Don't wanna be here? Send us removal request.

Text

Advanced Vision Inspection and Smart Data Collection for Industrial Intelligence | AHHA Labs

The LISA industrial AI solution by AHHA Labs is a powerful suite of AI-driven tools designed for vision inspection, anomaly detection, and real-time equipment monitoring. LISA enables factories to collect, analyze, and act on visual and sensor data at high speed—powering the next generation of smart manufacturing.

LISA Product Line

LISA Video

AI CCTV Monitoring for Industrial Safety and Security

LISA Video enables users to develop and deploy AI models on CCTV systems for real-time monitoring of industrial sites. It detects abnormal situations—such as unauthorized access, unsafe behavior, or equipment malfunctions—and triggers alerts instantly, enhancing site safety and operational awareness.

LISA Inspection

AI-Powered Vision Inspection and Predictive Maintenance

LISA Inspection is designed for visual inspection, anomaly detection, and predictive analysis of industrial equipment and components. It identifies defects, wear, or irregularities before they lead to failure, helping manufacturers prevent downtime, improve product quality, and optimize maintenance schedules.

LISA Scope

Real-Time Dashboard for Quality Monitoring and Anomaly Detection

LISA Scope provides a live dashboard that displays the results of AI inference from visual inspection processes. Operators and managers can monitor quality control data and detect anomalies in real time, enabling quick decision-making and process improvements across the production line.

If you are looking for a industrial AI platform, you can find it at AHHA Labs.

Click here if you are interested in AHHA Labs products.

View more: Advanced Vision Inspection and Smart Data Collection for Industrial Intelligence

0 notes

Text

DataCAMP: Revolutionizing Industrial AI for Real-Time Manufacturing Insights | AHHA Labs

AHHA Labs' DataCAMP is a data collection for Predictive AI specifically designed to meet the growing demands of modern manufacturing and production environments. It serves as an all-in-one solution that enables factories and industrial sites to harness the power of AI for data collection, processing, visualization, and predictive analysis in real-time.

Data CAMP: Zero Downtime in 3 Years with a Rust-Based Core Engine

24/7/365 Real-Time Processing of Manufacturing Big Data

Data CAMP is powered by a high-performance core engine built using the Rust programming language. Since its deployment in 2020 across numerous manufacturing lines, it has achieved zero downtime due to internal issues—delivering uninterrupted, real-time data processing around the clock, 365 days a year.

Why Rust? Speed, Safety, and Reliability

Fast and Efficient: Rust is renowned for its performance. Its compiler produces highly optimized machine code using the LLVM backend, minimizing runtime overhead while preserving expressive code. In many cases, Rust applications can match the performance of C or C++—making it ideal for data-intensive manufacturing environments.

Memory Ownership Safety: Rust enforces strict memory safety at compile time through its ownership and borrowing system, eliminating common issues such as data races and use-after-free errors. This ensures long-term stability by preventing memory leaks—crucial in 24/7 manufacturing systems where even a small memory issue can lead to a system freeze and costly downtime.

Built for Parallelism: Rust’s advanced concurrency model allows developers to write safe, parallel code with confidence. The language catches potential threading errors during compilation, not at runtime, enabling safer and more efficient use of multi-core systems. This is essential for processing data streams from multiple machines and sensors concurrently in a manufacturing environment.

Industrial Reliability, Proven in the Field

Data CAMP’s Rust-based core engine has consistently proven its robustness in real-world applications. Across dozens of manufacturing customers, it has processed terabytes of data daily without a single failure caused by the application itself.

If you are looking for a data collection solution, you can find it at AHHA Labs.

Click here if you are interested in AHHA Labs products.

View more: DataCAMP: Revolutionizing Industrial AI for Real-Time Manufacturing Insights

0 notes

Text

DataCAMP Data Collection Solution | AHHA Labs

AHHA Labs' DataCAMP data collection solution is a powerful industrial AI-driven platform designed to gather, process, and analyze data from various sources in real time. It enables manufacturers to optimize production, enhance equipment efficiency, and improve decision-making through smart data collection and AI analytics.

- Data CAMP Business intelligence enabled by user-friendly dashboard

Data CAMP offers a range of built-in statistical process control (SPC) solutions. Users can analyze patterns in collected manufacturing data and detect anomalous trends in real time.

Statistical process control (SPC) is a technique for managing production processes and quality. It helps companies maximize their assets, reduce rework or scrap, and produce more products that meet quality standards. Data CAMP provides a variety of SPC functions useful for manufacturing companies, allowing organizations to select and apply individual SPCs that fit their manufacturing context.

- Real-time process monitoring and anomaly detection

Data CAMP collects and analyzes manufacturing data to derive insights into processes and quality.

- I-MR, Xbar-R, Xbar-S chart

Monitor variability in the production process

Display Center Line (CL), Upper Control Limit (UCL), and Lower Control Limit (LCL)

Intuitively understand process status

- Process Capability Index (CPK) and Process Performance Index (PPK)

Measure how consistently the process operates within specification limits in the short and long term

- Parameter Correlation Analysis

Calculate the influence of different variables

Identify factors that significantly impact product quality

- Various Specification Management Functions

Define tolerance ranges for products and processes

The visual dashboard allows users to view each measurement in chronological order, observe variations between data points, and intuitively see the average value, range, and standard deviation of each sample group. This enables quick and accurate determination of the need for process improvement.

- Configure a manufacturing field-specific dashboard

Design an SPC application pipeline and configure visualization dashboards for your manufacturing context to enhance overall process efficiency, operational transparency, and accessibility, and to facilitate data-driven decisions. Organizations can consistently produce high-quality products, maintain competitiveness, and boost customer satisfaction.

If you are looking for data collection solution and industrial AI models, you can find it at AHHA Labs.

Click here if you are interested in AHHA Labs products.

View more: DataCAMP Data Collection Solution

0 notes

Text

Industrial AI solution Data CAMP Easy to use No-code Recipe UI | AHHA Labs

AHHA Labs' DataCAMP is an industrial AI solution designed to enhance manufacturing efficiency through advanced data analysis, real-time monitoring, and AI-driven predictive maintenance. It provides a comprehensive data management and AI automation system that enables industrial sites to optimize processes, reduce downtime, and improve product quality.

Data CAMP Easy to use No-code Recipe UI

Easily implement data pipelines optimized for manufacturing processes with a recipe-based, no-code, block-coding UI.

Easily organize your data pipelines with a no-code block-coding UI

Data CAMP supports a recipe-based, no-code block-coding UI. Users can combine individual recipe items with a drag-and-drop interface to visually configure and modify the entire pipeline, including data pre-processing and transformation.

For example, users can batch collect data such as sensor readings, inspection results, images, and acoustic data from various facilities and inspection equipment by specifying communication protocols like FTP and MELSEC. The collected data can be automatically converted to required formats, such as CSV or JSON, and set to automatically perform basic operations for analysis, including referencing, inserting, removing, merging data, pre-processing for statistics, and triggering events. The output file format for transmission and storage can be specified, and the communication protocol used by the parent system, such as DB or MES, can be specified to automatically transmit and store the processed data.

In short, users can efficiently collect, pre-process, transmit, store, and analyze massive amounts of manufacturing data without the need for complex coding.

High reliability with no-code solution

With a simple UI/UX based on no-code recipes, the application is also more reliable. Human coding can introduce errors, and poorly developed software can sometimes have cascading effects on manufacturing equipment. In the worst-case scenario, the entire system can go down.

This is unlikely to happen with Data CAMP, which uses pre-made recipe files to change settings, minimizing human error. Additionally, because it is organized as micro services, even if a recipe file is written incorrectly, it will only cause a specific pipeline to stop working and not have a cascading effect on other systems.

If you are looking for an industrial AI platform, you can find it at AHHA Labs.

Click here if you are interested in AHHA Labs products.

View more: Industrial AI solution Data CAMP Easy to use No-code Recipe UI

0 notes

Text

High-quality Data Collection AI-Driven Solutions | AHHA Labs

AHHA Labs' DataCAMP is an advanced data collection and management system designed to streamline data acquisition, organization, and processing for industrial applications. It is part of AHHA Labs' AI-driven solutions, ensuring efficient and high-quality data handling for various sectors, including manufacturing, automation, and industrial AI applications.

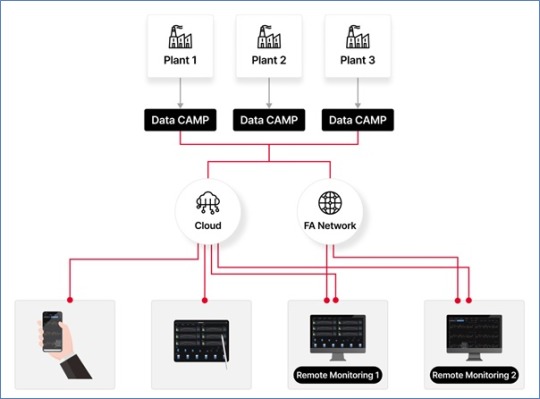

AHHA Labs' DataCAMP: Scalable and Flexible Industrial Data Collection System

Scalability with Micro-Service Architecture

DataCAMP is built on a micro-service architecture, enabling seamless scalability. Users can flexibly add or remove equipment, facilities, data, and features without requiring additional software development. This modular approach ensures adaptability to evolving industrial needs.

Flexible Deployment Options

DataCAMP supports both on-premises and cloud-based deployment, allowing manufacturers to choose the best option based on their infrastructure and operational requirements:

Cloud Deployment: Quick and cost-effective adoption without the need for additional server infrastructure. Ideal for companies looking for a fast setup with minimal upfront investment.

On-Premises Deployment: Offers long-term cost savings as data volume and complexity increase, making it a suitable option for organizations with extensive data management needs.

Additionally, DataCAMP allows for a hybrid approach, where it can be initially deployed in the cloud and later transitioned to an on-premises setup as needed.

Rapid Implementation

Once specifications are finalized and infrastructure preparation is complete, DataCAMP can be fully operational within two weeks. This quick deployment minimizes downtime and accelerates productivity.

Web-Based Accessibility for Real-Time Monitoring

DataCAMP features a web-based interface, providing real-time access to production site data. This ensures that teams can monitor, analyze, and respond to data insights from anywhere, without being restricted by time or location.

If you are looking for data collection for Predictive AI, you can find it at AHHA Labs.

Click here to if you are interested in AHHA Labs products.

View more: High-quality Data Collection AI-Driven Solutions

0 notes

Text

DataCAMP is a Cutting-edge Platform Designed for Big Data Intelligence | AHHA Labs

AHHA Labs' DataCAMP is a cutting-edge platform designed for big data intelligence, catering to the needs of modern industrial, enterprise, and data-driven ecosystems. It harnesses advanced AI and big data technologies to streamline data processing, analysis, and actionable insights.

DataCAMP Compatible with Legacy Systems Manage all manufacturing big data in an integrated manner with easy compatibility with legacy equipment, existing production systems, and commercial analysis tools.

Batch collect and transmit manufacturing data using various communication protocols.

DataCAMP widely supports most communication protocols used in industry, including FTP, network drives, TCP/IP sockets, Modbus/MELSEC, REDIS, and AMQP. Through this, users can conveniently collect all types of data, such as inspection images, inspection results, CCTV images, sound data, vibration data, and PLC data generated from various facilities and sensors. DataCAMP supports a user-friendly data query interface and data set export function, allowing easy transfer to various legacy systems such as MES and ERP as well as external commercial analysis tools.

Easy and fast automatic pre-processing

The data produced by numerous devices comes in various formats, such as CSV, JSON, and YAML. Since this equipment data is not directly compatible, each data set must be checked individually. To understand the entire factory status, you must convert each file format one by one and collect the data.

DataCAMP automates this process. Use the recipe function to convert and integrate various structured/unstructured data into the desired format. Users can directly specify the output data format for transmission and storage to legacy systems such as NAS and DB. DataCAMP also supports multiple techniques, including regular expressions (RegEx), a powerful string processing tool, to automatically perform data referencing, insertion, removal, merging, statistical pre-processing, and event triggering.

If you are looking for big data intelligence, you can find it at AHHA Labs.

Click here to if you are interested in AHHA Labs products.

View more: DataCAMP is a Cutting-edge Platform Designed for Big Data Intelligence

0 notes

Text

Real-Time AI-driven Anomaly Detection Solution | AHHA Labs

AHHA Labs' LISA is a real-time AI-driven anomaly detection solution designed to identify unusual patterns or irregularities in data. LISA uses advanced AI algorithms to monitor operations continuously, detecting anomalies in real time to prevent potential issues before they escalate.

This solution is particularly useful in industrial environments, ensuring operational efficiency, reducing downtime, and enabling predictive maintenance by identifying irregularities early.

Features of AHHA Labs' LISA

Unsupervised Learning Without Labeling

Build models quickly using only normal data with the Anomaly Detector.

Enjoy high usability across various processes with flexible model pipeline configuration.

User-Friendly Interface for Experts and Beginners

Enhance AI model development and usage with detailed indicators and visual heatmaps of model performance, ensuring accessibility for both domain experts and citizen scientists.

Automated and Customized

Accelerate model development with custom presets designed by AI experts.

Adapt to changing field conditions by flexibly adjusting thresholds to optimize performance.

Sustainability in AI System Operation

Utilize cutting-edge research methodologies for data generation and inspection.

Achieve industry-leading speed and performance at multiple global manufacturing sites.

If you are looking for industrial AI models, you can find them at AHHA Labs.

Click here to if you are interested in AHHA Labs products.

View more: Real-Time AI-driven Anomaly Detection Solution

0 notes

Text

Data CAMP Real-time Data Collection AI-Driven Solutions | AHHA Labs

AHHA Labs' Data CAMP is a real-time data collection system that seamlessly integrates with existing infrastructure. It is designed to collect, monitor, and analyze data efficiently. This solution helps organizations predict on-site conditions by leveraging real-time insights, enabling proactive decision-making and improved operational efficiency.

Features of AHHA Labs' Data CAMP

Compatible with Legacy Systems

Manage all manufacturing big data seamlessly by integrating easily with legacy equipment, existing production systems, and commercial analysis tools.

Scalable with Micro-Service Architecture

Add or remove equipment, facilities, data, and features flexibly without the need for additional software development, ensuring scalability.

Easy-to-Use No-Code Recipe UI

Simplify the implementation of data pipelines optimized for manufacturing processes using a recipe-based, no-code block coding interface.

Business Intelligence with a User-Friendly Dashboard

Analyze manufacturing data patterns and detect anomalous trends in real time using advanced statistical process control (SPC) capabilities.

Reliable Performance with Zero Downtime

Powered by a Rust-based core engine, Data CAMP processes manufacturing big data in real time with zero downtime, operating continuously 24/7/365 for over three years.

If you are looking for a real-time data collection AI driven solutions, you can find them at AHHA Labs.

Click here to if you are interested in AHHA Labs products.

View more: Real-time Data Collection AI-Driven Solutions

0 notes

Text

Industrial Real-time AI-driven Anomaly Detection | AHHA Labs

AHHA Labs offers an AI-driven industrial real-time anomaly detection solution designed to enhance operational efficiency and prevent downtime in industrial environments. Leveraging advanced artificial intelligence and machine learning technologies, AHHA Labs' solution ensures seamless monitoring and detection of anomalies across various equipment and production lines in real time.

Features of real-time AI-driven anomaly detection:

Real-time Monitoring Continuous analysis of operational data ensures instant anomaly detection to minimize disruptions.

AI-based Predictive Maintenance AI algorithms analyze historical and real-time data to predict potential equipment failures before they occur, reducing unplanned downtime.

High Accuracy Detection Utilizing deep learning models, AHHA Labs’ solution can detect even minor deviations or abnormalities that are often overlooked by conventional monitoring systems.

Customizable Alerts Immediate alerts are triggered for detected anomalies, allowing swift corrective action to maintain production quality and system integrity.

Scalable Deployment The solution can be implemented across various industrial applications, from manufacturing and energy to logistics and smart factories.

Comprehensive Analytics Detailed reports and analytics provide insights into operational inefficiencies, enabling informed decision-making and process optimization.

Benefits of AI-driven Industrial Real-time Anomaly Detection Solution:

Reduced Downtime: Proactive anomaly detection minimizes system failures and production delays.

Improved Efficiency: Optimized equipment performance ensures maximum output and resource utilization.

Enhanced Safety: Early detection of anomalies reduces risks to machinery and personnel.

If you are looking for real-time AI-driven anomaly detection and industrial AI models, you can find them at AHHA Labs.

Click here to if you are interested in AHHA Labs products.

View more: Industrial Real-time AI-driven Anomaly Detection

0 notes

Text

AI-specialized Company in South Korea | AHHA Labs

AHHA Labs is an AI specialized company that provides a wide range of services that meet the needs of modern industrial sites.

It develops various AI solutions, from data collection to real-time anomaly detection and predictive maintenance, focusing on industrial AI.

Automated Data Collection: AHHA Labs' solutions streamline the process of collecting data from various sensors and equipment within industrial facilities. This data becomes the foundation for further analysis and optimization.

Real-time Anomaly Detection: AI algorithms can analyze real-time data and identify any deviations from normal operating conditions. This allows for early detection of potential issues and equipment malfunctions.

Predictive Maintenance: By analyzing historical data and identifying patterns, AHHA Labs' AI solutions can predict when equipment is likely to fail. This allows for proactive maintenance and prevents costly downtime.

Benefits of Utilizing AHHA Labs' Industrial AI Solutions:

Ø Increased Efficiency: Automation of data collection and real-time response to anomalies lead to streamlined operations.

Ø Improved Productivity: Predictive maintenance prevents equipment failures and unplanned downtime, boosting overall productivity.

Ø Reduced Costs: Early detection of issues allows for preventive maintenance, reducing the need for costly repairs and replacements.

Ø Enhanced Safety: Proactive maintenance helps prevent accidents and injuries caused by equipment failure.

Ø Data-Driven Decision Making: AI-powered insights provide valuable data for informed decision-making, optimizing resource allocation and production processes.

Areas of Application for AHHA Labs' Solutions:

Ø Quality Control: Detecting defects in products and optimizing inspection processes.

Ø Energy Management: Monitoring energy consumption and identifying opportunities for efficiency improvements.

Ø Facility Management: Optimizing building operations and predicting maintenance needs for HVAC and other systems.

If you are looking for an AI-specialized company and industrial AI solution, you can find them at AHHA Labs.

Click here to if you are interested in AHHA Labs products.

View more: AI-specialized Company in South Korea

0 notes