#processcontroller

Explore tagged Tumblr posts

Text

Say Goodbye to Temperature Fluctuations in Industrial Processes!

🔥 Struggling with temperature control in your industrial setup? A small fluctuation can make a big impact on efficiency! Our Process and Temperature Controllers take the guesswork out of automation with smart PID microprocessor-based control.

📊 With dual LCD screens, you can easily monitor real-time temperature and process values. Plus, thanks to Fuzzy Logic technology, these controllers quickly stabilize temperatures, even after power disruptions.

💡 No more overshoots. No more inefficiencies. Just precise and reliable control for manufacturing and automation. Looking for a stable, efficient solution? 🚀 Upgrade your process control system today!

#IndustrialAutomation#ProcessControl#ManufacturingSolutions#SmartTech#EfficiencyMatters#IndustrialSolutions#AutomationSolutions#MechanicalSolutions#ElectricalSolutions#FastCal#PLC#SCADA#ControlPanelDesign#ProcessController#TemperatureController

0 notes

Text

youtube

The Global Vehicle Tracking Systems Market is experiencing significant growth, driven by key factors such as real-time surveillance, energy management integration in automobiles, and the increasing focus on safety and security within transportation services. The rapid adoption of 5G technology, the expansion of the ICT sector, and the rise of mobility-as-a-service (MaaS) are also fueling the demand for vehicle tracking systems.

#Vehicletrackingsystem#vehicletracking#vehiclechecking#vehicletransformation#processcontrol#automation#SemiconductorMarket#powerelectronics#semiconductorindustry#techtrends#energyefficiency#powertech#SemiconductorInnovation#Electronicsmarket#PowerSemiconductorTrends#marketresearchreport#marketresearch#acumenresearchandconsulting#marketresearchcompany#news#Youtube

1 note

·

View note

Text

How Omnex System’s Control Plan Software Elevates Quality Management in Manufacturing

In a world where product quality and process efficiency are critical to maintaining customer satisfaction and market competitiveness, the need for robust quality management tools is greater than ever. Control plan software stands at the center of quality assurance strategies, enabling manufacturers to standardize processes, monitor key product characteristics, and ensure regulatory compliance. Omnex System, a global leader in quality and enterprise management solutions, offers a next-generation control plan software that transforms the way businesses manage and improve their quality planning and execution processes.

This blog explores how Omnex System’s control plan software empowers manufacturers to align process controls with design and production strategies, reduce variation, improve audit readiness, and achieve sustainable excellence in quality.

What is Control Plan Software?

Control plan software is a specialized digital solution designed to document, manage, and automate control plans for manufacturing and production processes. A control plan outlines the critical to quality (CTQ) characteristics, measurement techniques, and control methods required to ensure product compliance and consistency throughout production.

Traditionally managed through spreadsheets or static documents, control plans are now being digitized for greater efficiency, traceability, and collaboration. Omnex System’s control plan software takes this digital transformation a step further by integrating with other APQP (Advanced Product Quality Planning) tools such as FMEA (Failure Mode and Effects Analysis), Process Flow Diagrams (PFD), and MSA (Measurement System Analysis) to deliver a holistic, intelligent quality management ecosystem.

Why Omnex System?

With over 35 years of experience in delivering enterprise-wide quality solutions, Omnex System has built a reputation for helping organizations adopt best-in-class quality and compliance practices. Its control plan software is used by leading companies in automotive, aerospace, electronics, medical devices, and other highly regulated industries.

Here’s why Omnex System’s control plan software stands out in a competitive market:

1. APQP-Integrated Environment

Omnex’s control plan software is part of a tightly integrated APQP suite that connects control plans with FMEA, process flows, and work instructions. This integration ensures that all risk analyses and control measures are synchronized, making it easier to update plans when processes or product designs change.

For example, if a critical failure mode is added in PFMEA, the software prompts users to reflect this change in the control plan—eliminating manual oversights and maintaining alignment between quality planning documents.

2. Cloud-Based Collaboration

In today’s global manufacturing landscape, teams are often distributed across multiple plants, countries, or suppliers. Omnex System’s cloud-based control plan software facilitates real-time collaboration, allowing stakeholders to access, update, and approve control plans from anywhere in the world.

This capability reduces communication delays, ensures that everyone is working on the latest version, and enables centralized quality oversight across distributed facilities.

3. Built-in Version Control and Audit Trails

Every change made to a control plan is automatically tracked with user ID, timestamp, and detailed revision history. This audit trail functionality is critical for demonstrating compliance with international quality standards such as ISO 9001, IATF 16949, AS9100, and FDA regulations.

With Omnex System, quality managers can quickly retrieve past versions of control plans, identify who made specific changes, and ensure complete transparency during internal or customer audits.

4. Templates and Customization

Omnex System’s control plan software includes industry-specific templates that allow users to jumpstart their planning process. Whether you're producing electronic components, automotive parts, or medical devices, the software provides the right starting structure while still allowing full customization to fit your organization’s unique process requirements.

5. Real-Time Data Insights

The software integrates seamlessly with real-time shop floor data, enabling dynamic updates and alerts when control parameters drift out of tolerance. This early warning capability empowers teams to take corrective action quickly—minimizing scrap, rework, and downtime.

Key Benefits of Omnex System’s Control Plan Software

✅ Improved Product Quality

By clearly defining process controls and aligning them with risk analysis, Omnex’s software ensures that critical characteristics are consistently monitored. This reduces the occurrence of defects and drives higher product reliability.

✅ Enhanced Operational Efficiency

Omnex System eliminate the need for manual document handling, reduce duplication of effort, and ensure that all departments—engineering, quality, and production—are aligned on control strategy.

✅ Strengthened Supplier Quality Management

Suppliers can be integrated into the same control plan platform, enabling visibility and consistency in outsourced manufacturing processes. This feature is particularly valuable for automotive and aerospace industries where supply chain quality is critical.

✅ Faster New Product Introductions (NPI)

With synchronized APQP tools, teams can accelerate product launches by ensuring that all risk assessments, process controls, and validation plans are completed in one connected environment.

✅ Scalability across Plants and Products

Whether you have one plant or a hundred, Omnex System’s control plan software is scalable to manage all your quality planning needs across sites, departments, and business units.

Implementation Strategy: How Omnex System Ensures Success

Transitioning from traditional spreadsheets to a modern control plan software solution may seem daunting. That’s why Omnex System offers a full suite of implementation services including:

Needs Assessment: Analyzing current quality planning practices to define a tailored deployment strategy

Software Configuration: Customizing fields, workflows, and templates to fit your processes

Training & Support: Providing comprehensive training for users, engineers, and quality managers

System Integration: Linking the control plan software with existing ERP, MES, or QMS systems for seamless data flow

Ongoing Updates & Enhancements: Continuous software improvement based on industry trends and customer feedback

Omnex’s implementation approach ensures fast adoption, minimal disruption, and long-term value for your organization.

Use Case: Automotive Manufacturer Reduces Defects by 40%

One of Omnex System’s Tier 1 automotive clients implemented the control plan software across five global locations. By integrating control plans with PFMEA and linking to real-time SPC data, they achieved:

40% reduction in production defects

30% faster time-to-market for new product launches

60% decrease in audit non-conformities

Real-time global visibility across plants

This example showcases the transformational power of digitizing control plan management using Omnex System.

Conclusion

In an increasingly competitive and regulated manufacturing environment, robust quality planning is not a luxury—it’s a necessity. Control plan software from Omnex System provides manufacturers with a powerful, integrated platform to standardize quality controls, reduce process variation, and drive continuous improvement.

Whether you're navigating industry standards like IATF 16949 or aiming to improve internal efficiency and product reliability, Omnex’s control plan software is a strategic investment that delivers measurable ROI.

For more info Contact Us : 1-800-360-1407 or send mail : [email protected] to get a quote

#ControlPlanSoftware#OmnexSystem#QualityManagement#APQP#FMEA#IATF16949#ManufacturingSoftware#ProcessControl#DigitalQuality#SmartManufacturing#QMS#QualityPlanning#EnterpriseQualityManagement#AutomotiveQuality#AerospaceCompliance#PFMEAIntegration#ComplianceSoftware#ProductionExcellence#ZeroDefectManufacturing#QualityEngineering

0 notes

Text

#DosingSystem#ChemicalDosing#IndustrialAutomation#DosimixTechnologies#WaterTreatment#ProcessControl#MeteringPump#EngineeringSolutions

1 note

·

View note

Text

🔧 HE 2610F Tension Sensor – Precision You Can Rely On!

Ensure safe and accurate load monitoring with our advanced tension sensor designed for ropes, cables, and chains. Ideal for heavy-duty lifting, hoisting, and industrial applications. Built for reliability, performance, and safety – the smart choice for force measurement!

✅ Towing Force & Thrust Measurement ✅ Lifting Equipment Inspection ✅ Line Tension & Process Control ✅ Hydraulic Force Monitoring

🔗 Engineered by Hariom Electronics – Experts in Precision Load Cells.

📞 Contact us today to know more!

#LoadCell#TensionSensor#ForceMeasurement#IndustrialAutomation#LiftingSolutions#LoadPin#HoistingEquipment#HeavyDutyTools#ProcessControl#MechanicalEngineering#SmartSensing#LoadMonitoring#HydraulicSystems#LineTension#HariomElectronics

0 notes

Text

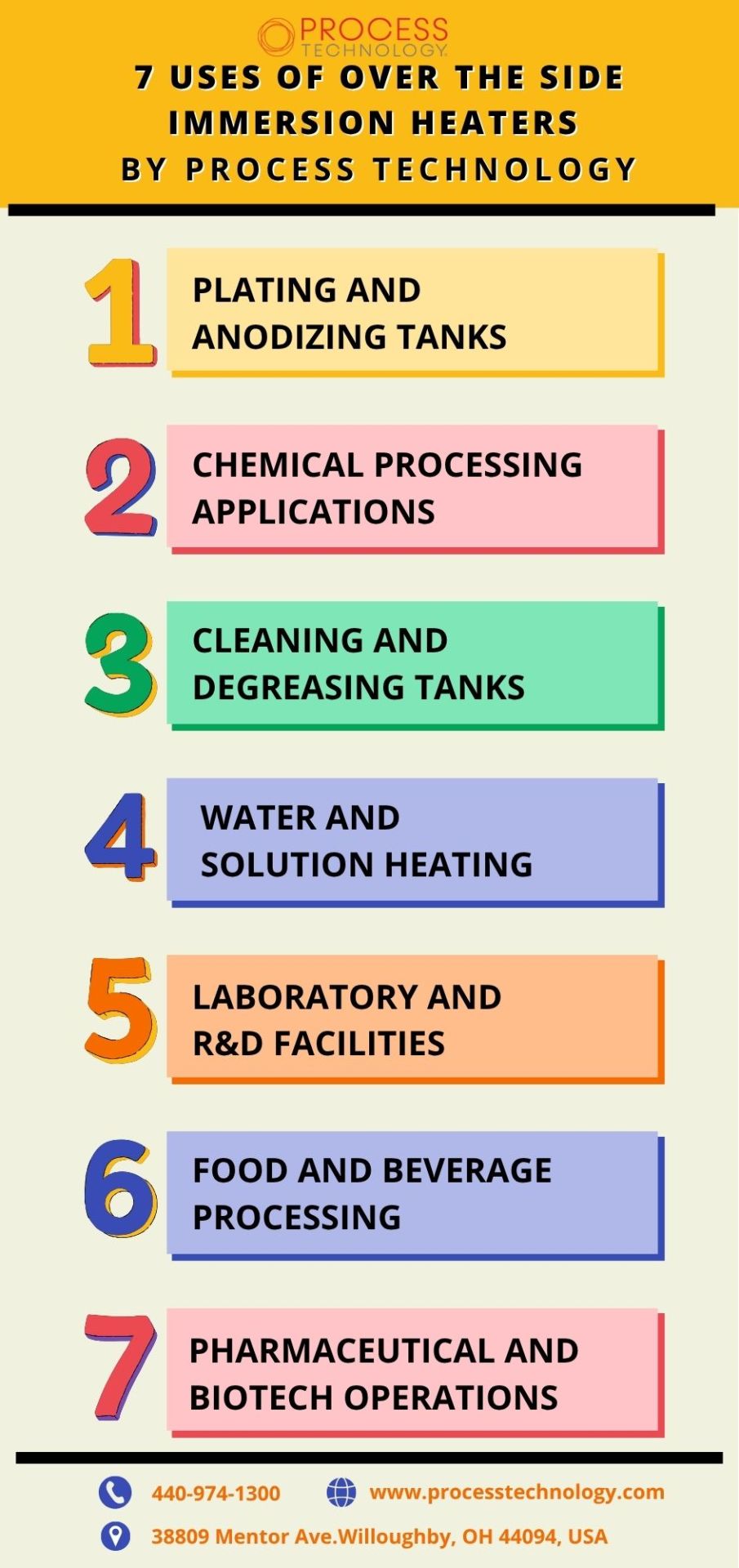

7 Uses of Over the Side Immersion Heaters by Process Technology

Discover high-performance over the side immersion heaters manufactured by the Process Technology which boasts of optimum efficiency and durability. Be it corrosive chemicals or water based solutions our Emmerson heaters are simple to fit, easy to service and designed to last. Learn how your processes may take advantage of the benefits of the advanced heating technology.

For more details Visit: https://www.processtechnology.com/product/electric-immersion-heaters/

#processtechnology#technology#immersionheaters#heaters#electric#OvertheSideImmersionHeaters#ImmersionHeater#Processcontrol#manufacturers#Designing#heatingsolutions

0 notes

Text

Make Engineering Data Work Harder with Smart Plant Instrumentation (SPI)

In industries where precision matters, scattered or outdated instrumentation data can lead to costly errors. That’s where Smart Plant Instrumentation (SPI) services from iPAC Automation step in.

With SPI, you can:

📁 Organize and manage all instrumentation data in one reliable system

🔍 Maintain traceability for every loop, tag, and spec

🛠️ Simplify updates during design changes or expansions

📐 Improve consistency in engineering deliverables

Whether you're handling a new greenfield project or managing changes in a complex brownfield plant, our SPI services help you stay accurate, aligned, and audit-ready.

✅ Experienced engineers ✅ Reliable project support ✅ Transparent documentation

📩 Reach out today through ipacautomation.com and let’s talk about building smarter plant documentation together.

#SmartPlantInstrumentation#InstrumentationEngineering#IndustrialAutomation#EngineeringServices#ProcessControl#iPACAutomation#PlantDesign

0 notes

Text

#SCADA#IndustrialAutomation#ProcessControl#SmartInfrastructure#MarketForecast#CloudIntegration#Cybersecurity#IIoT#SmartManufacturing#EnergyManagement

0 notes

Text

Valves in the cement industry aren’t just components—they’re enablers of efficiency, flow control, and operational safety. Dive into the mechanics behind every successful cement plant.

For more details visit at - https://www.primevalvesindia.com/blogs/valves-for-cement-industry

0 notes

Text

Process Analyzer Market - Industry Dynamics

According to Market Statistix, the Process Analyzer Market revenue and growth prospects are expected to grow at a significant rate during the analysis period of 2024-2032, with 2023 as the base year. Process Analyzer Market research is an ongoing process. Regularly monitor and evaluate market dynamics to stay informed and adapt your strategies accordingly. As a market research and consulting firm, we offer market research reports that focus on major parameters, including Target Market Identification, Customer Needs and Preferences, Thorough Competitor Analysis, Market Size and market Analysis, and other major factors. In the end, we provide meaningful insights and actionable recommendations that inform decision-making and strategy development.

The Process Analyzer Market is projected to experience steady growth, expanding at a CAGR of 5.5% over the forecast period.

Who are the key players operating in the industry?

ANTON PAAR, APPLIED ANALYTICS, MICHELL INSTRUMENTS, AMETEK, KYOTO ELECTRONICS, THERMO FISHER SCIENTIFIC, METTLER-TOLEDO, VEGA GRIESHABER, SARTORIUS, SIEMENS, ENDRESS+HAUSER, HORIBA, SINAR TECHNOLOGY, EMERSON, GOW MAC INSTRUMENTS, LEMIS BALTIC, BERTHOLD TECHNOLOGIES, SUEZ, YOKOGAWA ELECTRIC CORPORATION, SHIMADZU, ABB, SCHMIDT+HAENSCH, JUMO, HACH, OMEGA ENGINEERING

Request a sample on this latest research report Process Analyzer Market spread across 100+ pages and supported with tables and figures is now available @ https://www.marketstatistix.com/sample-report/global-process-analyzer-market

Process Analyzer Market Overview and Insights:

Market Statistix is solidifying its reputation as a leading market research and consulting service provider, delivering data-driven insights that help businesses make informed strategic decisions. By focusing on detailed demand analysis, accurate market forecasts, and competitive evaluations, we equip companies with the essential tools to succeed in an increasingly competitive landscape. This comprehensive Process Analyzer market analysis offers a detailed overview of the current environment and forecasts growth trends through 2032. Our expertise enables clients to stay ahead of the curve, providing actionable insights and competitive intelligence tailored to their industries.

What is included in Process Analyzer market segmentation?

The report has segmented the market into the following categories:

Segment by Type: Rackmount, Standard, Portable

Segment by Application: Mining, Food chemical, Oil and gas, Pharmaceutical, Power generation, Transmission, Beverages

Process Analyzer market is segmented by company, region (country), by Type, and by Application. Players, stakeholders, and other participants in the Process Analyzer market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by Type and by Application in terms of revenue and forecast for the period 2019-2032.

Have a query? Market an enquiry before purchase @ https://www.marketstatistix.com/enquiry-before-buy/global-process-analyzer-market

Competitive Analysis of the market in the report identifies various key manufacturers of the market. We do company profiling for major key players. The research report includes Competitive Positioning, Investment Analysis, BCG Matrix, Heat Map Analysis, and Mergers & Acquisitions. It helps the reader understand the strategies and collaborations that players are targeting to combat competition in the market. The comprehensive report offers a significant microscopic look at the market. The reader can identify the footprints of the manufacturers by knowing about the product portfolio, the global price of manufacturers, and production by producers during the forecast period.

As market research and consulting firm we offer market research report which is focusing on major parameters including Target Market Identification, Customer Needs and Preferences, Thorough Competitor Analysis, Market Size & Market Analysis, and other major factors.

Purchase the latest edition of the Process Analyzer market report now @ https://www.marketstatistix.com/buy-now?format=1&report=88

The Process Analyzer market research study ensures the highest level of accuracy and reliability as we precisely examine the overall industry, covering all the market fundamentals. By leveraging a wide range of primary and secondary sources, we establish a strong foundation for our findings. Industry-standard tools like Porter's Five Forces Analysis, SWOT Analysis, and Price Trend Analysis further enhance the comprehensiveness of our evaluation.

A Comprehensive analysis of consumption, revenue, market share, and growth rate is provided for the following regions:

-The Middle East and Africa region, including countries such as South Africa, Saudi Arabia, UAE, Israel, Egypt, and others.

-North America, comprising the United States, Mexico, and Canada.

-South America, including countries such as Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, and others.

-Europe (including Turkey, Spain, the Netherlands, Denmark, Belgium, Switzerland, Germany, Russia, the UK, Italy, France, and others)

-The Asia-Pacific region includes Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, the Philippines, South Korea, Thailand, India, Indonesia, and Australia.

Browse Executive Summary and Complete Table of Content @ https://www.marketstatistix.com/report/global-process-analyzer-market

Table of Contents for the Process Analyzer Market includes the following points:

Chapter 01 - Process Analyzer Executive Summary

Chapter 02 - Market Overview

Chapter 03 - Key Success Factors

Chapter 04 - Process Analyzer Market – Pricing Analysis Overview

Chapter 05 - Overview of the History of the Process Analyzer Market

Chapter 06 - Process Analyzer Market Segmentation [e.g. Type (Rackmount, Standard, Portable), Application (Mining, Food chemical, Oil and gas, Pharmaceutical, Power generation, Transmission, Beverages)]

Chapter 07 - Analysis of Key and Emerging Countries in the Process Analyzer

Chapter 08 - Process Analyzer Market Structure and Value Analysis

Chapter 09 - Competitive Landscape and Key Challenges in the Process Analyzer Market

Chapter 10 - Assumptions and Abbreviations

Chapter 11 - Market Research Approach for Process Analyzer

About Market Statistix:

Market Statistix is an expert in the area of global market research consulting. With the aid of our ingenious database built by experts, we offer our clients a broad range of tailored Marketing and Business Research Solutions to choose from. We assist our clients in gaining a better understanding of the strengths and weaknesses of various markets, as well as how to capitalize on opportunities. Covering a wide variety of market applications, We are your one-stop solution for anything from data collection to investment advice, covering a wide variety of market scopes from digital goods to the food industry.

Contact Information:

Market Statistix

Media & Marketing Manager

Call: +91 9067 785 685

Email: [email protected] Website: www.marketstatistix.com

#ProcessAnalyzer#IndustrialAutomation#RealTimeMonitoring#ProcessOptimization#AnalyticalInstruments#ChemicalProcessing#OilAndGasTechnology#PharmaManufacturing#QualityControl#RegulatoryCompliance#InlineAnalysis#ProcessControl#SmartManufacturing

0 notes

Text

𝗜𝘀 𝗠𝗲𝘅𝗶𝗰𝗼 𝘁𝗵𝗲 𝗡𝗲𝘅𝘁 𝗕𝗶𝗴 𝗛𝘂𝗯 𝗳𝗼𝗿 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗜𝗻𝘃𝗲𝘀𝘁𝗺𝗲𝗻𝘁𝘀? With industries across Latin America undergoing rapid digital transformation, 𝗠𝗲𝘅𝗶𝗰𝗼 𝗗𝗶𝘀𝘁𝗿𝗶𝗯𝘂𝘁𝗲𝗱 𝗖𝗼𝗻𝘁𝗿𝗼𝗹 𝗦𝘆𝘀𝘁𝗲𝗺 (𝗗𝗖𝗦) 𝗠𝗮𝗿𝗸𝗲𝘁 is emerging as a strategic hotspot for global investors and automation leaders.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗪𝗵𝘆 𝗶𝘁 𝗺𝗮𝘁𝘁𝗲𝗿𝘀: Mexico’s growing manufacturing sector, supported by strong automotive, oil & gas, and chemical industries, is fueling the demand for advanced DCS solutions that improve operational efficiency, safety, and scalability.

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀 : Mitsubishi Electric Corporation, ABB Ltd., Rockwell Automation Inc., Honeywell International Inc., Valmet OYJ, Toshiba Corporation, Schneider Electric SE, General Electrics and others.

𝗞𝗲𝘆 𝗱𝗿𝗶𝘃𝗲𝗿𝘀:

Surge in industrial automation projects

Government incentives for tech adoption

Increasing focus on energy efficiency and smart plant operations

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

𝗢𝗽𝗽𝗼𝗿𝘁𝘂𝗻𝗶𝘁𝘆 𝘀𝗻𝗮𝗽𝘀𝗵𝗼𝘁: Whether you're an investor looking for high-growth industrial tech ventures or a business exploring market expansion—Mexico’s DCS ecosystem is signaling long-term potential.

Now is the time to look beyond the usual markets and explore where the future is quietly unfolding.

#IndustrialAutomation#MexicoMarket#DCS#SmartManufacturing#InvestInMexico#BusinessOpportunity#ProcessControl#DigitalTransformation#AutomationGrowth

0 notes

Text

#SmartSensors#ProcessControl#IndustrialInnovation#pHSensing#IoT#Industry4.0#EnvironmentalCompliance#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

#HDIDigitalGauges#PressureMeasurement#OilAndGas#IndustrialTools#DigitalGauges#PressureGauges#KuwaitIndustry#PiezoresistiveSensors#IndustrialSafety#RealTimeMonitoring#NextOilSolutions#GaugeTechnology#EngineeringTools#PrecisionInstruments#DigitalPressureGauge#OilfieldEquipment#IndustrialInnovation#HDI2000B#ProcessControl#SmartGauges

0 notes

Text

Top Solenoid & Automated Ball Valves from Leading Actuated Valve Manufacturers

Introduction

If you're managing industrial systems, facility automation, or fluid handling operations, automated ball valves are likely already on your radar. Whether you're upgrading your infrastructure or starting a new project, choosing the right solenoid ball valve or pneumatically actuated ball valve can have a significant impact on efficiency, safety, and long-term ROI.

In this guide, we’ll walk you through what makes these valves essential, highlight key features, and explain why working with experienced actuated ball valve manufacturers like DynaQuip gives your business an edge.

What Are Automated Ball Valves?

Automated ball valves are valves that open or close via an electric, pneumatic, or hydraulic actuator—rather than manual operation. They’re widely used in industries like:

Water treatment

Chemical processing

HVAC systems

Food & beverage manufacturing

Agriculture and irrigation systems

These valves provide remote control, fail-safe reliability, and fast response times, which makes them ideal for automated systems and critical infrastructure.

Types of Actuated Ball Valves

Let’s break down the most common types of automated valves businesses are using in 2025:

⚙️ Pneumatically Actuated Ball Valves

These use compressed air to operate and are preferred when speed, durability, and cost-effectiveness are top priorities. Pneumatic valves are especially useful in environments where electrical components could pose safety risks.

🔌 Solenoid Ball Valves

These are electrically actuated using a solenoid coil, offering precise on/off control. Solenoid ball valves are excellent for applications that need frequent cycling, such as water dispensing, chemical dosing, or HVAC systems.

If you’re unsure which fits your application, our experts at DynaQuip can help you assess your system and recommend the best fit.

Why Work with a Trusted Actuated Ball Valve Manufacturer?

Not all valves are built the same. Working with reputable actuated ball valve manufacturers ensures:

Reliable performance under pressure

Longevity and corrosion resistance

Certified compliance with ANSI, ISO, and other standards

Custom configuration options for your industry

As a long-standing industry leader, DynaQuip provides high-quality pneumatic and solenoid valve solutions, backed by decades of engineering expertise.

Choosing the Right Valve for Your Application

When selecting a valve, consider these factors: CriteriaPneumatic ValveSolenoid ValvePower SourceCompressed airElectrical powerIdeal ForHarsh or explosive environmentsClean, controlled indoor environmentsResponse TimeVery fastFast, but may vary by modelMaintenanceLower in rugged setupsModerate; coil life is a factorCostGenerally lower upfrontSlightly higher for advanced controls

Still deciding? This helpful automated valve selection guide can help clarify which setup fits your workflow.

Key Features to Look For

A good automated valve should include:

Full port design for optimal flow

Corrosion-resistant materials like stainless steel or brass

Multiple actuator compatibility (pneumatic, electric, solenoid)

Fail-safe options like spring return

Quick-connect or flange mount options for ease of installation

As mentioned in this detailed valve buyer’s guide, getting the specs right is half the battle when automating fluid systems.

FAQ: Automated & Solenoid Ball Valves

How are solenoid and pneumatic ball valves different?

Solenoid valves use electricity to actuate, while pneumatic valves rely on air pressure. Pneumatics are often faster and better for hazardous environments.

Are pneumatically actuated valves energy efficient?

Yes, especially when air systems are already in place. They offer fast cycling with minimal power draw.

Can I use solenoid valves for corrosive fluids?

Yes, if the materials used (e.g., stainless steel or PTFE seals) are resistant to the specific chemicals.

How long do automated valves last?

With proper maintenance, automated valves can last 5–10+ years depending on cycle frequency and environment.

Where can I buy industrial-grade ball valves in the U.S.?

You can buy top-quality automated ball valves directly from DynaQuip — trusted by industries across the nation.

Quick Summary

Automated ball valves, whether solenoid- or pneumatically actuated, are essential for smart flow control in 2025. Choosing a reliable manufacturer like DynaQuip ensures long-term performance, system compatibility, and expert support when you need it.

#AutomatedValves#BallValves#PneumaticValves#SolenoidValves#FlowControl#ValveAutomation#IndustrialValves#IndustrialAutomation#SmartManufacturing#ProcessControl#FacilityManagement#EngineeringSolutions#DynaQuip#MadeInUSA#IndustrialSolutions#AutomationExperts

0 notes

Text

Reliable Portable Immersion Heaters by Process Technology

In search of a convenient and harmless heating? The immersion heater is the right option in Process Technology which is portable! It is also known to be easy to use, boils water in a short time and is very durable due to the quality of its materials. Office or lab, field or factory, this heater gives you mobile performance power with safe-as-you-go. Heat on demand and where you need it Be efficient, be flexible.

For more details Visit: https://www.processtechnology.com/products/electric-immersion-heaters/

#processtechnology#technology#immersionheaters#heaters#electric#powersupply#immersionheatersforwater#immersion#powerprocesssolutions#processcontrol#manufacturers#thermalpower#process#suppliers#industry

0 notes

Text

Looking to enhance your industrial batching process? This article explains precision batching systems in depth, highlighting their major components like load cells, control systems, and feeding mechanisms. Learn how they work together to deliver reliable, accurate, and efficient material handling, helping industries meet production goals with minimum waste.

#PrecisionBatching#BatchingSystems#IndustrialAutomation#MaterialHandling#ProcessEngineering#ManufacturingSolutions#EngineeringInnovation#AutomationTechnology#IndustrialEquipment#SmartManufacturing#PowderHandling#WeighingSystems#LoadCells#ProcessControl#BulkMaterialHandling#IndustrialBatching#EngineeringSolutions#MacawberIndia#AutomationSystems#ManufacturingTechnology

0 notes