Photo

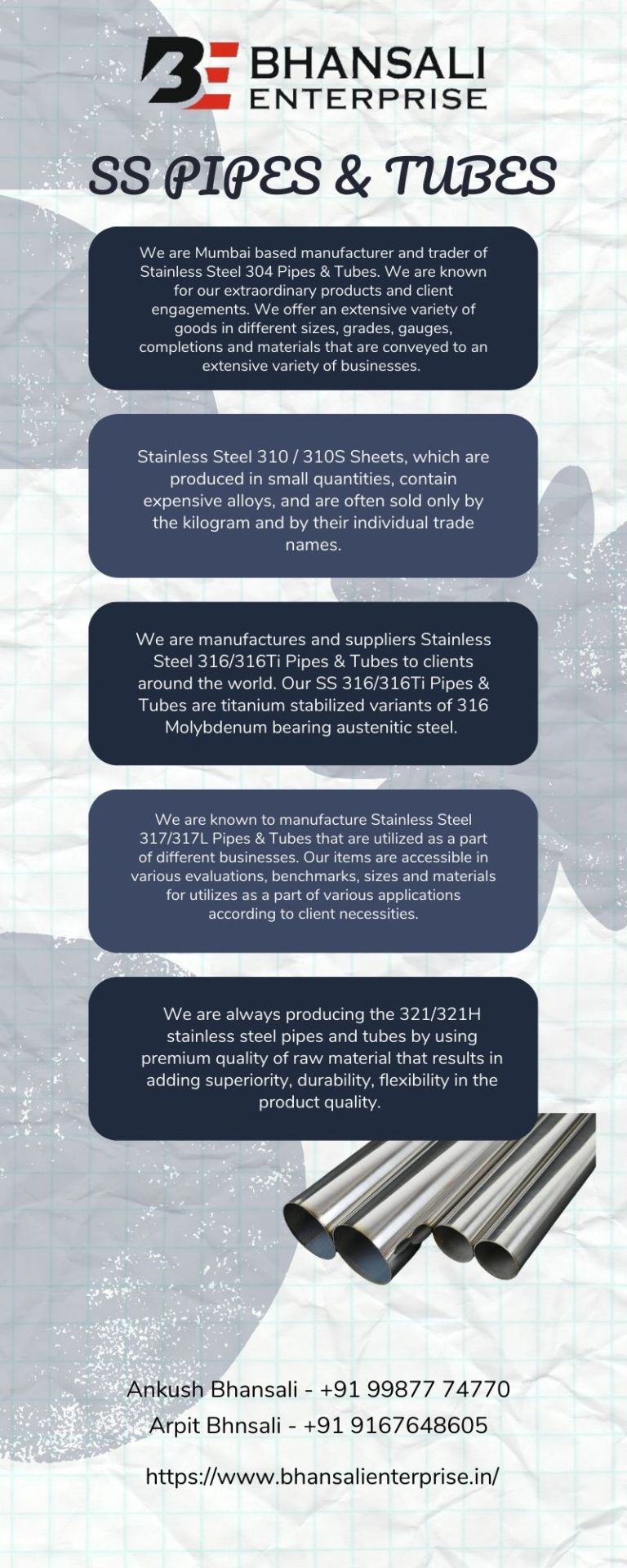

"SS Pipes & Tubes Manufacturer."

We are Mumbai based manufacturer and trader of SS 304 Pipes & Tubes. We are known for our extraordinary products and client engagements. We offer an extensive variety of goods in different sizes, grades, gauges, completions and materials that are conveyed to an extensive variety of businesses. Our SS 304 Pipes are stounding products with an exceptional finishing that we have on offer. We are suppliers, stocks and trades an extensive variety of goods to its clients around the world. Our group of experts monitor the changing market trends and demands to devise products as needs be. We are manufactures and suppliers Stainless Steel 316/316Ti Pipes & Tubes to clients around the world. Our SS 316/316Ti Pipes & Tubes are titanium stabilized variants of 316 Molybdenum bearing austenitic steel. We are known to manufacture Stainless Steel 317/317L Pipes & Tubes that are utilized as a part of different businesses. Our items are accessible in various evaluations, benchmarks, sizes and materials for utilizes as a part of various applications according to client necessities. We are a reliable supplier with a straightforward motive of supplying the high quality of product and maintain good market value. We are always producing the 321/321H stainless steel pipes and tubes by using premium quality of raw material that results in adding superiority, durability, flexibility in the product quality.

#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

1 note

·

View note

Video

undefined

tumblr

"Copper Bars Manufacturers."

Bhansali Enterprise is known around the world as a trustworthy business with a lot of customers. Copper Round Bars are offered by us because we are focused on our customers. We supply the bars in a variety of widths and wall thicknesses to meet the specifications of our customers. In addition, we provide prompt shipping by ordering consignments that are in good condition and meet your material requirements. Copper Round Bars are manufactured using alloy of superior quality at our well-functioning manufacturing unit. The entire scopes of bars are created under the severe direction of expert specialists alongside the viable utilization of accessible most recent innovation and present day devices. Bhansali Enterprise manufactures industrial Copper Square Bars of a high quality. We have a lot of ferrous and non-ferrous bars, which are popular in a variety of engineering fields. We are making square bars here in a variety of specifications, standards, designations, and non-standard sizes. The high-quality copper used in the processing of square bars further ensures their functionality. It is well-known for its greater strength and toughness. Additionally, it can be found in both magnetic and non-magnetic forms.

#stainless steel round bar#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india

0 notes

Photo

"Duplex SS Sheets Manufacturer & Exporter."

UNS S31803/2205 is a duplex grade with a ferritic-austenitic microstructure. The alloy consists of around 40-50% ferrite in the annealed condition. The duplex microstructure has the high strength of the ferritic grades whilst retaining the corrosion resistance of the austenitic grades. It is not uncommon to see the metal used as a practical solution to chloride-induced stress cracking, which is the achilles’ heel of stainless steel. Duplex Stainless Steel S31803 is the most common duplex grade in the market with high mechanical strength. It is widely used in Oil & Gas Industry, hydro power, pressure vessels, pulp & Equipment for the Paper Industry, Paper Industry, structural components and chemical tankers. The alloy is not intended to be used at temperatures above 300°C due to embrittlement.

#manufacturer of stainless steel in india#super duplex 2507#duplex 2205#duplex 2205 stainless steel#duplex stainless steel#super duplex stainless steel#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel distributor#steel manufacturers in india

0 notes

Photo

"Monel Alloy 400 Manufacturer."

Monel Alloy 400 is almost immune to chloride associated ion pressure corrosion cracking in ordinary environments. Although, its corrosion resistance is very good in reductive environments, it’s far taken into consideration to be bad in oxidative conditions. Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#monel metal composition#monel 400#monel metal#polished stainless steel#stainless steel manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

0 notes

Photo

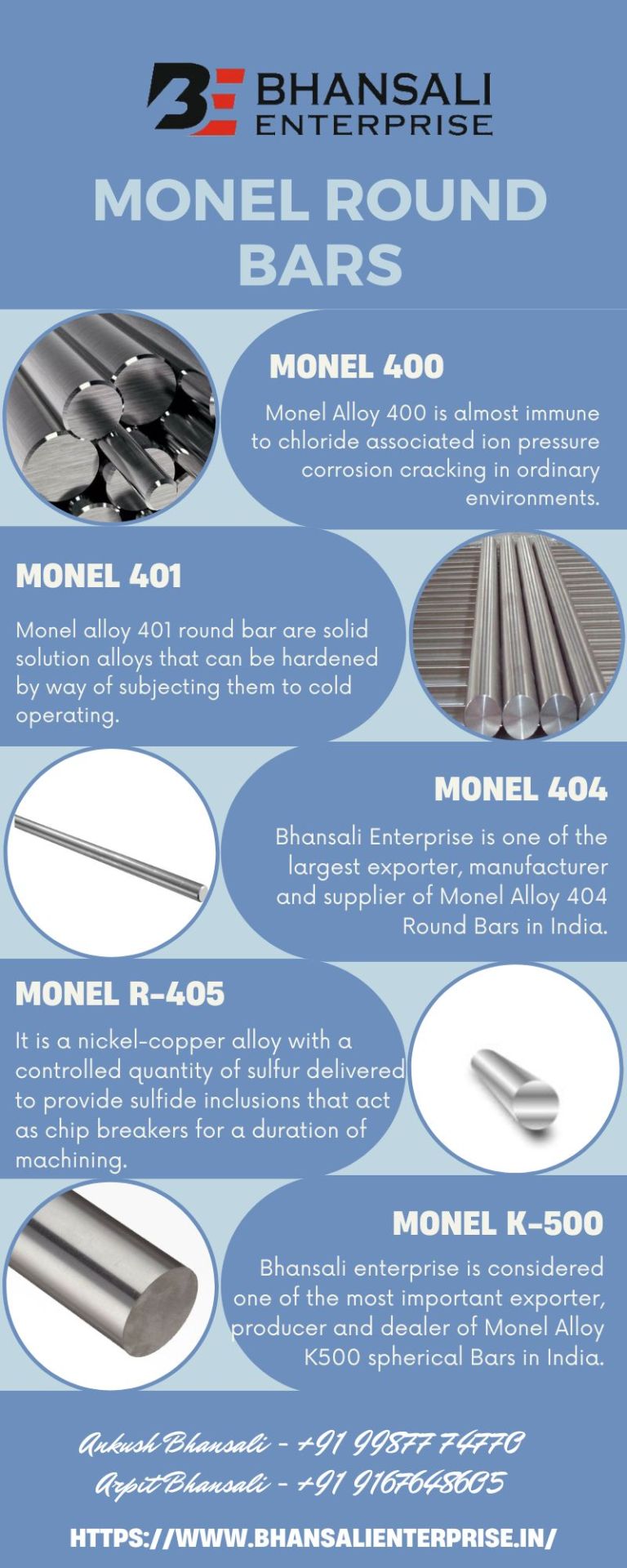

"Monel Round Bars."

Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength. MONEL 401 is designed to be used in unique electric powered and digital applications. The common kinds of MONEL 401 alloy are strip and wire. This datasheet will look at the chemical composition, properties and applications of MONEL 401 alloy. Bhansali Enterprise is one of the largest exporter, manufacturer and supplier of Monel Alloy 404 Round Bars in India. Monel 404 Round Bars is more resistant to nickel under reducing environments and more resistant than copper under oxidizing environments, where it does exhibit however improved resistance to reducing media than oxidizing. Monel Alloy 404 Rods is a Nickel-Copper alloy, resistant to sea water and steam at elevated temperatures, in addition to caustic and salt solutions. Monel Alloy R-405 is the unfastened machining model of Monel 400. It is a nickel-copper alloy with a controlled quantity of sulfur delivered to provide sulfide inclusions that act as chip breakers for the duration of machining. Bhansali enterprise is considered one of the most important exporter, producer and dealer of Monel Alloy K500 spherical Bars in India.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#monel metal composition#monel metal#stainless steel manufacturers in india#polished stainless steel

0 notes

Photo

"Nickel Alloy 201 Round Bars."

Nickel Alloy 201 Round Bar can be tracked down in solidified and tempered structure. An economically unalloyed nickel has phenomenal erosion opposition and has an exceptionally low electrical resistivity. It additionally has different elements like weldability, formability and high elasticity. The nickel utilized in Nickel 201 Rod items are 99.96 % unadulterated. The Nickel 201 Bar is utilized for various handling supplies, in particular to keep up with immaculateness of items in taking care of food sources, alkalies and manufactured strands. Specifically the 201 Nickel Alloy Triangular Bar can oppose hydroxides. Nickel UNS N02201 Bright Bar is a change of composite nickel 200. The change done on the ALLOY 201 HF ANN 1.00 DIA Forged Bar is by controlling the substance of carbon to about a maximum of around 0.02 %. The controlled substance of carbon, holds the COLD DRAWN Nickel 201 Round bar back from being embrittled by intergranular encourages at temperatures of 600° F to 1400° F in many cycles.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#nickel properties#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india

0 notes

Photo

"Brass Bars Manufacturer, Distributor & Exporter."

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical and electrical properties. It is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure. Brass has long been a popular material for decoration for its bright gold-like appearance, e.g. for drawer pulls and door knobs. It has also been widely used for all sorts of utensils due to many properties, such as low melting point, workability (both with hand tools and with modern turning and milling machines), durability, electrical and thermal conductivity. It is still commonly used in applications where low friction and corrosion resistance is required, such as locks, hinges, gears, bearings, ammunition casings, zippers, plumbing, hose couplings, valves, and electrical plugs and sockets.

#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india

0 notes

Photo

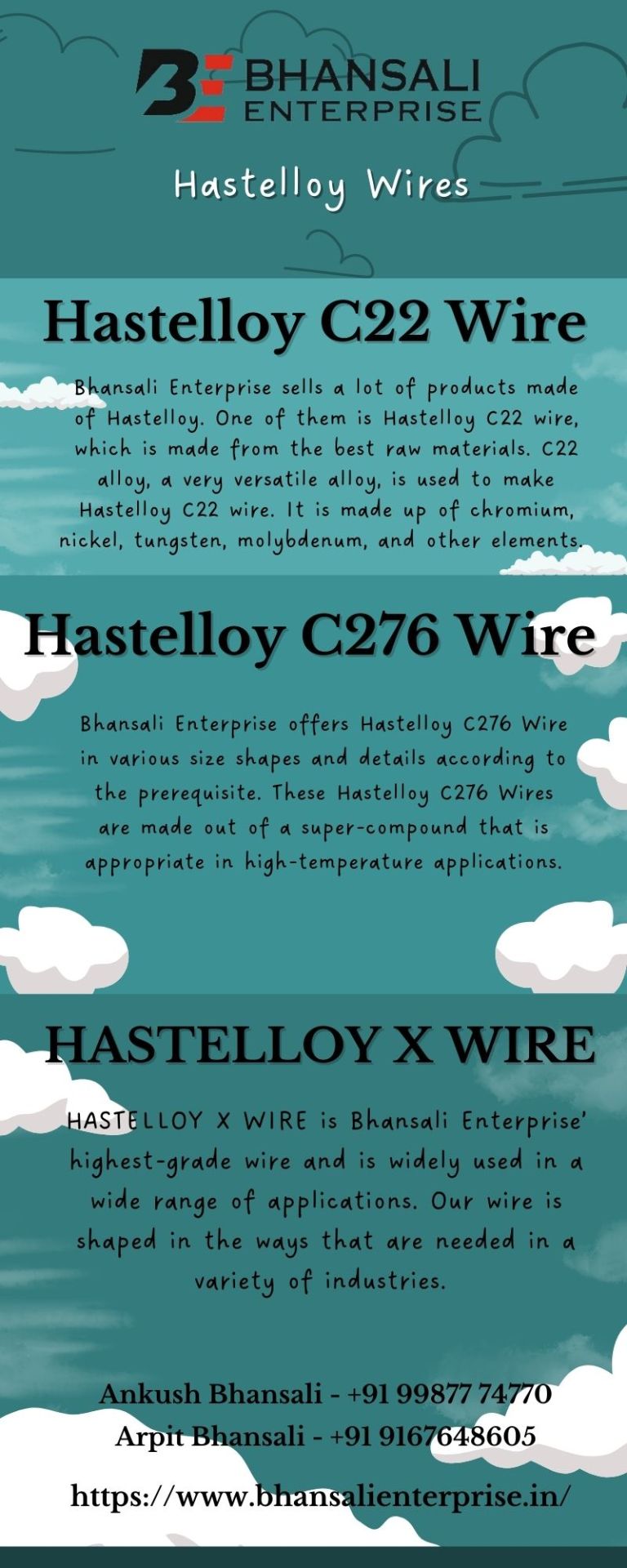

"Hatelloy Wires Manufacturer & Exporter."

Bhansali Enterprise sells a lot of products made of Hastelloy. One of them is Hastelloy C22 wire, which is made from the best raw materials. C22 alloy, a very versatile alloy, is used to make Hastelloy C22 wire. It is made up of chromium, nickel, tungsten, molybdenum, and other elements. Components made of material grade C22 have increased resistance to corrosion and a variety of industrial chemicals as a result of these elements. Bhansali Enterprise offers Hastelloy C276 Wire in various size shapes and details according to the prerequisite. These Hastelloy C276 Wires are made out of a super-compound that is appropriate in high-temperature applications. It is made up of chromium, nickel, and molybdenum alloy, which has excellent resistance to corrosion in an oxidizing environment. It is a corrosion-resistant alloy made of nickel, chromium, and molybdenum. Stress corrosion cracking, crevice corrosion, and pitting are all prevented by this alloy. These Hastelloy C276 Wires shows the capacity to limit the carbide precipitation while welding. Additionally, it exhibits excellent resistance to minimizing or preventing grain boundary precipitates during welding. HASTELLOY X WIRE is Bhansali Enterprise’ highest-grade wire and is widely used in a wide range of applications. Our wire is shaped in the ways that are needed in a variety of industries. These wires are held to specified standards, and dimensional changes define various specifications. With a higher Hastelloy grade, these wires are easier to form and more ductile. It has a higher tensile strength and is made specifically for use in applications at higher temperatures. HASTELLOY X, also known as a superalloy, is a high-performance alloy that keeps features like super strength, resistance to creep and cracking, and sustainability under high temperatures and corrosion.

#stainless steel wire#wire manufacturers#stainless steel wire manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#hastelloy composition#hastelloy c276 chemical composition#polished stainless steel#stainless steel manufacturers in india

0 notes

Video

undefined

tumblr

"Aluminium Round Bars Manufacturer & Exporter."

Aluminium 1100 Round Bar is manufactured and supplied by Bhansali Enterprise and is utilized in numerous industries and applications. These round bars, which are admirable for their resistance to erosion, are basically plates of mid-range quality. These round bars are made by us from raw materials of superior quality that have been thoroughly inspected by professionals to ensure that they are of the highest quality. Also, present day machines and instruments are utilized for assembling prevalent quality and exact components of the bar. We make products while keeping in mind what customers want and need. The softest and gentlest aluminum alloy, the 1100, is not used in high-pressure or high-strength applications. Additionally, we offer these bars to customers in a variety of sizes, shapes, and forms to meet their requirements. Bhansali Enterprise is one of the reputable businesses that has initiated the global distribution of beautiful Aluminum Alloy 2014 Round Bars. The compound 2014 round bars is by and large a sturdy, somewhat delicate, moldable metal, and lightweight item with wide appearance ranges. We are renowned for providing high-quality round bars with rods in custom sizes and built thicknesses to meet client demand as a leading exporter, manufacturer, and stockist. Our renowned customers place large orders to obtain it at a competitive price. You can order it as well and get it for a good price.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#aluminum 6061#aluminium square pipes#aluminum vs stainless steel#polished stainless steel#stainless steel manufacturers in india

0 notes

Photo

"Carbon Nickel Round Bars Manufacturer & Exporter."

Copper Nickel 70/30 is 70% copper, 30% nickel alloy with additions of iron and manganese. These elemental additions make it somewhat more resistant to corrosion and erosion and with slightly improved strength level than Copper Nickel 90/10, making it suitable for more demanding applications. In particular, its corrosion resistance is notably improved in high-velocity waters (up to 4.5m/s) and polluted seawater. Copper Nickel 70/30 is readily cold and welded without any special material. The most famous specifications to cover this alloy are the CN107 and C71500 designated, although the Naval Engineering specifications DEF STAN 02-780 or NES 780 offer tougher and strength controls on impurities and mechanical properties together with a mandatory impact value. Copper Nickel 70/30 Round Bar and Cupro Nickel 70/30 Hex Bars are primarily use when the most elevated level of precision are required alongside a brilliant completion. Cu-Ni 70/30 round poles are accessible in 1/4″ to 1 3/4″ width and satisfy ASTM B111 guidelines. Copper Nickel 70/30 UNS C71500 Round Bars. Cupro Nickel 70/30 Bus bars has great electric conductivity, erosion opposition and high formability.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india

0 notes

Photo

"Carbon Steel Round Bars Manufacturer."

We are one of the largest exporter, manufacturer and supplier of carbon steel Round Bar in India. Our offered range is developed using high-quality raw material and advanced technology. These are widely appreciated by a large number of clients due to their Robustness and precisely-engineering. These Round Bars are widely appreciated by our clients which are situated all round the nation. Our products are precisely designed and constructed by superior quality raw materials and sophisticated machinery. Bhansali Enterprise is a recognized manufacturer and exporter of High Carbon Round Bar, which contain a small amount of incidental elements left over from steelmaking. We also offer the same in different grades and specifications such as Round Bar Carbon Steel, Carbon Steel Round Bars, Low Carbon Round Bar, Carbon Steel Round Bars, and EN SERIES Carbon Steel Round Bars.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

0 notes

Photo

"Aluminium 1100 Round Bars Manufacturer & Distributor."

Aluminium 1100 Round Bar is manufactured and supplied by Bhansali Enterprise and is utilized in numerous industries and applications. These round bars, which are admirable for their resistance to erosion, are basically plates of mid-range quality. These round bars are made by us from raw materials of superior quality that have been thoroughly inspected by professionals to ensure that they are of the highest quality. Also, present day machines and instruments are utilized for assembling prevalent quality and exact components of the bar. We make products while keeping in mind what customers want and need. The softest and gentlest aluminum alloy, the 1100, is not used in high-pressure or high-strength applications. Even though this alloy is cold worked, spinning, drawing, and stamping are more common ways to shape it. These round bars display different highlights and properties like great consumption obstruction, weldability, formability, layered precision, and long help life. The material is infused with domestic and international specifications during the manufacturing of these bars. Additionally, we offer these bars to customers in a variety of sizes, shapes, and forms to meet their requirements.

#stainless steel round bar#stainless steel round bar manufacturer in india#manufacturer of stainless steel in india#ss round bar#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#aluminum vs stainless steel#aluminium pipes#aluminum 6061#aluminium square pipes#polished stainless steel#stainless steel manufacturers in india

0 notes

Photo

"Alloy Steel Round Bars Distributors."

These Alloy Steels F1 A182 Round Bars are low alloy chromium, molybdenum steel in addition to 1/4% Moly. known to deliver exceptional performance and are generally developed for meeting the demands of general corrosion service applications, in General, Engineering and Process Instrumentation applications, and also in heat transfer process equipment like Boilers, Heat Exchangers. Alloy Steel F5 A182 Round Bars are broadly utilized in General Engineering and Process Instrumentation, chemicals, cement, paper, pumps and process and other industries. These offered ranges of ASTM A182 Alloy Steel F9 Bars with a variety of surface finishes such as annealed condition, pickled condition, bright condition, polished condition, ground bright condition, a tempered condition in various sizes covering from 6MM to 300MM. We offer premium quality of Alloy Steel A182 F11 Round Bars with size range consist of 10MM Dia to 250MM Dia as per the national and international standards. We have well experienced and friendly staff with an objective to provide the best Alloy Steels F1 Round Bars and services to every customer. These Alloy Steels F22 Round Bars are broadly utilized in General Engineering and Process Instrumentation, chemicals, cement, paper, pumps and process and other industries.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#alloy 20 chemical composition#polished stainless steel#stainless steel manufacturers in india#alloys stainless steel

0 notes

Photo

"Steel Distributor."

Bhansali Enterprise strives to create a dominant presence in the Indian steel market through backward & forward integration. With its timeless business philosophy, backed by its resolve to serve clients with integrity and dedication, Bhansali Enterpsie is an optimistic corporation continuously scaling its operations to capture opportunities within & across the borders. From the widest range of flat bars to a whole range of stainless steel products, Bhansali Enterpsie has a unique product portfolio that caters to the markets across the steel value chain. Specializes in producing Stainless steel, Carbon steel, Monel, Inconel, Titanium grades, Hastelloy, Alloy Steel, Nickel Alloy, Copper, Brass Alloys and more. You name a steel product and we have it! For a complete list of our offerings, please check the product list on our website. The highly state-of-the-art infrastructure facility at Bhansali Enterprise undergoes regular update, for reasons of attaining a repudiated and dynamic position in the industry and to maintain high production capacity so that they can cater large quantity demands in limited time.

#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india

0 notes

Video

undefined

tumblr

"Stainless Steel Round Bars."

The quality assurance system is guided by principles that support our unique working culture which incorporates respect. We ensure that finest quality material is used for our products. Our team of experts maintain a vigil on the quality of the products. Every single piece is attached with test certificates and reports. We are continually improving our quality to serve our clients better. We help customers develop their energy resources; bringing world class capability and delivering it locally. Providing sources to customers for growing their business at their locality We are values your needs and help to grow in industry. We exercise stringent quality control measures for ensuring the accurate dimensions and mechanical properties of our products. we are believing to give the delivery of products within time assign by us and quick delivery as per the customers requirement.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel distributor#steel manufacturers in india#polished stainless steel#stainless steel manufacturers in india

0 notes

Photo

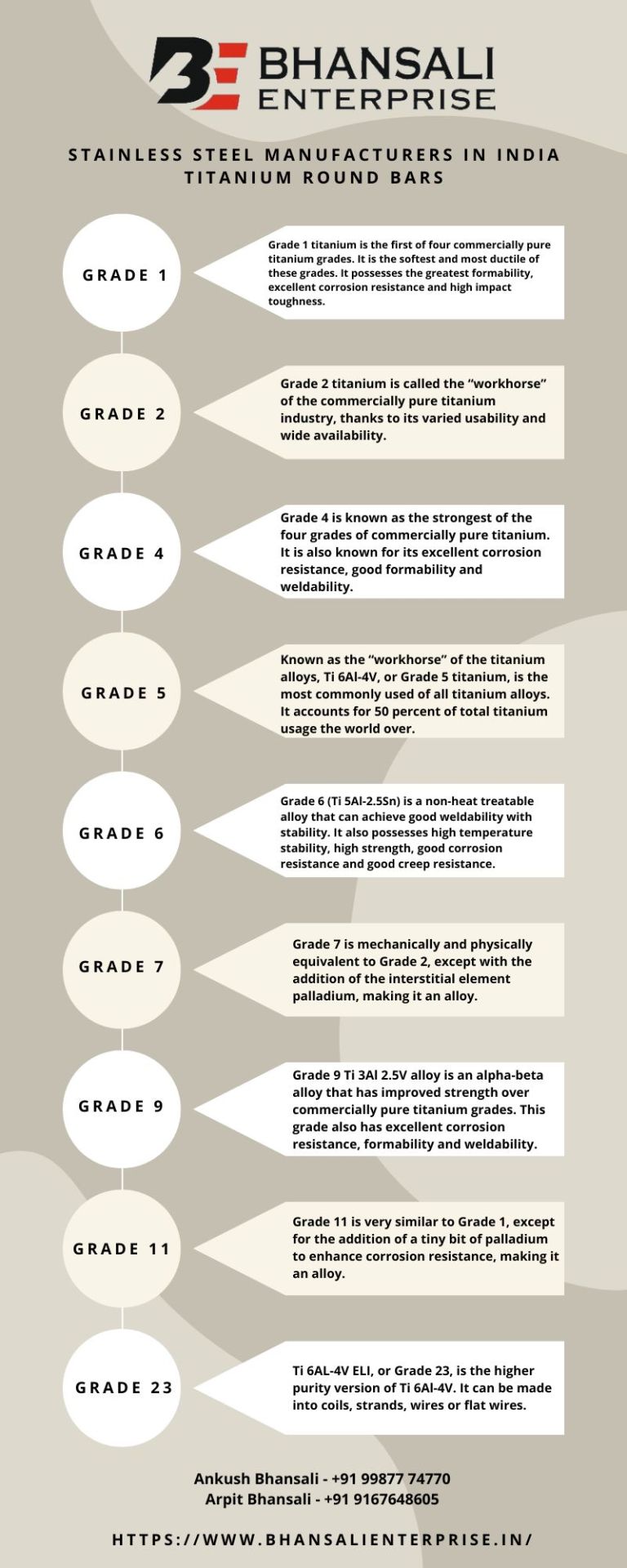

"Titanium Round Bar Grades."

Grade 1 titanium is the first of four commercially pure titanium grades. It is the softest and most ductile of these grades. It possesses the greatest formability, excellent corrosion resistance and high impact toughness. Grade 2 titanium is called the “workhorse” of the commercially pure titanium industry, thanks to its varied usability and wide availability. It shares many of the same qualities as Grade 1 titanium, but it is slightly stronger. Both are equally corrosion resistant. Grade 4 is known as the strongest of the four grades of commercially pure titanium. It is also known for its excellent corrosion resistance, good formability and weldability. Known as the “workhorse” of the titanium alloys, Ti 6Al-4V, or Grade 5 titanium, is the most commonly used of all titanium alloys. It accounts for 50 percent of total titanium usage the world over. Grade 6 (Ti 5Al-2.5Sn) is a non-heat treatable alloy that can achieve good weldability with stability. It also possesses high temperature stability, high strength, good corrosion resistance and good creep resistance. Creep refers to the phenomenon of plastic strain over long periods of time, which happens at high temperatures. Grade 7 is mechanically and physically equivalent to Grade 2, except with the addition of the interstitial element palladium, making it an alloy. Grade 7 possesses excellent weldability and fabricality, and is the most corrosion resistance of all titanium alloys. In fact, it is most resistant to corrosion in reducing acids. Grade 9 Ti 3Al 2.5V alloy is an alpha-beta alloy that has improved strength over commercially pure titanium grades. This grade also has excellent corrosion resistance, formability and weldability. Grade 11 is very similar to Grade 1, except for the addition of a tiny bit of palladium to enhance corrosion resistance, making it an alloy. Ti 6AL-4V ELI, or Grade 23, is the higher purity version of Ti 6Al-4V. It can be made into coils, strands, wires or flat wires.

#manufacturer of stainless steel in india#stainless steel round bar#Titanium grade 2#titanium grade 5#titanium pipes#titanium price in india per kg#polished stainless steel#stainless steel manufacturers in india#titanium price per kg in india#titanium rod#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

0 notes

Photo

"Hastelloy C22 Plates Manufacturer In India."

Hastelloy C22 plates are known to be produced and exported by Bhansali Enterprise. Because of their exceptional properties, these plates quickly determine which application best suits them. Hastelloy C22 Plates, which is also known as C22 alloy, is a multipurpose austenitic nickel-chromium-molybdenum-tungsten alloy that is more resistant to stress corrosion cracking, pitting, and corrosion. Additionally, this nickel alloy of grade C22 exhibits superior resistance in processes where reducing and oxidizing conditions are present. As a result, versatile plants that frequently encounter such “upset” conditions benefit from using Hastelloy C22. Because it is resistant to the formation of grain-boundary precipitates in the weld heat-affected region, this nickel alloy grade C22 is suitable for the majority of chemical procedure applications. Due to the formation of hazardous phases at temperatures above 1250 degrees Fahrenheit, Material C22 should not be used in these temperatures. Characteristics of Hastelloy C22: Hastelloy C22 has good resistance to oxidizing sources thanks to its high content of chromium, while its good resistance to reducing sources comes from molybdenum and tungsten. It is resistant to other corrosive substances well: wet chlorine, oxidizing acid chlorides, formic and acetic acids, ferric and cupric chlorides, seawater, brine, and numerous mixed or contaminated organic and inorganic chemical solutions.

#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

0 notes