#technical characteristics socket

Explore tagged Tumblr posts

Text

Understanding the technical characteristics of an electrical socket

In a previous article, our detailed guide helped you choose the electrical socket best suited to your functional and aesthetic needs. Whether they are conventional sockets, USB sockets or RJ45 sockets, they are all designed according to strict standards that are essential for them to work properly. To make the right choice, it’s also crucial to understand the technical specifications to ensure…

#20A electrical socket#32A electrical socket#domestic electrical outlet#electrical socket#electrical socket earth#faceplate design socket#faceplate socket design#plug mechanism#rj45 socket design#safety standards electrical socket#technical characteristics socket#usb-a design socket#usb-c design socket

0 notes

Text

Dragon skeletal anatomical diagram because I love taking on projects I and only I will enjoy. The idea is they evolved from theropod dinosaurs. Don't ask me how a tetrapod developed 6 limbs, I don't have answers for you.

Paleoheads feel free to nitpick any anatomical minutia I might have gotten wrong, I'm so here for it.

Inspired but not strictly following the dragons in the Eragon series.

Footnotes below the cut:

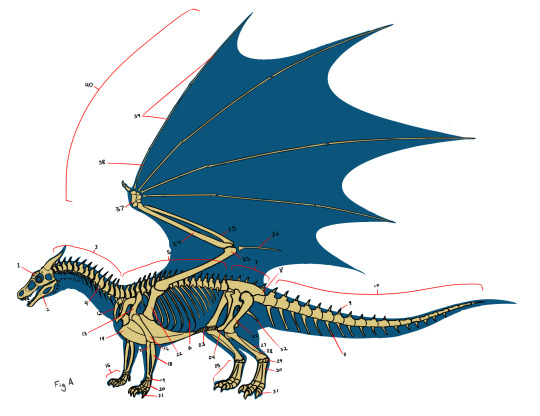

Fig A:

Spent a good while debating how to differentiate the naming for the forelegs and the wings, since they are technically duplicates of the same structure. I settled for "anterior" for the legs and "posterior" for the wings, but I also considered M. for "manus" referring to the legs, and A. for "ala" for the wings. ¯\_(ツ)_/¯

5. Dorsal Vertebrae 1-3 do not have dorsal spikes.

9. Dorsal spikes sprout from the spinous process and are surrounded by a kerotenous sheath. They become proportionally taller with age.

13. Anterior scapula is fused to the sternum and forms a ball-and-socket joint with the anterior humerus at the base.

14. Large keeled sternum for the attachment of flight muscles.

22. Posterior scapula is also fused to the sternum but the ball-and-socket joint is at the distal end.

36. The dracoid bone (or false finger) is a unique bone to dragons that I made up. It has a bony core and cartilaginous sheath. Inspired by the pteroid, a bone in pterosaurs, which also supports the wing membrane, but in a different location.

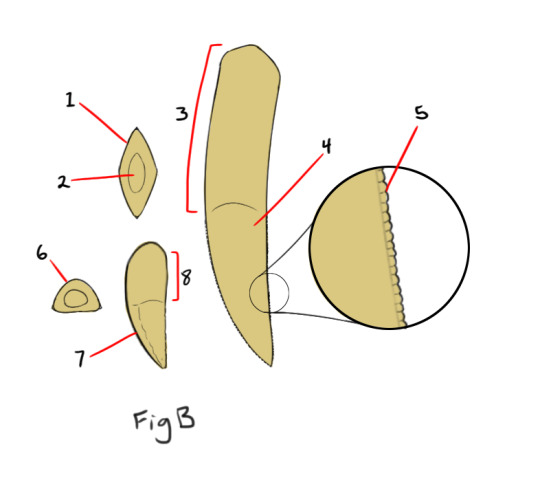

Fig B:

Dragons have anywhere from 46-54 teeth, but will always have 10 premaxillary teeth, four maxillary fangs (two on each side), 8 pre-fang dentary teeth, and 2 dentary fangs. The fangs slot into each other for gripping prey. Teeth are named after the bone they grow out of. Like other theropod dinosaurs, teeth are regrown throughout an individual's life.

1. Cross section of maxillary fang. Fangs are laterally compressed like blades for piercing and shearing off flesh.

4. Dragons have two maxillary fangs, with the first one being larger and visible when the mouth is closed. This "snaggle tooth" gets proportionally longer each time it regrows.

5. All dragon teeth have serrations.

6. Like T-Rex and other theropods, premaxillary teeth (and pre-fang dentary teeth) have a D-shaped cross section for delicately picking flesh from bones. Serrations are on the lateral sides and not anterior-posterior, like the fangs and post-fang teeth.

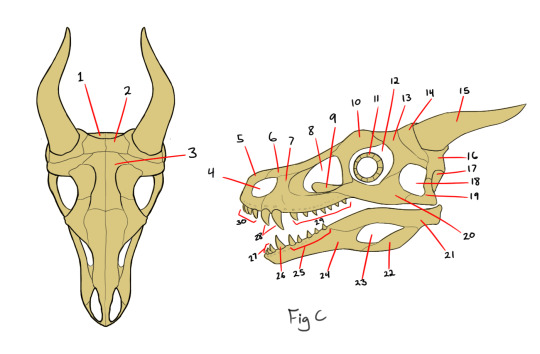

Fig C:

4. Dragons have proportionally enormous nostrils due to the high oxygen demands of flight.

8. The antoribital fenestra (and other openings in the skull) are very large in dragons to reduce the weight of the skull. This makes flight easier at the expense of bite force. While still capable of a formidable bite, it is no where near the power of a T-rex.

10. Large lacrimal bone gives the dragons their characteristic brows, and provides support for large lacrimal osteoderms.

11. Dragons have proportionally enormous eyes and excellent long-distance binocular vision.

14. Dragons horns are modified growths from the parietal bone, and thus called parietal horns. The supratemporal fenestra (holes most theropods have on the top/back of the skull) in dragons has closed to provide support for the parietal horns.

15. The parietal horn forms a bony core with a kerotenous sheath, much like their dorsal spikes (and goat horns). Grows continuously with age.

Thanks for reading!

#acy arts#my art#dragon skeleton#speculative biology#speculative zoology#dragon#the inheritance cycle#eragon#saphira#anatomical diagram#still workshopping the latin species name. kinda leaning towards Endunarus Draco#arts

100 notes

·

View notes

Text

Innovations In Flange Manufacturing: What UAE Suppliers Offer

Flanges are critical piping system fittings, serving as connectors, seals, and reinforcements for pipes, pumps, and valves employed in a multitude of industries. For UAE industries that require efficient flange supplier options, the region has a robust market with suppliers to address diverse industrial requirements.

Why Choose a Flanges Supplier in UAE?

UAE acts as a central location for oil, gas, petrochemical, water treatment, and construction sectors which require premium flanges to maintain their operational efficiency and safety standards.

The UAE suppliers of flanges offer an extensive range of products which consists of blind flanges and slip-on flanges together with weld neck flanges and socket weld flanges and threaded flanges and lap joint flanges that are produced using stainless steel and carbon steel and alloy steel and Inconel and Monel and Hastelloy materials.

The best suppliers including Ali Yaqoob, distribute multiple product lines which meet international standards ASME, ANSI, DIN as well as other standards to maintain safety during corrosive environments and high-pressure applications.

Best Flanges Suppliers in UAE deliver essential characteristics which define their quality.

Product Diversification: The suppliers supply flanges which range across all sizes and pressure ratings for applications starting from low-pressure water networks to high-pressure oil and gas pipelines.

Quality Assurance: The products meet high industry standards through their manufacturing process to provide durability while maintaining leak-tight seals and vibration and pressure fluctuation resistance.

Industry Expertise: Experienced suppliers give technical assistance to their clients for choosing appropriate flange types between welding neck flanges for pressure applications and threaded flanges for safe installation in hazardous environments.

Strategic Locations: Suppliers maintain warehouses and offices inside Dubai and Abu Dhabi as well as Sharjah and other UAE emirates which allows them to deliver quick service for projects across the UAE.

Flange Distributor in the United Arab Emirates: Ali Yaqoob Trade

Ali Yaqoob a reliable flange distributor, with a series of fittings and accessories to choose from. Their catalog includes blind and socket weld types for standard and specialty industrial applications, with weld neck and slip-on flanges. Ali Yaqoob serves as a one-stop shop for many local businesses because they prioritize product quality, price, and excellent customer service.

Conclusion

Your industrial piping systems require the top UAE flange supplier to ensure safety and keep operations running. With proven market players like Ali Yaqoob among others, businesses are able to get big selection, quality flanges, technical consultancy, as well as quality service, ensuring their projects at the utmost levels of performance and safety. Regardless of whether you require standard or customized flanges, in the region market can meet your requirements and is thus a very suitable destination to source industrial piping components.

0 notes

Text

Stainless Steel 904L Fasteners Manufacturer & Supplier in India – Akbar Fasteners

Stainless Steel 904L fasteners are an excellent choice for industries that demand high corrosion resistance and superior strength. As a leading Stainless Steel 904L Fasteners Manufacturer & Supplier in India, Akbar Fasteners delivers top-quality products trusted across various sectors such as chemical processing, oil & gas, pharmaceuticals, and marine engineering. Our commitment to precision engineering and reliable performance makes us a preferred partner for industrial fastener needs.

Overview of Stainless Steel 904L Fasteners

Stainless Steel 904L is an austenitic stainless steel grade that contains high levels of chromium, nickel, molybdenum, and copper. This combination offers outstanding resistance to pitting, stress corrosion cracking, and crevice corrosion in aggressive environments. SS 904L fasteners are widely used in applications that operate under high temperatures and harsh chemical exposure. These fasteners come in various forms, including bolts, nuts, washers, threaded rods, and studs.

Our fasteners are meticulously crafted using the latest manufacturing technology to ensure longevity and reliability. Whether it's offshore platforms, acid production units, or heat exchangers, 904L stainless steel delivers dependable performance in the most demanding situations.

Key Features and Properties of SS 904L Fasteners

One of the most significant advantages of using Stainless Steel 904L fasteners is their exceptional resistance to strong reducing acids, especially sulfuric acid. Unlike standard stainless steel grades, 904L performs efficiently in harsh conditions without degrading over time. Here are some key features:

High resistance to pitting and crevice corrosion

Excellent formability and weldability

High tensile and yield strength

Non-magnetic in annealed condition

Suitable for elevated temperature service

These characteristics make Stainless Steel 904L Fasteners an ideal choice for industries prioritizing longevity and safety.

Types of Stainless Steel 904L Fasteners We Offer

At Akbar Fasteners, we offer a comprehensive range of SS 904L fasteners to meet diverse industrial requirements. Our inventory includes:

Hex Bolts

Heavy Hex Nuts

Socket Head Cap Screws

Stud Bolts

Threaded Rods

Flat and Spring Washers

Each fastener is manufactured to precise dimensional tolerances and is available in both metric and imperial sizes. Our 904L Stainless Steel Bolts Nuts Studs are tested for strength and durability, ensuring optimal performance under extreme operating conditions.

Applications of SS 904L Fasteners in Various Industries

Due to their corrosion resistance and high mechanical strength, 904L fasteners are used across various high-stress industries. Common applications include:

Chemical processing plants

Seawater cooling systems

Pharmaceutical manufacturing units

Food and beverage processing equipment

Flue gas desulfurization systems

Oil refineries and offshore rigs

Our 904L Stainless Steel Bolts Nuts Studs, For Industrial use, ensure the durability and performance that engineers and designers depend on in their critical operations.

Why Choose Akbar Fasteners for 904L Fasteners?

Akbar Fasteners stands out for its unwavering commitment to quality and customer satisfaction. As a reputed Stainless Steel 904L Fasteners Manufacturer, we leverage our technical expertise and state-of-the-art machinery to deliver world-class fastening solutions. Here's why customers prefer us:

In-house testing for quality assurance

Custom manufacturing as per client specifications

Prompt delivery with efficient logistics

Competitive pricing and transparent service

Experienced workforce and professional support

Our customer-centric approach has made us a trusted SS 904L Fasteners Manufacturer & Supplier in Mumbai and beyond.

Quality Standards and Certifications

Quality is at the core of everything we do. Our manufacturing facility adheres to national and international standards such as ASTM, ASME, DIN, and ISO. Each fastener is subject to rigorous testing for mechanical strength, dimensional accuracy, and corrosion resistance. We provide complete traceability and test reports with every shipment to ensure total quality assurance.

We maintain robust internal controls and upgrade our machinery regularly to maintain our leadership as a reliable Stainless Steel 904L exporter in the global market. Clients can trust our products for consistency and premium performance in every delivery.

SS 904L Fasteners – Dimensional Range and Specifications

Akbar Fasteners offers SS 904L fasteners in a broad range of diameters, thread pitches, and lengths. Our products conform to global specifications including:

ASTM B649 for 904L round bars

ASTM A193 and A194 for bolts and nuts

DIN 933, DIN 934, and DIN 976

We provide fasteners in standard finishes such as plain, electro-galvanized, and hot-dip galvanized, based on customer requirements. Custom thread profiles and special coatings are available upon request.

Customization and Special Grades Available

We understand that each industry has unique operational needs. That’s why we offer tailored solutions, including non-standard sizes and specially coated SS 904L fasteners. Whether you require heat-treated components, PTFE-coated bolts, or acid-resistant studs, we have the capability to deliver precisely what your application demands.

We also stock and manufacture special alloy grades to support fast delivery for urgent requirements. This flexibility makes us an ideal partner for large-scale EPC contractors and OEMs.

Packaging and Timely Delivery Commitments

Each fastener is securely packed using moisture-proof, eco-friendly packaging materials to ensure damage-free delivery. We offer both domestic and international shipping options with reliable logistics partners. With streamlined processes and adequate stock, we are committed to timely dispatch and hassle-free order fulfillment.

Customers across the world rely on our precision-engineered fasteners, and our reputation as a dependable Stainless Steel 904L exporter has been built on our commitment to punctuality.

Global Exporter of Stainless Steel 904L Fasteners

With a robust distribution network, Akbar Fasteners proudly exports Stainless Steel 904L fasteners to countries in the Middle East, Europe, Southeast Asia, and Africa. Our dedication to international quality standards and client satisfaction has positioned us among the top exporters of industrial fasteners in India.

We understand global compliance norms, offer export-ready packaging, and ensure all shipments are accompanied by required documentation including country of origin certificates, mill test reports, and packing lists.

Client Testimonials and Success Stories

Our clients consistently share positive feedback on the durability, strength, and precision of our products. From petrochemical giants to infrastructure developers, our fasteners have proven their value in diverse projects. Repeat business from our clients is the strongest testimony to our product quality and service reliability.

Whether it's a turnkey refinery installation or a pharmaceutical processing plant, our 904L fasteners play a critical role in ensuring equipment safety and uptime.

How to Order Stainless Steel 904L Fasteners from Us

Ordering from Akbar Fasteners is a simple and hassle-free process. Visit our official website Akbarali Fasteners to browse our range of products or submit a quote request. Our sales team will respond promptly with technical details, pricing, and delivery schedules.

For direct inquiries, you can reach us at: Contact Person: Barkat Ali Phone: +91 99192 04560 Email: [email protected] Address: Kurla West, CST Road, India, India 400070

Partner with Akbar Fasteners today — your trusted Stainless Steel 904L Fasteners Manufacturer & Supplier in India — and experience the assurance of quality, precision, and professionalism.

0 notes

Text

Stainless Steel 321 Air Header Manufacturer, Exporter, Supplier in Malaysia – Mcneil Saudi Arabia

Introduction to Stainless Steel 321 Air Headers

Stainless Steel 321 air headers are specialized equipment used to distribute compressed air from a single source to multiple outlet ports. These headers are essential components in industrial pneumatic systems, particularly where precision, durability, and resistance to extreme temperatures are crucial. SS 321 is a titanium-stabilized austenitic stainless steel known for its excellent resistance to intergranular corrosion after exposure to high temperatures.

Industries such as oil and gas, chemical processing, marine, and power generation commonly rely on SS 321 air headers for their ability to function flawlessly in demanding conditions. The material’s high mechanical strength and robust performance under high-pressure conditions make it a reliable choice.

When selecting a reliable solution, consider choosing a product like the ss 321 air header, which provides stability and long-term reliability, especially in harsh industrial settings.

Why Choose Mcneil Saudi Arabia

Mcneil Saudi Arabia is an established leader in the field of industrial stainless steel solutions. Based in the SAIF-Zone, Sharjah, UAE, Mcneil serves a global clientele with a strong emphasis on quality, engineering precision, and customer service. The company specializes in the manufacture and export of stainless steel pipe fittings, flanges, valves, and instrumentation products.

With state-of-the-art infrastructure and a commitment to ISO 9001-certified processes, Mcneil ensures each product adheres to international manufacturing standards. The company’s reputation as a dependable ss 321 air header manufacturer in Malaysia is backed by years of industry experience and client trust.

Contact Details: 📞 Phone: 9870883613 📧 Email: [email protected] 📍 Address: SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Website: Mcneil Saudi Arabia

Advantages of SS 321 in Air Header Applications

SS 321 offers several critical advantages when used in air header applications. Its most significant strength is its heat resistance. It performs exceptionally well in environments with sustained temperatures between 500°C and 900°C. This makes it ideal for power plants and chemical industries where thermal cycling is constant.

The titanium content in SS 321 stabilizes the structure, making it less prone to intergranular corrosion compared to 304 or even 316 grades. This ensures longevity and safety in high-temperature pneumatic systems. Furthermore, its weldability and formability make it easy to fabricate into complex air header designs without sacrificing mechanical strength.

SS 321 is also non-magnetic and retains its mechanical properties over time, even under continuous exposure to pressure and temperature. These characteristics make it a top-tier choice for industries seeking reliable performance under tough operating conditions.

Technical Design and Product Features

Mcneil’s SS 321 air headers are designed with flexibility and efficiency in mind. They typically come in standard lengths ranging from 1 to 2 meters and can be configured with 4 to 24 outlet ports. These ports distribute compressed air to control valves and instruments across various systems, ensuring synchronized operation.

Connection types include NPT, BSP, and socket welds. End connections can be flanged, threaded, or butt-welded, depending on system requirements. The surface finish can be customized—options include pickling, passivation, or electro-polishing—for added corrosion resistance and visual appeal.

Each air header is labeled and documented for easy identification and traceability. Mcneil ensures that every product meets pressure testing standards and includes hydrostatic and pneumatic test certifications.

The company is recognized among the top ss 321 air header suppliers due to its versatile configurations and attention to detail.

Manufacturing Excellence at Mcneil

At Mcneil, the manufacturing process is defined by precision, quality, and strict control at every step. From sourcing certified raw materials to final assembly, each stage is meticulously supervised by skilled engineers and quality inspectors. Raw stainless steel is tested for mechanical and chemical properties before processing.

The air headers are fabricated using CNC technology for accurate cuts and threads. Welds are made using TIG and orbital methods, followed by radiographic and ultrasonic testing for quality assurance. Finished headers undergo hydrostatic testing to ensure pressure retention, followed by final inspection and documentation.

This attention to detail is what positions Mcneil among the leading exporters of ss 321 air header in Malaysia, delivering consistent quality every time.

Types and Custom-Built Solutions

Mcneil offers a wide range of air header models to suit specific industrial needs. Whether your application requires wall-mounted or skid-mounted air headers, vertical or horizontal orientation, Mcneil can customize it to your design.

Clients can request different outlet sizes, special mounting brackets, or additional accessories such as drain valves and pressure gauges. Coating options, including anti-rust and electro-polished finishes, are also available to enhance corrosion resistance and longevity.

As a trusted manufacturer of ss 321 air header manifold, Mcneil ensures your equipment integrates seamlessly into existing systems and delivers maximum efficiency.

Compliance and Certifications

Compliance with international standards is integral to Mcneil’s operations. All air headers are manufactured in accordance with ASME, ASTM, and ISO requirements. Each unit is accompanied by mill test certificates, pressure test results, and full material traceability.

Third-party inspections by agencies like SGS, TUV, and DNV can be arranged upon request, offering clients additional assurance. These credentials ensure that Mcneil’s products meet regulatory expectations across global markets.

Their commitment to certification and transparency has made Mcneil a preferred ss 321 air header exporter in the international supply chain.

Key Industries Served

Mcneil’s SS 321 air headers are deployed in a variety of industries that demand durability and performance. The oil and gas sector uses them for delivering compressed air to control valves and automated systems. In petrochemicals, the air headers withstand high temperatures and corrosive gases with ease.

Power generation plants use SS 321 headers in turbine control systems and heat exchanger units, where heat resistance is critical. In marine applications, their corrosion resistance helps avoid frequent replacements. These headers are also increasingly used in industrial automation systems for air distribution control.

For precision uses, such as instrumentation ss 321 air header, Mcneil provides solutions that meet stringent accuracy and cleanliness requirements.

Malaysia-Specific Export Strategy

Understanding Malaysia’s industrial landscape and compliance standards has allowed Mcneil to streamline its export operations. From Kuala Lumpur to Johor and Penang, Mcneil has successfully delivered custom-configured air headers to a wide range of industries.

The company handles all export documentation including commercial invoices, packing lists, certificates of origin, and test certificates. With prompt customer service and technical consultation, Mcneil has become one of the leading compressor ss 321 air header exporters in Malaysia.

Logistics and Safe Packaging

Packaging plays a vital role in the safe delivery of precision-engineered products. Mcneil follows international packaging norms using ISPM 15-certified wooden boxes, vacuum-sealed polythene wrapping, and silica gel to protect against moisture.

Each shipment is tracked, and customers receive regular updates from dispatch to delivery. Support is available 24/7 for assistance with shipping or customs queries. This commitment ensures clients who want to buy 321 air header at best price in Malaysia receive their orders securely and on time.

Value Proposition of Partnering with Mcneil

Working with Mcneil means you benefit from competitive pricing, engineering expertise, and responsive customer support. The company provides both off-the-shelf and made-to-order air headers, backed by technical drawings, design consultation, and lifecycle support.

Unlike many vendors, Mcneil offers a complete solution—from design to delivery—and stands by the quality of every product. These values position the company among the most reliable ss 321 air header supplier networks globally.

Customer Feedback and Project Insights

One of Mcneil’s major projects involved supplying over 80 SS 321 air headers to a Malaysian refinery near Bintulu. The headers were customized with 16 outlets and integrated drain valves, meeting specific installation parameters. The client reported flawless performance and excellent service support.

In another case, a marine maintenance company in Penang used Mcneil’s air headers for ship automation systems. The customer praised the quick delivery and corrosion resistance, essential in saltwater conditions.

Market Comparison and Industry Positioning

In a competitive market, Mcneil stands apart for its consistent quality, global certifications, and personalized customer service. While other suppliers may offer low-cost alternatives, Mcneil emphasizes reliability, documentation, and support.

This consistent delivery of value has made Mcneil a leader among the top ss 321 air header suppliers trusted across multiple sectors.

Environmental Commitment

Mcneil is deeply committed to sustainability and eco-friendly manufacturing. The company uses recyclable materials, energy-efficient machines, and waste-minimization techniques in its operations. It also complies with international environmental norms like REACH and RoHS.

The packaging materials used are also biodegradable or recyclable, further minimizing the environmental impact during transit and usage.

Frequently Asked Questions (FAQs)

1. What makes SS 321 different from SS 316 or 304? SS 321 has added titanium for stabilization, which prevents carbide precipitation, making it suitable for high-temperature use.

2. Can Mcneil provide customized air header designs? Yes, Mcneil specializes in both standard and custom-built air header manifolds based on specific client needs.

3. Are certifications and test reports included with the product? Absolutely. Each product includes pressure test reports, mill certificates, and full traceability documentation.

4. How long does it take to ship to Malaysia? Most orders are shipped within 10–15 business days depending on configuration and order size.

5. What industries typically use SS 321 air headers? They are used in oil & gas, chemical plants, marine, power generation, and instrumentation.

6. How can I place an order? You can contact Mcneil directly via phone at 9870883613 or email at [email protected].

Final Summary and Contact Information

If you’re looking for a dependable Stainless Steel 321 Air Header Manufacturer, Exporter, Supplier in Malaysia, Mcneil Saudi Arabia offers unmatched quality, customization, and service. From design to delivery, every air header is engineered to perform under pressure—literally.

Contact Mcneil Today: 📞 Phone: 9870883613 📧 Email: [email protected] 📍 SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Visit Mcneil Saudi Arabia

0 notes

Text

Stainless Steel 321 Air Header Manufacturer, Exporter, Supplier in Malaysia – Mcneil Steel & Alloys FZE

Introduction to Stainless Steel 321 Air Headers

Stainless Steel 321 air headers are specialized equipment used to distribute compressed air from a single source to multiple outlet ports. These headers are essential components in industrial pneumatic systems, particularly where precision, durability, and resistance to extreme temperatures are crucial. SS 321 is a titanium-stabilized austenitic stainless steel known for its excellent resistance to intergranular corrosion after exposure to high temperatures.

Industries such as oil and gas, chemical processing, marine, and power generation commonly rely on SS 321 air headers for their ability to function flawlessly in demanding conditions. The material’s high mechanical strength and robust performance under high-pressure conditions make it a reliable choice.

When selecting a reliable solution, consider choosing a product like the ss 321 air header, which provides stability and long-term reliability, especially in harsh industrial settings.

Why Choose Mcneil Steel & Alloys FZE

Mcneil Steel & Alloys FZE is an established leader in the field of industrial stainless steel solutions. Based in the SAIF-Zone, Sharjah, UAE, Mcneil serves a global clientele with a strong emphasis on quality, engineering precision, and customer service. The company specializes in the manufacture and export of stainless steel pipe fittings, flanges, valves, and instrumentation products.

With state-of-the-art infrastructure and a commitment to ISO 9001-certified processes, Mcneil ensures each product adheres to international manufacturing standards. The company’s reputation as a dependable ss 321 air header manufacturer in Malaysia is backed by years of industry experience and client trust.

Contact Details: 📞 Phone: 9870883613 📧 Email: [email protected] 📍 Address: SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Website: Mcneil Steel & Alloys FZE

Advantages of SS 321 in Air Header Applications

SS 321 offers several critical advantages when used in air header applications. Its most significant strength is its heat resistance. It performs exceptionally well in environments with sustained temperatures between 500°C and 900°C. This makes it ideal for power plants and chemical industries where thermal cycling is constant.

The titanium content in SS 321 stabilizes the structure, making it less prone to intergranular corrosion compared to 304 or even 316 grades. This ensures longevity and safety in high-temperature pneumatic systems. Furthermore, its weldability and formability make it easy to fabricate into complex air header designs without sacrificing mechanical strength.

SS 321 is also non-magnetic and retains its mechanical properties over time, even under continuous exposure to pressure and temperature. These characteristics make it a top-tier choice for industries seeking reliable performance under tough operating conditions.

Technical Design and Product Features

Mcneil’s SS 321 air headers are designed with flexibility and efficiency in mind. They typically come in standard lengths ranging from 1 to 2 meters and can be configured with 4 to 24 outlet ports. These ports distribute compressed air to control valves and instruments across various systems, ensuring synchronized operation.

Connection types include NPT, BSP, and socket welds. End connections can be flanged, threaded, or butt-welded, depending on system requirements. The surface finish can be customized—options include pickling, passivation, or electro-polishing—for added corrosion resistance and visual appeal.

Each air header is labeled and documented for easy identification and traceability. Mcneil ensures that every product meets pressure testing standards and includes hydrostatic and pneumatic test certifications.

The company is recognized among the top ss 321 air header suppliers due to its versatile configurations and attention to detail.

Manufacturing Excellence at Mcneil

At Mcneil, the manufacturing process is defined by precision, quality, and strict control at every step. From sourcing certified raw materials to final assembly, each stage is meticulously supervised by skilled engineers and quality inspectors. Raw stainless steel is tested for mechanical and chemical properties before processing.

The air headers are fabricated using CNC technology for accurate cuts and threads. Welds are made using TIG and orbital methods, followed by radiographic and ultrasonic testing for quality assurance. Finished headers undergo hydrostatic testing to ensure pressure retention, followed by final inspection and documentation.

This attention to detail is what positions Mcneil among the leading exporters of ss 321 air header in Malaysia, delivering consistent quality every time.

Types and Custom-Built Solutions

Mcneil offers a wide range of air header models to suit specific industrial needs. Whether your application requires wall-mounted or skid-mounted air headers, vertical or horizontal orientation, Mcneil can customize it to your design.

Clients can request different outlet sizes, special mounting brackets, or additional accessories such as drain valves and pressure gauges. Coating options, including anti-rust and electro-polished finishes, are also available to enhance corrosion resistance and longevity.

As a trusted manufacturer of ss 321 air header manifold, Mcneil ensures your equipment integrates seamlessly into existing systems and delivers maximum efficiency.

Compliance and Certifications

Compliance with international standards is integral to Mcneil’s operations. All air headers are manufactured in accordance with ASME, ASTM, and ISO requirements. Each unit is accompanied by mill test certificates, pressure test results, and full material traceability.

Third-party inspections by agencies like SGS, TUV, and DNV can be arranged upon request, offering clients additional assurance. These credentials ensure that Mcneil’s products meet regulatory expectations across global markets.

Their commitment to certification and transparency has made Mcneil a preferred ss 321 air header exporter in the international supply chain.

Key Industries Served

Mcneil’s SS 321 air headers are deployed in a variety of industries that demand durability and performance. The oil and gas sector uses them for delivering compressed air to control valves and automated systems. In petrochemicals, the air headers withstand high temperatures and corrosive gases with ease.

Power generation plants use SS 321 headers in turbine control systems and heat exchanger units, where heat resistance is critical. In marine applications, their corrosion resistance helps avoid frequent replacements. These headers are also increasingly used in industrial automation systems for air distribution control.

For precision uses, such as instrumentation ss 321 air header, Mcneil provides solutions that meet stringent accuracy and cleanliness requirements.

Malaysia-Specific Export Strategy

Understanding Malaysia’s industrial landscape and compliance standards has allowed Mcneil to streamline its export operations. From Kuala Lumpur to Johor and Penang, Mcneil has successfully delivered custom-configured air headers to a wide range of industries.

The company handles all export documentation including commercial invoices, packing lists, certificates of origin, and test certificates. With prompt customer service and technical consultation, Mcneil has become one of the leading compressor ss 321 air header exporters in Malaysia.

Logistics and Safe Packaging

Packaging plays a vital role in the safe delivery of precision-engineered products. Mcneil follows international packaging norms using ISPM 15-certified wooden boxes, vacuum-sealed polythene wrapping, and silica gel to protect against moisture.

Each shipment is tracked, and customers receive regular updates from dispatch to delivery. Support is available 24/7 for assistance with shipping or customs queries. This commitment ensures clients who want to buy 321 air header at best price in Malaysia receive their orders securely and on time.

Value Proposition of Partnering with Mcneil

Working with Mcneil means you benefit from competitive pricing, engineering expertise, and responsive customer support. The company provides both off-the-shelf and made-to-order air headers, backed by technical drawings, design consultation, and lifecycle support.

Unlike many vendors, Mcneil offers a complete solution—from design to delivery—and stands by the quality of every product. These values position the company among the most reliable ss 321 air header supplier networks globally.

Customer Feedback and Project Insights

One of Mcneil’s major projects involved supplying over 80 SS 321 air headers to a Malaysian refinery near Bintulu. The headers were customized with 16 outlets and integrated drain valves, meeting specific installation parameters. The client reported flawless performance and excellent service support.

In another case, a marine maintenance company in Penang used Mcneil’s air headers for ship automation systems. The customer praised the quick delivery and corrosion resistance, essential in saltwater conditions.

Market Comparison and Industry Positioning

In a competitive market, Mcneil stands apart for its consistent quality, global certifications, and personalized customer service. While other suppliers may offer low-cost alternatives, Mcneil emphasizes reliability, documentation, and support.

This consistent delivery of value has made Mcneil a leader among the top ss 321 air header suppliers trusted across multiple sectors.

Environmental Commitment

Mcneil is deeply committed to sustainability and eco-friendly manufacturing. The company uses recyclable materials, energy-efficient machines, and waste-minimization techniques in its operations. It also complies with international environmental norms like REACH and RoHS.

The packaging materials used are also biodegradable or recyclable, further minimizing the environmental impact during transit and usage.

Frequently Asked Questions (FAQs)

1. What makes SS 321 different from SS 316 or 304? SS 321 has added titanium for stabilization, which prevents carbide precipitation, making it suitable for high-temperature use.

2. Can Mcneil provide customized air header designs? Yes, Mcneil specializes in both standard and custom-built air header manifolds based on specific client needs.

3. Are certifications and test reports included with the product? Absolutely. Each product includes pressure test reports, mill certificates, and full traceability documentation.

4. How long does it take to ship to Malaysia? Most orders are shipped within 10–15 business days depending on configuration and order size.

5. What industries typically use SS 321 air headers? They are used in oil & gas, chemical plants, marine, power generation, and instrumentation.

6. How can I place an order? You can contact Mcneil directly via phone at 9870883613 or email at [email protected].

Final Summary and Contact Information

If you’re looking for a dependable Stainless Steel 321 Air Header Manufacturer, Exporter, Supplier in Malaysia, Mcneil Steel & Alloys FZE offers unmatched quality, customization, and service. From design to delivery, every air header is engineered to perform under pressure—literally.

Contact Mcneil Today: 📞 Phone: 9870883613 📧 Email: [email protected] 📍 SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Visit Mcneil Steel & Alloys FZE

0 notes

Text

Inconel Fasteners Manufacturer, Supplier & Exporter

In challenging industrial environments, Inconel Fasteners are recognized for their outstanding strength, durability, and resistance to extreme heat and corrosion. At Ananka Group, we are proud to be one of the top manufacturers, suppliers, and exporters of Inconel Fasteners in India, Providing a wide range of bolts, nuts, washers, screws, and studs crafted from premium Inconel alloys, mainly Inconel 600, 625, and 718.

These fasteners are especially suited for demanding sectors like aerospace, marine, energy, and chemical processing. With a strong inventory and adherence to global standards, we ensure reliable products and prompt delivery to our clients around the world.

Leading Inconel Fasteners Manufacturer in India

Ananka Group operates a modern manufacturing facility in India, equipped with advanced machinery and a skilled team focused on precision and quality. Our Inconel fasteners are manufactured with tight tolerances and superior surface finishes to meet rigorous industrial demands.

We offer Inconel fasteners in the following popular grades:

Inconel 600

Inconel 625

Inconel 718

Each fastener is produced following internationally recognized standards, such as ASTM, ASME, DIN, ISO, BS, and EN. We also provide custom solutions tailored to specific project needs, both in India and globally.

Applications and Specifications of Inconel Fasteners

Common Applications:

Inconel fasteners are ideal for harsh environments where high temperatures, intense stress, or corrosive conditions are present. They are commonly used in:

Jet engines and aircraft turbines

Offshore oil platforms and marine equipment

Power plants (nuclear and thermal)

Chemical processing plants

Heat exchangers and industrial reactors

Desalination plants and seawater systems

Technical Specifications:

Grades: 600, 625, 718, X-750

Standards: ASTM B166, B564, B446, B637

Thread Types: Metric, UNC, UNF, BSW, NPT

Types: Hex bolts, nuts, washers, studs, screws, threaded rods

Finish Options: Plain, Black Oxide, Zinc Plated, Nickel Coated

Inconel 625 – Essential Properties and Common Industrial Applications

Why Inconel 625 Stands Out:

Inconel 625 is a versatile alloy renowned for its exceptional strength and excellent corrosion resistance. It performs exceptionally well without needing heat treatment, making it ideal for harsh conditions.

Key Features:

High strength and fatigue resistance

Excellent corrosion and oxidation resistance

Operates in temperatures up to 1000°C (1832°F)

Resists chloride-induced stress corrosion cracking

Where It’s Used:

Jet engine exhaust systems

Submarine and marine parts

Nuclear reactors

Chemical processing units

Heat exchangers

Gas scrubbers and flue systems

Types of Inconel Fasteners We Offer

We design and manufacture a full line of Inconel Fasteners to support various industrial needs:

Fastener Type

Details

Inconel Bolts

Comprises hex bolts, heavy hex bolts, and anchor bolts

Inconel Nuts

Hex nuts, locking nuts, wing nuts, coupling nuts

Inconel Washers

Plain washers, flat washers, and spring washers

Inconel Screws

Self-tapping screws, socket head cap screws, machine screws

Inconel Studs

Fully threaded studs, double-end studs, tap-end studs

Inconel Threaded Rods

Ideal for high-pressure applications and tension bolting

All fasteners are made with precision and are available in both standard and custom sizes.

Your Reliable Inconel Fasteners Partner – Built for Extreme Conditions

At Ananka Group, our reputation is built on quality, consistency, and customer satisfaction. As a dependable manufacturer and global exporter, we ensure every Inconel fastener we produce meets the highest performance standards.

What Sets Us Apart:

Premium raw materials

Advanced CNC machinery

Rigorous quality control

On-time international deliveries

Competitive pricing

Product Highlights:

Withstands temperatures up to 1200°C

High tensile strength and durability

Non-magnetic characteristics

Outstanding resistance to seawater, oxidation, and chemicals

No matter your industry whether aerospace, marine, or chemical processing—we deliver fasteners that perform reliably under pressure.

Conclusion

Inconel Fasteners are essential for operations exposed to extreme heat, pressure, and corrosive conditions. Their superior performance and longevity make them a top choice across industries. As a leading Indian manufacturer and exporter, Ananka Group offers a broad selection of Inconel fasteners with customization options to meet unique specifications.

Partner with Ananka Group for dependable, high-quality fastening solutions crafted with precision and engineered to last.

Frequently Asked Questions (FAQ)

1. What are Inconel Fasteners used for?

Inconel fasteners are used in applications requiring high strength and corrosion resistance, such as aircraft engines, chemical plants, nuclear reactors, and offshore drilling.

2. Are Inconel fasteners better than stainless steel?

Yes, Inconel fasteners offer superior resistance to heat and corrosion compared to stainless steel, especially in extreme environments.

3. Are Inconel fasteners more expensive than regular fasteners?

Yes, they are generally more expensive due to the premium material and performance, but they offer longer service life and reliability.

4. Can Inconel fasteners be used in marine environments?

Absolutely. Inconel fasteners are ideal for marine applications as they resist seawater corrosion exceptionally well.

#ananka#anankafasteners#articles#inconel#inconelfasteners#fasteners#fastenersmanufacturer#manufacturing#supplier#exporter#inconelbolt#manufacturer#mumbai#tumblr blog#tumblr

0 notes

Text

The Critical Role of Low Contact Resistance in Power Socket Design

Introduction

In modern power socket design, ensuring long-term electrical performance and safety is essential. One often-overlooked but technically vital factor is contact resistance—the resistance encountered where conductive surfaces meet, such as between socket terminals and inserted plugs. High contact resistance can lead to localized heating, power loss, arc discharge, and even fire hazards. This article explores how to achieve low contact resistance through proper material selection, structural design, and manufacturing quality control, with a particular focus on terminal plating materials such as silver and gold.

1. What is Contact Resistance and Why Does It Matter?

Contact resistance refers to the resistance that occurs at the interface of two conductive materials in contact. While this resistance is usually small, it becomes critical in power sockets, especially under high current or long-term load.

Consequences of high contact resistance:

Heat generation at the contact point

Oxidation and corrosion of contact surfaces

Accelerated material degradation

Increased energy loss

Risk of socket failure or fire

2. Impact of Terminal Plating Materials

Terminal materials and their surface treatments play a decisive role in determining contact resistance. Below are common plating options and their characteristics:

2.1 Silver Plating

Advantages: Extremely low contact resistance High electrical conductivity Good thermal conductivity

Disadvantages: Susceptible to surface tarnishing (silver sulfide) Not ideal for corrosive or polluted environments

Application Example: Silver-plated terminals are commonly used in industrial-grade sockets where low resistance and high conductivity are prioritized over corrosion resistance.

2.2 Gold Plating

Advantages: Excellent corrosion resistance Stable contact resistance over time High reliability in low-voltage circuits

Disadvantages: Much higher cost Slightly higher resistance compared to silver

Application Example: Gold-plated terminals are used in medical devices and precision instruments, where contact reliability and long-term oxidation resistance are critical.

2.3 Tin Plating

Advantages: Cost-effective Acceptable performance in moderate conditions

Disadvantages: Higher contact resistance Vulnerable to fretting corrosion under vibration

Application Example: Tin plating is used in consumer-grade power sockets and low-cost applications where cost outweighs performance.

3. Structural and Mechanical Design Factors

Achieving low contact resistance is not only about materials. Mechanical design directly impacts how the contact force is distributed, which in turn affects resistance.

3.1 Contact Pressure

Higher contact pressure helps:

Break through oxide layers

Increase true contact area

Reduce micro-gap resistance

However, excessive pressure may lead to:

Mechanical fatigue

Plug insertion difficulty

Material deformation

Optimization Tip: Use spring-loaded or elastic contact structures to maintain consistent pressure without deformation.

3.2 Contact Surface Area

Larger surface area = lower resistance, assuming good contact. However:

Must be carefully balanced with size constraints

Too large may increase insertion force or reduce structural strength

3.3 Insertion-Extraction Cycle Design

Wear and oxidation occur over time. A well-designed socket:

Maintains low resistance after 5000–10000 plug-in cycles

Uses self-cleaning contact surfaces to remove oxide layers

4. Environmental Resistance and Surface Treatments

Environmental factors like humidity, dust, and chemical pollutants impact contact performance.

Protective strategies include:

Applying corrosion-resistant coatings

Using sealing structures to block contaminants

Designing moisture-drainage channels in sockets used outdoors or in humid areas

Example: Outdoor-grade sockets often use silver-nickel composite plating and sealed terminal chambers to combat corrosion and moisture.

5. Manufacturing and Quality Control

Even with ideal materials and design, manufacturing consistency is key to low contact resistance.

Critical quality control steps:

Surface roughness control of contact parts

Plating thickness inspection (e.g., silver ≥ 5μm)

Conductivity and resistance measurement in mass production

High-current cycle simulation test

Oxidation/aging test under elevated temperature and humidity

Best Practice: Implement automated optical inspection (AOI) and four-point resistance measurement systems in production lines to catch variations early.

6. Testing and Verification Methods

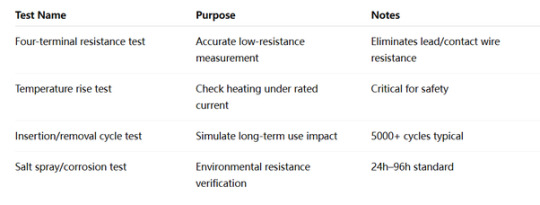

To ensure actual contact resistance meets design expectations, standard tests include:

Conclusion

Low contact resistance is not merely a technical detail—it is a core performance and safety indicator in power socket design. Through intelligent selection of plating materials (silver, gold, etc.), sound mechanical design (optimal contact force, wear-resistant structures), and rigorous quality control, manufacturers can significantly improve product lifespan, safety, and user satisfaction. In high-performance applications, investment in low contact resistance pays off in both product reliability and brand reputation.

en.dghongju.com

0 notes

Text

Maximizing Your Koi Pond with the Best Products Available with Beacon Koi Ltd

Koi pond keeping isn't a hobby; it is a piece of art that combines the aesthetics and visual appeal with the technical aspects of aquatic health. A healthy fish and a gleaming, clean pond are most important to those who keep koi. Beacon Koi Ltd are delighted to offer you an assortment of great products designed to take your pond care to new levels. From year-round feed supplements to advanced filtration systems, whatever you require we have for sale at our store in an attempt to help you make your pond paradise.

All Season Bee Propolis Feed: A Nutritional Powerhouse

Providing your koi with the correct food at the correct time of year will control their coloring, growth, and health. All Season Bee Propolis Feed is a great choice for koi keepers. The feed contains bee propolis, a natural substance known throughout the world as an immune system stimulant and antibacterial. It aids in digestion and keeps your koi in top health even in harsh winters when metabolism is low.

All Season Bee Propolis Feed gives your koi well-balanced nutrition and also helps lower the risk of infection. Its super-formulated diet is good for koi of any age, so this is a feed to use throughout the year. Getting a jump on winterizing your pond or strengthening your koi's immune system during the change of seasons, this feed is a must.

Burtons 3 Tier Stainless Steel Shower: A Water Quality Revolution

One of the secrets to healthy koi pond water is high-quality water, and the Burtons 3 Tier Stainless Steel Shower delivers. Designed for maximum biological filtration and oxygenation, this shower system is a great addition to maintain water sparkling crystal clear.

Constructed from high-grade stainless steel, this shower is rust-proof, weather-resistant, and long-lasting. It has three tiers and evenly distributes water over media layers to facilitate healthy bacteria growth. Healthy bacteria are utilized in the breakdown of waste and ammonia, resulting in a balanced and clean pond.

Easy to install and maintain, the Burtons 3 Tier Stainless Steel Shower is a savvy investment in koi health. It's especially invaluable in very large ponds, where water clarity and oxygenation are hard to achieve.

High-Tech Filtration with Burtons Pond Drum Filters

For serious pond owners, Beacon Koi Ltd offers a range of high-tech drum filters that are at the forefront of pond maintenance.

Burtons BD-150 Combi Pond Drum Filter with Bluetooth

Burtons BD-150 Combi Pond Drum Filter with Bluetooth is an ideal combination of innovation and efficacy as it relates to filtration. Since it has the built-in Bluetooth feature, it is possible to monitor and control how the filter is working from a distance. Such a clever feature ensures that the pond filtration system is always working at its optimum capacity even when you're not around.

BD-150 is best suited for ponds of size up to 20,000 liters and even smaller size, best suited for medium-sized installations. Compact with mechanical as well as biological filtration, here the waste materials are removed efficiently and harmless bacteria are stimulated. The self-cleaning feature of the drum minimizes the maintenance by a large percentage, so you can have more time for sitting near your pond and getting immersed in the surrounding peace and harmony.

Burtons BD-300 Combi Pond Filter with Socket Panel

For bigger ponds, Burtons BD-300 Combi Pond Filter with Socket Panel is highly recommended. It has as much as 30,000 liters when it comes to water it is capable of filtering through using its robust quality and clever designs in order to provide good performance. There is a built-in socket panel, which provides easy installation of additional pond equipment with straightforward installation of pond equipment.

It offers unrivaled filtration efficiency that will leave your water clear, clean, and safe for your koi. Its self-cleaning characteristic and simplicity offer a simple solution to keeping large koi ponds clean.

Why Burtons Pond Drum Filters?

Burtons Pond Drum Filters are extremely valued for reliability, efficiency, and premium features. They may be utilized for ponds of all dimensions and are effective in providing stable performance, thus your koi will be swimming contentedly in good health within a hygienic environment. The filters remove zero labor with the self-cleaning feature and provide water quality at an optimum level—a boon to all pond hobbyists.

Bring Your Pond Beauty and Quality with Best Accessories

Beyond useful aspects such as feed and filters, bringing your pond to look beautiful also matters. Your best accessories such as lighting and water features have the potential of making your pond look like an oasis. Alongside Beacon Koi Ltd's good products, it turns your koi pond into a health facility and also a garden showcase.

Join forces with Beacon Koi Ltd for all your Pond Requirements

We, at Beacon Koi Ltd, appreciate koi breeders' dedication and passion for the craft. It is for this reason that we also aim to provide high-quality products that are better and easier to use when keeping ponds. Our variety of unique products including the All Season Bee Propolis Feed, Burtons 3 Tier Stainless Steel Shower, and superior Burtons Pond Drum Filters takes care of every need of the pond keepers.

Whether you're an experienced koi owner or just starting out, we can guide you every step of the way. Check out our stock today and discover what Beacon Koi Ltd can do for you in assisting you in creating your dream pond.

0 notes

Text

Top 5 problems in using bursting strength tester and how to solve them

The packaging industry proves critical in getting products into consumers' hands in great condition. One major parameter in packaging quality control is the bursting strength testing of materials. The test provides manufacturers with information on the amount of pressure a package can withstand before getting damaged or ruptured so that it safeguards the integrity of the packaging during shipping and handling. To enhance the manufacturing process, advanced lab testing equipment has been offered by Test Your Product for the bursting strength test of packaging materials. The equipment is especially beneficial for industries relying on paper and paper-based products, which have been used widely in packaging over recent years.

Why Bursting Strength Testing is Important

The stability of the packing materials, such as paper, corrugated boxes, and allied products, is very important. Bursting strength, then, is the amount of pressure a given material can withstand without failure or rupture. Therefore, testing is important for several reasons:

Damage in Transit: Strong packing protects the product inside against damage from external forces during shipping.

Product Integrity: Good packaging assures that the product is intact and safe for end customers upon leaving the manufacturer's hand.

Customer Satisfaction: Good packaging creates a favorable customer impression regarding receiving goods in the best possible condition.

A Bursting Strength Tester: Test Your Product

The Test Your Product’s bursting strength tester with a digital display and printer is the accurate and reliable choice of the manufacturer who wants to conduct tests on the strength of packaging materials.

The following presents the features and benefits of the Bursting Strength Tester:

Functional Features:

Push Button Operation: User-friendly for any operator, including a beginner, to run the machine efficiently.

Built-In Thermal Printer: Automatically prints out and records the test results for prompt and efficient documentation.

Microprocessor-Based Display: Provides accurate and consistent readings, thus eliminating human errors in the test results.

Peak Hold Function: Retains the maximum burst for comparison with past tests and further analysis.

Memory: It stores up to nine previous tests for reference.

Highly Accurate Results: Gives trustworthy information even with the application of multidirectional force, ensuring evaluation accuracy.

Technical Specifications:

Load Range: From 0 to 40 kg/cm²

Accuracy: ±1 % from 10% to 90% of full-scale range

Resolution: 0.1kg/cm²

Grooved Test Specimen Holder: Provides a firm and uniform grip of the sample to improve reliability.

These advanced characteristics highlight the importance of the Test Your Product's Bursting Strength Tester for the manufacturers wishing to have quality assurance in their packaging materials.

Common Challenges in Bursting Strength Testing and How to Solve Them

While users may experience different problems while using the equipment provided by Test Your Product, such problems can easily be solved in several ways. Here are just five of the most common problems associated with this equipment and ways to remedy them:

Socket Issues: If the socket doesn’t work, check to see if the power supply is properly connected. It can rectify the problem most of the time.

Glycerin Leakage: Leakage happens quite often due to these loose parts. So, a wrench should be used to tighten the lower jaw to prevent further leakage.

Faulty Bursting of Readings: If the sample does not burst properly, it may be due to damage in the diaphragm. Replacing the diaphragm will solve this problem.

Invalid Outputs: The specimen alignment should be cross-checked before starting the test to avoid incorrect readings from a mismatch alignment of the specimens.

Extraordinary Noise: Strange noises sometimes arise from loose screws. Keep checking the machine to tighten all screws for its smooth operation.

Conclusion:

The packaging bursting strength test is an essential deciding factor in maintaining strength as well as durability. High-quality burst testing equipment from Test Your Product ensures that packaging is sufficiently energized and safely maintained by manufacturers. These reliable, accurate, user-friendly bursting strength testers have enabled businesses to reduce processes in inconsistent quality control and massive failures due to packaging.

To learn more on how our testing equipment for bursting can assist your business, or if you require technical support, contact Test Your Product today. Our expert team is all set to guide you further in ensuring optimal results.

0 notes

Text

Important Things You Need to Know About Disassembly of Diesel Genset

A diesel genset may malfunction after a certain period of use. It’s crucial to know how to troubleshoot diesel generator issues. Disassembly is an important part of the generator set repair work. If you want to dismantle and repair the generator yourself, you need to make some preparations and follow the normal disassembly methods to prevent damage to the machine or other accidents. In this article, Dingbo Power introduces several important things that you need to know about disassembly of diesel generator.

Principles of disassembly

To prevent various accidents and ensure smooth disassembly of the genset, the following principles should be followed during disassembly:

Firstly, understand the structural characteristics of diesel genset as well as its components and how it works. Secondly, for those diesel generators without technical data and instructions, be sure to record the torque of the disassembling parts when dismantling the generator sets. Thirdly, do not extend the scope of generator repair work at will. Finally, follow the specific principles of disassembly.

How do you prepare for the disassembly of diesel genset ?

When disassembling the diesel generator set, it’s necessary to make the following preparations before disassembly:

1.Understand the technical conditions of diesel genset

Before fixing the problem, you should have a comprehensive understanding of the fault situation, technical details and usage of the generator. For example, if oil burning of diesel engine arises, you need to determine in which cylinder the fault occurs, figure out the fault location and then dismantle and repair the genset.

2.Prepare technical materials and maintenance workplace

Before repairing a certain type of diesel genset, make sure you understand its repair guide and technical requirements. It’s worth noting that the repair technical standards of different types of diesel generators are not the same. If there is no technical data and instructions and the maintenance information of diesel generators from the same series is also missing, you should record various data before disassembling and all sorts of torques during the process of disassembly. In addition, prepare a certain place with enough space for the diesel genset, avoid dismantling it outdoors in windy or rainy conditions.

3.Prepare tools for disassembly

The common used tools of diesel generator sets include open-end wrenches, torx wrench, pliers, socket wrenches, adjustable wrenches, torque wrenches, hammers, wood hammers, hacksaw blades, etc. The special tools mainly include sleeves for dismantling connecting rod bolts and tools for assembling pistons and so on. The measuring tools include gauges for adjusting valve clearance, steel rulers, inside micrometers and outside micrometers for disassembling piston rings and steel rulers, etc. Hoisting tools include jacks, pry bars, sheave blocks and so on and so forth.

Additionally, prepare cleaning equipment, utensils and cleaning agents. Generally, use an oil basin and a brush as cleaning equipment and the cleaning agent is usually gasoline or diesel. Repair parts, various gaskets, appliances for labour protection and tags used for recording cylinder units, etc. should also be prepared before the disassembly of diesel genset.

What are the important things you need to know during disassembly?

As a crucial energy propeller, the internal-combustion engine needs to be paid attention to many details during operation to ensure its performance and service life. One of the key steps is to disassemble the diesel generator set after it has completely cooled. Disassembly with high temperature will cause thermal stress, which affects the cylinder blocks, cylinder heads and other components and results in permanent deformation, then affects the performance of the internal-combustion engine. Therefore, to prevent this from happening, the machine should be dismantled after cooling. This important principle should be kept in mind and followed to ensure the proper operation of the internal-combustion engine.

When dismantling the cylinder heads, connecting-rod caps, main bearing caps and other parts of the diesel genset, the bolts or nuts should be symmetrically and evenly loosened and carried out in 2-3 times in a specific sequence. Do not loosen the nuts or bolts on one side and then the other side, otherwise it may lead to uneven stress on the parts, causing deformation or crack damage.

Mark the mating parts of the machine carefully. For timing gears, pistons, connecting rods, bearing bushes, valves and other parts, as well as related adjusting shims, the marked parts need to be recorded and the unmarked parts need to be marked. The labels should be placed on an observable but non-working surface to avoid damage to the assembly datum plane and maintain the original assembly relationship of the equipment as much as possible. For some components, such as the wire connection points or joints on internal-combustion engines and generators, they can be marked with paint, score or hangtags, etc.

Disassembly of the diesel genset should be done cautiously, and all kinds of tools, especially special tools, should be used correctly. For example, you’d better use piston ring pliers when removing the piston rings and use spark plug sleeves with appropriate force when dismantling spark plugs. Otherwise, you may suffer hand injuries and the spark plugs may be damaged easily.

Conclusion

To ensure the safe disassembly and repair work of the diesel genset, you need to make enough preparations and pay attention to the technical details, the disassembly method of the parts, and the connection relationship between the parts. Always follow the normal disassembly steps when disassembling the generator set. It’s recommended that you contact your manufacturer or a professional if you have insufficient experience with the diesel generator set. For more help disassembling the genset or choosing the perfect diesel generator, please contact us today.

0 notes

Video

youtube

Electrical plugs and sockets are one of the most important basic elements in our daily lives, as they are our gateway to the world of electrical energy that powers our devices and tools.

Despite their apparent simplicity, they hide a world of diversity and complexity, as their types, shapes and technologies vary from country to country and region. In this comprehensive article, we will learn about everything related to electrical plugs and sockets, starting from their history and development to their different types, uses and the importance of safety when dealing with them.

History and development of electrical plugs and sockets

The history of electrical plugs and sockets dates back to the nineteenth century, when the first electrical systems began to appear in homes and factories. These systems were very primitive, and plugs and sockets were very different from what we know today. With the development of technology and the increase in demand for electrical energy, electrical connection systems have also evolved, and plugs and sockets have become more complex and safer. Learn more

Smart electrician in your home

Types of electrical plugs and sockets

There are many types of electrical plugs and sockets around the world, each with its own technical characteristics and uses.

https://t.me/kh_smart_services

0 notes

Text

Operation room control panels are being upgraded with time

Medical electrical equipment and a wide range of other goods and materials used in operating rooms are designed with specific hygiene standards in mind. All equipment, including the operating table, lighting, electrically powered devices, surgical tools, sockets, and pendants, is made by these standards and the associated regulations. Compact devices known as operating theatre control panels include many visual and control functions that must be present in an operating room. The operating theatre control panels are up-to-date, reliable devices made to maintain the optimal working conditions needed in the operating room and to create the most comfortable environment for the patient and the operating team.

Operating Room Control Panels from the 20th Century to the Present

Medical and technical personnel have benefited from operating theatre control panels for years. Throughout the years, they have continuously enhanced their capabilities and offered us a range of designs. Operating theatre control panel development is sustained by several factors, including growing requirements, new standards, the need for improved working conditions for medical and technical staff, the realisation that patients are being operated on in more hygienic and comfortable medical areas, the significance of electrical hardware to support faster and more reliable operations, and the fact that requirements are constantly changing. Since they were first used in the 1990s and gained popularity for their designs, including stainless steel front surfaces, operating theatre control panels have given us a lot of alternatives when it comes to front surfaces. Among the substitutes used in manufacturing operating room control panels are stainless steel, fibre alloy surfaces, membrane surfaces, special glass alloys, polycarbonate materials, and completely touch screen surfaces. The preference for surfaces that adhere to cleanliness standards is the most crucial factor to consider in this situation.

Improved functional features have been added to operating room control panels:

The operating Theatre Control Panels allow manual handling of all electrical controls. Another advantage is the capacity to exchange all of the information required for automating the air conditioning system. As previously stated, the operating room control panels include a variety of necessary control and visual characteristics.

Key Features:

General illumination control

A music transmission system

Superb Chronometer and Clock Performance

Management of the operating lamp;

The measure of the variation in room pressure

Both heat and humidity detector

Heater's control

HEPA filter's contamination indicator

Medical gas alarm panel

The structure and characteristics of operating theatre control panels are continuously changing, and new-generation solutions are being offered in light of today's rapidly expanding technological developments, visual concepts, and user-friendliness. In addition to these qualities, these panels also provide solutions for the latest generation. Hospital operating room control panels are gradually replacing their predecessors in response to the needs of physicians, medical staff, and administrators. These panels have several functions. Always look for the reputed best operation theatre manufacturer for your hospitals.

MHS Modular Healthcare System is a pioneer in the industry of medical equipment. Contact them for the best quotes and equipment.

0 notes

Text

Li-ion batteries may survive for a long time and only gradually

Dyson DC59 vs V6 The charge does not last 26 minutes in any situation. They say "26 minutes" since you'll be dragging the vacuum around without pulling the trigger throughout that period (yes, seriously). If you don't use the motorized attachments, you may anticipate 20 minutes on the non-max setting, and 17 minutes if you do. It takes 6 minutes at most (not sure whether that includes or excludes the attachments). I'm not familiar with your case, therefore I can't say if you need to purchase extra tools. The big direct drive cleaner head displayed, a smaller direct drive cleaner head, a crevice tool, a soft brush tool, and a hard brush tool were all included with my Dyson V6 Animal. On carpets and ceramic tile floors, the big direct drive tool is ideal. It pulls up a lot of dog hair and filth. For my wood flooring, I just purchased the Dyson Articulating Hard Floor Tool. I haven't put it to the test yet. I had the same question and was advised by Dyson support that I could obtain a new battery for $69. Li-ion batteries may survive for a long time and only gradually lose capacity, requiring more frequent charging. The charger, like most computers these days, is 110-240v. The prongs are typical USA 2 pin, however you may just as easily plug it into an adaptor and use it like any other laptop on any 110-240 electrical system socket. Yes, it is protected as long as it does not exhibit damage or destruction on my part, according to my phone contact to Dyson about this battery replacement in a two-year time period. Technically, the battery CAN be swapped rather quickly with a newly charged battery. Replacement batteries as well as additional charging cords may be bought on Amazon. If you have a backup charger or your charger cable is not installed within the wall mount bracket, the battery does not need to be charged in the vacuum. The battery is readily changed by unscrewing two tiny screws. Although not as handy as a snap-in battery, the Dyson V6 with HEPA filter and super-strong suction is a viable alternative for individuals who desire the Dyson V6's exceptional characteristics. In addition, the lower power option is sufficient for 80% of the time, resulting in a total of 20 minutes of operating time per battery. It sucks up the same amount of dust as a regular vacuum. Powered by the Dyson digital motor V6-2 Tier Radial Cyclonesevery floor type without the inconvenience of a wire-3x the suction power of any other cordless vacuum in use- It suckers up as much dust as a regular vacuum cleaner but without the cable. As long as you buy the product from an authorised seller, it comes with a two-year warranty on parts and labor. To remove ground-in debris, the direct-drive cleaning head forces bristles deep into the carpet. The soft roller cleaner head is kind on hard surfaces while being harsh on filth by simultaneously eliminating large debris and small dust. Lightweight and adaptable for quick cleaning around the house, The instant release trigger only uses battery power during cleaning; before initial usage, it must be charged for at least 3.5 hours. The trigger releases instantaneously after up to 20 minutes of intense, fade-free suction. Cleaning is the only time when battery power is needed. Designed to thoroughly clean pet-friendly homes, the filtration system’s totally sealed design catches 99.97% of particles as tiny as 0.3 microns, resulting in cleaner air. It quickly converts to a portable vacuum for cleaning around the house and vehicle. 2 year parts and labour warranty, which is activated automatically Emptying the garbage with a single click is hygienic. To release the dirt, just press a button. The purchase of this product will contribute 15% of the retail price to REDefforts to combat AIDS via the Global Fund. No cords, no hassle, just strong suction. The Dyson V6 vacuum is stored and recharged in a convenient docking station, so it’s always ready to use.

0 notes

Text

Why and How to Choose the Best Stainless-Steel Flanges?

Stainless steel flanges, commonly known as SS flanges, play a crucial role in connecting pipes, valves, and other equipment in various industries. These flanges provide a secure and leak-free connection, ensuring the smooth operation of pipelines. However, choosing the best stainless-steel flanges requires careful consideration of several factors.

In this blog, we will explore the importance of selecting high-quality SS flanges and provide valuable insights on how to make the right choice for your specific requirements.

Importance of Selecting the Best Stainless-Steel Flanges:

When it comes to pipeline systems, the quality of flanges is of paramount importance. SS flanges offer numerous advantages, including exceptional corrosion resistance, durability, high strength, and heat resistance. These features make stainless steel flanges suitable for a wide range of applications in industries such as oil and gas, chemical, petrochemical, food processing, and pharmaceutical.

Choosing substandard flanges can result in leakages, system failures, and safety hazards. Inferior quality Stainless steel flanges may not withstand the high pressure and temperature conditions in industrial environments, leading to costly repairs and downtime. Therefore, it is crucial to invest in the best stainless-steel flanges to ensure long-lasting and reliable performance.

Factors to Consider When Choosing Stainless-Steel Flanges:

1. Flange Standards: The first step in choosing the right SS flanges is to consider the relevant industry standards. Various organizations, such as ASME, ANSI, and ASTM, have established standards for flange dimensions, materials, and performance. Ensure that the flanges you select comply with the appropriate standards to guarantee compatibility and safety.