Bengbu Aipu Compressor Manufacturing Co.,Ltd. was founded in June 2002 relying on such location advantages.With the registry capital of 6 millions RMB,the standard workshop of 4000 square meters, 8 technical and R & D personnel and 3 senior engineers, our company focuses on the design,manufacturing and technical development of the compressors in the natural gas recovery field. https://www.aipucompressor.com/

Don't wanna be here? Send us removal request.

Text

Solutions

https://www.aipucompressor.com/solutions/

Compressor For LPG

All the compressor skid is easy to operate and maintain, with small space and less pipes.Characteristics of performance:Smooth running,low noise,simple structure,convenient operation.

Compressor For CNG

CNG Compressor is often used for medium size CNG filling station,especially for CNG standard and daughter station.It is horizontal reciprocating (piston) compressor.

Recycle Compressor For BOG

BOG reciprocating gas recovery systems are widely used in natural gas and LNG cryogenic tanks for LNG tanker after tanker unloading inside. BOG compressible recovered for natural gas.

0 notes

Text

Z-type BOG Compressor

https://www.aipucompressor.com/products/z-type-bog-compressor.html

The outstanding advantage of the Z-type boil off compressor is the small floor space, and its balance of inertia force can reach the best level. The cylinder centerline is perpendicular to the ground, so the cylinder does not bear the gravity of the piston assembly. The lubricating oil can be evenly distributed along the cylinder wall. Our Z-type boil off gas compressor has the characteristics of minimum wear and uniform distribution, good gas sealing conditions, and the long working life of cylinder and airtight element.

Z-type BOG Boil Off Gas Recondenser Features

Designed for specific processes, stable operation and high reliability.

Compact structure, small footprint, easy installation and simple bog compressor operation.

Flexible load adjustment, wide gas intake range and wide application range.

The overall skid-mounted design, low noise, easy to install in urban areas.

High boil off gas recovery system efficiency, low operation and maintenance costs.

Z-type BOG Vertical Reciprocating Compressor Application

BOG compressor is also known as BOG recondenser or boil off gas recondenser. It is mainly applied to LNG operating companies including LNG filling station, L-CNG filling station, LNG gasification stations, and others.

Technical Parameters and Specifications of Z-type BOG Recondenser

Model

Capacity (Nm3/h)

Inlet pressure (Mpa)

Outlet pressure (Mpa)

Motor power (KW)

Outline measurement (mm)

ZW-3.8/(0.2~0.5)-3.5

260

0.02~0.05

0.35

22

2500*1300*1800

ZW-3.5/(0.2~3)-3.5

450

0.02~0.3

0.35

22

2500*1300*1800

ZW-3.5/(0.2~5)-3.5

630

0.02~0.5

0.35

22

2500*1300*1800

ZF-0.45/(1.5~4.5)-250

100

0.15-0.45

25

30

2150*1800*2000

ZF-0.55/(1.5~4.5)-250

120

0.15-0.45

25

37

2150*1800*2000

ZF-0.65/(1.5~4.5)-250

150

0.15-0.45

25

45

2150*1800*2000

ZH-0.45/(1.5~4.5)-250

100

0.15-0.45

25

30

2150*1800*2000

ZH-0.55/(1.5~4.5)-250

120

0.15-0.45

25

37

2150*1800*2000

ZH-0.45/(1.5~4.5)-250

120

0.15-0.45

25

30

2150*1800*2000

ZH-0.55/(1.5~4.5)-250

150

0.15-0.45

25

37

2150*1800*2000

ZH-0.65/(1.5~4.5)-250

200

0.15-0.45

25

45

2150*1800*2000

ZF-0.15/(8~11)-220

100

0.8-1.1

22

22

1600*1800*1800

ZF-0.25/(8~11)-220

150

0.8-1.1

22

37

1800*2000*2000

ZF-0.55/(8~11)-220

200

0.8-1.1

22

45

1800*2000*2000

ZW-1.5/(1~4)-6

200

0.1-0.4

0.6

15

1400*1400*1500

ZW-2.0/(1~4)-6

400

0.1-0.4

0.6

22

1400*1400*1500

ZW-3.0/(1~4)-6

600

0.1-0.4

0.6

30

1600*1600*1600

0 notes

Text

Z-type Ammonia Gas Compressor

https://www.aipucompressor.com/products/z-type-ammonia-gas-compressor.html

In addition to discharging liquid ammonia, ammonia reciprocating compressors for sale are widely used in the fields of medicine, fertilizer, national defense, light industry, etc. Ammonia compressors with reasonable prices are one of the most important equipment for manufacturing nitrogen fertilizer and nitric acid. Ammonia is an important reagent in the laboratory, an alkaline disinfectant against sarin, and a thermosetting phenolic resin catalyst. In daily life, it is used as a detergent, neutralizer, alkaloid leaching agent, photo-printing, etc. It is a compressor in oil and gas industry, and is also widely used in the environmental protection industry and are the key equipment for flue gas denitration in power plants.

Z-type Ammonia Reciprocating Compressor Features

The whole machine has the characteristics of complete configuration, simple structure, and convenient maintenance.

Compact structure, stable operation, high reliability, complete control.

Multiple functions, small size, lightweight, low power, stable and reliable operation, etc.

Good safety performance of the ammonia compressors can create maximum economic benefits for users.

The unit type design reduces the area of the machine room, reduces the workload of operation and maintenance, and saves investment.

Z-type Ammonia Gas Compressor Application

This type of ammonia compressor is widely used in chemical plants, ammonia station liquid ammonia discharge, power plant denitrification, etc.

0 notes

Text

V-type Hydrogen Gas Compressor

https://www.aipucompressor.com/products/v-type-hydrogen-gas-compressor.html

This series of hydrogen booster compressors are mainly used for (methanol, natural gas, coal gas) cracking hydrogen production, water electrolysis hydrogen production, hydrogen filling bottle, benzene hydrogenation, tar hydrogenation, catalytic cracking, and other hydrogen booster compressors. Aipu is one of the leading hydrogen compressor manufacturers, we have various types of hydrogen compressors for sale such as hydrogen recycle compressors, high-pressure hydrogen compressors, hydrogen booster compressors, reciprocating hydrogen compressors, small hydrogen compressors, etc.

V-type Hydrogen Gas Compressor Features

Designed specifically for process flow.

The whole hydrogen gas compressor is skid-mounted, with advanced structure and good sealing.

Wide working pressure range and wide flow range of the hydrogen recycle compressor.

Stable operation, convenient maintenance and perfect automatic control protection of the hydrogen compression system.

Energy-saving and environmental protection, easy to operate and maintain.

V-type Hydrogen Gas Compressor Application

This type of industrial compressor with good hydrogen compressor price is widely used in various hydrogen production systems, polysilicon industry, hydrogen filling bottles, benzene hydrogenation, ammonia decomposition and other processes.

Technical Parameters and Specifications of V-type Hydrogen Booster Compressor

No.

Model

Flow rate (Nm3/h)

Inlet pressure (Mpa)

Discharge pressure (Mpa)

Medium

Motor power (KW)

overall dimension (mm)

1

VW-5.8/0.7-15

510

0.07

1.5

H2

75

2500*2100*1400

2

VW-4.9/2-20

750

0.2

2

H2

90

2800*2100*1400

0 notes

Text

Other Compressors

https://www.aipucompressor.com/products/other-compressor/

Gas Compressor Manufacturer - Your professional supplier and reliable partner!

There are different types of reciprocating gas compressors, such as hydrogen gas compressor, industrial compressor, ammonia gas compressor and piston gas compressor, etc. Generally, they pressurize the gas to some desired pressure to meet people's demands although the compressing mediums are different.

Types of Other Compressors

V-type Hydrogen Gas Compressor

Hydrogen Gas Compressor belongs to the special compressor. Therefore, when using a hydrogen recycle compressor, please DO pay attention to the explosion-proof and anti-flammable conditions.

Z-type Ammonia Gas Compressor

Z-type Ammonia Gas Compressor is vertical compressor, it has one or more rows of compression cylinders for low rate flow conditions.

0 notes

Text

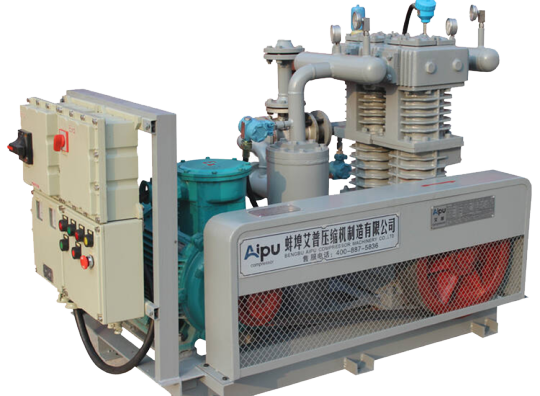

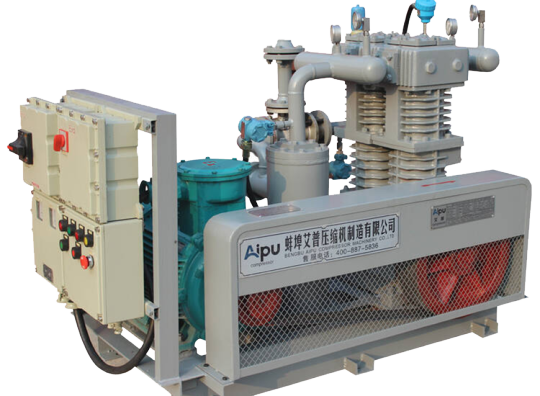

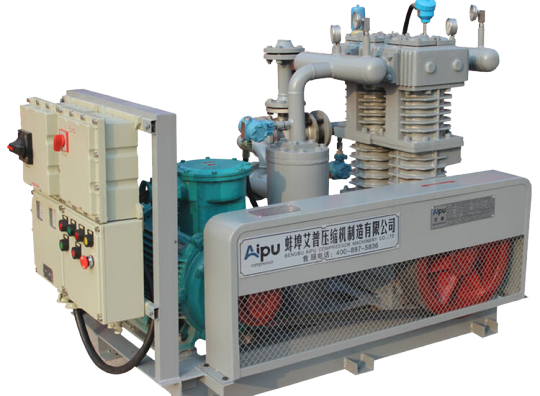

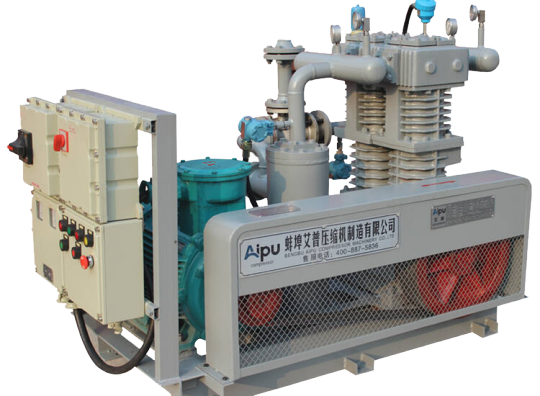

M-type CNG Compressor

https://www.aipucompressor.com/products/m-type-cng-compressor.html

The CNG compressor package includes an M-type CNG compressor unit, which is an integral skid-mounted compressor unit, which is specially designed for compressed natural gas filling stations. It complies with JB/T10289 "Natural Gas Compressor for Automobile Gas Stations", JB/T9105 "Technical Conditions for Large Reciprocating Piston Compressors" and GB50156-2002 The standard of "Code for Design and Construction of Automobile Refueling Stations", manufactured by Bengbu Aipu Compressor Manufacturing Co., Ltd.

This type of CNG compressor package is mainly composed of a compressor host, an explosion-proof main motor, a coupling and a non-sparking guard, an intake filter, a separator at all levels, a process pipeline system, a cooler, a control system, a base, etc. The intake and exhaust of the compressor, the drain of the separator, the venting of the safety valve, the power cable sheath, and the control cable piping are connected to the skid side.

1 note

·

View note

Text

LPG Compressor

https://www.aipucompressor.com/products/lpg-compressor/

Liquefied petroleum gas (LPG) series oil-free lubricating compressor is one of our domestic products with the characteristics of low speed, high strength components, smooth operations, long service life, convenient maintenance and great LPG compressor prices. Among them, the ZW series compressor is in unit form. It integrates compressor, gas-liquid separator, filter, two-position four-way valve, safety valve, checks valve, explosion-proof motor and chassis. It has the advantages of small volume, lightweight, low noise, good sealing, easy installation and simple operation. LPG compression is mainly used for the unloading, loading, dumping, residual gas recovery and residual liquid recovery of LPG. It is widely used in LPG storage and distribution station, gasification station, gas mixing station, gas filling stations and so on, it is the key equipment in the LPG industry.

Among our types of gas compressor, LPG gas compressors are one of the best. They are mainly used for the transportation and pressurization of liquefied petroleum gas or gases with similar properties. Therefore, such LPG compressors using LPG compressor oil to operate are the key equipment for liquefied petroleum gas stations, LPG car filling stations, and mixed gas stations, and they are also the ideal equipment to pressurize and recover the gases for chemical companies. Aipu is one of the leading LPG compressor manufacturers, we provide the best LPG gas compressor with reasonable prices.

Types of LPG Compressor

Z-type LPG Compressor

Z-type liquefied petroleum gas (LPG) compressor is a skid-mounted, vertical, single-acting, air-cooled, non-lubricated, reciprocating piston structure unit.It is composed of main engine.

LPG Compressor Working Principle

After the cracking gas below C4 comes out of the separation tower, it enters the inlet of the compressor and pressurizes to 8-12kg in the cylinder of the compressor.

At the same time, it cools and removes heat. When the temperature is lower than the critical temperature (the temperature of gaseous and liquid transformation), most of these gases will liquefy, and only a small amount of carbon can not liquefy. It is called dry gas and will be treated separately.

The liquefied gas is pumped to the pressure storage tank for storage! According to the need can be transported and sub packed, such as car tanker, civil LPG tank and so on.

LPG Gas Compressor FAQs

What are the precautions for LPG compressors?

When the liquid enters the separator of the LPG compressor, it must be stopped immediately;

When the LPG gas compressor starts to run, and it is found that the oil pump has no pressure, it should be stopped immediately;

If the sound of the cylinder and moving parts is abnormal, stop and check immediately;

If each instrument indicates that it exceeds the specified range, stop the gas compressor immediately;

When you smell the burning smell from the machine, you should stop the working of the LPG compressor for inspection;

Check the temperature and vibration of each part of the motor and compressor, and stop if there is any abnormality;

When the safety valve of the LPG compressor fails, it should be shut down for maintenance;

What is liquefied petroleum gas (LPG) ? what's its application?

Liquefied Petroleum Gas (LPG), one of the petroleum products, is a mixture of propane and butane, usually accompanied by a small amount of propylene and butene.

Main application: Used as a raw material for the petrochemical industry, and it can also be used as fuel.

Liquefied petroleum gas is mainly used as a petrochemical raw material, used for hydrocarbon cracking to produce ethylene or steam reforming to produce synthesis gas, and can be used as industrial, civil, and internal combustion engine fuel. The main quality control indicators are evaporation residue and sulfur content, and sometimes olefin content is also controlled. Liquefied petroleum gas is a flammable substance. When its content in the air reaches a certain concentration range, it will explode when exposed to an open flame.

Where can liquefied petroleum gas (LPG) be applied?

With the development of the petrochemical industry, liquefied petroleum gas, as a basic chemical raw material and a new type of fuel, has attracted more and more attention. In chemical production, ethylene, propylene, butene, butadiene, etc. are obtained from liquefied petroleum gas after separation, which is used to produce synthetic plastics, synthetic rubber, synthetic fibers, and pharmaceuticals, explosives, dyes and other products. Using liquefied petroleum gas as fuel, because of its high calorific value, no smoke, no carbon residue, easy operation and use, has been widely used in people's lives. In addition, liquefied petroleum gas is also used for cutting metal, baking agricultural products and roasting in industrial kilns.

0 notes

Text

D-type CNG Compressor

https://www.aipucompressor.com/products/d-type-cng-compressor.html

D-type CNG compressor machine is a mounted skid structure with the advantages of easy installation and convenient maintain. It is indispensable equipment of CNG filling station which consists of a compressor unit, metering device, gas purifying dryer, gas storage device, sequence control plate, gas column, gas dispenser and other components. The CNG compressor system is widely used in CNG Filling Standard Station. CNG Filling Daughter Station and CNG Filling Mother Station.

D-type CNG Compressor Feature

Safe and reliable: Wearing parts are of international famous brands, with a lifetime of 6000-8000 hours.

Environmental protection and energy-saving: Low vibration, low noise and economical operating costs.

Diversified product structure: Products with M-type and D-type structures are available, OEM is welcomed.

The high degree of automation: Siemens PLC control, ABB soft start (or frequency conversion start), automatic shutdown of failure with sound and light alarm.

D-type CNG Compressor Application

Flow rate per unit: 100-2000Nm3/h

Drive power: 45-280KW

Inlet pressure: 0.05-4.0Mpa

Power supply: 380V/220V, 3-phrase

Medium: Natural gas (Be in line with Class || gas quality standard stipulated in GB17820 of "Natural Gas")

D-type CNG Compressor Specifications

Model

Medium

Rotation speed (RPM)

Inlet pressure(MPa)

Discharge pressure(MPa)

Flow rate m3/min

Outline dimension(mm)

Motor power (KW)

Weight (t)

DFD-3.85/(2-4)-250

CNG

740

0.2-0.4

25

3.85

6750×3700×3500

185

15

DFD-4.2(1-3)-250

CNG

985

0.1-0.3

25

4.2

6750×3700×3500

185

15

DF-1.3/(10-16)-250

CNG

740

1-1.6

25

1.3

6250×3500×3100

185

15

DF-2.4/(4-6)-250

CNG

740

0.4-0.6

25

2.4

6270×3500×3000

165

15

DF-2.86/(2.5-5)-250

CNG

740

0.25-0.5

25

2.86

6270×3500×3000

185

15

DFD-1.6/(8-16)-250

CNG

740

0.8-1.6

25

1.6

6800×3800×3600

220

18

DFD-1.95/(5-12)-250

CNG

740

0.5-1.2

25

1.95

6800×3700×3500

220/204

19

DF-2/15-250

CNG

740

1.5

25

2

6750×3500×3100

250/245

18

0 notes

Text

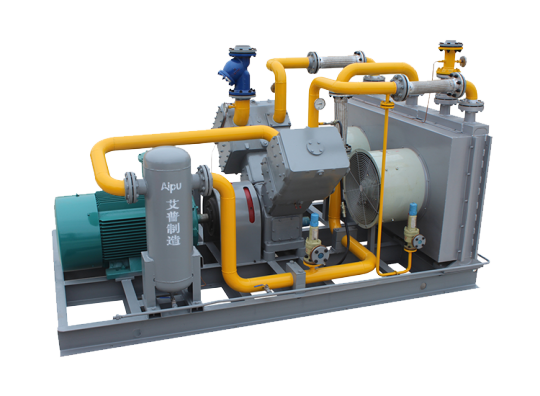

CNG Compressor

https://www.aipucompressor.com/products/cng-compressor/

Gas Compressor Manufacturer - Your professional supplier and reliable partner!

As common equipment in the process of natural gas extraction, storage, transportation and sale, CNG gas compressor for sale is widely used in all aspects of natural gas production,transportation and sales at home and abroad. Domestic CNG compressor manufacturers became active in the 1980s and was initially developed and produced by Sichuan Jianyang Air Compressor Plant and Sichuan Petroleum Administration Bureau. After years of development, the domestic natural gas compressor manufacturing industry has made great progress, some skid models can basically replace similar overseas products, we can see this progress particularly in the China CNG compressor market.

Types of CNG Compressor

D-type CNG Compressor

D-type safe CNG compressor has complete functions, reliable and stable performance, good comprehensive technical performance, and it has reached the technical level to replace similar products in the world.

M-type CNG Compressor

M-type CNG Compressor with good price is mainly designed for high flow rate conditions. With the symmetrical balance cylinders, CNG compressor system has the great advantages of smooth operation, small vibration, low noise and long life of easy - damaged parts.

CNG Compressor Fields of Application

Standard CNG Filling Station

Daughter CNG Filling Station

CNG company

Oil and gas treatment plant

CNG Compressor Working Principle

In order to reduce the damage of CNG compressor parts and prolong the service life of the compressor, the daily maintenance and maintenance of the natural gas compressor is very important and necessary. Daily maintenance work mainly includes regular lubrication of equipment and oil exchange, equipment anti-corrosion work, regular proofreading equipment accuracy, so as to minimize the wear and failure of parts, so that the equipment as far as possible in the normal CNG compressor working state. The specific maintenance process of the CNG gas compressor is generally divided into quarterly maintenance, semi-annual maintenance and annual maintenance.

CNG Compressor FAQs

How Is Cng Compressed?

CNG is produced by compressing natural gas to less than 1% of its volume at standard atmospheric pressure. To provide an adequate driving range, CNG has stored onboard a vehicle in a compressed gaseous state at a pressure of up to 3,600 pounds per square inch.

What Is Cng Why Cng Is Better Than Diesel?

Compared to diesel and even to petrol, natural gas creates far fewer nitrogen oxides (NOx) and particulate matter (PM) when combusted. The combustion process is also quieter. CNG is therefore a better 'urban' fuel than diesel. Lower CO2 emissions, both tailpipe, and well-to-wheel.

What Does Ngv Signify?

NGV stands for Natural Gas Vehicle, which is a car or truck powered by compressed natural gas (CNG) instead of conventional gasoline or diesel. Currently, it is popular at home and abroad, especially in the urban public transportation area. It has lots of advantages, such as lower fuel cost, little air pollution, less loss of vehicle components, etc.

0 notes

Text

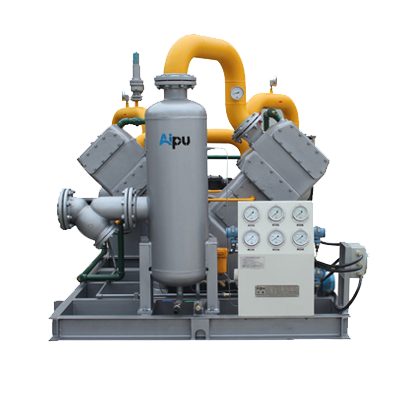

BOG Compressor

https://www.aipucompressor.com/products/bog-compressor/

Gas Compressor Manufacturer - Your professional supplier and reliable partner!

The design of the BOG recycling compressor complies with the API618 international standard, and the manufacturing complies with the GB/T19001-ISO/9001 standard. Boil off gas compressors has the leading technology, safety and reliability, stable quality, high recovery efficiency, and a wide range of applications, which can meet the needs of BOG release and recovery of boil-off gas compressor for LNG plant operating companies under different working conditions. Aipu is a professional manufacturer of boil off compressors and a comprehensive BOG recycling solution provider.

Types of BOG Compressor

Z-type BOG Compressor

Z-type BOG Compressor is mainly suitable for the working conditions requiring low flow rate and limited workspace at site.

V-type BOG Recovery Compressor

Boil Off Gas Compressor Fields of Application

LNG recycle from tank truck or vessel

Well gas recycle in oil field

Associated gas recycle in oil field

Residual gas recycle

Boil Off Compressor Operation

As the core component of the gas recycling system, the boil-off gas compressor directly affects the operation of the boil-off gas recovery system. BOG compressors are usually working under the temperature of air intake -80~-160℃ and working pressure 0.4~6.4Mpa. The parts in contact with low-temperature gas must be the corresponding low-temperature material, and the system must also set up a temperature controller. At the same time, considering the bog compressor operation economy, it is required that the unit volume refrigerating capacity of boil off compressor should be large output, the compression ratio of the cycle gas compressor should be low, and the operation of each component can be guaranteed to be reliable at low temperature. For the purpose of preventing gas leakage at low temperatures, the shaft seal performance of BOG compressor should be good. A lubricating oil should be able to have good flow performance at low temperatures.

BOG compressor FAQs

What is BOG?

BOG stands for Boil Off Gas, it refers to cryogenic liquid in the storage tank, such as LNG (-162℃), low-temperature propane(-40~-42℃), low-temperature alkane (0~-2℃), etc., is volatilized to gas after receiving external heat

What is BOG compressor?

BOG compressor is a compressor used to compress BOG. General BOG compressors use oil-free reciprocating compressors, and the working principle is the same as that of ordinary reciprocating gas compressors. The difference is that the inlet of BOG compressor sucks in low-temperature gas, so the first-stage cylinder and piston of the compressor must be resistant to low temperatures and prevent freezing. Oil-free lubrication is generally achieved by using labyrinth seals or special piston rings.

Why must BOG be recycled?

There are two main reasons:

1.The need for the safety of the LNG (or other gas) system itself. BOG may cause the overloading of the storage or the system.

2. BOG itself is a very clean fuel. Discharging into the air is not only a needless waste but also the discharge of combustible gas into the air is potentially dangerous. The main component of BOG is methane, and methane is a gas with a strong greenhouse effect. According to the second scientific assessment report of the International IPCC "Intergovernmental Panel on Climate Change", the greenhouse effect coefficient (GWP) of methane is 21 times that of carbon dioxide.

0 notes

Text

AIPU COMPRESSOR

https://www.aipucompressor.com/products/

Bengbu Aipu Compressor Manufacturing Co., Ltd. is a professional manufacturer of gas compressors from China. Our main products include BOG compressors, LPG compressors, CNG compressors, and other gas compressors for CNG/LNG tank trucks, CNG filling station, LNG filling station, LNG gasification station, L-CNG filling station, LNG storage station, LNG peak regulation station, LNG receiving station, LPG filling station, chemical plant, oil and gas plant, etc. Each of Aipu piston reciprocating compressors is designed and manufactured professionally on the basis of the technical data and requirements from the end-users. As one of the leading reciprocating natural gas compressor manufacturers, we have different types of gas compressors for sale such as industrial reciprocating compressors, natural gas booster compressors, reciprocating compressors, etc., which are offered at a reasonable price. We keep developing new technology and manufacturing processes to improve our different types of gas compressors and gas compression systems so that they could meet the market demand and the users' expectations. Here you can find our natural gas compressor for sale.

BOG Compressor

BOG compressors also called boil-off gas compressors, are widely used to recover natural gas and boil-off gas left after the unloading of LNG cryogenic tanks and CNG tankers. The boil-off gas recovery system would be recovered and pressurized to CNG refilling station or pipeline network to achieve the dual purpose of maximum economic efficiency and environmental protection.

Z-type BOG Compressor

V-type BOG Recovery Compressor

LPG Compressor

LPG compressors, one type of gas compressors for sale, are widely applied in liquefied petroleum gas stations, LPG car filling stations and mixed gas stations, and they are also an ideal equipment for chemical plants to pressurize the gases and benefit themselves from it, and popular in the areas of loading and unloading of LPG tank truck and vessel and bottle filling and tank decanting of LPG and similar media.

Z-type LPG Compressor

CNG Compressor

CNG compressor is often used for medium size CNG filling stations, especially for CNG standard and daughter stations. It is a reciprocating (piston) gas compressor, which uses reciprocating compressor oil to operate and is mainly composed of the main compression,anti-explosive electric motor, cooling unit, lubrication unit, internal connection pipeline, safety valve, and the blow-down valve, the PLC control cabinet, etc. Currently, we have many natural gas compressors with reasonable prices for sale and they are widely used in the domestic and overseas markets.

D-type CNG Compressor

M-type CNG Compressor

Other Compressors

There are different types of gas compressors, such as hydrogen gas compressor, ammonia gas compressor, electric gas compressor, gas booster compressor, etc. Generally, they pressurize the gas to some desired pressure to meet people's demands although the compressing mediums are different.

V-type Hydrogen Gas Compressor

Z-type Ammonia Gas Compressor

Compressor Solutions

Aipu, one of the oil and gas compressor manufacturers in oil and gas industry can be widely seen in the field of gas recovery and storage, oil and gas plants, liquefied petroleum gas (LPG) filling stations, CNG filling stations, chemical areas, etc., its professional design and manufacture of oil and gas compressors with great prices meet the national standards and industrial requirements as well as the needs of users.

Compressor For LPG

Compressor For CNG

Recycle Compressor For BOG

0 notes

Text

Z-type BOG Compressor

The outstanding advantage of the Z-type boil off compressor is the small floor space, and its balance of inertia force can reach the best level. The cylinder centerline is perpendicular to the ground, so the cylinder does not bear the gravity of the piston assembly. The lubricating oil can be evenly distributed along the cylinder wall. Our Z-type boil off gas compressor has the characteristics of minimum wear and uniform distribution, good gas sealing conditions, and the long working life of cylinder and airtight element.

Z-type BOG Compressor Features

Designed for specific processes, stable operation and high reliability.

Compact structure, small footprint, easy installation and simple bog compressor operation.

Flexible load adjustment, wide gas intake range and wide application range.

The overall skid-mounted design, low noise, easy to install in urban areas.

High boil off gas recovery system efficiency, low operation and maintenance costs.

Z-type BOG Compressor Application

It is mainly applied to LNG operating companies including LNG filling station, L-CNG filling station, LNG gasification station and others.

Technical Parameters and Specifications of Z-type BOG Compressor

Model

Capacity (Nm3/h)

Inlet pressure (Mpa)

Outlet pressure (Mpa)

Motor power (KW)

Outline measurement (mm)

ZW-3.8/(0.2~0.5)-3.5

260

0.02~0.05

0.35

22

2500*1300*1800

ZW-3.5/(0.2~3)-3.5

450

0.02~0.3

0.35

22

2500*1300*1800

ZW-3.5/(0.2~5)-3.5

630

0.02~0.5

0.35

22

2500*1300*1800

ZF-0.45/(1.5~4.5)-250

100

0.15-0.45

25

30

2150*1800*2000

ZF-0.55/(1.5~4.5)-250

120

0.15-0.45

25

37

2150*1800*2000

ZF-0.65/(1.5~4.5)-250

150

0.15-0.45

25

45

2150*1800*2000

ZH-0.45/(1.5~4.5)-250

100

0.15-0.45

25

30

2150*1800*2000

ZH-0.55/(1.5~4.5)-250

120

0.15-0.45

25

37

2150*1800*2000

ZH-0.45/(1.5~4.5)-250

120

0.15-0.45

25

30

2150*1800*2000

ZH-0.55/(1.5~4.5)-250

150

0.15-0.45

25

37

2150*1800*2000

ZH-0.65/(1.5~4.5)-250

200

0.15-0.45

25

45

2150*1800*2000

ZF-0.15/(8~11)-220

100

0.8-1.1

22

22

1600*1800*1800

ZF-0.25/(8~11)-220

150

0.8-1.1

22

37

1800*2000*2000

ZF-0.55/(8~11)-220

200

0.8-1.1

22

45

1800*2000*2000

ZW-1.5/(1~4)-6

200

0.1-0.4

0.6

15

1400*1400*1500

ZW-2.0/(1~4)-6

400

0.1-0.4

0.6

22

1400*1400*1500

ZW-3.0/(1~4)-6

600

0.1-0.4

0.6

30

1600*1600*1600

https://www.aipucompressor.com/products/z-type-bog-compressor.html

0 notes

Text

Z-type Ammonia Gas Compressor

In addition to discharging liquid ammonia, ammonia reciprocating compressors for sale are widely used in the fields of medicine, fertilizer, national defense, light industry, etc. Ammonia compressors with reasonable prices are one of the most important equipment for manufacturing nitrogen fertilizer and nitric acid. Ammonia is an important reagent in the laboratory, an alkaline disinfectant against sarin, and a thermosetting phenolic resin catalyst. In daily life, it is used as a detergent, neutralizer, alkaloid leaching agent, photo-printing, etc. It is a compressor in oil and gas industry, and is also widely used in the environmental protection industry and are the key equipment for flue gas denitration in power plants.

Z-type Ammonia Gas Compressor Features

The whole machine has the characteristics of complete configuration, simple structure, and convenient maintenance.

Compact structure, stable operation, high reliability, complete control.

Multiple functions, small size, lightweight, low power, stable and reliable operation, etc.

Good safety performance of the ammonia compressors can create maximum economic benefits for users.

The unit type design reduces the area of the machine room, reduces the workload of operation and maintenance, and saves investment.

Z-type Ammonia Gas Compressor Application

This type of ammonia compressor is widely used in chemical plants, ammonia station liquid ammonia discharge, power plant denitrification, etc.

https://www.aipucompressor.com/products/z-type-ammonia-gas-compressor.html

0 notes

Text

V-type Hydrogen Gas Compressor

This series of hydrogen booster compressors are mainly used for (methanol, natural gas, coal gas) cracking hydrogen production, water electrolysis hydrogen production, hydrogen filling bottle, benzene hydrogenation, tar hydrogenation, catalytic cracking and other hydrogen booster compressors. There are many types of hydrogen compressors for sale such as

hydrogen recycle compressor, high pressure hydrogen compressor, hydrogen booster compressor, reciprocating hydrogen compressor, small hydrogen compressor, etc.

Get a Quote!

V-type Hydrogen Gas Compressor

V-type Hydrogen Gas Compressor Features

Designed specifically for process flow.

The whole hydrogen gas compressor is skid-mounted, with advanced structure and good sealing.

Wide working pressure range and wide flow range of the hydrogen recycle compressor.

Stable operation, convenient maintenance and perfect automatic control protection of the hydrogen compression system.

Energy-saving and environmental protection, easy to operate and maintain.

V-type Hydrogen Gas Compressor Application

This type of industrial compressor with good hydrogen compressor price is widely used in various hydrogen production systems, polysilicon industry, hydrogen filling bottles, benzene hydrogenation, ammonia decomposition and other processes.

Technical Parameters and Specifications of V-type Hydrogen Gas Compressor

No.

Model

Flow rate (Nm3/h)

Inlet pressure (Mpa)

Discharge pressure (Mpa)

Medium

Motor power (KW)

overall dimension (mm)

1

VW-5.8/0.7-15

510

0.07

1.5

H2

75

2500*2100*1400

2

VW-4.9/2-20

750

0.2

2

H2

90

2800*2100*1400

https://www.aipucompressor.com/products/v-type-hydrogen-gas-compressor.html

0 notes

Text

Other Compressors

Gas Compressor Manufacturer - Your professional supplier and reliable partner!

There are different types of reciprocating gas compressors, such as hydrogen gas compressor, industrial compressor, ammonia gas compressor and piston gas compressor, etc. Generally, they pressurize the gas to some desired pressure to meet people's demands although the compressing mediums are different.

Types of Other Compressors

V-type Hydrogen Gas Compressor

Hydrogen Gas Compressor belongs to the special compressor. Therefore, when using a hydrogen recycle compressor, please DO pay attention to the explosion-proof and anti-flammable conditions.

More details

Z-type Ammonia Gas Compressor

Z-type Ammonia Gas Compressor is vertical compressor, it has one or more rows of compression cylinders for low rate flow conditions.

More details

https://www.aipucompressor.com/products/other-compressor/

0 notes

Text

M-type CNG Compressor

The CNG compressor package includes an M-type CNG compressor unit, which is an integral skid-mounted compressor unit, which is specially designed for compressed natural gas filling stations. It complies with JB/T10289 "Natural Gas Compressor for Automobile Gas Stations", JB/T9105 "Technical Conditions for Large Reciprocating Piston Compressors" and GB50156-2002 The standard of "Code for Design and Construction of Automobile Refueling Stations", manufactured by Bengbu Aipu Compressor Manufacturing Co., Ltd.

This type of CNG compressor package is mainly composed of a compressor host, an explosion-proof main motor, a coupling and a non-sparking guard, an intake filter, a separator at all levels, a process pipeline system, a cooler, a control system, a base, etc. The intake and exhaust of the compressor, the drain of the separator, the venting of the safety valve, the power cable sheath, and the control cable piping are connected to the skid side.

https://www.aipucompressor.com/products/m-type-cng-compressor.html

0 notes

Text

LPG Compressor

Gas Compressor Manufacturer - Your professional supplier and reliable partner!

Liquefied petroleum gas (LPG) series oil-free lubricating compressor is one of our domestic products with the characteristics of low speed, high strength components, smooth operations, long service life, convenient maintenance and great LPG compressor prices. Among them, the ZW series compressor is in unit form. It integrates compressor, gas-liquid separator, filter, two-position four-way valve, safety valve, checks valve, explosion-proof motor and chassis. It has the advantages of small volume, lightweight, low noise, good sealing, easy installation and simple operation. LPG compression is mainly used for the unloading, loading, dumping, residual gas recovery and residual liquid recovery of LPG. It is widely used in LPG storage and distribution station, gasification station, gas mixing station, gas filling stations and so on, it is the key equipment in the LPG industry.

Among our types of gas compressor, LPG gas compressors are one of the best. They are mainly used for the transportation and pressurization of liquefied petroleum gas or gases with similar properties. Therefore, such LPG compressors using LPG compressor oil to operate are the key equipment for liquefied petroleum gas stations, LPG car filling stations, and mixed gas stations, and they are also the ideal equipment to pressurize and recover the gases for chemical companies. Aipu is one of the leading LPG compressor manufacturers, we provide the best LPG gas compressor with reasonable prices.

Types of LPG Compressor

Z-type LPG Compressor

Z-type liquefied petroleum gas (LPG) compressor is a skid-mounted, vertical, single-acting, air-cooled, non-lubricated, reciprocating piston structure unit.It is composed of main engine.

More details

https://www.aipucompressor.com/products/lpg-compressor/

0 notes