#vibration analysis

Explore tagged Tumblr posts

Text

Unlocking Equipment Reliability with Vibration Analysis

In today’s fast-paced industrial world, keeping equipment running smoothly is critical. Unexpected breakdowns can lead to costly downtime, safety issues, and loss of productivity.

Visit Us: https://semeq.com/en/blog/unlocking-equipment-reliability-with-vibration-analysis/

0 notes

Text

What is Importance of Vibration Analysis for Rotating Machineries?

Explore the critical role of vibration analysis in maintaining rotating machinery, ensuring operational efficiency and preventing costly breakdowns.

0 notes

Text

How Motor Current Signature Analysis Enhances Machine Reliability and Efficiency

In the world of industrial machinery, maintenance is crucial for ensuring longevity, reliability, and efficiency. While traditional maintenance methods focus on regular inspections and replacements, they can often be reactive, fixing issues after they arise. Predictive maintenance, on the other hand, helps identify potential issues before they lead to costly downtime. One of the most effective predictive maintenance techniques is Motor Current Signature Analysis (MCSA), a method that provides deep insights into motor health by analyzing current waveforms. In this blog, we’ll explore how MCSA improves machine reliability and efficiency and introduce Vibrotech, a leading provider of MCSA services.

What is Motor Current Signature Analysis?

Motor Current Signature Analysis (MCSA) is a non-invasive diagnostic technique used to monitor the condition of electric motors. It works by analyzing the electrical currents drawn by the motor to detect abnormalities and signs of mechanical or electrical faults. Through MCSA, maintenance teams can identify issues such as rotor bar damage, stator faults, bearing issues, and air gap irregularities—all of which can affect the motor’s performance.

Unlike other methods, MCSA does not require equipment disassembly. Sensors are used to capture the current signals, which are then processed and analyzed to identify unique signatures indicating different types of motor faults. This makes MCSA a highly efficient and cost-effective way to maintain motor health without interrupting production.

How MCSA Enhances Machine Reliability

Early Fault Detection: MCSA can identify motor issues long before they become critical, allowing for early intervention. This ability to detect faults at an early stage significantly improves machine reliability, as potential problems can be fixed proactively. For example, an MCSA analysis might reveal small variations in current flow indicative of bearing wear. Addressing this early can prevent total bearing failure, which might otherwise lead to severe machine downtime or expensive repairs.

Reduction of Unexpected Failures: Machine failures can lead to costly downtime, disrupt production schedules, and even pose safety risks to operators. By regularly using MCSA to monitor motor conditions, maintenance teams can spot issues and schedule repairs during planned downtime, rather than waiting for an unexpected failure. This proactive approach helps to ensure that machines are operating optimally, which is essential for reliable production.

Improved Maintenance Scheduling: With MCSA, maintenance teams can move from a reactive or time-based maintenance schedule to a predictive approach. Rather than conducting maintenance at arbitrary intervals, they can schedule it based on the actual condition of the equipment. This approach not only prevents unexpected failures but also avoids unnecessary maintenance, saving both time and resources.

Extending Motor Lifespan: MCSA helps protect motors from extensive wear and tear. By catching faults early, maintenance can be more targeted, and repairs can address specific issues without causing additional strain on other components. This leads to a longer lifespan for the motor and other parts of the machine, which contributes to overall machine reliability.

Enhancing Machine Efficiency with MCSA

Reduced Energy Consumption: When a motor is operating with faulty components, it often requires more power to function, leading to inefficiency and higher energy costs. MCSA can detect faults that increase energy consumption, allowing maintenance teams to rectify them and restore the motor’s energy efficiency. This, in turn, helps lower operating costs and improves the sustainability of the operation.

Optimized Performance: A well-maintained motor runs more smoothly, which improves the overall performance of the machine it powers. MCSA helps maintain motor health, which means machines run closer to their optimal performance levels. This can improve production rates, reduce waste, and contribute to a more efficient manufacturing process.

Lower Maintenance Costs: Predictive maintenance methods like MCSA reduce the need for frequent checks and unnecessary part replacements. By targeting specific issues rather than performing blanket repairs, companies can save on maintenance costs. In the long term, MCSA can drastically reduce expenses related to motor maintenance by minimizing unnecessary interventions.

Enhanced Production Quality: Reliable and efficient machines produce more consistent outputs. When a motor is malfunctioning, it may cause irregularities in the production process. For example, in processes requiring precise speed control, a motor fault could result in poor-quality products or defective batches. By ensuring motors are in top condition, MCSA helps maintain the quality of production, which is crucial in sectors like automotive, aerospace, and electronics manufacturing.

Vibrotech: A Leader in MCSA Services

For companies looking to implement Motor Current Signature Analysis, choosing a service provider with expertise and high-quality equipment is essential. Vibrotech offers top-notch MCSA services, leveraging advanced diagnostic tools and skilled professionals to provide comprehensive analysis and actionable insights.

Vibrotech’s approach to MCSA includes thorough data analysis and customized reports, enabling maintenance teams to make well-informed decisions. Their experience with industrial machinery across sectors makes them an invaluable partner for businesses looking to improve machine reliability and efficiency. Vibrotech doesn’t just provide data; they interpret it, allowing clients to understand the health of their motors in detail and plan maintenance accordingly.

By choosing Vibrotech for MCSA, companies can gain peace of mind knowing they are investing in machine longevity, efficiency, and overall productivity. Whether it’s a large industrial facility or a smaller setup, Vibrotech has the solutions to help minimize downtime and keep operations running smoothly.

Conclusion

Motor Current Signature Analysis is an invaluable tool in the realm of predictive maintenance. By providing early fault detection, optimizing energy consumption, and ensuring smooth machine performance, MCSA plays a vital role in enhancing both machine reliability and efficiency. Companies that adopt MCSA as part of their maintenance strategy can enjoy significant cost savings and a boost in productivity.

For organizations seeking the best MCSA services, Vibrotech stands out as a trusted provider with the experience and tools to deliver exceptional results. Their expertise in motor diagnostics, paired with a commitment to customer satisfaction, ensures that businesses receive precise, insightful data to optimize their maintenance strategies. With Vibrotech, companies are empowered to maximize their equipment’s potential, minimize costly downtime, and focus on what they do best—growing their business.

0 notes

Text

Review of Common Failure Cases -- Power Plant

Review of Faults and Failures: Case Studies from Thermal Power Plants Thermal power plants are complex facilities that convert heat energy into electrical power, typically using coal, natural gas, or oil as fuel. Due to their high-temperature, high-pressure environments, these plants are susceptible to a variety of operational failures and faults. This review explores case studies of common…

#condition monitoring#Engineering#failure modes#failures#IOT#Maintenance#Performance monitoring#reliability#technology#vibration analysis

0 notes

Text

Data Science Training

Embark on a transformative data science training journey and acquire a deep understanding of statistical analysis, predictive modeling, and machine learning algorithms. Gain hands-on experience with real-world datasets, explore data visualization techniques, and unlock the power of data-driven decision-making. Equip yourself with the essential skills and tools needed to extract actionable insights from complex data and drive innovation in diverse industries. Join our comprehensive training program and become a proficient data scientist ready to tackle complex data challenges. For more details about Data Science Training kindly visit our site.

0 notes

Text

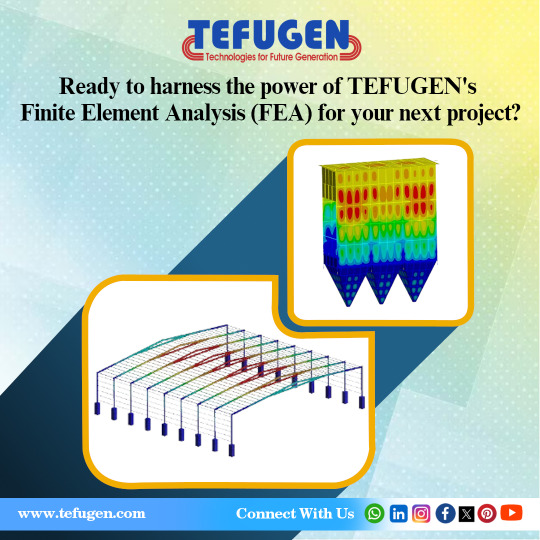

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

#Finite Element Analysis Consulting Services in India#FEA Analysis Services#FEA Consulting Engineers#FEA Consultants in Trichy#FEA#Finite Element Method#Structural Analysis#Stress Analysis#Static Analysis#Dynamic Analysis#Thermal Analysis#Fluid Flow Analysis#Vibration Analysis#Fatigue Analysis#Buckling Analysis#Modal Analysis#Meshing#Boundary Conditions#Material Properties#Convergence#Post-processing#Optimisation#Mesh Generation#Simulation Software

0 notes

Text

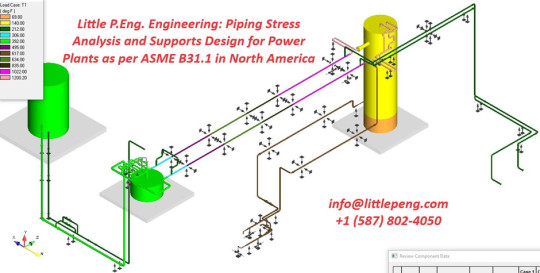

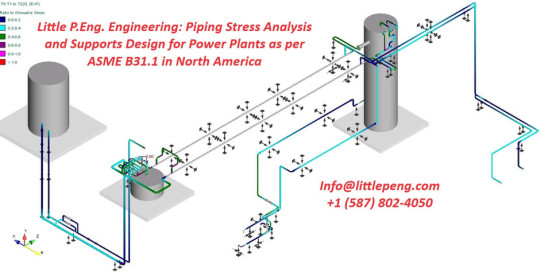

Little P.Eng. Engineering: Piping Stress Analysis and Supports Design for Power Plants as per ASME B31.1 in North America

In the world of power generation, safety and reliability are paramount. Power plants play a critical role in supplying electricity to homes, businesses, and industries across Canada and the United States. To ensure the seamless operation of these facilities, various standards and codes are in place, with ASME B31.1 being one of the most important. In this article, we'll explore how Little P.Eng. Engineering specializes in piping stress analysis and supports design for power plants, adhering to ASME B31.1 guidelines. We'll delve into the significance of this expertise and its impact on power plant operations across North America.

Understanding ASME B31.1

ASME B31.1, officially titled "Power Piping," is a widely recognized standard developed by the American Society of Mechanical Engineers (ASME). This standard provides guidelines for the design, construction, inspection, and maintenance of piping systems in power plants, including fossil fuel, nuclear, and geothermal facilities. Compliance with ASME B31.1 is mandatory for power plant operators in North America, as it ensures the safety and reliability of piping systems under various operating conditions.

The Importance of Piping Stress Analysis

Piping systems in power plants are subjected to a wide range of stresses and loads, including pressure, temperature variations, vibrations, and seismic forces. Failure to adequately analyze and address these stresses can lead to catastrophic failures, resulting in downtime, safety hazards, and financial losses. Piping stress analysis is the process of evaluating how these stresses affect the integrity of the piping system, and it is a crucial step in ensuring the reliability of power plants.

Little P.Eng. Engineering employs a team of experienced engineers who specialize in performing comprehensive piping stress analysis for power plants across Canada and the USA. Their expertise in ASME B31.1 compliance ensures that every analysis is conducted with the highest level of precision and adherence to industry standards.

Supports Design in Compliance with ASME B31.1

Properly designed and implemented supports are essential for maintaining the structural integrity of piping systems in power plants. ASME B31.1 outlines specific requirements for piping supports, including their design, material selection, and installation. Little P.Eng. Engineering excels in the design of piping supports that meet ASME B31.1 standards, ensuring that power plants operate without compromising safety or efficiency.

The company's approach to supports design encompasses factors such as thermal expansion, weight distribution, and the prevention of excessive loads on equipment and structures. Their engineers use advanced software and modeling techniques to optimize the support system, ensuring that it can withstand the stresses imposed by various operating conditions.

Benefits of Working with Little P.Eng. Engineering

4.1. Compliance Assurance

Little P.Eng. Engineering's primary focus is to ensure that power plants in Canada and the USA are fully compliant with ASME B31.1. Their team of experts has an in-depth understanding of the standard's intricate requirements, ensuring that every project they undertake adheres to the highest industry standards.

4.2. Safety Enhancement

By conducting rigorous piping stress analysis and designing supports that meet ASME B31.1 criteria, Little P.Eng. Engineering enhances the safety of power plant operations. Their comprehensive approach minimizes the risk of pipe failures, leaks, and other potential hazards, ultimately protecting both plant personnel and the surrounding environment.

4.3. Increased Reliability

Power plant downtime can result in significant financial losses and disruptions in energy supply. Little P.Eng. Engineering's expertise in piping stress analysis and supports design minimizes the likelihood of unexpected failures, contributing to increased reliability and operational continuity for power plants.

4.4. Cost Efficiency

Efficient piping systems and well-designed supports can also lead to cost savings in the long run. By optimizing the design and minimizing unnecessary maintenance and repairs, Little P.Eng. Engineering helps power plant operators reduce operational costs while maintaining high standards of safety and reliability.

Case Studies

To illustrate the practical application of Little P.Eng. Engineering's expertise, let's take a look at a couple of case studies from their portfolio:

5.1. Fossil Fuel Power Plant in Alberta, Canada

Little P.Eng. Engineering was engaged to perform piping stress analysis for a fossil fuel power plant in Alberta, Canada. The analysis revealed potential issues related to thermal expansion and vibration. The engineering team designed and implemented supports that addressed these concerns, ensuring the safe and efficient operation of the plant under various operating conditions. As a result, the plant experienced reduced downtime and enhanced reliability.

5.2. Nuclear Power Plant in New York, USA

For a nuclear power plant in New York, Little P.Eng. Engineering conducted a comprehensive review of the piping support system to ensure compliance with ASME B31.1. Their engineers identified several areas for improvement, including the reinforcement of supports to withstand seismic forces. By implementing these enhancements, the plant achieved greater safety and compliance with regulatory requirements.

Conclusion

Little P.Eng. Engineering's specialization in piping stress analysis and supports design as per ASME B31.1 is indispensable for power plants across Canada and the USA. Their commitment to compliance, safety enhancement, increased reliability, and cost efficiency makes them a trusted partner in the energy industry. With a proven track record of successful projects and a team of experienced engineers, Little P.Eng. Engineering plays a vital role in ensuring the continued operation and success of power plants in North America. Collaborating with such experts is not just a choice but a necessity in an industry where safety and reliability are paramount.

Tags:

Meena Rezkallah

Little P.Eng. Engineering

Piping Stress Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Industry Standards

Cost Efficiency

ASME B31.1 Compliance

Power Plant Safety

Piping Supports Design

North American Power Plants

Fossil Fuel Plants

Nuclear Power Plants

Geothermal Facilities

Power Plant Reliability

Power Plant Downtime

Vibration Analysis

Seismic Forces

Compliance Assurance

Safety Enhancement

Supports Optimization

Regulatory Requirements

Case Studies

Energy Industry

Operational Continuity

ASME Standards

Power Plant Operations

Power Plant Maintenance

Engineering Services

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Meena Rezkallah#Little P.Eng. Engineering#Piping Stress Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Industry Standards#Cost Efficiency#ASME B31.1 Compliance#Power Plant Safety#Piping Supports Design#North American Power Plants#Fossil Fuel Plants#Nuclear Power Plants#Geothermal Facilities#Power Plant Reliability#Power Plant Downtime#Vibration Analysis#Seismic Forces#Compliance Assurance#Safety Enhancement#Supports Optimization#Regulatory Requirements#Case Studies#Energy Industry#Operational Continuity#ASME Standards#Power Plant Operations#Power Plant Maintenance

0 notes

Text

Explore the power of on-site dynamic balancing through vibration analysis. Discover how this advanced technique enhances predictive maintenance, prolongs equipment lifespan, and optimizes machinery performance. Ensure precision and reliability in your operations with expert insights on dynamic balancing and vibration analysis.

To know more, visit- https://www.vibrotech.co.in/our-services/vibration-analysis

#Vibration Analysis#Vibration Monitoring#Vibration Measurement#Vibration Control System#Vibration Testing#Vibration Audit#FFT Analysers#vibration analysis solutions#vibration analysis providers#benefits of vibration analysis

0 notes

Text

0 notes

Text

So about the new poster ST just uploaded:

A couple noteworthy things right off the bat :

1) This poster is dated June 13 1986. Now correct me if im wrong, but wasn't it March/April when we left off? This is way after that. This is s5 territory. Explains the outfit description as well. Could the hooded jacket be this? We dont see El go near the highschool in s4 either.

2) The inclusion of missing CHILD and TEEN in the poster is so fucking suspicious regarding age and identity fuckery re: El and Jane.

3)

El saying this line is super interesting as compared to the Henry line in TFS " What are you going to do? Rewrite the ending?" directed to Joyce. So excited to see the connection there.

4) The "mysterious dissapearance" mentioned here vs The Vanishing of X X...something is really up there and suddenly the identity of Nell's character in s5 becomes even more obscure. Jane, is that you?

5) Why is her height listed as 5.4 if she is 5.6 IN THE PHOTO USED HERE. Unless of course (static noise)

Anyway. Normal hours 🔥💖

#stranger things#stranger things 5#st5 spoilers#el hopper#jane hopper#stranger things analysis#fucking vibrating btw

124 notes

·

View notes

Text

Top-Notch Vibration Analysis Solutions At SEMEQ In Missouri

Ensure your equipment operates at peak efficiency with Semeq’s vibration analysis services. Our proactive approach helps detect early signs of wear, misalignment, and imbalances. Count on our experts to deliver tailored insights, empowering you to make smarter maintenance decisions and boost productivity.

Visit Us: https://semeq.com/en/solutions/

0 notes

Text

Explore why monitoring asset condition is vital in the Food & Beverages industry for ensuring product quality, safety, and operational efficiency.

0 notes

Text

Vibration Analysis in Chennai: Cutting-Edge Techniques for Machinery Health

In today’s industrial landscape, predictive maintenance and equipment reliability are critical for operational efficiency. As the industrial hub of South India, Chennai is home to numerous sectors such as automotive, manufacturing, power generation, and petrochemicals, all of which rely heavily on machinery and rotating equipment. Ensuring these machines operate optimally without unexpected breakdowns requires sophisticated monitoring methods, with vibration analysis standing out as one of the most effective techniques. In Chennai, vibration analysis is emerging as a powerful, cutting-edge tool that keeps machinery in peak condition, reduces downtime, and enhances productivity.

Understanding Vibration Analysis

Vibration analysis is a technique used to monitor the health and performance of machinery by analyzing the vibrations that machinery produces during operation. Since all rotating and reciprocating machines generate unique vibration patterns, monitoring these patterns can reveal underlying issues like misalignment, imbalance, bearing failures, and gear faults before they escalate into major breakdowns. The method involves using highly sensitive accelerometers and software tools that capture, filter, and analyze vibration signals. Through this process, operators and maintenance teams can diagnose and pinpoint potential failures in advance, ensuring corrective action is taken at the right time.

Why Vibration Analysis is Essential in Chennai’s Industries

Chennai’s industrial landscape is vast, and in sectors such as manufacturing, petrochemicals, and power plants, any unplanned machine downtime can lead to significant revenue losses. Equipment failures also pose safety risks, especially in high-stakes industries like power generation and petrochemical processing. Vibration analysis in Chennai provides companies with a preventive maintenance solution that enhances the longevity of critical assets, reduces repair costs, and improves workplace safety. By utilizing this advanced technique, Chennai-based industries can ensure seamless production cycles, minimize financial losses, and safeguard their workforce.

Key Components of Vibration Analysis

Vibration analysis relies on several components, each playing a critical role in machinery diagnostics:

Sensors: Accelerometers and velocity sensors detect and record vibrations across multiple axes. These sensors capture vibration data at high frequencies, allowing for a detailed analysis of even minor irregularities.

Data Acquisition Systems: These systems collect and store vibration data from the sensors. They often include hardware and software that convert raw data into a usable format for further processing.

Analysis Software: Software solutions are used to process and interpret vibration data. These tools offer real-time monitoring, fault diagnostics, trend analysis, and reporting features that help maintenance teams make data-driven decisions.

Expert Interpretation: Skilled analysts interpret the data, identifying potential issues and recommending maintenance actions. In Chennai, companies providing vibration analysis services employ trained engineers with deep expertise in vibration patterns and machinery diagnostics.

Cutting-Edge Techniques in Vibration Analysis

As Chennai’s industries adopt vibration analysis, modern techniques and tools are making the process more accurate and insightful than ever:

Wireless Vibration Sensors: New wireless sensors transmit vibration data to cloud-based systems, enabling real-time monitoring without physical connections. This technology is particularly useful in remote or hazardous areas of Chennai’s industries, such as power plants and oil refineries, where traditional wired systems may be impractical.

FFT (Fast Fourier Transform) Analysis: FFT transforms complex vibration data into simple frequency components, making it easier to identify specific issues like imbalance, misalignment, and bearing defects. Chennai-based industries benefit from this precision, allowing them to target and resolve issues promptly.

Machine Learning Algorithms: With advancements in artificial intelligence, machine learning algorithms can analyze large sets of vibration data, detect patterns, and predict potential failures. Machine learning has become invaluable in Chennai’s larger manufacturing plants, where it enables predictive maintenance on a massive scale and reduces reliance on manual analysis.

Portable Vibration Analyzers: Compact and portable vibration analyzers allow technicians to perform on-site diagnostics quickly and effectively. These devices are highly versatile, enabling companies in Chennai to conduct regular equipment checks without interrupting their operations.

Ultrasonic Vibration Analysis: Ultrasonic analysis detects high-frequency sounds that are typically beyond human hearing and is effective for diagnosing lubrication issues and identifying early bearing failures. This technique is especially beneficial in Chennai’s manufacturing facilities, where machinery operates at high speeds and requires precise lubrication.

Benefits of Vibration Analysis in Chennai

The benefits of implementing vibration analysis in Chennai’s industries are wide-ranging, impacting not just maintenance practices but also operational outcomes:

Reduced Downtime: By identifying potential issues before they lead to catastrophic failures, vibration analysis helps industries minimize unplanned downtime, keeping production lines running smoothly.

Cost Savings: Preventive maintenance is far more cost-effective than emergency repairs. Vibration analysis enables Chennai-based companies to manage repair schedules, reducing costly last-minute repairs.

Improved Safety: Equipment malfunctions can endanger workers. By proactively monitoring machinery health, companies ensure a safer workplace, complying with safety regulations and enhancing employee morale.

Enhanced Equipment Lifespan: Proper maintenance extends the operational life of machinery. With vibration analysis, companies can ensure their equipment operates efficiently for a longer time, delaying the need for costly replacements.

Environmental Compliance: Efficiently maintained machinery operates with lower energy consumption and reduced emissions, helping Chennai’s industries adhere to environmental regulations.

Choosing a Vibration Analysis Partner in Chennai

Selecting the right provider for vibration analysis in Chennai is essential for gaining the full benefits of this technique. The ideal partner should offer industry-specific expertise, advanced diagnostic tools, and a track record of helping clients improve machinery health. As companies in Chennai become more aware of the advantages of vibration analysis, several local and international service providers are offering state-of-the-art solutions tailored to the region’s industries.

The Future of Vibration Analysis in Chennai

With rapid advancements in sensor technology, machine learning, and real-time data processing, vibration analysis is set to become even more effective. Chennai’s industries are poised to embrace these innovations, enabling smarter, more reliable maintenance practices that will strengthen Chennai’s reputation as a major industrial center.

In conclusion, vibration analysis in Chennai represents a critical investment in machinery health, operational efficiency, and workplace safety. By adopting these cutting-edge techniques, Chennai-based industries are positioned to achieve superior performance and remain competitive in an increasingly demanding market.

0 notes

Text

Apparently there's currently discussion in science (humanities in particular) about whether video essays could be accepted as academic writing on par with the academic papers we currently have

I think that's awesome as fuck tbh

#brief ramble#a lot of “texts” these days are visual media#it only makes sense that discussion of it should be able to emulate this#and so many video essayists already do academia level research and writing#philosophy tube#hbomberguy#defunctland#come to mind especially#and a lot of media analysis these days comes in form of video essays#same with sociology#jessie gender#sarah z#alexander avila#cj the x#and so many more#obviously academic video essays would have a bunch of extra requirements and citation guidelines#and you probably cant put in that many jokes#but maybe itll also help make academia more accessible??#oh hey and maybe the whole plagiarism thing wouldnt go as unchecked#honestly the day 'cj the x' becomes an academic source i am rejoining the science#that guy just makes my brain vibrate on the exactly right frequency

242 notes

·

View notes

Text

SAP success factor

SAP Success Factors is a cloud-based HCM factor that provides the best solution in supporting core HR and payroll management, talent acquisition management, HR analytics, and overall employee lifecycle processes. For more details visit our official website.

0 notes