#machinetools

Explore tagged Tumblr posts

Text

three TOS Boring Machines Available: TOS 63A and TOS WH 63 , TOS WHN 11

Precision-engineered for high-performance boring operations, this machine ensures accuracy and efficiency in every task. Perfect for demanding metalworking projects.

Mudar-M Metalworking Machine Tools Trading offering metalworking machinery from leading manufacturers in Europe, Taiwan, Japan, and China.

Contact Us or Visit our website today.

Email: [email protected] or [email protected]

WhatsApp: +359878840661 or +359878840660

Website: www.mudar-m.com

#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial#TOS#UsedMachines

1 note

·

View note

Text

⚙️ Milling Machine Market to Hit USD 18.88 Billion by 2032 – Powered by Versatility in Metal Cutting 🛠️

📊 The global milling machine market was valued at USD 13.22 billion in 2018 and is projected to reach USD 18.88 billion by 2032, growing at a CAGR of 2.4% during the forecast period.

🌍 Europe led the global market in 2018, accounting for 30.03% share, owing to its robust manufacturing infrastructure and widespread adoption of precision engineering solutions.

🔧 Milling machines are vital tools used across industries for metal-cutting and shaping, offering high versatility in operations such as:

Drilling

Chamfering

Slot Cutting

Turning

Fillet Making

These machines are extensively adopted in automotive, precision engineering, and general machinery sectors due to their high-performance standards and multifunctionality.

🧩 By Type:

Vertical Mills

Horizontal Mills

Others

🏭 By Application:

Automotive

General Machinery

Precision Engineering

Transport Machinery

Others

🏢 Top Milling Machine Manufacturers:

DATRON Dynamics, Inc. (USA)

Haas Automation, Inc. (USA)

YAMAZAKI MAZAK CORPORATION (Japan)

Amera-Seiki (USA)

FANUC CORPORATION (Japan)

ANDERSON EUROPE GMBH (Germany)

Hurco Companies, Inc. (USA)

Okuma Corporation (Japan)

KNUTH Werkzeugmaschinen GmbH (Germany)

EMCO Group (Austria)

📌 Key Industry Developments:

🏫 UNHInnovation installed a Datron milling machine at its student-run ECenter (Durham, NH), enabling prototyping of wood, metal, foam & acrylic—empowering student innovation.

🏭 Baker Industries installed an EcoMill 5-axis machine by EMCO Group to manufacture large-scale frames and lay-up tools—boosting aerospace & automotive production capabilities.

🔍 With the ongoing demand for precision machining, prototyping, and industrial automation, the global milling machine market is anticipated to sustain steady growth, supported by R&D, educational institutions, and strategic mergers.

🔗 Full Report Access: 👉https://www.fortunebusinessinsights.com/milling-machine-market-102582

#MillingMachines#MetalCutting#PrecisionEngineering#VerticalMill#HorizontalMill#CNCMachines#ManufacturingTechnology#IndustrialMachinery#MachineTools#CAGR2032#Datron#EMCO#Okuma#FANUC#EuropeManufacturing

0 notes

Text

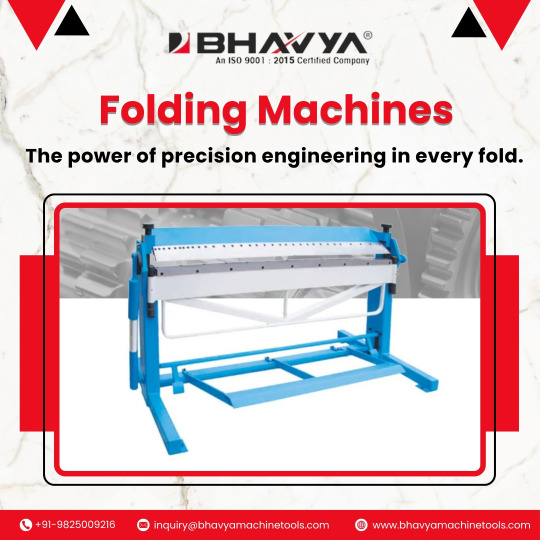

Looking for precision and performance in your sheet metal folding process? Look no further than Bhavya Machine Tools’ Folding Machines. Our machines come with quick-release systems, counterbalance beams, and optional back gauge compatibility to ensure flawless results every time. Visit for more: https://www.bhavyamachinetools.com/products/folding-machine

#BhavyaMachineTools#FoldingMachines#PrecisionEngineering#SheetMetal#Manufacturing#MachineTools#Metalworking

0 notes

Text

Revolving Center for CNC Machine: Vishal Machine Tools

Discover high-quality Revolving Centers for CNC machines at Vishal Machine Tools. Designed for precision and durability, our revolving centers ensure smooth operations and high accuracy in machining tasks. Trusted by professionals across industries for performance and reliability. Explore our range today to enhance your CNC machine's productivity and lifespan.

0 notes

Text

JB Rock Bolt is a manufacturers, suppliers & exporters of Rock Bolts, Self Drilling Anchor Bolt part like hollow bar & rod, threaded rods & thread bars, tie rods, coil rods, SDA Bars etc.

Visit Here:-

#rockbolt#JB#selfdrilling#anchorbolts#hollowbar#rod#threadedrods#threadedbars#tierods#coilrods#SDABars#Bridge#tunnel#construction#pumps#machinetools#engineering#constructionindustry#HimachalPradesh#rebarcouplers#bridgeconstruction

0 notes

Text

13mmJT6 Sanou Drill Chuck

0 notes

Text

Dynemech Anti-Vibration Technology Screw Support DLC Series Mounts

Designed especially to Reduce Vibration and Improve Machine Stability, Dynemech Anti-Vibration Technology DLC series mounts You only need to fix the Mount under the Machine using the given screw. Not essential to bolt the machine to the floor.

Dynemech Anti-Vibration Technology DLC Series It absorbs Low-Frequency Vibrations, so allowing your Machine to run more precisely. Easy levelling made possible by DLC Series Mounts defines both long-term performance and machine accuracy. DLC Mounts help minimize damage caused by continuous vibration regardless of the type of machine—plastic injection molding, die casting, or printing unit. They extend machine life, consistent output, and reduced maintenance needs.

Control of Vibration Using Dynemech Anti-Vibration Technology

One reliable brand among Vibration Control Solutions is Dynemech Anti-Vibration Technology. Our main goal is to let companies maximize machine performance by means of Vibration Reduction, Stability, and simplicity of use.

Dynemech’s Anti-Vibration products come in a variety of forms; among our most sold lines is the DLC Series. Since we know the several needs of different machines, we offer consistent, reasonable, tested in-real-world solutions.

Dynemech Anti-Vibration Technology indicates that you are selecting a company with Controlling Vibration as main emphasis. We want to level your operations and increase machine health.

Basic and robust screw supports for mountings

The Dynemech Anti-Vibration Technology Essential DLC Series consists in Screw Support Mounts. Installable these Mounts allow great simplicity. You basically run them under the machine. They absorb shocks and vibrations running and maintain a level and steady machine.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #ScrewSupportMounts, #VibrationControl, #AntiVibration, #MachineMounts, #IndustrialEquipment, #ToolRoomMachines, #InjectionMouldingMachines, #DieCastingMachines, #VibrationIsolation, #MachineryStability, #EngineeringSolutions, #Manufacturing, #VibrationDampers, #DynemechVibrationTechnology, #VibrationMounts, #MachineTools, #IndustrialMachinery

Contact Us: +91-9810760131 Email: [email protected] Explore Our Solutions: vibrationmountsindia.com

#Dynemech#ScrewSupportMounts#VibrationControl#AntiVibration#MachineMounts#IndustrialEquipment#ToolRoomMachines#InjectionMouldingMachines#DieCastingMachines#VibrationIsolation#MachineryStability#EngineeringSolutions#Manufacturing#VibrationDampers#DynemechVibrationTechnology#VibrationMounts#MachineTools#IndustrialMachinery

0 notes

Text

Used Alpine Tube Bender – Illustrated Breakdown

Shareable infographic showing Alpine Tube Bender benefits and manual references.

0 notes

Video

youtube

Renishaw QC20 W Wireless Ballbar - A powerful tool for machine tool performance diagnosis

0 notes

Text

Flat Bed CNC Lathe Machines: Precision Engineering for Complex Parts

Flat Bed CNC Lathe Machines are designed for high-precision machining of complex parts. Their rigid structure and advanced CNC technology enable accurate turning, drilling, and threading operations. Ideal for industries requiring detailed and intricate components, these machines offer enhanced productivity and consistent quality in manufacturing processes.

#FlatBedCNC#CNCExpand#LatheMachine#CNCPrecision#ManufacturingAutomation#CNCEngineering#MachineTools#CNCpractices#MillingTechnology#PrecisionMachining#CNCWorkers#LatheDies#CNCOptimization#FlatBedMachining#CNCInnovation#MachiningSolutions#ManufacturingExcellence#CNCManufacturing#CNCWorkshop#TechInManufacturing

0 notes

Text

Unlocking the Power and Precision of Machine Tool Fabrication Equipment

Explore Accurpress India’s advanced solutions in press brakes, turret punch presses, shears, and automation systems. Designed for unmatched accuracy, strength, and productivity—trusted by global manufacturers like GM, Ford, and Boeing.

🔧 Servo-electric & hydraulic press brakes 🔩 CNC-controlled shearing systems 🛠️ High-precision turret punch press 🤖 Robotic automation for bending & punching

🔗 https://accurpress.in/ 📧 [email protected] | [email protected]

#Accurpress#MachineTools#PressBrakes#PunchPress#ShearPower#AutomationSolutions#MetalFabrication#CNCmachines#IndustrialMachinery#MadeInIndia#ManufacturingExcellence#PrecisionEngineering

0 notes

Text

Mudar-M Metal Working Machinery: Bulgarian Excellence That Lasts Generations

At Mudar-M Metal Working Machinery, we're proud to offer Bulgarian metalworking machines renowned globally for their exceptional durability and reliability. These aren't just machines they're an investment in continuous production and a legacy to pass down through generations.

From the workshops of the United States to the factories of Africa, celebrated for their unwavering performance and longevity. As Bulgaria's second-largest reseller of pre-owned machinery,

While machines from China, Japan, Taiwan, and other European countries have their merits, Bulgarian metalworking machines consistently set the gold standard for robustness and a never-quit attitude.

Interested in acquiring a machine that delivers relentless production?

Contact us directly or reach out to one of our regional partners.

Mudar-M Metal Working Machinery

* WhatsApp: +359878840660, +359878840661

* Email: [email protected]

* Website: www.mudar-m.com

#Metalworking #Lathe #MachineTools #CNC #Manufacturing #Engineering #Metalwork #Machinery #IndustrialEquipment #Durability #QualityMachines

#metalworking#lathe#machinery#machinetools#manufacturing#engineering#forsale#metalwork#milling#industrial

1 note

·

View note

Text

⚙️🤖 CNC Machine Market Outlook: 2024–2032 🛠️✨

📊 The global CNC (computer numerical control) machine market was valued at USD 95.29 billion in 2024 and is projected to grow from USD 101.22 billion in 2025 to USD 195.59 billion by 2032, showcasing a strong CAGR of 9.9% during the forecast period.

🌏 Asia Pacific dominates the global CNC market with a 55.32% share in 2024, driven by advanced manufacturing capabilities and rising industrial automation.

🇺🇸 In the U.S., the CNC machine tools market is expected to grow significantly, reaching an estimated USD 15.03 billion by 2032, fueled by rapid technological advancements in the manufacturing sector.

💡 From precision machining to smart factories, CNC machines are powering the future of modern manufacturing.

🔗 https://www.fortunebusinessinsights.com/industry-reports/computer-numerical-controls-cnc-machine-tools-market-101707

#CNCmachines#IndustrialAutomation#SmartManufacturing#PrecisionEngineering#MachineTools#AsiaPacific#USMarket#Industry40#ManufacturingTrends#TumblrIndustry

0 notes

Text

Bhavya Machine Tools is thrilled to be part of the 10th India Machine Tools Show at Yashobhoomi Convention Centre, Dwarka, New Delhi!

We’re showcasing our advanced and efficient range of industrial machinery at Hall No. 2, Stall No. P-2 from 11th to 14th July 2025 – and the energy here is incredible!

Visit - https://www.bhavyamachinetools.com

#BhavyaMachineTools#MachineTools#Exhibition#MachinetoolsExhibition#IndiaMachineTools#Delhi#Exhibition2025

0 notes

Text

#SW#aerospace#SWIndia#Manufacturing#MachineTools#GermanEngineering#IndiaExpansion#electronicsnews#technologynews

0 notes

Text

Dynemech Series DR – Precision Anti-Vibration Mounts for Tapped-Base Machinery

The Dynemech Anti-Vibration Technology Series DR is a collection of high-quality Anti-Vibration Damping Blocks designed for use with tapless hole machine bases. One example of the Dynemech Machinery Raiser Damping Blocks Series DR is a product that exemplifies the highest level of developed Vibration Isolation and Levelling Technology for industrial equipment. Dynemech Machinery Raiser Damping Series DR Damping Blocks are intended exclusively for applications involving tapped hole base machines. These damping blocks offer the ideal combination of improved vibration reduction, accurate load handling, and mechanical stability. Anti-Vibration Technology developed by Dynemech Systems Pvt Ltd, specifically designed for use with tap-based machinery

Machine bases that feature tapped holes for installation are found on a variety of precision machines, such as computer numerical control (CNC) machines, presses, and injection moulding systems. These kinds of combinations are specifically designed to be interfaced with by series DR mounts throughout the design process. It is possible to precisely mill a center depression on the top surface of each damping block to correspond with the diameter of the bolt that is located at the base of the machine. Enhanced axial alignment, less lateral movements, and precise bolt seating are all outcomes that can be achieved with the utilization of this cutting-edge interface. Performance and safety are both improved when dynamic loads are applied to the system. Among the most important functional advantages offered by Dynemech Machinery Raiser Damping Blocks

1. Innovative Vibration Isolation Technology

It is the high-damping elastomeric core that serves as the primary component of the Dynemech Machinery Raiser Damping Blocks Series DR mount. In addition to ensuring that the quality of surface finish is improved, tool wear and tool failure are minimized, machine and component life is increased, measurement and machining accuracy is enhanced, and a wide variety of machine-generated vibrations, both low-frequency and high-frequency, are absorbed by such a specially designed material, it also ensures that the quality of surface finish is improved.

2. Interface for Bolt Resting That Is Highly Secure

Because of the top dimple, which is meticulously created based on the size of the bolt, there is no longer a requirement for external alignment fixtures for the bolt. The following are some of the benefits that this innovation makes possible:

• Secure mounting without the possibility of sliding;

• Installation that is both quick and error-free

• Reduced stress concentration on machine bases. 3. Adjustment of the Height of the Device

The Series DR Mounts come equipped with a straightforward and durable levelling system that enables vertical adjustment in order to:

Ensure that the machine is aligned in the most effective manner Reduce the amount of grouting that is required for the foundation, make adjustments to accommodate uneven flooring, and make it simpler to move or rearrange machinery with less effort. The distribution of loads and the protection of the floor The structure not only provides long-term stability under high static or dynamic loads, but it also decreases point loading on floors and protects against floor surfaces breaking or stress damage. Also, the structure provides protection against stress damage. Applications across a Wide Range of Different Industrial Constituencies

Equipment Related to Dynemech Raiser Damping Blocks Series DR Damping Blocks have applications in a wide variety of machinery and industries, including but not limited to: CNC centers for turning, milling, grinding, and EDM; injection and blow moulding machines; hydraulic, pneumatic, and mechanical presses; spinning and textile machinery; laser cutting and sheet metal machinery; packaging, labelling, and automation systems; printing equipment and high-speed rotating equipment for printing operations There are benefits to both operations and business.

The machine's productivity and accuracy are increased, the maintenance downtime caused by vibration is reduced, the noise emission in the manufacturing area is reduced, the operator's comfort and security are increased, the machine is fully portable without the need for anchoring, and the return on investment is increased quickly due to its lifespan and reliability. It Is Possible to Customize the Technical Specifications of Dynemech Machinery Raiser Damping Blocks

Dynemech Systems Pvt. Ltd is able to modify the dimple diameter, mounting dimensions, and load of the Series DR blocks in accordance with the particular requirements of your equipment and the state of your floor. It is feasible to find specific solutions for high-tonnage and specialized vibration circumstances. Some examples of these solutions include shock and impact dampening. Using Dynemech's Anti-Vibration Technology: Why Should You Do So?

Due to the fact that Dynemech Systems Pvt. Ltd. has over twenty years of experience in Vibration Isolation and machine installation solutions, it is relied upon by some of the most prestigious manufacturers in the world.

Because Dynemech Systems Pvt Ltd is dedicated to innovation, quality, and performance, the Dynemech Machinery Raiser Damping Blocks Series DR range is a demonstration of this commitment. As a result, your machines will always be operating at their highest level of efficiency.

Dynemech Anti-Vibration Technology has produced the most extensive selection of Anti-Vibration Pads, silent blocks, shock, and noise control products available on the market and has developed them.

In addition to that, we are also involved in the production of a wide range of Anti-Vibration Pads, equipment mounts, spring mounts, and anti-vibration controlling pads.

Dynemech Anti-Vibration Technology is responsible for the production of Anti-Vibration Pads as of the highest quality.

The Dynemech Anti-Vibration Technology Anti Vibration Pad is the best possible solution to this challenge. Combining exceptional rubber polymers with cork results in the production of a product that is superior in terms of its resistance to age, compression set, water, and oil respectively.

Anti-Vibration Pads manufactured by Dynemech Systems Pvt Ltd have a wide range of applications, including but not limited to fans, motors, compressors, conveyors, air conditioning plants, diesel generators, commercial machines, power/impact presses, pumps, CNC machines, and refrigeration facilities, to name just a few examples. The elimination of machine vibration is a perfect application for our quiet blocks.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #SeriesDR, #AntiVibrationMounts, #VibrationIsolation, #MachineLeveling, #DampingBlocks, #IndustrialMounts, #MachinerySupports, #CNCStability, #InjectionMolding, #Metalworking, #PrecisionMachining, #PressMachineSupport, #ManufacturingEquipment, #MechanicalEngineering, #IndustrialAutomation, #MachineTools, #EngineeringSolutions, #VibrationControl

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#Dynemech#SeriesDR#AntiVibrationMounts#VibrationIsolation#MachineLeveling#DampingBlocks#IndustrialMounts#MachinerySupports#CNCStability#InjectionMolding#Metalworking#PrecisionMachining#PressMachineSupport#ManufacturingEquipment#MechanicalEngineering#IndustrialAutomation#MachineTools#EngineeringSolutions#VibrationControl

0 notes