligence, multi-function and efficiency. The following are the main trends and application scenarios of the intelligent development of industrial control LCD screens:

1. Intelligent function integration

Modern industrial control LCD screens not only have basic display functions, but also integrate a variety of intelligent functions. For example, through deep learning algorithms, the screen can recognize the user's operating habits and automatically adjust the interface layout and interaction methods. In addition, industrial control screens also support Internet of Things technology, can receive and display data from multiple devices and systems in real time, and support remote monitoring and predictive maintenance.

2. Optimization of human-computer interaction

Industrial control LCD screens are constantly optimized in terms of human-computer interaction, supporting technologies such as touch screens, voice recognition and gesture control to improve the convenience and efficiency of operation. For example, in Lenovo's intelligent edge product line, industrial control screens combine AI technology to improve the inspection efficiency and accuracy of quality inspection production lines.

3. High-resolution and high-contrast display

In order to meet the needs of complex industrial scenarios, the resolution and contrast of industrial control LCD screens are constantly improving. High-resolution screens can clearly display more information, while high contrast ensures good visibility even in strong light environments.

Shenzhen Zhiyan Optronics Co., Ltd. (zylcdshop.com) is a trusted China-based distributor specializing in high-quality LCD screens.

#crystal display#touch screen module#laptop screen replacement#lvds controller board#lvds lcd display#lcd touch#display lcd screen#lvds#lcd screen module#3.5 inch tft lcd#panel touch#5 inch touch screen#display control board

0 notes

Text

61016718 Timer Relay for SANY machinery

61016718 Timer Relay SANY spare parts Mail:[email protected] 10209048 Shaft 10038369M 销铸坯30*130/G1-9- 22066697 Cylinder rod welding assembly SPHSK-0070 10420524 SANY PARTS 160101080007A006 Water Pump 10208433 Cylinder end 24911259 Vertical Plate 24919292 SANY PARTS 10241491 Bottom forging stock of cylinder (BZM500 160102040014B050 Spring Cap 10102445 Right lasting 180102080234A Chamfering Cutter 10100447 Protective Plate 10187498L SANY PARTS 10119539 钻模JZ-163 10185504L SANY PARTS 21033636 SANY PARTS 10022376L 弯板料坯QY100.1.1.3-2(L) 160101070020A020 Cover Plate 10213845 SANY PARTS 10277257 SANY PARTS 52001688 SANY PARTS 520255 CH230B-AB-35120-01-1 * 22060728 LED power cable SPEEA-0898 24919965 SANY PARTS 10027117 connecting plate [email protected] 24916065 SANY PARTS 61018850 防尘圈260×275×13 LVD 180102990277A Bell Milling 22063768 4th boom body SP447T30-A 10412673 SANY PARTS 10108725 Short bending handrail 10217777 SANY PARTS 501734 Plug 61031480 扭矩扳手开口头19 配NB-100 准达 10063727 Square Tube 61001734 Door Lock 10483301 SANY PARTS 160101080035A031 harness bracket welding part 180605000625A Check Valve 180110020005A collet 919111300011A Reduction motor 10267507 SANY PARTS 22062802 SPS16500HT CRANE SP303-ST-J 10077641 SANY PARTS 160102090063A338 Shock Absorber 22038949 Ladder welding assembly SP1212C01-A30 180604000760A Amair 61012508 内齿套54×84×47/Z45 180102080023B Chamfer Milling Cutter 160102080025B099 Screw, Twelve Point Cap 10041772 Copper Tube 160102150009A025 Spacer Plate 10185470 Grease nipple 51001491 SANY PARTS 180106990283A Ball Type Rough Boring Head 22024989 Crane ZJ00246 24901436 SANY PARTS 59005722 SANY PARTS 160201000018A Water Pump 180699001056A safety warning 24900269 Washer 6735633380 Sleeve SPELG-0012 /ELG 009 161001000005A161 O-ring 10448541 Steel Pipe Assy 10504101B SANY PARTS 160102070056A003 Multi-wedge Belt 10174979 Right adjusting plate 160102050021B116 Secondary Balance Mechanism 160102120008A061 Rear Pto Gear Shaft 180106060181A Boring Blade 61030448 电控系统SRTG522312 180102060078A Thread Milling 10015547 Inner right-angle bent plate (left 21034814 Rope stop rod 21034791 Rigid board 10661371 Left upper baffle 180109990271A Other Tool Holders 10027861 Lower circular table SR330.5.3.5.3.1-1 160801010363A029 Fc Bracket 22024351 Reinforced plate SPBS002A0113 10530422 SANY PARTS 10208473 Clapboard 5 61012862 Trumpf digit control punch upper die 160801010466A003 Intercooler 61003375 Stainless Steel Tee 61026302 Timing Indicator 61027960 Circuit breaker 180299000273A O Washer 51000916 SANY PARTS 10115202 Back Plate 24003682 Rubber Hose 10431962 外部接线腔接线图J2HⅠ.10X.2-5 10492023 SY5418THB 56ⅡTruck-mounted concrete 10112135 Main boom sensor harness installation 24901069 Valve Block 51003674 iron lock 10628569 reinforced plate 160101060001A024 Air Compressor 10041277 Supporting Plate 22004062 Bottom board SP301S0132 10674181 Water tank body 521953 HYD MOTOR * 10685827 Gear Shaft 22057208 Chassis assembly of 12m SP1212C01KD 160101020001A156 Screw 160101050021A095 Fuel Injector Harness Assembly 10175686 Reinforced plate 10505172 SANY PARTS 22067544 Flange SP202F0101 10120629 SANY PARTS 10004624 Upper wall panel 10568176 SANY PARTS 180109020062A 模块化刀柄系统BT50-CN63-75L 67340296650 Presing plate SPEFA-0980 919081400026A UPVC 168899000652A Air Intake Pipe Welding Part 21018593 Split pin 22036382 extension cylinder SPUP-0336 /BB UP1172 180109010483A Full Type Tool Holder System 21011872 Pipe 10138741M m 10015740 Body part 10115873 Plate 24003021 Circular Copper Rod 10452922 钢管HZS180LFQ.4.2-1 918080900082 PP法兰DN80/PN10 22058496 Plate SPKMG00699A1001 61000046 磨头丝母MW1450B 10010780 Power case 160102060060A086 Sealing Gasket 10059178 SANY PARTS 10679865 SANY PARTS 10063231 A/C Cover Assy. 24907264 SANY PARTS 24911844 Tension wheel group 24919002 SANY PARTS 9190226000037 滤网(粗滤)175-49-11221 160801020151A006 Radiator 61028764 bolt 530403 SOLENOID KIT 10173739 SANY PARTS 160102180007A123 Oil Pan 10537197 SANY PARTS 21022832 Main riser 22044152 Gear box assembly SPKHY00397 [email protected] 10032540 Earring 21012156 PFEIFER bag rope end-0322A026 23-26 Read the full article

0 notes

Text

The vibration test machine plays a crucial role in the fields of product development, quality control, and environmental testing. Among the leading technologies in this area is the LISUN LVD-100KG Electrodynamic Vibration Generator System, which employs electromagnetic systems to simulate various vibration conditions. This article explores the working principles, capabilities, and applications of this advanced vibration test machine, providing detailed insights into its functionalities and specifications. LVD 100KG Electrodynamic Vibration Generator System Introduction to Electrodynamic Vibration Testing Vibration testing is essential for evaluating a product’s durability and performance under different environmental conditions. It helps identify potential design flaws and ensures compliance with industry standards. The LISUN LVD-100KG Electrodynamic Vibration Generator System is a state-of-the-art solution that enables precise simulation of vibration scenarios, such as sinusoidal waves, frequency modulation, sweep frequency, programmable vibrations, octave and logarithmic frequencies, high acceleration, amplitude control, and time control. Key Features of the LISUN LVD-100KG System The LISUN LVD-100KG vibration test machine offers the following key features: • Wide Frequency Range: The system supports a frequency range of 5 Hz to 5,000 Hz, accommodating a broad spectrum of test requirements. • High Acceleration: With acceleration levels up to 100 g, it can simulate extreme conditions. • Multiple Waveform Testing: Capable of generating sinusoidal, random, and transient waveforms. • Precision Control: Features amplitude and time control for accurate simulation. • User-Friendly Interface: Includes software for easy programming and real-time monitoring. • Environmental Integration: Can be combined with climatic chambers for simultaneous vibration and environmental testing. Applications of Vibration Test Machines The LISUN LVD-100KG Electrodynamic Vibration Generator System is widely used in various industries, including: • Automotive: Testing components such as engines, suspensions, and electronics. • Aerospace: Simulating launch and flight conditions for satellites and equipment. • Electronics: Evaluating the durability of circuit boards and devices. • Industrial Equipment: Assessing the resilience of machinery and tools under dynamic loads. • Consumer Products: Ensuring the reliability of household appliances and gadgets. Detailed Functional Capabilities Functionality Description Sinusoidal Wave Testing Simulates repetitive and predictable vibrations to test material fatigue and resonance frequencies. Frequency Modulation Evaluates performance across varying frequencies within a set range. Sweep Frequency Testing Gradually shifts frequencies to detect weak points or resonance. Programmable Testing Allows users to customize vibration patterns for specific applications. Octave and Logarithmic Tests Conducts frequency tests that increase exponentially for precise analysis. High Acceleration Testing Simulates extreme conditions to test structural integrity. Amplitude Control Provides precise adjustments for testing different vibration intensities. Time Control Ensures consistent testing over set durations. Example Test Scenarios Case Study 1: Automotive Electronics Durability An automotive manufacturer used the LISUN LVD-100KG vibration test machine to evaluate the durability of an onboard electronic control unit. The test involved sinusoidal vibration simulations at varying frequencies (20 Hz to 200 Hz) over 24 hours. Results showed improved design robustness after iterative testing. Case Study 2: Satellite Component Testing A satellite manufacturer employed the system to simulate launch vibrations. The test used high acceleration and logarithmic frequency sweeps, successfully identifying weak points in structural components. Technical Specifications Parameter Specification Frequency Range 5 Hz – 5,000 Hz Maximum Acceleration 100 g Maximum Displacement ±25 mm Payload Capacity 100 kg Temperature Range -40°C to +80°C Power Supply 220 V/50 Hz or 380 V/60 Hz Software Support Windows-based, real-time Advantages of the LISUN LVD-100KG System • Enhanced Accuracy: High-precision sensors ensure reliable data. • Versatility: Compatible with various test protocols and industry standards. • Efficiency: Quick setup and programmable testing save time. • Durability: Robust design for extended operational life. • Comprehensive Support: Includes installation, training, and maintenance services. Conclusion The LISUN LVD-100KG Electrodynamic Vibration Generator System is a versatile and powerful tool for vibration testing. Its ability to simulate diverse vibration conditions with precision makes it indispensable for industries requiring rigorous product evaluation. With its advanced features and proven reliability, this vibration test machine continues to set benchmarks in testing technology. For more information about the LISUN LVD-100KG Electrodynamic Vibration Generator System, Read the full article

0 notes

Text

Upgrade of OTA System Based on Forlinx OK3568-C Single Board Computer

OTA is a way to upgrade the system for the device without loss, and can remotely deploy new functions to the product. We can not only download the OTA upgrade package through the network, but also upgrade the device by downloading the OTA upgrade package to the SD card or U disk.

In this article, we will introduce the OTA upgrade process, the process of local upgrade program recovery, and the technical details of the upgrade through the Forlinx Embedded OK3568-C development board.

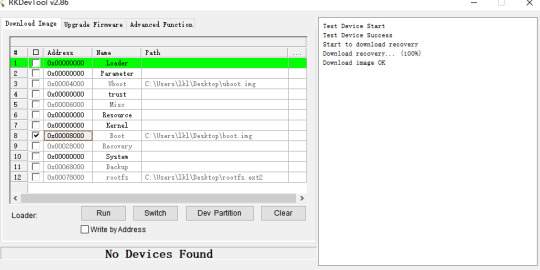

1. Making recovery.img

Recovery The associated source code path:

buildroot/output/OK3568-recovery/build/recovery-develop

If any of the source files in the above directory have been modified, you need to perform the following actions:

(1). forlinx@ubuntu:~/OK3568-linux-source$ source envsetup.sh

(2). Select the recovery configuration for a platform and enter 96

(3). forlinx@ubuntu:~/OK3568-linux-source$ make recovery-dirclean && make recovery #Clear the compilation product and recompile

(4). forlinx@ubuntu:~/OK3568-linux-source$ make rkupdate-dirclean && make rkupdate #Clear the compilation product and recompile

If you have not modified the source code files in the above directory, then do the following directly:

(1). forlinx@ubuntu:~/OK3568-linux-source$ ./build.sh recovery #compile to generate recovery.img

(2). forlinx@ubuntu:~/OK3568-linux-source$ ./mkfirmware.sh

# Copy the generated firmware to the rockdev/ directory

Flash/OK3568-linux-source/buildroot/output/OK3568-recovery/images/recovery.img file.

Click Device Partition Table, tick 9, select recovery path, and click Execute.

2. Make an upgrade image

How to verify that the upgrade was successful? We need to have a preliminary understanding of the boot.img file holds the device tree and kernel, and we just need to make appropriate changes to the device tree or kernel. This routine updates the boot.img file as an example, with appropriate changes to the device tree.

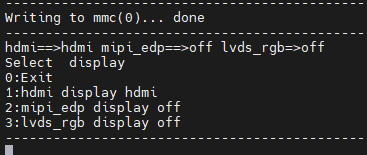

Modify the device tree:

/OK3568-linux-source/kernel/arch/arm64/boot/dts/rockchip/OK3568-C-common.dtsi,Modify the forlinx _ control node as follows. By default, only the HDMI output is turned on, leaving the MIPI and LVDS outputs off.

Modify the file:

/OK3568-linux-source/tools/linux/Linux_Pack_Firmware/rockdev/package-file

Modify this file as required, this routine updates boot.img as an example, so comment out the other .img files. Users can adjust this file to meet product update requirements.

This routine takes the example of modifying the device tree display and recompiling the kernel after modifying the device tree.

forlinx@ubuntu:~ /OK3568-linux-source$ ./build.sh kernel #modify the device tree, then regenerate the kernel

forlinx@ubuntu:~/OK3568-linux-source$ ./build.sh updateimg #package Upgrade Package Firmware

Use /Ok3568--linux-source/rockdev/update.img file to upgrade.

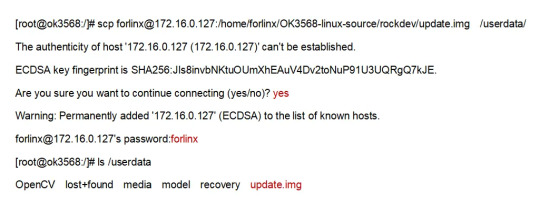

3. Upgrade operation

SD card or USB flash drive upgrade

Mount the SD card or USB disk to the /run/media directory of the OK3568-C development board by default. Copy the update.img image file to the /userdata directory of the OK3568-C development board, and the system will detect the upgrade package in this directory and upgrade it automatically after rebooting the board.

FTP server upgrade

Execute the following command on the OK3568-C development board to copy the upgrade package file from the server to the development board for upgrading.

After the download is complete use the following command to upgrade:

update ota /userdata/update.img

During the upgrade process, the device will enter recovery mode and upgrade automatically, after the upgrade is successful, it will enter the normal normal system.

4. Verify the test results

Power up the OK3568-C development board and the serial terminal will enter the uboot screen selection interface by holding down the space bar. The phenomenon of flashing default factory image files: by default, HDMI, MIPI, and LVDS three outputs are enabled.

Phenomenon after flashing upgrade package image file: Only HDMI display is enabled, and the other two outputs are closed.

5. Safety instructions

When creating the update.img firmware, remember you can choose to include all partitions or just specific ones. Modify the package-file to remove unnecessary partitions, reducing the update.img size.

If ''recovery.img'' is included in the ''package-file,'' it won't be upgraded in Recovery mode. To prevent issues where power loss during recovery.img upgrading could disrupt the upgrade of other partitions, it's recommended to upgrade this partition under normal system mode. When executing the update command, the system will first check if ''recovery.img'' is included in the update.img package. If so, it will upgrade the recovery partition before entering Recovery mode to upgrade other partition firmware.

It's not recommended to include the ''misc'' partition in the update.img. Even if it's included, the upgrade program will ignore it when detected. Even if the ''misc'' partition is upgraded, the recovery program will still clear all commands and parameters in the ''misc'' partition after a successful upgrade, which may not yield the expected results.

If the update.img package is placed in the ''userdata'' partition in flash memory, ensure that ''userdata.img'' is not included in the package-file. This is because it may lead to file system damage, potentially causing the OEM or user data partition to fail to mount successfully after the upgrade. If upgrading from an SD card or USB disk, you can pack user data. img to upgrade the user data partition. After the upgrade is completed, the user data partition will be re-sized.

With that, the entire process of OTA upgrades has been explained. Users can follow the instructions in this article for experimentation. Once they are familiar with the operations described in this article, they can modify U-Boot, the kernel, or the file system to remotely upgrade their products via OTA. This enables them to fix bugs in their products, making it more convenient to optimize and iterate on their products.

Originally published at www.forlinx.net.

0 notes

Text

Ibm E74 Monitor Driver For Mac

Ibm Drivers free download - CopyTrans Drivers Installer, Adaptec ASPI Drivers, IBM SPSS Statistics, and many more programs.

Ibm E74 Monitor Driver For Mac Computers

Ibm E74 Monitor Driver Download

Ibm E74 Monitor Driver For Mac

Ibm E74 Monitor Driver For Mac Os

Dock your USB 3.0 equipped Mac or Windows laptop with support for several dual monitor configurations using the included video adapters. Connect and charge your USB devices with 5x USB 3.0 ports, including two Fast-Charge USB ports. Save space on your desktop by placing the dock in a vertical orientation with the included dock stand.

IBM E54 - CRT monitor - 15' overview and full product specs on CNET.

Description

Solid-Performing Server Subsystems

These uniprocessor, entry servers deliver solid, economical performanceby coupling Pentium III or Celeron processors with high-speed, ECC memoryand either ATA-100 EIDE or Ultra160 storage subsystems.

The xSeries 200 uses the VIA Core chipsets (VT82C694T and VT82C686B) tooptimize throughput from processors to memory, and to the 32-bit PCI bus.

Ibm E74 Monitor Driver For Mac Computers

Standard xSeries 200 Configurations

Additional features include:

System board — Supports high-speed 128 MB, 256 MB, and 512 MB 133 MHzSDRAM ECC unbuffered DIMMs

33 MHz PCI bus — Streams data between processor, or memory, and the I/Osubsystems

Models with a 32-bit, Ultra160 (LVD) SCSI PCI Adapter (Adaptec29160lp) — Supports high-speed (160 MB/s) internal storage solutions

Full-duplex, 10/100 Mbps Ethernet PCI controller — Speeds networkcommunications to LAN clients

Processor upgrade capability — Slower clocked processors can beupgraded to:

1 GHz Pentium III upgrade (32P0650)

1.13 GHz Pentium III upgrade (32P0651)

1.26 GHz Pentium III upgrade (32P0652)

330-watt worldwide, voltage-sensing power supply with auto restart —Supports maximum configurations and minimizes operator intervention aftera temporary power outage

Three full-speed fans (Pentium models), or two full-speed fans (Celeronmodels) plus one variable fan in the power supply cools:

Up to 1.5 GB system memory

Mixing memory sizes

Five full-length adapter card slots — Support multiple adapters fornetwork or data storage

Seven drive bays supporting up to 293.6 GB of internal disk storage:

Dual integrated ATA-100 EIDE controllers — Supporting up to twoadditional EIDE devices

20.4 GB ATA-100 EIDE HDD (100 MB/s maximum date transfer)

SCSI models include:

Wake on LAN — Used for legacy LAN adapters to remotely turn the serveron from an off state

Wake on LAN and Alert on LAN — Supported on the integrated Ethernetcontroller

Alert on LAN — Supports legacy LAN adapters with this function

PCI slot for Alert on LAN2 — Supports LAN adapters with this capability

Flash EPROM write protection

Gated RESET — Used for power management

SMBus Isolation — Isolates one bus section and required systemcomponents during system power-down from other buses and components toprevent current leakage into devices without power

PXE support

SM BIOS

MAC Address on PC Box

LANClient Control Manager™ (LCCM)

The xSeries 200 also features IBM Director, a powerful, highlyintegrated, systems management software solution built on industrystandards and designed for ease of use. Now you can exploit yourexisting enterprise or workgroup management environments and use theInternet to securely access and manage physically dispersed IT assetsmore efficiently. It can help reduce costs through:

This gives the IT administrator comprehensive, virtual on-site control ofxSeries servers through the ability to remotely:

Inventory and display detailed system and component information

Reset or power cycle the server

Monitor thresholds on server health including:

Fans

Power supplies

PFA on HDDs

Define automated actions such as:

Memory

Processor

HDDs

Identify potential performance bottlenecks and react to prevent downtime

Monitor, manage, and configure RAID subsystems without taking themoffline

IBM Director provides integration into leading workgroup and enterprisesystems management environments, via Upward Integration Modules. Thisenables the advanced management capabilities built into xSeries serversto be accessed from:

Ibm E74 Monitor Driver Download

The xSeries 200 comes with a number of tools and programs designed tomake ownership a positive experience. From the start, IBM has programsto help you purchase, get your server running, and keep it running overthe long haul. And, IBM can help your company maintain ownership oftechnology leadership servers.

IBM Server Start Up Support provides additional installation assistanceduring the first 90 days from the start of your warranty period on selectdevices, adapters, and network operating systems from IBM and non-IBMvendors.

The ServerProven™,6 program lets you confidently configure yourserver with various devices and operating systems. This Web-basedprogram provides compatibility information from actual testing of thexSeries 200 with various adapters and devices.

The ServerGuide CD library includes online publications, utilities, anddrivers that assist you in loading of popular network operating systems.

Electronic support on the Web provides additional support in aneasy-to-use format.

Available in over 100 countries, TechConnect is the information resourcefor xSeries servers. TechConnect focuses on assisting highly skilledprofessionals who are supporting xSeries servers by providing them withthe information they need about products and technologies. TechConnectmembers have access to spec sheets, white papers, red books,configurators, performance information, and more. IBM certification is also available to those requiring formal industrycredentials validating their server skills. For additional details or tojoin today, visit:

http://www.ibm.com/pc/techconnect

Category: Printer Manufacturer: brother industries ltd Caution Level: Safe Download File Size: 0.98Mb Operating System: win xp Latest Version / Release Date: Version 1.07 / 26 Aug 2008

Windows device driver information for Brother HL-2140 series

This model is a compact laser printer that has high quality output and has consistent performance. Brother HL-2140 has a printing speed of 23ppm with 2400 x 600 resolution and 10,000 pages maximum monthly duty series giving the user high quality result and high image quality. The Brother HL-2140 holds 250 sheets of paper in its tray and has manual bypass slot for trouble-free supply on connectivity thru USB connection. This machine can be utilized on both windows platform and Mac Operating system; this is very convenient for users who have small office on their home. This is handier than a regular InkJet printer. InkJets only gives average quality in terms of image resolution, speed and paper handling. The Brother Company is the second most popular brand of laser printer in the market today. Consumers and users will get the best performance, quality and warranty.

Outdated Drivers?

Unless you update your drivers regularly you may face hardware performance issues. Johnson 150 1996 repair manual.

Ibm E74 Monitor Driver For Mac

To check your drivers you should manually verify every device on your system for driver updates

Ibm E74 Monitor Driver For Mac Os

The Brother HL-2140 series Software installation is very handy; loading its appropriate driver will automatically identify the USB connection without any intervention. The software will provide a status monitor for the machine this includes compound pages per sheet, watermarks and poster printing. There will be no duplexer fitted on the Brother HL-2140 series, except that in the Internet there is always an additional software help in terms on reproducing a double-sided image on manual default. The machine will need minimum requirements in installing the printer, on windows XP it will need Pentium processor that has the speed of 300MHz, 128MB to 256MB RAM memory and 50MB disk space. On Mac Operating system, all models meet the system requirements but still it will need 160MB RAM memory and 80MB disk space. It is highly recommended you run a free registry scan for Windows and Brother HL-2140 series errors before installing any driver updates.

0 notes

Text

MSI MS-CF17: 3.5 inch Fanless SBC With Raptor Lake-P CPUs

MSI MS-CF17

3.5″ SBC for Fanless, Ultra Low-Power, High-Performance, and Wide Temperature Solution with Intel Raptor Lake-P

MSI introduced the MS-CF17 a Strong 3.5″ single-board computer (SBC) designed for a variety of industrial applications. Operating systems like as digital signage, edge computing, industrial automation, and transportation systems can all benefit from the MS-CF17’s Intel 13th Gen Raptor Lake-P processors.

With fanless operation and a broad temperature range (-40°C to 70°C), the MS-CF17 is built to perform well in challenging conditions. For applications like industrial automation or outdoor digital signage installations, where dependability and performance are essential, this makes it ideal. Suitable for graphics-intensive activities like AI-driven analytics and advanced imaging systems, the board has an integrated Intel Iris Xe graphics engine and supports up to 32GB of DDR5 memory.

Four 2.5G LAN ports, four HDMI connectors (enabling quadruple separate displays), M.2 M key PCIe Gen4 for storage, and M.2 B/E key slots for expansions provide an abundance of connectivity options that enable a smooth integration into complicated systems. Since it can accommodate many displays and provide real-time analytics, the MS-CF17 is a preferred option for applications that demand fast data processing. For applications where data protection is critical, the onboard TPM 2.0 also offers improved security.

For edge computing, digital signage, and industrial automation applications, the MS-CF17 is a great option because of these qualities.

Industrial Automation: Its sturdy construction, wide temperature support, and many I/O options enable factory machine control, system monitoring, and process automation.

Edge Computing: Smart grids, surveillance systems, and Internet of Things applications use edge computing to process data and make real-time decisions. It possesses strong processing capabilities and fast connectivity.

Digital signage: In public areas, shopping centers, and transit hubs, dynamic and aesthetically appealing content can be displayed because to its support for quadruple independent displays.

Transportation Systems: Because of its small size and sturdy construction, the MS-CF17 is perfect for use in control systems, in-car computers, and passenger information systems in the transportation industry.

AI and Imaging Systems: The MS-CF17 is a prime choice for AI-driven analytics, medical imaging, and other graphics-intensive applications due to its integrated powerful Intel Iris Xe graphics and support for sophisticated memory configurations.

Businesses seeking to deploy dependable, high-performance computing solutions in demanding situations will find the MSI MS-CF17 to be an indispensable tool due to its capabilities and application areas.

MS-CF17 Features

Intel Raptor Lake-P Embedded/Industrial SKU Series, 13th Generation

Up to 32GB of DDR5 5200 MHz SODIMM space

Four independent monitors (one LVDS/eDP and one HDMI)

Four RJ-45 2.5GbE LAN ports

One M.2 E key and one M.2 B key (with NANO SIM-holder).

Storage: 1 SATA 3.0 and 1 M.2 M key

4 COM (4 RS-485), 4 USB 2.0, 4 USB 3.2 Gen 2, DIO, and Audio

TPM 2.0 on board

DC-IN 12–24V Wide Voltage (OCP & OVP)

Wide temperature range of operation supported

FAQs

What are the benefits of the MS-CF17’s fanless design and wide temperature range?

Its fanless design makes it perfect for demanding industrial environments since it guarantees silent operation and removes the possibility of fan failure. Operation in harsh conditions is made possible by the wide temperature range (-40°C to 70°C), which guarantees dependability and performance.

How does the MS-CF17 benefit AI and imaging applications?

The MS-CF17 can manage the rigorous processing demands of AI algorithms and high-resolution imagery thanks to its potent Intel Iris Xe graphics engine and compatibility for up to 32GB of DDR5 memory.

What is the role of the MS-CF17’s connectivity options in high-speed data processing?

● With its four 2.5G LAN connections, the board enables quick and effective data transfer across networks. ● For applications like edge computing and industrial automation, real-time data processing and analysis are made possible by this high-speed communication. ● The MS-CF17 also has four HDMI connections, which enable the use of four independent screens. It is perfect for applications that need to monitor several data streams at once or require complicated visualizations due to its multi-display functionality.

Read more on Govindhtech.com

#MSI#MSIMSCF17#MSCF17#SBC#singleboardcomputer#IntelRaptorLakeP#govindhtech#news#technology#technologies#TechNews#technologynews#technologytrends

1 note

·

View note

Text

Tianma Square Touch Panels and Controller Board Solutions

For industrial environments requiring uniform visual layouts or compact square displays, Tianma’s square LCD display modules offer a specialized solution. Commonly deployed in equipment dashboards, control panels, or GUI-based instrumentation, their square display format provides consistent UX alongside modern touch features.

Tianma square display modules are available with touch panel overlays—transforming a standard industrial screen into a multitouch industrial touch monitor. These modules are paired with robust controller boards that deliver LVDS or HDMI/parallel input, handling signal timing, backlight control, and touch-sensor input decoding.

The LCD modules from Tianma offer high contrast, extended temperature tolerance, and LED backlights adaptable for outdoor and industrial lighting environments. Many of these industrial touch panels carry IP-rated front glances, enabling reliable use in wet or dusty areas.

If you’re building systems with square-format layout standards—medical test systems, lab diagnostics, or embedded control panels—Tianma’s square touch display modules can provide consistent branding and front-end aesthetics while still offering rugged performance.

These controller boards are fully documented and customizable. OEMs can reprogram backlight behavior, mount optional glove-compatible capacitive sensors, or adjust frame buffering. The result is an industrial digital LCD display tailored precisely to both operational and human interface demands.

In summary, Tianma square LCD modules married with programmable controller boards offer a modular, touchscreen-ready solution for industrial equipment needing square-format screens. These industrial touch LCD displays are ideal for standardized layouts, embedded control panels, or space-efficient GUI dashboards—combining ruggedness, touch usability, and design flexibility in an industrial-grade visual package.

For more LCD display information,click HERE.

#lcd touch#display lcd screen#lvds#lcd screen module#3.5 inch tft lcd#panel touch#5 inch touch screen#display control board#7 inch tft display#7 inch tft#lcd display 7 inch#lcd board#industrial screen#ips lcd display#3.5 inch display#lcd screens replacement#custom screen

0 notes